Dynamic Response of Sandwich Tubes with Continuously Density-Graded Aluminum Foam Cores under Internal Explosion Load

Abstract

:1. Introduction

2. Finite-Element Simulation

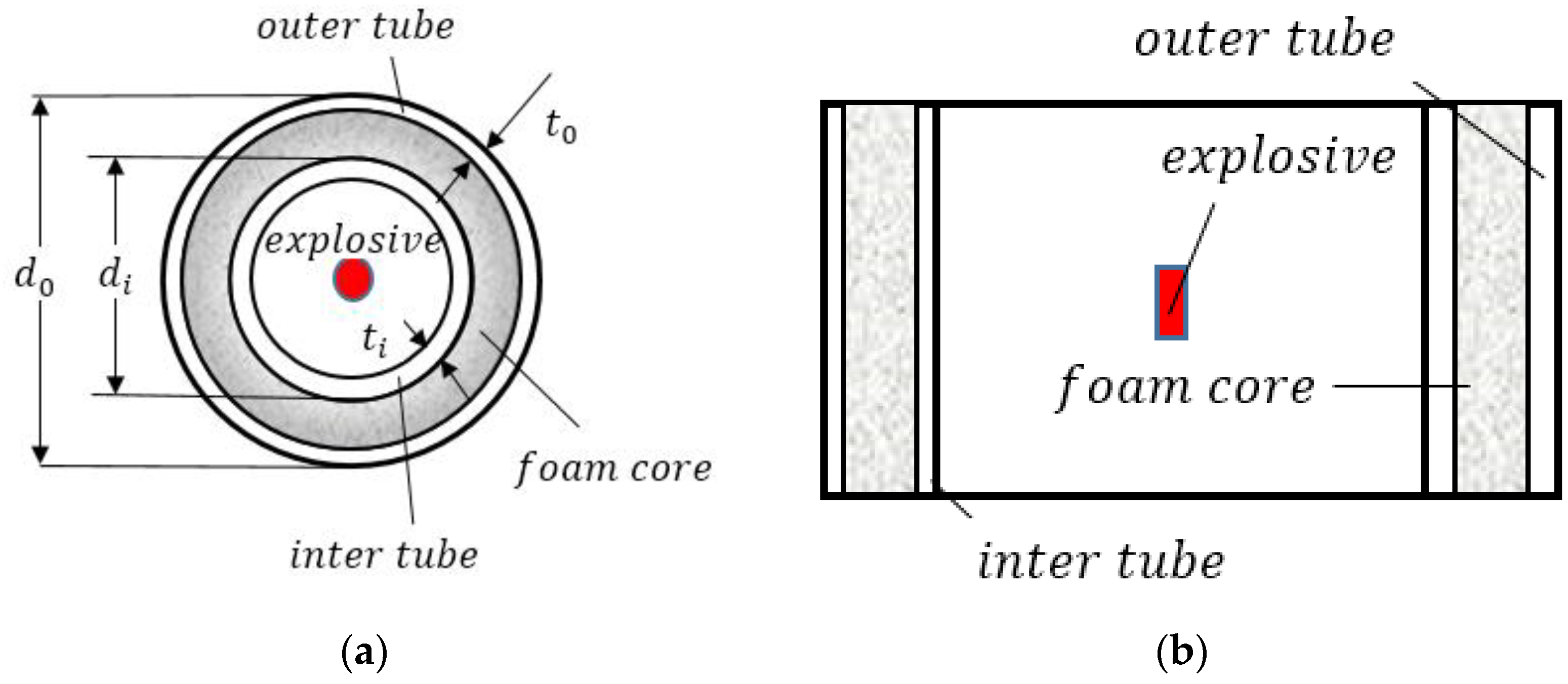

2.1. Sandwich Tube Finite-Element Model

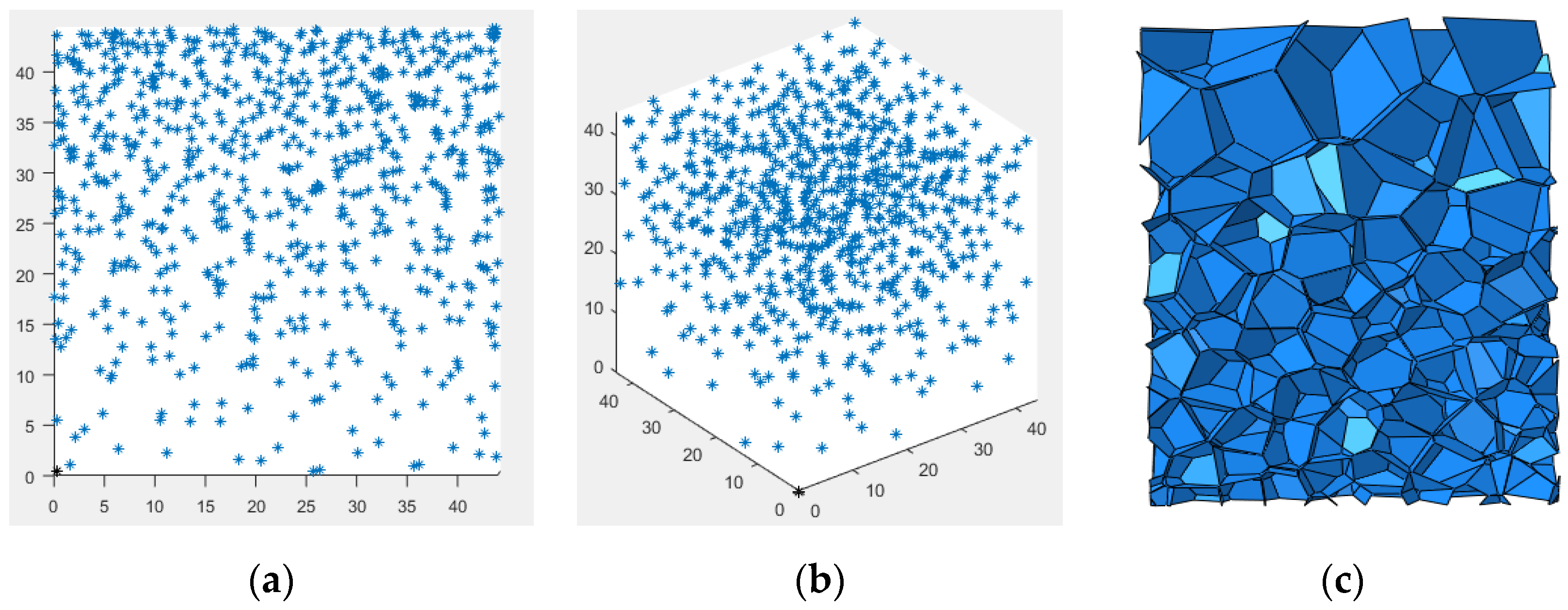

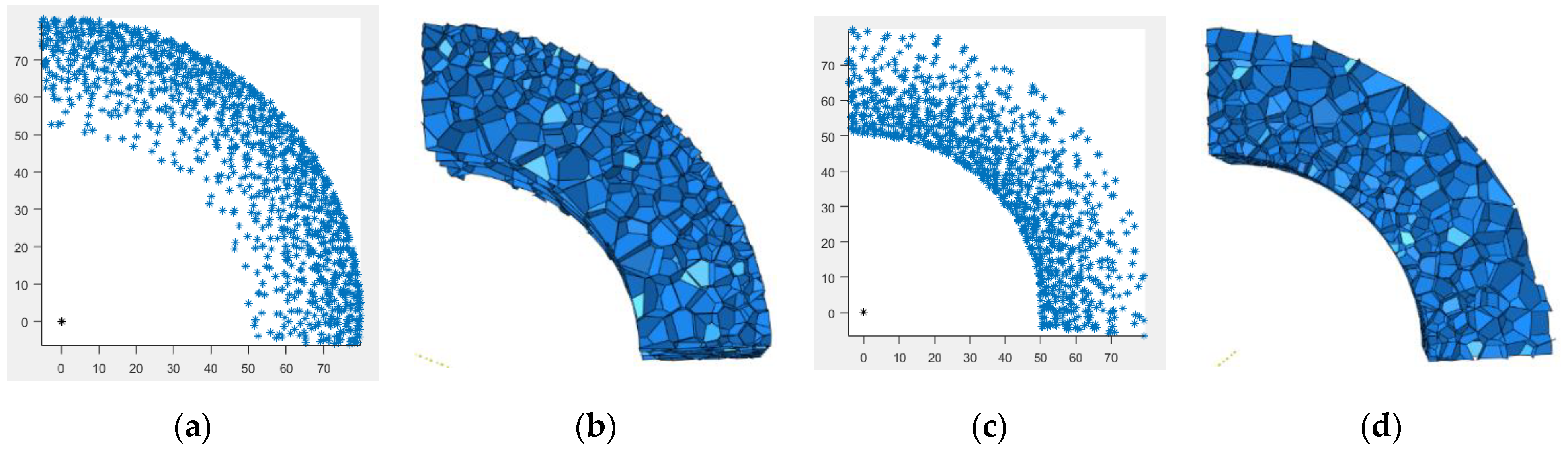

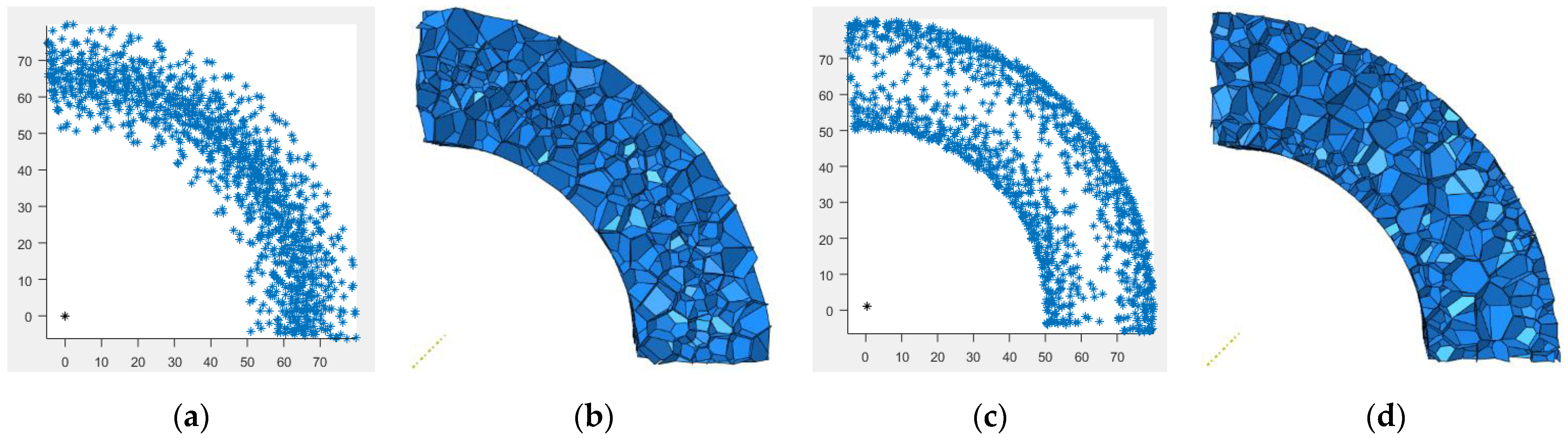

2.1.1. Cylindrical 3D-Voronoi Foam Model

2.1.2. Meso Parameter Statistics

2.1.3. Finite-Element Model of the Sandwich Tube

2.2. Material Properties

2.3. Finite-Element Model Verification

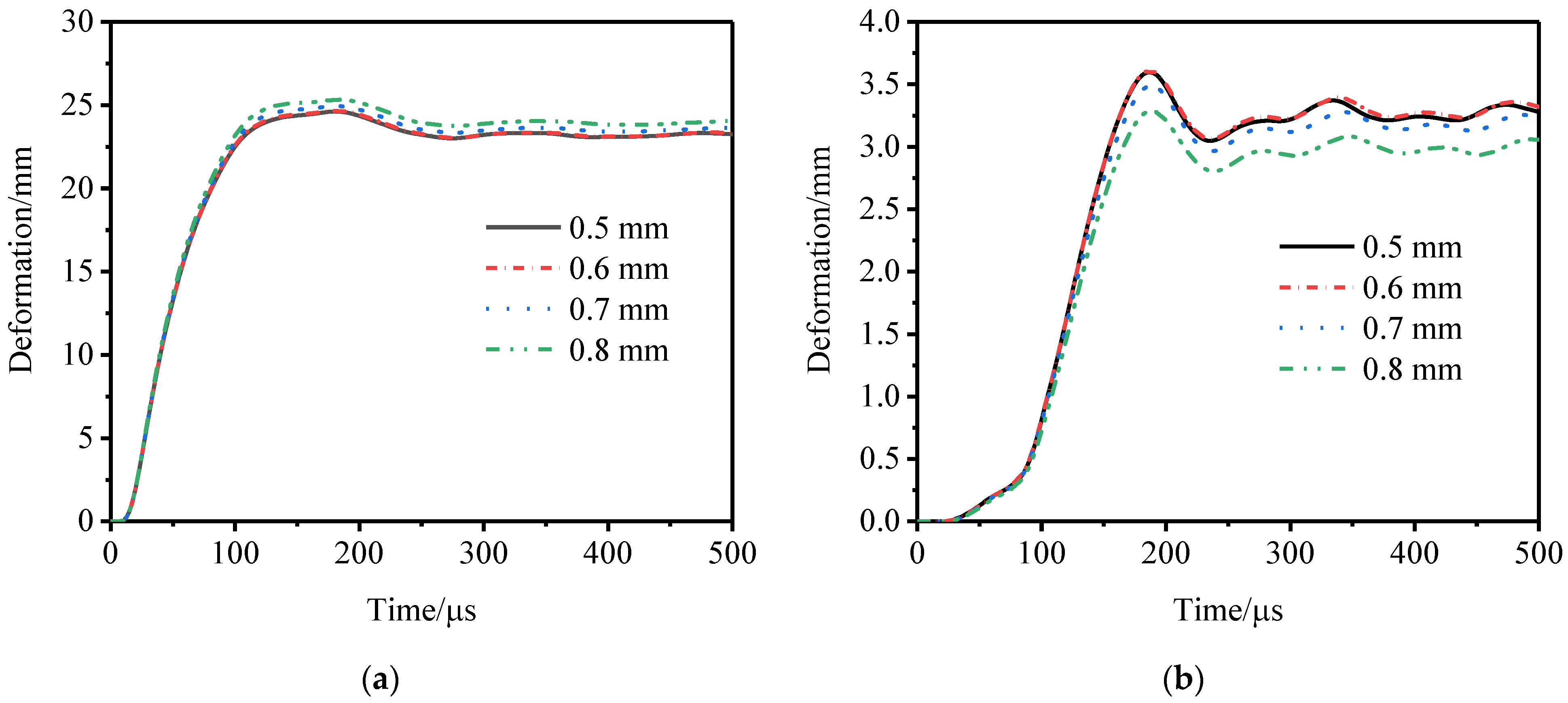

2.3.1. Mesh Sensitivity Verification

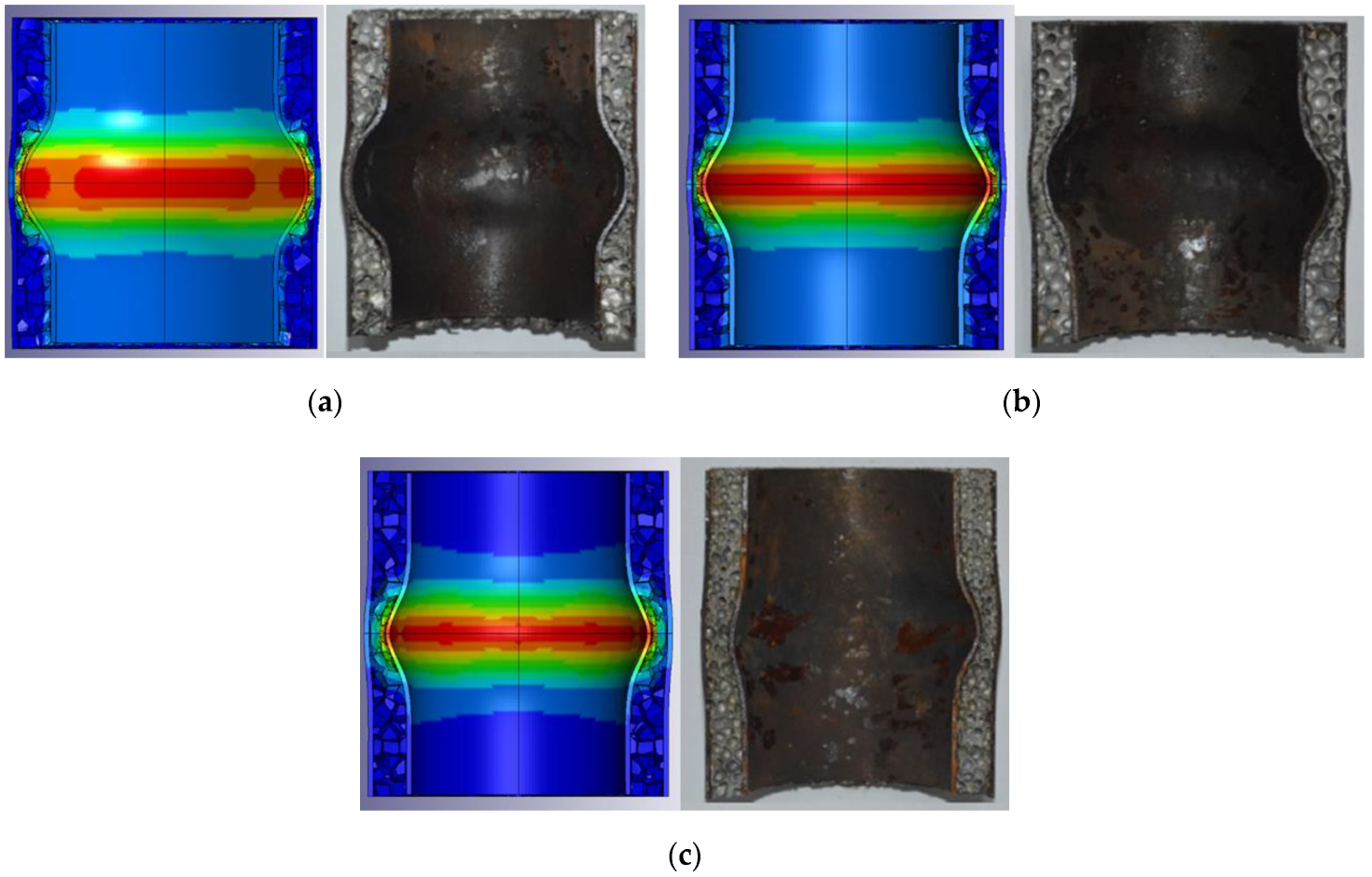

2.3.2. Comparison between Numerical Simulation and Experimental Results

3. Results and Discussion

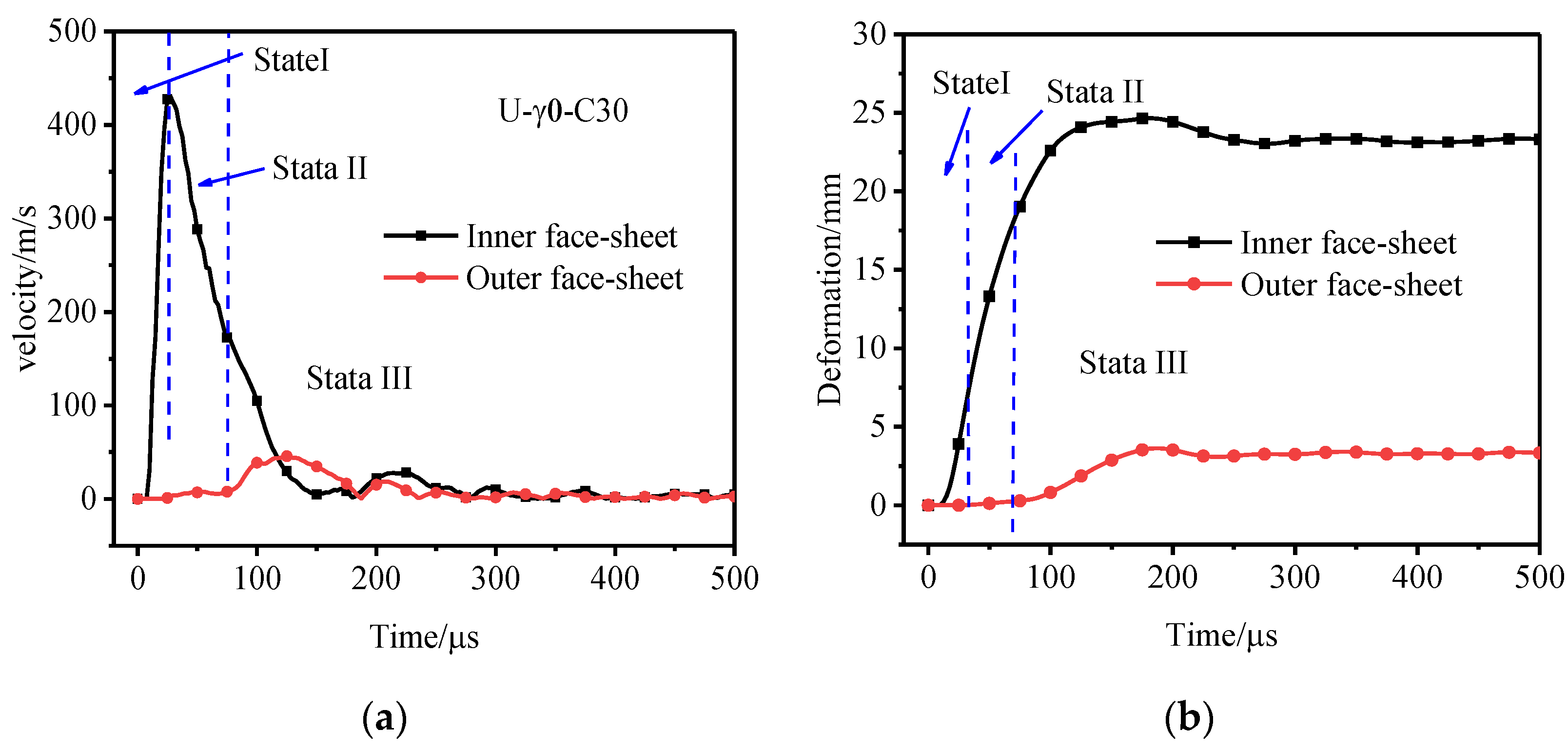

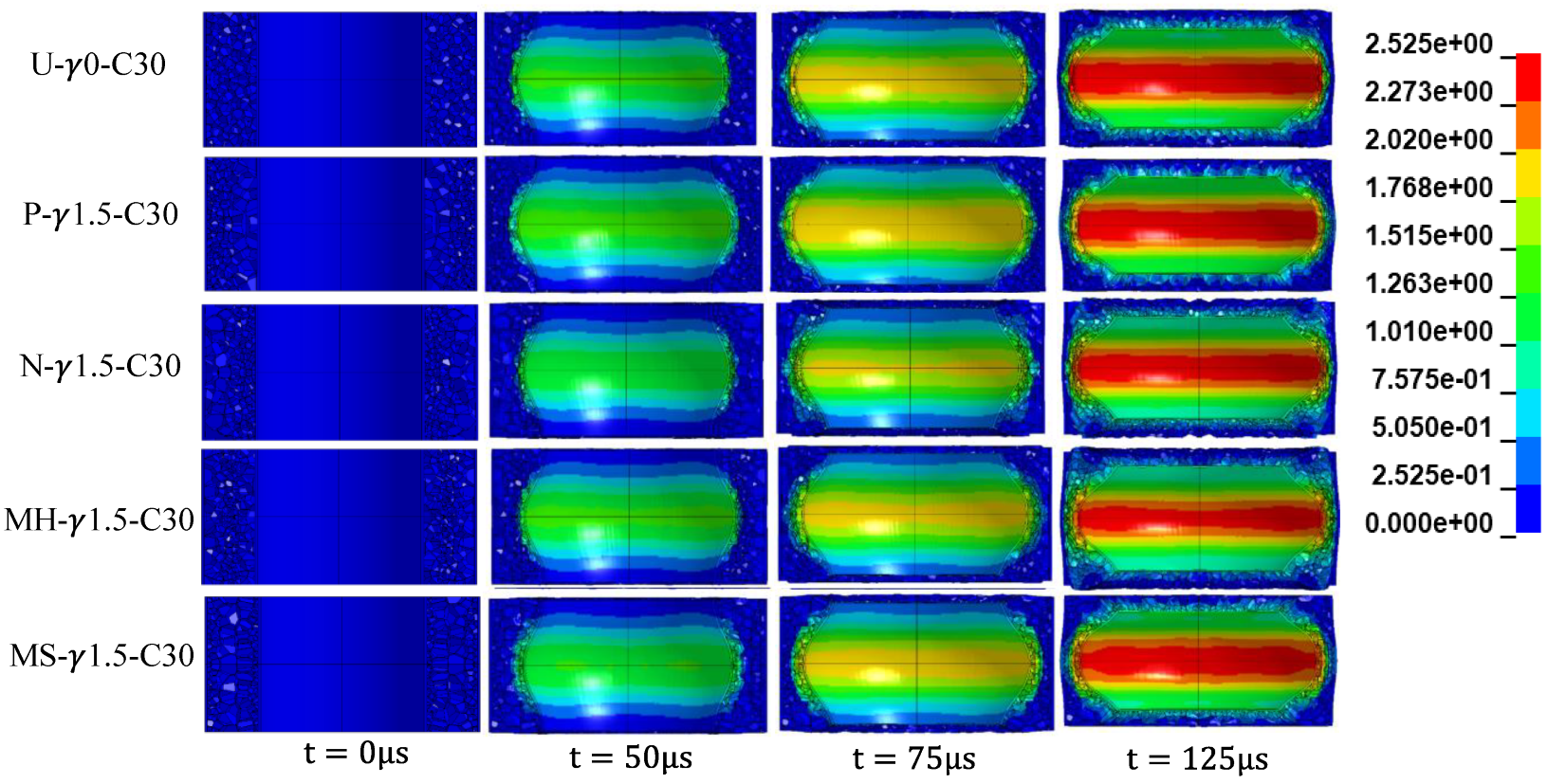

3.1. Deformation Process

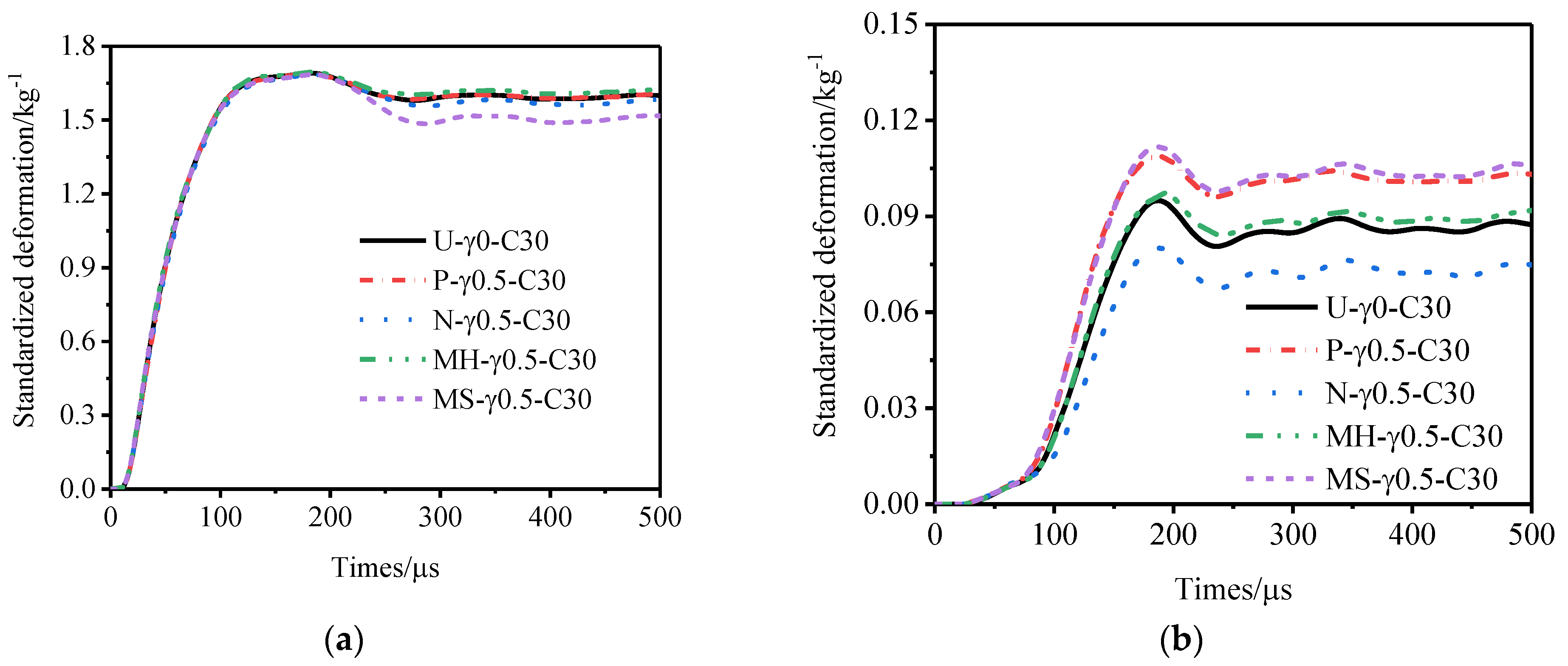

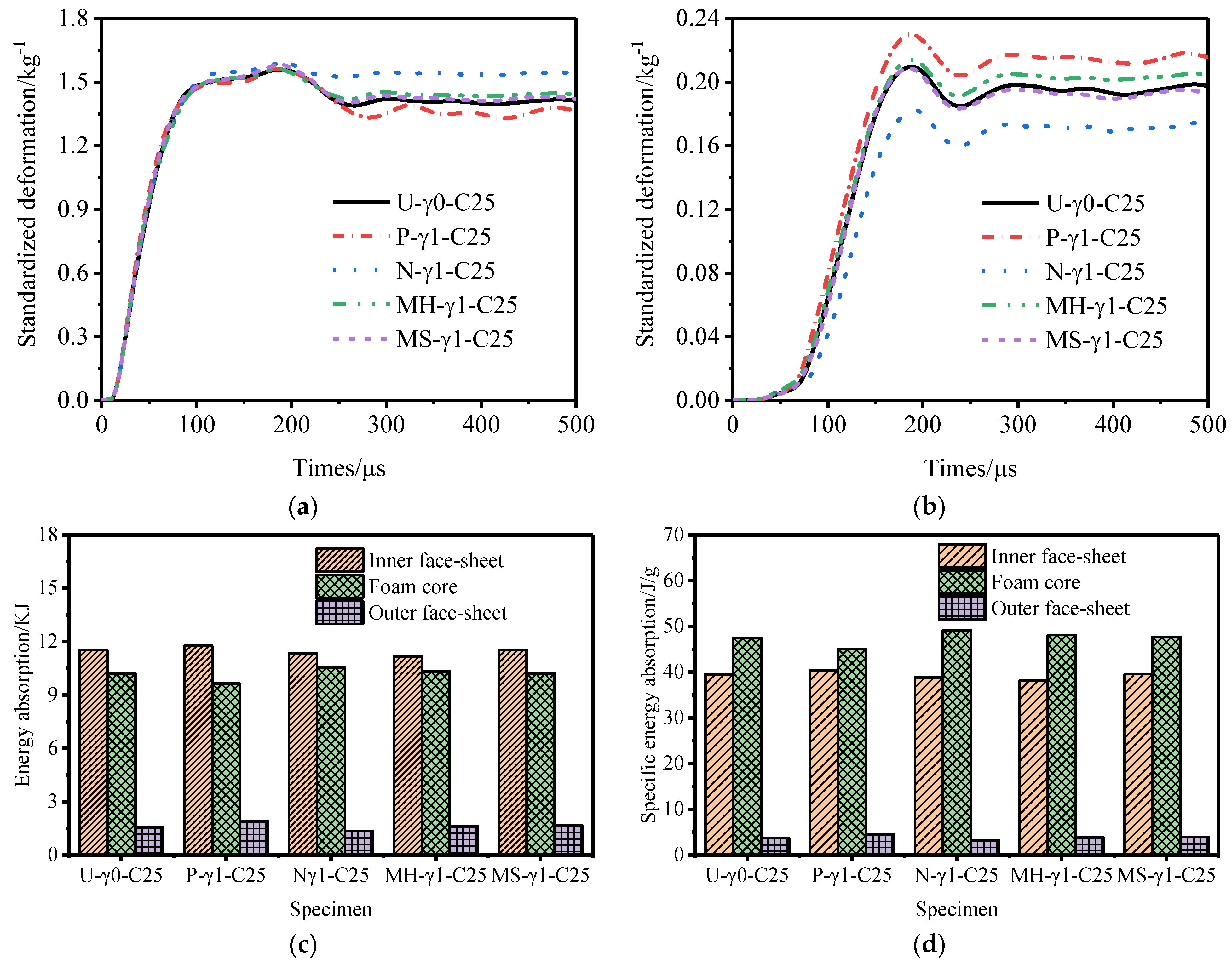

3.2. Influence of the Core Density Distribution

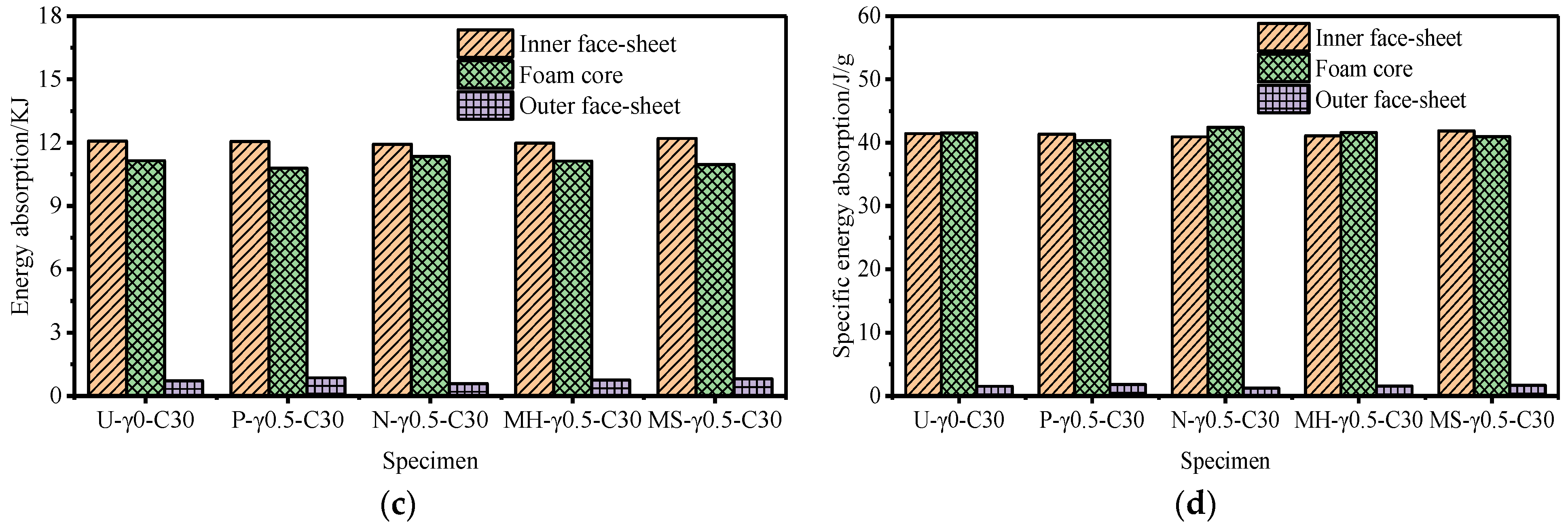

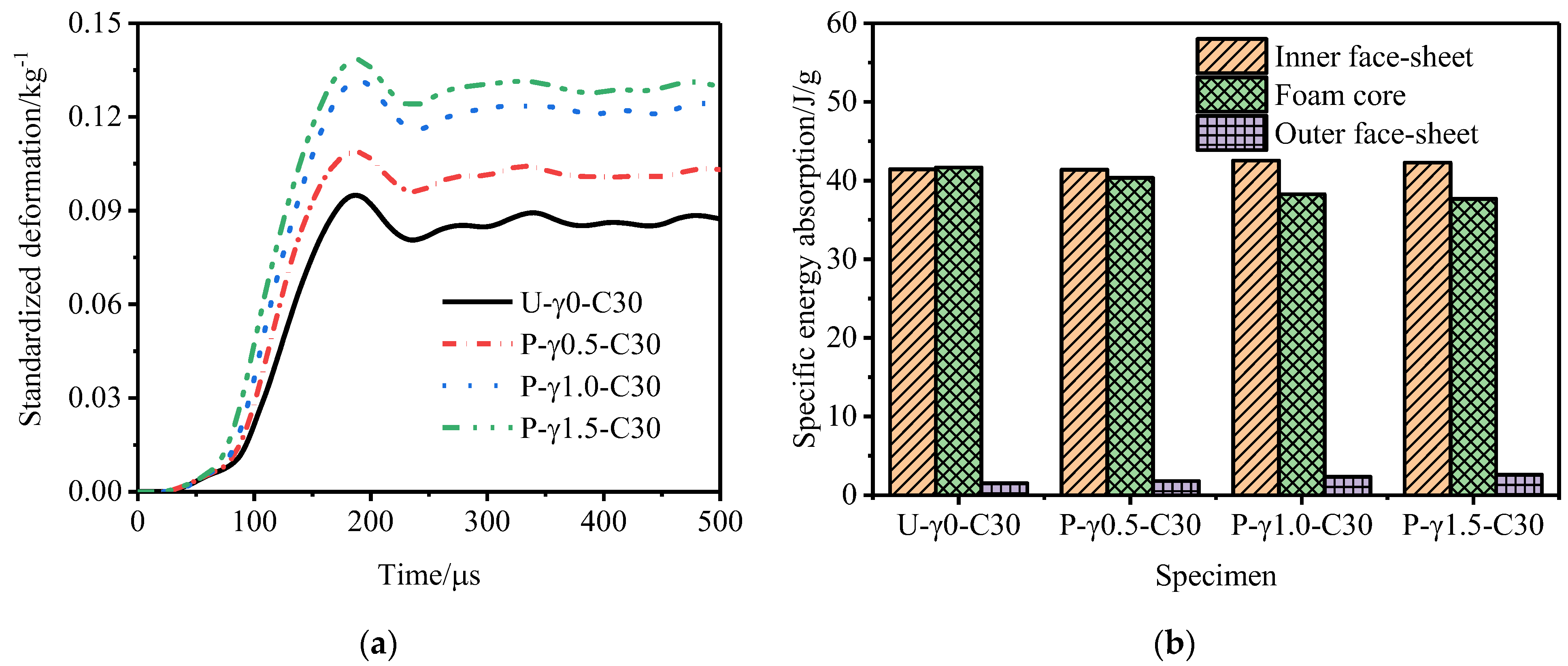

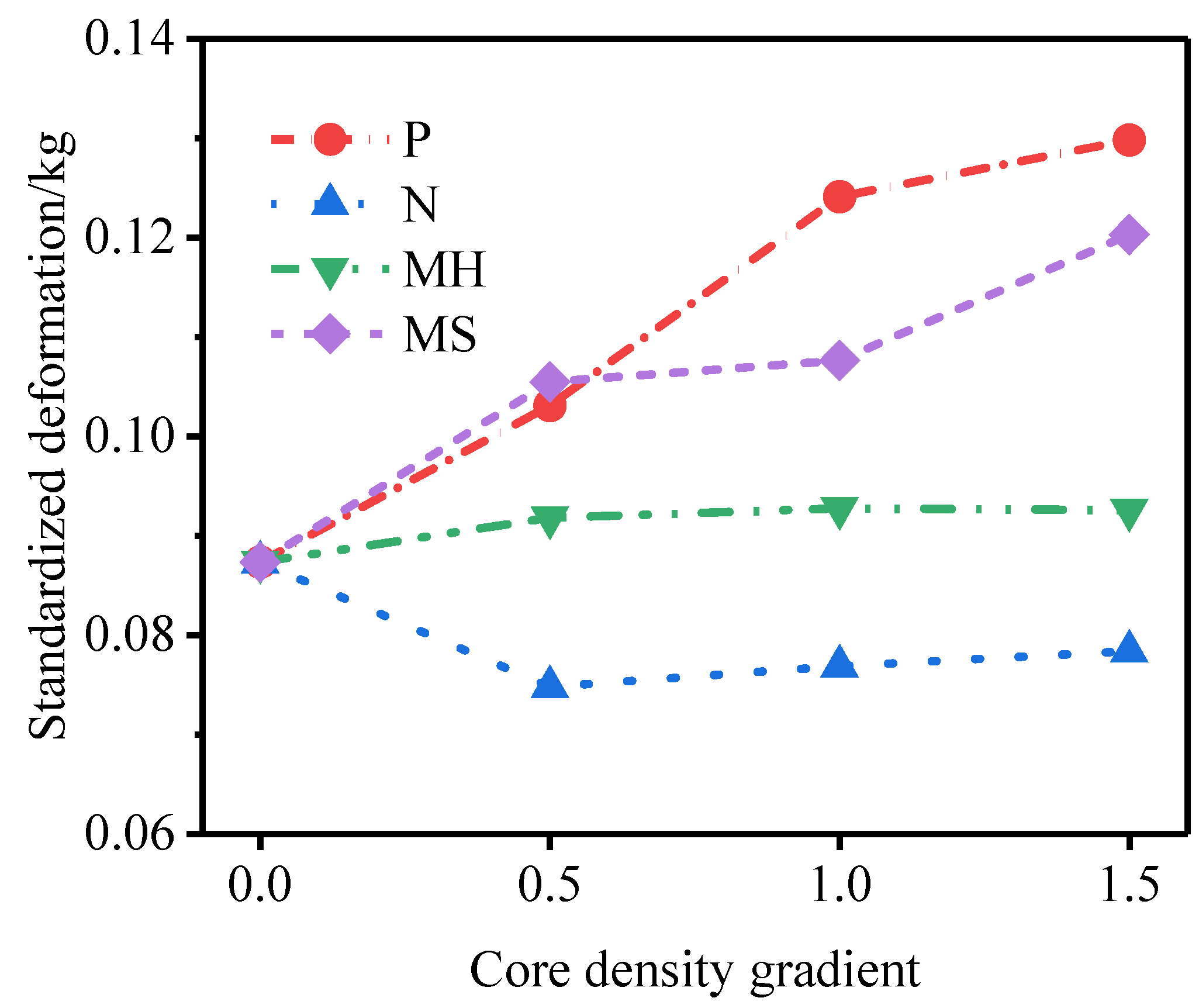

3.3. Influence of the Core Density Gradient

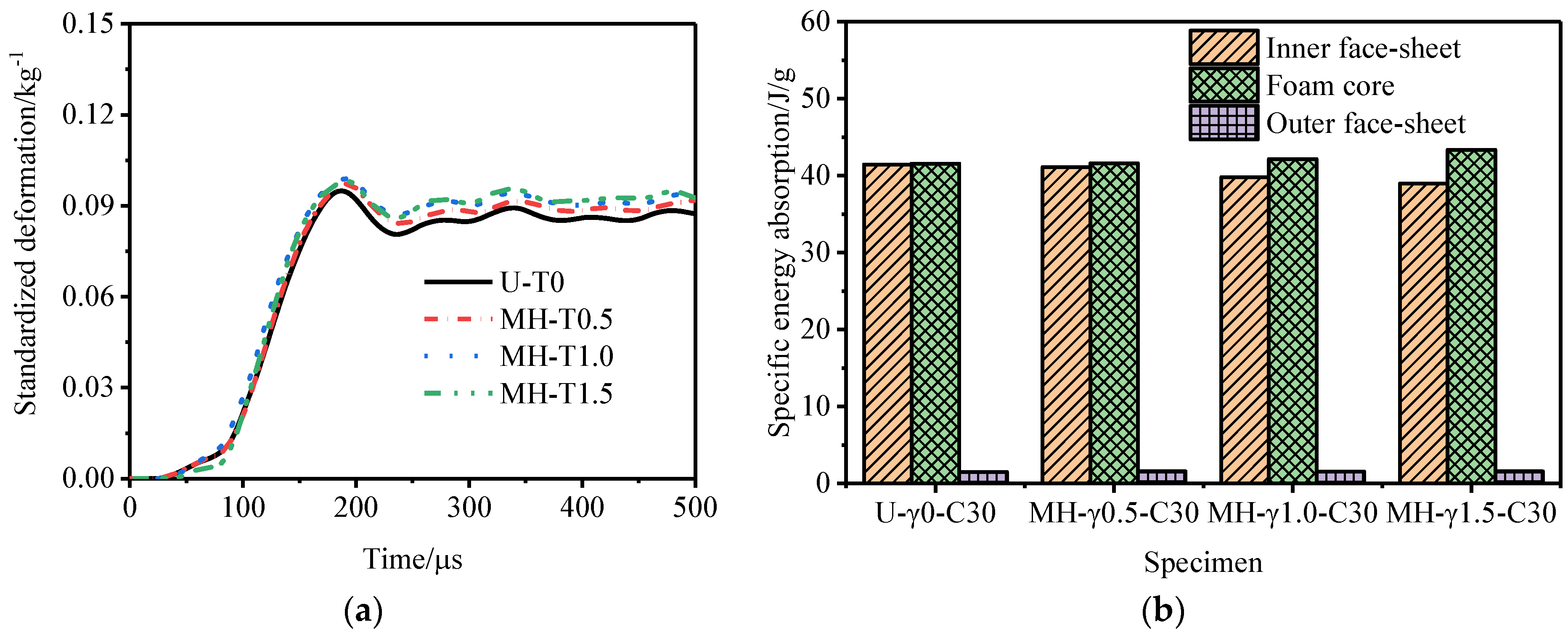

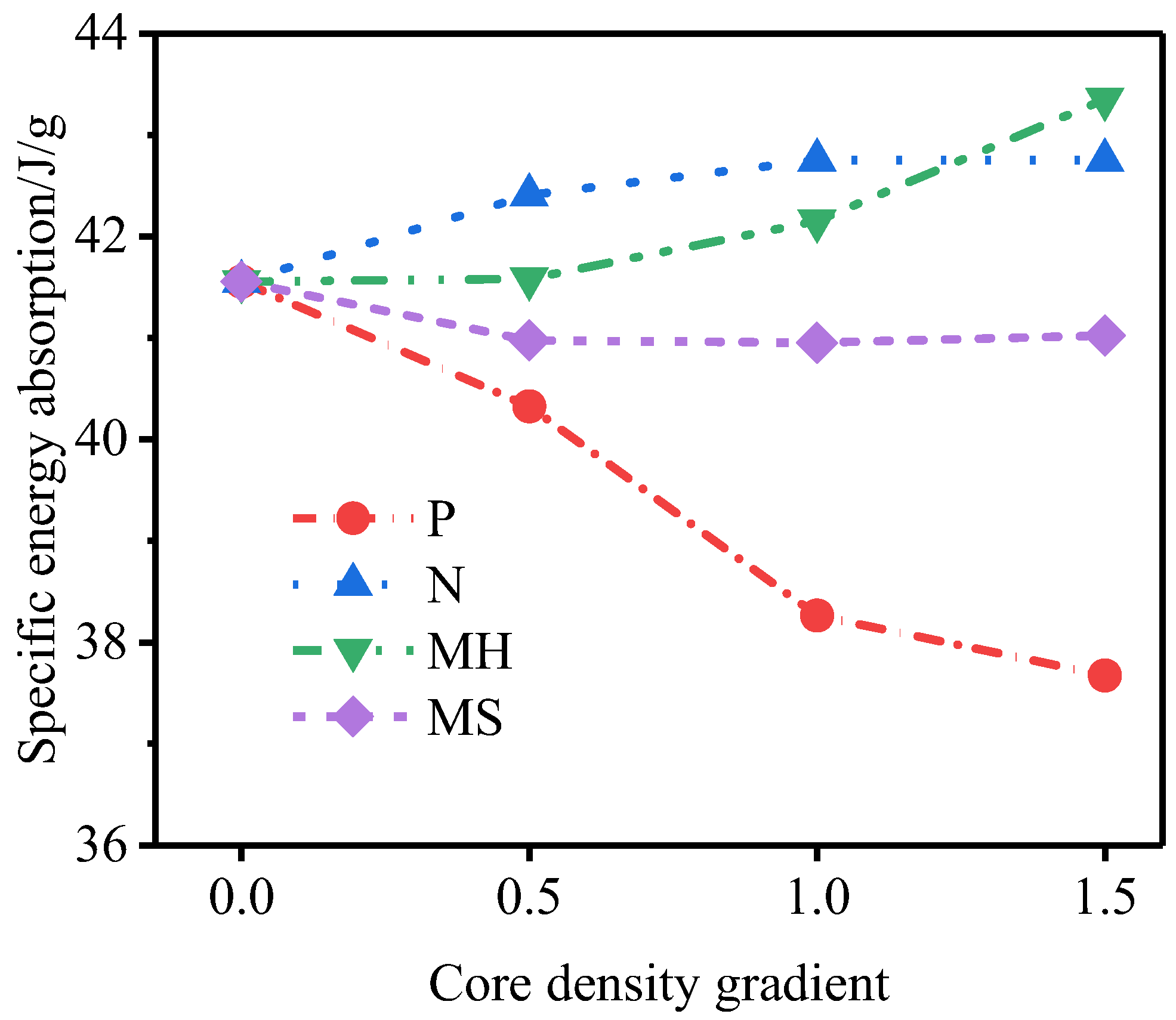

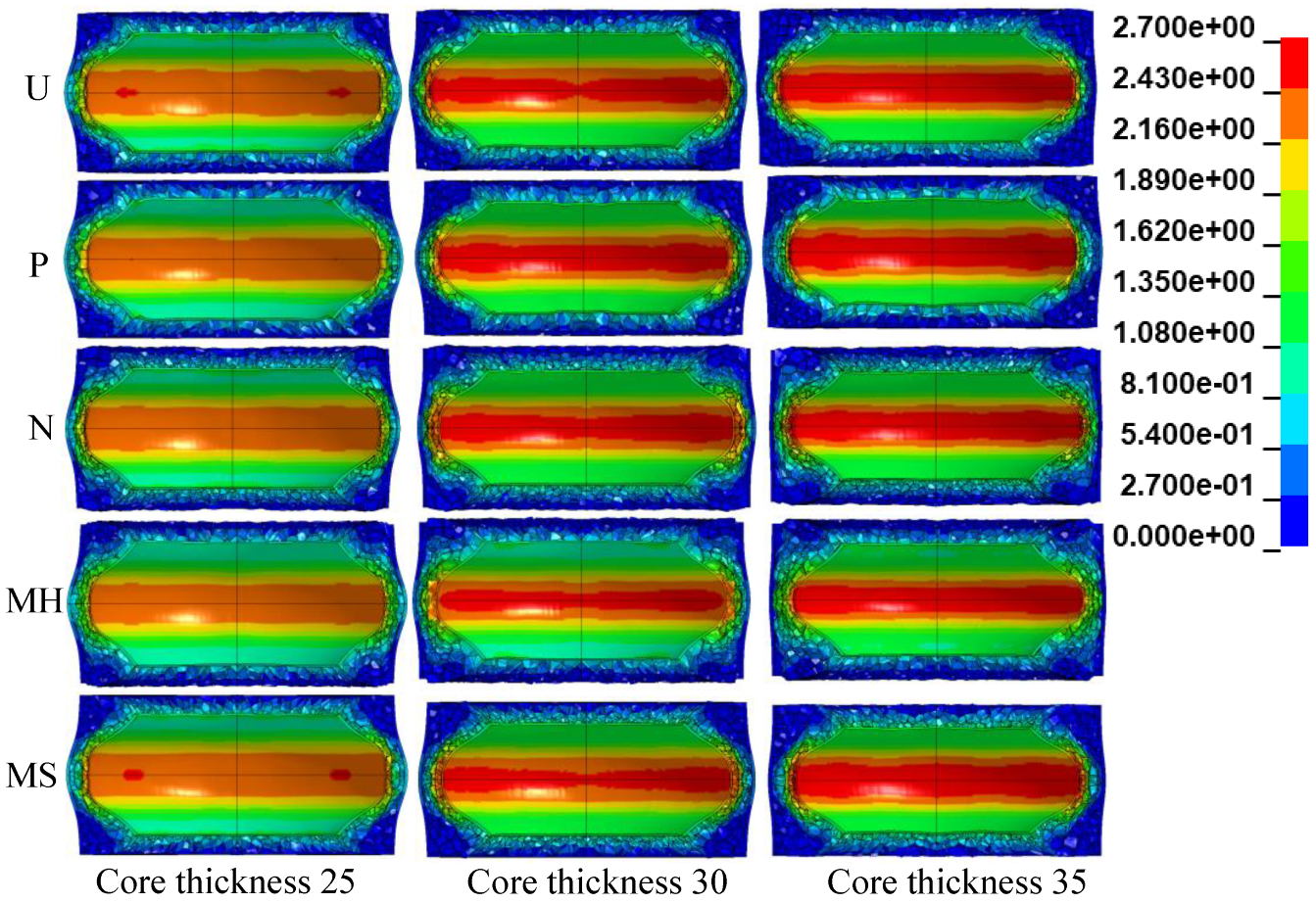

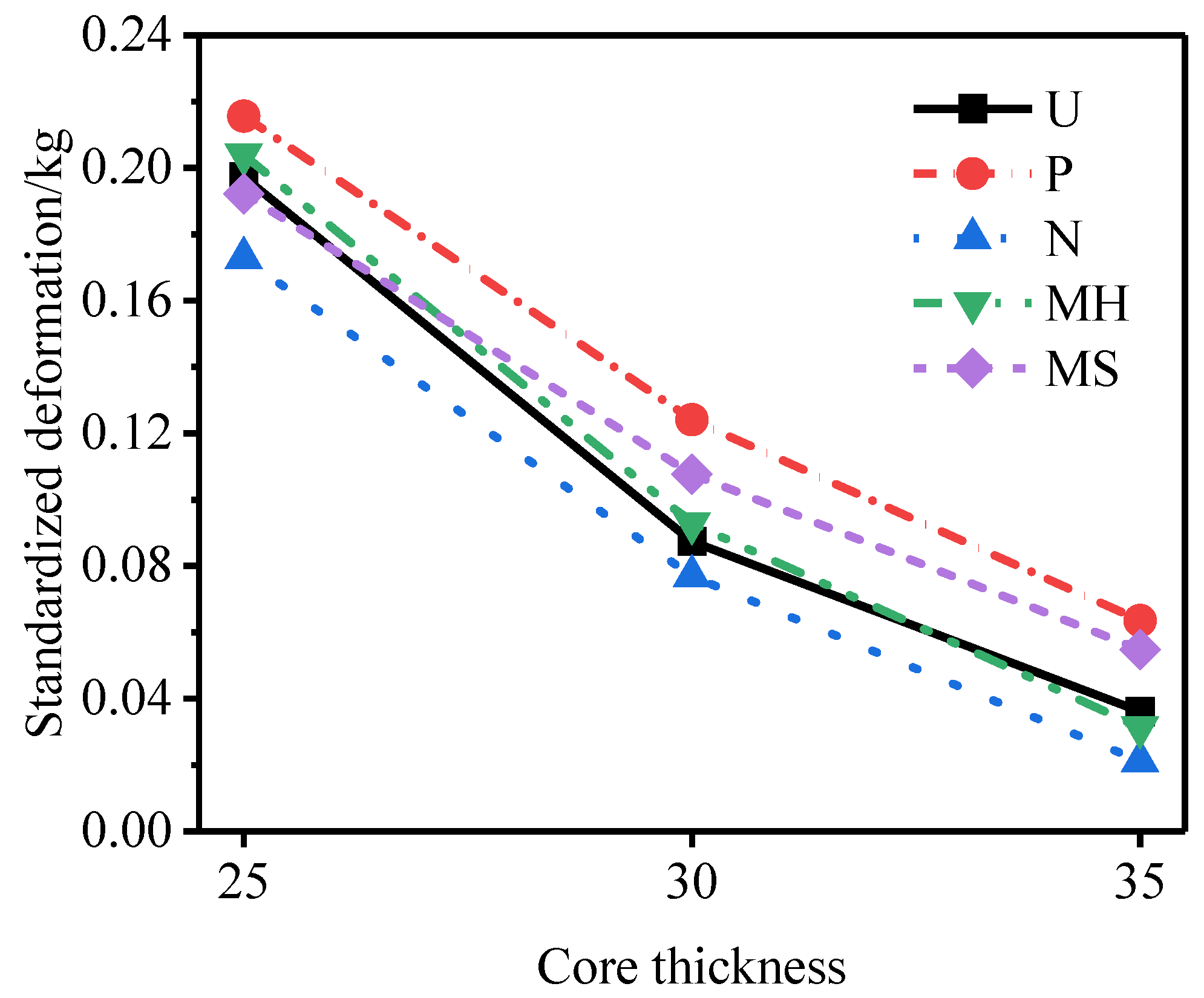

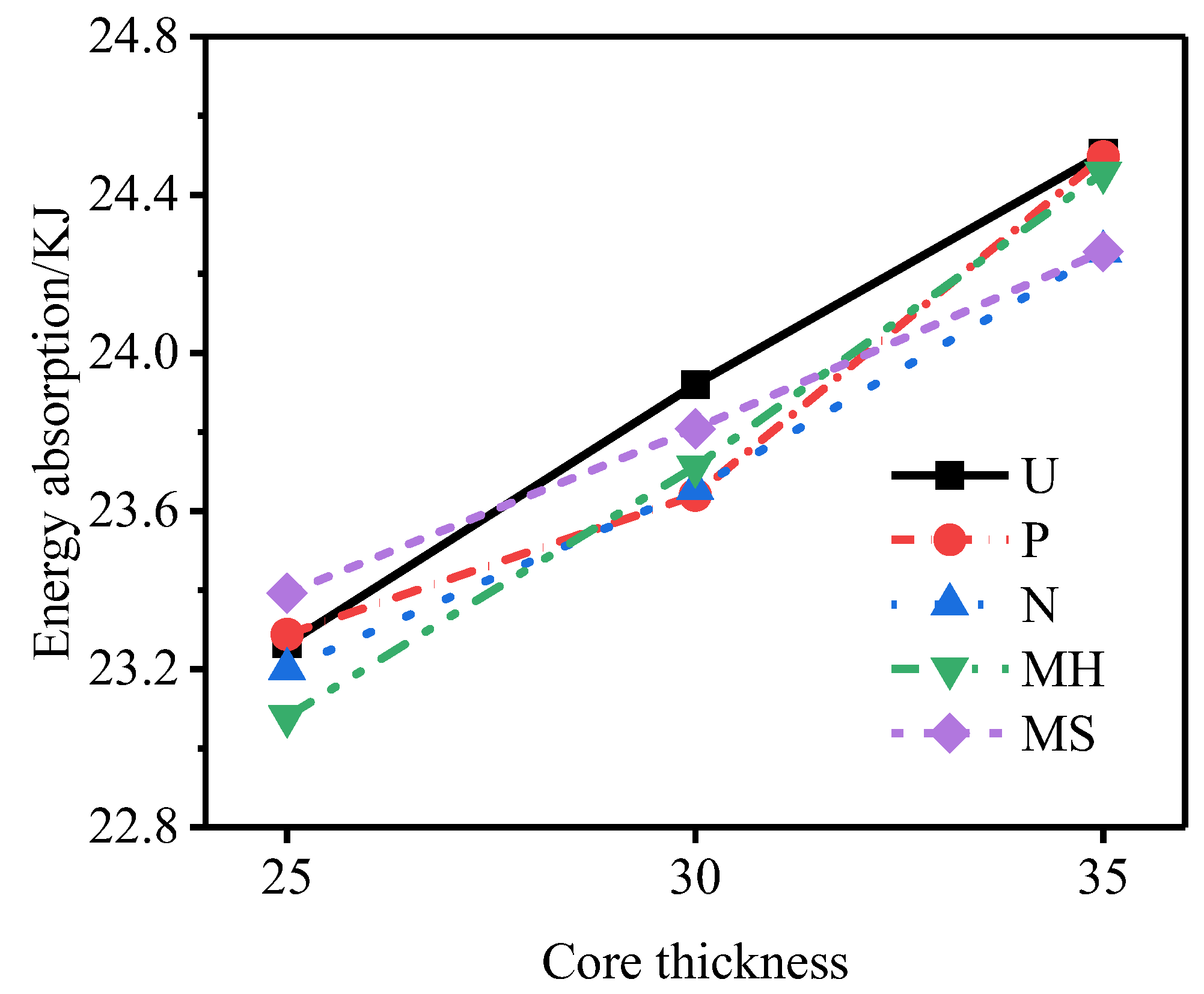

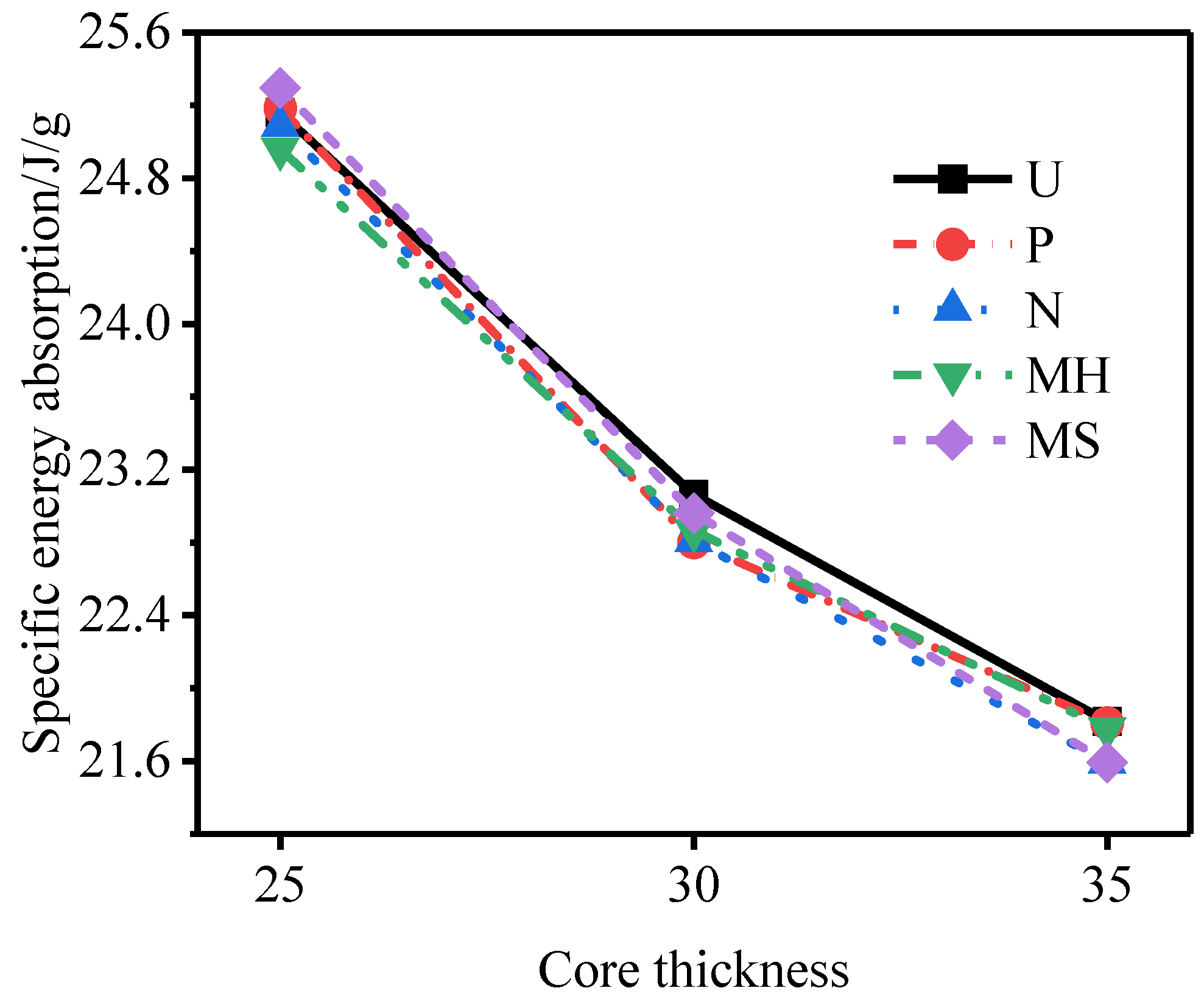

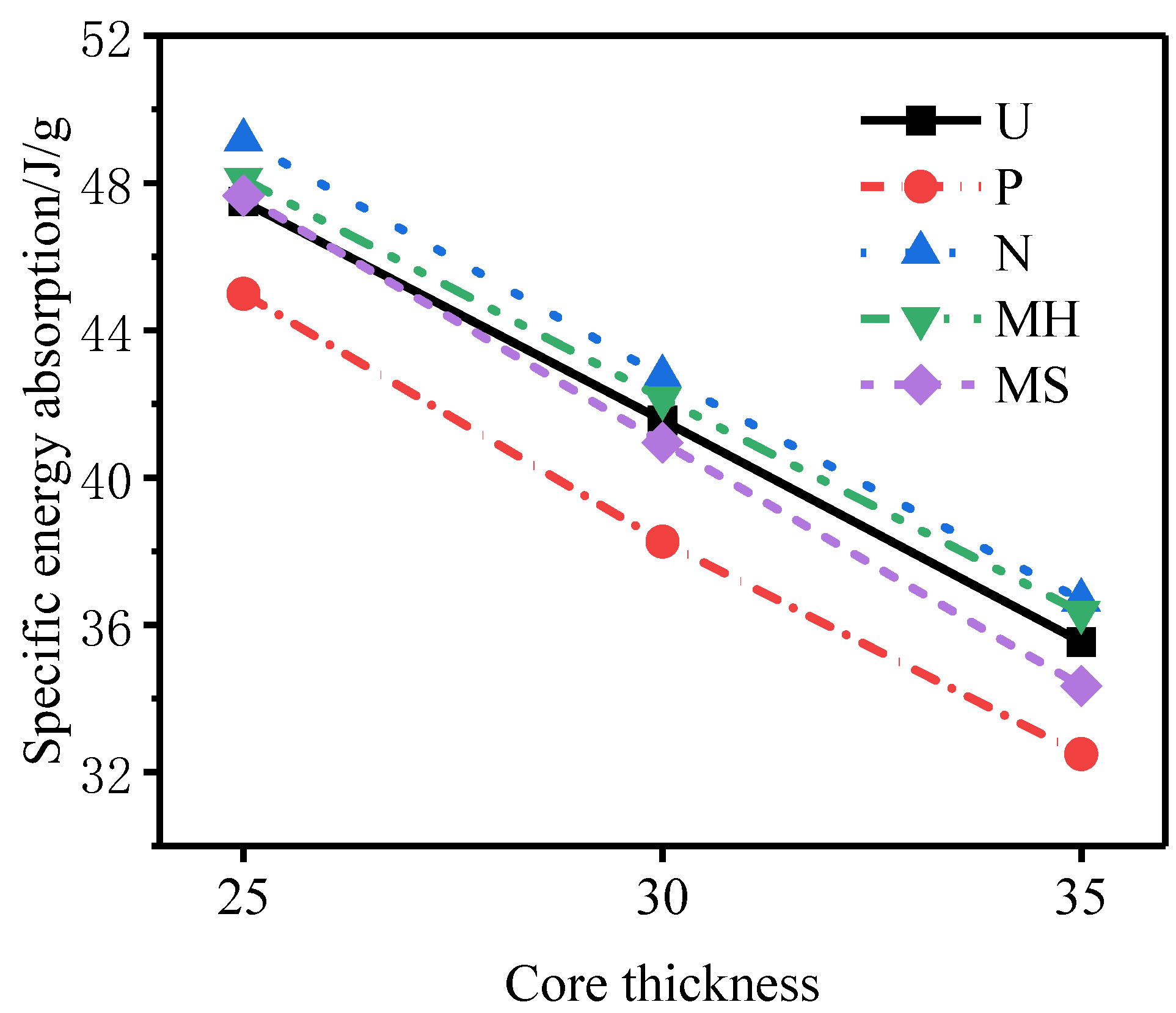

3.4. Influence of the Core Thickness

4. Conclusions

- (1)

- When the core density gradient is the same, the deformation of the outer tube of the N-type sandwich tube and the specific energy absorption of the core are better than those of the U-type sandwich tube. The deformation of the outer tubes of P-type and MS-type and the specific energy absorption of the core are worse than those of the U-type sandwich tube. The deformation of the MH-type outer tube is worse than that of the U-type sandwich tube, but its core displays better specific energy absorption than that of the U-type sandwich tube.

- (2)

- For N-type sandwich tubes, with decrease in the core density gradient, the deformation of the outer tube decreases but the specific energy absorption by the core is basically unchanged. For MH-type sandwich tubes, with an increase in the core density gradient, the deformation of the outer tube decreases and the specific energy absorption of the core increases. For P type and MS-type sandwich tube, with an increase in the core density gradient, the deformation of the outer tube increases and the specific energy absorption of the core decreases. Among the five gradient sandwich tubes, the N-type sandwich tube displays the best resistance to an explosion.

- (3)

- Under the same explosive load, although increasing the core thickness will reduce the total specific energy absorption by the sandwich tube, it will effectively reduce the deformation of the outer tube and increase the total energy absorption. The degree of improvement of the deformation of the outer tube is far greater than the reduction in the specific energy absorption. Considering the deformation of the outer tube and the specific energy absorption of the core, the resistance of the N-type sandwich tube to an explosion is still the best for the three core thicknesses.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Gu, W.B.; Xie, X.B.; Yuan, Q.; Chen, Y.T.; Jiang, T. Explosion Resistance of Three-Dimensional Mesoscopic Model of Complex Closed-Cell Aluminum Foam Sandwich Structure Based on Random Generation Algorithm. Complexity 2020, 2020, 1–16. [Google Scholar]

- Li, Y.; Lv, Z.; Wang, Y. Blast response of aluminum foam sandwich panel with double V-shaped face plate. Int. J. Impact Eng. 2020, 144, 103666. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, Z.; Yu, T.; Xin, D. Mechanical properties and energy absorption capabilities of aluminium foam sandwich structure subjected to low-velocity impact. Constr. Build. Mater. 2021, 273, 121996. [Google Scholar] [CrossRef]

- Shen, J.H.; Lu, G.X.; Zhao, L.M.; Zhang, Q.M. Short sandwich tubes subjected to internal explosive loading. Eng. Struct. 2013, 55, 56–65. [Google Scholar] [CrossRef]

- Cheng, Y.S.; Liu, M.X.; Zhang, P.; Xiao, W.; Zhang, C.Z. The effects of foam filling on the dynamic response of metallic corrugated core sandwich panel under air blast loading – Experimental investigations. Int. J. Mech Sci. 2018, 145, 378–388. [Google Scholar] [CrossRef]

- Jing, L.; Liu, K.; Su, X.; Guo, X. Experimental and numerical study of square sandwich panels with layered-gradient foam cores to air-blast loading. Thin-Walled Struct. 2021, 161, 107445. [Google Scholar] [CrossRef]

- Sun, G.Y.; Wang, E.D.; Zhang, J.T.; Li, S.Q.; Zhang, Y.; Li, Q. Experimental study on the dynamic responses of foam sandwich panels with different facesheets and core gradients subjected to blast impulse. Int. J. Impact Eng. 2020, 13, 103327. [Google Scholar] [CrossRef]

- Li, J.F.; Qin, Q.H.; Zhang, J.X. Internal blast resistance of sandwich cylinder with lattice cores. Int. J. Mech Sci. 2021, 191, 106107. [Google Scholar] [CrossRef]

- Latour, M.; D’Aniello, M.; Landolfo, R.; Rizzano, G. Experimental and numerical study of double-skin aluminium foam sandwich panels in bending. Thin-Walled Struct. 2021, 164, 107894. [Google Scholar] [CrossRef]

- Liang, M.; Li, X.; Lin, Y.; Zhang, K.; Lu, F. Multiobjective blast-resistance optimization of gradient foam sandwiched cylindrical container. Thin-Walled Struct. 2020, 157, 107114. [Google Scholar] [CrossRef]

- Wang, E.D.; Li, Q.; Sun, G.Y. Computational analysis and optimization of sandwich panels with homogeneous and graded foam cores for blast resistance. Thin-Walled Struct. 2020, 147, 106494. [Google Scholar] [CrossRef]

- Qi, C.; Yang, S.; Yang, L.J.; Wei, Z.Y.; Lu, Z.H. Blast resistance and multi-objective optimization of aluminum foam-cored sandwich panels. Compos. Struct. 2013, 105, 45–57. [Google Scholar] [CrossRef]

- Karagiozova, D.; Langdon, G.S.; Nurick, G.N.; Niven, T. The influence of a low density foam sandwich core on the response of a partially confined steel cylinder to internal air-blast. Int. J. Impact Eng. 2016, 92, 32–49. [Google Scholar] [CrossRef]

- Lu, J.Y.; Wang, Y.H.; Zhai, X.M.; Zhi, X.D.; Zhou, H.Y. Impact behavior of a cladding sandwich panel with aluminum foam-filled tubular cores. Thin-Walled Struct. 2021, 169, 108459. [Google Scholar] [CrossRef]

- Karagiozova, D.; Alves, M. Compaction of a double-layered metal foam block impacting a rigid wall. Int. J. Solids Struct. 2014, 51, 2424–2438. [Google Scholar] [CrossRef] [Green Version]

- Cao, B.T.; Hou, B.; Zhao, H.; Li, Y.L.; Liu, J.G. On the influence of the property gradient on the impact behavior of graded multilayer sandwich with corrugated cores. Int. J. Impact Eng. 2018, 113, 98–105. [Google Scholar] [CrossRef]

- Liu, H.; Ng, B.F. Dynamic response of density-graded foam subjected to soft impact. Compos. Struct. 2022, 284, 115145. [Google Scholar] [CrossRef]

- Zhu, Y.F.; Sun, Y.G. Low-velocity impact response of multilayer foam core sandwich panels with composite face sheets. Int. J. Mech. Sci. 2021, 209, 106704. [Google Scholar] [CrossRef]

- Liu, H.B.; Liu, J.; Kaboglu, C.; Zhou, J.; Kong, X.S.; Li, S.P.; Blackman, B.R.K.; Kinloch, A.J.; Dear, J.P. Modelling the quasi-static flexural behaviour of composite sandwich structures with uniform- and graded-density foam cores. Eng. Fract. Mech. 2022, 259, 108121. [Google Scholar] [CrossRef]

- Jing, L.; Zhao, L.M. Blast resistance and energy absorption of sandwich panels with layered gradient metallic foam cores. J. Sandw. Struct. Mater. 2017, 21, 464–482. [Google Scholar] [CrossRef]

- Li, X.Y.; Zhang, G.D.; Liang, M.Z.; Tian, Z.D. Research on Blast Resistance of the Cylinder with Aluminium Foam under Internal Explosive Load. J. Phys. Conf. Ser. 2022, 2202, 012024. [Google Scholar] [CrossRef]

- Zhang, J.X.; Zhou, R.F.; Wang, M.S.; Qin, Q.H.; Ye, Y.; Wang, T.J. Dynamic response of double-layer rectangular sandwich plates with metal foam cores subjected to blast loading. Int. J. Impact Eng. 2018, 122, 265–275. [Google Scholar] [CrossRef]

- Jing, L.; Su, X.Y.; Chen, D.; Yang, F.; Zhao, L.M. Experimental and numerical study of sandwich beams with layered-gradient foam cores under low-velocity impact. Thin-Walled Struct. 2019, 135, 227–244. [Google Scholar] [CrossRef]

- Duan, Y.; Ding, Y.; Liu, Z.Y.; Hou, N.D.; Zhao, X.H.; Liu, H.F.; Zhao, Z.Q.; Hou, B.; Li, Y.L. Effects of cell size vs. cell-wall thickness gradients on compressive behavior of additively manufactured foams. Compos. Sci.Technol. 2020, 199, 108339. [Google Scholar] [CrossRef]

- Liang, M.; Li, X.; Lin, Y.; Zhang, K.; Lu, F. Theoretical Analysis of Blast Protection of Graded Metal Foam-Cored Sandwich Cylinders/Rings. Materials 2020, 13, 3903. [Google Scholar] [CrossRef]

- Liang, M.; Li, X.; Lin, Y.; Zhang, K.; Lu, F. Dynamic Compressive Behaviors of Two-Layer Graded Aluminum Foams under Blast Loading. Materials 2019, 12, 1445. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.J.; Wang, Z.H.; Zhao, L.M. Dynamic response of functionally graded cellular materials based on the Voronoi model. Compos. Part B 2016, 85, 176–187. [Google Scholar] [CrossRef]

- Liang, M.Z.; Lu, F.Y.; Zhang, G.D.; Li, X.Y. Experimental and numerical study of aluminum foam-cored sandwich tubes subjected to internal air blast. Compos. Part B-Eng. 2017, 125, 134–143. [Google Scholar] [CrossRef]

- Liang, M.Z.; Zhang, G.D.; Lu, F.Y.; Li, X.Y. Blast resistance and design of sandwich cylinder with graded foam cores based on the Voronoi algorithm. Thin-Walled Struct. 2017, 112, 98–106. [Google Scholar] [CrossRef]

- Zheng, Z.J.; Yu, J.L.; Li, J.R. Dynamic crushing of 2D cellular structures: A finite element study. Int. J. Impact Eng. 2005, 32, 650–664. [Google Scholar] [CrossRef]

- Yin, H.F.; Xiao, Y.Y.; Wen, G.L.; Qing, Q.X.; Deng, Y.F. Multiobjective optimization for foam-filled multi-cell thin-walled structures under lateral impact. Thin-Walled Struct. 2015, 94, 1–12. [Google Scholar] [CrossRef]

- Borovinšek, M.; Vesenjak, M.; Hokamoto, K.; Ren, Z. An Experimental and Computational Study of the High-Velocity Impact of Low-Density Aluminum Foam. Materials 2020, 13, 1949. [Google Scholar] [CrossRef] [PubMed]

- Patil, S.; Murkute, R.; Shirafkan, N.; Markert, B. Deformation of Stacked Metallic Sheets by Shock Wave Loading. Metals 2018, 8, 679. [Google Scholar] [CrossRef] [Green Version]

- Vesenjak, M.; Borovinšek, M.; Ren, Z.; Irie, S.; Itoh, S. Behavior of Metallic Foam under Shock Wave Loading. Metals 2012, 2, 258–264. [Google Scholar] [CrossRef]

| Material | Density/kg/m3 | Young’s Modulus/GPa | A/MPa | B/MPa | n | c | m |

|---|---|---|---|---|---|---|---|

| Steel | 7850 | 210 | 507 | 320 | 0.28 | 0.064 | 1.06 |

| Material | Density/ kg/m3 | Detonation Velocity/m/s | A/GPa | B/GPa | R1 | R2 | ω | E/GJ/m3 | V |

|---|---|---|---|---|---|---|---|---|---|

| JHL-3 | 1650 | 7050 | 611 | 10.7 | 4.4 | 1.2 | 0.35 | 8.9 | 1.0 |

| Specimen Number | Outer Tube Diameter d0/mm | Inner Tube Diameter di/mm | Outer Tube Wall Thickness t0/mm | Inner Tube Wall Thickness ti/mm | Relative Density ρ/% | Specimen Quality M/g | Core Density Gradient |

|---|---|---|---|---|---|---|---|

| U-0-C30 | 163 | 100 | 1.5 | 1.5 | 10 | 1037 | 0 |

| P-1.0-C30 | 163 | 100 | 1.5 | 1.5 | 10 | 1037 | 1 |

| N-1.0-C30 | 163 | 100 | 1.5 | 1.5 | 10 | 1037 | 1 |

| MH-1.0-C30 | 163 | 100 | 1.5 | 1.5 | 10 | 1037 | 1 |

| MS-1.0-C30 | 163 | 100 | 1.5 | 1.5 | 10 | 1037 | 1 |

| P-0.5-C30 | 163 | 100 | 1.5 | 1.5 | 10 | 1037 | 0.5 |

| N-0.5-C30 | 163 | 100 | 1.5 | 1.5 | 10 | 1037 | 0.5 |

| MH-0.5-C30 | 163 | 100 | 1.5 | 1.5 | 10 | 1037 | 0.5 |

| MS-0.5-C30 | 163 | 100 | 1.5 | 1.5 | 10 | 1037 | 0.5 |

| P-1.5-C30 | 163 | 100 | 1.5 | 1.5 | 10 | 1037 | 1.5 |

| N-1.5-C30 | 163 | 100 | 1.5 | 1.5 | 10 | 1037 | 1.5 |

| MH-1.5-C30 | 163 | 100 | 1.5 | 1.5 | 10 | 1037 | 1.5 |

| MS-1.5-C30 | 163 | 100 | 1.5 | 1.5 | 10 | 1037 | 1.5 |

| Specimen Number | Outer Tube Diameter d0/mm | Inner Tube Diameter di/mm | Outer Tube Wall Thickness t0/mm | Inner Tube Wall Thickness ti/mm | Relative Density ρ/% | Specimen Quality M/g | Core Density Gradient |

|---|---|---|---|---|---|---|---|

| U-0-C35 | 173 | 100 | 1.5 | 1.5 | 10 | 1123.2 | 0 |

| P-1.0-C35 | 173 | 100 | 1.5 | 1.5 | 10 | 1123.2 | 1 |

| N-1.0-C35 | 173 | 100 | 1.5 | 1.5 | 10 | 1123.2 | 1 |

| MH-1.0-C35 | 173 | 100 | 1.5 | 1.5 | 10 | 1123.2 | 1 |

| MS-1.0-C35 | 173 | 100 | 1.5 | 1.5 | 10 | 1123.2 | 1 |

| U-0-C25 | 153 | 100 | 1.5 | 1.5 | 10 | 924.7 | 0 |

| P-1.0-C25 | 153 | 100 | 1.5 | 1.5 | 10 | 924.7 | 1 |

| N-1.0-C25 | 153 | 100 | 1.5 | 1.5 | 10 | 924.7 | 1 |

| MH-1.0-C25 | 153 | 100 | 1.5 | 1.5 | 10 | 924.7 | 1 |

| MS-1.0-C25 | 153 | 100 | 1.5 | 1.5 | 10 | 924.7 | 1 |

| Specimen Number | Inner Tube Diameter /mm | Outer Tube Diameter/mm | Specimen Length/mm | Relative Density | Numerical Simulation | Experimental Results | Relative Error | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Inner Tube/mm | Outer Tube/mm | Inner Tube/mm | Outer Tube/mm | Inner Tube/ mm | Outer Tube/ mm | |||||

| T1 | 67 | 90 | 100 | 11% | 9.930 | 0.564 | 9.80 | 0.58 | 1.33% | 2.76% |

| T3 | 67 | 90 | 100 | 11% | 8.483 | 0.806 | 9.35 | 0.745 | 9.27% | 8.19% |

| T5 | 67 | 90 | 100 | 11% | 6.867 | 0.706 | 6.90 | 0.75 | 1.65% | 5.87% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, A.; Yu, X.; Wang, H.; Li, Y.; Zhang, J.; Fan, X. Dynamic Response of Sandwich Tubes with Continuously Density-Graded Aluminum Foam Cores under Internal Explosion Load. Materials 2022, 15, 6966. https://doi.org/10.3390/ma15196966

Wang A, Yu X, Wang H, Li Y, Zhang J, Fan X. Dynamic Response of Sandwich Tubes with Continuously Density-Graded Aluminum Foam Cores under Internal Explosion Load. Materials. 2022; 15(19):6966. https://doi.org/10.3390/ma15196966

Chicago/Turabian StyleWang, Anshuai, Xuehui Yu, Han Wang, Yu Li, Jie Zhang, and Xueling Fan. 2022. "Dynamic Response of Sandwich Tubes with Continuously Density-Graded Aluminum Foam Cores under Internal Explosion Load" Materials 15, no. 19: 6966. https://doi.org/10.3390/ma15196966

APA StyleWang, A., Yu, X., Wang, H., Li, Y., Zhang, J., & Fan, X. (2022). Dynamic Response of Sandwich Tubes with Continuously Density-Graded Aluminum Foam Cores under Internal Explosion Load. Materials, 15(19), 6966. https://doi.org/10.3390/ma15196966