The Influence of Textile Substrates on the Performance of Textronic RFID Transponders

Abstract

:1. Introduction

1.1. Motivation

1.2. State of the Art

1.3. Characteristics of Textile Substrates

1.4. Basic Parameters of Substrate

2. Materials and Methods

2.1. Measurements of Substrate Properties

2.1.1. Sample under Tests

- x—group of samples;

- y—type of fabric in the selected group of samples Gx;

- z—number of the sample in the subgroup GxMy.

2.1.2. Measurements of Thickness

2.1.3. Measurements of Dielectric Permittivity

2.2. Influence of Substrates on the Performance of RFIDtex Transponders

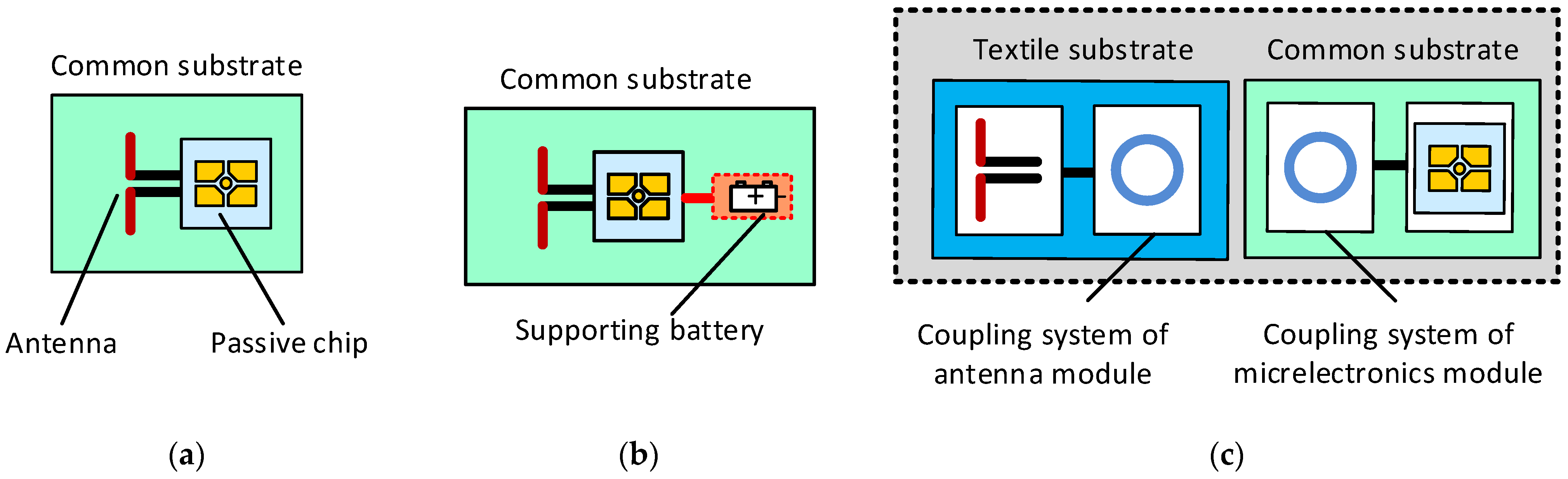

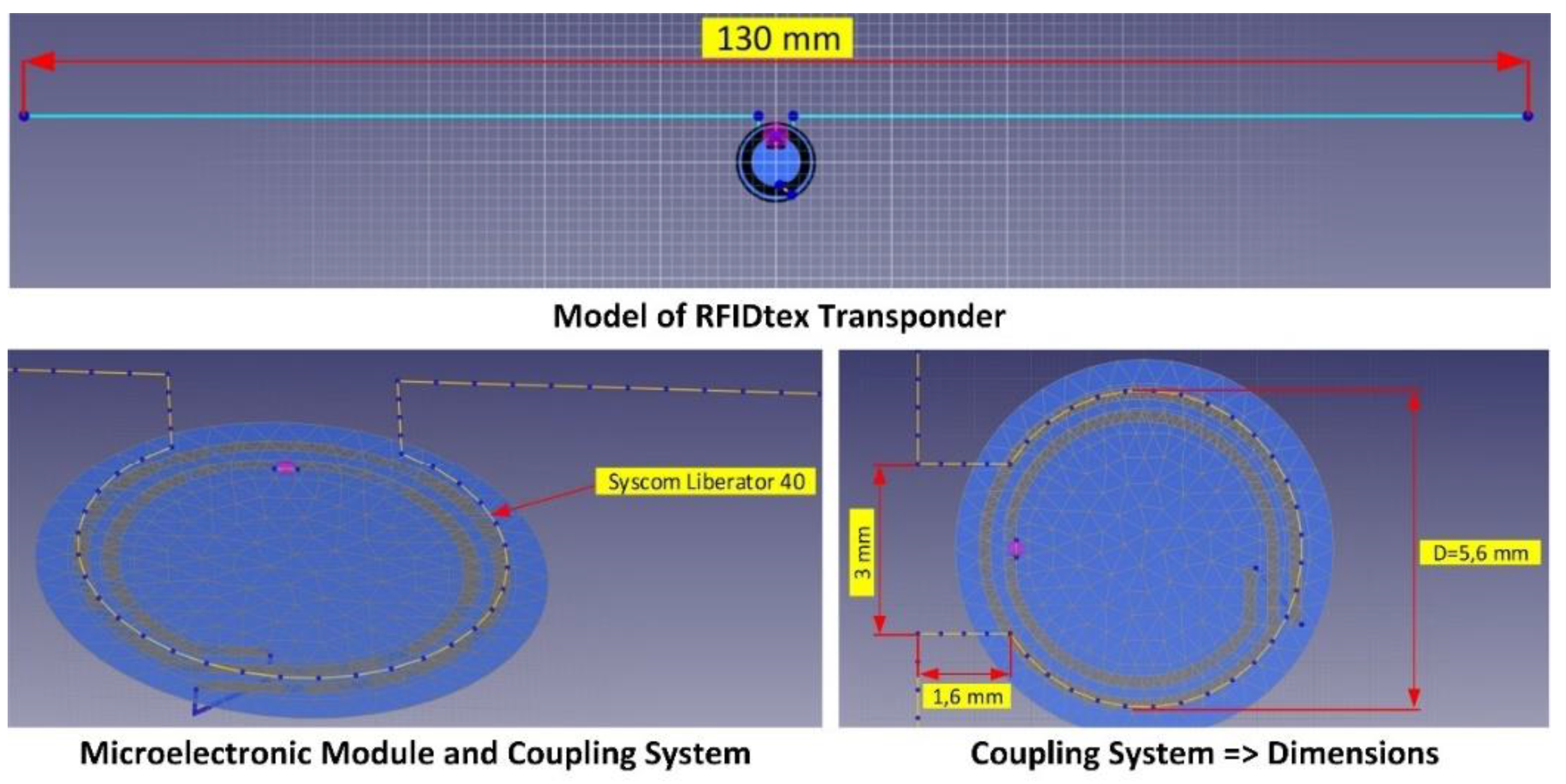

2.2.1. Design of RFIDtex Transponder

2.2.2. Input Data to Numerical Model

2.2.3. Analysis of Substrate Impact

2.2.4. Verification of Numerical Calculations

3. Results

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dias, T. Electronic Textiles: Smart Fabrics and Wearable Technology, 1st ed.; Woodhead Publishing: Cambridge, UK, 2015. [Google Scholar]

- Jansen, K.M.B. Performance Evaluation of Knitted and Stitched Textile Strain Sensors. Sensors 2020, 20, 7236. [Google Scholar] [CrossRef] [PubMed]

- Stoppa, M.; Chiolerio, A. Wearable electronics and smart textiles: A critical review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alonso-González, L.; Ver-Hoeye, S.; Fernández-García, M.; Vázquez-Antuña, C.; Las-Heras Andrés, F. From Threads to Smart Textile: Parametric Characterization and Electromagnetic Analysis of Woven Structures. IEEE Access 2019, 7, 1486–1501. [Google Scholar] [CrossRef]

- Luo, C.; Gil, I.; Fernández-García, R. Wearable Textile UHF-RFID Sensors: A Systematic Review. Materials 2020, 13, 3292. [Google Scholar] [CrossRef]

- Atanasova, G.L.; Atanasov, B.N.; Atanasov, N.T. Fully Textile Dual-Band Logo Antenna for IoT Wearable Devices. Sensors 2022, 22, 4516. [Google Scholar] [CrossRef]

- Paracha, K.N.; Abdul Rahim, S.K.; Soh, P.J.; Khalily, M. Wearable Antennas: A Review of Materials, Structures, and Innovative Features for Autonomous Communication and Sensing. IEEE Access 2019, 7, 56694–56712. [Google Scholar] [CrossRef]

- Jouali, R.; Aoutoul, M.; Ouahmane, H.; Ahmad, S.; Had, A.; El Moukhtafi, F.; Parchin, N.O.; See, C.H.; Abd-Alhameed, R. Design of an Analog RFID-Based Tag Antenna with Opened Circuited L-Shaped Stubs for Applications in Localization. Electronics 2022, 11, 1027. [Google Scholar] [CrossRef]

- Moradi, E.; Koski, K.; Björninen, T.; Sydänheimo, L.; Rabaey, J.M.; Carmena, J.M.; Rahmat-Samii, Y.; Ukkonen, L. Miniature implantable and wearable on-body antennas: Towards the new era of wireless body-centric systems. IEEE Antennas Propag. Mag. 2014, 56, 271–291. [Google Scholar]

- Jankowski-Mihułowicz, P.; Węglarski, M. Definition, characteristics and determining parameters of antennas in terms of synthesizing the interrogation zone in RFID systems. In Radio Frequency Identification, 1st ed.; Crepaldi, P.C., Pimenta, T.C., Eds.; Intech: London, UK, 2017; Chapter 5; pp. 65–119. [Google Scholar]

- Finkenzeller, K. RFID Handbook—Fundamentals and Applications in Contactless Smart Cards, Radio Frequency Identification and Near-Field Communication, 3rd ed.; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar]

- Jankowski-Mihułowicz, P.; Węglarski, M.; Chamera, M.; Pyt, P. Textronic UHF RFID Transponder. Sensors 2021, 21, 1093. [Google Scholar] [CrossRef]

- Mohamadzade, B.; Hashmi, R.M.; Simorangkir, R.B.V.B.; Gharaei, R.; Rehman, S.U.; Abbasi, Q.H. Recent Advances in Fabrication Methods for Flexible Antennas in Wearable Devices: State of the Art. Sensors 2019, 19, 2312. [Google Scholar] [CrossRef] [Green Version]

- Cupal, M.; Raida, Z. Slot Antennas Integrated into 3D Knitted Fabrics: 5.8 GHz and 24 GHz ISM Bands. Sensors 2022, 22, 2707. [Google Scholar] [CrossRef] [PubMed]

- El Gharbi, M.; Fernández-García, R.; Ahyoud, S.; Gil, I. A Review of Flexible Wearable Antenna Sensors: Design, Fabrication Methods, and Applications. Materials 2020, 13, 3781. [Google Scholar] [CrossRef] [PubMed]

- Mikulić, D.; Šopp, E.; Bonefačić, D.; Šipuš, Z. Textile Slotted Waveguide Antennas for Body-Centric Applications. Sensors 2022, 22, 1046. [Google Scholar] [CrossRef] [PubMed]

- Saba, R.; Deleruyelle, T.; Alarcon, J.; Egels, M.; Pannier, P. A Resistant Textile Tag Antenna for RFID UHF Frequency Band. In Proceedings of the IEEE International Conference on RFID—Technologies and Applications (RFID—TA), Nice, France, 5–7 November 2012. [Google Scholar]

- Kapetanakis, T.N.; Nikolopoulos, C.D.; Petridis, K.; Vardiambasis, I.O. Wearable Textile Antenna with a Graphene Sheet or Conductive Fabric Patch for the 2.45 GHz Band. Electronics 2021, 10, 2571. [Google Scholar] [CrossRef]

- Ali, S.M.; Sovuthy, C.; Imran, M.A.; Socheatra, S.; Abbasi, Q.H.; Abidin, Z.Z. Recent Advances of Wearable Antennas in Materials, Fabrication Methods, Designs, and Their Applications: State-of-the-Art. Micromachines 2020, 11, 888. [Google Scholar] [CrossRef] [PubMed]

- Ivsic, B.; Bonefacic, D.; Bartolic, J. Considerations on Embroidered Textile Antennas for Wearable Applications. IEEE Antennas Wirel. Propag. Lett. 2013, 12, 1708–1711. [Google Scholar] [CrossRef]

- Liu, F.X.; Kaufmann, T.; Xu, Z.; Fumeaux, C. Wearable Applications of Quarter-Wave Patch and Half-Mode Cavity Antennas. IEEE Antennas Wirel. Propag. Lett. 2015, 14, 1478–1481. [Google Scholar] [CrossRef]

- Wang, P.; Dong, L.; Wang, H.; Li, G.; Di, Y.; Xie, X.; Huang, D. Passive Wireless Dual-Tag UHF RFID Sensor System for Surface Crack Monitoring. Sensors 2021, 21, 882. [Google Scholar] [CrossRef]

- Koski, K.; Sydänheimo, L.; Rahmat-Samii, Y.; Ukkonen, L. Fundamental Characteristics of Electro-Textiles in Wearable UHF RFID Patch Antennas for Body-Centric Sensing Systems. IEEE Trans. Antennas Propag. 2014, 62, 6454–6462. [Google Scholar] [CrossRef]

- Patron, D.; Mongan, W.; Kurzweg, T.P.; Fontecchio, A.; Dion, G.; Anday, E.K.; Dandekar, K.R. On the Use of Knitted Antennas and Inductively Coupled RFID Tags for Wearable Applications. IEEE Trans. Biomed. Circuits Syst. 2016, 10, 1047–1057. [Google Scholar] [CrossRef]

- Benouakta, S.; Hutu, F.D.; Duroc, Y. UHF RFID Temperature Sensor Tag Integrated into a Textile Yarn. Sensors 2022, 22, 818. [Google Scholar] [CrossRef] [PubMed]

- Kapetanakis, T.N.; Pavec, M.; Ioannidou, M.P.; Nikolopoulos, C.D.; Baklezos, A.T.; Soukup, R.; Vardiambasis, I.O. Embroidered Βow-Tie Wearable Antenna for the 868 and 915 MHz ISM Bands. Electronics 2021, 10, 1983. [Google Scholar] [CrossRef]

- Abdulghafor, R.; Turaev, S.; Almohamedh, H.; Alabdan, R.; Almutairi, B.; Almutairi, A.; Almotairi, S. Recent Advances in Passive UHF-RFID Tag Antenna Design for Improved Read Range in Product Packaging Applications: A Comprehensive Review. IEEE Access 2021, 9, 63611–63635. [Google Scholar] [CrossRef]

- Datamars: UHF Laundrychi 40I. Technical Data. Available online: https://textile-id.com/ (accessed on 1 October 2022).

- Bauch, G. The Fashion Designer’s Textile Directory: A Guide to Fabrics’ Properties, Characteristics, and Garment-Design Potential, 2nd ed.; B.E.S. Publishing: New York, NY, USA, 2018. [Google Scholar]

- Hashim, F.F.; Mahadi, W.N.L.B.; Abdul Latef, T.B.; Othman, M.B. Key Factors in the Implementation of Wearable Antennas for WBNs and ISM Applications: A Review WBNs and ISM Applications: A Review. Electronics 2022, 11, 2470. [Google Scholar] [CrossRef]

- IEC 80000-6:2008; International System of Quantities. Part 6: Electromagnetism. International Organization for Standardization: Geneva, Switzerland, 2008.

- Jankowski-Mihułowicz, P.; Lichoń, W.; Węglarski, M. A Procedure for validating impedance parameters of HF/UHF RFID transponder antennas. In Methods and Techniques of Signal Processing in Physical Measurements; MSM2018, Lecture Notes in Electrical Engineering; Hanus, R., Mazur, D., Kreischer, C., Eds.; Springer: Cham, Switzerland, 2019; Volume 548, pp. 101–118. [Google Scholar]

- Ali, W.K.W.; Al-Charchafchi, S.H. Using equivalent dielectric constant to simplify the analysis of patch microstrip antenna with multi-layer substrates. In Antennas: Gateways to the Global Network, Proceedings of the IEEE Antennas and Propagation Society International Symposium, Held in Conjunction with USNC/URSI National Radio Science Meeting, Atlanta, GA, USA, 21–26 June 1998; Cat. No. 98CH36; Institute of Electrical and Electronics Engineers: Piscataway, NJ, USA, 1998; Volume 2, pp. 676–679. [Google Scholar]

- ISO 5084:1996; Textiles—Determination of Thickness of Textiles and Textile Products. International Organization for Standardization: Geneva, Switzerland, 1996.

- Schultz, J.W. A new dielectric analyzer for rapid measurement of microwave substrates up to 6 GHz. In Proceedings of the 40th Annual Meeting and Symposium of the Antenna Measurement Techniques Association (AMTA), Williamsburg, VA, USA, 4–9 November 2018. [Google Scholar]

- Compass Technology. Epsilometer Measurement System: User and Software Guide; Compass Technology: Alpharetta, GA, USA, 2018. [Google Scholar]

- Liu, P.; Yao, Z.; Ng, W.M.H.; Zhou, J.; Kong, L.B.; Yue, K. Facile synthesis of ultrasmall Fe3O4 nanoparticles on MXenes for high microwave absorption performance. Compos. Part A Appl. Sci. Manuf. 2018, 115, 371–382. [Google Scholar] [CrossRef]

- Jiao, Z.; Huyan, W.; Yang, F.; Yao, J.; Tan, R.; Chen, P.; Tao, X.; Yao, Z.; Zhou, J.; Liu, P. Achieving Ultra-Wideband and Elevated Temperature Electromagnetic Wave Absorption via Constructing Lightweight Porous Rigid Structure. Nano-Micro Lett. 2022, 14, 173. [Google Scholar] [CrossRef]

- NXP: SL3S1214 UCODE 7m. Available online: www.nxp.com (accessed on 11 April 2022).

- DuPONT: Pyralux LF9150R. Available online: www.dupont.com (accessed on 11 April 2022).

- PACKLitzWire 10 × 0.04 mm, 2 × 52. Available online: www.packlitzwire.com (accessed on 11 April 2022).

- Moraru, A.; Ursachi, C.; Helerea, E. A NewWashable UHF RFID Tag: Design, Fabrication, and Assessment. Sensors 2020, 20, 3451. [Google Scholar] [CrossRef]

- Checkline: D-2010 Motorized Precision Material Thickness Gauge. Available online: www.checkline.eu (accessed on 19 October 2021).

- Schmid & Partner Engineering AG: DAK-TL2 Fast and Precise Dielectric Measurements of Thin Layers. Available online: https://speag.swiss (accessed on 19 October 2021).

| Sample No. | Material Composition | Kind of Garment |

|---|---|---|

| #1 | 100% polyester | Skirt |

| #2 | 60% cotton, 40% polyester | Dress |

| #3 | 100% cotton | Skirt |

| #4 | 100% nylon | Nylon jacket |

| #5 | 100% viscose | Skirt |

| #6 | 95% polyester, 5% viscose | Dress |

| No. | Index | Material Composition | No. | Index | Material Composition |

|---|---|---|---|---|---|

| 1 | G1M1S1 | 82% polyester 18% spandex | 17 | G2M1S1 | 85% nylon 15% spandex |

| 2 | G1M2S1 | 100% cotton 110 gsm | 18 | G2M2S1 | 92% nylon 8% spandex |

| 3 | G1M3S1 | 97% polyester 3% spandex | 19 | G2M3S1 | 91.5% nylon 8.5% spandex (yellow) |

| 4 | G1M4S1 | 95% cotton 5% spandex | 20 | G2M4S1 | 89.8% nylon 10.2% spandex (pink) |

| 5 | G1M5S1 | 80% polyamide 20% spandex | 21 | G2M5S1 | 90% nylon 10% spandex (pink) |

| 6 | G1M6S1 | 95% polyester 5% spandex | 22 | G2M6S1 | 85% nylon 10% spandex + 5% (green) |

| 7 | G1M7S1 | 99% cotton 1% viscose | 23 | G2M7S1 | 90% nylon 10% spandex (blue) |

| 8 | G1M8S1 | 100% polyester 220 gsm | 24 | G2M8S1 | 90% nylon 10% spandex (red) |

| 9 | G1M9S1 | 100% polyester 260 gsm | 25 | G2M9S1 | 81% nylon 19% spandex (claret) |

| 10 | G1M10S1 | 100% polyester (navy blue) | 26 | G2M10S1 | 88.5% nylon 11.5% spandex (beige) |

| 11 | G1M11S1 | 100% polyester (gray) | 27 | G2M11S1 | 75% nylon 25% nylon (pink) |

| 12 | G1M12S1 | 100% polyester (black) | 28 | G2M12S1 | 88.5% nylon 11.5% spandex (beige) |

| 13 | G1M13S1 | 100% polyester (gray) | 29 | G2M13S1 | 87.6% nylon 12.4% spandex (pink) |

| 14 | G1M14S1 | 100% polyester (white) | 30 | G2M14S1 | 85% nylon 15% spandex (blue) |

| 15 | G1M15S1 | 100% polyester 280 gsm | 31 | G2M14S2 | 85% nylon 15% spandex (creamy) |

| 16 | G1M16S1 | 92% polyester 8% metallized thread | 32 | G2M15S1 | 84% nylon 16% spandex (blue) |

| 33 | G2M16S1 | 87.2% nylon 12.8% spandex (red) | |||

| 34 | G2M17S1 | 90.2% nylon 9.8% spandex (sky blue) | |||

| 35 | G2M18S1 | 84.4% nylon 15.6% spandex (black) | |||

| 36 | G2M18S2 | 84.4% nylon 15.6% spandex (white) | |||

| 37 | G2M19S1 | 65.8% nylon 17.7% spandex 16.5% polyester (beige) | |||

| 38 | G2M20S1 | 89% nylon 11% spandex (blue) | |||

| 39 | G2M21S1 | 86.1% nylon 13.9% spandex (black) | |||

| 40 | G2M22S1 | 88.7% nylon 11.3% spandex (black) |

| Type | Sample #1 | Sample #2 | Sample #3 | Sample #4 | Sample #5 | Sample #6 |

|---|---|---|---|---|---|---|

| No. | mm | mm | mm | mm | mm | mm |

| 1 | 0.305 | 0.171 | 0.342 | 0.072 | 0.151 | 0.048 |

| 2 | 0.300 | 0.168 | 0.346 | 0.070 | 0.148 | 0.046 |

| 3 | 0.300 | 0.166 | 0.353 | 0.070 | 0.147 | 0.044 |

| 4 | 0.296 | 0.170 | 0.342 | 0.070 | 0.151 | 0.045 |

| 5 | 0.305 | 0.165 | 0.341 | 0.072 | 0.147 | 0.044 |

| Average | 0.301 | 0.168 | 0.345 | 0.071 | 0.149 | 0.045 |

| No. | Index | Thickness | Average | No. | Index | Thickness | Average |

|---|---|---|---|---|---|---|---|

| – | – | mm | mm | – | – | mm | mm |

| 1 | G1M1S1 | 0.66 | 0.66 | 56 | G1M12S1 | 3.32 | 3.25 |

| 2 | G1M1S2 | 0.66 | 57 | G1M12S2 | 3.26 | ||

| 3 | G1M1S3 | 0.66 | 58 | G1M12S3 | 3.08 | ||

| 4 | G1M1S4 | 0.66 | 59 | G1M12S4 | 3.28 | ||

| 5 | G1M1S5 | 0.65 | 60 | G1M12S5 | 3.31 | ||

| 6 | G1M2S1 | 0.37 | 0.37 | 61 | G1M13S1 | 3.38 | 3.42 |

| 7 | G1M2S2 | 0.36 | 62 | G1M13S2 | 3.32 | ||

| 8 | G1M2S3 | 0.37 | 63 | G1M13S3 | 3.36 | ||

| 9 | G1M2S4 | 0.37 | 64 | G1M13S4 | 3.44 | ||

| 10 | G1M2S5 | 0.37 | 65 | G1M13S5 | 3.59 | ||

| 11 | G1M3S1 | 1.06 | 1.05 | 66 | G1M14S1 | 4.76 | 4.66 |

| 12 | G1M3S2 | 1.00 | 67 | G1M14S2 | 4.81 | ||

| 13 | G1M3S3 | 1.04 | 68 | G1M14S3 | 4.53 | ||

| 14 | G1M3S4 | 1.09 | 69 | G1M14S4 | 4.60 | ||

| 15 | G1M3S5 | 1.06 | 70 | G1M14S5 | 4.61 | ||

| 16 | G1M4S1 | 0.72 | 0.71 | 71 | G1M15S1 | 4.13 | 4.15 |

| 17 | G1M4S2 | 0.71 | 72 | G1M15S2 | 4.08 | ||

| 18 | G1M4S3 | 0.70 | 73 | G1M15S3 | 4.57 | ||

| 19 | G1M4S4 | 0.71 | 74 | G1M15S4 | 4.02 | ||

| 20 | G1M4S5 | 0.71 | 75 | G1M15S5 | 3.94 | ||

| 21 | G1M5S1 | 0.60 | 0.61 | 76 | G1M16S1 | 4.90 | 4.79 |

| 22 | G1M5S2 | 0.62 | 77 | G1M16S2 | 4.81 | ||

| 23 | G1M5S3 | 0.61 | 78 | G1M16S3 | 4.64 | ||

| 24 | G1M5S4 | 0.61 | 79 | G1M16S4 | 4.76 | ||

| 25 | G1M5S5 | 0.62 | 80 | G1M16S5 | 4.86 | ||

| 26 | G1M6S1 | 0.22 | 0.22 | 81 | G2M1S1 | 0.83 | |

| 27 | G1M6S2 | 0.22 | 82 | G2M2S1 | 0.74 | ||

| 28 | G1M6S3 | 0.22 | 83 | G2M3S1 | 0.82 | ||

| 29 | G1M6S4 | 0.21 | 84 | G2M4S1 | 0.90 | ||

| 30 | G1M6S5 | 0.22 | 85 | G2M5S1 | 1.06 | ||

| 31 | G1M7S1 | 0.72 | 0.72 | 86 | G2M6S1 | 1.29 | |

| 32 | G1M7S2 | 0.70 | 87 | G2M7S1 | 0.59 | ||

| 33 | G1M7S3 | 0.71 | 88 | G2M8S1 | 0.59 | ||

| 34 | G1M7S4 | 0.72 | 89 | G2M9S1 | 0.66 | ||

| 35 | G1M7S5 | 0.73 | 90 | G2M10S1 | 0.61 | ||

| 36 | G1M8S1 | 1.86 | 1.90 | 91 | G2M11S1 | 0.75 | |

| 37 | G1M8S2 | 1.94 | 92 | G2M12S1 | 0.74 | ||

| 38 | G1M8S3 | 1.86 | 93 | G2M13S1 | 0.56 | ||

| 39 | G1M8S4 | 1.96 | 94 | G2M14S1 | 0.76 | ||

| 40 | G1M8S5 | 1.88 | 95 | G2M14S2 | 0.77 | ||

| 41 | G1M9S1 | 2.03 | 1.96 | 96 | G2M15S1 | 0.54 | |

| 42 | G1M9S2 | 1.99 | 97 | G2M16S1 | 0.66 | ||

| 43 | G1M9S3 | 1.85 | 98 | G2M17S1 | 0.81 | ||

| 44 | G1M9S4 | 1.95 | 99 | G2M18S1 | 0.63 | ||

| 45 | G1M9S5 | 1.99 | 100 | G2M18S2 | 0.61 | ||

| 46 | G1M10S1 | 2.35 | 2.22 | 101 | G2M19S1 | 0.85 | |

| 47 | G1M10S2 | 2.29 | 102 | G2M20S1 | 0.80 | ||

| 48 | G1M10S3 | 2.18 | 103 | G2M21S1 | 0.55 | ||

| 49 | G1M10S4 | 2.14 | 104 | G2M22S1 | 0.66 | ||

| 50 | G1M10S5 | 2.14 | |||||

| 51 | G1M11S1 | 2.91 | 2.82 | ||||

| 52 | G1M11S2 | 2.75 | |||||

| 53 | G1M11S3 | 2.88 | |||||

| 54 | G1M11S4 | 2.86 | |||||

| 55 | G1M11S5 | 2.69 |

| Sample #1 | Sample #2 | Sample #3 | Sample #4 | Sample #5 | Sample #6 | |

|---|---|---|---|---|---|---|

| εr | 0.815 | 0.964 | 0.939 | 0.998 | 0.992 | 0.997 |

| tgδ | 0.881 | 0.957 | 0.933 | 0.986 | 0.940 | 0.959 |

| Sample #1 | Sample #2 | Sample #3 | Sample #4 | Sample #5 | Sample #6 | |

|---|---|---|---|---|---|---|

| εr | 0.08 | 0.12 | 0.088 | 0.09 | 0.18 | 0.06 |

| tgδ | 0.0027 | 0.0073 | 0.0025 | 0.0067 | 0.0085 | 0.0078 |

| No. | Sample | εr | tgδ |

|---|---|---|---|

| 1 | G1M1Sz | 0.988 | 0.981 |

| 2 | G1M2Sz | 0.999 | 0.996 |

| 3 | G1M3Sz | 0.998 | 0.942 |

| 4 | G1M4Sz | 1.000 | 0.989 |

| 5 | G1M5Sz | 0.994 | 0.996 |

| 6 | G1M6Sz | 0.997 | 0.995 |

| 7 | G1M7Sz | 1.000 | 0.988 |

| 8 | G1M8Sz | 0.999 | 0.980 |

| 9 | G1M9Sz | 0.999 | 0.981 |

| 10 | G1M10Sz | 0.992 | 0.982 |

| 11 | G1M11Sz | 1.000 | 0.968 |

| 12 | G1M12Sz | 1.000 | 0.999 |

| 13 | G1M13Sz | 1.000 | 0.980 |

| 14 | G1M14Sz | 1.000 | 0.999 |

| 15 | G1M15Sz | 1.000 | 0.996 |

| 16 | G1M16Sz | 0.997 | 0.993 |

| 17 | G2M1–22Sz | 0.763 | 0.460 |

| Parameter | Value |

|---|---|

| Sensitivity of reading | −16 dBm |

| Sensitivity of writing | −21 dBm |

| EPC memory | 128 bit |

| User memory | 32 bit |

| Input impedance @ 915 MHz | (12.8−j 248) Ω |

| Substrate Thickness | εr | tgδ |

|---|---|---|

| 152 µm | 2.855 | 0.110 |

| Real Part of Impedance Re (ZTA) | Imaginary Part of Impedance Im (ZTA) | Power Transfer Coefficient τ |

|---|---|---|

| 10.20 Ω | 284.06 Ω | 0.58 |

| Number of Strands | Nominal Diameter | Total Diameter without Insulation | Total Diameter with Silk Insulation | Diameter of Double Silk Insulation |

|---|---|---|---|---|

| 10 | 0.04 mm | 0.186 mm | 0.256 mm | 0.070 mm |

| No. | Sample | Average Value of εr | Average Value of tgδ | Average Value of Thickness, mm |

| 1 | G1M1Sz | 1.53 | 0.0051 | 0.66 |

| 2 | G1M2Sz | 1.78 | 0.0241 | 0.37 |

| 3 | G1M3Sz | 1.65 | 0.0001 | 1.05 |

| 4 | G1M4Sz | 1.75 | 0.0255 | 0.71 |

| 5 | G1M5Sz | 1.54 | 0.0123 | 0.61 |

| 6 | G1M6Sz | 1.62 | 0.0506 | 0.22 |

| 7 | G1M7Sz | 1.80 | 0.0333 | 0.72 |

| 8 | G1M8Sz | 1.84 | 0.0000 | 1.90 |

| 9 | G1M9Sz | 1.93 | 0.0000 | 1.96 |

| 10 | G1M10Sz | 1.51 | 0.0000 | 2.22 |

| 11 | G1M11Sz | 1.30 | 0.0000 | 2.82 |

| 12 | G1M12Sz | 1.35 | 0.0000 | 3.25 |

| 13 | G1M13Sz | 1.32 | 0.0000 | 3.42 |

| 14 | G1M14Sz | 1.42 | 0.0000 | 4.66 |

| 15 | G1M15Sz | 1.39 | 0.0000 | 4.15 |

| 16 | G1M16Sz | 1.55 | 0.0000 | 4.79 |

| 17 | G2M1Sz | 1.57 | 0.0015 | 0.83 |

| 18 | G2M2Sz | 1.60 | 0.0001 | 0.74 |

| 19 | G2M3Sz | 1.58 | 0.0001 | 0.82 |

| 20 | G2M4Sz | 1.72 | 0.0012 | 0.90 |

| 21 | G2M5Sz | 1.57 | 0.0000 | 1.06 |

| 22 | G2M6Sz | 1.75 | 0.0001 | 1.29 |

| 23 | G2M7Sz | 1.57 | 0.0049 | 0.59 |

| 24 | G2M8Sz | 1.62 | 0.0038 | 0.59 |

| 25 | G2M9Sz | 1.43 | 0.0004 | 0.66 |

| 26 | G2M10Sz | 1.43 | 0.0015 | 0.61 |

| 27 | G2M11Sz | 1.66 | 0.0043 | 0.75 |

| 28 | G2M12Sz | 1.24 | 0.0002 | 0.74 |

| 29 | G2M13Sz | 1.48 | 0.0002 | 0.56 |

| 30 | G2M14Sz | 1.37 | 0.0002 | 0.76 |

| 31 | G2M15Sz | 1.48 | 0.0001 | 0.54 |

| 32 | G2M16Sz | 1.53 | 0.0024 | 0.66 |

| 33 | G2M17Sz | 1.48 | 0.0026 | 0.81 |

| 34 | G2M18Sz | 1.66 | 0.0031 | 0.62 |

| 35 | G2M19Sz | 1.38 | 0.0001 | 0.85 |

| 36 | G2M20Sz | 1.36 | 0.0002 | 0.80 |

| 37 | G2M21Sz | 1.36 | 0.0002 | 0.55 |

| 38 | G2M22Sz | 1.80 | 0.0012 | 0.66 |

| Parameter | Value |

|---|---|

| Forward link | DSB-ASK, Tari = 25 µs |

| Return link | FM0, 40 kHz |

| Command | Query |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jankowski-Mihułowicz, P.; Węglarski, M.; Wilczkiewicz, B.; Chamera, M.; Laskowski, G. The Influence of Textile Substrates on the Performance of Textronic RFID Transponders. Materials 2022, 15, 7060. https://doi.org/10.3390/ma15207060

Jankowski-Mihułowicz P, Węglarski M, Wilczkiewicz B, Chamera M, Laskowski G. The Influence of Textile Substrates on the Performance of Textronic RFID Transponders. Materials. 2022; 15(20):7060. https://doi.org/10.3390/ma15207060

Chicago/Turabian StyleJankowski-Mihułowicz, Piotr, Mariusz Węglarski, Bartłomiej Wilczkiewicz, Mateusz Chamera, and Grzegorz Laskowski. 2022. "The Influence of Textile Substrates on the Performance of Textronic RFID Transponders" Materials 15, no. 20: 7060. https://doi.org/10.3390/ma15207060