Evaluation of the Performance of Different Types of Fibrous Concretes Produced by Using Wollastonite

Abstract

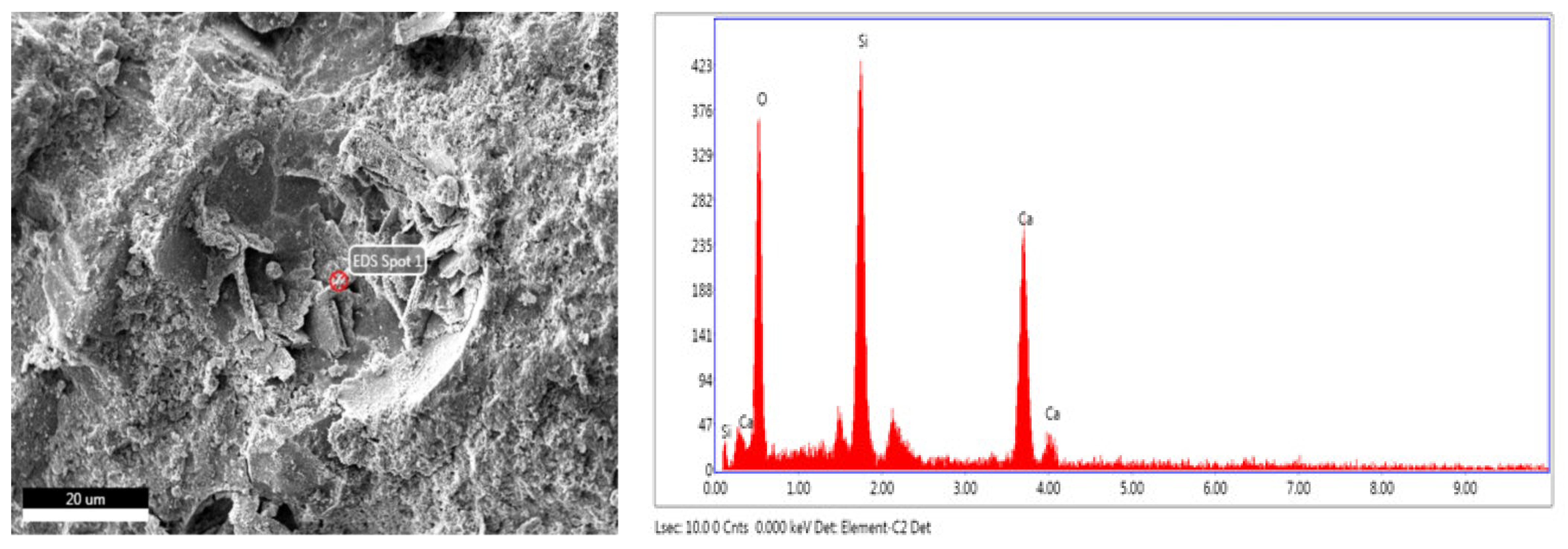

:1. Introduction

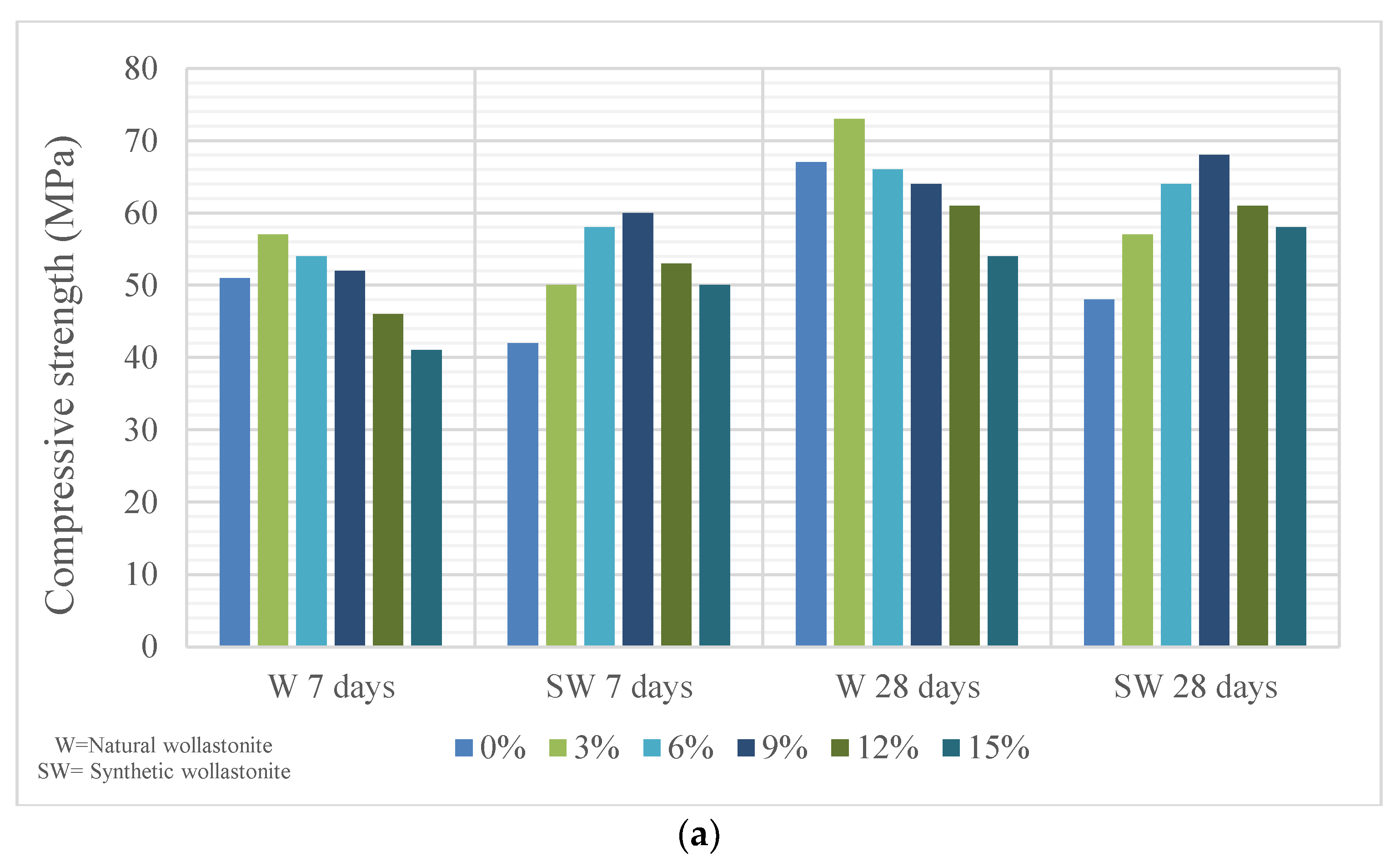

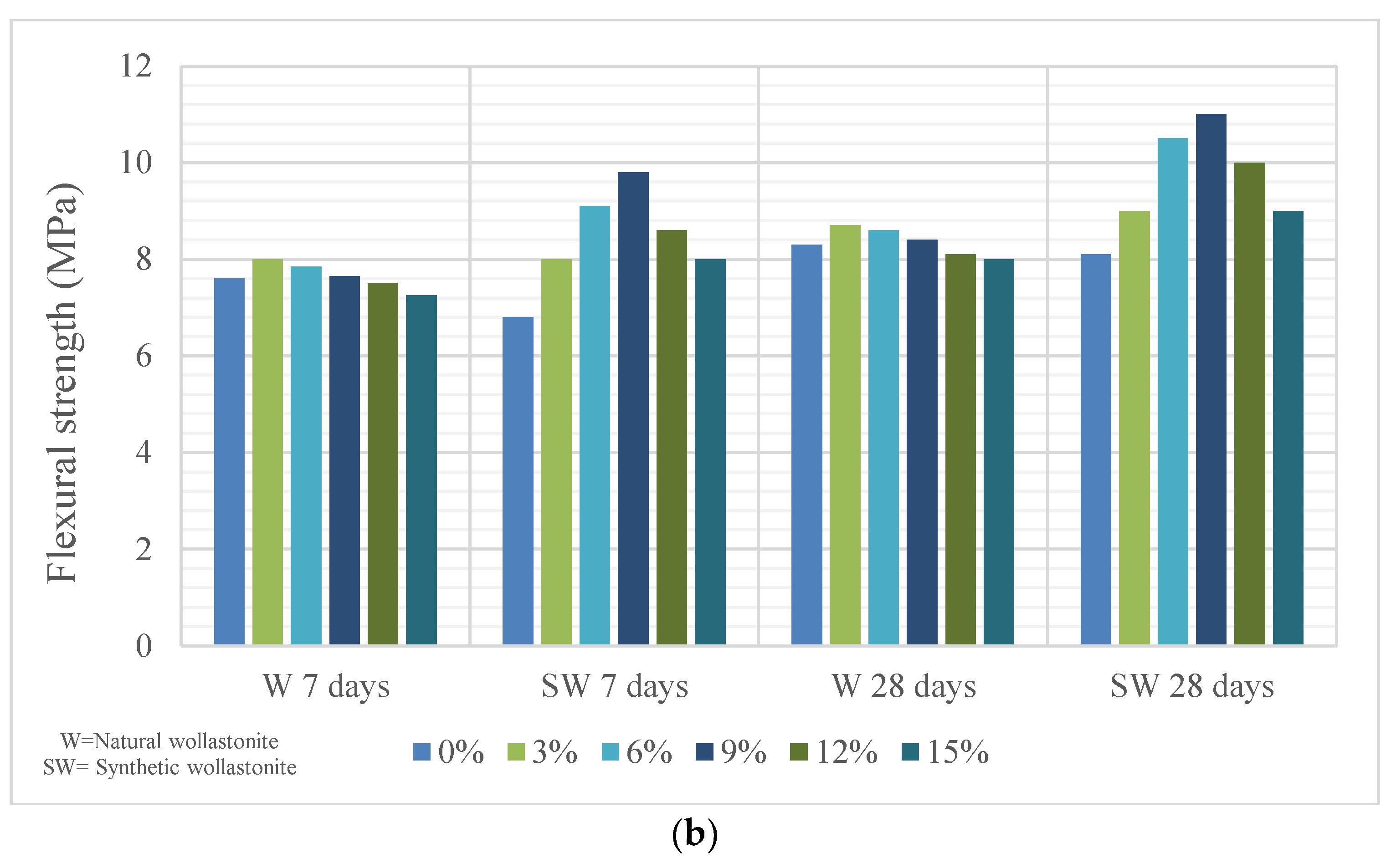

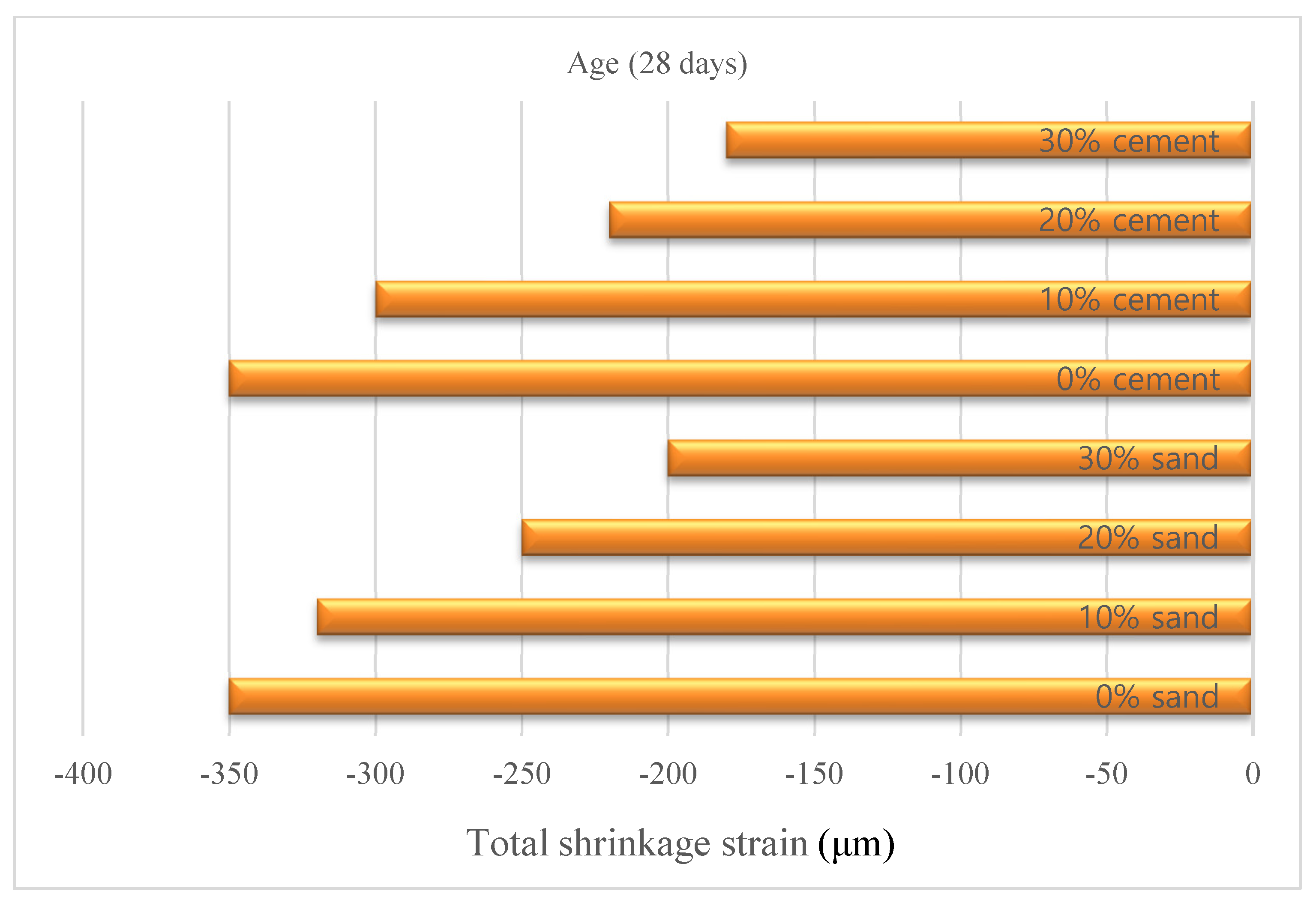

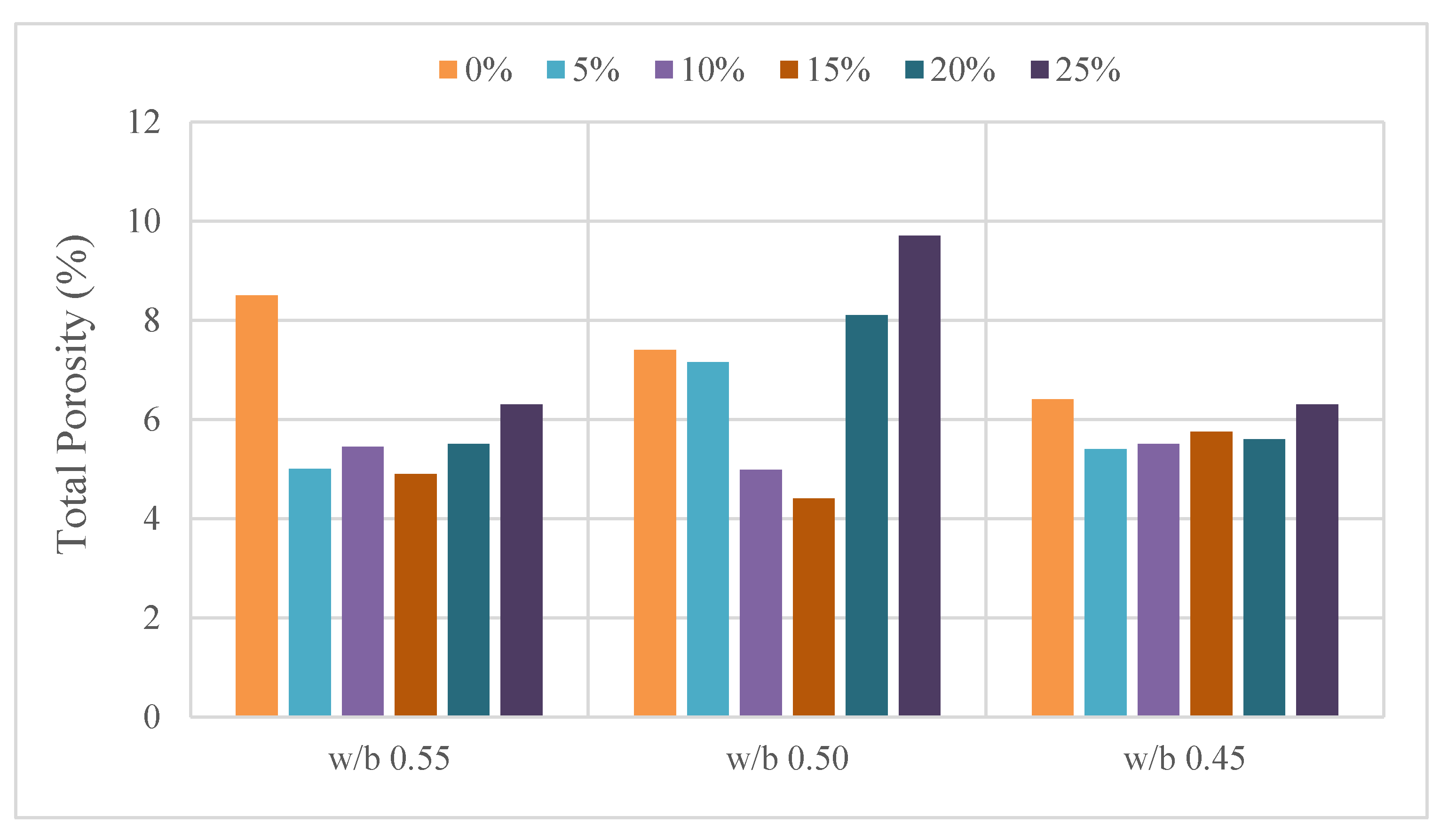

2. Cement Paste and Mortar

3. Conventional Concrete

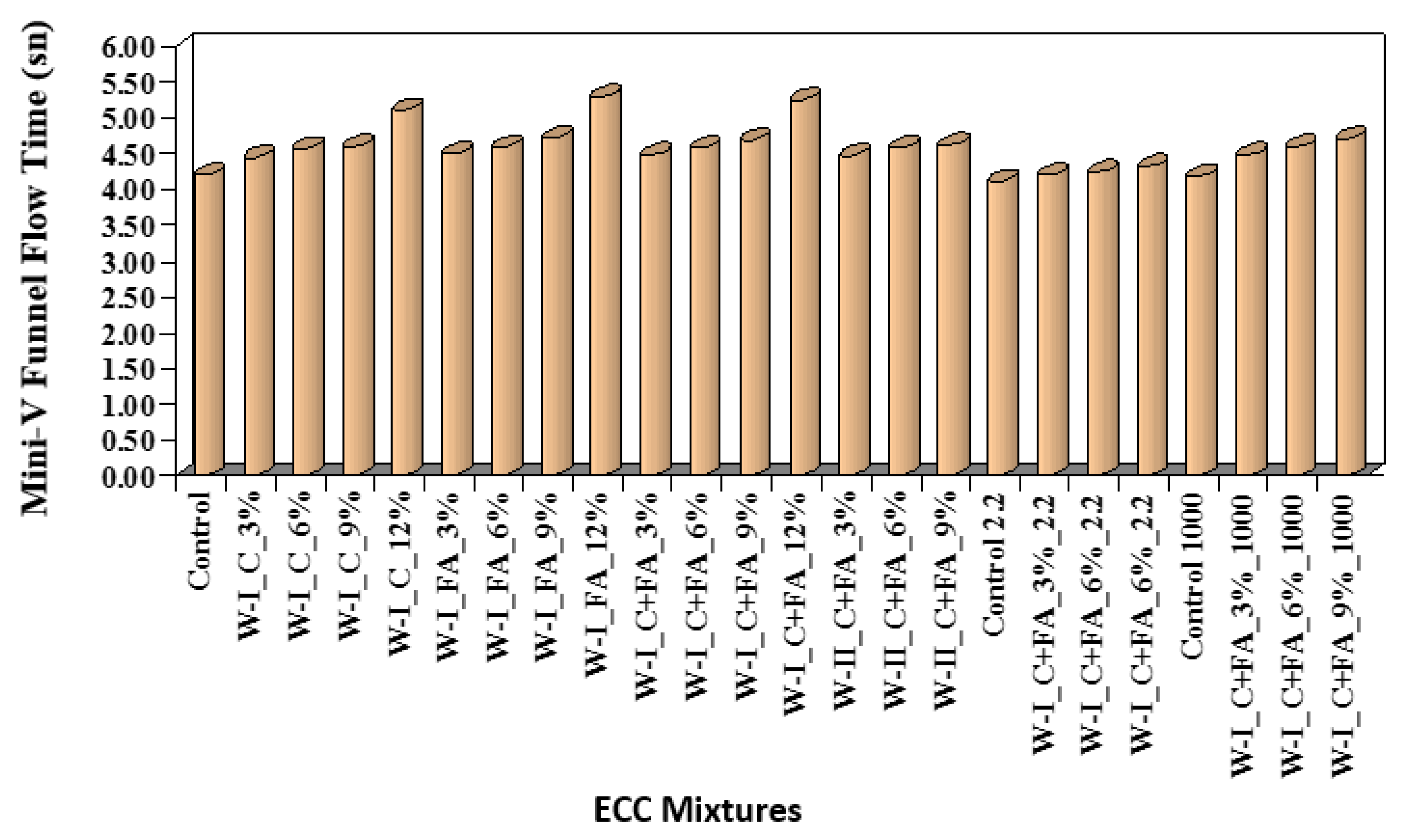

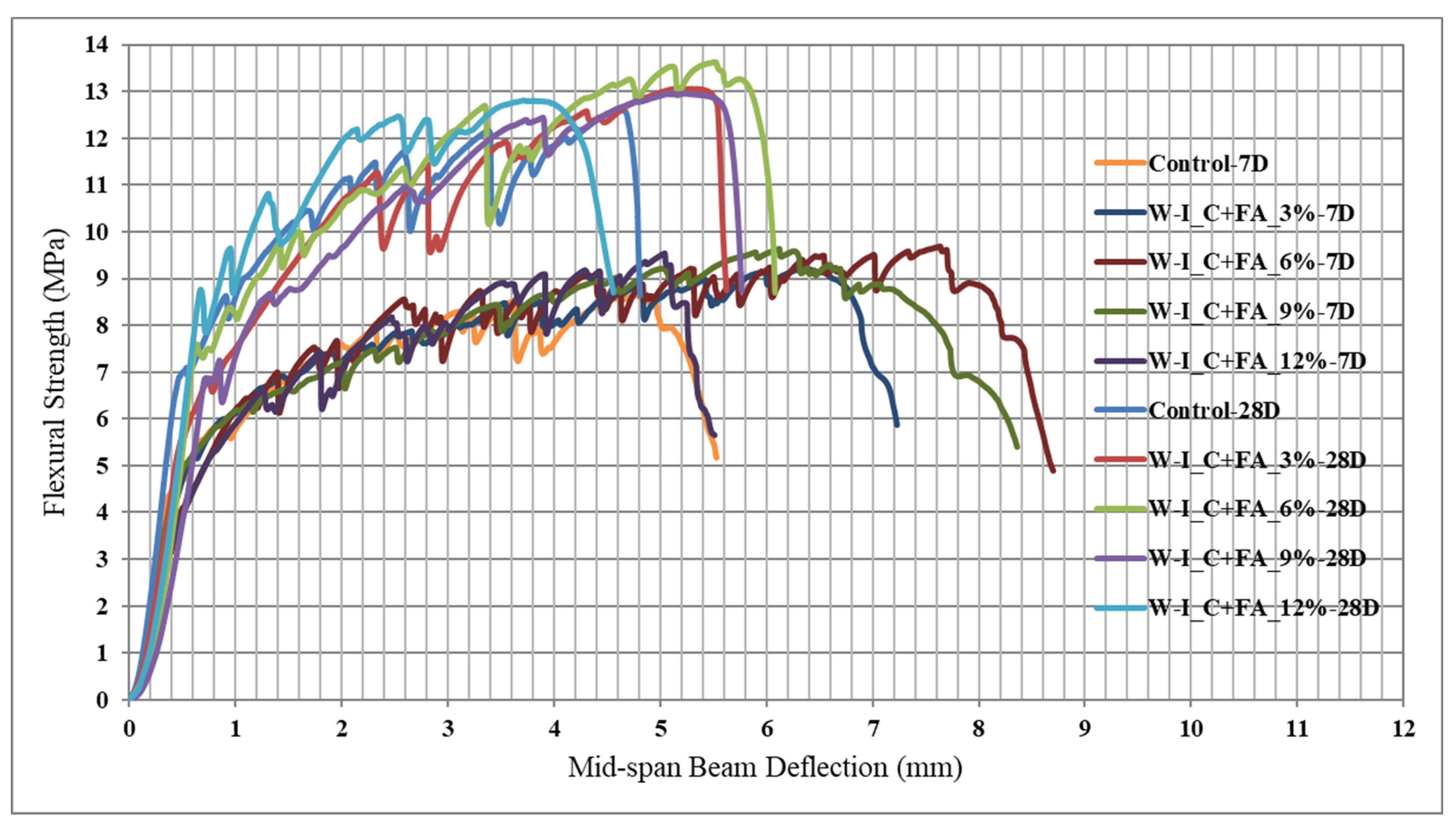

4. Engineered Cementitious Composite (ECC)

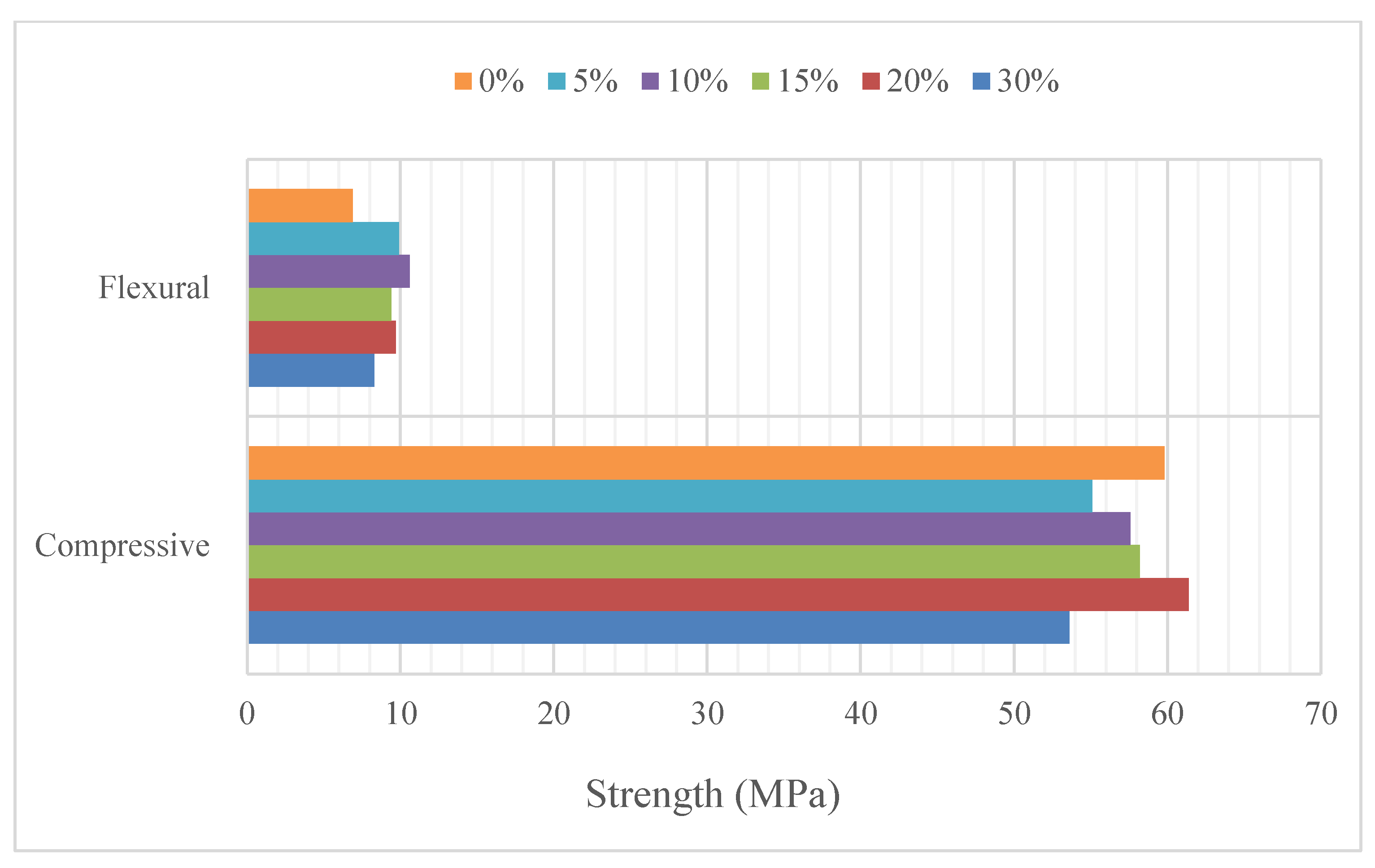

5. Geopolymer Concrete

6. Self-Compacting Concrete

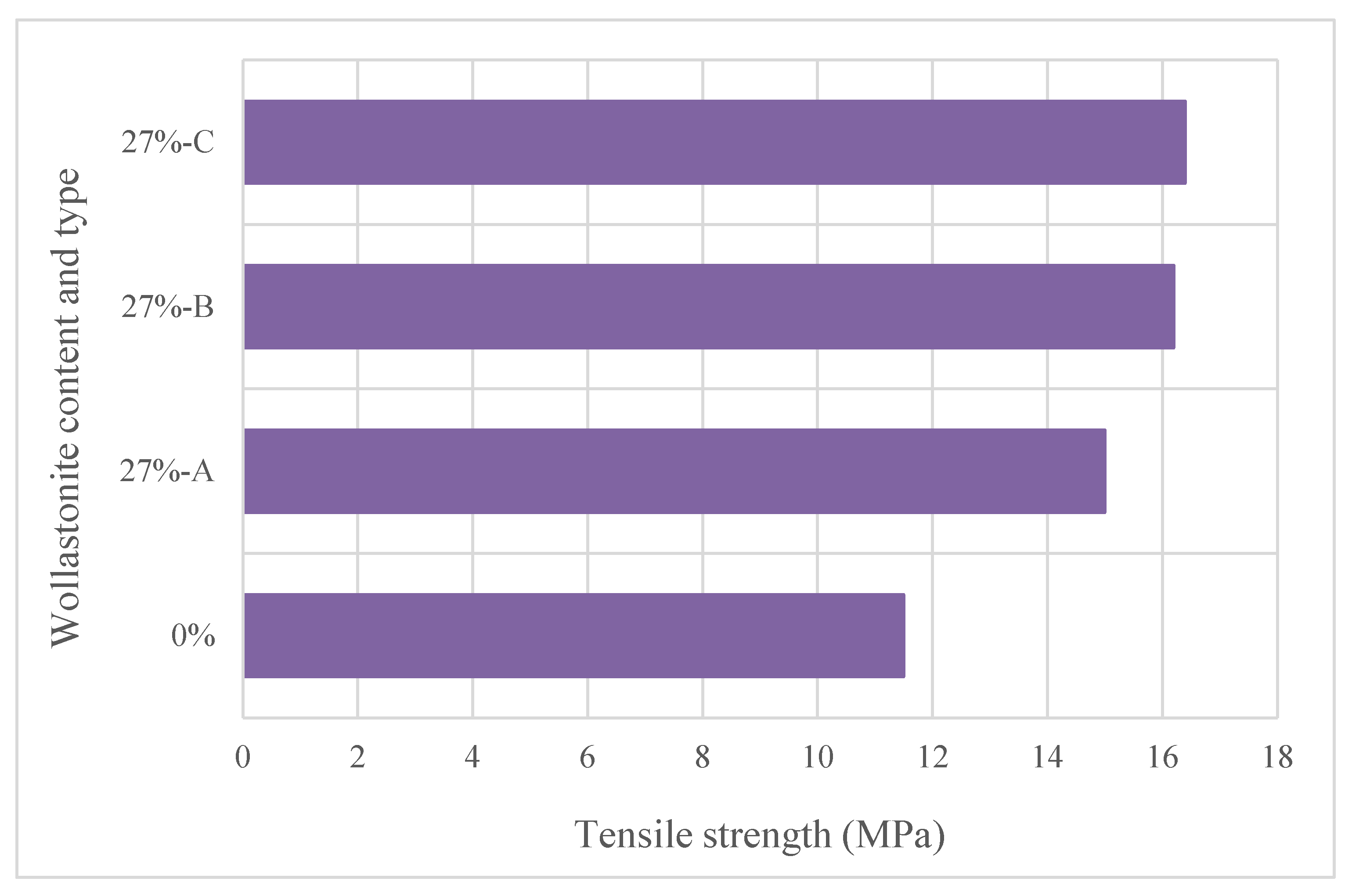

7. Ultra-High-Performance Concrete

8. Pavement Concrete

9. Conclusions

- In the use of cement paste and mortar of wollastonite, rates of 3–10% usage instead of cement demonstrated a positive effect, while this rate increased up to 30% in sand. Wollastonite and different material combinations also provided applicable results. The use of synthetic wollastonite instead of cement by up to 10% for improving the performance characteristics of mortar is crucial for sustainability.

- In the range of 10–15%, use of wollastonite instead of cement enhanced the mechanical and durability properties of conventional concrete. The positive effect of using a combination of fly ash and wollastonite up to 60% was also available in the studies.

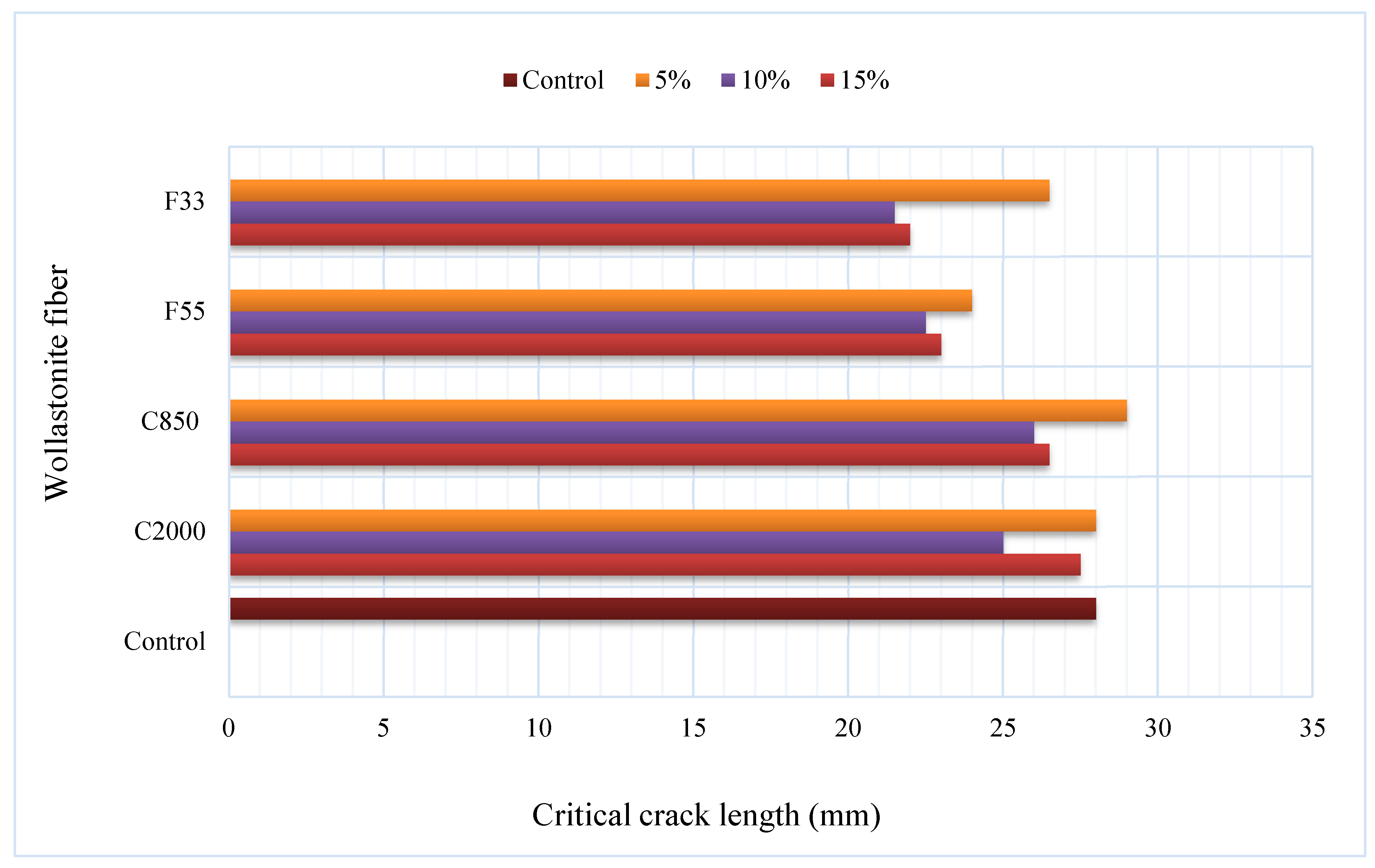

- Superior performance characteristics of engineered cementitious composite (ECC) are further enhanced with wollastonite, and 6% wollastonite substitution was stated as the optimum ratio. In addition, synthetic wollastonite with high aspect ratios of 44:1 and 33:1 was tested. The synthetic wollastonite with an aspect ratio of 44:1 showed better performance than 33:1. The effect of high aspect ratio was observed on ECC.

- Wollastonite was used instead of a precursor and sand in geopolymer concrete. The low mechanical property disadvantage of geopolymer was partially eliminated with the utilization of wollastonite. Strength increases were achieved with the use of 10–20% instead of sand.

- Positive performance properties were obtained from self-compacting concrete produced with wollastonite, both alone and in combination with different materials, up to 30% replacement.

- In ultra-high-performance concrete, the usage of wollastonite 27% instead of sand and up to 12% instead of cement increased the performance properties. Wollastonite can also increase sustainability without losing its performance properties.

- Only wollastonite and different material combinations were tested in pavements. Positive effects were observed in the use of up to 15% wollastonite.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Erdoğan, T.Y. Beton; ODTÜ Geliştirme Vakfı Yayıncılık ve İletişim: Ankara, Turkey, 2007. [Google Scholar]

- Bhasya, V.; Bharatkumar, B.H. Mechanical and Durability Properties of Concrete Produced with Treated Recycled Concrete Aggregate. ACI Mater. J. 2018, 115, 209–217. [Google Scholar] [CrossRef] [Green Version]

- Jalil, A.; Khitab, A.; Ishtiaq, H.; Bukhari, S.H.; Arshad, M.T.; Anwar, W. Evaluation of Steel Industrial Slag as Partial Replacement of Cement in Concrete. Civ. Eng. J. 2019, 5, 181–190. [Google Scholar] [CrossRef]

- Arif, R.; Khitab, A.; Kırgız, M.S.; Khan, R.B.N.; Tayyab, S.; Khan, R.A.; Anwar, W.; Arshad, M.T. Experimental Analysis on Partial Replacement of Cement with Brick Powder in Concrete. Case Stud. Constr. Mater. 2021, 15, e00749. [Google Scholar] [CrossRef]

- Kumar Mehta, P.; M Monteiro, P.J. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw Hill: New York, NY, USA, 2017. [Google Scholar]

- Kannan, D.M.; Aboubakr, S.H.; EL-Dieb, A.S.; Reda Taha, M.M. High Performance Concrete Incorporating Ceramic Waste Powder as Large Partial Replacement of Portland Cement. Constr. Build. Mater. 2017, 144, 35–41. [Google Scholar] [CrossRef]

- Öz, H.Ö.; Güneş, M. The Effects of Synthetic Wollastonite Developed with Calcite and Quartz on High Performance Mortars. Struct. Concr. 2021, 22, E257–E272. [Google Scholar] [CrossRef]

- Chen, W.; Liu, W.; Geng, Y.; Ohnishi, S.; Sun, L.; Han, W.; Tian, X.; Zhong, S. Life Cycle Based Emergy Analysis on China’s Cement Production. J. Clean. Prod. 2016, 131, 272–279. [Google Scholar] [CrossRef]

- Huang, H.; Guo, R.; Wang, T.; Hu, X.; Garcia, S.; Fang, M.; Luo, Z.; Maroto-Valer, M.M. Carbonation Curing for Wollastonite-Portland Cementitious Materials: CO2 Sequestration Potential and Feasibility Assessment. J. Clean. Prod. 2019, 211, 830–841. [Google Scholar] [CrossRef]

- Humphreys, K.; Mahasenan, M. Towards a Sustainable Cement Industry: Climate Change; Substudy 8; World Business Council for Sustainable Development (WBCSD): Geneva, Switzerland, 2002. [Google Scholar]

- Mikulčić, H.; Klemeš, J.J.; Vujanović, M.; Urbaniec, K.; Duić, N. Reducing Greenhouse Gasses Emissions by Fostering the Deployment of Alternative Raw Materials and Energy Sources in the Cleaner Cement Manufacturing Process. J. Clean. Prod. 2016, 136, 119–132. [Google Scholar] [CrossRef]

- Atmaca, A.; Atmaca, N. Carbon Footprint Assessment of Residential Buildings, a Review and a Case Study in Turkey. J. Clean. Prod. 2022, 340, 130691. [Google Scholar] [CrossRef]

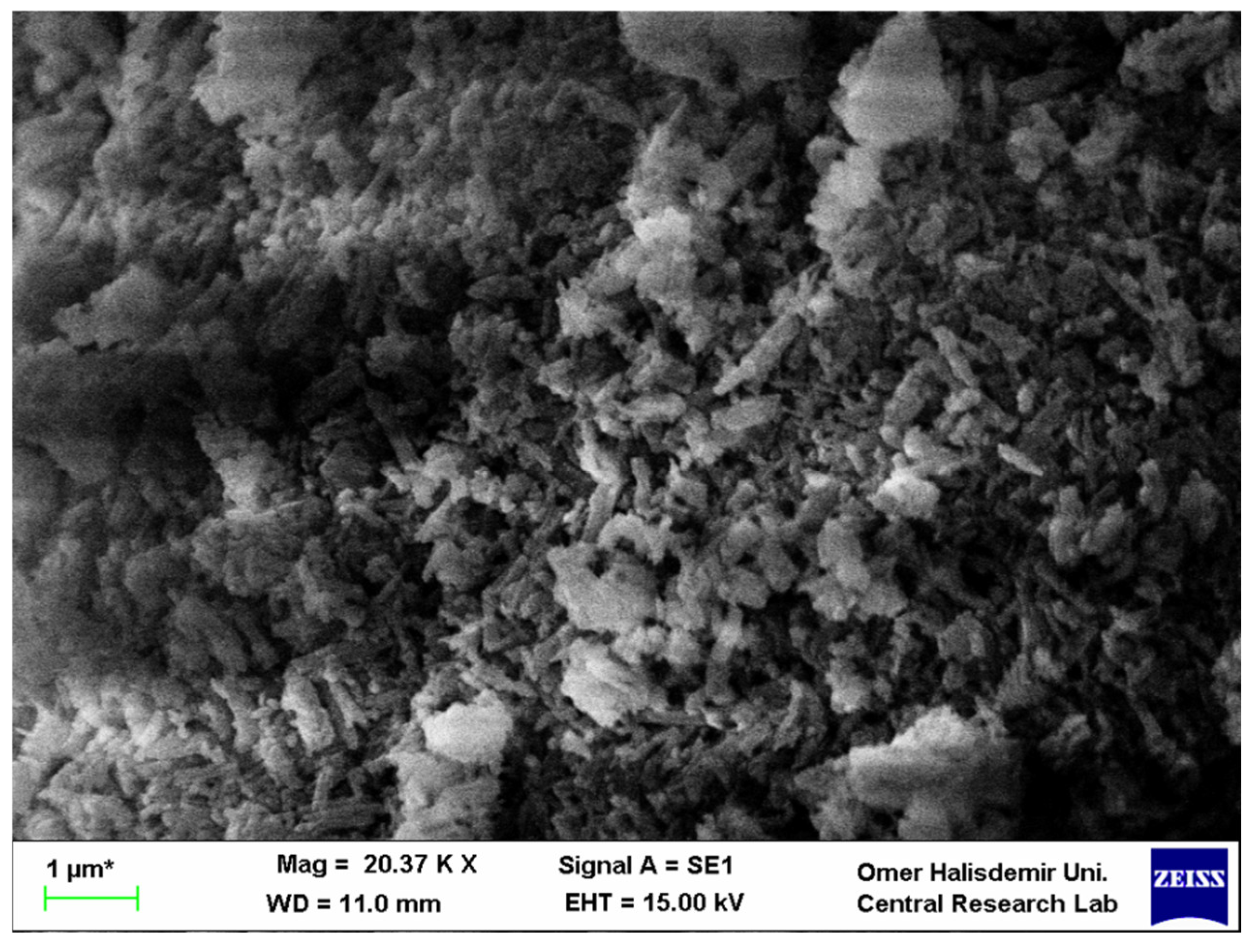

- Yücel, H.E.; Özcan, S. Strength Characteristics and Microstructural Properties of Cement Mortars Incorporating Synthetic Wollastonite Produced with a New Technique. Constr. Build. Mater. 2019, 223, 165–176. [Google Scholar] [CrossRef]

- Nair, N.A.; Sairam, V. Research Initiatives on the Influence of Wollastonite in Cement-Based Construction Material—A Review. J. Clean. Prod. 2021, 283, 124665. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, C.; Zhou, S.; Luo, C. The Self-Gelation Properties of Calcined Wollastonite Powder. Constr. Build. Mater. 2021, 290, 123061. [Google Scholar] [CrossRef]

- Maxim, L.D.; McConnell, E.E. A Review of the Toxicology and Epidemiology of Wollastonite. Inhal. Toxicol. 2008, 17, 451–466. [Google Scholar] [CrossRef]

- Saxena, S.K.; Kumar, M.; Chundawat, D.S.; Singh, N.B. Utilization of Wollastonite in Cement Manufacturing. Mater. Today Proc. 2020, 29, 733–737. [Google Scholar] [CrossRef]

- Ahmad, F.; Ullah, S.; Oñate, E.; Al-Sehemi, A.G.; Yeoh, G.H. An Investigation on Thermal Performance of Wollastonite and Bentonite Reinforced Intumescent Fire-Retardant Coating for Steel Structures. Constr. Build. Mater. 2019, 228, 116734. [Google Scholar] [CrossRef]

- Paul, F.K. Mineral Descriptions-Wollastonite, Optical Mineralogy, 4th ed.; McGraw Hill: New York, NY, USA, 1977. [Google Scholar]

- Ransinchung RN, G.D.; Kumar, B. Investigations on Pastes and Mortars of Ordinary Portland Cement Admixed with Wollastonite and Microsilica. J. Mater. Civ. Eng. 2010, 22, 305–313. [Google Scholar] [CrossRef]

- Soliman, A.M.; Nehdi, M.L. Effect of Natural Wollastonite Microfibers on Early-Age Behavior of UHPC. J. Mater. Civ. Eng. 2012, 24, 816–824. [Google Scholar] [CrossRef]

- Harabi, A.; Chehlatt, S. Preparation Process of a Highly Resistant Wollastonite Bioceramics Using Local Raw Materials: Effect of B2O3 Additions on Sintering and Mechanical Properties. J. Therm. Anal. Calorim. 2013, 111, 203–211. [Google Scholar] [CrossRef]

- Obeid, M.; Mont, M.; Schneider, J.; Rodrigues, A.; Obeid, M.M. Crystallization of Synthetic Wollastonite Prepared from Local Raw Materials. Int. J. Mater. Chem. 2014, 4, 79–87. [Google Scholar] [CrossRef]

- Shamsudin, R.; ’Atiqah Abdul Azam, F.; Abdul Hamid, M.A.; Ismail, H. Bioactivity and Cell Compatibility of β-Wollastonite Derived from Rice Husk Ash and Limestone. Materials 2017, 10, 1188. [Google Scholar] [CrossRef]

- He, Z.; Shen, A.; Lyu, Z.; Li, Y.; Wu, H.; Wang, W. Effect of Wollastonite Microfibers as Cement Replacement on the Properties of Cementitious Composites: A Review. Constr. Build. Mater. 2020, 261, 119920. [Google Scholar] [CrossRef]

- Low, N.M.P.; Beaudoin, J.J. Flexural Strength and Microstructure of Cement Binders Reinforced with Wollastonite Micro-Fibres. Cem. Concr. Res. 1993, 23, 905–916. [Google Scholar] [CrossRef]

- Ransinchung, G.D.; Kumar, B.; Kumar, V. Assessment of Water Absorption and Chloride Ion Penetration of Pavement Quality Concrete Admixed with Wollastonite and Microsilica. Constr. Build. Mater. 2009, 23, 1168–1177. [Google Scholar] [CrossRef]

- Dey, V.; Kachala, R.; Bonakdar, A.; Mobasher, B. Mechanical Properties of Micro and Sub-Micron Wollastonite Fibers in Cementitious Composites. Constr. Build. Mater. 2015, 82, 351–359. [Google Scholar] [CrossRef]

- Kalkan, Ş.O.; Yavaş, A.; Güler, S.; Torman Kayalar, M.; Sütçü, M.; Gündüz, L. An Experimental Approach to a Cementitious Lightweight Composite Mortar Using Synthetic Wollastonite. Constr. Build. Mater. 2022, 341, 127911. [Google Scholar] [CrossRef]

- Vichaphund, S.; Kitiwan, M.; Atong, D.; Thavorniti, P. Microwave Synthesis of Wollastonite Powder from Eggshells. J. Eur. Ceram. Soc. 2011, 31, 2435–2440. [Google Scholar] [CrossRef]

- Emrullahoǧlu, S.B.; Emrullahoǧlu, C.B.; Emrullahoǧlu, Ö.F. Syntetic Wollastonite Production from Raw and Tailing Materials. Key Eng. Mater. 2004, 264–268, 2485–2488. [Google Scholar] [CrossRef]

- Kalla, P.; Rana, A.; Chad, Y.B.; Misra, A.; Csetenyi, L. Durability Studies on Concrete Containing Wollastonite. J. Clean. Prod. 2015, 87, 726–734. [Google Scholar] [CrossRef]

- Yücel, H.E.; Öz, H.Ö.; Güneş, M.; Kaya, Y. Rheological Properties, Strength Characteristics and Flexural Performances of Engineered Cementitious Composites Incorporating Synthetic Wollastonite Microfibers with Two Different High Aspect Ratios. Constr. Build. Mater. 2021, 306, 124921. [Google Scholar] [CrossRef]

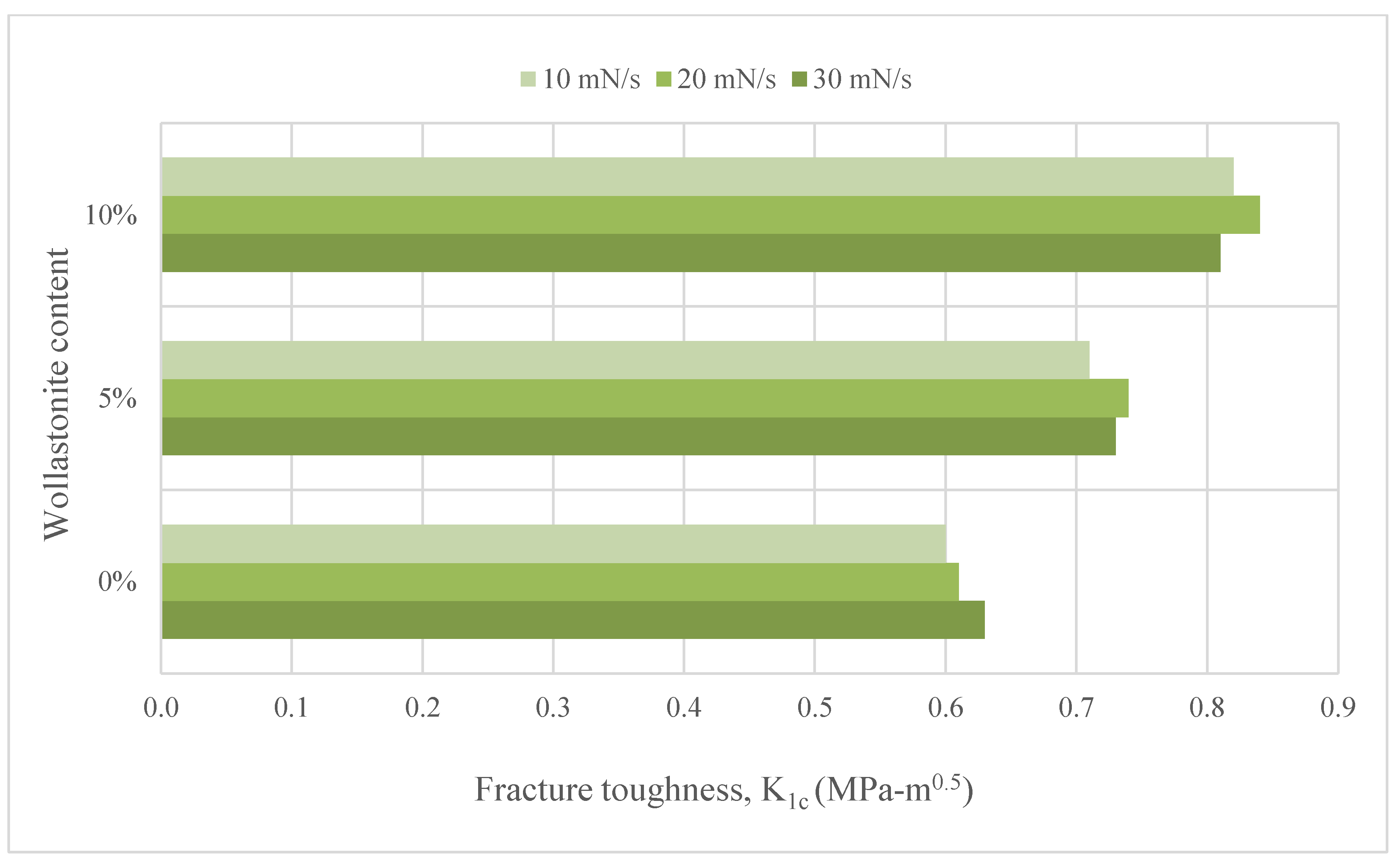

- Doner, S.; Lyngdoh, G.A.; Nayak, S.; Das, S. Fracture Response of Wollastonite Fiber-Reinforced Cementitious Composites: Evaluation Using Micro-Indentation and Finite Element Simulation. Ceram. Int. 2022, 48, 15493–15503. [Google Scholar] [CrossRef]

- Öz, H.Ö.; Yücel, H.E.; Güneş, M.; Malkoç, B. The Effects on High Performance Mortars of Natural Wollastonite. NOHU J. Eng. Sci. 2020, 9, 966–974. [Google Scholar] [CrossRef]

- Khan, R.I.; Ashraf, W. Effects of Ground Wollastonite on Cement Hydration Kinetics and Strength Development. Constr. Build. Mater. 2019, 218, 150–161. [Google Scholar] [CrossRef]

- Abdel Wahab, M.; Abdel Latif, I.; Kohail, M.; Almasry, A. The Use of Wollastonite to Enhance the Mechanical Properties of Mortar Mixes. Constr. Build. Mater. 2017, 152, 304–309. [Google Scholar] [CrossRef]

- Leemann, A.; Winnefeld, F.; Münch, B.; Läng, F. Carbonated Wollastonite—An Effective Supplementary Cementitious Material? J. Microsc. 2022, 286, 120–125. [Google Scholar] [CrossRef] [PubMed]

- Mathur, R.; Misra, A.K.; Goel, P.; Mathur, R.; Misra, A.K.; Goel, P. Influence of Wollastonite on Mechanical Properties of Concrete. J. Sci. Ind. Res. 2007, 66, 1029–1034. [Google Scholar]

- Kh, K. Research of Light-Weight Concrete Properties on Base Wollastonite Addition. Middle Eur. Sci. Bull. 2021, 8. [Google Scholar] [CrossRef]

- Aziza, K.; Kh, K.; Aziza, K. Durability Characteristics of Concrete Admixed with Wollastonite Mineral. Eur. J. Life Saf. Stab. 2021, 5, 9–13. [Google Scholar]

- Kuldasheva, A.; Saidmuratov, B.; Kuldashev, H. The Use of Wollastonite Fiber to Enhance the Mechanical Properties of Cement Compositions. Int. J. Progress. Sci. Technol. 2020, 22, 37–45. [Google Scholar]

- Kalla, P.; Misra, A.; Gupta, R.C.; Csetenyi, L.; Gahlot, V.; Arora, A. Mechanical and Durability Studies on Concrete Containing Wollastonite-Fly Ash Combination. Constr. Build. Mater. 2013, 40, 1142–1150. [Google Scholar] [CrossRef]

- Kumar Mandrawalia, A.; Gaur, A. Compressive and Sorptivity Characteristic of Concrete Modified with Wollastonite Fibre and Waste Granite Fines. Mater. Today Proc. 2021, 42, 1012–1016. [Google Scholar] [CrossRef]

- Atiş, C.D.; Görür, E.B.; Karahan, O.; Bilim, C.; Ilkentapar, S.; Luga, E. Very High Strength (120 MPa) Class F Fly Ash Geopolymer Mortar Activated at Different NaOH Amount, Heat Curing Temperature and Heat Curing Duration. Constr. Build. Mater. 2015, 96, 673–678. [Google Scholar] [CrossRef]

- Choi, Y.C.; Park, B. Effects of High-Temperature Exposure on Fractal Dimension of Fly-Ash-Based Geopolymer Composites. J. Mater. Res. Technol. 2020, 9, 7655–7668. [Google Scholar] [CrossRef]

- Hemalatha, P.; Ramujee, K. Influence of Nano Material (TiO2) on Self Compacting Geo Polymer Concrete Containing Flyash, GGBS and Wollastonite. Mater. Today Proc. 2021, 43, 2438–2442. [Google Scholar] [CrossRef]

- Bong, S.H.; Nematollahi, B.; Xia, M.; Nazari, A.; Sanjayan, J. Properties of One-Part Geopolymer Incorporating Wollastonite as Partial Replacement of Geopolymer Precursor or Sand. Mater. Lett. 2020, 263, 127236. [Google Scholar] [CrossRef]

- Bong, S.H.; Nematollahi, B.; Xia, M.; Ghaffar, S.H.; Pan, J.; Dai, J.G. Properties of Additively Manufactured Geopolymer Incorporating Mineral Wollastonite Microfibers. Constr. Build. Mater. 2022, 331, 127282. [Google Scholar] [CrossRef]

- Ren, D.; Yan, C.; Duan, P.; Zhang, Z.; Li, L.; Yan, Z. Durability Performances of Wollastonite, Tremolite and Basalt Fiber-Reinforced Metakaolin Geopolymer Composites under Sulfate and Chloride Attack. Constr. Build. Mater. 2017, 134, 56–66. [Google Scholar] [CrossRef]

- Guo, L.; Wu, Y.; Xu, F.; Song, X.; Ye, J.; Duan, P.; Zhang, Z. Sulfate Resistance of Hybrid Fiber Reinforced Metakaolin Geopolymer Composites. Compos. Part B Eng. 2020, 183, 107689. [Google Scholar] [CrossRef]

- Archez, J.; Texier-Mandoki, N.; Bourbon, X.; Caron, J.F.; Rossignol, S. Influence of the Wollastonite and Glass Fibers on Geopolymer Composites Workability and Mechanical Properties. Constr. Build. Mater. 2020, 257, 119511. [Google Scholar] [CrossRef]

- Vishnu, N.; Kolli, R.; Ravella, D.P. Studies on Self-Compacting Geopolymer Concrete Containing Flyash, GGBS, Wollastonite and Graphene Oxide. Mater. Today Proc. 2021, 43, 2422–2427. [Google Scholar] [CrossRef]

- Jindal, A.; Ransinchung, R.N.G.D.; Kumar, P. Behavioral Study of Self-Compacting Concrete with Wollastonite Microfiber as Part Replacement of Sand for Pavement Quality Concrete (PQC). Int. J. Transp. Sci. Technol. 2020, 9, 170–181. [Google Scholar] [CrossRef]

- Gouse Mohiuddin, M.D.; Malagavelli, V.; kumar Balguri, P. Influence of Wollastonite-GGBS on Properties of Ternary Blended Self Compacting Concrete. Mater. Today Proc. 2022, 62, 3027–3032. [Google Scholar] [CrossRef]

- Sharma, S.K. Properties of SCC Containing Pozzolans, Wollastonite Micro Fiber, and Recycled Aggregates. Heliyon 2019, 5, e02081. [Google Scholar] [CrossRef] [Green Version]

- Kwon, S.; Nishiwaki, T.; Choi, H.; Mihashi, H. Effect of Wollastonite Microfiber on Ultra-High-Performance Fiber-Reinforced Cement-Based Composites Based on Application of Multi-Scale Fiber-Reinforcement System. J. Adv. Concr. Technol. 2015, 13, 332–344. [Google Scholar] [CrossRef]

- Soliman, A.M.; Nehdi, M.L. Effects of Shrinkage Reducing Admixture and Wollastonite Microfiber on Early-Age Behavior of Ultra-High Performance Concrete. Cem. Concr. Compos. 2014, 46, 81–89. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Shoaei, P.; Bahrami, N. Recycled Ceramic Waste High Strength Concrete Containing Wollastonite Particles and Micro-Silica: A Comprehensive Experimental Study. Constr. Build. Mater. 2019, 201, 11–32. [Google Scholar] [CrossRef]

- Ransinchung, G.D.; Kumar, P.N. Laboratory Study on Use of Wollastonite Micro-Fibers for Abrasion Resistance of Pavement Quality Concrete. In Proceedings of the International Conference on Engineering and Information Technology “ICEIT2012”, Toronto, ON, Canada, 17–18 September 2012. [Google Scholar]

- Kumar, R. Wollastonite Mineral Fibre in Manufacturing of an Economical Pavement Concrete. In Proceedings of the Fourth International Conference on Sustainable Construction Materials and Technologies, Las Vegas, NV, USA, 7–11 August 2016. [Google Scholar]

| Chemical Analysis (%) | Wollastonite |

|---|---|

| CaO | 44.55 |

| SiO2 | 50.78 |

| Al2O3 | 0.83 |

| Fe2O3 | 0.17 |

| MgO | 0.47 |

| SO3 | 0.04 |

| K2O | 0.001 |

| Na2O | 0.363 |

| TiO2 | 0.49 |

| Mix | W/b Ratio | OPC | * WF | CA | FA | * WGF | Water | * SPDosage % |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.35 | 425 | 0 | 1298 | 628 | 0 | 148.75 | 1.25 |

| 2 | 0.35 | 382.5 | 42.5 | 1298 | 565.2 | 62.8 | 148.75 | 1.3 |

| 3 | 0.35 | 382.5 | 42.5 | 1298 | 502.4 | 125.6 | 148.75 | 1.5 |

| 4 | 0.35 | 382.5 | 42.5 | 1298 | 439.6 | 188.4 | 148.75 | 1.65 |

| 5 | 0.35 | 382.5 | 42.5 | 1298 | 376.8 | 251.2 | 148.75 | 1.9 |

| 6 | 0.35 | 382.5 | 42.5 | 1298 | 314 | 314 | 148.75 | 2.1 |

| Study in Literature | Wollastonite Replacement | Effect of Wollastonite |

|---|---|---|

| [34] | 5–10% instead of cement | Increment about 34% fracture toughness |

| [35] | 0–15% instead of cement | Increment about 12% compressive and increment about 6% flexural strength |

| [36] | 0–50% instead of cement | Decrease in workability and increment in cement hydration |

| [28] | 5–15% instead of cement | Increment in crack growth resistance and ductility |

| [37] | 10–30% instead of cement and sand | Increment in initial setting time and decrease about 47% drying shrinkage |

| [7] | 0–12% instead of cement (synthetic wollastonite) | Increment about 8% compressive and increment about 11% flexural strength; decrease about 15% water sorptivity coefficient, about 4% rapid chloride permeability and about 25% gas permeability |

| [32] | 0–25% instead of cement | Decrease in porosity, water permeability, chloride diffusion and carbonation depth |

| [43] | 0–25% instead of cement | Increment in resistance against corrosion |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dutkiewicz, M.; Yücel, H.E.; Yıldızhan, F. Evaluation of the Performance of Different Types of Fibrous Concretes Produced by Using Wollastonite. Materials 2022, 15, 6904. https://doi.org/10.3390/ma15196904

Dutkiewicz M, Yücel HE, Yıldızhan F. Evaluation of the Performance of Different Types of Fibrous Concretes Produced by Using Wollastonite. Materials. 2022; 15(19):6904. https://doi.org/10.3390/ma15196904

Chicago/Turabian StyleDutkiewicz, Maciej, Hasan Erhan Yücel, and Fatih Yıldızhan. 2022. "Evaluation of the Performance of Different Types of Fibrous Concretes Produced by Using Wollastonite" Materials 15, no. 19: 6904. https://doi.org/10.3390/ma15196904

APA StyleDutkiewicz, M., Yücel, H. E., & Yıldızhan, F. (2022). Evaluation of the Performance of Different Types of Fibrous Concretes Produced by Using Wollastonite. Materials, 15(19), 6904. https://doi.org/10.3390/ma15196904