Manufacturing and Characterization of Wide-Bundle Bamboo Scrimber: A Comparison with Other Engineered Bamboo Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Design

2.3. Fiberization

2.4. Calculation of Specific Surface Area (SSA)

2.5. Panel Fabrication

2.6. Physical and Mechanical Properties Testing

3. Results

3.1. Structural Characteristics of WBS

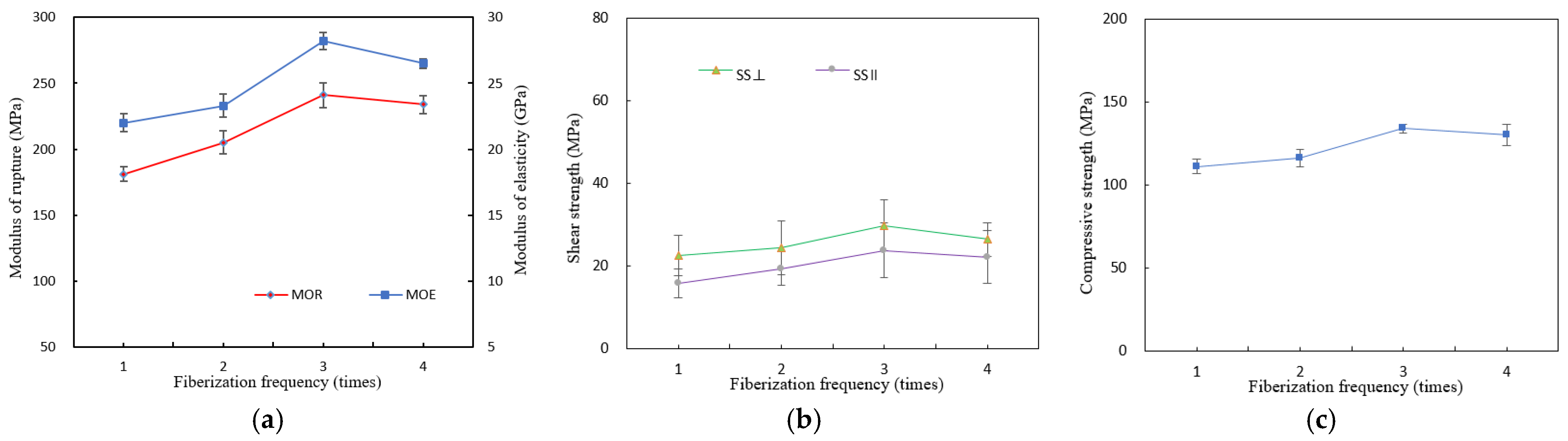

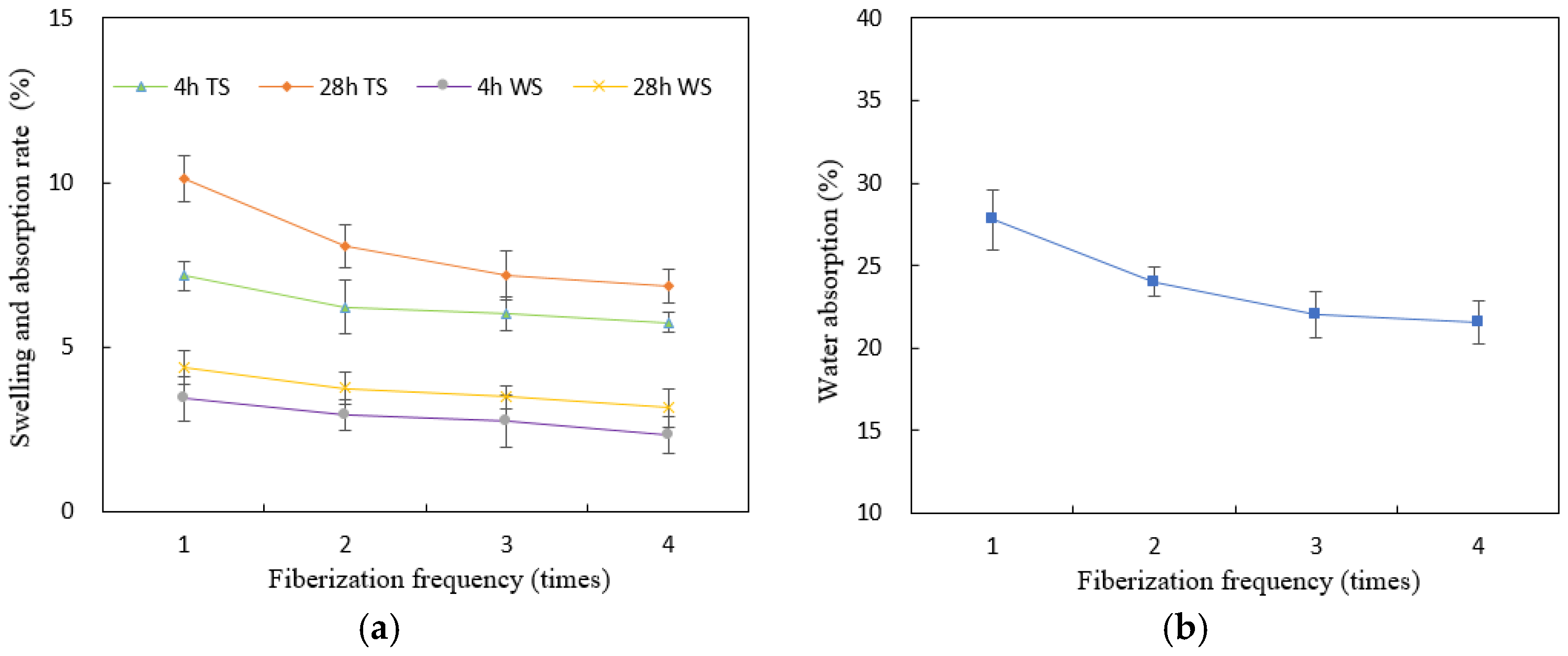

3.2. Effect of Fiberization on the Scrimber Properties

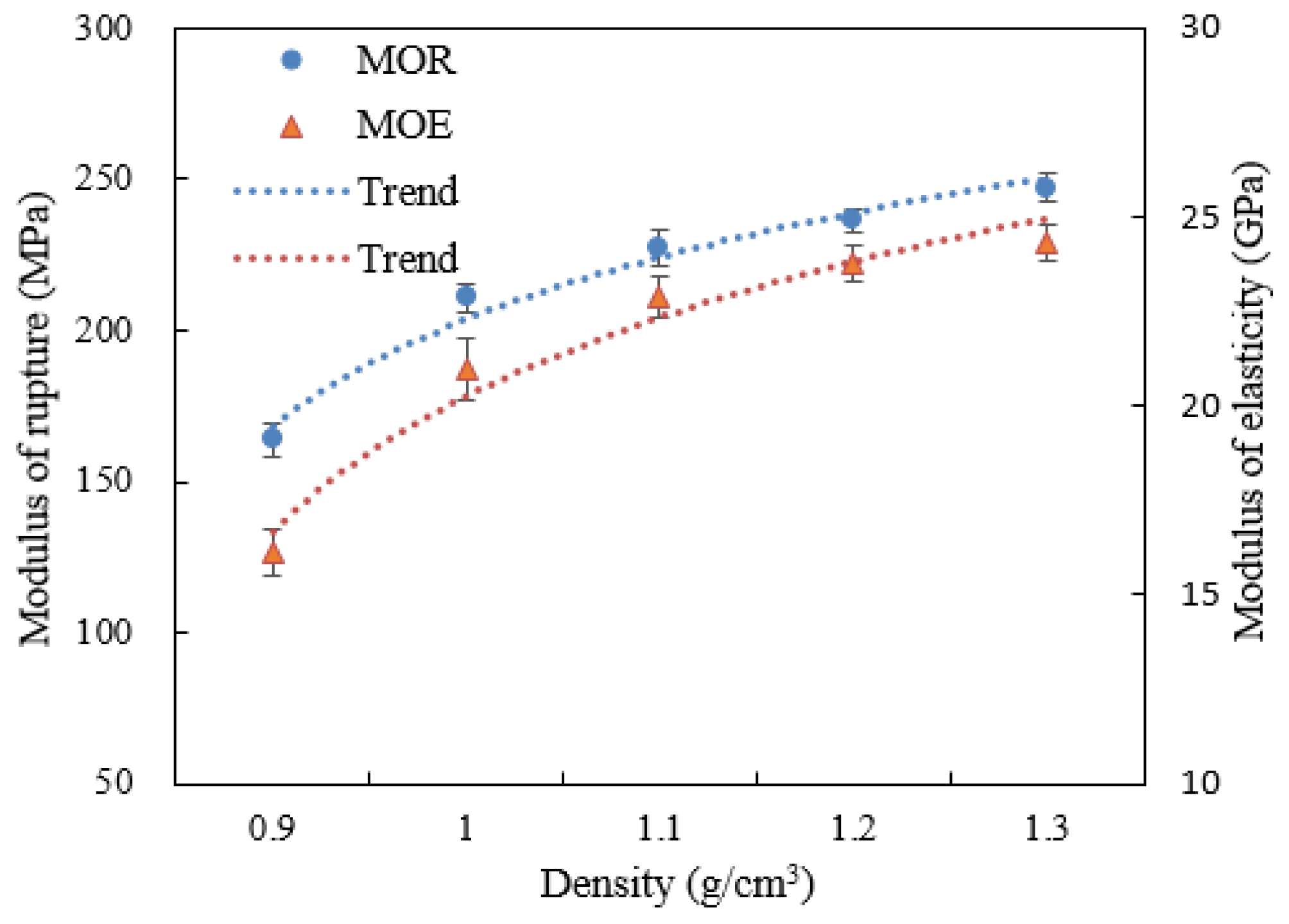

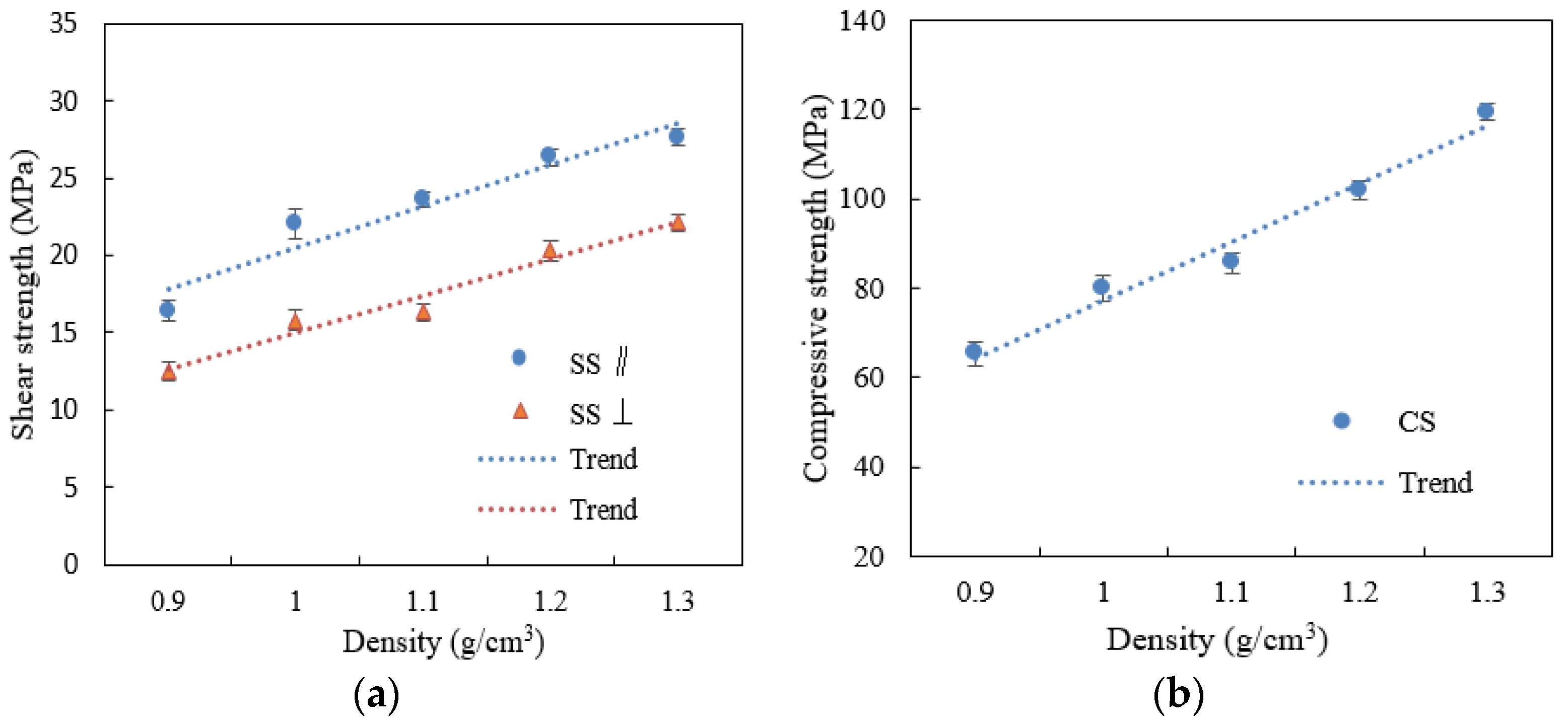

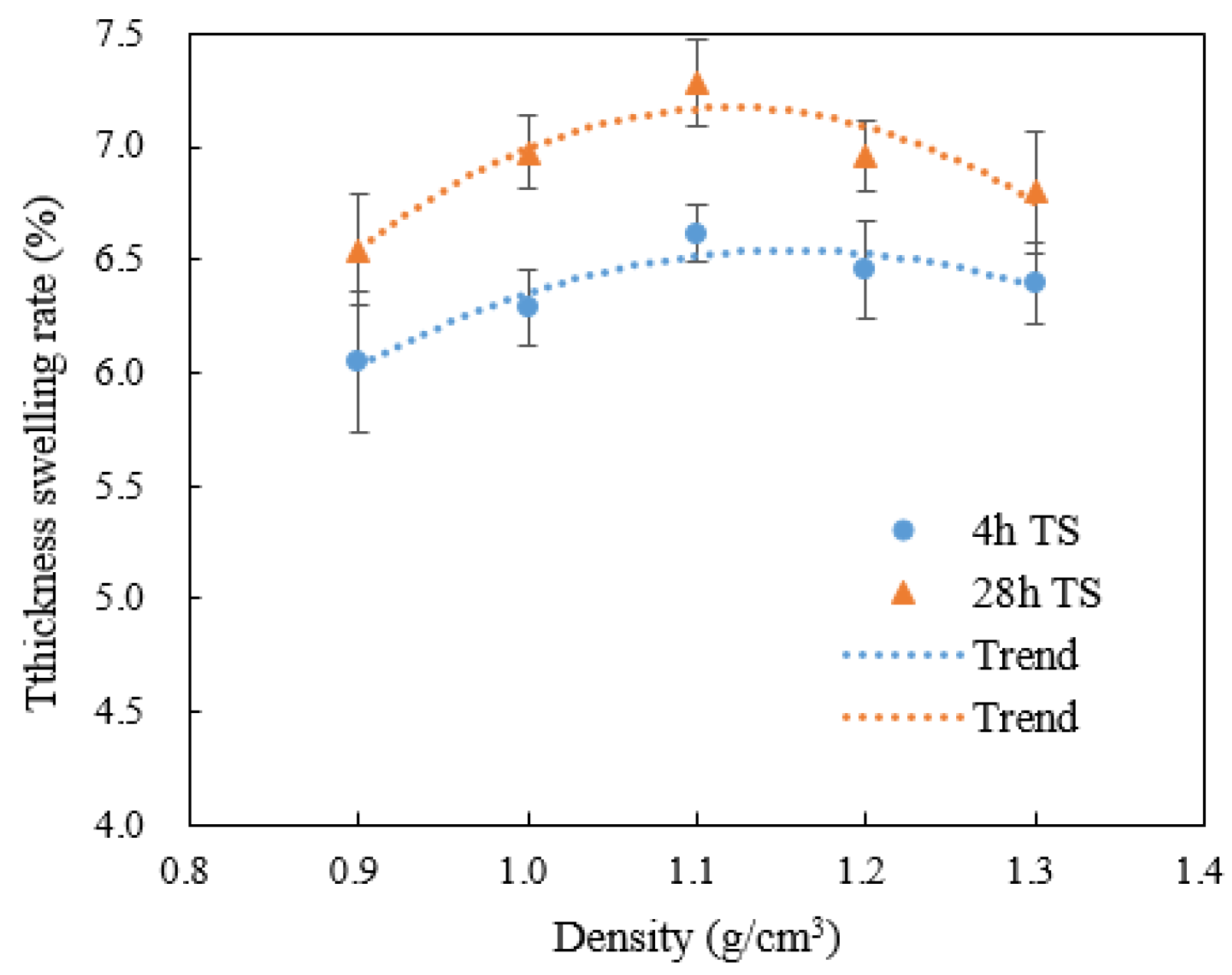

3.3. Effect of Density on the Scrimber Properties

3.4. Impact of Densification on the Microstructure of Scrimber

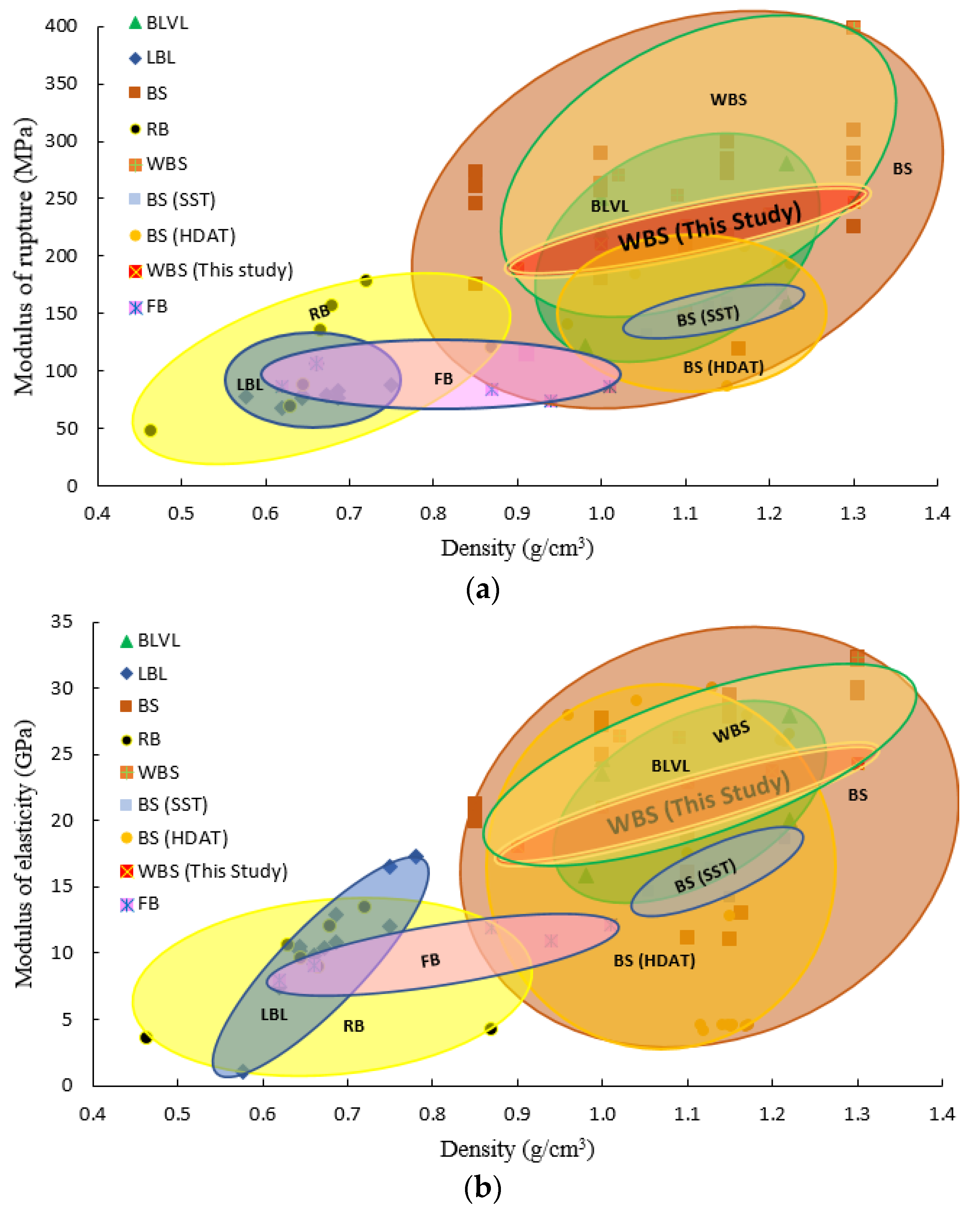

3.5. Performance Comparison of WBS with Other Engineered Bamboo Materials

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Du, H.; Mao, F.; Li, X.; Zhou, G.; Xu, X.; Han, N.; Sun, S.; Gao, G.; Cui, L.; Li, Y.; et al. Mapping Global Bamboo Forest Distribution Using Multisource Remote Sensing Data. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2018, 11, 1458–1471. [Google Scholar] [CrossRef]

- King, C.; van der Lugt, P.; Long, T.T.; Yanxia, L. Integration of Bamboo Forestry into Carbon Markets. Policy Brief, INBAR. 2021. Available online: https://www.inbar.int/wpcontent/uploads/2021/03/Mar-2021_Integration-of-Bamboo-Forestry-into-Carbon-Markets-2.pdf (accessed on 2 August 2021).

- Xiao, Y.; Zhou, Q.; Shan, B. Design and construction of modern bamboo bridges. J. Bridge Eng. 2010, 15, 533–541. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Smith, I.; Frangi, A. Technologies enabling advanced urban timber construction. Proc. Inst. Civ. Eng. Civ. Eng. 2015, 168, 17–22. [Google Scholar] [CrossRef]

- Correal, J.F.; Echeverry, J.S.; Yamin, L.E.; Ramírez, F. Experimental Behaviour of Structural size glued laminated Guadua bamboo members. In Proceedings of the World Conference on Timber Engineering, Quebec City, QC, Canada, 10–14 August 2014; pp. 2–3. [Google Scholar]

- Mauritz, R. Production and material performance of long strand wood composites. Wood Res. 2006, 51, 37–50. [Google Scholar]

- Hutchings, B. Scrimber. In Proceedings of the International Conference on Timber Engineering, Seattle, WA, USA, 19–22 September 1988; pp. 525–533. [Google Scholar]

- Yu, W.; Yu, Y. Development and prospect of wood and bamboo scrimber industry in China. China Wood Ind. 2013, 27, 5–8. [Google Scholar]

- Huang, J.K.; Young, W.B. The mechanical, hygral, and interfacial strength of continuous bamboo fiber reinforced epoxy composites. Compos. Part B Eng. 2019, 166, 272–283. [Google Scholar] [CrossRef]

- Okubo, K.; Fujii, T.; Thostenson, E.T. Multi-scale hybrid biocomposite: Processing and mechanical characterization of bamboo fiber reinforced PLA with microfibrillated cellulose. Compos. Part A Appl. Sci. Manuf. 2009, 40, 469–475. [Google Scholar] [CrossRef]

- Huang, D.; Zhou, A.; Bian, Y. Experimental and analytical study on the nonlinear bending of parallel strand bamboo beams. Constr. Build. Mater. 2013, 44, 585–592. [Google Scholar] [CrossRef]

- Lopez, L.; Correal, J. Exploratory study of the glued laminated bamboo Guadua angustifolia as a structural material. Maderas Cienc. Technol. 2009, 11, 171–182. [Google Scholar] [CrossRef]

- Gu, L.; Zhou, Y.; Mei, T.; Zhou, G.; Xu, L. Carbon Footprint Analysis of Bamboo Scrimber Flooring—Implications for Carbon Sequestration of Bamboo Forests and Its Products. Forests 2019, 10, 51. [Google Scholar] [CrossRef]

- Yu, Y.; Zhu, R.; Wu, B.; Hu, Y.A.; Yu, W. Fabrication, material properties, and application of bamboo scrimber. Wood Sci. Technol. 2015, 49, 83–98. [Google Scholar] [CrossRef]

- Wang, J. Bamboo scrimber: Novel technology and novel product. China Wood Ind 1989, 3, 52–53. [Google Scholar]

- Yu, Y.; Liu, R.; Huang, Y.; Meng, F.; Yu, W. Preparation, physical, mechanical, and interfacial morphological properties of engineered bamboo scrimber. Constr. Build. Mater. 2017, 157, 1032–1039. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Y.; Yang, X.; Ji, H.; Zhong, T.; Wang, G. A comparative study of the microstructure and water permeability between flattened bamboo and bamboo culm. J. Wood Sci. 2019, 65, 64. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, Y.; Ji, Y.; Zhu, R.; Sun, Y.; Yu, Y.; Yu, W. Engineering the surface properties of bamboo scrimber to enhance the gluing properties. Polym. Compos. 2022, 43, 5465–5475. [Google Scholar] [CrossRef]

- Li, N.; Bao, M.; Rao, F.; Shu, Y.; Huang, C.; Huang, Z.; Chen, Y.; Bao, Y.; Guo, R.; Xiu, C. Improvement of surface photostability of bamboo scrimber by application of organic UV absorber coatings. J. Wood Sci. 2019, 65, 1–9. [Google Scholar] [CrossRef]

- Chung, M.J.; Wang, S.Y. Mechanical properties of oriented bamboo scrimber boards made of Phyllostachys pubescens (moso bamboo) from Taiwan and China as a function of density. Holzforschung. 2018, 72, 151–158. [Google Scholar] [CrossRef]

- Chen, S.; Wei, Y.; Hu, Y.; Zhai, Z.; Wang, L. Behavior and strength of rectangular bamboo scrimber columns with shape and slenderness effects. Mater. Today Commun. 2020, 25, 101392. [Google Scholar] [CrossRef]

- Li, H.; Zhang, H.; Qiu, Z.; Su, J.; Wei, D.; Lorenzo, R.; Yuan, C.; Liu, H.; Zhou, C. Mechanical properties and stress strain relationship models for bamboo scrimber. J. Renew. Mater. 2020, 1, 13–27. [Google Scholar] [CrossRef]

- Fu, B.; Li, X.; Yuan, G.; Chen, W.; Pan, Y. Preparation and flame retardant and smoke suppression properties of bamboo-wood hybrid scrimber filled with calcium and magnesium nanoparticles. J. Nanomater. 2014, 2014, 959135. [Google Scholar] [CrossRef]

- Hu, Y.; He, M.; Zhu, R.; Zhang, Y.; Yu, Y.; Yu, W. Influence of dyeing treatment on the performance of bamboo-based fibre composites. J. Trop. For. Sci. 2016, 28, 112–120. [Google Scholar]

- Wu, Z.; Huang, D.; Wei, W.; Wang, W.; Wang, X.A.; Wei, Q.; Niu, M.; Lin, M.; Rao, J.; Xie, Y. Mesoporous aluminosilicate improves mildew resistance of bamboo scrimber with CuBP anti-mildew agents. J. Clean. Prod. 2019, 209, 273–282. [Google Scholar] [CrossRef]

- Shangguan, W.; Gong, Y.; Zhao, R.; Ren, H. Effects of heat treatment on the properties of bamboo scrimber. J. Wood Sci. 2016, 62, 383–391. [Google Scholar] [CrossRef]

- Yu, W. Current status and future development of bamboo scrimber industry in China. China Wood Ind. 2012, 1, 11–14. [Google Scholar]

- Nkeuwa, W.N.; Zhang, J.; Semple, K.E.; Chen, M.; Xia, Y.; Dai, C. Bamboo-based composites: A review on fundamentals and processes of bamboo bonding. Compos. Part B Eng. 2022, 2022, 109776. [Google Scholar] [CrossRef]

- Yu, Y.; Huang, X.; Yu, W. A novel process to improve yield and mechanical performance of bamboo fiber reinforced composite via mechanical treatments. Compos. Part B Eng. 2014, 56, 48–53. [Google Scholar] [CrossRef]

- Huang, Y.; Ji, Y.; Yu, W. Development of bamboo scrimber: A literature review. J. Wood Sci. 2019, 65, 1–10. [Google Scholar] [CrossRef]

- Hu, Y.; He, M.; Semple, K.; Chen, M.; Pineda, H.; Zhou, C.; Dai, C. Characterizing Mat Formation of Bamboo Fiber Composites: Horizontal Density Distribution. Materials 2021, 14, 1198. [Google Scholar] [CrossRef]

- Pineda, H.; Semple, K.; Chen, M.; Dai, C. Computer simulation of the mat formation of bamboo scrimber composites. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106542. [Google Scholar] [CrossRef]

- Dai, C.; Steiner, P.R. On horizontal density variation in randomly-formed short-fibre wood composite boards. Compos. Part A Appl. Sci. Manuf. 1997, 28, 57–64. [Google Scholar] [CrossRef]

- Dai, C. Modelling Structure and Processing Characteristics of a Randomly-Formed Wood-Flake Composite Mat. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 1994. [Google Scholar]

- Dai, C.; Yu, C.; Zhou, C. Theoretical modeling of bonding characteristics and performance of wood composites. Part I. Inter-element contact. Wood Fiber Sci. 2007, 39, 48–55. [Google Scholar]

- Dai, C.; Steiner, P.R. Compression behavior of randomly formed wood flake mats. Wood Fiber Sci. 1993, 349–358. [Google Scholar]

- Zhou, C.; Smith, G.D.; Dai, C. Characterizing hydro-thermal compression behavior of aspen wood strands. Holzforschung 2009, 5, 609–617. [Google Scholar] [CrossRef]

- Dai, C.; Yu, C. Heat and mass transfer in wood composite panels during hot-pressing: Part I. A physical-mathematical model. Wood Fiber Sci. 2004, 585–597. [Google Scholar]

- Dai, C.; Yu, C.; Xu, C.; He, G. Heat and mass transfer in wood composite panels during hot pressing: Part 4. Experimental investigation and model validation. Holzforschung 2007, 61, 83–88. [Google Scholar] [CrossRef]

- Jin, J.; Dai, C.; Hsu, W.E.; Yu, C. Properties of strand boards with uniform and conventional vertical density profiles. Wood Sci. Technol. 2009, 43, 559–574. [Google Scholar] [CrossRef]

- Zhu, R.X.; Yu, W.J. Effect of Density on Physical and Mechanical Properties of Reconstituted Small-Sized Bamboo Fibrous Sheet Composite. Adv. Mater. Res. 2011, 150–151, 634–639. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, Y.; Yu, W. Effects of internal structure and chemical compositions on the hygroscopic property of bamboo fiber reinforced composites. Appl. Surf. Sci. 2019, 492, 936–943. [Google Scholar] [CrossRef]

- Sharma, B.; Gatoo, A.; Bock, M.; Mulligan, H.; Ramage, M. Engineered bamboo: State of the art. Proc. Inst. Civ. Eng. Constr. Mater. 2015, 168, 57–67. [Google Scholar] [CrossRef]

- Wei, Y.; Ji, X.; Duan, M.; Li, G. Flexural performance of bamboo scrimber beams strengthened with fiber-reinforced polymer. Constr. Build. Mater. 2017, 142, 66–82. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, W. Effects of thermal treatment on surface color, dimensional stability and mechanical properties of bamboo-based fiber composites. In Proceedings of the International Conference on Biobase Material Science and Engineering, Changsha, China, 21–23 October 2012; pp. 132–136. [Google Scholar]

- Kumar, A.; Vlach, T.; Laiblova, L.; Hrouda, M.; Kasal, B.; Tywoniak, J.; Hajek, P. Engineered bamboo scrimber: Influence of density on the mechanical and water absorption properties. Constr. Build. Mater. 2016, 127, 815–827. [Google Scholar] [CrossRef]

- Lorenzo, R.; Godina, M.; Mimendi, L.; Li, H. Determination of the physical and mechanical properties of moso, guadua and oldhamii bamboo assisted by robotic fabrication. J. Wood Sci. 2020, 66, 1–11. [Google Scholar] [CrossRef]

- Ribeiro, R.A.S.; Ribeiro, M.G.S.; Miranda, I.P. Bending strength and nondestructive evaluation of structural bamboo. Constr. Build. Mater. 2017, 146, 38–42. [Google Scholar] [CrossRef]

- Chung, K.F.; Yu, W. Mechanical properties of structural bamboo for bamboo scaffoldings. Eng. Struct. 2002, 24, 429–442. [Google Scholar] [CrossRef]

- Huang, Y.; Fei, B.; Wei, P.; Zhao, C. Mechanical properties of bamboo fiber cell walls during the culm development by nanoindentation. Ind. Crops Prod. 2016, 92, 102–108. [Google Scholar] [CrossRef]

- Dixon, P.G.; Gibson, L.J. The structure and mechanics of Moso bamboo material. J. R. Soc. Interface 2014, 11, 20140321. [Google Scholar] [CrossRef]

- Zhou, H.; Wei, X.; Smith, L.M.; Wang, G.; Chen, F. Evaluation of uniformity of bamboo bundle veneer and bamboo bundle laminated veneer lumber (BLVL). Forests 2019, 10, 921. [Google Scholar] [CrossRef]

- He, S.; Xu, J.; Wu, Z.; Yu, H.; Chen, Y.; Song, J. Effect of bamboo bundle knitting on enhancing properties of bamboo scrimber. Eur. J. Wood Wood Prod. 2018, 76, 1071–1078. [Google Scholar] [CrossRef]

- Chen, F.; Jiang, Z.; Deng, J.; Wang, G.; Zhang, D.; Zhao, Q.; Cai, L.; Shi, S.Q. Evaluation of the uniformity of density and mechanical properties of bamboo-bundle laminated veneer lumber (BLVL). BioResources 2014, 9, 554–565. [Google Scholar] [CrossRef]

- Deng, J.; Chen, F.; Li, H.; Wang, G.; Shi, S.Q. The effect of PF/PVAC weight ratio and ambient temperature on moisture absorption performance of bamboo-bundle laminated veneer lumber. Polym. Compos. 2016, 37, 955–962. [Google Scholar] [CrossRef]

- Deng, J.; Li, H.; Wang, G.; Chen, F.; Zhang, W. Effect of removing extent of bamboo green on physical and mechanical properties of laminated bamboo-bundle veneer lumber (BLVL). Eur. J. Wood Wood Prod. 2015, 73, 499–506. [Google Scholar] [CrossRef]

- Lee, A.W.; Bai, X.; Bangi, A.P. Selected properties of laboratory-made laminated-bamboo lumber. Holzforschung 1998, 207–210. [Google Scholar] [CrossRef]

- Rittironk, S.; Elnieiri, M. Investigating laminated bamboo lumber as an alternate to wood lumber in residential construction in the United States. In Modern Bamboo Structures; CRC Press: Boca Raton, FL, USA, 2008; pp. 95–108. [Google Scholar]

- Sharma, B.; Gatóo, A.; Bock, M.; Ramage, M. Engineered bamboo for structural applications. Constr. Build. Mater. 2015, 81, 66–73. [Google Scholar] [CrossRef]

- Nugroho, N.; Ando, N. Development of structural composite products made from bamboo II: Fundamental properties of laminated bamboo lumber. J. Wood Sci. 2001, 47, 237–242. [Google Scholar] [CrossRef]

- Dauletbek, A.; Li, H.; Xiong, Z.; Lorenzo, R. A review of mechanical behavior of structural laminated bamboo lumber. Sustain Struct. 2021, 1, 000004. [Google Scholar] [CrossRef]

- Chen, G.; Yu, Y.; Li, X.; He, B. Mechanical behavior of laminated bamboo lumber for structural application: An experimental investigation. Eur. J. Wood Wood Prod. 2020, 78, 53–63. [Google Scholar] [CrossRef]

- Su, J.; Li, H.; Xiong, Z.; Lorenzo, R. Structural design and construction of an office building with laminated bamboo lumber. Sustain. Struct. 2021, 1, 000010. [Google Scholar] [CrossRef]

- Yang, Y.; Fahmy, M.F.; Pan, Z.; Zhan, Y.; Wang, R.; Wang, B.; Feng, B. Experimental study on basic mechanical properties of new BFRP-bamboo sandwich structure. Constr. Build. Mater. 2020, 264, 120642. [Google Scholar] [CrossRef]

- Sinha, A.; Way, D.; Mlasko, S. Structural performance of glued laminated bamboo beams. J. Struct. Eng. 2014, 140, 04013021. [Google Scholar] [CrossRef]

- Lou, Z.; Yuan, T.; Wang, Q.; Wu, X.; Hu, S.; Hao, X.; Liu, X.; Li, Y. Fabrication of crack-free flattened bamboo and its macro-/micromorphological and mechanical properties. J. Renew. Mater. 2021, 9, 959. [Google Scholar] [CrossRef]

- Fang, C.; Jiang, Z.; Sun, Z.; Liu, H.; Zhang, X.; Zhang, R.; Fei, B. An overview on bamboo culm flattening. Constr. Build. Mater. 2018, 171, 65–74. [Google Scholar] [CrossRef]

- Dai, C.; Yu, C.; Jin, J. Theoretical modeling of bonding characteristics and performance of wood composites. Part IV. Internal bond strength. Wood Fiber Sci. 2008, 40, 146–160. [Google Scholar]

- Sun, X.; He, M.; Li, Z. Novel engineered wood and bamboo composites for structural applications: State-of-art of manufacturing technology and mechanical performance evaluation. Constr. Build. Mater. 2020, 249, 118751. [Google Scholar] [CrossRef]

| Expt. | Experimental Factors | Level | ||||

|---|---|---|---|---|---|---|

| a | Board density (g/cm3) | 1.00 | ||||

| Fiberization frequency (times) | 1 | 2 | 3 | 4 | ||

| b | Fiberization frequency (times) | 3 | ||||

| Board density (g/cm3) | 0.90 | 1.00 | 1.10 | 1.20 | 1.30 | |

| Bundle Type | Number of Strips per Culm | Width (mm) | Thickness (mm) | Diameter (mm) | Utilization Rate (%) | Photo of Bundles | |

|---|---|---|---|---|---|---|---|

| Wide-bundle Bamboo Scrimber | 3–4 | 200–250 (234) | 10–12 (10.95) | 1.35–1.72 (1.54) | 92 |  | |

| Narrow-bundle Bamboo Scrimber | 4–8 | 30–60 (45) | 10–12 (10.32) | 1.15–1.52 (1.34) | 80 |  | |

| Traditional Bamboo Scrimber bundles | 6–10 | 20–30 (23) | 8–10 (8.32) | 2–3 (2.32) | 50–55 |  | |

| Fiberization Frequency (Times) | Outer Green Removal Rate (%) | Diameter of Bamboo Bundles (mm) | Resin Loading (%) | Specific Surface Area (1/mm) | Cross-Sectional Photo of Bamboo Fiber Bundles (5 mm Scale Bar) |

|---|---|---|---|---|---|

| 1 | 34.23 (4.75) | 4.21 (0.32) | 26.45 (4.32) | 1.74 |  |

| 2 | 56.76 (8.37) | 3.13 (0.21) | 47.21 (5.13) | 2.41 |  |

| 3 | 79.11 (10.88) | 2.54 (0.13) | 58.17 (4.55) | 3.32 |  |

| 4 | 94.23 (13.23) | 1.89 (0.15) | 72.44 (6.73) | 3.54 |  |

| Products | Density (kg/cm3) | Modulus of Rupture (MPa) | Modulus of Elasticity (GPa) | Reference | |

|---|---|---|---|---|---|

| WBS | 1.02–1.3 | 253.23–398 | 26.35–32.3 | Yu et al. [30] | |

| Yu et al. [43] | |||||

| BS | 0.85–1.3 | 119–398 | 13–32.3 | Huang et al. [31] | Yu et al. [15] |

| Sharma et al. [44] | Shang et al. [27] | ||||

| Wei et al. [45] | Zhang et al. [46] | ||||

| Yu et al. [17] | Kumar et al. [47] | ||||

| RB | 0.68–0.87 | 69.1–122.46 | 3.6–13.5 | Lorenzo et al. [48] | Yu et al. [17] |

| Ribeiro et al. [49] | Sharma et al. [44] | ||||

| Chung et al. [50] | Huang et al. [51] | ||||

| Dixon et al. [52] | Yu et al. [30] | ||||

| BLVL | 0.98–1 | 121.31–280 | 15.83–24.61 | Zhou et al. [53] | He et al. [54] |

| Chen et al. [55] | Deng et al. [56] | ||||

| Deng et al. [57] | |||||

| LBL | 0.62–0.78 | 67.7–88 | 7.4–17.3 | Andy et al. [58] | Yu et al. [30] |

| Rittironk et al. [59] | Sharma et al. [60] | ||||

| FB | 0.62–1.01 | 74–115.13 | 4.49–12.1 | Andy et al. [58] | Huang et al. [31] |

| Rittironk et al. [59] | Sharma et al. [44] | ||||

| Wenji Yu et al. [30] | Nugroho et al. [61] | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Y.; Xiong, L.; Li, Y.; Semple, K.; Nasir, V.; Pineda, H.; He, M.; Dai, C. Manufacturing and Characterization of Wide-Bundle Bamboo Scrimber: A Comparison with Other Engineered Bamboo Composites. Materials 2022, 15, 7518. https://doi.org/10.3390/ma15217518

Hu Y, Xiong L, Li Y, Semple K, Nasir V, Pineda H, He M, Dai C. Manufacturing and Characterization of Wide-Bundle Bamboo Scrimber: A Comparison with Other Engineered Bamboo Composites. Materials. 2022; 15(21):7518. https://doi.org/10.3390/ma15217518

Chicago/Turabian StyleHu, Yuan, Luyao Xiong, Yanbo Li, Kate Semple, Vahid Nasir, Hugo Pineda, Mei He, and Chunping Dai. 2022. "Manufacturing and Characterization of Wide-Bundle Bamboo Scrimber: A Comparison with Other Engineered Bamboo Composites" Materials 15, no. 21: 7518. https://doi.org/10.3390/ma15217518

APA StyleHu, Y., Xiong, L., Li, Y., Semple, K., Nasir, V., Pineda, H., He, M., & Dai, C. (2022). Manufacturing and Characterization of Wide-Bundle Bamboo Scrimber: A Comparison with Other Engineered Bamboo Composites. Materials, 15(21), 7518. https://doi.org/10.3390/ma15217518