Effect of Different Etching Times with Hydrofluoric Acid on the Bond Strength of CAD/CAM Ceramic Material

Abstract

:1. Introduction

2. Materials and Methods

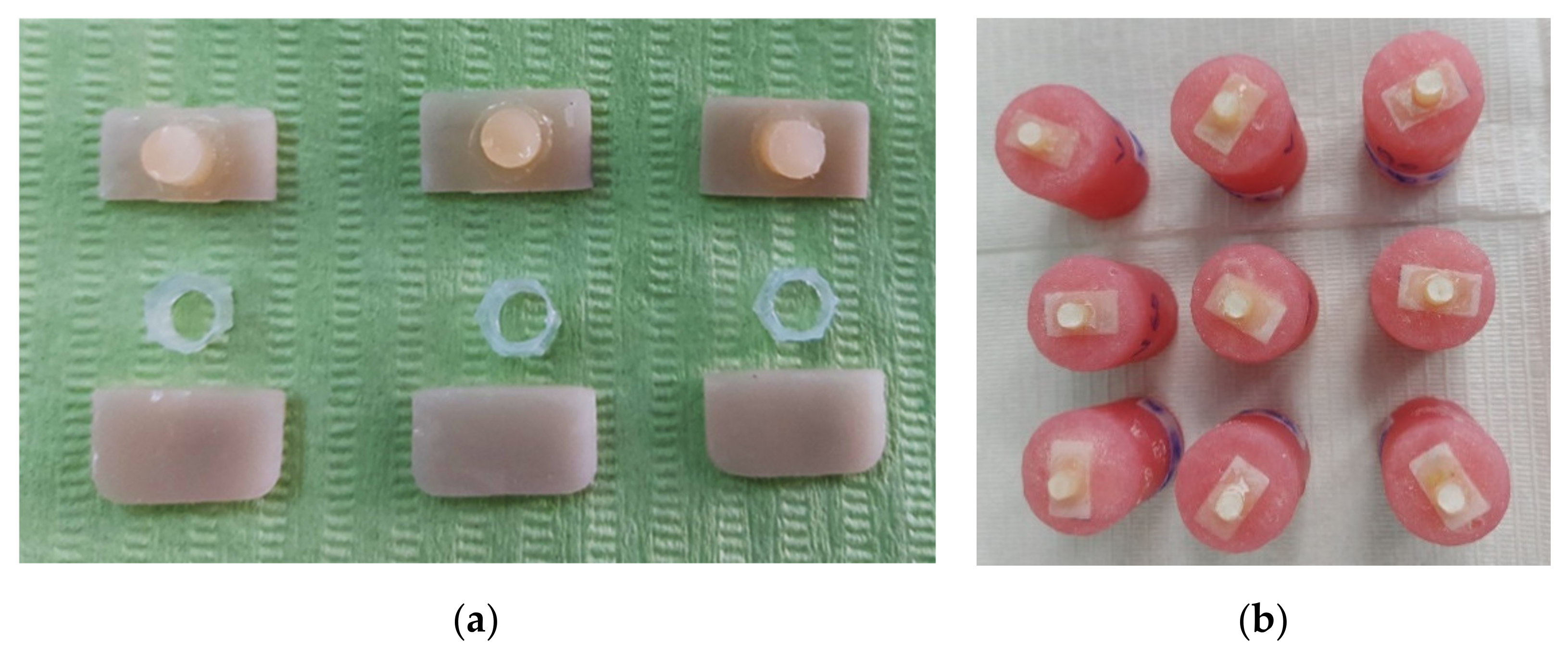

2.1. Specimen Preparation

2.2. Micro-Shear Bond Strength Test

2.3. Failure Mode

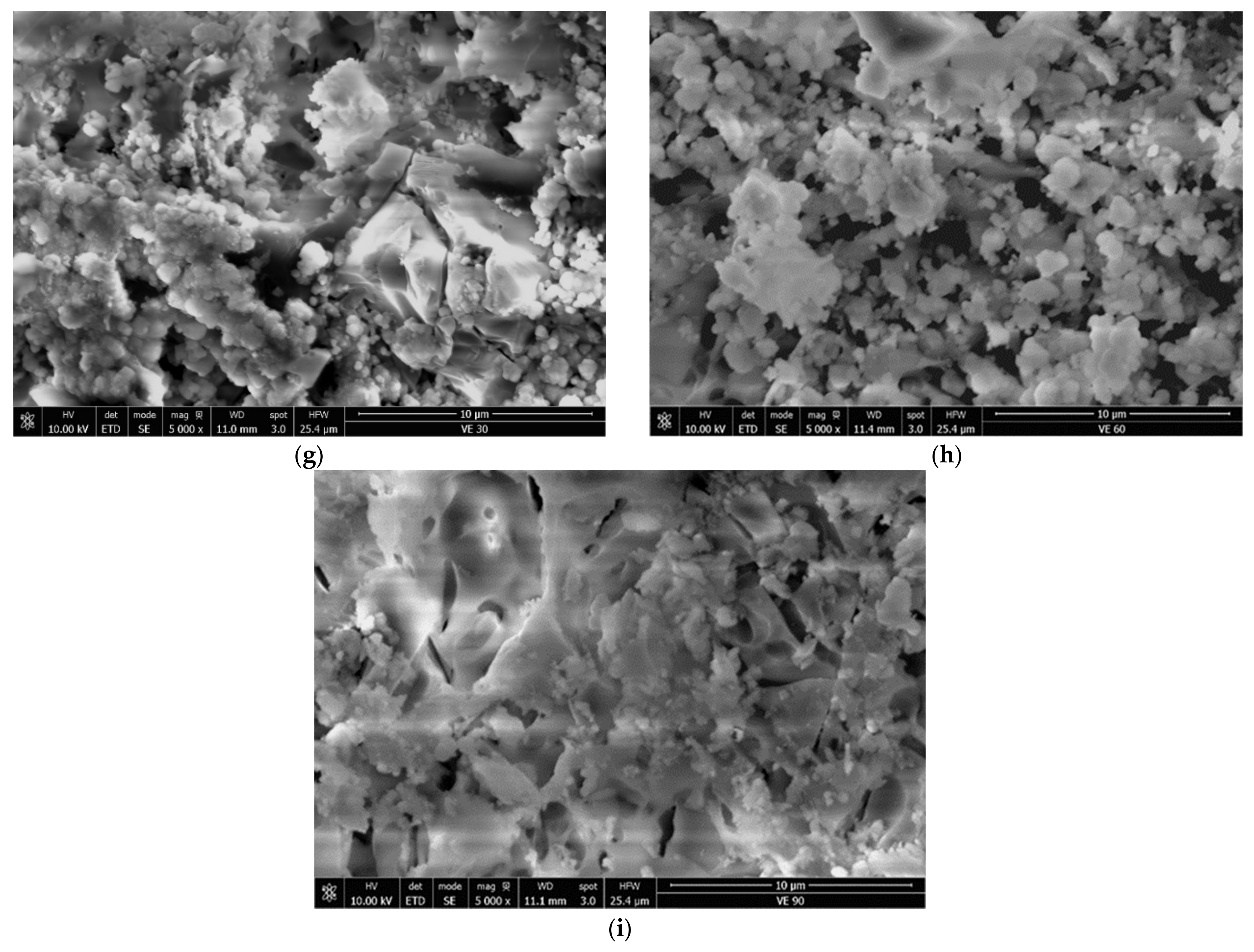

2.4. SEM Images

2.5. Statistical Analysis

3. Results

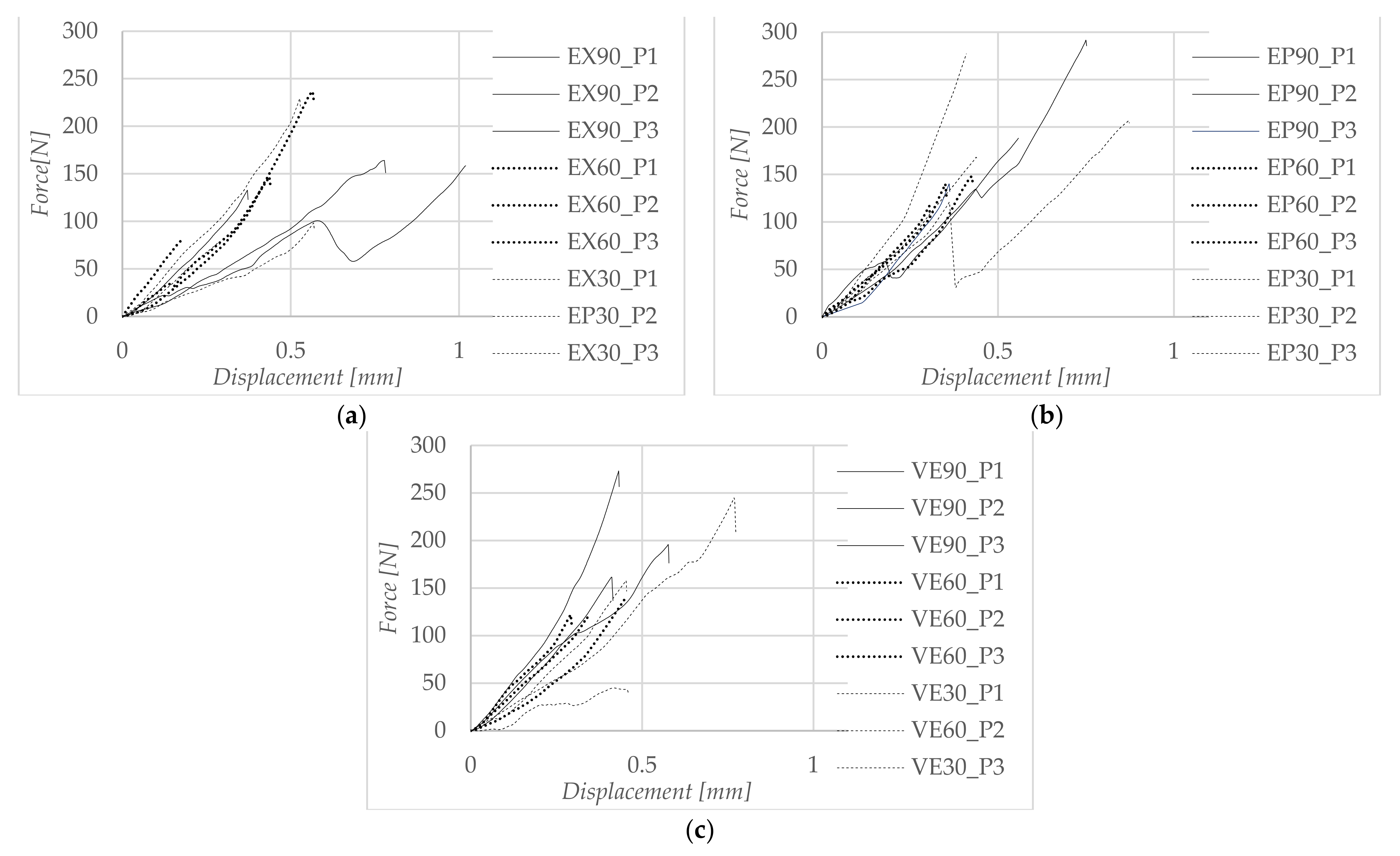

3.1. Micro-Shear Bond Strength Test

3.2. Statistical Analysis

3.3. Failure Mode

3.4. SEM Images

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hallmann, L.; Ulmer, P.; Kern, M. Effect of microstructure on the mechanical properties of lithium disilicate glass-ceramics. J. Mech. Behav. Biomed. Mater. 2018, 82, 355–370. [Google Scholar] [CrossRef] [PubMed]

- Skorulska, A.; Piszko, P.; Rybak, Z.; Szymonowicz, M.; Dobrzyński, M. Review on Polymer, Ceramic and Composite Materials for CAD/CAM Indirect Restorations in Dentistry—Application, Mechanical Characteristics and Comparison. Materials 2021, 14, 1592. [Google Scholar] [CrossRef] [PubMed]

- Helbling, F.; Özcan, M. Adhesion of resin cement to contemporary hybrid ceramic and polymeric CAD/CAM materials: Effect of conditioning methods and ageing. J. Adhes. Sci. Technol. 2019, 33, 886–902. [Google Scholar] [CrossRef] [Green Version]

- Bajraktarova-Valjakova, E.; Korunoska-Stevkovska, V.; Kapusevska, B.; Gigovski, N.; Bajraktarova-Misevska, C.; Grozdanov, A. Contemporary Dental Ceramic Materials, A Review: Chemical Composition, Physical and Mechanical Properties, Indications for Use. Open Access Maced. J. Med Sci. 2018, 6, 1742–1755. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, D.; Guo, J.; Wang, X.; Zhang, S.; He, L. Effects of crystal size on the mechanical properties of a lithium disilicate glass-ceramic. Mater. Sci. Eng. A 2016, 669, 332–339. [Google Scholar] [CrossRef]

- Hynková, K.; Voborná, I.; Linke, B.; Levin, L. State of the Art Article. Acta Stomatol. Marisiensis 2021, 4, 7–17. [Google Scholar] [CrossRef]

- Zhang, Z.; Guo, J.; Sun, Y.; Tian, B.; Zheng, X.; Zhou, M.; He, L.; Zhang, S. Effects of crystal refining on wear behaviors and mechanical properties of lithium disilicate glass-ceramics. J. Mech. Behav. Biomed. Mater. 2018, 81, 52–60. [Google Scholar] [CrossRef]

- Bebsh, M.; Haimeur, A.; França, R. The Effect of Different Surface Treatments on the Micromorphology and the Roughness of Four Dental CAD/CAM Lithium Silicate-Based Glass-Ceramics. Ceramics 2021, 4, 467–475. [Google Scholar] [CrossRef]

- Levartovsky, S.; Bohbot, H.; Shem-Tov, K.; Brosh, T.; Pilo, R. Effect of Different Surface Treatments of Lithium Disilicate on the Adhesive Properties of Resin Cements. Materials 2021, 14, 3302. [Google Scholar] [CrossRef] [PubMed]

- Conejo, J.; Ozer, F.; Mante, F.; Atria, P.J.; Blatz, M.B. Effect of surface treatment and cleaning on the bond strength to polymer-infiltrated ceramic network CAD-CAM material. J. Prosthet. Dent. 2020, 126, 698–702. [Google Scholar] [CrossRef] [PubMed]

- Da Silva, L.H.; De Lima, E.; Miranda, R.B.D.P.; Favero, S.S.; Lohbauer, U.; Cesar, P.F. Dental ceramics: A review of new materials and processing methods. Braz. Oral Res. 2017, 31, e58. [Google Scholar] [CrossRef]

- Da Silva, P.N.F.; Martinelli-Lobo, C.M.; Bottino, M.A.; de Melo, R.M.; Valandro, L.F. Bond strength between a polymer-infiltrated ceramic network and a composite for repair: Effect of several ceramic surface treatments. Braz. Oral Res. 2018, 32, e28. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Avram, L.; Goguta, L.; Galatanu, S.-V.; Opris, C.; Ille, C.; Jivanescu, A. Material Thickness Influence on Fracture Load of Polymer Infiltrated Ceramic Network CAD/CAM Restorations. Mater. Plast. 2021, 58, 8–17. [Google Scholar] [CrossRef]

- Vichi, A.; Fonzar, R.F.; Carrabba, M.; Louca, C.; Scotti, N.; Mazzitelli, C.; Breschi, L.; Goracci, C. Comparison between Hydrofluoric Acid and Single-Component Primer as Conditioners on Resin Cement Adhesion to Lithium Silicate and Lithium Disilicate Glass Ceramics. Materials 2021, 14, 6776. [Google Scholar] [CrossRef] [PubMed]

- Charoenbhakdee, S.; Lauvahutanon, S.; Sirimethawong, Y.; Jiangkongkho, P. Effect of Silane Coupling Agent on the Shear Bond Strength Between Lithium Disilicate Glass Ceramic and Composite Resin: Original articles. CM Dent. J. 2022, 43, 1–12. [Google Scholar]

- Nogueira, I.D.O.; de Oliveira, P.F.G.; Magno, M.B.; Ferreira, D.M.T.P.; Maia, L.C.; Rabello, T. Does the application of an adhesive layer improve the bond strength of etched and silanized glass-ceramics to resin-based materials? A systematic review and meta-analysis. J. Prosthet. Dent. 2021, 125, 56–64. [Google Scholar] [CrossRef]

- Tamac, E.; Kumbuloglu, T.O.; Toksavul, S.; Toman, M.; Sarikanat, M. Effects of sandblasting and silicoating on bond strength between titanium and porcelain. Niger. J. Clin. Pract. 2018, 21, 1177–1181. [Google Scholar] [PubMed]

- Grégoire, G.; Poulet, P.-P.; Sharrock, P.; Destruhaut, F.; Tavernier, B. Hydrofluoric acid etching versus self-etching glass ceramic primer: Consequences on the interface with resin cements. Oral Health Care 2019, 4, 1–7. [Google Scholar] [CrossRef]

- Kim, R.J.-Y.; Woo, J.-S.; Lee, I.-B.; Yi, Y.-A.; Hwang, J.-Y.; Seo, D.-G. Performance of universal adhesives on bonding to leucite-reinforced ceramic. Biomater. Res. 2015, 19, 11. [Google Scholar] [CrossRef] [Green Version]

- El-Damanhoury, H.M.; Gaintantzopoulou, M.D. Self-etching ceramic primer versus hydrofluoric acid etching: Etching efficacy and bonding performance. J. Prosthodont. Res. 2018, 62, 75–83. [Google Scholar] [CrossRef]

- Kömürcüoğlu, M.B.; Sağırkaya, E.; Tulga, A. Influence of different surface treatments on bond strength of novel CAD/CAM restorative materials to resin cement. J. Adv. Prosthodont. 2017, 9, 439–446. [Google Scholar] [CrossRef] [PubMed]

- Baldi, A.; Comba, A.; Tempesta, R.M.; Carossa, M.; Pereira, G.K.R.; Valandro, L.F.; Paolone, G.; Vichi, A.; Goracci, C.; Scotti, N. External Marginal Gap Variation and Residual Fracture Resistance of Composite and Lithium-Silicate CAD/CAM Overlays after Cyclic Fatigue over Endodontically-Treated Molars. Polymers 2021, 13, 3002. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, V.V.B., Jr.; Oliani, M.G.; Nogueira, L., Jr.; Silva, J.M.F.; Araújo, R.M. Analysis and Comparison of Different Bond Strength Tests. JSM Dent. 2016, 4, 1076. [Google Scholar]

- Bruzi, G.; Carvalho, A.O.; Giannini, M.; Maia, H.P.; Magne, P. Post-etching cleaning influences the resin shear bond strength to CAD/CAM lithium-disilicate ceramics. Appl. Adhes. Sci. 2017, 5, 17. [Google Scholar] [CrossRef] [Green Version]

- Ismail, A.M.; Bourauel, C.; ElBanna, A.; Eldin, T.S. Micro versus Macro Shear Bond Strength Testing of Dentin-Composite Interface Using Chisel and Wireloop Loading Techniques. Dent. J. 2021, 9, 140. [Google Scholar] [CrossRef]

- Romanini-Junior, J.C.; Kumagai, R.Y.; Ortega, L.F.; Rodrigues, J.A.; Cassoni, A.; Hirata, R.; Reis, A.F. Adhesive/silane application effects on bond strength durability to a lithium disilicate ceramic. J. Esthet. Restor. Dent. 2018, 30, 346–351. [Google Scholar] [CrossRef] [PubMed]

- Ilie, N.; Ruse, N.D. Shear bond strength vs interfacial fracture toughness—Adherence to CAD/CAM blocks. Dent. Mater. 2019, 35, 1769–1775. [Google Scholar] [CrossRef] [PubMed]

- Farag, S.M.; Ghoneim, M.M.; Afifi, R.R. Effect of Die Spacer Thickness on the Microshear Bond Strength of CAD/CAM Lithium Disilicate Veneers. Int. J. Dent. 2021, 2021, 4593131. [Google Scholar] [CrossRef] [PubMed]

- Maño, E.P.; Algarra, R.M.; Fawzy, A.; Leitune, V.C.B.; Collares, F.M.; Feitosa, V.; Sauro, S. In Vitro Bonding Performance of Modern Self-Adhesive Resin Cements and Conventional Resin-Modified Glass Ionomer Cements to Prosthetic Substrates. Appl. Sci. 2020, 10, 8157. [Google Scholar] [CrossRef]

- Sarahneh, O.; Günal-Abduljalil, B. The effect of silane and universal adhesives on the micro-shear bond strength of current resin-matrix ceramics. J. Adv. Prosthodont. 2021, 13, 292–303. [Google Scholar] [CrossRef] [PubMed]

- Rani, S.; Kansal, R.; Kumar, M.; Kumar, S.; Issar, G. Comparative evaluation of shear bond strength of newer resin cement (RelyX ultimate and RelyX U200) to lithium disilicate and zirconia ceramics as influenced by thermocycling. Contemp. Clin. Dent. 2018, 9, 601–606. [Google Scholar] [CrossRef] [PubMed]

- Aldhafyan, M.; Silikas, N.; Watts, D.C. Influence of curing modes on thermal stability, hardness development and network integrity of dual-cure resin cements. Dent. Mater. 2021, 37, 1854–1864. [Google Scholar] [CrossRef] [PubMed]

- Ustun, S.; Ayaz, E.A. Effect of different cement systems and aging on the bond strength of chairside CAD-CAM ceramics. J. Prosthet. Dent. 2021, 125, 334–339. [Google Scholar] [CrossRef] [PubMed]

- Lanza, M.D.S.; Vasconcellos, W.A.; De Miranda, G.L.P.; Peixoto, R.T.R.D.C.; Lanza, L.D. Different bonding agents effect on adhesive bond strength: Lithium disilicate glass ceramic. Rev. Odontol. UNESP 2020, 49, e20200020. [Google Scholar] [CrossRef]

- Wong, A.C.H.; Tian, T.; Tsoi, J.K.H.; Burrow, M.F.; Matinlinna, J.P. Aspects of adhesion tests on resin–glass ceramic bonding. Dent. Mater. 2017, 33, 1045–1055. [Google Scholar] [CrossRef]

- Barjaktarova-Valjakova, E.; Grozdanov, A.; Guguvcevski, L.; Korunoska-Stevkovska, V.; Kapusevska, B.; Gigovski, N.; Mijoska, A.; Bajraktarova-Misevska, C. Acid Etching as Surface Treatment Method for Luting of Glass-Ceramic Restorations, part 1: Acids, Application Protocol and Etching Effectiveness. Open Access Maced. J. Med Sci. 2018, 6, 568–573. [Google Scholar] [CrossRef] [Green Version]

- Yanakiev, S.; Medical College; Yordanov, B.; Marinova-Takorova, M.; Filaretova, Y. Hydrofluoric Acid Etching Patterns and Surface Morphology of Three Silica-Based Ceramic Materials. J. IMAB—Annu. Proceeding Sci. Pap. 2022, 28, 4325–4329. [Google Scholar] [CrossRef]

- Günal-Abduljalil, B.; Önöral, Ö.; Ongun, S. Micro-shear bond strengths of resin-matrix ceramics subjected to different surface conditioning strategies with or without coupling agent application. J. Adv. Prosthodont. 2021, 13, 180–190. [Google Scholar] [CrossRef]

- Puppin-Rontani, J.; Sundfeld, D.; Costa, A.; Correr, A.; Borges, G.; Sinhoreti, M.; Correr-Sobrinho, L. Effect of Hydrofluoric Acid Concentration and Etching Time on Bond Strength to Lithium Disilicate Glass Ceramic. Oper. Dent. 2017, 42, 606–615. [Google Scholar] [CrossRef]

- França, R.; Bebsh, M.; Haimeur, A.; Fernandes, A.C.; Sacher, E. Physicochemical surface characterizations of four dental CAD/CAM lithium disilicate-based glass ceramics on HF etching: An XPS study. Ceram. Int. 2020, 46, 1411–1418. [Google Scholar] [CrossRef]

- Almiro, M.; Marinho, B.; Delgado, A.H.S.; Rua, J.; Monteiro, P.; Santos, I.C.; Proença, L.; Mendes, J.J.; Gresnigt, M.M.M. Increasing Acid Concentration, Time and Using a Two-Part Silane Potentiates Bond Strength of Lithium Disilicate–Reinforced Glass Ceramic to Resin Composite: An Exploratory Laboratory Study. Materials 2022, 15, 2045. [Google Scholar] [CrossRef] [PubMed]

- Keshmiri, N.; Alaghehmand, H.; Mokhtarpour, F. Effect of Hydrofluoric Acid Surface Treatments on Surface Roughness and Three-Point Flexural Strength of Suprinity Ceramic. Front. Dent. 2020, 17, 1. [Google Scholar] [CrossRef] [PubMed]

- Straface, A.; Rupp, L.; Gintaute, A.; Fischer, J.; Zitzmann, N.U.; Rohr, N. HF etching of CAD/CAM materials: Influence of HF concentration and etching time on shear bond strength. Head Face Med. 2019, 15, 21. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Souza, K.B.; Moura, D.M.D.; Da Silva, S.E.G.; De Araújo, G.M.; Pinto, R.D.A.S.; Leite, F.P.P.; Özcan, M.; Souza, R.O.D.A.E. Effect of different surface treatments and multimode adhesive application on the Weibull characteristics, wettability, surface topography and adhesion to CAD/CAM lithium disilicate ceramic. J. Appl. Oral Sci. 2020, 28, e20200122. [Google Scholar] [CrossRef]

- Zogheib, L.V.; Della Bona, A.; Kimpara, E.T.; McCabe, J.F. Effect of hydrofluoric acid etching duration on the roughness and flexural strength of a lithium disilicate-based glass ceramic. Braz. Dent. J. 2011, 22, 45–50. [Google Scholar] [CrossRef] [Green Version]

- Kalavacharla, V.; Lawson, N.; Ramp, L.; Burgess, J. Influence of Etching Protocol and Silane Treatment with a Universal Adhesive on Lithium Disilicate Bond Strength. Oper. Dent. 2015, 40, 372–378. [Google Scholar] [CrossRef]

| Material | Type | Manufacturer | Composition |

|---|---|---|---|

| Empress CAD | Leucite-reinforced glass ceramic CAD/CAM block | Ivoclar-Vivadent Schaan Liechtenstein | Leucite-reinforced glass-ceramic (SiO2, Al2O3, K2O, Na2O and pigments) |

| IPS e.max CAD | Lithium disilicate glass ceramic CAD/CAM block | Ivoclar-Vivadent Schaan Liechtenstein | Glass ceramic with lithium disilicate fillers (SiO2, Li2O, K2O, MgO, Al2O3, P2O5, other oxides and pigments) |

| Vita Enamic | Polymer infiltrated CAD/CAM block | Vita Zahnfabrik, Bad Säckingen, Germany | 86 wt% feldspar ceramic, 14 wt% polymer (UDMA, TEGDMA) SiO2, Al2O3, Na2O, K2O, B2O3, CaO, TiO2, TEG-DMA, UDMA |

| Yellow Porcelain Etch | Ceramic etching gel | PPH Cerkamed Wojciech Pawlowski Stalowa Wola, Poland | Hydrofluoric acid 9.5% |

| Single Bond Universal | Universal adhesive | 3M ESPE Dental Products, St. Paul, MN, USA | MDP phosphate monomer. Dimethacrylate resins. HEMA. Vitrebond. Copolymer. Filler. Ethanol. Water. Initiators. Silane |

| RelyX Ultimate Adhesive | Dual-cure resin cement | 3M ESPE Dental Products, St. Paul, MN, USA | 10-Methacryloxydecyl dihydrogenphosphate (MDP) Dimethacrylate resins. HEMA. Vitrebond. Copolymer. Filler. Ethanol. Water. Initiators. Silane |

| Descriptive—EP | ||||||||

|---|---|---|---|---|---|---|---|---|

| Time | N | Mean | Std. Deviation | Std. Error | 95% Confidence Interval for Mean | Minimum | Maximum | |

| Lower Bound | Upper Bound | |||||||

| 30 | 6 | 17.42467 | 3.842316 | 1.568619 | 13.39240 | 21.45693 | 12.901 | 22.343 |

| 60 | 6 | 11.06450 | 1.146762 | 0.468164 | 9.86105 | 12.26795 | 9.394 | 12.376 |

| 90 | 6 | 18.10983 | 4.733010 | 1.932243 | 13.14284 | 23.07682 | 11.286 | 23.792 |

| Total | 18 | 15.53300 | 4.687373 | 1.104824 | 13.20202 | 17.86398 | 9.394 | 23.792 |

| Descriptive—EX | ||||||||

|---|---|---|---|---|---|---|---|---|

| Time | N | Mean | Std. Deviation | Std. Error | 95% Confidence Interval for Mean | Minimum | Maximum | |

| Lower Bound | Upper Bound | |||||||

| 30 | 6 | 10.60383 | 5.237264 | 2.138104 | 5.10766 | 16.10000 | 5.933 | 18.260 |

| 60 | 6 | 12.73050 | 5.419664 | 2.212569 | 7.04291 | 18.41809 | 6.489 | 19.607 |

| 90 | 6 | 11.68317 | 0.712398 | 0.290835 | 10.93555 | 12.43078 | 10.586 | 12.394 |

| Total | 18 | 11.67250 | 4.201647 | 0.990338 | 9.58307 | 13.76193 | 5.933 | 19.607 |

| Descriptive—VE | ||||||||

|---|---|---|---|---|---|---|---|---|

| Time | N | Mean | Std. Deviation | Std. Error | 95% Confidence Interval for Mean | Minimum | Maximum | |

| Lower Bound | Upper Bound | |||||||

| 30 | 6 | 9.97600 | 4.406027 | 1.798753 | 5.35216 | 14.59984 | 2.706 | 14.284 |

| 60 | 6 | 10.09017 | 1.260952 | 0.514781 | 8.76688 | 11.41345 | 8.703 | 11.895 |

| 90 | 6 | 15.13233 | 4.657223 | 1.901303 | 10.24488 | 20.01979 | 10.387 | 22.871 |

| Total | 18 | 11.73283 | 4.321713 | 1.018638 | 9.58370 | 13.88197 | 2.706 | 22.871 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Avram, L.T.; Galațanu, S.-V.; Opriș, C.; Pop, C.; Jivănescu, A. Effect of Different Etching Times with Hydrofluoric Acid on the Bond Strength of CAD/CAM Ceramic Material. Materials 2022, 15, 7071. https://doi.org/10.3390/ma15207071

Avram LT, Galațanu S-V, Opriș C, Pop C, Jivănescu A. Effect of Different Etching Times with Hydrofluoric Acid on the Bond Strength of CAD/CAM Ceramic Material. Materials. 2022; 15(20):7071. https://doi.org/10.3390/ma15207071

Chicago/Turabian StyleAvram, Liane Tabitha, Sergiu-Valentin Galațanu, Carmen Opriș, Cristian Pop, and Anca Jivănescu. 2022. "Effect of Different Etching Times with Hydrofluoric Acid on the Bond Strength of CAD/CAM Ceramic Material" Materials 15, no. 20: 7071. https://doi.org/10.3390/ma15207071