A Feasible and Promising Strategy for Improving the Solar Selectivity and Thermal Stability of Cermet-Based Photothermal Conversion Coatings

Abstract

:1. Introduction

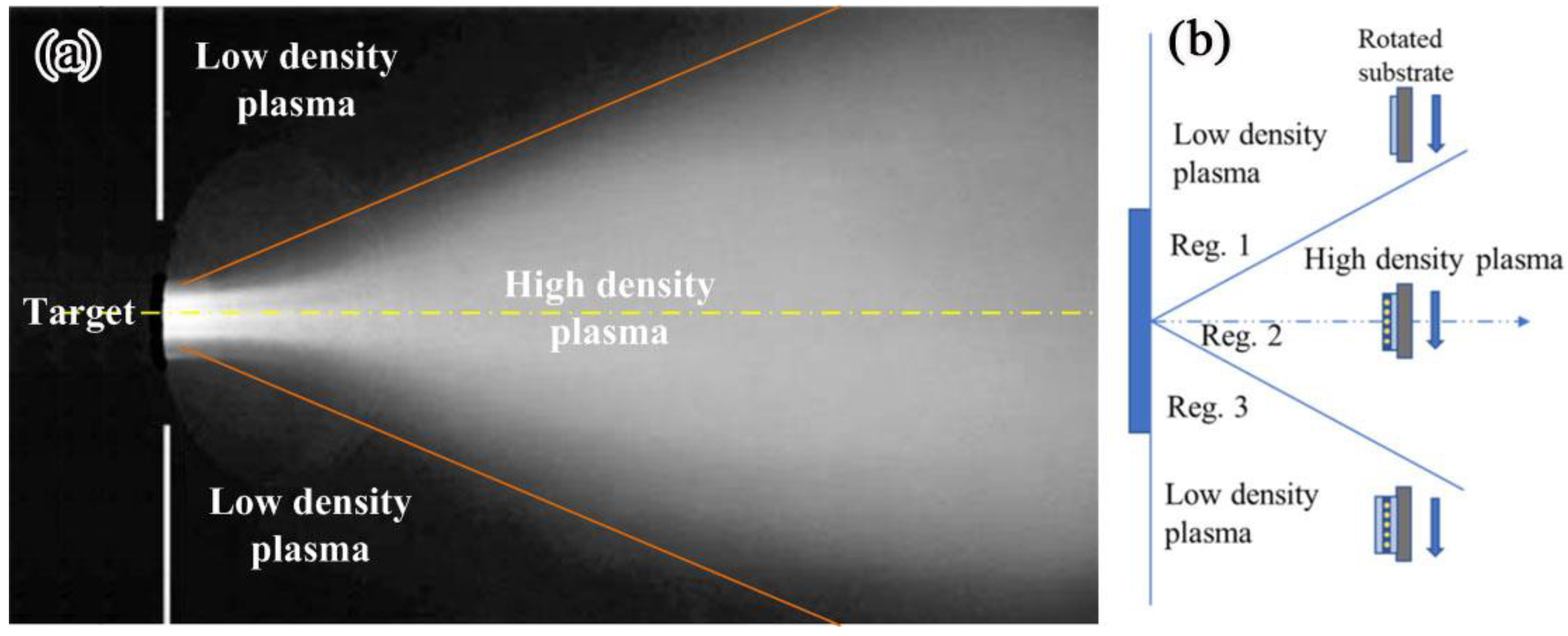

2. Materials and Methods

2.1. Sample Preparation and Annealing

2.2. Characterization

2.3. Optical Properties Tests

2.4. Numerical Simulations

3. Results

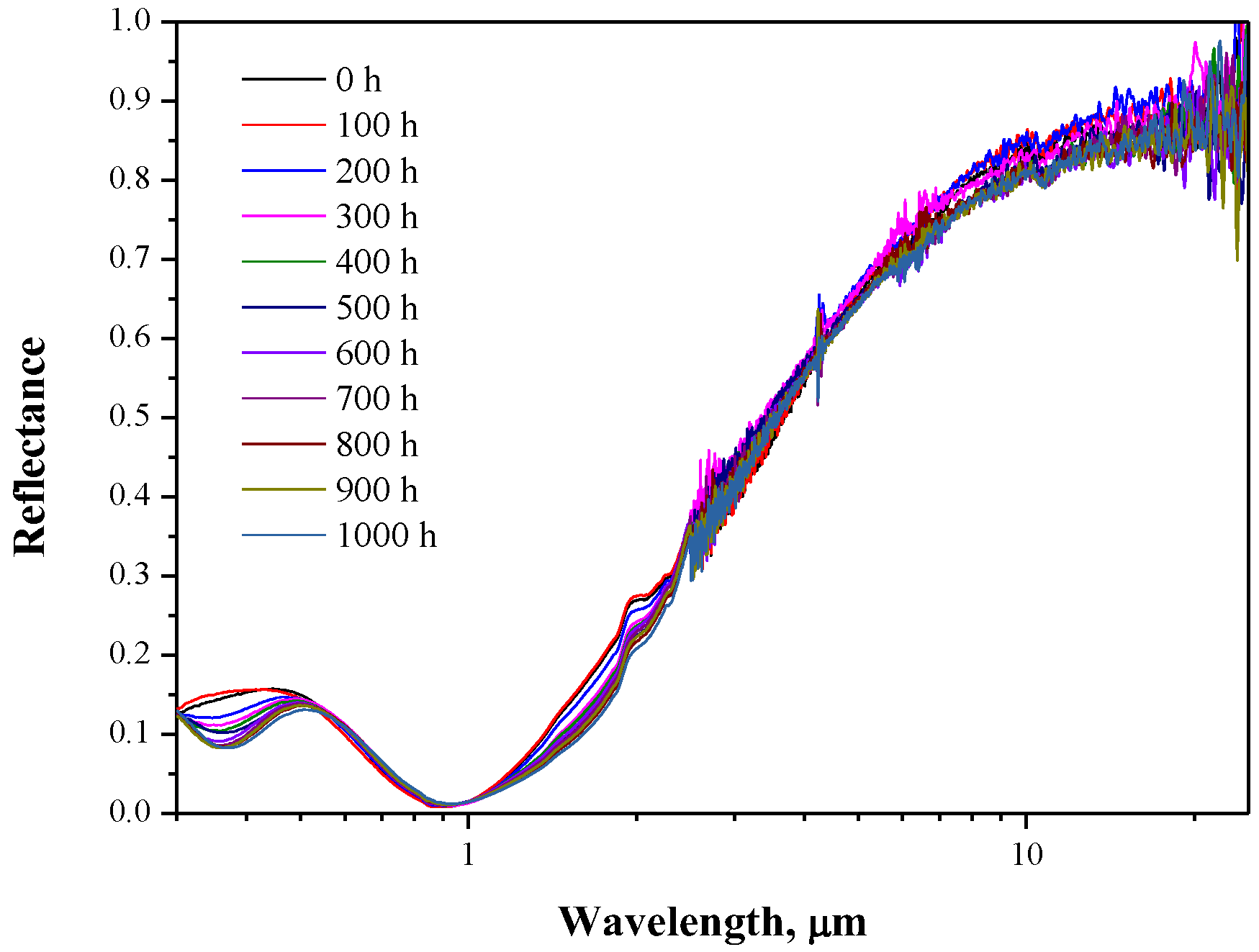

3.1. Optical Properties and Thermal Stability of the Multilayer Coatings

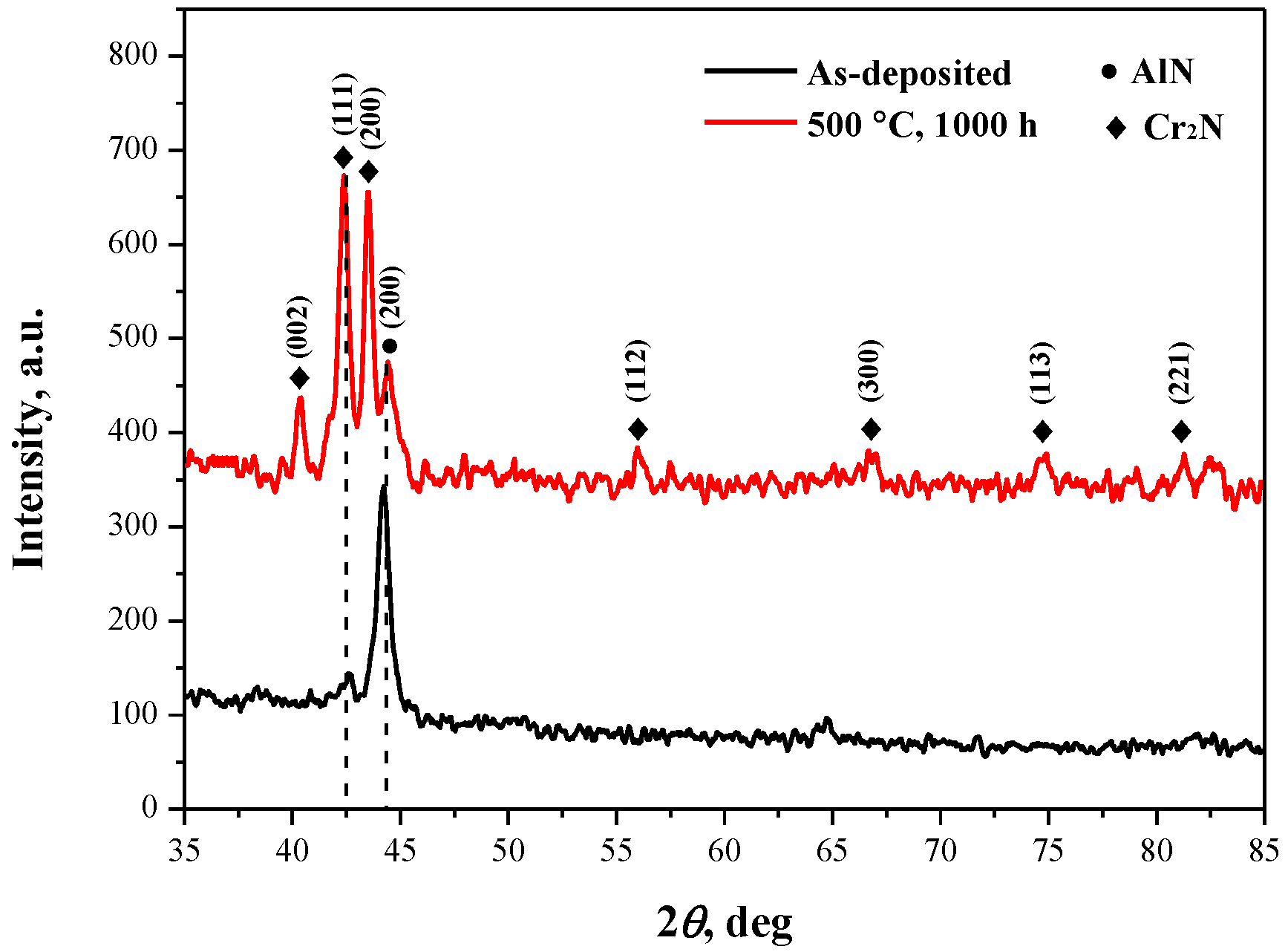

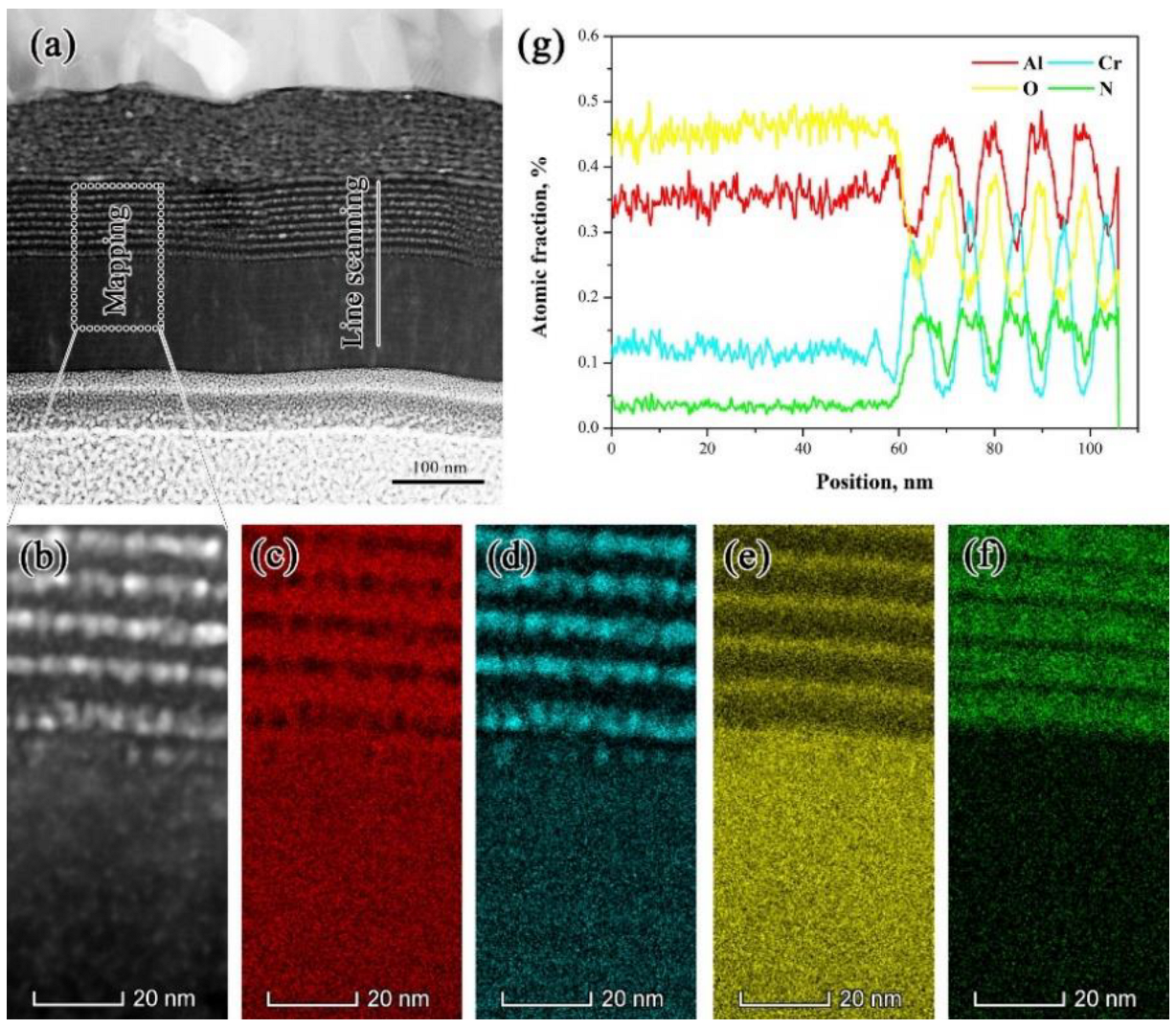

3.2. Microstructural and Compositional Evolution of the Solar Selective Absorbing Coatings during Long-Term Annealing

4. Discussion

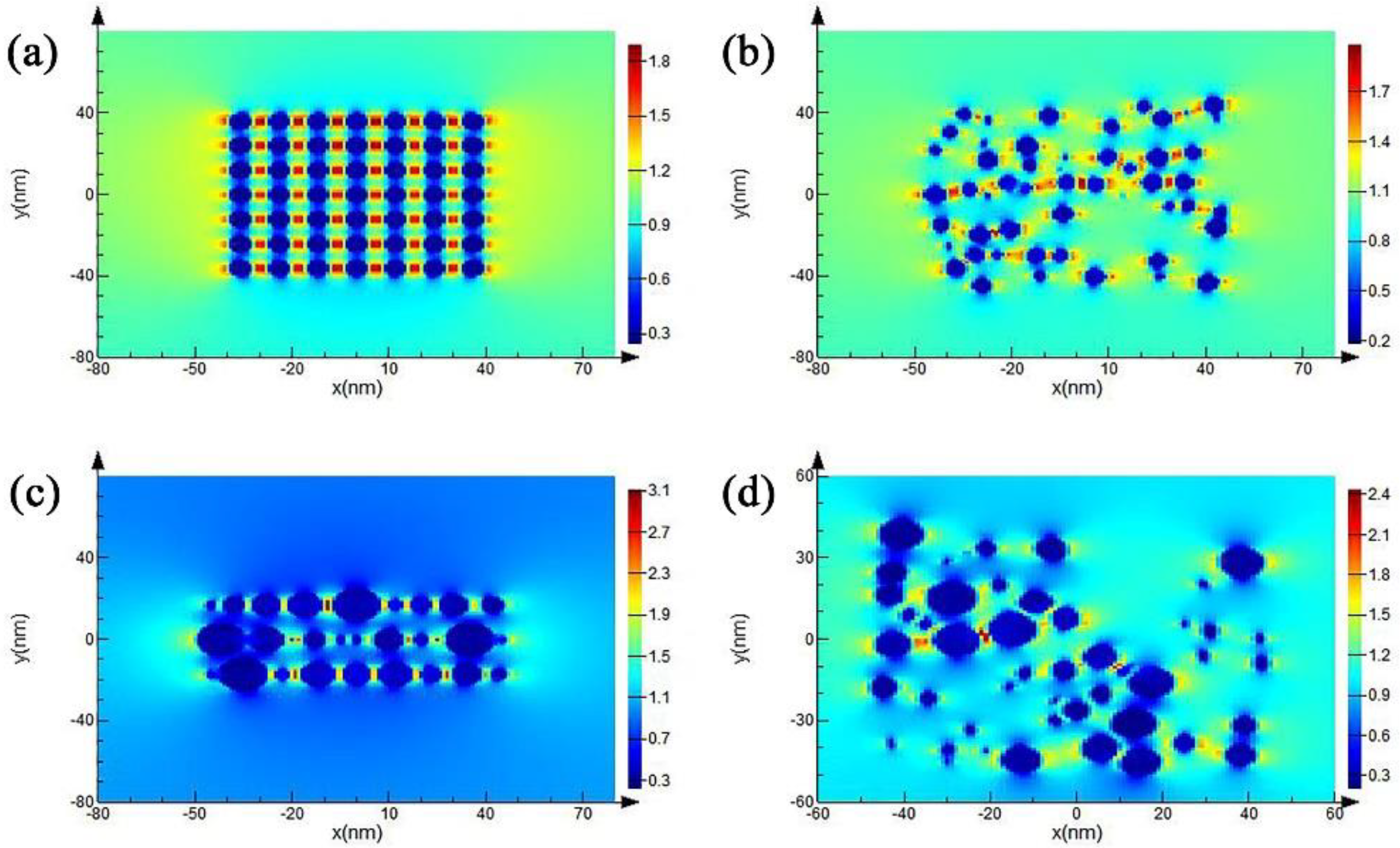

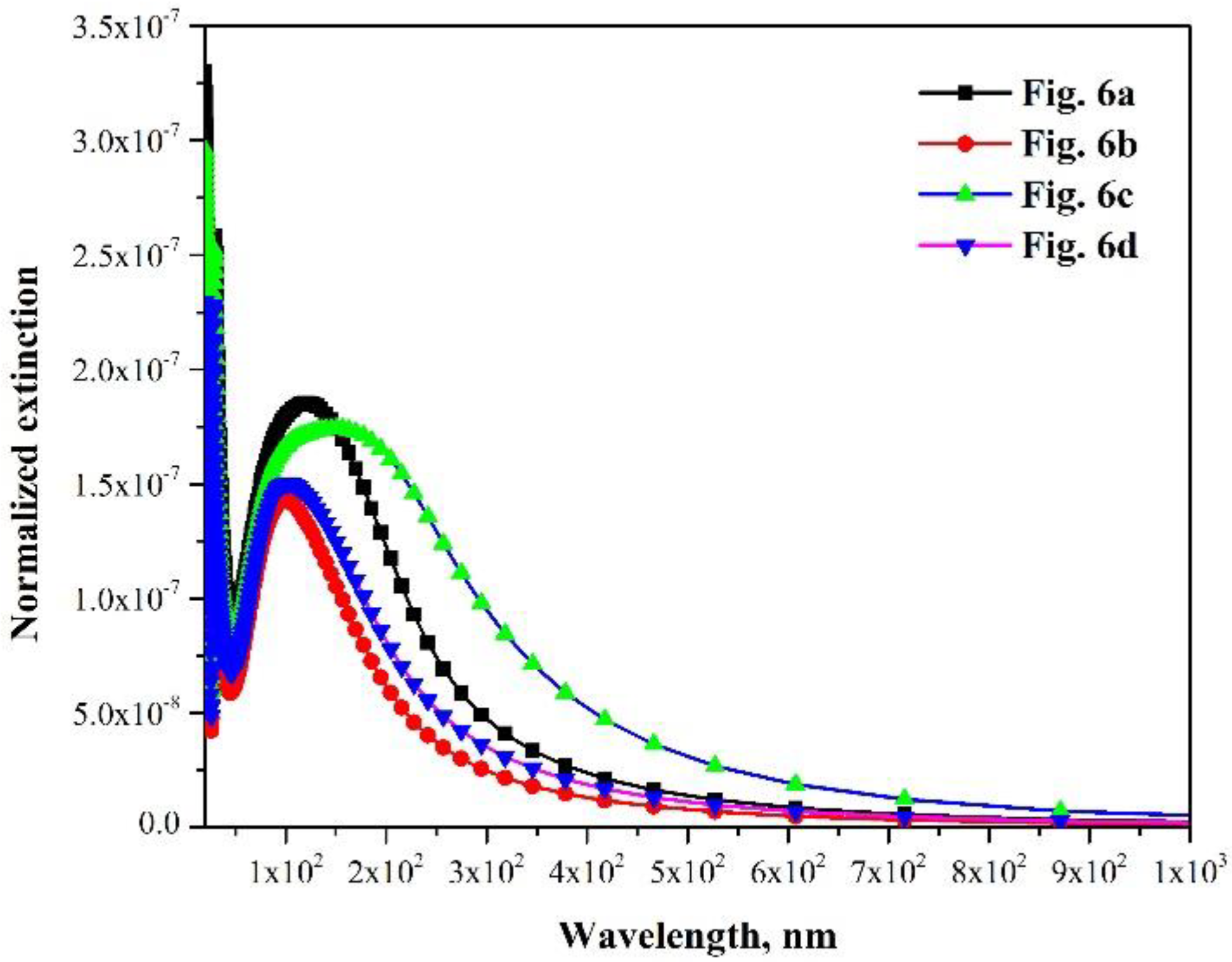

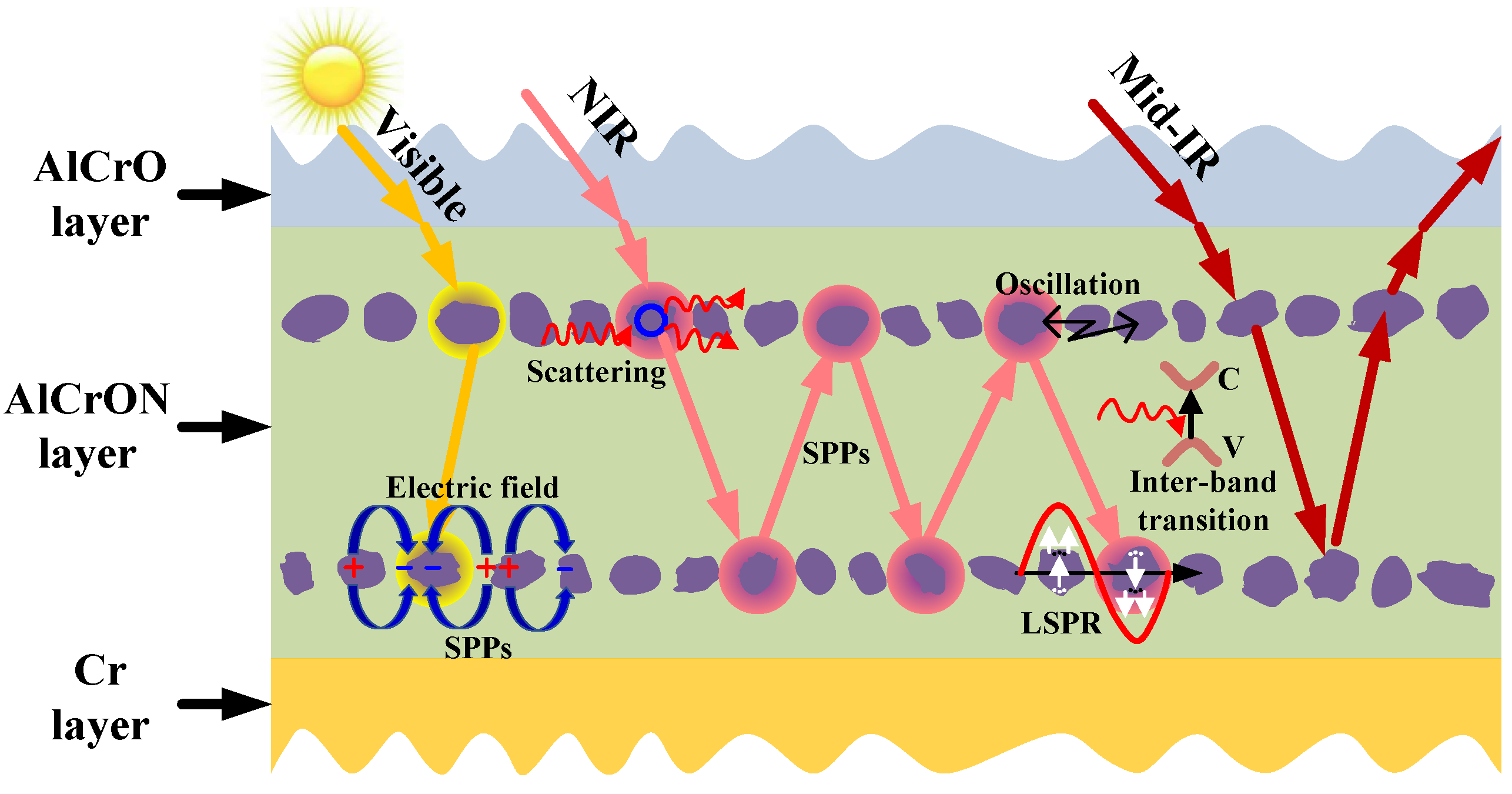

4.1. Spectrally Selective Absorbing Mechanism of the Layered Multilayer Coating

4.2. Thermal Strengthening Mechanism

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chaturvedi, R.; Islam, A.; Sharma, K. A review on the applications of PCM in thermal storage of solar energy. Mater. Today Proc. 2021, 43, 293–297. [Google Scholar] [CrossRef]

- Zhang, Q.C. Recent progress in high-temperature solar selective coatings. Sol. Energy Mater. Sol. Cells 2000, 62, 63–74. [Google Scholar] [CrossRef]

- Selvakumar, N.; Barshilia, H.C. Review of physical vapor deposited (PVD) spectrally selective coatings for mid- and high-temperature solar thermal applications. Sol. Energy Mater. Sol. Cells 2012, 98, 1–23. [Google Scholar] [CrossRef]

- Xu, K.; Du, M.; Hao, L.; Mi, J.; Yu, Q.; Li, S. A review of high-temperature selective absorbing coatings for solar thermal applications. J. Mater. 2020, 6, 167–182. [Google Scholar] [CrossRef]

- Meng, J.P.; Guo, R.R.; Li, H.; Zhao, L.M.; Liu, X.P.; Li, Z. Microstructure and thermal stability of Cu/Zr0.3Al0.7N/Zr0.2Al0.8N/Al34O60N6 cermet-based solar selective absorbing coatings. Appl. Surf. Sci. 2018, 440, 932–938. [Google Scholar] [CrossRef]

- Tsegay, M.G.; Gebretinsae, H.G.; Sackey, J.; Arendse, C.J.; Nuru, Z.Y. Structural and optical properties of Pt-Al2O3 double cermet as selective solar absorber. Mater. Today Proc. 2020, 36, 571–575. [Google Scholar] [CrossRef]

- Wang, X.; Gao, J.; Hu, H.; Zhang, H.; Liang, L.; Javaid, K.; Zhuge, F.; Cao, H.; Wang, L. High-temperature tolerance in WTi-Al2O3 cermet-based solar selective absorbing coatings with low thermal emissivity. Nano Energy 2017, 37, 232–241. [Google Scholar] [CrossRef]

- Kotilainen, M.; Mizohata, K.; Honkanen, M.; Vuoristo, P. Influence of microstructure on temperature-induced ageing mechanisms of different solar absorber coatings. Sol. Energy Mater. Sol. Cells 2014, 120, 462–472. [Google Scholar] [CrossRef]

- Wang, X.; Yuan, X.; Gong, D.; Cheng, X.; Li, K. Optical properties and thermal stability of AlCrON-based multilayer solar selective absorbing coating for high temperature applications. J. Mater. Res. Technol. 2021, 15, 6162–6174. [Google Scholar] [CrossRef]

- Liu, H.D.; Wan, Q.; Lin, B.Z.; Wang, L.L.; Yang, X.F.; Wang, R.Y.; Gong, D.Q.; Wang, Y.B.; Ren, F.; Chen, Y.M.; et al. The spectral properties and thermal stability of CrAlO-based solar selective absorbing nanocomposite coating. Sol. Energy Mater. Sol. Cells 2014, 122, 226–232. [Google Scholar] [CrossRef]

- Li, Y.; Lin, C.; Wu, Z.; Chen, Z.; Chi, C.; Cao, F.; Mei, D.; Yan, H.; Tso, C.Y.; Chao, C.Y.H.; et al. Solution-Processed All-Ceramic Plasmonic Metamaterials for Efficient Solar–Thermal Conversion over 100–727 °C. Adv. Mater. 2021, 33, 2005074. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Luo, T.; Li, Q.; Cheng, X.; Li, K. High performance aperiodic metal-dielectric multilayer stacks for solar energy thermal conversion. Sol. Energy Mater. Sol. Cells 2019, 191, 372–380. [Google Scholar] [CrossRef]

- Wang, X.; Li, K.; Cheng, X. Resistant transition-metal-nitrides based coatings for solar energy conversion. J. Eur. Ceram. Soc. 2021, 41, 4076–4085. [Google Scholar] [CrossRef]

- Palik, E.D. Preface. In Handbook of Optical Constants of Solids; Palik, E.D., Ed.; Academic Press: Burlington, ON, Canada, 1997; pp. xvii–xviii. [Google Scholar]

- Lin, K.-T.; Lin, H.; Yang, T.; Jia, B. Structured graphene metamaterial selective absorbers for high efficiency and omnidirectional solar thermal energy conversion. Nat. Commun. 2020, 11, 1389. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cao, F.; Kraemer, D.; Sun, T.; Lan, Y.; Chen, G.; Ren, Z. Enhanced Thermal Stability of W-Ni-Al2O3 Cermet-Based Spectrally Selective Solar Absorbers with Tungsten Infrared Reflectors. Adv. Energy Mater. 2015, 5, 1401042. [Google Scholar] [CrossRef]

- Anders, A. Cathodic Arcs; Springer: Cham, Switzerland, 2008. [Google Scholar]

- Schuller, J.A.; Barnard, E.S.; Cai, W.; Jun, Y.C.; White, J.S.; Brongersma, M.L. Plasmonics for extreme light concentration and manipulation. Nat. Mater. 2010, 9, 193–204. [Google Scholar] [CrossRef]

- Hutter, E.; Fendler, J.H. Exploitation of Localized Surface Plasmon Resonance. Adv. Mater. 2004, 16, 1685–1706. [Google Scholar] [CrossRef]

- Shalev, G.; Schmitt, S.W.; Brönstrup, G.; Christiansen, S. Maximizing the ultimate absorption efficiency of vertically-aligned semiconductor nanowire arrays with wires of a low absorption cross-section. Nano Energy 2015, 12, 801–809. [Google Scholar] [CrossRef]

- Li, W.; Guler, U.; Kinsey, N.; Naik, G.V.; Boltasseva, A.; Guan, J.; Shalaev, V.M.; Kildishev, A.V. Refractory Plasmonics with Titanium Nitride: Broadband Metamaterial Absorber. Adv. Mater. 2014, 26, 7959–7965. [Google Scholar] [CrossRef]

- Halas, N.J.; Lal, S.; Chang, W.-S.; Link, S.; Nordlander, P. Plasmons in Strongly Coupled Metallic Nanostructures. Chem. Rev. 2011, 111, 3913–3961. [Google Scholar] [CrossRef]

- Barnes, W.L. Surface plasmon–polariton length scales: A route to sub-wavelength optics. J. Opt. A Pure Appl. Opt. 2006, 8, S87–S93. [Google Scholar] [CrossRef]

- Barnes, W.L.; Dereux, A.; Ebbesen, T.W. Surface plasmon subwavelength optics. Nature 2003, 424, 824–830. [Google Scholar] [CrossRef] [PubMed]

- Willets, K.A.; van Duyne, R.P. Localized Surface Plasmon Resonance Spectroscopy and Sensing. Annu. Rev. Phys. Chem. 2007, 58, 267–297. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cao, F.; Tang, L.; Li, Y.; Litvinchuk, A.P.; Bao, J.; Ren, Z. A high-temperature stable spectrally-selective solar absorber based on cermet of titanium nitride in SiO2 deposited on lanthanum aluminate. Sol. Energy Mater. Sol. Cells 2017, 160, 12–17. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Zhang, X.; Li, Q.; Min, J.; Cheng, X. Spectral properties of AlCrNO-based multi-layer solar selective absorbing coating during the initial stage of thermal aging upon exposure to air. Sol. Energy Mater. Sol. Cells 2018, 188, 81–92. [Google Scholar] [CrossRef]

| Annealing Time, h | α | ε | α/ε | PC |

|---|---|---|---|---|

| 0 | 0.909 | 0.163 | 5.58 | - |

| 100 | 0.911 | 0.150 | 6.07 | −0.0085 |

| 200 | 0.913 | 0.144 | 6.34 | −0.7785 |

| 300 | 0.914 | 0.157 | 5.82 | −0.008 |

| 400 | 0.916 | 0.180 | 5.09 | 0.0015 |

| 500 | 0.917 | 0.180 | 5.09 | 0.0005 |

| 600 | 0.918 | 0.180 | 5.10 | −0.0005 |

| 700 | 0.919 | 0.183 | 5.02 | 0 |

| 800 | 0.920 | 0.185 | 4.97 | 0 |

| 900 | 0.923 | 0.185 | 4.99 | −0.003 |

| 1000 | 0.922 | 0.185 | 4.98 | −0.002 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Kang, Y.; Yuan, X.; Gong, D.; Li, K. A Feasible and Promising Strategy for Improving the Solar Selectivity and Thermal Stability of Cermet-Based Photothermal Conversion Coatings. Materials 2022, 15, 6847. https://doi.org/10.3390/ma15196847

Wang X, Kang Y, Yuan X, Gong D, Li K. A Feasible and Promising Strategy for Improving the Solar Selectivity and Thermal Stability of Cermet-Based Photothermal Conversion Coatings. Materials. 2022; 15(19):6847. https://doi.org/10.3390/ma15196847

Chicago/Turabian StyleWang, Xiaobo, Yabin Kang, Xiaopeng Yuan, Dianqing Gong, and Kewei Li. 2022. "A Feasible and Promising Strategy for Improving the Solar Selectivity and Thermal Stability of Cermet-Based Photothermal Conversion Coatings" Materials 15, no. 19: 6847. https://doi.org/10.3390/ma15196847