Effect of Core–Shell Rubber Nanoparticles on the Mechanical Properties of Epoxy and Epoxy-Based CFRP

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Manufacturing of the Test Samples

2.3. Testing Methods

2.3.1. Morphology Analysis

2.3.2. Tensile Tests

2.3.3. Fracture Toughness Tests

2.3.4. Interlaminar Fracture Toughness Tests

2.3.5. Density Measurements

2.3.6. Thermal Mechanical Analysis

3. Results and Discussion

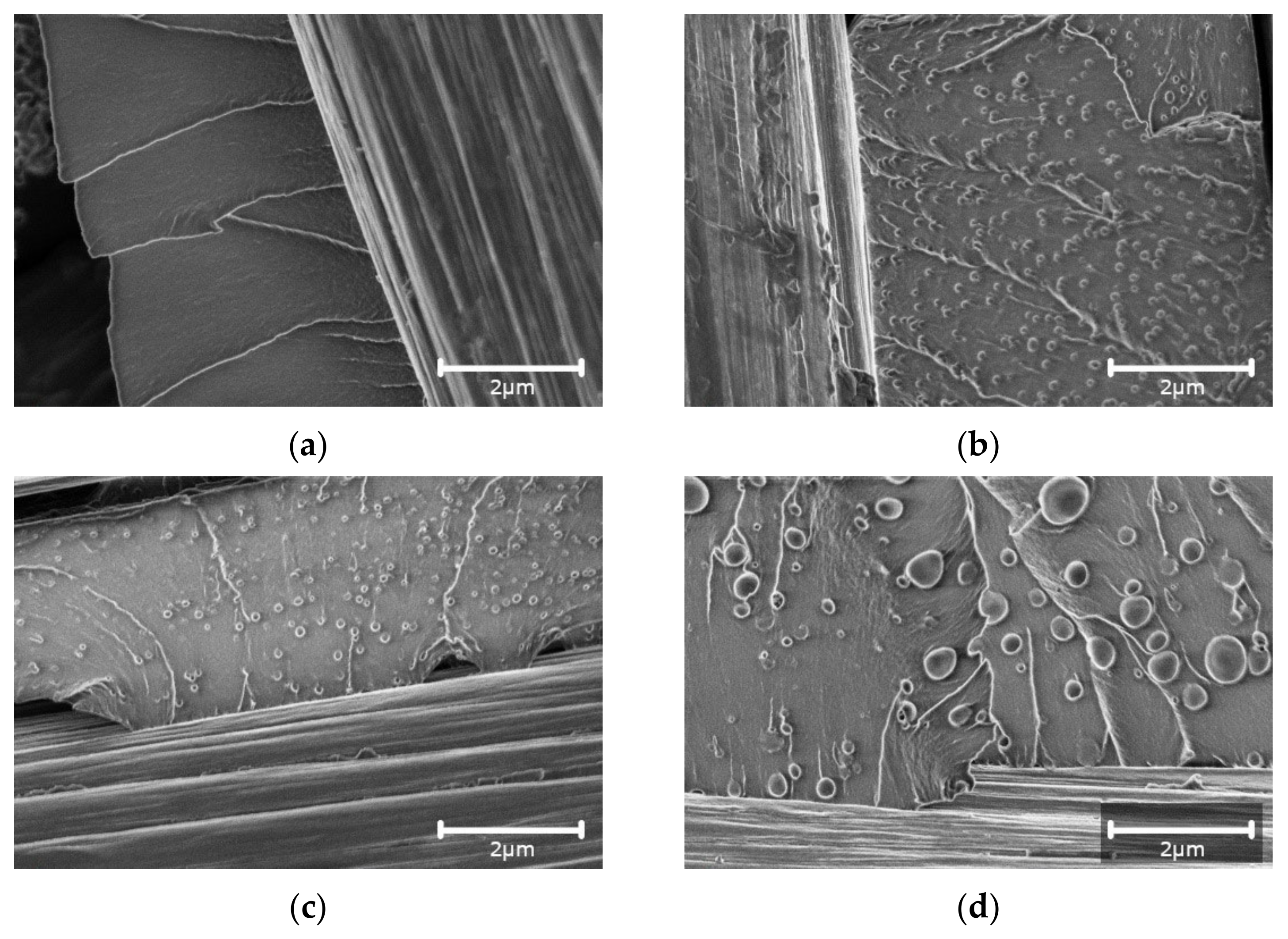

3.1. Morphology of the Fracture Surface

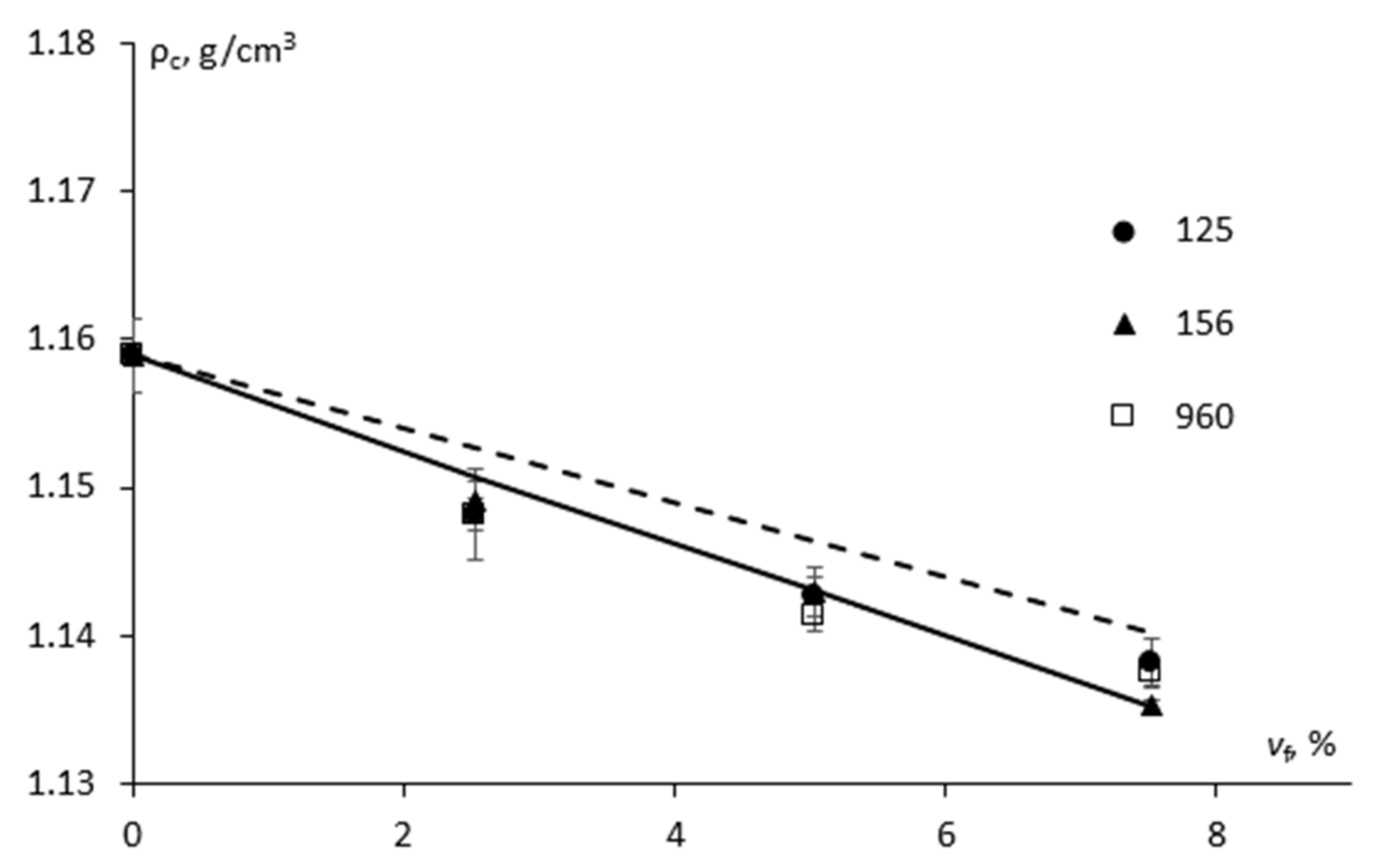

3.2. Density and Porosity

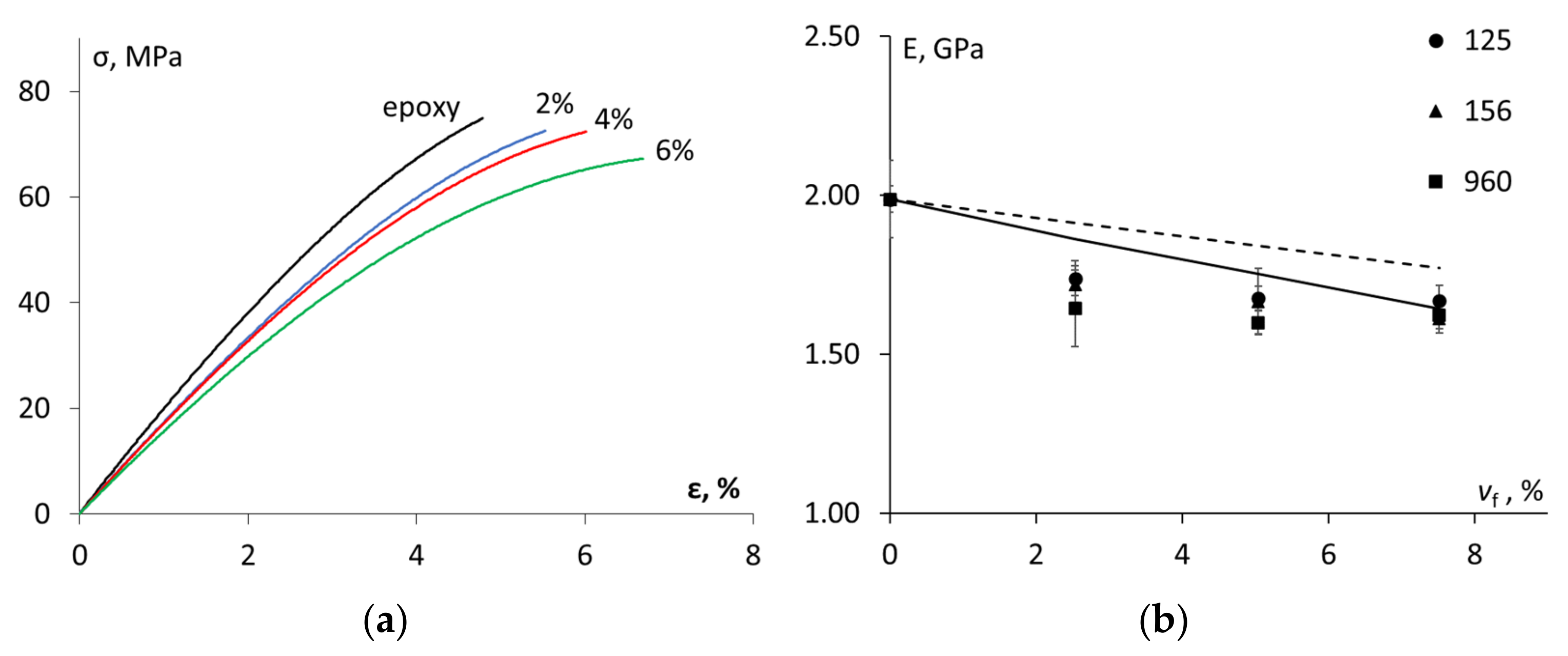

3.3. Tensile Properties and Glass Transition Temperature

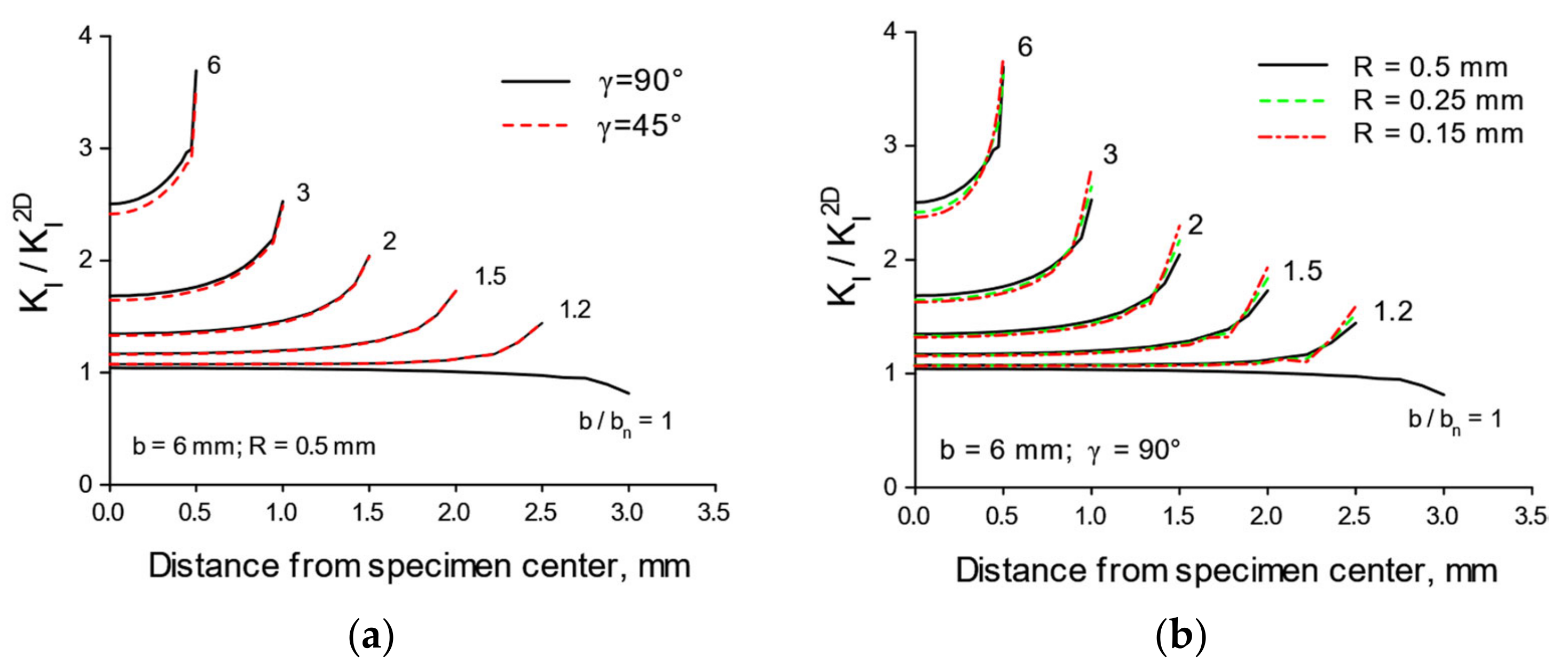

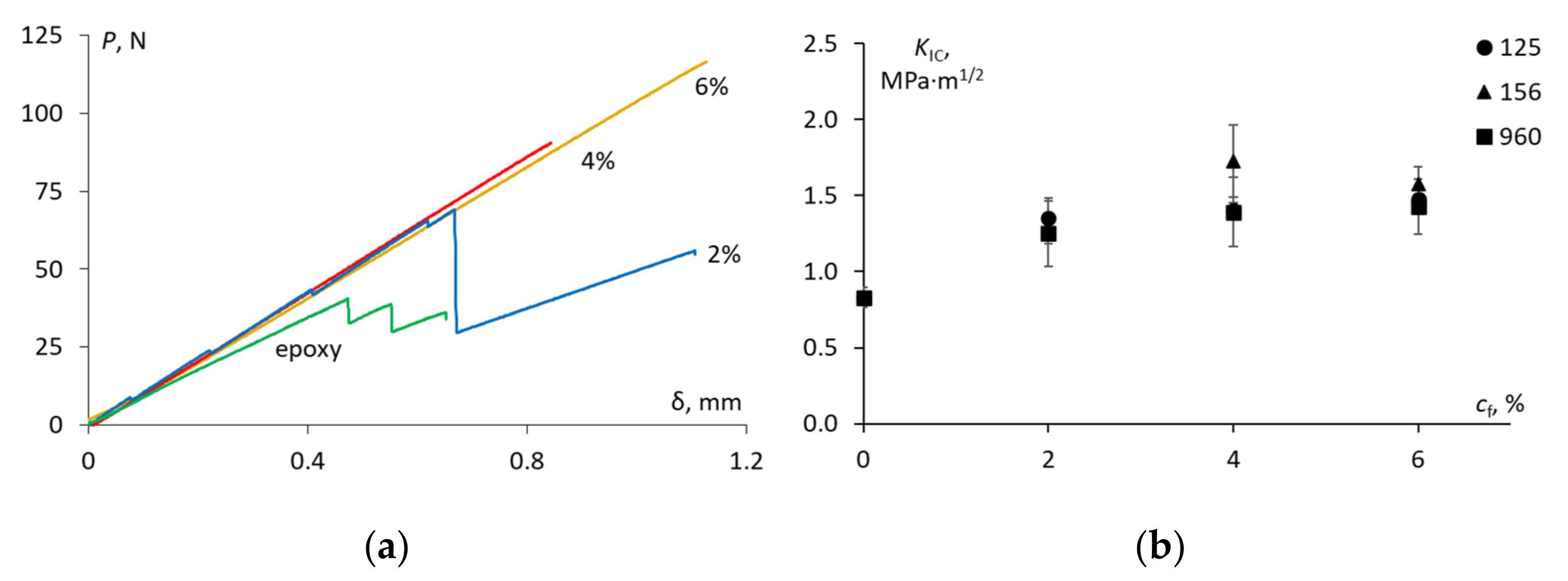

3.4. Fracture Toughness

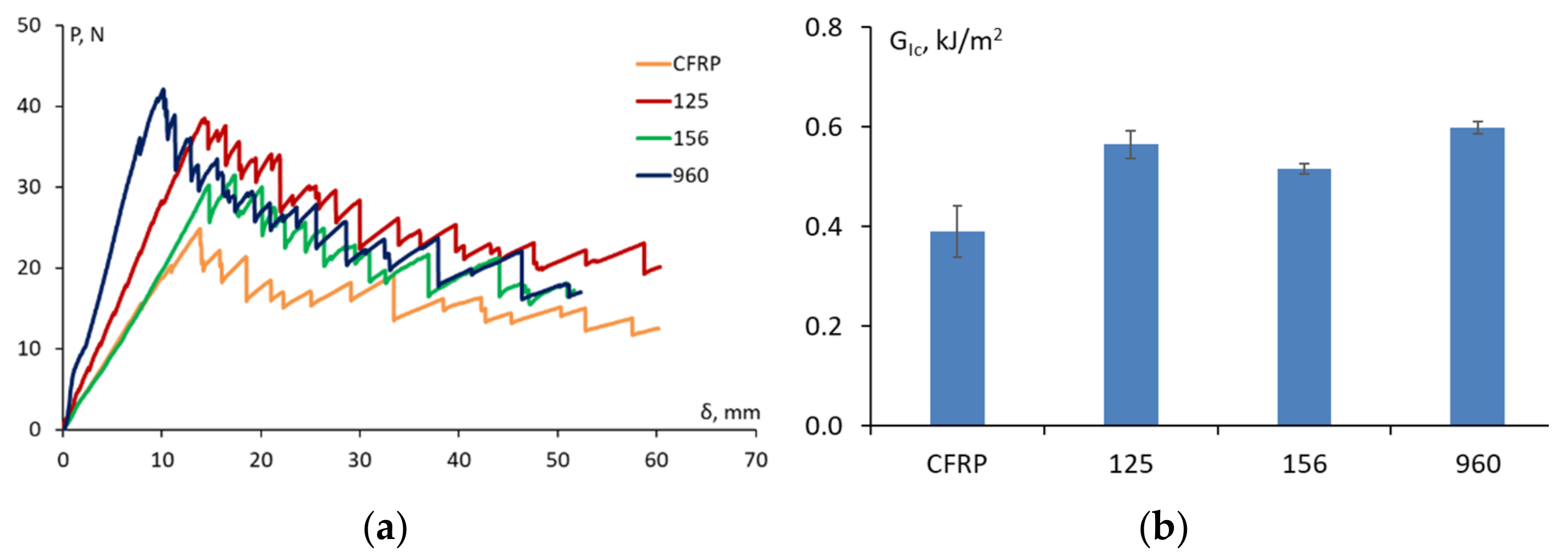

3.5. Interlaminar Fracture Toughness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Grooves Angle γ | Specimen Width b, mm | ||

|---|---|---|---|

| 6 | 12 | 24 | |

| 45° | 0.54 | 0.55 | 0.59 |

| 90° | 0.56 | 0.59 | 0.65 |

References

- Aniskevich, A.; Glaskova-Kuzmina, T. Effect of moisture on elastic and viscoelastic properties of fibre reinforced plastics: Retrospective and current trends. In Creep and Fatigue in Polymer Matrix Composites, 2nd ed.; Guedes, R.M., Ed.; Woodhead Publishing: Amsterdam, The Netherlands, 2019; pp. 83–120. [Google Scholar] [CrossRef]

- Nunes, S.G.; Saseendran, S.; Joffe, R.; Amico, S.C.; Fernberg, P.; Varna, J. On Temperature-Related Shift Factors and Master Curves in Viscoelastic Constitutive Models for Thermoset Polymers. Mech. Compos. Mater. 2020, 56, 573–590. [Google Scholar] [CrossRef]

- Giannakopoulos, G.; Masania, K.; Taylor, A.C. Toughening of epoxy using core-shell particles. J. Mater. Sci. 2011, 46, 327–338. [Google Scholar] [CrossRef]

- Day, R.J.; Lovell, P.A.; Wazzan, A.A. Thermal and mechanical characterization of epoxy resins toughened using preformed particles. Polym. Int. 2001, 50, 849–857. [Google Scholar] [CrossRef]

- Qian, J.Y.; Pearson, R.A.; Dimonie, V.L.; El-Aasser, M.S. Synthesis and application of core–shell particles as toughening agents for epoxies. J. Appl. Polym. Sci. 1995, 58, 439–448. [Google Scholar] [CrossRef]

- Shen, J.; Zhang, Y.; Qiu, J.; Kuang, J. Core-shell particles with an acrylate polyurethane core as tougheners for epoxy resins. J. Mater. Sci. 2004, 39, 6383–6384. [Google Scholar] [CrossRef]

- Quan, D.; Ivankovic, A. Effect of core-shell rubber (CSR) nano-particles on mechanical properties and fracture toughness of an epoxy polymer. Polymer 2015, 66, 16–28. [Google Scholar] [CrossRef]

- Tang, L.C.; Zhang, H.; Sprenger, S.; Ye, L.; Zhang, Z. Fracture mechanisms of epoxy-based ternary composites filled with rigid-soft particles. Compos. Sci. Technol. 2012, 72, 558–565. [Google Scholar] [CrossRef]

- Dadfar, M.R.; Ghadami, F. Effect of rubber modification on fracture toughness properties of glass reinforced hot cured epoxy composites. Mater. Des. 2013, 47, 16–20. [Google Scholar] [CrossRef]

- Material Datasheet for CHS-Epoxy 582 by Spolchemie (Czech Republic). Available online: https://www.spolchemie.cz/en/product.chs-epoxy-582/?msclkid=77435be2bb3011ec852121a4067dc4ca (accessed on 11 August 2022).

- Material Datasheet for Telalit 0420 by Spolchemie (Czech Republic). Available online: https://www.spolchemie.cz/en/product.telalit-0420/?msclkid=2065552fbb3111ec82d92b19f5b9d09c (accessed on 11 August 2022).

- Material Datasheet for ACE MX-125, ACE MX-156, and ACE MX-960 by Kaneka (Belgium). Available online: https://www.kaneka.be/sites/default/files/uploads/brochures/MX/Kaneka-leaflet-Kane-Ace-Product-properties.pdf?msclkid=a2acc2d9bb3311ecb184043310b58907 (accessed on 11 August 2022).

- Material Datasheet for Carbon Fabric by Havel Composites (Czech Republic). Available online: https://havel-composites.com/cs/produkty/uhlikova-tkanina-kc-160g-m2-3k-platno-s-120-cm-3568-4896 (accessed on 20 September 2022).

- ISO 527-1; Plastics—Determination of Tensile Properties-Part 1: General Principles. ISO: Geneva, Switzerland, 2012.

- ISO 527-2; Plastics—Determination of Tensile Properties-Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012.

- Beres, W.; Ashok, K.K.; Thambraj, R. A tapered double-cantilever-beam specimen designed for constant-K testing at elevated temperatures. J. Test. Eval. 1997, 25, 536–542. [Google Scholar] [CrossRef]

- ASTM Standard D 5528-01; Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. ASTM International: West Conshohocken, PA, USA, 2004.

- Boon, Y.D.; Joshi, S.C. A review of methods for improving interlaminar interfaces and fracture toughness of laminated composites. Mater. Today Commun. 2022, 22, 100830. [Google Scholar] [CrossRef]

- ImageJ Software. Available online: https://imagej.nih.gov/ij/index.html (accessed on 11 August 2022).

- ASTM Standard E 1545-01; Standard Test Method for Assignment of the Glass Transition Temperature by Thermomechanical Analysis. ASTM International: West Conshohocken, PA, USA, 2002.

- Van Velthem, P.; Gabriel, S.; Pardoen, T.; Bailly, C.; Ballout, W. Synergy between phenoxy and CSR tougheners on the fracture toughness of highly cross-linked epoxy-based composites. Polymers 2021, 13, 2477. [Google Scholar] [CrossRef] [PubMed]

- Glaskova-Kuzmina, T.; Zotti, A.; Borriello, A.; Zarrelli, M.; Aniskevich, A. Basalt fibre composite with carbon nanomodified epoxy matrix under hydrothermal ageing. Polymers 2021, 13, 532. [Google Scholar] [CrossRef] [PubMed]

- Glaskova-Kuzmina, T.; Aniskevich, A.; Papanicolaou, G.; Portan, D.; Zotti, A.; Borriello, A.; Zarrelli, M. Hydrothermal aging of an epoxy resin filled with carbon nanofillers. Polymers 2020, 12, 1153. [Google Scholar] [CrossRef] [PubMed]

- Forental’, G.A.; Sapozhnikov, S.B. Numerical-experimental estimation of the mechanical properties of an epoxy nanocomposite. Mech. Compos. Mater. 2011, 47, 521–528. [Google Scholar] [CrossRef]

- Lagzdins, A.; Zilaucs, A.; Beverte, I.; Andersons, J.; Cabulis, U. A refined strut model for describing the elastic properties of highly porous cellular polymers reinforced with short fibers. Mech. Compos. Mater. 2017, 53, 321–334. [Google Scholar] [CrossRef]

- Hansen, T.C. Influence of aggregate and voids on modulus of elasticity of concrete, cement mortar, and cement paste. Int. Concr. Abstr. Portal 1965, 62, 193–216. [Google Scholar] [CrossRef]

- Yoshitake, I.; Rajabipour, F.; Mimura, Y.; Scanlon, A. A prediction method of tensile Young’s modulus of concrete at early age. Adv. Civ. Eng. 2012, 2012, 391214. [Google Scholar] [CrossRef] [Green Version]

- Becu, L.; Maazouz, A.; Sautereau, H.; Gerard, J.F. Fracture behavior of epoxy polymers modified with core-shell rubber particles. J. Appl. Polym. Sci. 1997, 65, 2419–2431. [Google Scholar] [CrossRef]

- Quan, D.; Mischo, C.; Binsfeld, L.; Ivankovic, A.; Murphy, N. Fracture behaviour of carbon fibre/epoxy composites interleaved by MWCNT- and graphene nanoplatelet-doped thermoplastic veils. Compos. Struct. 2020, 235, 111767. [Google Scholar] [CrossRef]

- Ning, H.; Li, J.; Hu, N.; Yan, C.; Liu, Y.; Wu, L.; Liu, F.; Zhang, J. Interlaminar mechanical properties of carbon fiber reinforced plastic laminates modified with graphene oxide interleaf. Carbon 2015, 91, 224–233. [Google Scholar] [CrossRef] [Green Version]

- Freed, C.; Krafft, J. Effect of side grooving on measurements of plane-strain fracture toughness. J. Mater. 1966, 1, 770–790. [Google Scholar]

- Lemmens, R.J.; Dai, Q.; Meng, D.D. Side-groove influenced parameters for determining fracture toughness of self-healing composites using a tapered double cantilever beam specimen. Theor. Appl. Fract. Mech. 2014, 74, 23–29. [Google Scholar] [CrossRef]

- Garoz Gómez, D.; Gilabert, F.A.; Tsangouri, E.; Van Hemelrijck, D.; Hillewaere, X.K.D.; Du Prez, F.E.; Van Paepegem, W. In-depth numerical analysis of the TDCB specimen for characterization of self-healing polymers. Int. J. Solids Struct. 2015, 64–65, 145–154. [Google Scholar] [CrossRef]

| Additive Name | Core Material | CSR Size, nm |

|---|---|---|

| ACE MX-125 | Styrene butadiene | 100 |

| ACE MX-156 | Polybutadiene | 100 |

| ACE MX-960 | Siloxane | 300 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glaskova-Kuzmina, T.; Stankevics, L.; Tarasovs, S.; Sevcenko, J.; Špaček, V.; Sarakovskis, A.; Zolotarjovs, A.; Shmits, K.; Aniskevich, A. Effect of Core–Shell Rubber Nanoparticles on the Mechanical Properties of Epoxy and Epoxy-Based CFRP. Materials 2022, 15, 7502. https://doi.org/10.3390/ma15217502

Glaskova-Kuzmina T, Stankevics L, Tarasovs S, Sevcenko J, Špaček V, Sarakovskis A, Zolotarjovs A, Shmits K, Aniskevich A. Effect of Core–Shell Rubber Nanoparticles on the Mechanical Properties of Epoxy and Epoxy-Based CFRP. Materials. 2022; 15(21):7502. https://doi.org/10.3390/ma15217502

Chicago/Turabian StyleGlaskova-Kuzmina, Tatjana, Leons Stankevics, Sergejs Tarasovs, Jevgenijs Sevcenko, Vladimir Špaček, Anatolijs Sarakovskis, Aleksejs Zolotarjovs, Krishjanis Shmits, and Andrey Aniskevich. 2022. "Effect of Core–Shell Rubber Nanoparticles on the Mechanical Properties of Epoxy and Epoxy-Based CFRP" Materials 15, no. 21: 7502. https://doi.org/10.3390/ma15217502

APA StyleGlaskova-Kuzmina, T., Stankevics, L., Tarasovs, S., Sevcenko, J., Špaček, V., Sarakovskis, A., Zolotarjovs, A., Shmits, K., & Aniskevich, A. (2022). Effect of Core–Shell Rubber Nanoparticles on the Mechanical Properties of Epoxy and Epoxy-Based CFRP. Materials, 15(21), 7502. https://doi.org/10.3390/ma15217502