Effect of Ultra-High Pressure Sintering and Spark Plasma Sintering and Subsequent Heat Treatment on the Properties of Si3N4 Ceramics

Abstract

:1. Introduction

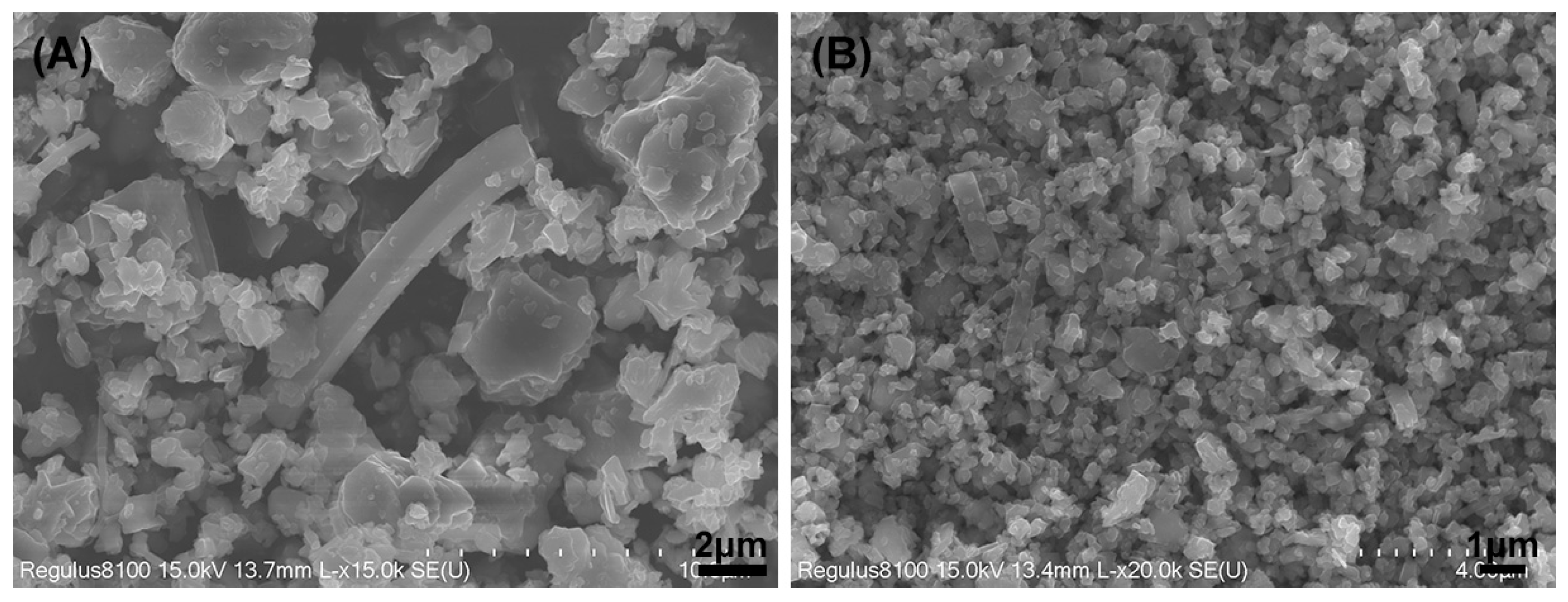

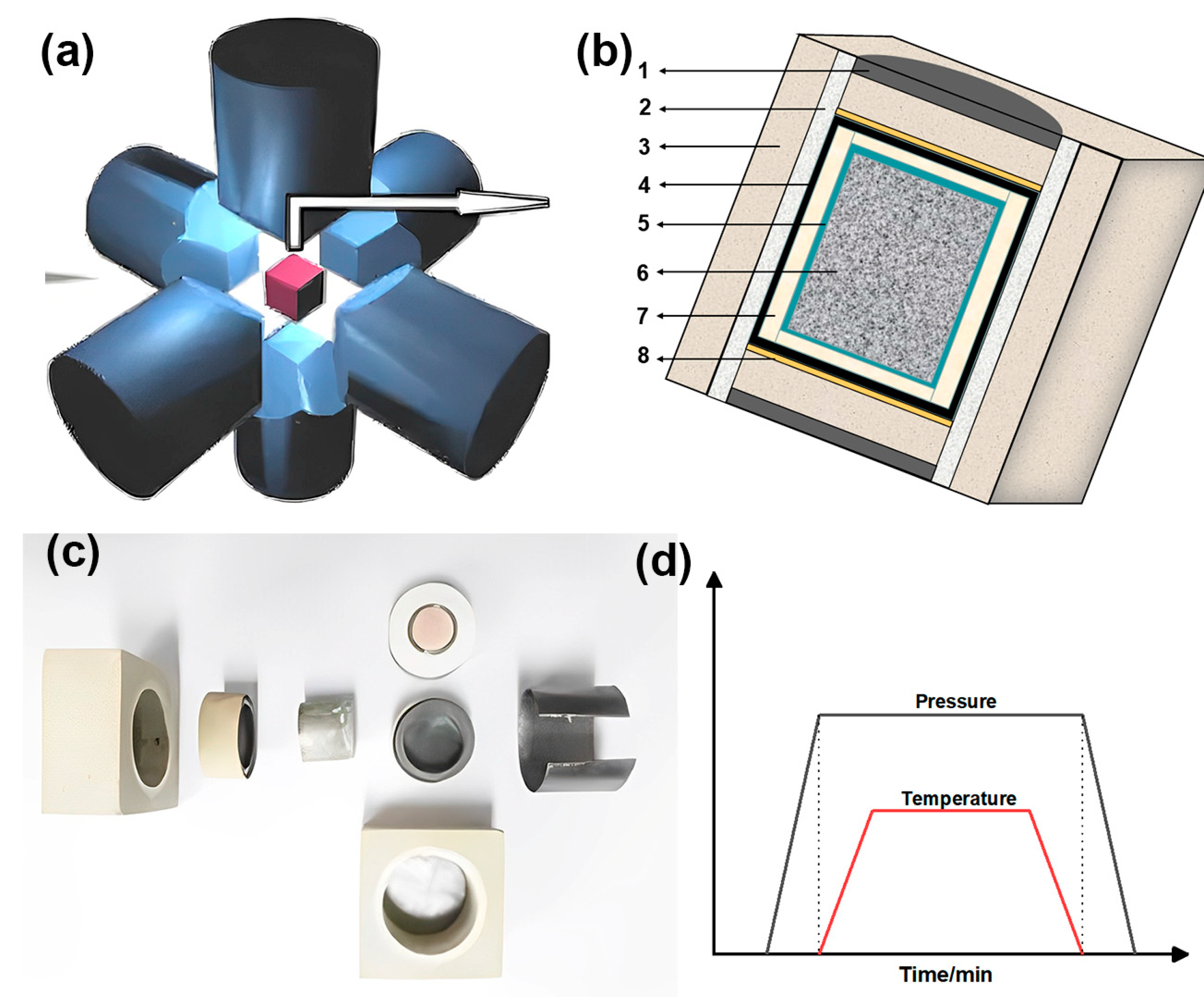

2. Materials and Methods

3. Results and Discussion

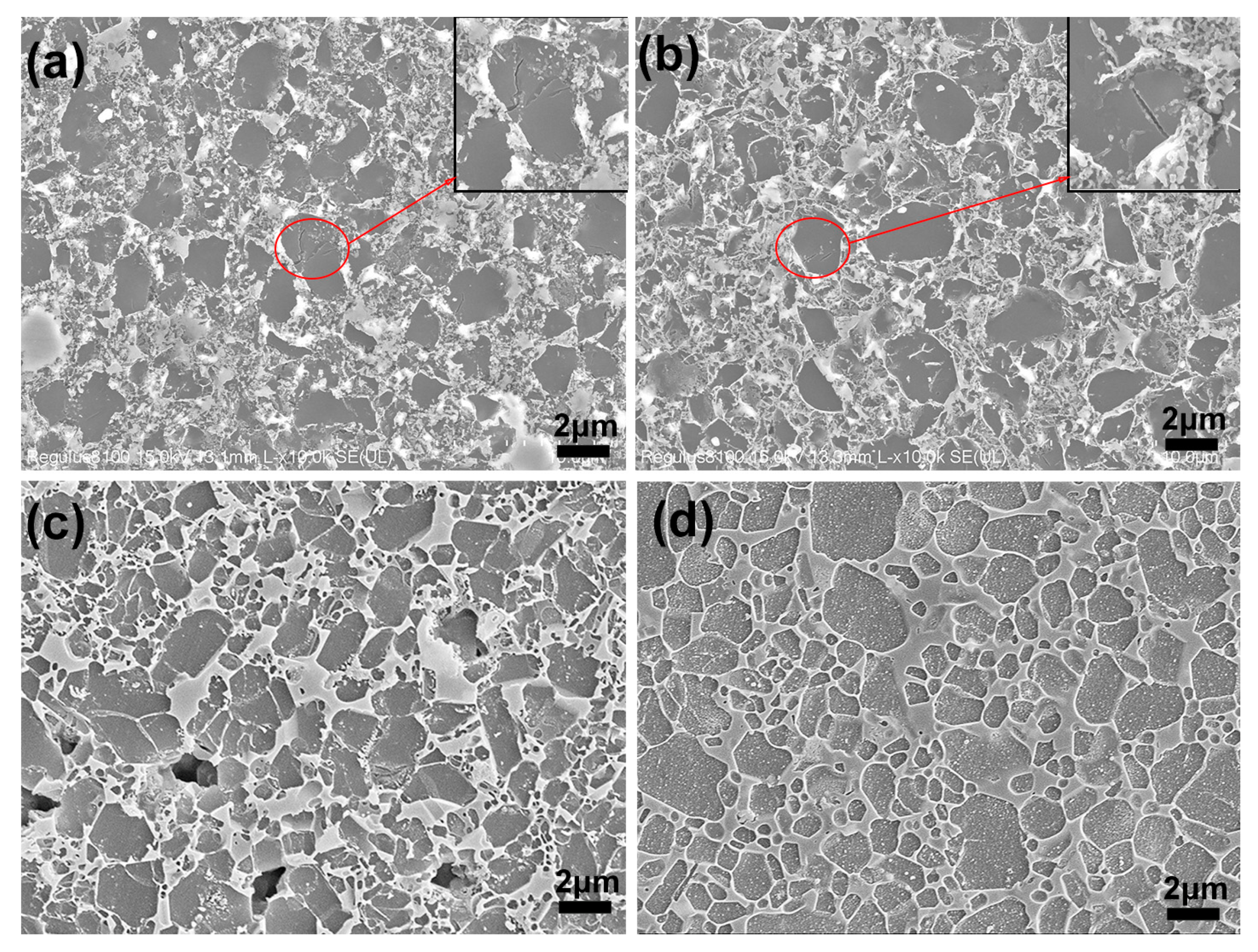

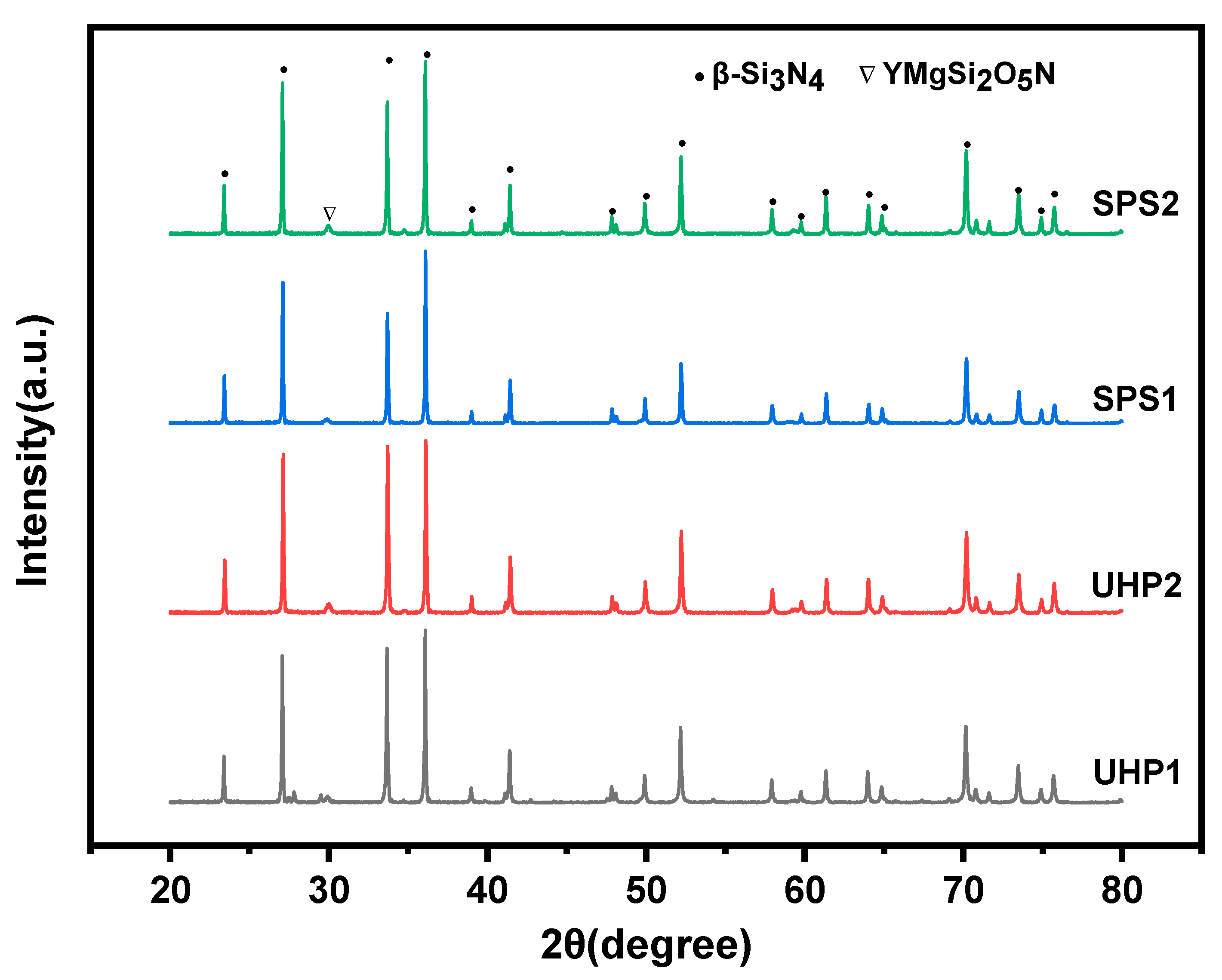

3.1. SPS and UHP Sintering

3.2. Heat Treatment

4. Conclusions

- (1)

- Compared with UHP sintering, SPS can fabricate dense Si3N4 ceramics with coarse β-Si3N4 powders as raw materials in a shorter time and promote the α-to-β phase transition;

- (2)

- Coarse β-Si3N4 grains were partially fragmented during ultra-high pressure sintering under high pressure in 5 GPa, thereby reducing the number of the nucleus, which is a benefit for the growth of the elongated grains. Therefore, sample UHP1 achieved the highest fracture strength (822 MPa) and fracture toughness (6.6 MPa·m1/2), due to the interlocking structure of toughened elongated grains grown from residual coarse β-Si3N4 grains during heat treatment. Due to the bimodal microstructure with some large grains distributed among small grains, the fracture strength (817 MPa) and fracture toughness (6.2 MPa·m1/2) of sample SPS1 was comparable to sample UHP2 due to the high density;

- (3)

- SPS samples achieved higher thermal conductivity on account of a larger mean diameter of grains compared with ultra-high pressure sintering samples. The high thermal conductivity of Sample SPS1 was 71 W·m−1·K−1 due to the high density and the reduced grain boundary phase.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, T.X.; Zhang, X.H.; Han, W.B. Effect of Si3N4 nanowires on the mechanical properties and dielectric constant of porous Si3N4 ceramics. J. Ceram. Soc. Jpn. 2019, 127, 602–605. [Google Scholar] [CrossRef] [Green Version]

- Jiang, C.X.; Zhuang, Y.H.; Wang, J.J.; Liao, S.J.; Zhou, L.J.; Li, S.; Zhao, Y.X. Preparation, microstructure, and properties of GPS silicon nitride ceramics with beta-Si3N4 seeds and nanophase additives. Int. J. Appl. Ceram. Technol. 2022, 19, 2533–2544. [Google Scholar]

- Hu, F.; Xie, Z.-P.; Zhang, J.; Hu, Z.-L.; An, D. Promising high-thermal-conductivity substrate material for high-power electronic device: Silicon nitride ceramics. Rare Met. 2020, 39, 463–478. [Google Scholar] [CrossRef]

- Haggerty, J.S.; Lightfoot, A. Opportunities for Enhancing the Thermal Conductivity of SiC and Si3N4 Ceramics Through Improved Processing. J. Am. Ceram. Soc. 1995, 16, 475–487. [Google Scholar]

- You, Z.; Hyuga, H.; Dai, K.; Yoshizawa, Y.I.; Ohji, T.; Hirao, K. Development of high-thermal-conductivity silicon nitride ceramics. J. Asian Ceram. Soc. 2015, 3, 221–229. [Google Scholar]

- Zeng, Y.; Zuo, K.; Yao, D.; Li, S.; Chen, H.; Wang, W. Preparation of Silicon Nitride with High Thermal Conductivity and High Flexural Strength Using YbH2-MgO as Sintering Additive. J. Inorg. Mater. 2021, 36, 959–966. [Google Scholar]

- Wang, W.; Yao, D.; Liang, H.; Xia, Y.; Zuo, K.; Yin, J.; Zeng, Y.P. Improved thermal conductivity of β-Si3N4 ceramics by lowering SiO2/Y2O3 ratio using YH2 as sintering additive. J. Am. Ceram. Soc. 2020, 103, 5567–5572. [Google Scholar] [CrossRef]

- Zhang, J.; Cui, W.; Li, F.; Du, S.; Tian, Z.; Sun, S.; Chen, K.; Liu, G. Effects of MgSiN2 addition and post-annealing on mechanical and thermal properties of Si3N4 ceramics. Ceram. Int. 2020, 46, 15719–15722. [Google Scholar] [CrossRef]

- Jia, H.; Li, J.; Rui, N.; Ye, C.; Ru, H.; Liu, B.; E, Y.; Li, H. Fabrication of β-Si3N4 for high thermal conductivity under ultra-high pressure. Ceram. Int. 2018, 44, 23288–23292. [Google Scholar]

- Luo, J.; Li, J.G.; Li, M.J.; Shen, Q.; Zhang, Y.L. Low-temperature densification by plasma activated sintering of Mg2Si-added Si3N4. Ceram. Int. 2019, 45, 15128–15133. [Google Scholar] [CrossRef]

- Huang, M.Z.; Huang, Y.; Ou, J.; Wu, Y.Y.; Wang, J.Y.; Wu, S.H. Effect of a new nonoxide additive, Y3Si2C2, on the thermal conductivity and mechanical properties of Si3N4 ceramics. Int. J. Appl. Ceram. Technol. 2022, 19, 3403–3409. [Google Scholar] [CrossRef]

- Hu, F.; Zhu, T.; Xie, Z.; Liu, J.; Hu, Z.; An, D. Elimination of grain boundaries and its effect on the properties of silicon nitride ceramics. Ceram. Int. 2020, 46, 12606–12612. [Google Scholar] [CrossRef]

- Hu, F.; Zhu, T.; Xie, Z.; Liu, J. Effect of composite sintering additives containing non-oxide on mechanical, thermal and dielectric properties of silicon nitride ceramics substrate. Ceram. Int. 2021, 47, 13635–13643. [Google Scholar] [CrossRef]

- Duan, Y.; Liu, N.; Zhang, J.; Zhang, H.; Li, X. Cost effective preparation of Si3N4 ceramics with improved thermal conductivity and mechanical properties. J. Eur. Ceram. Soc. 2020, 40, 298–304. [Google Scholar] [CrossRef]

- Liang, H.; Wang, W.; Zuo, K.; Xia, Y.; Yao, D.; Yin, J.; Zeng, Y. Effect of LaB6 addition on mechanical properties and thermal conductivity of silicon nitride ceramics. Ceram. Int. 2020, 46, 17776–17783. [Google Scholar] [CrossRef]

- Wang, W.D.; Yao, D.X.; Liang, H.Q.; Xia, Y.F.; Zuo, K.H.; Yin, J.W.; Zeng, Y.P. Effect of the binary nonoxide additives on the densification behavior and thermal conductivity of Si3N4 ceramics. J. Am. Ceram. Soc. 2020, 103, 5891–5899. [Google Scholar] [CrossRef]

- Li, S.; Izui, H.; Okano, M.; Zhang, W.; Watanabe, T. Microstructure and mechanical properties of ZrO2(Y2O3)–Al2O3 nanocomposites prepared by spark plasma sintering. J. Part. Sci. 2012, 10, 7. [Google Scholar] [CrossRef]

- Sayyadi-Shahraki, A.; Rafiaei, S.M.; Ghadami, S.; Nekouee, K.A. Densification and mechanical properties of spark plasma sintered Si3N4/ZrO2 nano-composites. J. Alloys Compd. 2019, 776, 798–806. [Google Scholar] [CrossRef]

- Jojo, N.; Shongwe, M.B.; Tshabalala, L.C.; Olubambi, P.A. Effect of Sintering Temperature and Yttrium Composition on the Densification, Microstructure and Mechanical Properties of Spark Plasma Sintered Silicon Nitride Ceramics with Al2O3 and Y2O3 Additives. Silicon 2019, 11, 2689–2699. [Google Scholar] [CrossRef]

- Li, J.L.; Chen, F.; Niu, J.Y. Low temperature sintering of Si3N4 ceramics by spark plasma sintering technique. Adv. Appl. Ceram. 2014, 110, 20–24. [Google Scholar] [CrossRef]

- Peng, G.-H.; Liang, M.; Liang, Z.-H.; Li, Q.-Y.; Li, W.-L.; Liu, Q. Spark Plasma Sintered Silicon Nitride Ceramics with High Thermal Conductivity Using MgSiN2 as Additives. J. Am. Ceram. Soc. 2009, 92, 2122–2124. [Google Scholar] [CrossRef]

- Yang, C.; Ding, J.; Ma, J.; Zhang, B.; Ye, F.; Wu, Y.; Liu, Q. Microstructure tailoring of high thermal conductive silicon nitride through addition of nuclei with spark plasma sintering and post-sintering heat treatment. J. Alloys Compd. 2019, 785, 89–95. [Google Scholar] [CrossRef]

- Wu, C.; Yang, S.; Li, Y.; Ma, Y.; Zhang, L.; Liu, J.; Han, S. Microstructural evolution and electrochemical properties of the ultra-high pressure treated La0.70Mg0.30Ni3.3 hydrogen storage alloy. J. Alloys Compd. 2016, 665, 231–239. [Google Scholar] [CrossRef]

- Matovic, B.; Maletaskic, J.; Prikhna, T.; Urbanovich, V.; Girman, V.; Lisnichuk, M.; Todorovic, B.; Yoshida, K.; Cvijovic-Alagic, I. Characterization of B4C-SiC ceramic composites prepared by ultra-high pressure sintering. J. Eur. Ceram. Soc. 2021, 41, 6789. [Google Scholar] [CrossRef]

- Gu, J.F.; Zou, J.; Liu, J.H.; Wang, H.; Zhang, J.Y.; Wang, W.M.; Fu, Z.Y. Sintering highly dense ultra-high temperature ceramics with suppressed grain growth. J. Eur. Ceram. Soc. 2020, 40, 1086–1092. [Google Scholar] [CrossRef]

- Shen, Z.; Sun, J.; Liu, S.; Liu, Y. Research on Ultra-high pressure sintering of silicon nitride fine powder. J. High Press. Phys. 1993, 4, 267–273. (In Chinese) [Google Scholar]

- Shen, Z.; S, J.; Liu, S.; Liu, Y. Research on Ultra-high pressure sintering of silicon nitride fine powder-rare earth oxide. J. High Press. Phys. 1993, 1, 1–10. (In Chinese) [Google Scholar]

- Hu, Q.; Tong, G.; Wu, W.; Liu, F.; Qian, H.; Hong, D. Selective preparation and enhanced microwave electromagnetic characteristics of polymorphous ZnO architectures made from a facile one-step ethanediamine-assisted hydrothermal approach. Crystengcomm 2013, 15, 1314–1323. [Google Scholar] [CrossRef]

- Chang, R.; Rhodes, C.G. High-Pressure Hot-Pressing of Uranium Carbide Powders and Mechanism of Sintering of Refractory Bodies. J. Am. Ceram. Soc. 1962, 45, 379–382. [Google Scholar] [CrossRef]

- Kong, J.H.; Ma, H.J.; Jung, W.K.; Hong, J.; Jun, K.; Kim, D.K. Self-reinforced and high-thermal conductivity silicon nitride by tailoring α-β phase ratio with pressureless multi-step sintering. Ceram. Int. 2021, 47, 13057–13064. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, B.; Li, C.; Wang, L.; Wang, S.; Shi, Z.; Yang, J. Fabrication of Si3N4 ceramics with high thermal conductivity and flexural strength via novel two-step gas-pressure sintering. J. Eur. Ceram. Soc. 2022, 42, 4846–4854. [Google Scholar] [CrossRef]

| Property | β-Si3N4 | α-Si3N4 |

|---|---|---|

| α-phase content/mass% | 18 | >90 |

| Oxygen/mass% | <0.8 | <2.2 |

| Aluminum/ppm | <3 | <400 |

| Calcium/ppm | <3 | <400 |

| Iron/ppm | <3 | <50 |

| D50/μm | 1.8–2.7 | 0.8 |

| Specimens | Composition in Mass/% | Sintering Condition | |||||

|---|---|---|---|---|---|---|---|

| β-Si3N4 | α-Si3N4 | MgO | Y2O3 | Sintering Temperature (°C) | Holding Time (min) | Pressure | |

| UHP1 | 76 | 18 | 3 | 3 | 1550 | 15 | 5 GPa |

| UHP2 | 92 | 5 | 3 | 1550 | 15 | 5 GPa | |

| SPS1 | 76 | 18 | 3 | 3 | 1550 | 3 | 40 MPa |

| SPS2 | 92 | 5 | 3 | 1550 | 3 | 40 MPa | |

| Specimens | Bulk Density (g cm−3) | Relative Density (%) | β-Phase Content |

|---|---|---|---|

| UHP1 | 3.211 | 99.2 | 86.96% |

| UHP2 | 3.218 | 99.3 | 87.85% |

| SPS1 | 3.187 | 98.5 | 99.47% |

| SPS2 | 3.214 | 99.2 | 92% |

| Specimens | Bulk Density (g cm−3) | Relative Density (%) | Vickers Hardness (HV) | Fracture Strength (MPa) | Fracture Toughness (Mpa·m1/2) |

|---|---|---|---|---|---|

| UHP1 | 3.216 | 99.4 | 1918 | 569 | 5.6 |

| UHP2 | 3.221 | 99.4 | 1709 | 822 | 6.6 |

| SPS1 | 3.230 | 99.8 | 1890 | 817 | 6.2 |

| SPS2 | 3.223 | 99.5 | 1367 | 760 | 6.0 |

| Specimens | Mean Diameter (μm) | Area Fraction of Grain Boundary (Area %) | Thermal Diffusivity (mm s−1) | Thermal Conductivity (W·m−1·K−1) |

|---|---|---|---|---|

| UHP1 | 0.6 | 36 | 20.175 | 44 |

| UHP2 | 0.8 | 39 | 22.314 | 49 |

| SPS1 | 0.9 | 33 | 32.384 | 71 |

| SPS2 | 1.0 | 40 | 26.455 | 58 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, X.; Li, X.; Huang, J.; Ge, C.; Yu, Q. Effect of Ultra-High Pressure Sintering and Spark Plasma Sintering and Subsequent Heat Treatment on the Properties of Si3N4 Ceramics. Materials 2022, 15, 7309. https://doi.org/10.3390/ma15207309

Lv X, Li X, Huang J, Ge C, Yu Q. Effect of Ultra-High Pressure Sintering and Spark Plasma Sintering and Subsequent Heat Treatment on the Properties of Si3N4 Ceramics. Materials. 2022; 15(20):7309. https://doi.org/10.3390/ma15207309

Chicago/Turabian StyleLv, Xiaoan, Xianhui Li, Junwei Huang, Changchun Ge, and Qi Yu. 2022. "Effect of Ultra-High Pressure Sintering and Spark Plasma Sintering and Subsequent Heat Treatment on the Properties of Si3N4 Ceramics" Materials 15, no. 20: 7309. https://doi.org/10.3390/ma15207309

APA StyleLv, X., Li, X., Huang, J., Ge, C., & Yu, Q. (2022). Effect of Ultra-High Pressure Sintering and Spark Plasma Sintering and Subsequent Heat Treatment on the Properties of Si3N4 Ceramics. Materials, 15(20), 7309. https://doi.org/10.3390/ma15207309