Reducing Threading Dislocations of Single-Crystal Diamond via In Situ Tungsten Incorporation

Abstract

:1. Introduction

2. Experimental

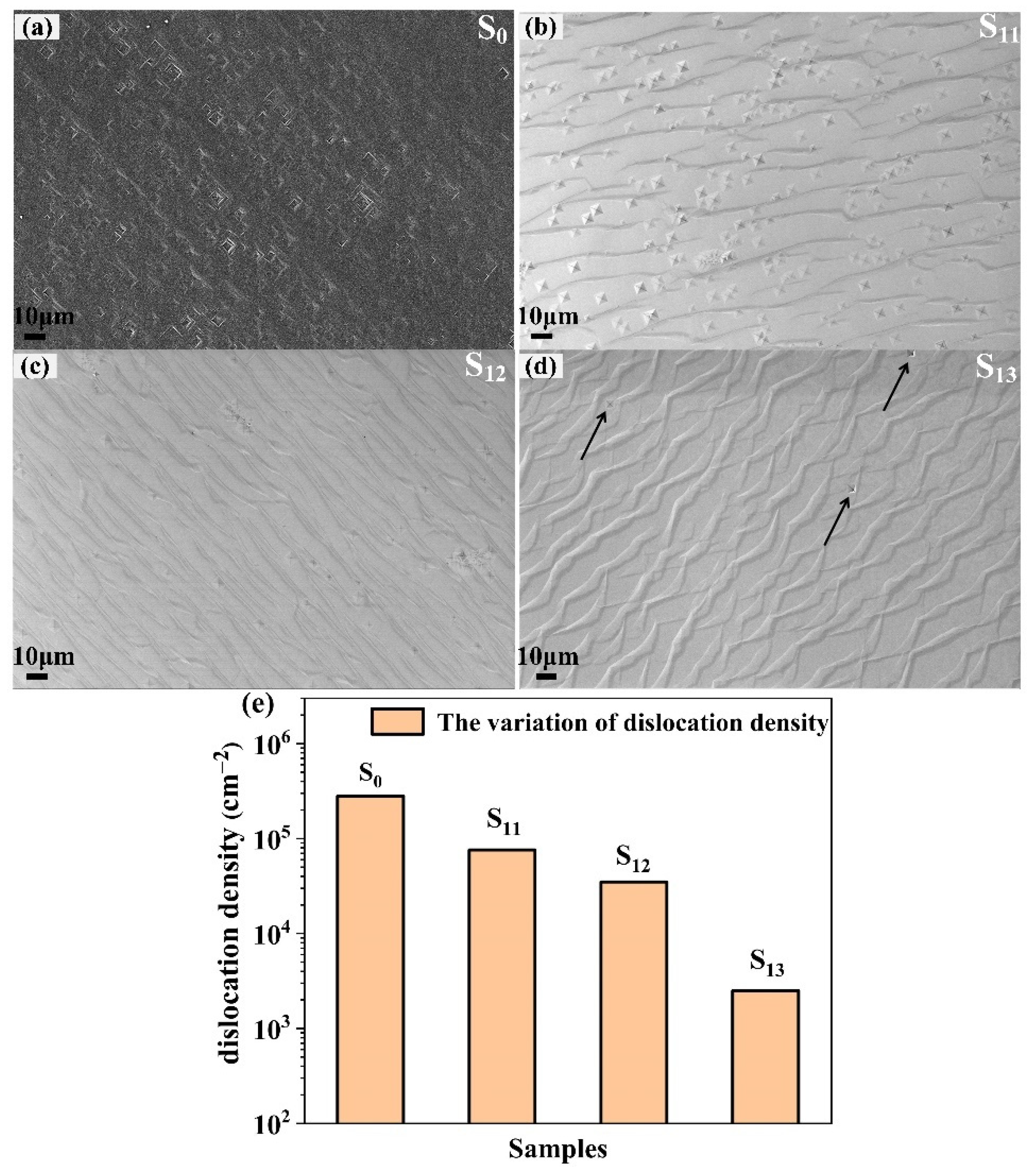

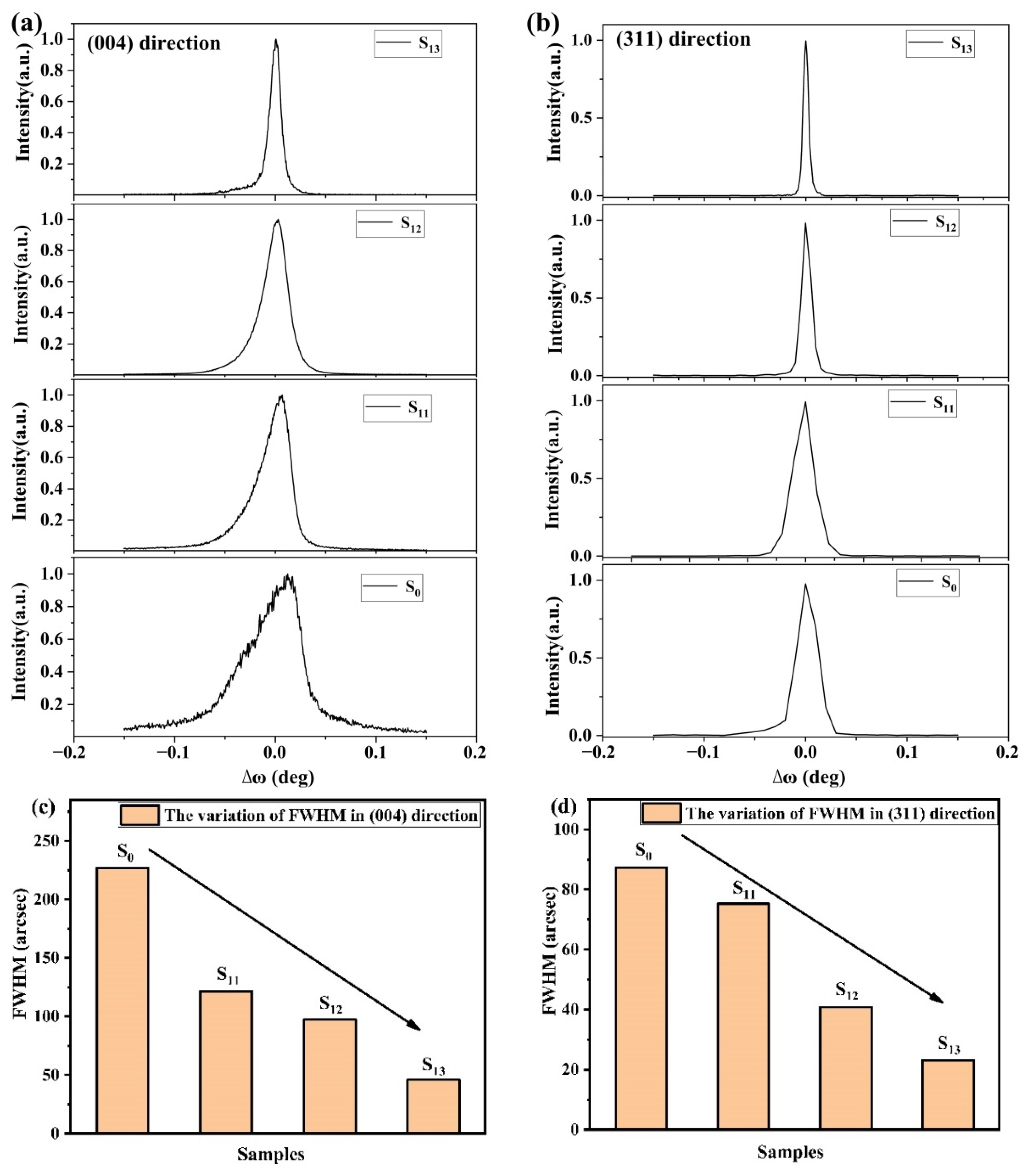

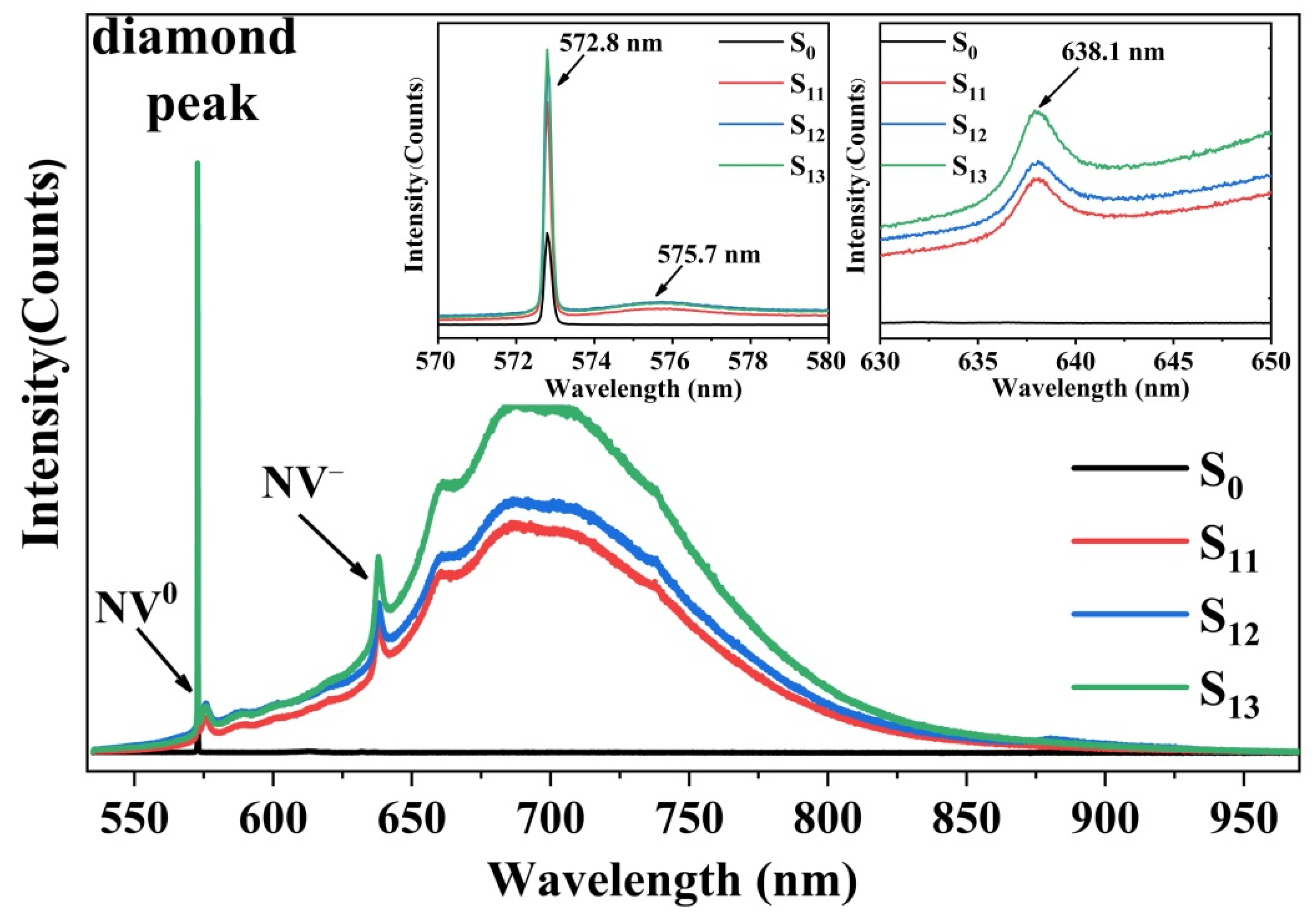

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Z.; Sang, L.; Huang, J.; Wang, L.; Koizumi, S.; Liao, M. Tailoring the magnetic properties of galfenol film grown on single-crystal diamond. J. Alloys Compd. 2021, 858, 157683. [Google Scholar] [CrossRef]

- Kitabayashi, Y.; Kudo, T.; Tsuboi, H.; Yamada, T.; Xu, D.; Shibata, M.; Matsumura, D.; Hayashi, Y.; Syamsul, M.; Inaba, M.; et al. Normally-Off C-H Diamond MOSFETs with Partial C-O Channel Achieving 2-kV Breakdown Voltage. IEEE Electron Device Lett. 2017, 38, 363–366. [Google Scholar] [CrossRef]

- Yang, N.; Yu, S.; MacPherson, J.V.; Einaga, Y.; Zhao, H.; Zhao, G.; Swain, G.M.; Jiang, X. Conductive diamond: Synthesis, properties, and electrochemical applications. Chem. Soc. Rev. 2019, 48, 157–204. [Google Scholar] [CrossRef]

- Wang, K.; Guo, R.; Ding, S.; Wang, H.; Tian, Y.; Wang, Y. Temperature dependence of optical centres in ultrapure diamond after 200 keV electron irradiation. J. Phys. D Appl. Phys. 2020, 53, 135303. [Google Scholar] [CrossRef]

- Wei, Q.; Zhang, X.; Lin, F.; Wang, R.; Chen, G.; Wang, H. Fabrication of a Micron-Scale Three-Dimensional. Materials 2021, 14, 3006. [Google Scholar] [CrossRef] [PubMed]

- Shao, G.; Wang, J.; Zhang, S.; Wang, Y.; Wang, W.; Wang, H.X. Surface morphology and microstructure evolution of single crystal diamond during different homoepitaxial growth stages. Materials 2021, 14, 5964. [Google Scholar] [CrossRef] [PubMed]

- Isberg, J.; Hammersberg, J.; Johansson, E.; Wikström, T.; Twitchen, D.J.; Whitehead, A.J.; Coe, S.E.; Scarsbrook, G.A. High carrier mobility in single-crystal plasma-deposited diamond. Science 2002, 297, 1670–1672. [Google Scholar] [CrossRef] [PubMed]

- Pernegger, H.; Roe, S.; Weilhammer, P.; Eremin, V.; Frais-Kölbl, H.; Griesmayer, E.; Kagan, H.; Schnetzer, S.; Stone, R.; Trischuk, W.; et al. Charge-carrier properties in synthetic single-crystal diamond measured with the transient-current technique. J. Appl. Phys. 2005, 97, 073704. [Google Scholar] [CrossRef] [Green Version]

- Barjon, J.; Jomard, F.; Tallaire, A.; Achard, J.; Silva, F. Determination of exciton diffusion lengths in isotopically engineered diamond junctions. Appl. Phys. Lett. 2012, 100, 122107. [Google Scholar] [CrossRef]

- Teraji, T. High-quality and high-purity homoepitaxial diamond (100) film growth under high oxygen concentration condition. J. Appl. Phys. 2015, 118, 115304. [Google Scholar] [CrossRef]

- Srimongkon, K.; Ohmagari, S.; Kato, Y.; Amornkitbamrung, V.; Shikata, S.I. Boron inhomogeneity of HPHT-grown single-crystal diamond substrates: Confocal micro-Raman mapping investigations. Diam. Relat. Mater. 2016, 63, 21–25. [Google Scholar] [CrossRef]

- Liu, Z.; Fu, J.; Liu, Z.; Wang, Y.; Fan, S.; Wen, F.; Wang, W.; Wang, K.; Ahmed, I.; Wang, H.X. Enhancing diamond NV center density in HPHT substrate and epitaxy lateral overgrowth layer by tungsten pattern. Mater. Lett. 2019, 240, 233–237. [Google Scholar] [CrossRef]

- Ganesan, K.; Ajikumar, P.K.; Ilango, S.; Mangamma, G.; Dhara, S. Si and N—Vacancy color centers in discrete diamond nanoparticles: Raman and fluorescence spectroscopic studies. Diam. Relat. Mater. 2019, 92, 150–158. [Google Scholar] [CrossRef] [Green Version]

- Pandey, M.; D’Cunha, R.; Tyagi, A.K. Defects in CVD diamond: Raman and XRD studies. J. Alloys Compd. 2002, 333, 260–265. [Google Scholar] [CrossRef]

- Moore, M.; Nailer, S.G.; Wierzchowski, W.K. Optical and X-ray topographic studies of dislocations, growth-sector boundaries, and stacking faults in synthetic diamonds. Crystals 2016, 6, 71. [Google Scholar] [CrossRef] [Green Version]

- Thomas, E.L.H.; Mandal, S.; Brousseau, E.B.; Williams, O.A. Silica based polishing of {100} and {111} single crystal diamond. Sci. Technol. Adv. Mater. 2014, 15. [Google Scholar] [CrossRef] [Green Version]

- Tallaire, A.; Achard, J.; Brinza, O.; Mille, V.; Naamoun, M.; Silva, F.; Gicquel, A. Growth strategy for controlling dislocation densities and crystal morphologies of single crystal diamond by using pyramidal-shape substrates. Diam. Relat. Mater. 2013, 33, 71–77. [Google Scholar] [CrossRef]

- Girolami, M.; Bellucci, A.; Calvani, P.; Flammini, R.; Trucchi, D.M. Radiation-assisted Frenkel-Poole transport in single-crystal diamond. Appl. Phys. Lett. 2013, 103, 083502. [Google Scholar] [CrossRef]

- Naamoun, M.; Tallaire, A.; Doppelt, P.; Gicquel, A.; Legros, M.; Barjon, J.; Achard, J. Reduction of dislocation densities in single crystal CVD diamond by using self-assembled metallic masks. Diam. Relat. Mater. 2015, 58, 62–68. [Google Scholar] [CrossRef]

- Tallaire, A.; Brinza, O.; Mille, V.; William, L.; Achard, J. Reduction of Dislocations in Single Crystal Diamond by Lateral Growth over a Macroscopic Hole. Adv. Mater. 2017, 29, 1604823. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Zhang, J.; Wang, X.; Zhang, M.; Wang, H. Fabrication of low dislocation density, single-crystalline diamond via two-step epitaxial lateral overgrowth. Crystals 2017, 7, 114. [Google Scholar] [CrossRef] [Green Version]

- Tang, Y.H.; Golding, B. Stress engineering of high-quality single crystal diamond by heteroepitaxial lateral overgrowth. Appl. Phys. Lett. 2016, 108, 052101. [Google Scholar] [CrossRef]

- Kim, S.W.; Kawamata, Y.; Takaya, R.; Koyama, K.; Kasu, M. Growth of high-quality one-inch free-standing heteroepitaxial (001) diamond on (112¯0) sapphire substrate. Appl. Phys. Lett. 2020, 117, 202102. [Google Scholar] [CrossRef]

- Mehmel, L.; Issaoui, R.; Brinza, O.; Tallaire, A.; Mille, V.; Delchevalrie, J.; Saada, S.; Arnault, J.C.; Bénédic, F.; Achard, J. Dislocation density reduction using overgrowth on hole arrays made in heteroepitaxial diamond substrates. Appl. Phys. Lett. 2021, 118, 061901. [Google Scholar] [CrossRef]

- Tsubouchi, N.; Mokuno, Y. Microstructures of threading dislocation bundles included in CVD homoepitaxial diamond plates. Diam. Relat. Mater. 2017, 78, 44–48. [Google Scholar] [CrossRef]

- Boussadi, A.; Tallaire, A.; Kasu, M.; Barjon, J.; Achard, J. Reduction of dislocation densities in single crystal CVD diamond by confinement in the lateral sector. Diam. Relat. Mater. 2018, 83, 162–169. [Google Scholar] [CrossRef]

- Ohmagari, S.; Yamada, H.; Tsubouchi, N.; Umezawa, H.; Chayahara, A.; Tanaka, S.; Mokuno, Y. Large reduction of threading dislocations in diamond by hot-filament chemical vapor deposition accompanying W incorporations. Appl. Phys. Lett. 2018, 113, 032108. [Google Scholar] [CrossRef]

- Dai, L.; Niu, G.; Zhao, J.; Zhao, H.; Liu, Y.; Wang, Y.; Zhang, Y.; Wu, H.; Wang, L.; Pfützenreuter, D.; et al. Toward van der Waals epitaxy of transferable ferroelectric barium titanate films: Via a graphene monolayer. J. Mater. Chem. C 2020, 8, 3445–3451. [Google Scholar] [CrossRef]

- Yamada, H.; Chayahara, A.; Mokuno, Y.; Kato, Y.; Shikata, S. A 2-in. mosaic wafer made of a single-crystal diamond. Appl. Phys. Lett. 2014, 104, 102110. [Google Scholar] [CrossRef]

- Sumiya, H.; Toda, N.; Nishibayashi, Y.; Satoh, S. Crystalline perfection of high purity synthetic diamond crystal. J. Cryst. Growth 1997, 178, 485–494. [Google Scholar] [CrossRef]

- Tsubouchi, N.; Mokuno, Y.; Chayahara, A.; Shikata, S. Crystallinity of freestanding large undoped single crystal diamond plates produced using pre-ion-implanted substrates and lift-off processes. Diam. Relat. Mater. 2010, 19, 1259–1262. [Google Scholar] [CrossRef]

- Petráková, V.; Nesládek, M.; Taylor, A.; Fendrych, F.; Cígler, P.; Ledvina, M.; Vacík, J.; Štursa, J.; Kučka, J. Luminescence properties of engineered nitrogen vacancy centers in a close surface proximity. Phys. Status Solidi Appl. Mater. Sci. 2011, 208, 2051–2056. [Google Scholar] [CrossRef]

- Doi, Y.; Fukui, T.; Kato, H.; Makino, T.; Yamasaki, S.; Tashima, T.; Morishita, H.; Miwa, S.; Jelezko, F.; Suzuki, Y.; et al. Pure negatively charged state of the NV center in n -type diamond. Phys. Rev. B 2016, 93, 081203. [Google Scholar] [CrossRef] [Green Version]

- Bergman, L.; Nemanich, R.J. Raman and photoluminescence analysis of stress state and impurity distribution in diamond thin films. J. Appl. Phys. 1995, 78, 6709–6719. [Google Scholar] [CrossRef]

- Miao, X.; Chen, L.; Ma, H.; Fang, C.; Guo, L.; Wang, Z.; Yang, Z.; Zhao, Z.; Jia, X. High-pressure and high-temperature treatment of N-rich B-doped diamonds. CrystEngComm 2019, 21, 3961–3965. [Google Scholar] [CrossRef]

- Surovtsev, N.V.; Kupriyanov, I.N.; Malinovsky, V.K.; Gusev, V.A.; Pal’yanov, Y.N. Effect of nitrogen impurities on the Raman line width in diamond. J. Phys. Condens. Matter 1999, 11, 4767–4774. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; Lin, F.; Niu, G.; Su, J.; Yan, X.; Wei, Q.; Wang, W.; Wang, K.; Yu, C.; Wang, H.-X. Reducing Threading Dislocations of Single-Crystal Diamond via In Situ Tungsten Incorporation. Materials 2022, 15, 444. https://doi.org/10.3390/ma15020444

Wang R, Lin F, Niu G, Su J, Yan X, Wei Q, Wang W, Wang K, Yu C, Wang H-X. Reducing Threading Dislocations of Single-Crystal Diamond via In Situ Tungsten Incorporation. Materials. 2022; 15(2):444. https://doi.org/10.3390/ma15020444

Chicago/Turabian StyleWang, Ruozheng, Fang Lin, Gang Niu, Jianing Su, Xiuliang Yan, Qiang Wei, Wei Wang, Kaiyue Wang, Cui Yu, and Hong-Xing Wang. 2022. "Reducing Threading Dislocations of Single-Crystal Diamond via In Situ Tungsten Incorporation" Materials 15, no. 2: 444. https://doi.org/10.3390/ma15020444