A Suggested Equivalent Method for a Drainage Structure to Analyze Seepage in Tailings Dam

Abstract

1. Introduction

2. Introduction of Saturated-Unsaturated Seepage Theory

2.1. Government Equations

2.2. Computation Implementation

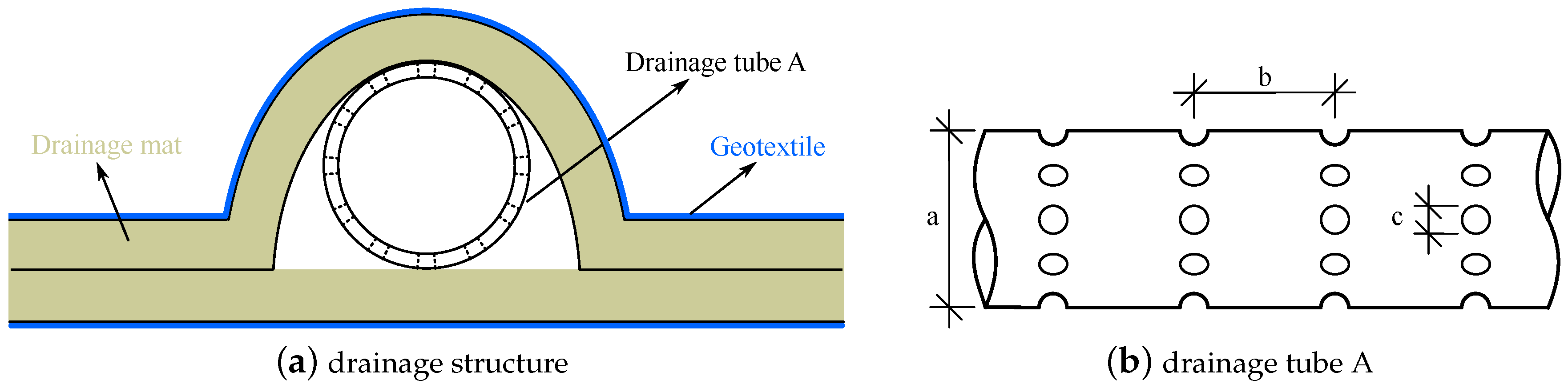

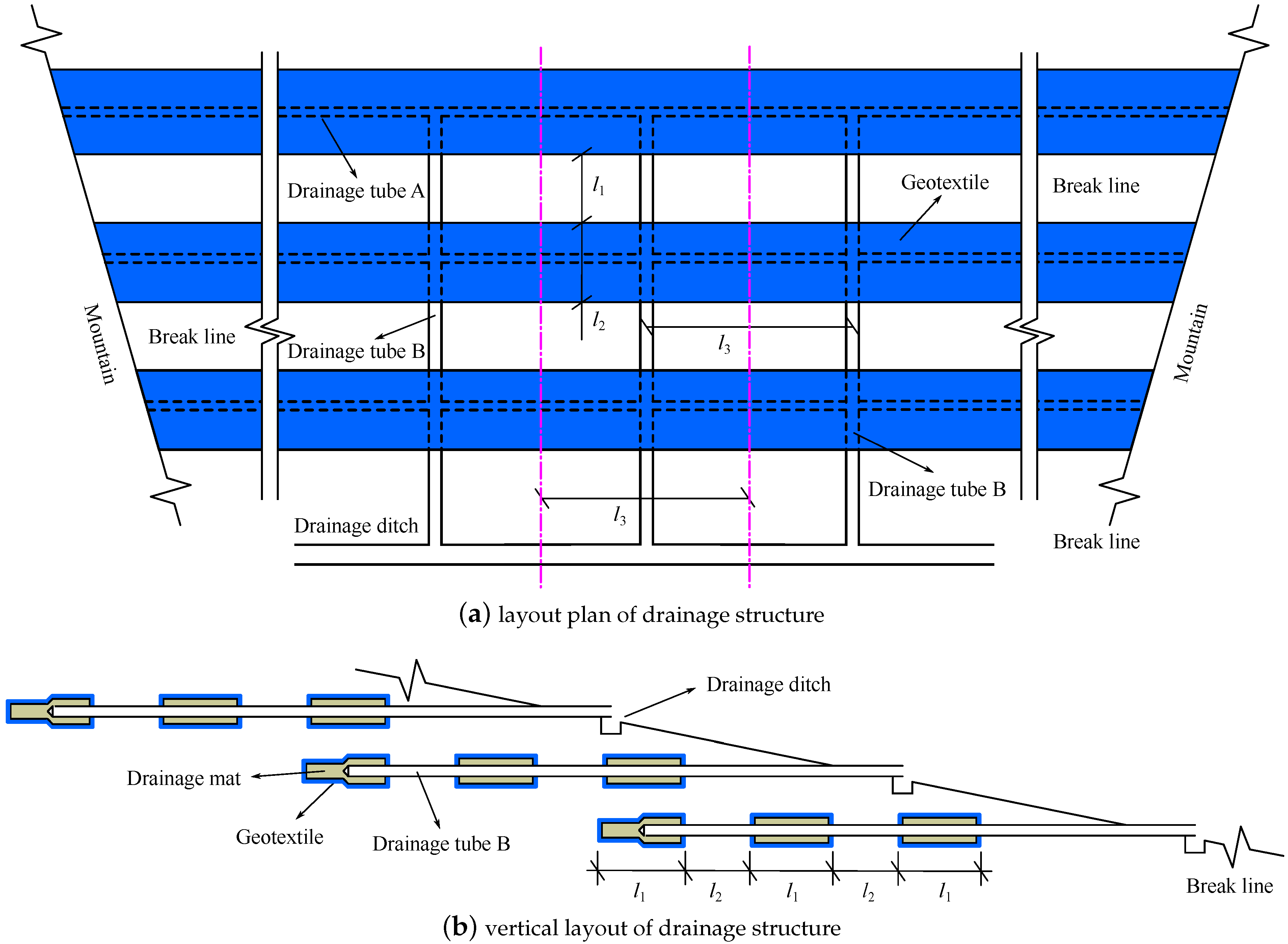

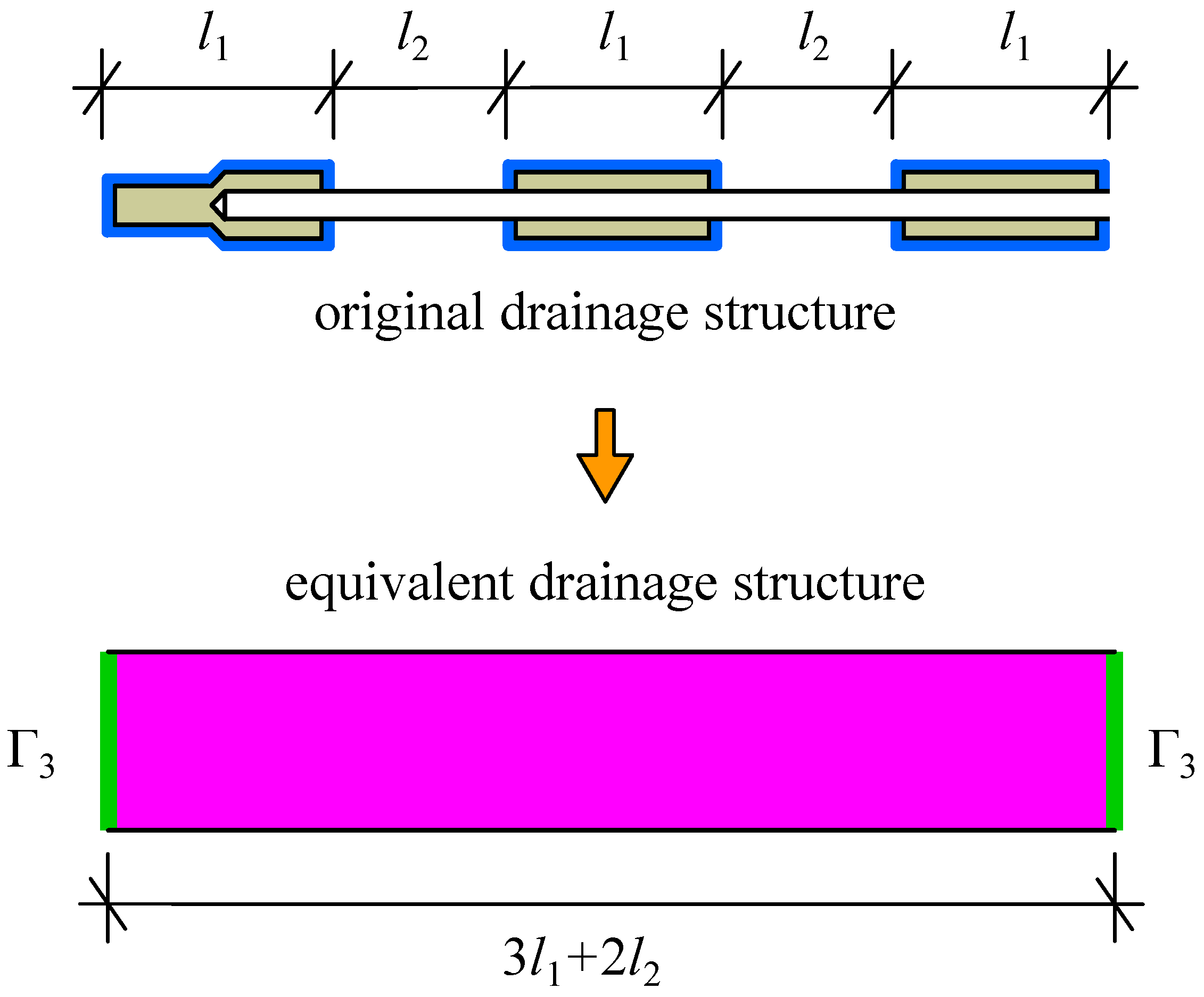

3. Equivalent Seepage Analysis Method for Drainage Structure

3.1. Equivalent Seepage Analysis Method

3.2. Verification of the Suggested Method

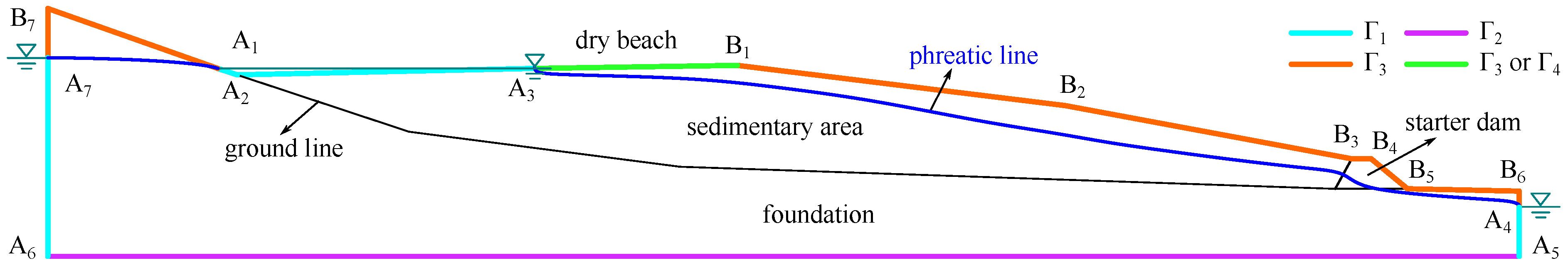

4. Case Study: Seepage Analysis of a Tailings Dam

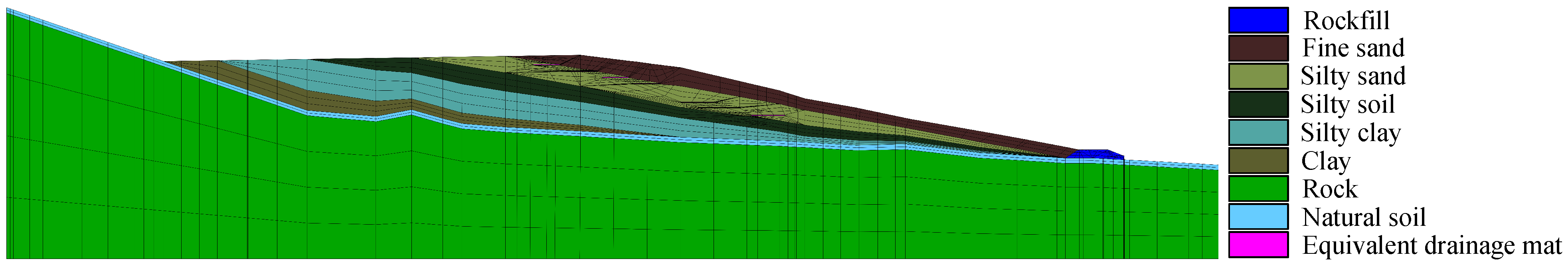

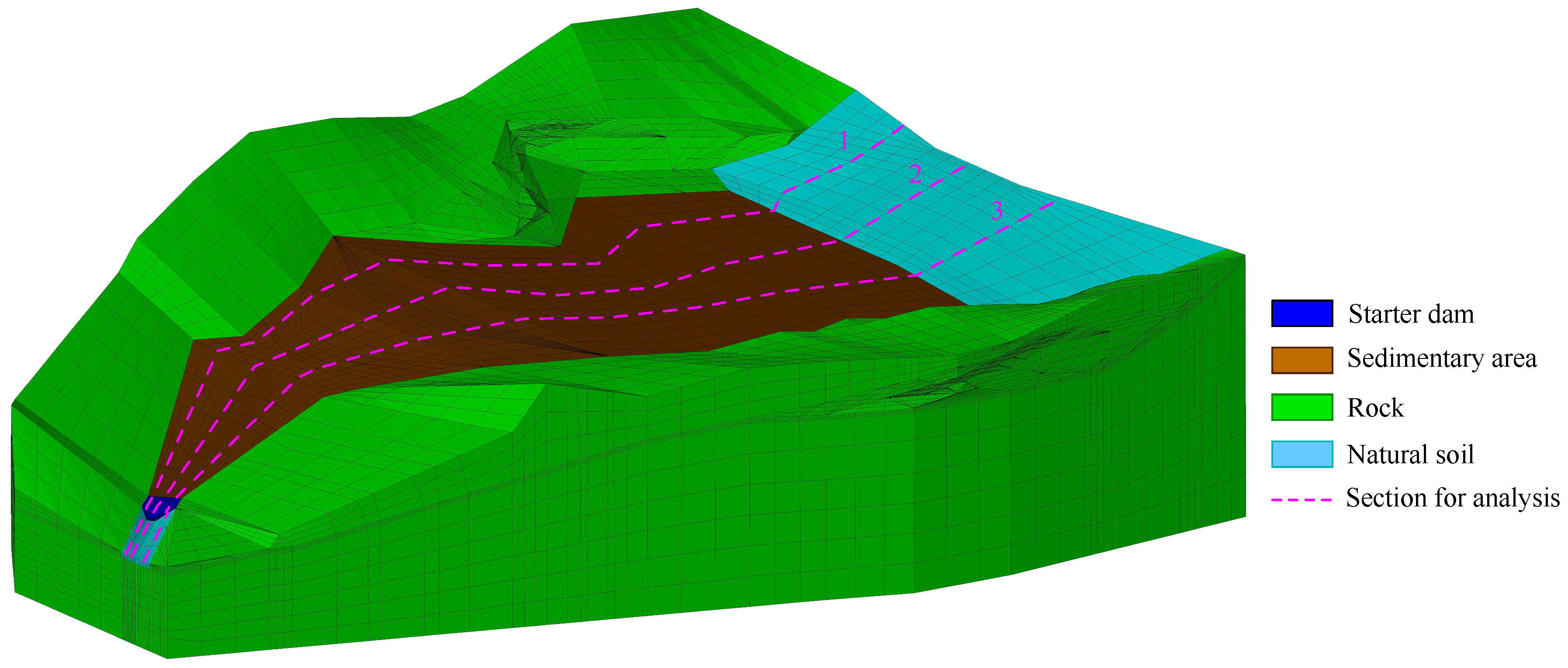

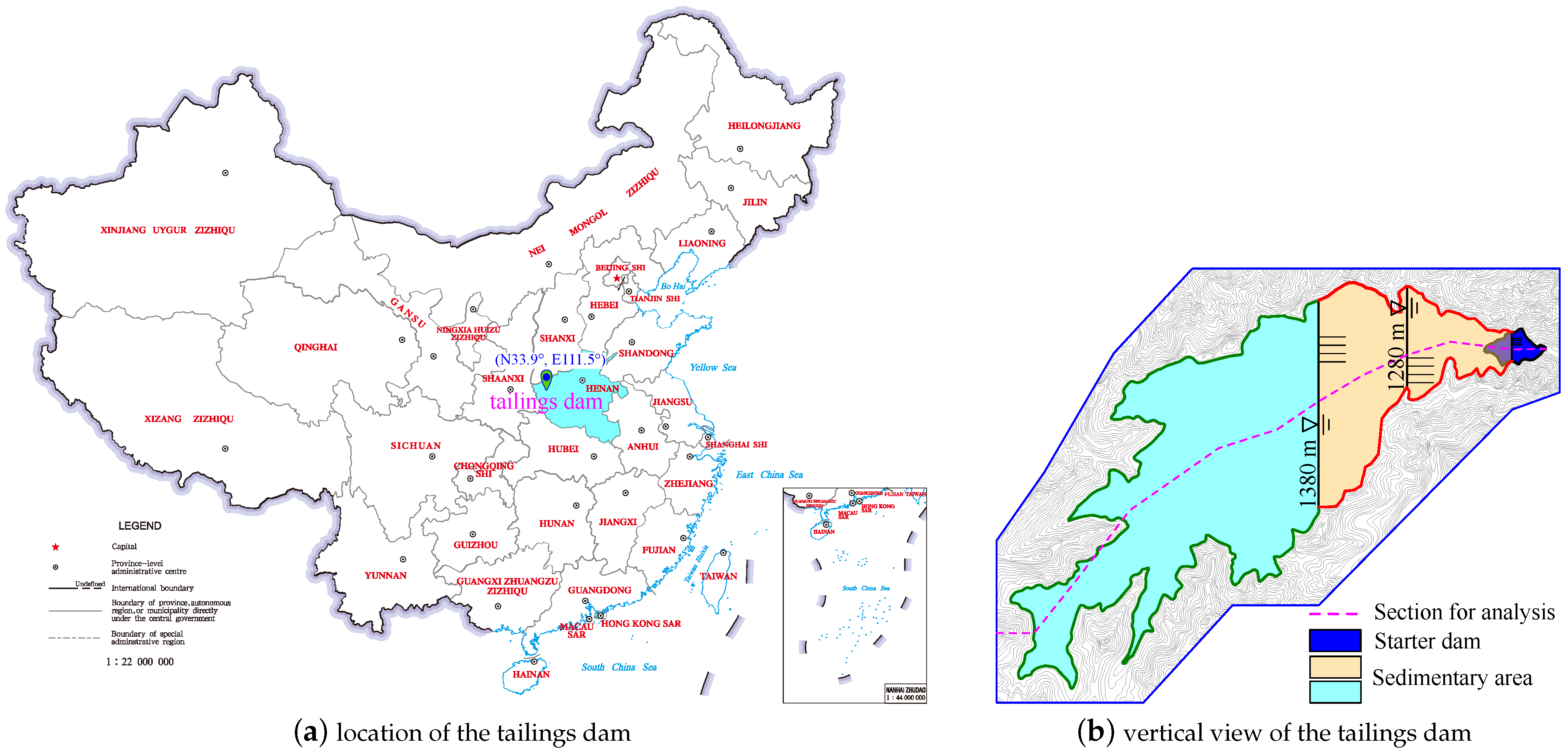

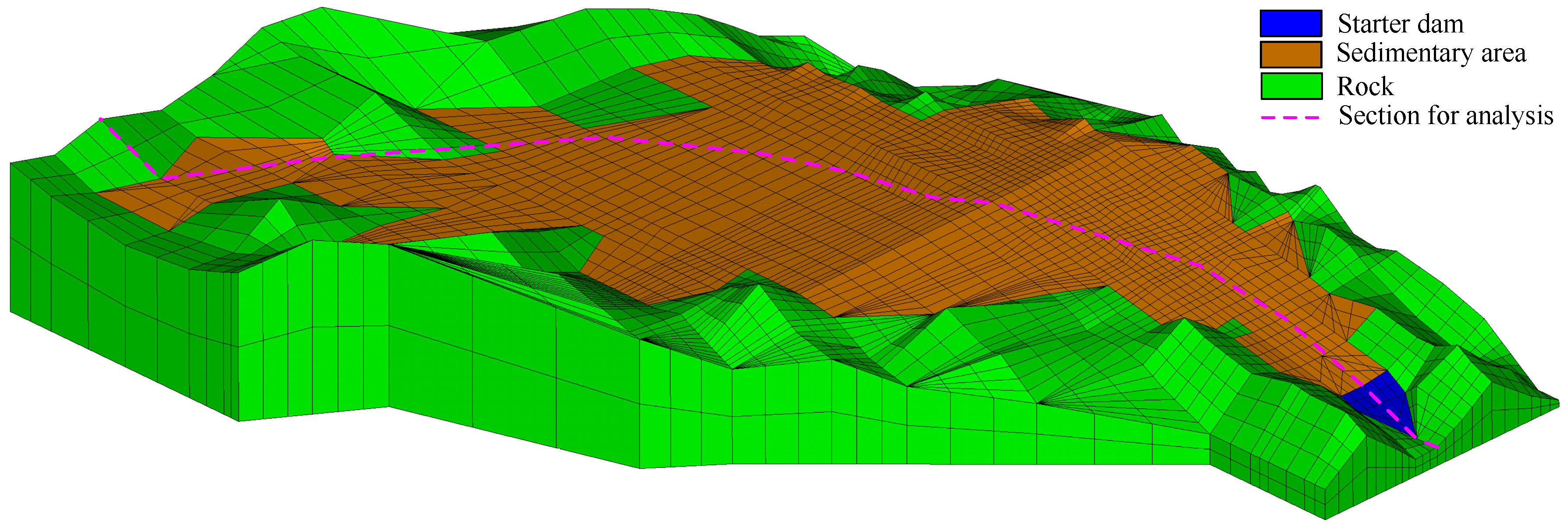

4.1. Introduction of the Tailings Dam

4.2. Permeability of Equivalent Drainage Structure

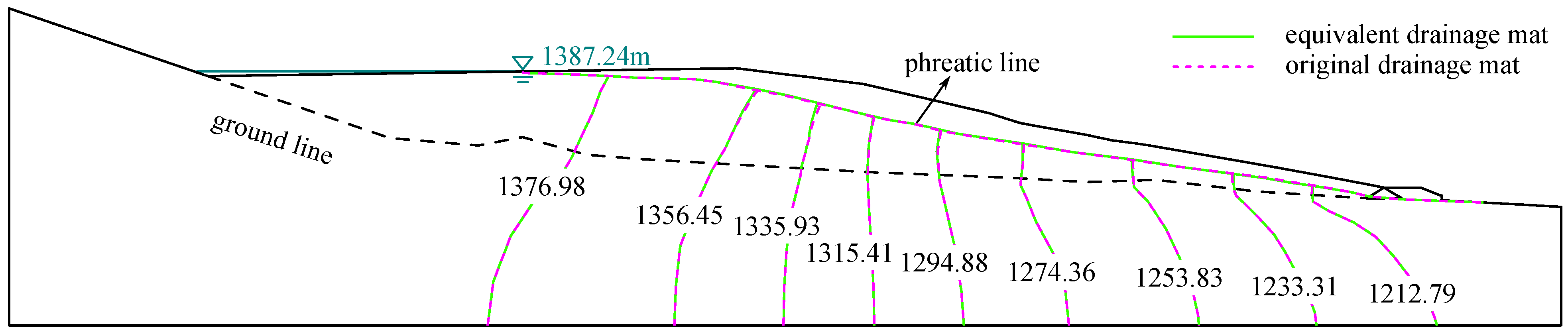

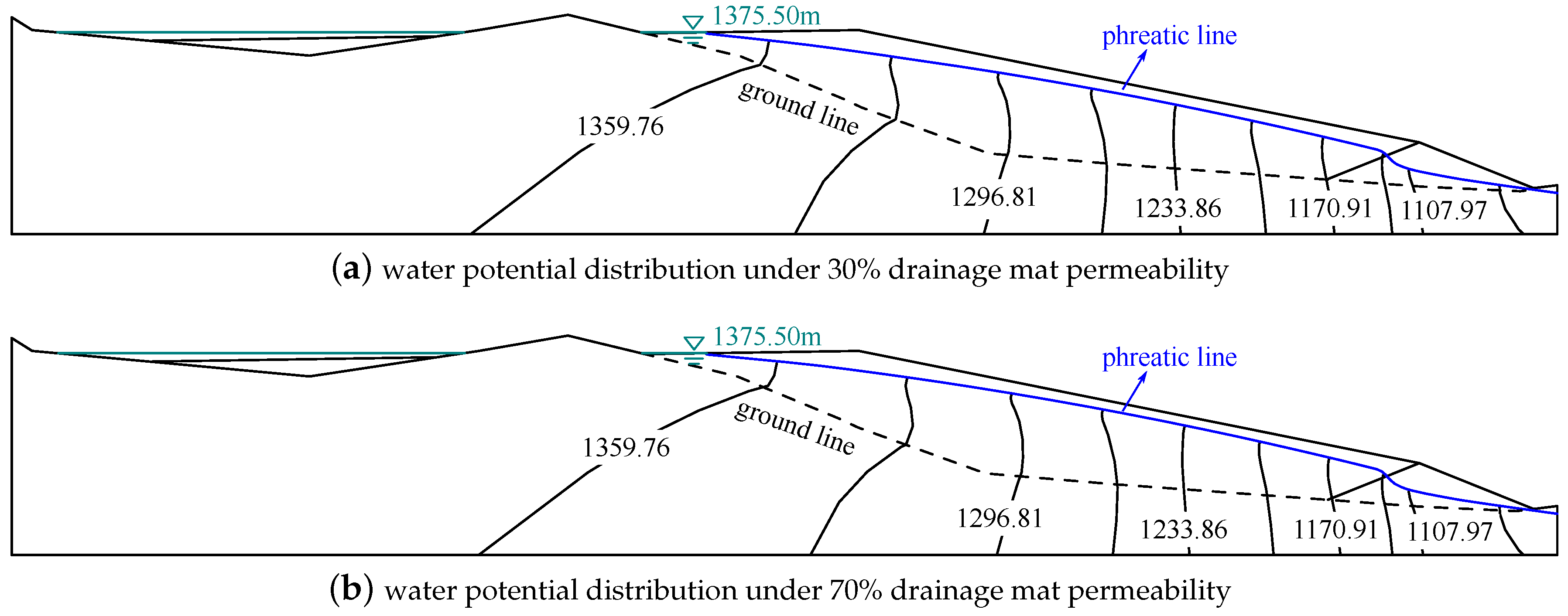

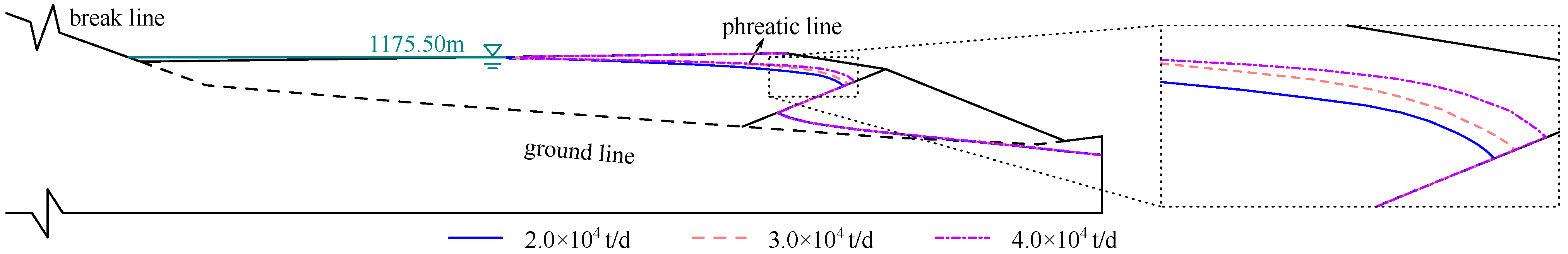

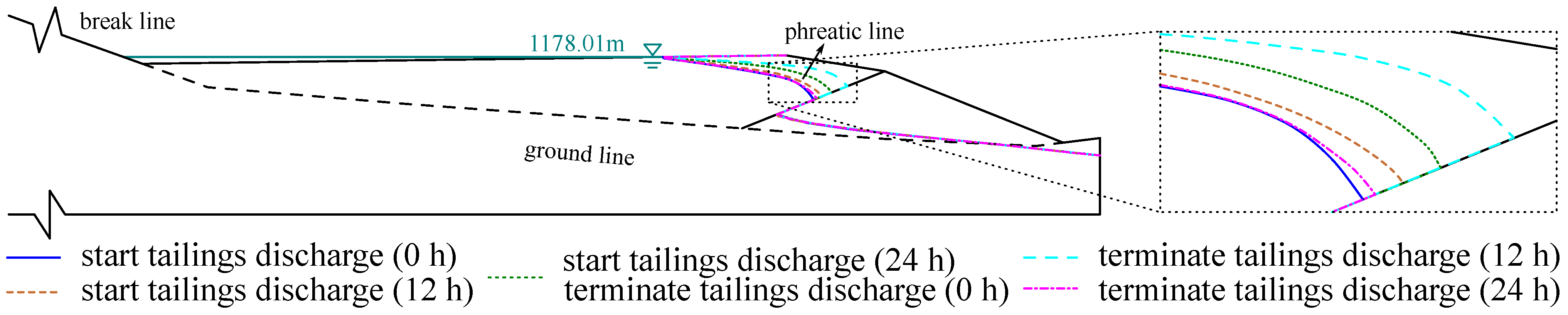

4.3. Seepage Analysis of the Tailings Dam

5. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, L.; Tim, T.W.; Xie, H.; Yang, J.; Shi, Z. A global-scale spatial assessment and geodatabase of mine areas. Glob. Planet. Chang. 2021, 204, 103578. [Google Scholar] [CrossRef]

- Piciullo, L.; Storrøsten, E.B.; Liu, Z.; Nadim, F.; Lacasse, S. A new look at the statistics of tailings dam failures. Eng. Geol. 2022, 303, 106657. [Google Scholar] [CrossRef]

- Che, D.; Liang, A.; Li, X.; Ma, B. Remote sensing assessment of safety risk of iron tailings pond based on runoff coefficient. Sensors 2018, 18, 4373. [Google Scholar] [CrossRef]

- Lumbroso, D.; McElroy, C.; Goff, C.; Collell, M.R.; Petkovsek, G.; Wetton, M. The potential to reduce the risks posed by tailings dams using satellite-based information. Int. J. Disaster Risk Reduct. 2019, 38, 101209. [Google Scholar] [CrossRef]

- Burritt, R.L.; Christ, K.L. Water risk in mining: Analysis of the Samarco dam failure. J. Clean. Prod. 2018, 178, 196–205. [Google Scholar] [CrossRef]

- Zheng, B.; Zhang, D.; Liu, W.; Yang, Y.; Yang, H. Use of basalt fiber-reinforced tailings for improving the stability of tailings dam. Materials 2019, 12, 1306. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, X.; Chen, X.; Xie, C. Numerical Simulation of Tailings Flow from Dam Failure over Complex Terrain. Materials 2022, 15, 2288. [Google Scholar] [CrossRef] [PubMed]

- Pan, Z.; Zhang, C.; Ma, C.; Ma, L.; Gan, S. Study on the permeability characteristics of tailings with different particle sizes and the variation of the saturation line of tailings dam. In Proceedings of the U.S. Rock Mechanics/Geomechanics Symposium, Online. 18–25 June 2021; Volume All Days, ARMA-2021-1044. 2021. Available online: https://onepetro.org/ARMAUSRMS/proceedings-abstract/ARMA21/All-ARMA21/ARMA-2021-1044/467879 (accessed on 15 August 2022).

- do Carmo, F.F.; Kamino, L.H.Y.; Junior, R.T.; de Campos, I.C.; do Carmo, F.F.; Silvino, G.; da Silva Xavier de Castro, K.J.; Mauro, M.L.; Rodrigues, N.U.A.; de Souza Miranda, M.P.; et al. Fundão tailings dam failures: The environment tragedy of the largest technological disaster of Brazilian mining in global context. Perspect. Ecol. Conserv. 2017, 15, 145–151. [Google Scholar] [CrossRef]

- Mura, J.; Gama, F.; Paradella, W.; Negrão, P.; Carneiro, S.; de Oliveira, C.; Brandão, W. Monitoring the vulnerability of the dam and dikes in Germano iron mining area after the collapse of the tailings dam of Fundão (Mariana-MG, Brazil) using DInSAR techniques with TerraSAR-x data. Remote Sens. 2018, 10, 1507. [Google Scholar] [CrossRef]

- Zhuang, Y.; Jin, K.; Cheng, Q.; Xing, A.; Luo, H. Experimental and numerical investigations of a catastrophic tailings dam break in Daye, Hubei, China. Bull. Eng. Geol. Environ. 2021, 81, 9. [Google Scholar] [CrossRef]

- Lumbroso, D.; Davison, M.; Body, R.; Petkovšek, G. Modelling the Brumadinho tailings dam failure, the subsequent loss of life and how it could have been reduced. Nat. Hazards Earth Syst. Sci. 2021, 21, 21–37. [Google Scholar] [CrossRef]

- Rotta, L.H.S.; Alcântara, E.; Park, E.; Negri, R.G.; Lin, Y.N.; Bernardo, N.; Mendes, T.S.G.; Filho, C.R.S. The 2019 Brumadinho tailings dam collapse: Possible cause and impacts of the worst human and environmental disaster in Brazil. Int. J. Appl. Earth Obs. Geoinf. 2020, 90, 102119. [Google Scholar] [CrossRef]

- Ammirati, L.; Chirico, R.; Martire, D.D.; Mondillo, N. Application of multispectral remote sensing for mapping flood-affected zones in the Brumadinho mining district (Minas Gerais, Brasil). Remote Sens. 2022, 14, 1501. [Google Scholar] [CrossRef]

- Rodríguez, R.; Muñoz-Moreno, A.; Caparrós, A.V.; García-García, C.; Brime-Barrios, Á.; Arranz-González, J.C.; Rodríguez-Gómez, V.; Fernández-Naranjo, F.J.; Alcolea, A. How to prevent flow failures in tailings dams. Mine Water Environ. 2021, 40, 83–112. [Google Scholar] [CrossRef]

- Dong, L.; Deng, S.; Wang, F. Some developments and new insights for environmental sustainability and disaster control of tailings dam. J. Clean. Prod. 2020, 269, 122270. [Google Scholar] [CrossRef]

- Islam, K.; Murakami, S. Global-scale impact analysis of mine tailings dam failures: 1915–2020. Glob. Environ. Chang. 2021, 70, 102361. [Google Scholar] [CrossRef]

- Clarkson, L.; Williams, D. An overview of conventional tailings dam geotechnical failure mechanisms. Min. Metall. Explor. 2021, 38, 1305–1328. [Google Scholar] [CrossRef]

- Shakhane, T.; Nkhumeleni, M.; Ntokoane, M.; Makara, M. Evaluating seepage through a homogenous embankment: Part of monitoring a tailings storage facility. Mine Water Environ. 2021, 41, 103–118. [Google Scholar] [CrossRef]

- Gildeh, H.K.; Halliday, A.; Arenas, A.; Zhang, H. Tailings dam breach analysis: A review of methods, practices, and uncertainties. Mine Water Environ. 2020, 40, 128–150. [Google Scholar] [CrossRef]

- Lyu, Z.; Chai, J.; Xu, Z.; Qin, Y.; Cao, J. A comprehensive review on reasons for tailings dam failures based on case history. Adv. Civ. Eng. 2019, 2019, 4159306. [Google Scholar] [CrossRef]

- Hu, S.; Chen, Y.; Liu, W.; Zhou, S.; Hu, R. Effect of seepage control on stability of a tailings dam during its staged construction with a stepwise-coupled hydro-mechanical model. Int. J. Min. Reclam. Environ. 2014, 29, 125–140. [Google Scholar] [CrossRef]

- Özer, A.T.; Bromwell, L.G. Stability assessment of an earth dam on silt/clay tailings foundation: A case study. Eng. Geol. 2012, 151, 89–99. [Google Scholar] [CrossRef]

- Yin, G.; Li, G.; Wei, Z.; Wan, L.; Shui, G.; Jing, X. Stability analysis of a copper tailings dam via laboratory model tests: A Chinese case study. Miner. Eng. 2011, 24, 122–130. [Google Scholar] [CrossRef]

- Han, X.; Li, H.; Su, M.; An, P. Spatial network analysis of surface soil pollution from heavy metals and some other elements: A case study of the Baotou region of China. J. Soils Sediments 2018, 19, 629–640. [Google Scholar] [CrossRef]

- Xu, B.; Wang, Y. Stability analysis of the Lingshan gold mine tailings dam under conditions of a raised dam height. Bull. Eng. Geol. Environ. 2014, 74, 151–161. [Google Scholar] [CrossRef]

- Pak, A.; Nabipour, M. Numerical study of the effects of drainage systems on saturated/unsaturated seepage and stability of tailings dams. Mine Water Environ. 2017, 36, 341–355. [Google Scholar] [CrossRef]

- Arcila, E.J.A.; Moreira, C.A.; Camarero, P.L.; Casagrande, M.F.S. Identification of flow zones inside and at the base of a uranium mine tailings dam using geophysics. Mine Water Environ. 2021, 40, 308–319. [Google Scholar] [CrossRef]

- Wei, Z.; Yin, G.; Wan, L.; Li, G. A case study on a geotechnical investigation of drainage methods for heightening a tailings dam. Environ. Earth Sci. 2016, 75, 106. [Google Scholar] [CrossRef]

- Galera, J.M.; de la Fuente, F.; García, J.; Calleja, M.; Pozo, V. Design and construction of a tailings dam over an ancient tailings facility at La Parrilla mine. Mine Water Environ. 2021, 40, 63–73. [Google Scholar] [CrossRef]

- Dang, M.; Chai, J.; Xu, Z.; Qin, Y.; Cao, J.; Liu, F. Soil water characteristic curve test and saturated-unsaturated seepage analysis in Jiangcungou municipal solid waste landfill, China. Eng. Geol. 2020, 264, 105374. [Google Scholar] [CrossRef]

- Li, Z.; Liu, N.; Wei, S.; Li, Y. Analysis on application of new in-situ vertical expansion technology to domestic waste landfill. In Proceedings of the 2021 Science and Technology Annual Meeting of Chinese Society for Environmental Sciences, Tianjin, China, 19–21 October 2021; Chemistry/Metallurgy/Environment/Mine Industry. pp. 505–511. (In Chinese). [Google Scholar] [CrossRef]

- Wang, T.; Zhou, Y.; Lv, Q.; Zhu, Y.; Jiang, C. A safety assessment of the new Xiangyun phosphogypsum tailings pond. Miner. Eng. 2011, 24, 1084–1090. [Google Scholar] [CrossRef]

- Zhang, C.; Chai, J.; Cao, J.; Xu, Z.; Qin, Y.; Lv, Z. Numerical simulation of seepage and stability of tailings dams: A case study in Lixi, China. Water 2020, 12, 742. [Google Scholar] [CrossRef]

- Wu, P.; Liang, B.; Jin, J.; Zhou, K.; Guo, B.; Yang, Z. Solution and stability analysis of sliding surface of tailings pond under rainstorm. Sustainability 2022, 14, 3081. [Google Scholar] [CrossRef]

- Liu, C.; Shen, Z.; Gan, L.; Xu, L.; Zhang, K.; Jin, T. The seepage and stability performance assessment of a new drainage system to increase the height of a tailings dam. Appl. Sci. 2018, 8, 1840. [Google Scholar] [CrossRef]

- Ren, J.; zhong Shen, Z.; Yang, J.; zhen Yu, C. Back analysis of the 3d seepage problem and its engineering applications. Environ. Earth Sci. 2016, 75, 113. [Google Scholar] [CrossRef]

- Gan, L.; Chen, G.; Shen, Z. A new approach to permeability inversion of fractured rock masses and its engineering application. Water 2020, 12, 734. [Google Scholar] [CrossRef]

- van Genuchten, M.T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

- Inoue, J.; Masumoto, K. Numerical experiments by saturated-unsaturated flow inversion for permeability and boundary conditions of multi-layers aquifer. J. Jpn. Soc. Civ. Eng. Ser. Appl. Mech. AM 2018, 74, 55–64. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China, Beijing. Code for Design of Tailings Facilities (GB 50863–2013). 2013. Available online: https://www.mohurd.gov.cn/gongkai/fdzdgknr/zfhcxjsbwj/202204/20220428_765949.html (accessed on 1 August 2022).

| Materials | Position | Permeability (m/s) | (%) | (%) | (m) | n | (m) |

|---|---|---|---|---|---|---|---|

| Fine sand | Sedimentary area | 20 | 0.5 | 0.03 | 3 | ||

| Silty sand | Sedimentary area | 18 | 0.5 | 0.02 | 2.5 | ||

| Silty soil | Sedimentary area | 15 | 0.5 | 0.015 | 2 | ||

| Silty clay | Sedimentary area | 11 | 0.5 | 0.005 | 1 | ||

| Clay | Sedimentary area | 12 | 0.5 | 0.005 | 1 | ||

| Clay | Natural soil | 14 | 0.5 | 0.005 | 1 | ||

| Drainage mat | Sedimentary area | 50 | 0.1 | 0.5 | 10 | ||

| Rockfill | Starter dam | 10 | 2.0 | 0.5 | 10 | ||

| Rock | Dam foundation | 5 | 0.3 | 0.010 | 1.5 |

| Materials | Position | Permeability (m/s) | (%) | (%) | (m) | n | (m) |

|---|---|---|---|---|---|---|---|

| Fine sand | Sedimentary area | 20 | 0.5 | 0.03 | 3 | ||

| Silty sand | Sedimentary area | 18 | 0.5 | 0.02 | 2.5 | ||

| Silty soil | Sedimentary area | 15 | 0.5 | 0.015 | 2 | ||

| Silty clay | Sedimentary area | 11 | 0.5 | 0.005 | 1 | ||

| Clay | Sedimentary area | 12 | 0.5 | 0.005 | 1 | ||

| Drainage mat | Sedimentary area | 50 | 0.1 | 0.5 | 10 | ||

| Rockfill | Starter dam | 10 | 2.0 | 0.5 | 10 | ||

| Rock | Dam foundation | 5 | 0.3 | 0.012 | 1.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Shen, Z.; Liu, D.; Xu, L.; Gan, L.; Long, Y. A Suggested Equivalent Method for a Drainage Structure to Analyze Seepage in Tailings Dam. Materials 2022, 15, 7154. https://doi.org/10.3390/ma15207154

Zhang H, Shen Z, Liu D, Xu L, Gan L, Long Y. A Suggested Equivalent Method for a Drainage Structure to Analyze Seepage in Tailings Dam. Materials. 2022; 15(20):7154. https://doi.org/10.3390/ma15207154

Chicago/Turabian StyleZhang, Hongwei, Zhenzhong Shen, Detan Liu, Liqun Xu, Lei Gan, and Yifei Long. 2022. "A Suggested Equivalent Method for a Drainage Structure to Analyze Seepage in Tailings Dam" Materials 15, no. 20: 7154. https://doi.org/10.3390/ma15207154

APA StyleZhang, H., Shen, Z., Liu, D., Xu, L., Gan, L., & Long, Y. (2022). A Suggested Equivalent Method for a Drainage Structure to Analyze Seepage in Tailings Dam. Materials, 15(20), 7154. https://doi.org/10.3390/ma15207154