1. Introduction

Commercial general-purpose superconducting quantum interference devices (SQUID) have become ubiquitous experimental tools in laboratories where magnetic characterization and investigations of nanometer-scale objects is important and frequently indispensable in providing the vital insight into investigations. The range of objects include, in particular, ultrathin films [

1,

2], nanoparticles [

3,

4], and inclusions in magnetically dilute systems [

5,

6,

7], 2D [

8,

9], and 1D [

10,

11] systems, or systems in which their surface matters [

12], like topological insulators [

13,

14,

15]. In the prevailing number of cases, the materials of interest are on a solid state substrate, which make the mounting of the sample relatively easy; a breadth of relevant experimental codes has been elaborated and methods for eliminating various pitfalls have been presented [

16,

17,

18,

19,

20], which were reviewed by Pereira [

21]. In this context, a new window of experimental opportunities was opened by the elaboration of methodology and full quantification of the in situ substrate compensational method [

22], which allows for truly precise integral magnetometry of nanometer scale objects with absolute sensitivity down to 10

−8 emu [

23] or of thin antiferromagnetic layers [

24].

However, there exists a wide spectrum of subjects in which SQUID magnetometry cannot be performed according to the rules elaborated for solid state objects. These are shapeless bodies, like irregular small bits or fragments, powdered materials, generally understood soft condensed materials [

25], and all other chemical compounds and biological specimens, frequently of a strong spintronics [

26] or therapeutic relevance [

27,

28,

29,

30]. These systems usually exhibit very weak magnetic properties, and they are predominantly diamagnets. Only a handful of them allow for the use of methods developed within the solid state approach to magnetometry—these that can be bound by weakly magnetic glues without any degradation effects. One of such very convenient bonding agents is the so-called GE varnish [

31], which dissolves very easily in ethanol and works (bonds) down to the lowest temperatures. If the investigated material does not decompose or change its properties in ethanol, the investigated substance can be stabilized in the GE varnish and be affixed firmly to common sample holders, like rectangular pieces of semiconducting compound, and then mounted into plastic straws [

32] or deposited on Si [

25,

33,

34]. In all other cases, different, usually custom devised approaches had to be developed [

35]. As far as the present authors can judge, none of them can be regarded as magnetically transparent or being able to provide truly quantitative results.

In this context, small capsules appear to be the solution of choice in magnetometry of small quantities of shapeless materials, which evade other known methods of sample mounting for the measurements [

36,

37]. There are many varieties of capsules available, but for the magnetometry the capsules should be first of all small, to minimize their own magnetic contribution to the research, and colorless (transparent), to minimize the amount of dyes that usually add a paramagnetic contribution to their generally diamagnetic response. These and other contaminants make their magnetic properties difficult to standardize. The second serious issue related to the capsule-based magnetometry is the lack of simple and magnetically clean means to firmly fix the specimen-containing capsule to the magnetometer sample holder. By far the most popular Quantum Design (QD) [

38] lines of magnetometers—MPMS-XL and the MPMS-3 VSM SQUID—have provided means to use transparent drinking straws for sample housing. Indeed, most of the SQUID magnetometry research has been performed with an aid of these straws [

20,

39,

40]; other, more clean but elaborate solutions are exercised less often [

19,

22].

It turns out the inner diameter of the straws provided by QD exceeds the outer diameter of capsules that can be obtained from the same source. Neither size 4 gelatin capsules (GC) nor #5 polycarbonate capsules (PCC) can be stabilized firmly within these straws, so various means of their stabilization have been exercised. Most of these ad hoc solutions, like indentations of the straw below and above the capsule [

37], insertion of pieces of cotton wool, various plastic sticks, or short pieces of somehow deformed straws might have proven sufficient for the fixing problem, but each of them introduces their own magnetic contamination to the measurement process. Therefore, these solutions work very well only when the researched signals are strong, exceeding at least by an order magnitude the total magnetic signal of the capsule and its harness within the straw. However, frequently, the researched material is characterized by a weak magnetic response, say of a range typical for common diamagnetic substances, and/or for various technological reasons only miniscule amounts are available for the studies. Therefore, a new approach to precision integral magnetometry is needed to give a better experimental account in these situations where the investigated signals are far smaller than that of the capsule and its surroundings.

In this report we provide a complete solution to tackle the challenges related to precision integral magnetometry of miniscule amounts of shapeless substances. The method we put forward here combines both the capsules and modified plastic straws in a magnetically clean manner that allows the determination of the absolute magnitude of the magnetic moment of single-milligram-small diamagnetic samples with 1% accuracy. The method is validated for a crystalline body and exemplified for a powder sample. It has clear potential to considerably impact the research of these liquid solutions and wet biological specimens that will withstand the dry environment of the SQUID sample chamber without marked modifications to their properties. The latter line of research has not yet been exercised by the authors.

Our report is organized as follows. We first introduce the method of permanent plastic straw modification that produces straws with customized (reduced) internal diameter. This makes them suitable to accommodate capsules and provides sufficiently strong grip permitting 4 cm long scans in 1 Hz oscillating mode of the fast averaging mode, the so-called reciprocal space option (RSO) of the MPMS systems. We then introduce the method of in situ compensation of the signal of the specimen-housing capsule by substantially restoring the symmetry of the specimen holder that is otherwise broken by the presence of the capsule. We provide the complete record of the assembly process of the capsule compensational sample holder (C-CSH) and show that a 30-fold reduction of the apparent mass of the capsule, that is, the mass of the capsule that is sensed by the SQUID, is readily possible. We finally validate our method by measuring the complete temperature dependence of the magnetic susceptibility of a 2.1 mg small crystallite of diamagnetic SnTe in our C-CSH. Other measurements of a 2.9 mg sample of common turmeric powder exemplifies the applicability of our approach to investigations of equally small amounts of powders, which we quantify numerically. All of these accomplishments are done using only data reduction that is based on the standard output files of the MPMS system (*.dat files). It is shown that none of the excessive post-measurement data treatment is necessary. The method outlined here has been proven to be suitable for measurement from 2 to approximately 330 K and in the whole range of the magnetic fields available within the magnetometer and to be compatible with the RSO mode of measurements.

2. Materials and Methods

The main purpose of this report is to provide the reader with the complete method developed to in situ compensate for a large magnetic contribution brought about by common capsules, frequently employed to house soft matter or just shapeless specimens, which are difficult to be fixed to a reasonable sample holder for the intended magnetic studies. Therefore, in this section we stipulate only that the main building blocks of the self-compensating assembly are polycarbonate or gelatin capsules arranged in trains with (nearly) identical neighbors, which are all fixed into thermoplastically modified plastic drinking straws. All these elements are available directly from Quantum Design (San Diego, CA 92121, USA), and we advise to use this source for the sake of standardization. Gelatin capsules (GC) of size 4, or #4, are provided as item QDS-AGC1. The polycarbonate (PCC) ones of size 5 (smaller), or #5, can be ordered as item QDS-AGC3. Both are packed in bunches of 100. However, the inner diameter of the straws provided by QD (about 5.3 mm) exceeds the outer diameter of standard capsules, which are about 4.6 and 5 mm for PCC #5 and GC #4, respectively.

2.1. The Capsules

Apart from the mismatch of the external diameters of capsules with the inner diameter of straw, which determines the amount of effort required to fix them to a sample holder, there are other important factors that need to be discussed here. These are: (i) their magnetic susceptibility, which determines the magnitude of the magnetic response or the signal brought by the capsule to the total magnetic moment m registered during the measurement, (ii) their mass, which quantifies the weight of the sample that can be housed in the given capsule to produce an easy distinguishable magnetic response, and (iii) alignment (proper centering) issues of small specimens. The last factor is somehow the derivative of the former two. In these respects, there are virtually no problems or constraints for investigation of ferromagnetic materials of which even nanograms can dwarf the response of the capsule, particularly at a weak magnetic field. The method of compensation we put forward here will be certainly suitable for such samples, but in the report, we put our emphasis on weakly magnetic substances that are characterized by the weakest magnetic responses—the diamagnetic bodies. Our effort has been directed to minimize as much as possible the response of the capsule, so as to bring forward the weak or even very weak response of the specimen and to quantify its magnitude with a very high accuracy.

Both types of capsules have different sizes and masses. The #5 PCCs range between 22 and 35 mg and the #4 GCs between 30 and 44 mg, but it turns out that both types are characterized by a similar mass susceptibility

χ of about −6.3(2) × 10

−7 emu/g/Oe. Therefore, for the sake of simplicity and to relate the results to the similarly diamagnetic specimens of a very small mass, wherever possible, the magnetic results are converted to the mass of an idealized, yet quite typical, mass of polycarbonate capsules, i.e., to 30 mg. In that sense this conversion will make the conclusion of our findings independent of the magnitude of the magnetic field

H, at which the measurements are taken, as both signals of the capsule(s) and the specimen scale similarly with

H. Additionally, for the sake of argument, we define a standard reference diamagnetic material (SRDM) and assign to it magnetic susceptibility

χSRDM = −5 × 10

−7 emu/g/Oe, that is, a kind of broadly understood average between room temperature magnitudes of

χ of capsules and other commonly met materials as: Si (

χSi ≅ −1.2 × 10

−7 emu/g/Oe), GaAs (

χGaAs ≅ −2.25 × 10

−7 emu/g/Oe) [

41], or sapphire (

χsapphire ≅ −3.5 × 10

−7 emu/g/Oe) [

17].

2.1.1. Hygroscopicity of Gelatin Capsules—Time Domain Studies

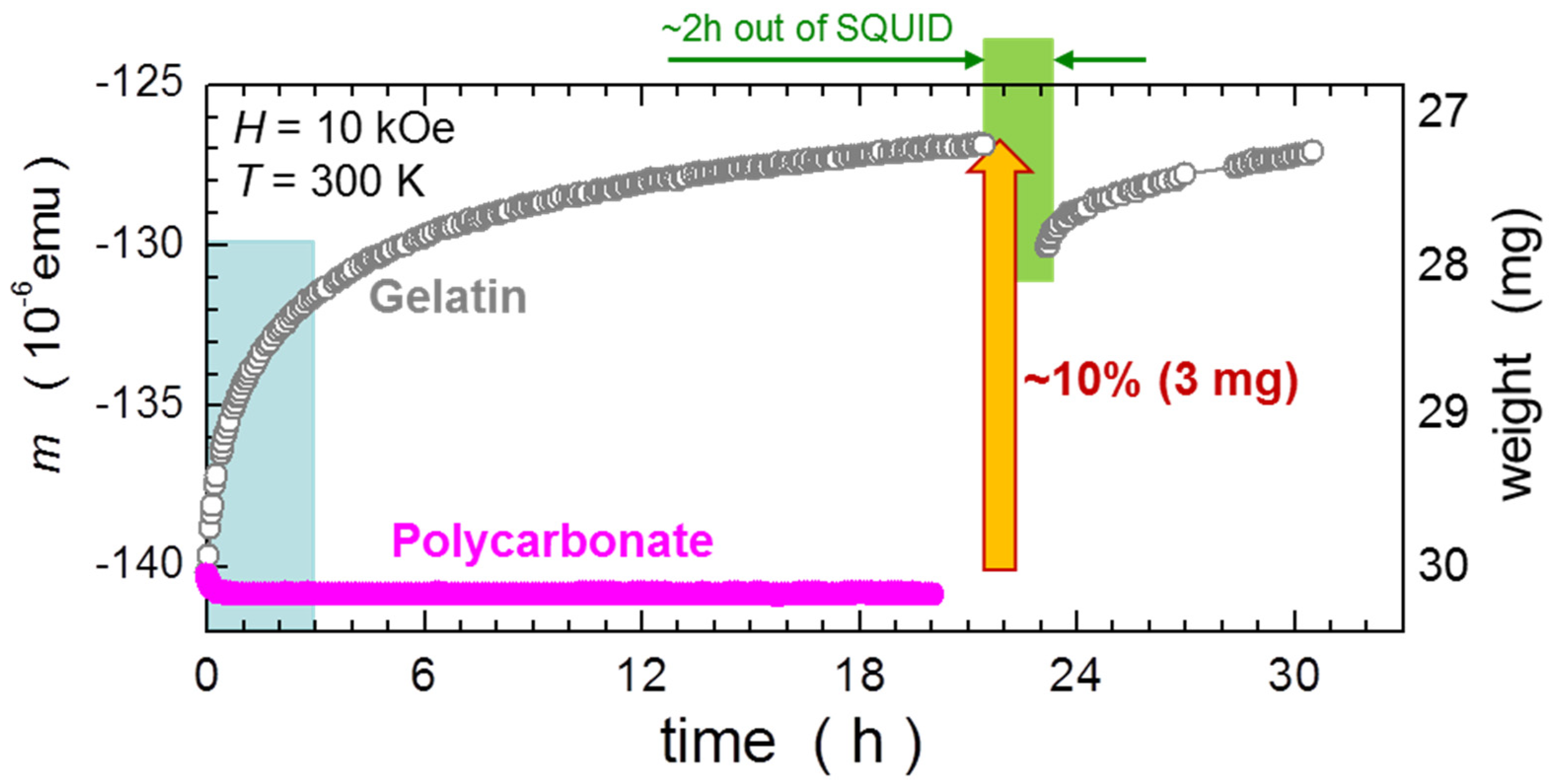

We decided to standardize the magnetic results to the mass of typical polycarbonate capsules because they can be regarded as stable in ambient conditions, in stark contrast to the gelatin ones, which are highly hygroscopic. As the result, they are changing their mass in response to the surrounding humidity. The effect is particularly strong after insertion a typical GC to the SQUID chamber. In

Figure 1, we compare time dependencies of

m of both types of capsules. The effects seen for the GC are paramount, its time dependence of

m is very substantial. There are some basic features which need to be highlighted:

Within 20 h spent in the dry residual helium atmosphere in the SQUID sample chamber, the capsule lost nearly 10% of its magnetic response. This ties precisely with the equivalent loss of about 3 mg of its weight—recorded accordingly at the key points of this investigation (the numbers are given in the caption). The equivalent mass of the capsule is indicated on the right Y-scale. This magnitude of change of mass is 50% greater than the mass of the sample that is used for the validation of our C-CSH presented further in the report;

Two-thirds of this change takes place within the first 3 h. In other words, the change of the signal during the typical time needed for the measurement of a standard m(H) hysteresis curve corresponds to the full mass (that is to the total signal) of about 2 mg of SRDM;

Upon removing the sample from the SQUID for about 2 h, the capsule regains approximately 0.8 mg of its weight, but when reinserted to the chamber, the process restarts again and continues with a similar pace. We assign these environmental changes to desorption and absorption of water vapor;

The same test executed for a polycarbonate capsule indicated only a very weak gain in m (an equivalent of less than 0.2 mg of its mass) seen within first 20 min of the test. This process saturates swiftly and no m dependence on time is subsequently detected, as expected for a polycarbonate material.

2.1.2. Temperature Dependence

The temperature dependent studies of single capsules are summarized in

Figure 2. Similar to the

Figure 1, we scale

m of GC to that of PCC and both relate to the standard mass of 30 mg. Importantly, for this measurement the GC has been kept in the pumped SQUID chamber for nearly 5 h to somehow saturate the dehydration of the gelatin. There are two major features of these results:

The temperature induced changes are relatively small down to about 50 K and relate to about 0.2 mg of SRDM. This is an encouraging result; however, the gelatin capsule had to be seasoned in the SQUID for about 5 h before the T-scan commenced;

Below about 50 K, strong paramagnetic contributions occur, which corrupt the otherwise ideal diamagnetism of the capsules. It is instructive to relate the reduction of the magnetic response of the capsules to an apparent change of mass of a sample corresponding to SRDM. We find that this change is as strong as above 3 mg for GCs, and is approximately half the magnitude in PCCs. This finding puts a strong constraint on precision magnetometry at low temperatures of miniscule samples requiring encapsulation. Importantly, this effect is practically impossible to compensate for due to unavoidable misalignment errors, discussed in the next section. The only positive aspect of this feature is that it is fully reversible with T.

In the main section of this report we show that all these detrimental properties to precision magnetometry of miniscule specimens can be substantially reduced—more than ten times—that is, it can be brought to the level corresponding to 0.2 mg of SRDM.

2.1.3. Capsules as Containers for SQUID Magnetometry (Centering Issues)

The factor that practically precludes precision integral magnetometry using capsules as housing carriers of miniscule samples of a very small

m is the challenge of the adequate centering of the whole sample holder (alignment) and related inability of the extraction of the credible magnitudes of

m of the scrutinized specimen. We remark first that there is no centering problem when the investigated material fills the whole volume of the capsule, as exemplified by the first four capsules in

Figure 3. The magnetic moment of the sample is distributed evenly along the length of the sample and the MultiVu centering routine will direct the user to the proper alignment, marked as the black dashed line. There are also no big issues with establishing the accurate magnitude of

m of such massive amounts of material. The reference measurement of the empty capsule will provide the correct magnitudes of the background signal. Alternatively, the studies can be carried out within the automatic background subtraction (ABS) method frame.

The problems begin when a small specimen with a weak magnetic response occupies only the bottom end of the capsule, as exemplified by the fifth capsule in

Figure 3. Such an object will cause only a small deviation to the dominant response of the capsule. Certainly, one can use a custom-made magnetic marker attached to the bottom of the capsule (

Appendix A) to center the sample holder at this location. There is, however, a limited accuracy, or reproducibility in placing the marker, so the alignment errors are unavoidable. We evaluate the misalignment errors by multiple fitting of the SQUID response function (SRF,

Appendix B) to the typical scan of a standard capsule, each time setting a different center position

z0 for SRF. The resulting dependence of

m on

z0 is depicted in

Figure 4 by pink bullets. For convenience, we express the magnitude of

m by the corresponding weight. As can be seen,

m drops sizably when we move away from the center of the capsule,

z0 = 2.0 cm. More informative is the derivative of this dependency, as it directly quantifies the magnitude of the misalignment errors. We read that it is as high as 10% of the mass of the capsule or simply about 3 mg of the SRDM per one millimeter of the misalignment, when one wants to extract the moment located at the vicinity of the bottom of the capsule. Clearly, only strong magnetic materials can be accurately investigated in such a manner.

2.2. Reduction of the Diameter of the Straws

The clear drinking straws can be regarded as the main workhorses of the commercial integral magnetometers due to their “stealthy” properties. Interestingly, these properties are not related to their negligible weak magnetic properties. On the contrary, the magnetic susceptibility of the material of the straw is quite high for a diamagnetic substance: χstraw ≅ 8.8 × 10−7 emu/g/Oe. At least, such a number has been established at room temperature for a 5 mm long piece of a straw coming from the same batch of straws used in this study. This is some 60–70% more than that of the capsules and of SRDM.

The straws earned their reasonably good reputation [

20,

32] as they are sufficiently homogeneous and long, so that during the scanning movement no appreciable changes of the magnetic flux are sensed by the detection circuit of the SQUID. The same straws constitute therefore the basic scaffolding within which the in situ compensation assembly is nested. However, the typical internal diameter of the straw is about 5.2 mm, so it exceeds the external diameter of the either type of capsules considered for the use in the magnetometric effort. The capsules move freely along the whole length of the unmodified straw. Since it is hard to design a magnetically stealthy harness for the stabilization of their position in the straw, we present a method for adequate reduction of the diameter of the straw that allows for precise, reproducible, and above all, harness-free firm fixing of capsules. Most conveniently, the design we put forward withstands even very long measurement runs performed in the oscillatory RSO mode without any noticeable change of its alignment with respect to the sensing coils, so no changes to the everyday experimental routines are necessary.

The key factor allowing the required modification of the diameter of the straws is their thermoplasticity. The straws become plastic at approximately 80–100 °C, and only if they are cooled in the adequate mold do they preserve the shape imposed by that mold, at least until reheated back to be plastic again. As the capsules have their external diameter smaller than the straws, we reduce the diameter of the straws by the following procedure:

We select four straight straws that we clean thoroughly in ethanol. One of them is left aside;

Next, we incise the wall of the remaining three straws along almost their whole length. That is, the cutting starts approximately 6–8 mm from one end and in one steady move is continued until the other end of the straw is reached. A sharp and clean scalpel blade should be used. The incision should be as smooth as possible, torn edges should be avoided—they are likely sources of additional magnetic signals, which makes such a straw useless as the sample holder;

We now insert the first of these three cut straws into the uncut one. Obviously, despite being cut along their length, the cut straws preserve their original diameter. Therefore, to nest a cut straw into the uncut one, the inserted straw has to curl a bit to reduce its external diameter to the internal diameter of the uncut one. We press the straw as far as it goes. It stops where the incision begins;

We continue the process with the second straw. This one has to curl more to nest into the reduced clearance of the already joined first two straws;

The third inserted straw has to curl even more, so a noticeable resistance can be felt. One can skip this point if serious problems occur. Actually, it is the second straw that we aim for. The reduction of its diameter is sufficient to firmly hold the #5 PCC capsule. All four (three) combined straws should be now heated to approximately 80 °C. Any laboratory heater will do. At this temperature, the material softens and the straws are re-formed to their new diameter set by the outer straw. In this sense the external uncut straw serves as a mold for the whole stack. The whole assembly ready for baking is depicted in

Figure 5;

We typically allow the straws to stay there for about half an hour, after which we let them to naturally cool down to room temperature. After the cool down, the straws can be separated. Three (two) straws with new diameters has been formed. We mark them as S0 (the uncut one) and consecutively, S1, S2, and S3. We confirm upon multiple tests that neither the smooth incision nor the baking and shape modifications introduce any noticeable modification to the magnetic homogeneity of the straws.

The thickness of the wall of the straw is about 0.15 mm. At the first glance this may indicate that straw S1 has its internal diameter reduced by 0.3 mm, S2 by 0.6 mm, and so on. However, the clearance of straw S1 is smaller due to the overlap of the walls along the incision. Therefore, its clearance is reduced by three thicknesses of the wall, that is by 0.45 mm, to approximately 4.8 mm. Straw S2 has to curl even more in S0 and S1, so its clearance is further reduced to approximately 4.3 mm. We note that this is already less than the external diameter of the PCC #5, and straw S2 is found to be the best suitable to house these capsules.

The main usefulness of the modification described above stems from the existence of the incision along the nearly whole length of the straws. This permits the insertion of object(s) larger than the current clearance of the straw. The walls of the cut straw step apart in the vicinity of the object(s) to locally increase the clearance. Effectively a bulge is formed, as exemplified in

Figure 6. Within the bulge, the walls of the straw press against the object, say a capsule (but it can be a rectangular sample of other crystalline material), and the friction between the walls and the objects holds the object firmly in place. The grip is so sufficient that the authors have never experienced any shift of the position of a #5 capsule in an S2 straw, even being loaded up to 180 mg. The measurements of the empty capsules presented in

Figure 1 and

Figure 2 were performed having the investigated capsules clamped by the expanding walls of an S2 straw. The same straw accommodates #4 capsules, except the bulge gets larger.

It is a matter of trial and error to find the best configuration. The authors have tested that straw S2 flawlessly holds a #5 capsule filled up to 150 mg during 20 h long 1.5 Hz and 4 cm long RSO measurement. For larger diameters, straw S1 should be used. It can house any capsule from #4 to #1. The latter has the external diameter of approximately 6.9 mm, however, in this case we suggest using a second S1 straw wrapped around the first one to increase the clamping grip.

We summarize this part by emphasizing that the single incision along the nearly entire length of the straw allows:

A permanent reduction of its diameter (clearance) during an adequate heat treatment;

Practically unrestricted movement along the straw of objects with effective diameters exceeding the modified diameter of the straw;

A position-stabilizing grip sufficient to withstand acceleration and deceleration forces during the RSO measurements.

2.3. Magnetic Measurements

All measurements in the report have been taken using two commercial MPMS-XL magnetometers operating to a maximum field of

Hmax = 50 and 70 kOe, located at the Institute of Physics, Polish Academy of Sciences in Warsaw. Therefore, most of the technical remarks are strictly applicable to these units. However, the considerations presented below are so general that the required adaptive modifications could be employed to sizably improve the credibility of the research studies in other types of magnetometers, such as the SX700 of Cryogenic Ltd. (London, UK) [

42] and the more popular SQUID-VSM MPMS3 of Quantum Design.

One of the main advantages of the in situ compensation method described here is that it is fully compatible with the RSO measurement mode, embedded in the MPMS-XL systems. The method has been derived to work with it, tested and validated using this improved oscillatory (mechanical) method of scanning. It allows for the collection of more scans in a given unit of time, which after the averaging procedure provide higher sensitivity and a reasonable sense of the experimental error. All the data presented here are collected by setting the scan length to 4 cm and RSO frequency to 1 Hz. Six measurements each consisting of four oscillations (24 scans all together to be averaged) are used to define the magnitude of each single experimental point. Further consideration on these setting can be found in

Appendix C. Both the linear and iterative regression modes of the fitting routine (extraction method of the magnitude of the magnetic moment

m) are used depending on the specific requirements. We use the sweep approach for the temperature

T dependent studies.

4. Discussion: Validation and an Example of the True Potential

In the previous section we introduced the whole concept of in situ magnetic compensation of the signal of common capsules that allow the investigation of various shapeless specimens in commercial SQUID magnetometers. In the following section, we will validate to method developed here to highlight its quite remarkable experimental potential.

In order to validate the method, we investigate a very small fragment of a crystalline material that is meant to mimic other specimens of a miniscule amount. An irregular 2.1 mg crystallite of SnTe is chosen. SnTe is a narrow gap semiconductor, the sole representative of the so called topological crystalline isolators [

45]. The investigated material was grown using the self-selecting vapour growth method [

46]. At room temperature its magnetic susceptibility is approximately

χSnTe = −4.6 × 10

−7 emu/g/Oe (which ties well with our arbitrary taken magnitude of

χ of SRDM), but most importantly for the validation tests,

χSnTe shows a very strong temperature dependence. We benchmark

χSnTe(

T) first. To this end we measure a 58 mg large piece of the material, indicated in

Figure 12 by the grey arrow. For this measurement, this large crystallite is fixed inside the S3 narrowed straw. One of its transverse dimensions sufficiently exceeds the internal diameter of this straw so the bulged straw provides the necessary grip to stabilize its location within the straw. The results are indicated as dark gray bullets in

Figure 13.

We next select the main test material, a small 2.1 mg SnTe crumb, indicated by the orange oval in

Figure 12. First, we confirm that its magnetic susceptibility is identical to that of its larger neighbor. To accurately establish the absolute magnitudes of

χ(

T) of this tiny crystallite, we glue it to one of our standard Si sample holders. That is possible because it has two flat walls. We use an equivalently small droplet of strongly diluted GE-varnish [

31]. We separately evaluate that at the same field of 10 kOe and in the whole

T-range, the magnetic contribution of the solution used by us to fix the sample stays well below the error bars of the results obtained for the 2.1 mg sample, so it is disregarded in further data reduction. The results are marked by orange symbols in

Figure 13, confirming the expected magnetic characteristics of the test piece.

The final two measurements are performed with this small test SnTe piece loaded (i) into a single PCC capsule, and (ii) into the central capsule of C-CSH. In both cases, we also measure the reference

T-dependencies of the (i) empty capsule and (ii) empty C-CSH, which are subtracted accordingly. For both measurements the sample holder is centered on the bottom of the sample-housing capsule using the method outlined in

Appendix A. All four measurements are done according to the same sequence. The results of the measurements performed in a single PCC are marked as open gray circles in

Figure 13. They differ markedly from those two established previously. Obviously, the alignment error takes its toll here. We evaluated this error in

Section 2.1.3 to be around 3 mg/mm for a standard diamagnetic material at the position corresponding to the bottom of the housing capsule (See

Figure 4). Taking 0.5 mm as a reasonable estimation of the typical misalignment, one should expect about 1.5 mg uncertainty, which is about 70% of the mass of the test sample. Indeed, we find that the absolute values of

χSnTe established in this approach differ by a factor of two at room temperature, which conforms favorably to our crude estimation. Certainly, with the identical alignment of the capsule for both these measurements. one should get a perfect reproduction of the dark grey (benchmark) or the orange results. In the authors’ view, this is beyond the reach of the standard approach in the case of such minute signals. In contrast, the main part of the temperature dependence is captured quite reasonably, at least above approximately 50 K, where the

T-responses of the

m of the capsules are reasonably flat. Below 50 K, where the PM contribution of capsules becomes substantial (c.f.

Figure 2), a small difference in alignment prevents an adequate elimination of this signal and the specific magnetic properties of the capsule mar the true properties of the investigated material. It is worth noting that one can arrive at the last conclusion only after prior knowledge of the results.

A very different outcome is obtained when this tiny crystallite is investigated in the C-CSH. Importantly, as well as in the first case, the test sample is located at the bottom of a similar housing capsule, but the several-dozen times smaller sensitivity to misalignment makes the results obtained in C-CSH practically insensitive to this issue. The expected uncertainty band in this case is only 0.1 mg/mm, which for 0.5 mm inaccuracy yields the uncertainty as low as 2.5% of the mass of the test crystallite. This final step of the validation of the in situ compensation method is marked in

Figure 13 using brown symbols. It must be noted that a precise one-to-one correspondence has been achieved, which strongly underlines the practical power of the in situ compensation and its potential. It shows that it can work very effectively in a broad range of environmental parameters, providing very accurate magnitudes of magnetic moments of even minute specimens of substances exhibiting very weak magnetic signatures.

One very important technical note is appropriate here, which highlights another practical advantage of the routine usage of the in situ compensation outlined in this report. We strongly emphasize that the compensation for the unbalanced signal of the empty C-CSH has been done by a simple subtraction of the results reported by the magnetometer in the respective *.dat files. The only restrictions to be enforced on the system are: (i) to perform the

T-dependence with the “Auto Tracking” option set on, and (ii) to use the “linear regression” algorithm. Apart from these, all the results reported here are obtained using the RSO method of measurements and the “Sweep” approach mode during the measurements in temperature domain. No Automatic Background Subtraction mode is necessary, neither is a cumbersome “scan-by-scan” subtraction of the reference measurements [

10]. Any approach like the latter calls for excessive numerical effort and would likely cause delays in data reduction. In the method put forward here it is sufficient to operate only on the basic output *.dat files yielded by the magnetometer. In the authors’ view, this very convenient property is the result of the perfectly even symmetry of the SRF and the unprecedented insensitivity to small alignment errors. The first fitting constricts channels least mean square (LMS) routines, in their fitting effort, onto specific even-parity components in the signal under processing. That is why it is impossible to correctly extract the magnitude of a weak moment located at the bottom of a single capsule, as considered in

Section 2.1.3. Colloquially speaking, there is still too much of even-parity signal of the capsule itself at its bottom that this contribution takes over the searched weak source of signal. In contrast, as shown in

Figure 8c, the response of the same capsule abutted by other similar capsules is highly complicated, without any dominant parity. Therefore, the same weak signal effectively breaks out and is quite correctly evaluated by LMS procedures, as exemplified in the following example.

In order to illustrate why the approach described above yields so surprisingly accurate magnitudes of very weak magnetic moments, we scrutinize the exact form of the scans recorded during these two measurements: the

T-dependencies of the empty C-CSH and the same C-CSH with the 2.1 mg test piece of SnTe loaded to the central capsule. As the sole representatives, we take the very first points of these two measurements. For both measurements the C-CSH assembly was centered once, i.e., before the entire validation test, using the method described in

Appendix A. There is generally no need for a second centering (correction) after inserting (removing) the sample into (from) the central capsule and reassembling the C-CSH. Just the basic care exerted during these processes allows the reconstruction of the identical enough C-CSH; a repeated centering is not needed. Moreover, the centering process on its own does not provide more accuracy than the careful reassembly of the C-CSH. Our experience gained along the development process, substantiated by the analysis of the misalignment errors (

Figure 9), says that 0.5 mm reproducibility is probably the best possible result and that it is sufficient.

In

Figure 14a, open light grey circles and dark grey bullets mark the shape of the response of the empty C-CSH and with 2.1 mg test crystallite loaded to the central capsule, respectively. Clearly, none of the scans resemble the typical shape of the SRF. The orange bullets represent the calculated point-by-point difference between these two scans yielding the sole contribution brought about by the insertion of the test sample. This shape exhibits a very clear correspondence to the signal expected for a diamagnetic substance, and the solid red line marks the fit of the SRF centered at the center of the scan window, i.e., where the whole assembly was centered. The match is exceptionally good and the

z-shift of about 1 mm indicates the inaccuracy in alignments of the C-CSH assembly for these two measurements. The fit yields

mSnTe = −9.64 μemu. The corresponding magnitude of the magnetic susceptibility is marked by a yellow cross in

Figure 13. This result corresponds to the ABS methods at its best.

Now we separately extract the magnetic moments from each of the two experimental scans given in

Figure 14a. They are plotted in

Figure 14b,c, together with the corresponding fits, marked as solid lines of matching colors. In the first case,

Figure 14b, the fit yields the residual moment of the empty C-CSH

mC-CSH = +1.4 μemu. In the second case,

Figure 14c, after insertion of the sample the fit yields

mS = −8.25 μemu. Obviously, at first glance, neither of the two fits can be classified as satisfactory. The fitted functions cut somewhat freely across the experimental points, taking rather little notice of the pattern formed by the experimental points. This is actually acceptable, as the fitting routine seeks the even-parity component, the SRF, and only these “frequencies” that correspond to

z0 = 2 cm. It is therefore no surprise that the difference of the magnitudes of

m returned by the fittings yields the correct magnitude of

mSnTe =

mS −

mC-CSH = −9.65 μemu, a mere 0.1% different value than established in

Figure 14a.

Finally, we exemplify the usefulness of the in situ compensation method in biological and medical studies by performing measurements of common turmeric powder. We emphasize that the investigated sample has not been prepared in any standard manner, e.g., Association of Analytical Chemists standard methods, specific for biological substances. The powder originates from a commercial herbs retailer [

47]. A quantity of 2.9 mg of the powder is loaded to the #5 PCC and measured in C-CSH. This amount of material forms about a 1.5 mm thin layer occupying the bottom of the capsule; however, some of the powder spreads all over the capsule. As is shown in

Figure 3, a nearly fully loaded #5 PCC accommodates approximately 70–80 mg of fresh turmeric powder. We do not focus on absolute magnitudes of

m in this measurement., primarily because after loading to the SQUID sample chamber, a weak drift in the magnetic signal is observed. Similar to the gelatin, water evaporates form the fresh turmeric powder in the dry environment of the SQUID sample chamber, so for fully quantitative studies the proper preparation of such a material is mandatory. In this measurement, we aim at properties at the low temperatures end. All the data presented below are corrected for the residual weak signal of the empty C-CSH.

We start from room temperature

m(

H) presented as orange symbols in

Figure 15b. The negative slope confirms the diamagnetic character of turmeric, although a small near zero feature indicated that a small amount of ferromagnetic (FM) component is present. This may well be a contamination due to preparation of the spice at its place of origin. From the slope of this

m(

H), we evaluate the diamagnetic susceptibility as

χturmeric ≅ −3.3 × 10

−7 emu/g/Oe. The results of the

T-dependence of

m presented in

Figure 15a indicate that turmeric turns from a diamagnetic substance into the paramagnetic (PM) one at low temperatures. To quantify this PM component, we measure

m(

H) at two very low temperatures: 1.8 and 5 K, shown in

Figure 15b. Clearly, the two dependencies have a Brillouin-like character at high magnetic fields, with noticeable FM-like deviations around

H = 0, similar to that at 300 K.

In order to accurately separate the PM signal in our turmeric sample, we invoke the fact that in most cases it is only the PM component that is responsible for changes of

m(

H) at low temperatures, a condition met in many magnetically composite systems in which the technique presented below worked with a very high precision [

3,

48,

49,

50]. The diamagnetism should not depend on

T, so should most of the FM contaminations, as latter are typically characterized by a very high spin coupling temperatures. Indeed, the

m(

T) dependence does not indicate any magnetic phase transition below 300 K. In such circumstances the calculated difference between the experimental points obtained at these two low temperatures should only reflect the change in the PM component—all other contributions get canceled. The magenta filled area and the corresponding symbols in

Figure 15b represent this difference. The required information on the spin state is obtained from fitting of this difference by the theoretical formulae describing the difference of the two Brillouin functions taken at 1.8 and 5 K. Its particular form and relevant technical details are given in

Appendix D. The best fit is obtained for

NS = 5.3(1) × 10

15 of

S = 2 spins in the sample, which indicates their mass concentration

xS ≅ 1.8 × 10

19 per gram of this particular powder. The other spin values of

S = 3/2 and 5/2 definitely yielded worse fits. The value of

S = 2 indicates Fe

4+ ions, as this transition metal dominates by far the other transition metals in turmeric [

51]. This analysis quantifies the dominant contribution; it does not preclude the presence of other unpaired spins in the material. Commercial magnetometers are volume probes and are not element specific, so they are limited in this respect. However, although this result cannot be regarded as a standard for the turmeric powder, it is only the employment of the C-CSH that makes such as analysis quantitative. It has to be noted that, as shown in

Figure 2, the capsules themselves do exhibit PM properties, and this PM of capsules would mar the results of the analysis presented above. In contrast, the self-compensation of the magnetic properties of capsules in the C-CSH assembly eradicates this detrimental property, as documented for both kinds of capsules in

Figure 10 in the

T-domain and in

Figure 11 in the

H-domain.

Where the magnetic fields are concerned, it has to be noted that the “stealthy” properties of C-CSH also lead to much smaller errors of

m caused by the trapped field of the superconducting magnet [

19,

20,

52,

53,

54]. They are also reduced 20 to 30 times, from a level of about +4 × 10

−7 emu when the specimen is housed in a single capsule to the magnetometer noise level of 10

−8 emu in C-CSH. Note that the shift of

m due to the presence of uncompensated capsules on the return from a trip to high positive fields causes a shift of

m towards positive values and it will be negative on the trip back from high negative fields, adding a FM-like hysteresis feature to the results of considerably high height of about 8 × 10

−7 emu, an important value to address in the precise magnetometry of weak signals.