Physiomechanical and Surface Characteristics of 3D-Printed Zirconia: An In Vitro Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Microstructure, Crystalline Phase Distribution, and Grain Size (nm)

2.2. Density (g/cm3) and Apparent Porosity (%)

2.3. Surface Roughness, Ra (µm)

2.4. Wettability/Contact Angle (°)

2.5. Microhardness (VHN)

2.6. Biaxial Flexural Strength (MPa) and Weibull Modulus

2.7. SEM Analysis

3. Results

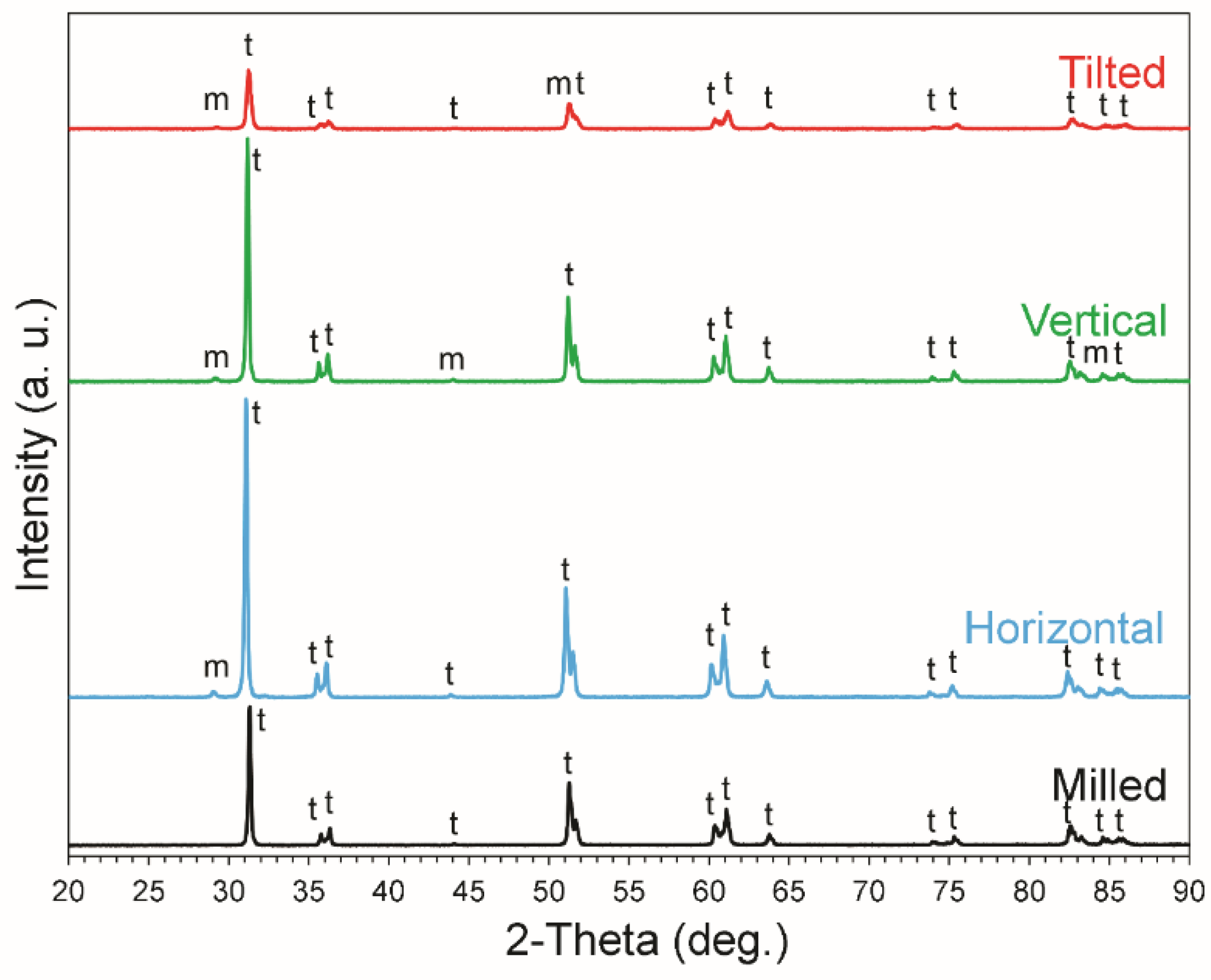

3.1. Crystalline Phase Distribution and Grain Size

3.2. Density (g/cm3) and Apparent Porosity (%)

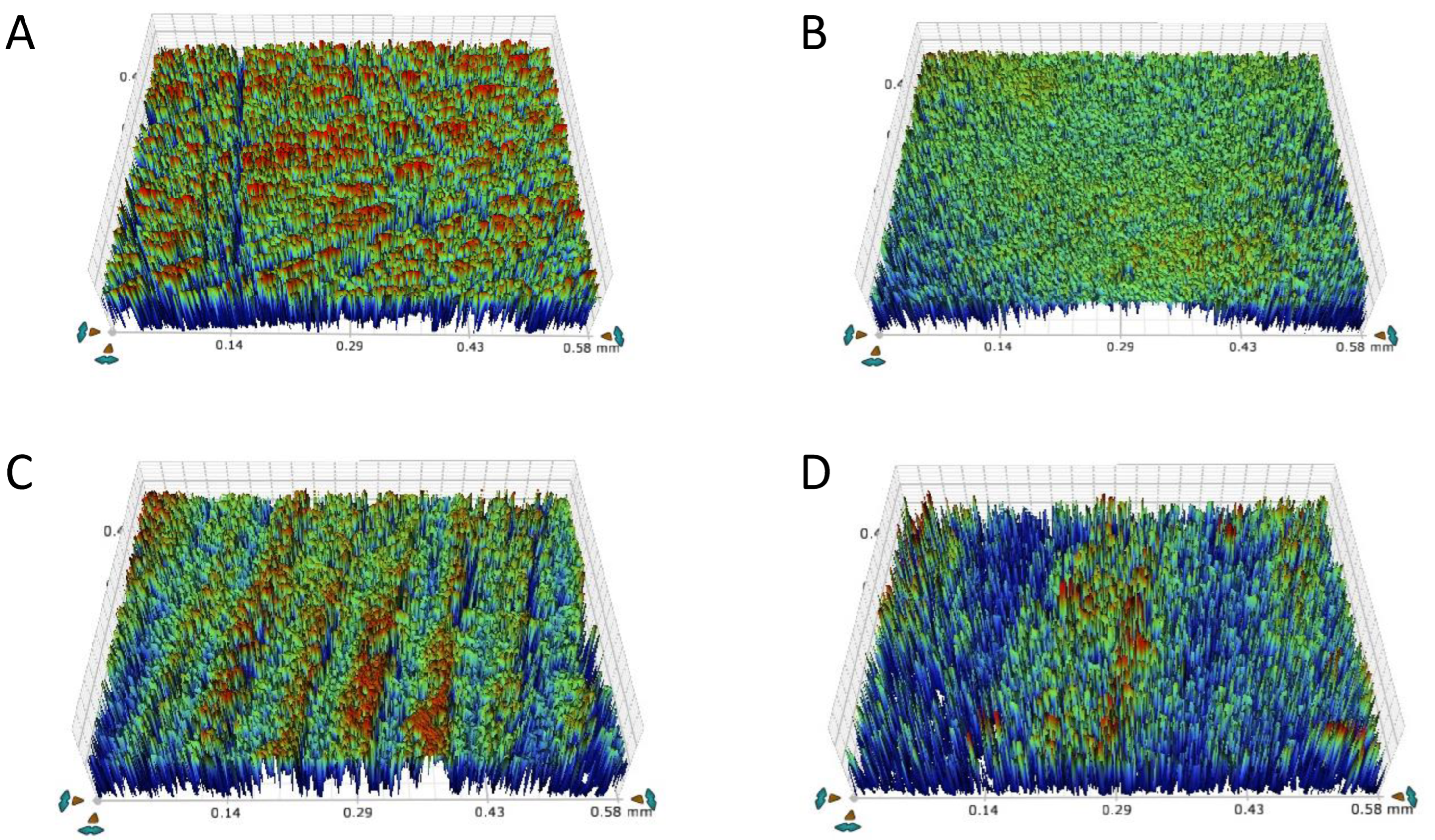

3.3. Surface Roughness, Ra (µm)

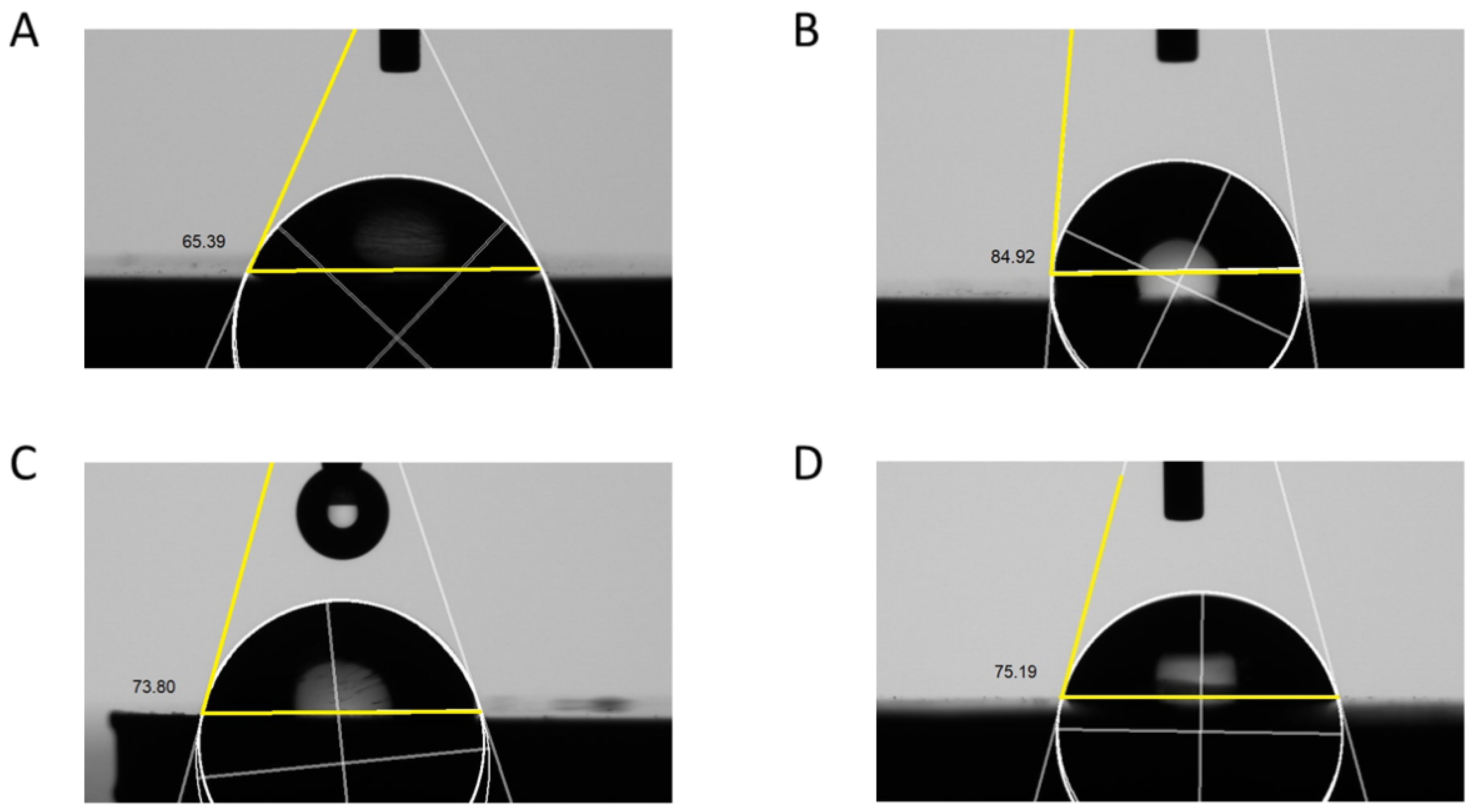

3.4. Wettability/Contact Angle (°)

3.5. Microhardness (VHN)

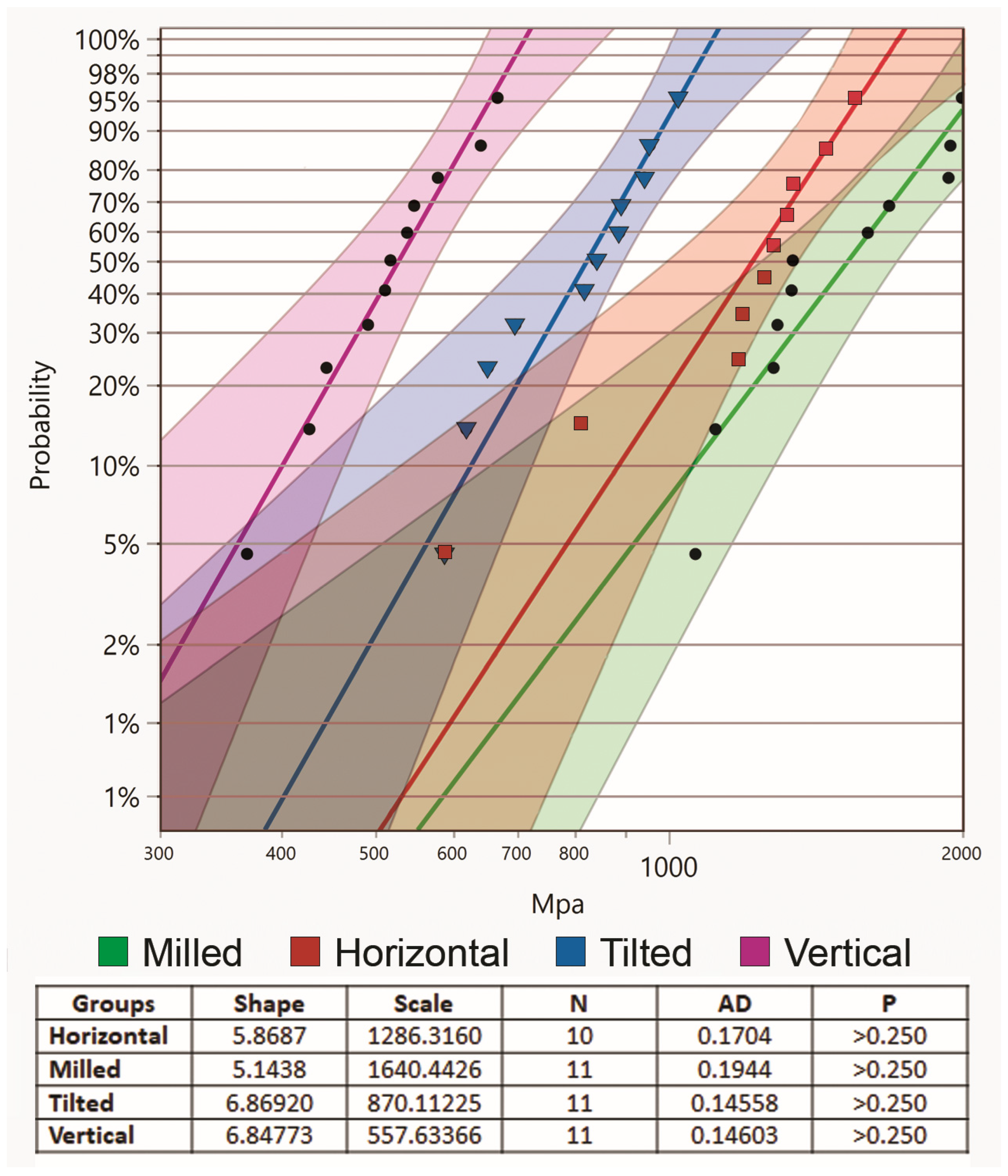

3.6. Biaxial Flexural Strength (MPa) and Weibull Modulus

3.7. SEM Analysis

3.7.1. Initial Analysis

3.7.2. SEM Analysis of Fractured Specimens

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Botelho, M.G.; Dangay, S.; Shih, K.; Lam, W.Y.H. The effect of surface treatments on dental zirconia: An analysis of biaxial flexural strength, surface roughness and phase transformation. J. Dent. 2018, 75, 65–73. [Google Scholar] [CrossRef] [PubMed]

- Branco, A.C.; Silva, R.; Santos, T.; Jorge, H.; Rodrigues, A.R.; Fernandes, R.; Bandarra, S.; Barahona, I.; Matos, A.P.A.; Lorenz, K.; et al. Suitability of 3D printed pieces of nanocrystalline zirconia for dental applications. Dent. Mater. 2020, 36, 442–455. [Google Scholar] [CrossRef] [PubMed]

- Baysal, N.; Tuğba Kalyoncuoğlu, Ü.; Ayyıldız, S. Mechanical Properties and Bond Strength of Additively Manufactured and Milled Dental Zirconia: A Pilot Study. J. Prosthodont. 2022, 31, 629–634. [Google Scholar] [CrossRef] [PubMed]

- Moqbel, N.M.; Al-Akhali, M.; Wille, S.; Kern, M. Influence of Aging on Biaxial Flexural Strength and Hardness of Translucent 3Y-TZP. Materials 2020, 13, 27. [Google Scholar] [CrossRef] [Green Version]

- Guilardi, L.F.; Pereira, G.K.; Wandscher, V.F.; Rippe, M.P.; Valandro, L.F. Mechanical behavior of yttria-stabilized tetragonal zirconia polycrystal: Effects of different aging regimens. Braz. Oral Res. 2017, 31, e94. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kashkari, A.; Yilmaz, B.; Brantley, W.A.; Schricker, S.R.; Johnston, W.M. Fracture analysis of monolithic CAD-CAM crowns. J. Esthet. Restor. Dent. 2019, 31, 346–352. [Google Scholar] [CrossRef] [PubMed]

- Revilla-León, M.; Methani, M.M.; Morton, D.; Zandinejad, A. Internal and marginal discrepancies associated with stereolithography (SLA) additively manufactured zirconia crowns. J. Prosthet. Dent. 2020, 124, 730–737. [Google Scholar] [CrossRef] [PubMed]

- Zandinejad, A.; Das, O.; Barmak, A.B.; Kuttolamadom, M.; Revilla-León, M. The Flexural Strength and Flexural Modulus of Stereolithography Additively Manufactured Zirconia with Different Porosities. J. Prosthodont. 2022, 31, 434–440. [Google Scholar] [CrossRef]

- Roperto, R.C.; Lopes, F.C.; Porto, T.S.; Teich, S.; Rizzante, F.A.P.; Gutmacher, Z.; Sousa-Neto, M.D. CAD/CAM diamond tool wear. Quintessence Int. 2018, 49, 781–786. [Google Scholar] [CrossRef] [PubMed]

- Al Hamad, K.Q.; Al Quran, F.A.; Jwaied, S.Z.; Al-Dwairi, Z.N.; Al-Rashdan, B.A.; Baba, N.Z. Effect of CAD/CAM Bur Deterioration on the Surface Roughness of Ceramic Crowns. J. Prosthodont. 2022, 31, 320–325. [Google Scholar] [CrossRef] [PubMed]

- Turkyilmaz, I.; Wilkins, G.N.; Yun, S. Moving from analogue to digital workflows in dentistry: Understanding undermilling and overmilling as detrimental factors in fabricating CAD/CAM crowns. Prim. Dent. J. 2022, 11, 59–61. [Google Scholar] [CrossRef]

- Dawood, A.; Marti Marti, B.; Sauret-Jackson, V.; Darwood, A. 3D printing in dentistry. Br. Dent. J. 2015, 219, 521–529. [Google Scholar] [CrossRef]

- Schweiger, J.; Edelhoff, D.; Güth, J.F. 3D Printing in Digital Prosthetic Dentistry: An Overview of Recent Developments in Additive Manufacturing. J. Clin. Med. 2021, 10, 2010. [Google Scholar] [CrossRef] [PubMed]

- Barazanchi, A.; Li, K.C.; Al-Amleh, B.; Lyons, K.; Waddell, J.N. Additive Technology: Update on Current Materials and Applications in Dentistry. J. Prosthodont. 2017, 26, 156–163. [Google Scholar] [CrossRef] [PubMed]

- Pillai, S.; Upadhyay, A.; Khayambashi, P.; Farooq, I.; Sabri, H.; Tarar, M.; Lee, K.T.; Harb, I.; Zhou, S.; Wang, Y.; et al. Dental 3D-Printing: Transferring Art from the Laboratories to the Clinics. Polymers 2021, 13, 157. [Google Scholar] [CrossRef] [PubMed]

- Khanlar, L.N.; Salazar Rios, A.; Tahmaseb, A.; Zandinejad, A. Additive Manufacturing of Zirconia Ceramic and Its Application in Clinical Dentistry: A Review. Dent. J. 2021, 9, 104. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Wang, Y.; Hu, M.; Wang, Y.; Xv, Y.; Liu, Y.; Sun, Y. Strength and Adaptation of Stereolithography-Fabricated Zirconia Dental Crowns: An In Vitro Study. Int. J. Prosthodont. 2019, 32, 439–443. [Google Scholar] [CrossRef]

- Wang, W.; Yu, H.; Liu, Y.; Jiang, X.; Gao, B. Trueness analysis of zirconia crowns fabricated with 3-dimensional printing. J. Prosthet. Dent. 2019, 121, 285–291. [Google Scholar] [CrossRef]

- Li, H.; Song, L.; Sun, J.; Ma, J.; Shen, Z. Dental ceramic prostheses by stereolithography-based additive manufacturing: Potentials and challenges. Adv. Appl. Ceram. 2019, 118, 30–36. [Google Scholar] [CrossRef] [Green Version]

- Park, S.M.; Park, J.M.; Kim, S.K.; Heo, S.J.; Koak, J.Y. Flexural Strength of 3D-Printing Resin Materials for Provisional Fixed Dental Prostheses. Materials 2020, 13, 3970. [Google Scholar] [CrossRef]

- Keßler, A.; Dosch, M.; Reymus, M.; Folwaczny, M. Influence of 3D-printing method, resin material, and sterilization on the accuracy of virtually designed surgical implant guides. J. Prosthet. Dent. 2022, 128, 196–204. [Google Scholar] [CrossRef] [PubMed]

- Alharbi, N.; Osman, R.B.; Wismeijer, D. Factors Influencing the Dimensional Accuracy of 3D-Printed Full-Coverage Dental Restorations Using Stereolithography Technology. Int. J. Prosthodont. 2016, 29, 503–510. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Osman, R.B.; Alharbi, N.; Wismeijer, D. Build Angle: Does It Influence the Accuracy of 3D-Printed Dental Restorations Using Digital Light-Processing Technology? Int. J. Prosthodont. 2017, 30, 182–188. [Google Scholar] [CrossRef]

- Alharbi, N.; Osman, R.; Wismeijer, D. Effects of build direction on the mechanical properties of 3D-printed complete coverage interim dental restorations. J. Prosthet. Dent. 2016, 115, 760–767. [Google Scholar] [CrossRef]

- Shim, J.S.; Kim, J.E.; Jeong, S.H.; Choi, Y.J.; Ryu, J.J. Printing accuracy, mechanical properties, surface characteristics, and microbial adhesion of 3D-printed resins with various printing orientations. J. Prosthet. Dent. 2020, 124, 468–475. [Google Scholar] [CrossRef] [PubMed]

- Tahayeri, A.; Morgan, M.; Fugolin, A.P.; Bompolaki, D.; Athirasala, A.; Pfeifer, C.S.; Ferracane, J.L.; Bertassoni, L.E. 3D printed versus conventionally cured provisional crown and bridge dental materials. Dent. Mater. 2018, 34, 192–200. [Google Scholar] [CrossRef]

- Lee, E.H.; Ahn, J.S.; Lim, Y.J.; Kwon, H.B.; Kim, M.J. Effect of layer thickness and printing orientation on the color stability and stainability of a 3D-printed resin material. J. Prosthet. Dent. 2022, 127, e1–e784. [Google Scholar] [CrossRef] [PubMed]

- Revilla-León, M.; Jordan, D.; Methani, M.M.; Piedra-Cascón, W.; Özcan, M.; Zandinejad, A. Influence of printing angulation on the surface roughness of additive manufactured clear silicone indices: An in vitro study. J. Prosthet. Dent. 2021, 125, 462–468. [Google Scholar] [CrossRef]

- Nakai, H.; Inokoshi, M.; Nozaki, K.; Komatsu, K.; Kamijo, S.; Liu, H.; Shimizubata, M.; Minakuchi, S.; Van Meerbeek, B.; Vleugels, J.; et al. Additively Manufactured Zirconia for Dental Applications. Materials 2021, 14, 3694. [Google Scholar] [CrossRef]

- Hofer, A.K.; Rabitsch, J.; Jutrzenka-Trzebiatowska, D.; Hofstetter, C.; Gavalda-Velasco, I.; Schlacher, J.; Schwentenwein, M.; Bermejo, R. Effect of binder system on the thermophysical properties of 3D-printed zirconia ceramics. Int. J. Appl. Ceram. Technol. 2022, 19, 174–180. [Google Scholar] [CrossRef] [PubMed]

- Mei, Z.; Lu, Y.; Lou, Y.; Yu, P.; Sun, M.; Tan, X.; Zhang, J.; Yue, L.; Yu, H. Determination of Hardness and Fracture Toughness of Y-TZP Manufactured by Digital Light Processing through the Indentation Technique. BioMed Res. Int. 2021, 2021, 6612840. [Google Scholar] [CrossRef]

- Revilla-León, M.; Al-Haj Husain, N.; Barmak, A.B.; Pérez-López, J.; Raigrodski, A.J.; Özcan, M. Chemical Composition and Flexural Strength Discrepancies Between Milled and Lithography-Based Additively Manufactured Zirconia. J. Prosthodont. 2022. [Google Scholar] [CrossRef]

- Lu, Y.; Mei, Z.; Zhang, J.; Gao, S.; Yang, X.; Dong, B.; Yue, L.; Yu, H. Flexural strength and Weibull analysis of Y-TZP fabricated by stereolithographic additive manufacturing and subtractive manufacturing. J. Eur. Ceram. Soc. 2020, 40, 826–834. [Google Scholar] [CrossRef]

- Schiltz, J.; Render, T.; Gatrell, B.A.; Qu, H.; Steiner, C.; McGinn, P.; Schmid, S. Wear behavior of additive manufactured zirconia. Procedia Manuf. 2020, 48, 821–827. [Google Scholar] [CrossRef]

- Harrer, W.; Schwentenwein, M.; Lube, T.; Danzer, R. Fractography of zirconia-specimens made using additive manufacturing (LCM) technology. J. Eur. Ceram. Soc. 2017, 37, 4331–4338. [Google Scholar] [CrossRef]

- Osman, R.B.; van der Veen, A.J.; Huiberts, D.; Wismeijer, D.; Alharbi, N.M. 3D-printing zirconia implants; a dream or a reality? An in-vitro study evaluating the dimensional accuracy, surface topography and mechanical properties of printed zirconia implant and discs. J. Mech. Behav. Biomed. Mater. 2017, 75, 521–528. [Google Scholar] [CrossRef]

- ISO 6872:2015; Dentistry-Ceramic Materials—Part 4: Types, Classes, and Their Identification. ISO: Geneva, Switzerland, 2015.

- BSI-BS EN 623-2; Advanced Technical Ceramics—Monolithic Ceramics—General and Textural Properties Part 2: Determination of Density and Porosity. BSI: London, UK, 1993.

- Noro, A.; Kaneko, M.; Murata, I.; Yoshinari, M. Influence of surface topography and surface physicochemistry on wettability of zirconia (tetragonal zirconia polycrystal). J. Biomed. Mater. Res. B Appl. Biomater. 2013, 101, 355–363. [Google Scholar] [CrossRef]

- Opalinska, A.; Malka, I.; Dzwolak, W.; Chudoba, T.; Presz, A.; Lojkowski, W. Size-dependent density of zirconia nanoparticles. Beilstein J. Nanotechnol. 2015, 6, 27–35. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Özcan, M.; Hallmann, L.; Ender, A.; Mehl, A.; Hammerlet, C.H. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin. Oral. Investig. 2013, 17, 269–274. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, H.; Song, L.; Sun, J.; Ma, J.; Shen, Z. Stereolithography-fabricated zirconia dental prostheses: Concerns based on clinical requirements. Adv. Appl. Ceram. 2020, 119, 236–243. [Google Scholar] [CrossRef] [Green Version]

- Roulet, J.F.; Schepker, K.L.; Truco, A.; Schwarz, H.C.; Rocha, M.G. Biaxial flexural strength, crystalline structure, and grain size of new commercially available zirconia-based ceramics for dental appliances produced using a new slip-casting method. J. Mech. Behav. Biomed. Mater. 2021, 114, 104180. [Google Scholar] [CrossRef] [PubMed]

- Žmak, I.; Ćorić, D.; Mandić, V.; Ćurković, L. Hardness and Indentation Fracture Toughness of Slip Cast Alumina and Alumina-Zirconia Ceramics. Materials 2019, 13, 122. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bollen, C.; Lambrechts, P.; Quirynen, M. Comparison of surface roughness of oral hard materials to the threshold surface roughness for bacterial plaque retention: A review of the literature. Dent. Mater. 1997, 13, 258–269. [Google Scholar] [CrossRef]

- Anusavice, K.J.; Chen, C.; Rawls, H.R. Phillips Science of Dental Materials, 12th ed.; Elsevier: St. Louis, MI, USA, 2013; Chapter 4; p. 48. [Google Scholar]

- Revilla-León, M.; Al-Haj Husain, N.; Ceballos, L.; Özcan, M. Flexural strength and Weibull characteristics of stereolithography additive manufactured versus milled zirconia. J. Prosthet. Dent. 2021, 125, 685–690. [Google Scholar] [CrossRef] [PubMed]

- Bergler, M.; Korostoff, J.; Torrecillas-Martinez, L.; Mante, F.K. Ceramic Printing—Comparative Study of the Flexural Strength of 3D Printed and Milled Zirconia. Int. J. Prosthodont. 2021. [Google Scholar] [CrossRef]

- Lerner, H.; Nagy, K.; Pranno, N.; Zarone, F.; Admakin, O.; Mangano, F. Trueness and precision of 3D-printed versus milled monolithic zirconia crowns: An in vitro study. J. Dent. 2021, 113, 10379. [Google Scholar] [CrossRef]

- Wang, W.; Sun, J. Dimensional accuracy and clinical adaptation of ceramic crowns fabricated with the stereolithography technique. J. Prosthet. Dent. 2021, 125, 657–663. [Google Scholar] [CrossRef]

| Group | Material | Manufacturer | Technology | Sintering Protocol | Composition * | Orientation | |

|---|---|---|---|---|---|---|---|

| Subtractive Manufacturing (SM) | IPS e.max ZirCAD LT | Ivoclar vivadent AG | Dry milling using a 5-axis milling machine (PM7)- | Immediate sintering at max. temp 1500 °C for 9 h | Element/compound | wt% | Vertical within the disc |

| ZrO2 | 88.0–95.5 | ||||||

| Y2O3 | >4.5–≤6.0 | ||||||

| HfO2 | ≤5.0 | ||||||

| Al2O3 | ≤1.0 | ||||||

| Other oxides for coloring | ≤1.0 | ||||||

| Additive Manufacturing (AM) | 3DMix ZrO2 | 3DCeram | Stereo-lithography using a 3D-printer (CERAMAKER C900 Flex, 3DCeram Sinto, France) | Debinding by raising temp. slowly to 1000 °C then cooling slowly. Followed by sintering at max. temp. 1450 °C for ~ 20 h | Element | ppm | Horizontal (0°) Tilted (45°) Vertical (90°) |

| Li | 0.21 | ||||||

| Na | 9.2 | ||||||

| Mg | 9.2 | ||||||

| Al | ~2800 | ||||||

| Si | 380 | ||||||

| Y | Matrix | ||||||

| Zr | Matrix | ||||||

| Ag | <200 | ||||||

| Cd | <200 | ||||||

| Hf | ~21,000 | ||||||

| Ta | <10 | ||||||

| Property | Milled Group | 3D-Printed Groups | p-Value | ||

|---|---|---|---|---|---|

| Horizontal | Vertical | Tilted | |||

| Density (g/cm3) | 6.065 (0.116) | 5.978 (0.061) | 5.987 (0.223) | 5.942 (0.266) | 0.802 |

| Apparent porosity (%) | 0.923 (0.591) | 0.948 (1.086) | 0.970 (0.350) | 1.945 (1.509) | 0.318 |

| Roughness (µm) | 0.542 (0.087) B | 0.626 (0.043) AB | 0.660 (0.046) AB | 0.688 (0.080) A | 0.020 * |

| Wettability/Contact angle (°) | 69.41 (13.18) A | 89.11 (5.22) B | 75.34 (9.24) AB | 73.39 (3.1) A | 0.013 * |

| Hardness (VHN) | 1548.2 (62.32) | 1676.61 (37.77) | 1609.54 (87.55) | 1634.96 (98.1) | 0.092 |

| Biaxial flexural strength (MPa) | 1507.27 (340.10) A | 1186.73 (283.47) B | 521.51 (88.76) C | 810.92 (148.84) C | <0.001 * |

| Average grain size- measured from SEM (nm) ! | 448 ± 97.1 | 420 ± 151.8 | 458 ± 152.0 | 418 ± 139.1 | - |

| Crystalline size (Imax)- measured from XRD (nm) ! | 96 | 96 | 96 | 57 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abualsaud, R.; Abussaud, M.; Assudmi, Y.; Aljoaib, G.; Khaled, A.; Alalawi, H.; Akhtar, S.; Matin, A.; Gad, M.M. Physiomechanical and Surface Characteristics of 3D-Printed Zirconia: An In Vitro Study. Materials 2022, 15, 6988. https://doi.org/10.3390/ma15196988

Abualsaud R, Abussaud M, Assudmi Y, Aljoaib G, Khaled A, Alalawi H, Akhtar S, Matin A, Gad MM. Physiomechanical and Surface Characteristics of 3D-Printed Zirconia: An In Vitro Study. Materials. 2022; 15(19):6988. https://doi.org/10.3390/ma15196988

Chicago/Turabian StyleAbualsaud, Reem, Maissan Abussaud, Yara Assudmi, Ghadah Aljoaib, Abrar Khaled, Haidar Alalawi, Sultan Akhtar, Asif Matin, and Mohammed M. Gad. 2022. "Physiomechanical and Surface Characteristics of 3D-Printed Zirconia: An In Vitro Study" Materials 15, no. 19: 6988. https://doi.org/10.3390/ma15196988