Effects of Fiber and Surface Treatment on Airport Pavement Concrete against Freeze–Thawing and Salt Freezing

Abstract

1. Introduction

2. Experimental Program

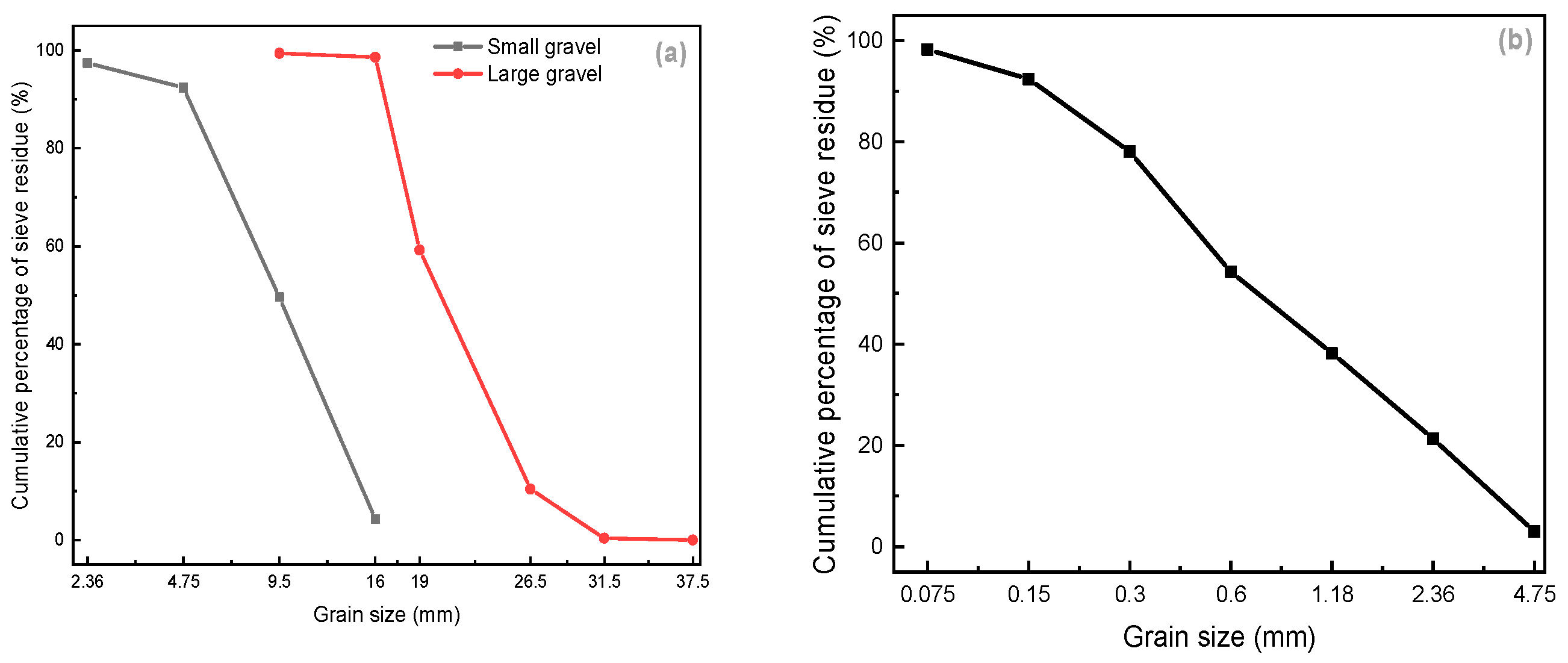

2.1. Raw Materials

2.2. Mix Design and Specimen Preparation

2.3. Mechanical Tests

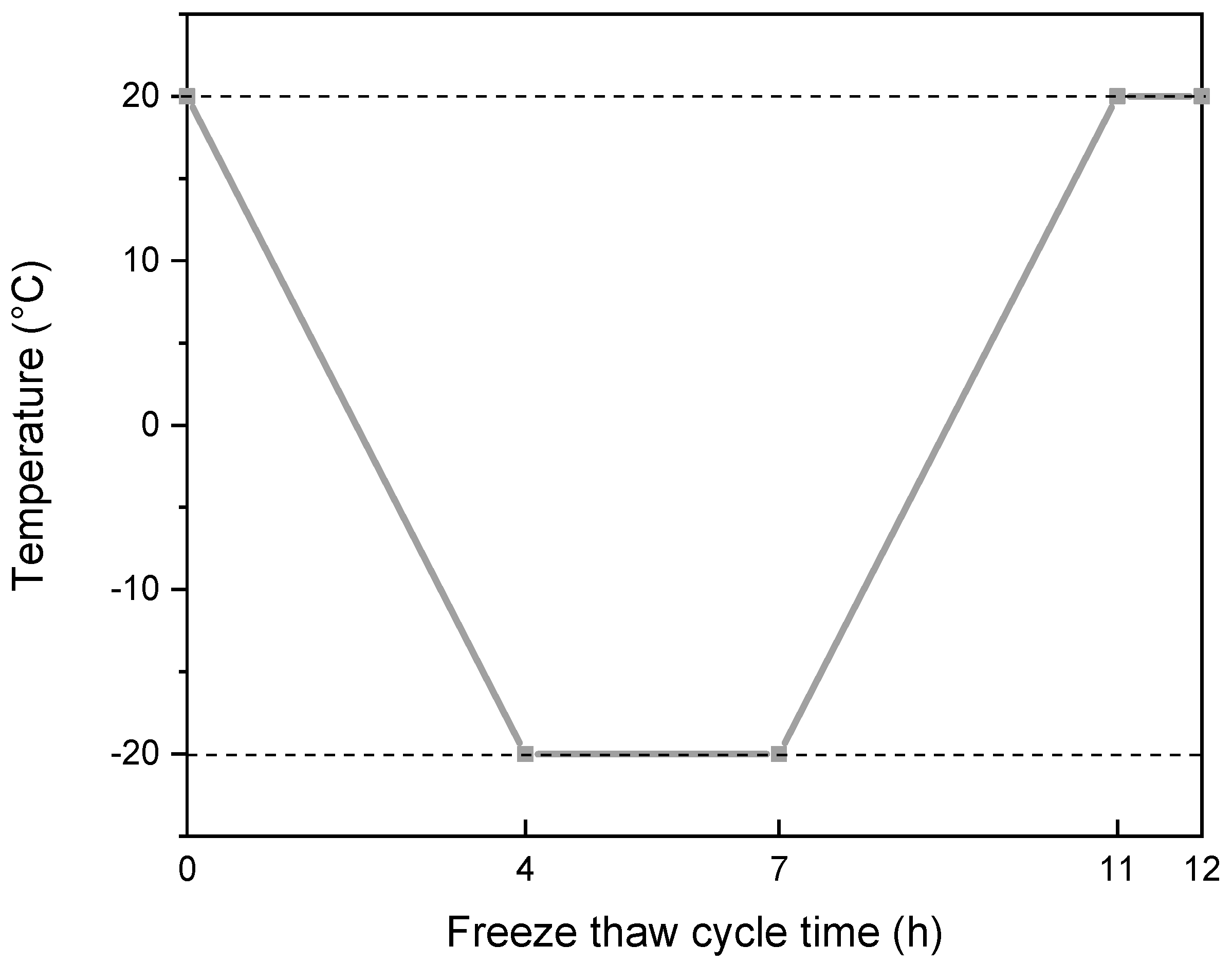

2.4. Freeze–Thaw Cycle Test

2.5. Salt-Freezing Test

2.6. Mercury Intrusion Porosimetry (MIP)

2.7. X-ray Diffraction (XRD)

2.8. Scanning Electron Microscopy (SEM)

3. Results

3.1. Compressive and Flexural Strength of Concrete

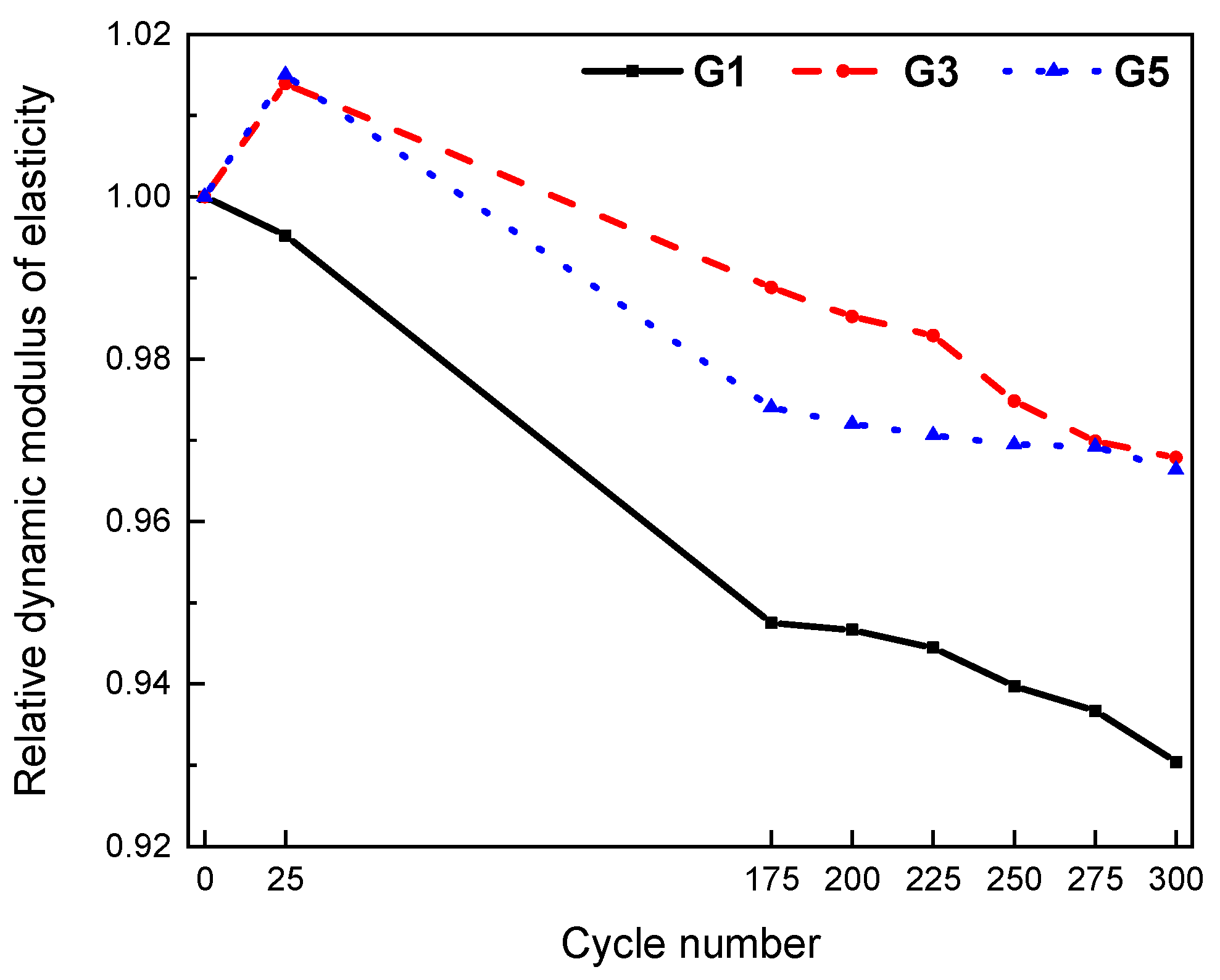

3.2. Frost Resistance of Fiber Reinforced Concrete under Freeze–Thawing

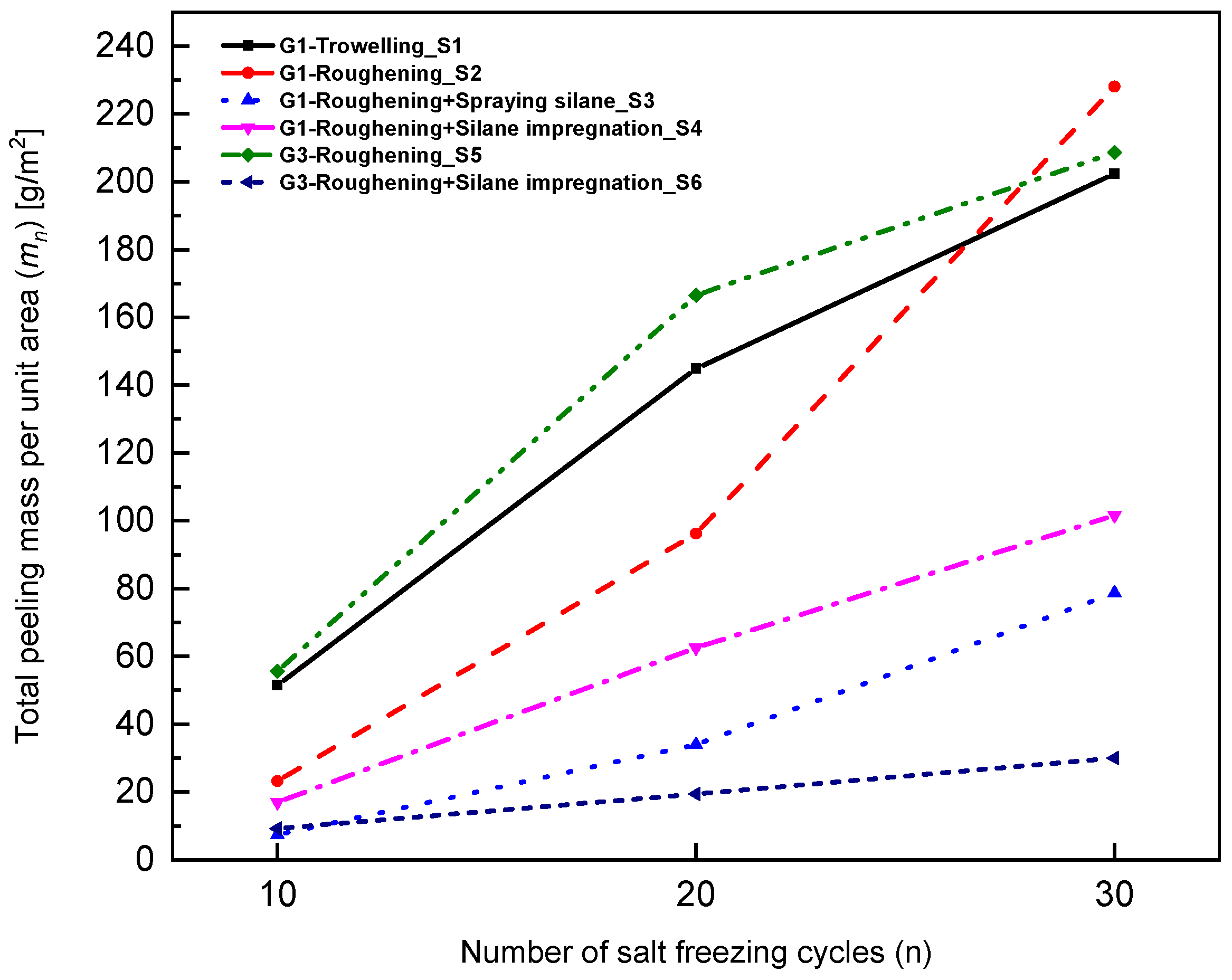

3.3. Effect of Surface Treatment Methods on the Salt Freezing of Fiber-Reinforced Concrete

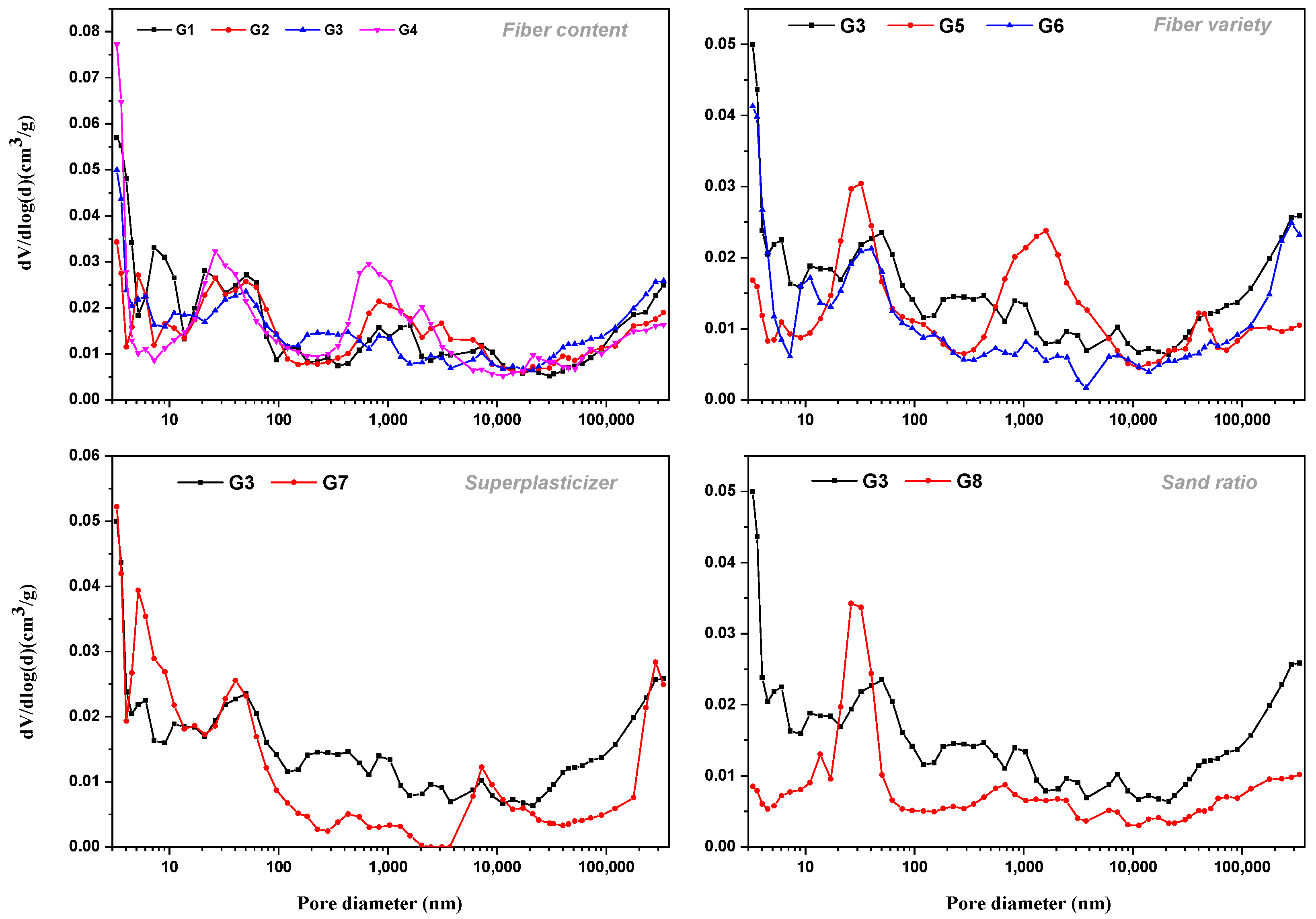

3.4. Pore Structure Characteristics of Fiber-Reinforced Concrete

3.4.1. Effect of Superplasticizer and Sand Ratio

3.4.2. Effect of Fiber Contents and Types

3.5. XRD Results

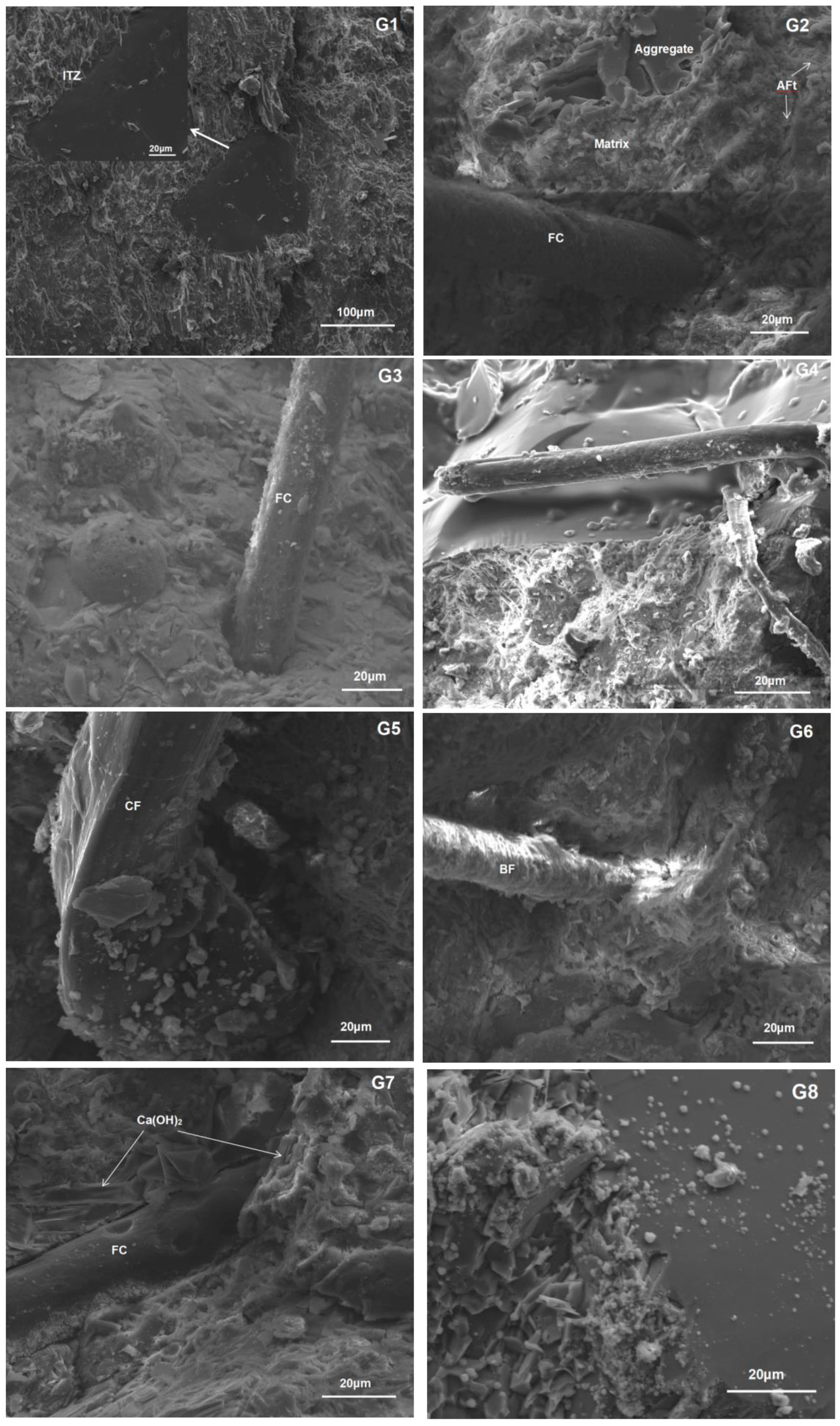

3.6. Microstructure of Interface Transition Zone

4. Discussion

4.1. Influence of Fiber Types and Contents on Concrete Strength

4.2. Effect of Fiber Types on Frost Resistance of Concrete

4.3. Effect of Surface Treatments on Salt Freezing of Concrete

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, W.; Wu, Y.; Di, L. Study on freeze-thaw test of airport pavement concrete in cold area. Subgrade Eng. 2011, 2, 123–125. [Google Scholar]

- Green, M.; Bisby, L.; Beaudoin, Y.; Labossière, P. Effect of freeze-thaw cycles on the bond durability between fibre rein. Can. J. Civ. Eng. 2000, 27, 949–959. [Google Scholar] [CrossRef]

- Kankam, C. Impact resistance of palm kernel fiber-reinforced concrete pavement slab. J. Ferrocem. 1999, 29, 279–286. [Google Scholar]

- Cui, Y.; Chen, Y.; Cen, G.; Peng, G. Comparative Study on the Effect of organic and inorganic fiber on the anti-wheel impact performance of airport pavement concrete under freeze-thaw environment. Constr. Build. Mater. 2019, 211, 284–297. [Google Scholar] [CrossRef]

- Chen, Y.; Cen, G.; Cui, Y. Comparative study on the effect of synthetic fiber on the preparation and durability of airport pavement concrete. Constr. Build. Mater. 2018, 184, 34–44. [Google Scholar] [CrossRef]

- Farnam, Y.; Todak, H.; Spragg, R.; Weiss, J. Electrical response of mortar with different degrees of saturation and deicing salt solutions during freezing and thawing. Cem. Concr. Comp. 2015, 59, 49–59. [Google Scholar] [CrossRef]

- Deja, J. Freezing and deicing salt resistance of blast furnace slag concretes. Cem. Concr. Comp. 2003, 25, 357–361. [Google Scholar] [CrossRef]

- Paluri, Y.; Mogili, S.; Mudavath, H.; Pancharathi, R. A study on the influence of steel fibers on the performance of Fine Reclaimed Asphalt Pavement (FRAP) in pavement quality concrete. Mater. Today Proc. 2020, 32, 657–662. [Google Scholar] [CrossRef]

- Chen, Y.; Cen, G.; Cui, Y. Comparative analysis on the anti-wheel impact performance of steel fiber and reticular polypropylene synthetic fiber reinforced airport pavement concrete under elevated temperature aging environment. Constr. Build. Mater. 2018, 192, 818–835. [Google Scholar] [CrossRef]

- Sassani, A.; Arabzadeh, A.; Ceylan, H.; Kim, S.; Sadati, S.; Gopalakrishnan, K.; Taylor, P.; Abdualla, H. Carbon fiber-based electrically conductive concrete for salt-free deicing of pavements. J. Clean. Prod. 2018, 203, 799–809. [Google Scholar] [CrossRef]

- Par, K.; Paulino, G.; Roesler, J. Cohesive fracture model for functionally graded fiber reinforced concrete. Cem. Concr. Res. 2010, 40, 956–965. [Google Scholar]

- Wu, H.; Zhao, J.; Wang, Z. Study on micro-structure and durability of fiber concrete. Res. J. Appl. Sci. Eng. Technol. 2013, 5, 659–664. [Google Scholar] [CrossRef]

- Liu, D.; Xu, W.; Cheng, Z.; Zhou, Z.; Cai, X.; Zhao, B. Improvement test on frost resistance of concrete and engineering application of test fruitage. Environ. Earth. Sci. 2013, 69, 161–170. [Google Scholar]

- Miao, C.; Mu, R.; Qian, T.; Wei, S. Effect of sulfate solution on the frost resistance of concrete with and without steel fiber reinforcement. Cem. Concr. Res. 2002, 32, 31–34. [Google Scholar] [CrossRef]

- Joshani, M.; Koloor, S.S.R.; Abdullah, R. Damage mechanics model for fracture process of steel-concrete composite slabs. Appl. Mech. Mater. 2012, 165, 339–345. [Google Scholar] [CrossRef]

- Shokravi, H.; Mohammadyan-Yasouj, S.E.; Koloor, S.S.R.; Petrů, M.; Heidarrezaei, M. Effect of Alumina Additives on Mechanical and Fresh Properties of Self-Compacting Concrete: A Review. Processes 2021, 9, 554. [Google Scholar] [CrossRef]

- BS EN 1504-2004; Products and Systems for the Protection and Repair of Concrete Structures-Definitions, Requirements, Quality Control and Evaluation of Conformity. British Standards Institution: London, UK, 2004.

- JTS 153-2015; Standard for Durability Design of Port and Waterway Engineering Structure. China Communication Press Co., Ltd.: Beijing, China, 2015.

- JTJ 275-2000; Corrosion Prevention Technical Specification for Concrete Structures of Marine Harbour Engineering. China Communication Press Co., Ltd.: Beijing, China, 2000.

- Wang, Q.; Luan, H.; Fan, Y. Chloride resistance of concrete with isobutyl-triethoxy-silane. J. Guangxi Univ. (Nat. Sci. Ed.) 2015, 40, 876–882. [Google Scholar]

- Jiang, X.; Qin, M.; Xiao, J.; Zhang, Y.; Xu, W. Influence of silane impregnation conditions on anti-corrosion effect of concrete. Railw. Eng. Chin. 2013, 07, 146–149. [Google Scholar]

- GB 175-2007; Common Portland Cement. China Quality Standards Publishing & Media Co., Ltd.: Beijing, China, 2007.

- GB 8076-2008; Concrete Admixtures. China Quality Standards Publishing & Media Co., Ltd.: Beijing, China, 2008.

- GB 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Quality Standards Publishing & Media Co., Ltd.: Beijing, China, 2019.

- GB 50082-2009; Standard for Test Methods of long-Term Performance and Durability of Ordinary Concrete. China Quality Standards Publishing & Media Co., Ltd.: Beijing, China, 2009.

- MH 5006-2015; Specifications for Construction of Aerodrome Cement Concrete Pavement. Civil Aviation Administration of China: Beijing, China, 2015.

- Paul, S.C.; Babafemi, A.J. Performance of strain hardening cement-based composite (SHCC) under various exposure conditions. Cogent Eng. 2017, 4, 1345608. [Google Scholar] [CrossRef]

- Meng, C.; Li, W.; Cai, L.; Shi, L.; Jiang, C. Experimental research on durability of high-performance synthetic fibers reinforced concrete: Resistance to sulfate attack and freezing-thawing. Constr. Build. Mater. 2020, 262, 120055. [Google Scholar] [CrossRef]

- Li, K.; Jing, W.; Yang, R. Review on silane impregnation of concrete surface and its long-term hydrophobic performance. J. Chin. Ceram Soc. 2019, 47, 1181–1190. [Google Scholar]

- Wang, J.; Xu, L.; Li, M.; He, H.; Wang, Y.; Xiang, D.; Lin, S.; Zhong, Y.; Zhao, H. Effect of pre-carbonation on the properties of cement paste subjected to high temperatures. J. Build. Eng. 2022, 51, 104337. [Google Scholar] [CrossRef]

- Xu, L.; Wang, J.; Li, K.; Lin, S.; Li, M.; Hao, T.; Ling, Z.; Xiang, D.; Wang, T. A systematic review of factors affecting properties of thermal-activated recycled cement. Resour. Conserv. Recy. 2022, 185, 106432. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Yu, J.; Xu, L.; Li, M.; Cheng, J.; Li, Z. Effects of sodium sulfate and potassium sulfate on the properties of calcium sulfoaluminate (CSA) cement based grouting materials. Constr. Build. Mater. 2022, 353, 129045. [Google Scholar] [CrossRef]

- Zhang, J.; Stang, H.; Li, V. Crack bridging model for fiber reinforced concrete under fatigue tension. Int. J. Fatigue. 2001, 23, 655–670. [Google Scholar] [CrossRef]

- Zhang, J.; Stang, H. Application of stress crack width relationship in predicting the flexural behavior of fiber reinforced concrete. Cem. Concr. Res. 1998, 28, 439–452. [Google Scholar] [CrossRef]

- Camps, G.; Turatsinze, A.; Sellier, A.; Escadeillas, G.; Bourbon, X. Steel-fibre-reinforcement and hydration coupled effects on concrete tensile behaviour. Eng. Fract. Mech. 2008, 75, 5207–5216. [Google Scholar] [CrossRef]

- Mohammadi, Y.; Singh, S.; Kaushik, S. Properties of steel fibrous concrete containing mixed fibres in fresh and hardened state. Constr. Build. Mater. 2008, 22, 956–965. [Google Scholar] [CrossRef]

- Dong, F.; Wang, H.; Yu, J.; Liu, K.; Guo, Z.; Duan, X.; Qiong, X. Effect of freeze-thaw cycling on mechanical properties of polyethylene fiber and steel fiber reinforced concrete. Constr. Build. Mater. 2021, 295, 123427. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, S.; Niu, D.; Fu, Q. Quantitative evaluation of the characteristics of air voids and their relationship with the permeability and salt freeze-thaw resistance of hybrid steel-polypropylene fiber-reinforced concrete composites. Cem. Concr. Comp. 2022, 125, 104292. [Google Scholar] [CrossRef]

- Jones, P.; Austin, S.; Robins, P. Predicting the flexural load-deflection response of steel fibre reinforced concrete from strain, crack-width, fibre pull-out and distribution data. Mater. Struct. 2008, 41, 449–463. [Google Scholar] [CrossRef]

- Małek, M.; Jackowski, M.; Łasica, W.; Kadela, M. Characteristics of Recycled Polypropylene Fibers as an Addition to Concrete Fabrication Based on Portland Cement. Materials 2020, 13, 1827. [Google Scholar] [CrossRef] [PubMed]

- Małek, M.; Jackowski, M.; Łasica, W.; Kadela, M.; Wachowski, M. Mechanical and Material Properties of Mortar Reinforced with Glass Fiber: An Experimental Study. Materials 2021, 14, 698. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, H.; Wang, J.; He, F. Effects of highly crystalized nano C-S-H particles on performances of Portland cement paste and its mechanism. Crystals 2020, 10, 816. [Google Scholar] [CrossRef]

- Hang, H.; Wang, Y.; Wang, J. Effects of aggregate micro fines (AMF), aluminum sulfate and polypropylene fiber (PPF) on properties of machine-made sand concrete. Appl. Sci. 2019, 9, 2250. [Google Scholar]

- Wang, J.; Xie, J.; He, J.; Sun, M.; Zhao, J. Combined use of silica fume and steel fibre to improve fracture properties of recycled aggregate concrete exposed to elevated temperature. J. Mater. Cycles Waste Manag. 2020, 22, 62–877. [Google Scholar] [CrossRef]

- Xie, J.; Zhao, J.; Wang, J.; Huang, P.; Liu, J. Investigation of the high-temperature resistance of sludge ceramsite concrete with recycled fine aggregates and GGBS and its application in hollow blocks. J. Build. Eng. 2021, 34, 101954. [Google Scholar] [CrossRef]

- Wang, J. Steady-state chloride diffusion coefficient and chloride migration coefficient of cracks in concrete. J. Mater. Civ. Eng. 2017, 29, 0417117. [Google Scholar] [CrossRef]

- Wang, J.; Liu, E. The relationship between steady-state chloride diffusion and migration coefficients in cementitious materials. Mag. Concr. Res. 2020, 72, 1016–1026. [Google Scholar] [CrossRef]

- Herb, H.; Gerdes, A.; Brenner-Weiß, G. Characterization of silane-based hydrophobic admixtures in concrete using TOF-MS. Cem. Concr. Res. 2015, 70, 77–82. [Google Scholar] [CrossRef]

| Characteristic | Large Gravel 16–31.5 mm | Small Gravel 4.75–16 mm |

|---|---|---|

| Apparent density | 2.716 | 2.731 |

| Water absorption rate | 0.63 | 0.60 |

| Mud content (%) | 0.9 | 0.8 |

| Crushing value (%) | / | 17.9 |

| Fiber Type | Diameter μm | Tensile Strength/MPa | Density g/cm3 | Modulus of Elasticity/GPa | Elongation % | Length mm |

|---|---|---|---|---|---|---|

| FC | 40 | 1252 | 1.31 | 11.7 | 21 | 18 |

| CF | 18 | 960 | 1.10 | 9 | 3.5 | 18 |

| BF | 150 | 1930 | 2.65 | 80 | 3 | 20 |

| Group | Cement (kg/m3) | Sand (kg/m3) | Large Gravel (kg/m3) | Small Gravel (kg/m3) | Water (kg/m3) | Sand Ratio | Fiber Content (kg/m3) | Fiber Type | Superplasticizer (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|

| G1 | 330 | 611.40 | 784.63 | 641.97 | 132.00 | 0.30 | 0 | 0 | 6.6 |

| G2 | 330 | 611.40 | 784.63 | 641.97 | 132.00 | 0.30 | 1.0 | FC | 6.6 |

| G3 | 330 | 611.40 | 784.63 | 641.97 | 132.00 | 0.30 | 1.4 | FC | 6.6 |

| G4 | 330 | 611.40 | 784.63 | 641.97 | 132.00 | 0.30 | 1.8 | FC | 6.6 |

| G5 | 330 | 611.40 | 784.63 | 641.97 | 132.00 | 0.30 | 1.4 | CF | 6.6 |

| G6 | 330 | 611.40 | 784.63 | 641.97 | 132.00 | 0.30 | 1.4 | BF | 6.6 |

| G7 | 330 | 611.40 | 784.63 | 641.97 | 132.00 | 0.30 | 1.4 | FC | 0 |

| G8 | 330 | 570.64 | 807.05 | 660.31 | 132.00 | 0.28 | 1.4 | FC | 6.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, L.; Lai, Y.; Ma, D.; Wang, J.; Li, M.; Li, L.; Gao, Z.; Liu, Y.; He, P.; Zhang, Y. Effects of Fiber and Surface Treatment on Airport Pavement Concrete against Freeze–Thawing and Salt Freezing. Materials 2022, 15, 7528. https://doi.org/10.3390/ma15217528

Xu L, Lai Y, Ma D, Wang J, Li M, Li L, Gao Z, Liu Y, He P, Zhang Y. Effects of Fiber and Surface Treatment on Airport Pavement Concrete against Freeze–Thawing and Salt Freezing. Materials. 2022; 15(21):7528. https://doi.org/10.3390/ma15217528

Chicago/Turabian StyleXu, Lei, Yong Lai, Daoxun Ma, Junjie Wang, Molan Li, Le Li, Zhibin Gao, Yan Liu, Pukang He, and Yi Zhang. 2022. "Effects of Fiber and Surface Treatment on Airport Pavement Concrete against Freeze–Thawing and Salt Freezing" Materials 15, no. 21: 7528. https://doi.org/10.3390/ma15217528

APA StyleXu, L., Lai, Y., Ma, D., Wang, J., Li, M., Li, L., Gao, Z., Liu, Y., He, P., & Zhang, Y. (2022). Effects of Fiber and Surface Treatment on Airport Pavement Concrete against Freeze–Thawing and Salt Freezing. Materials, 15(21), 7528. https://doi.org/10.3390/ma15217528