Synthesis of Three-Dimensional Carbon Nanosheets and Its Flux Pinning Mechanisms in C-Doped MgB2 Superconductors

Abstract

:1. Introduction

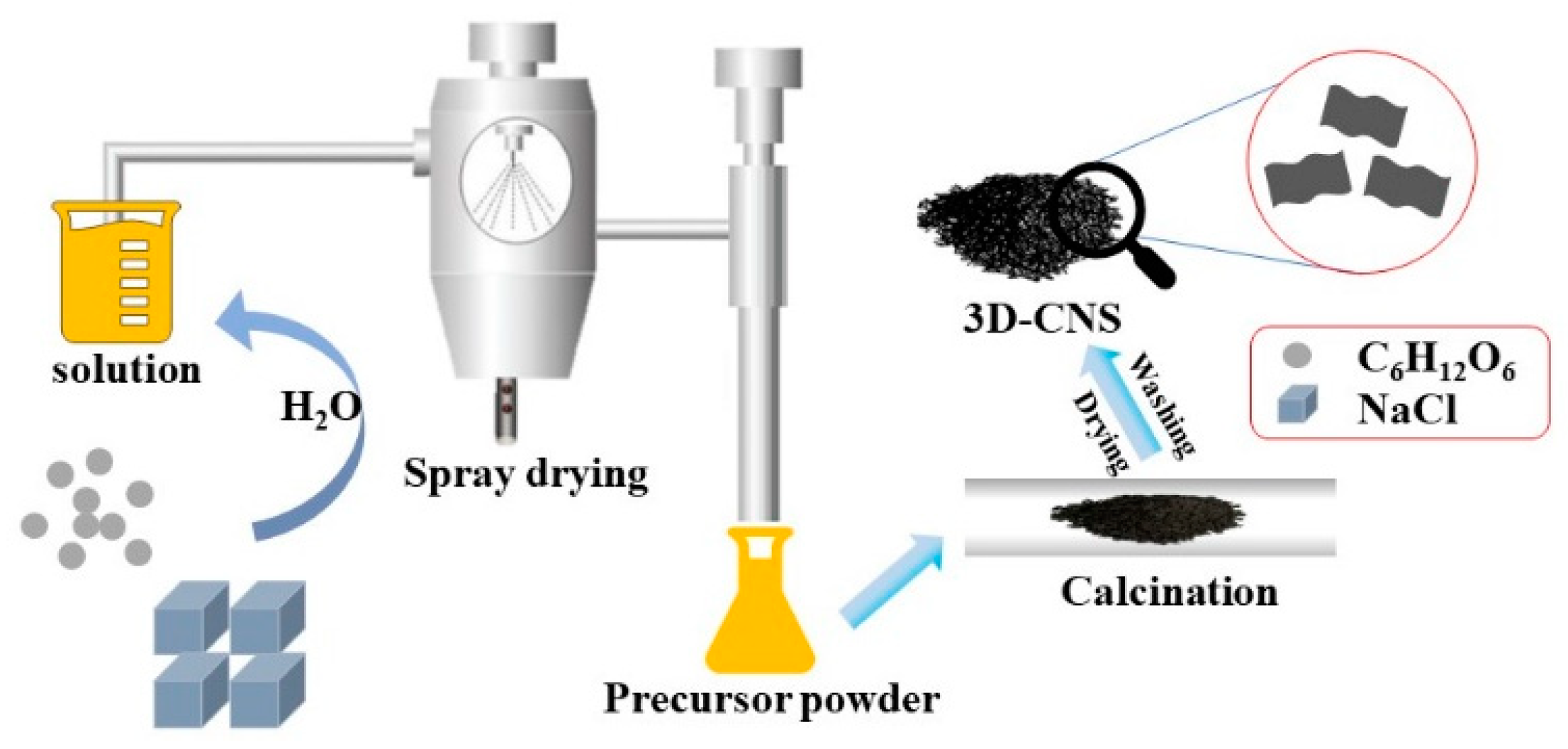

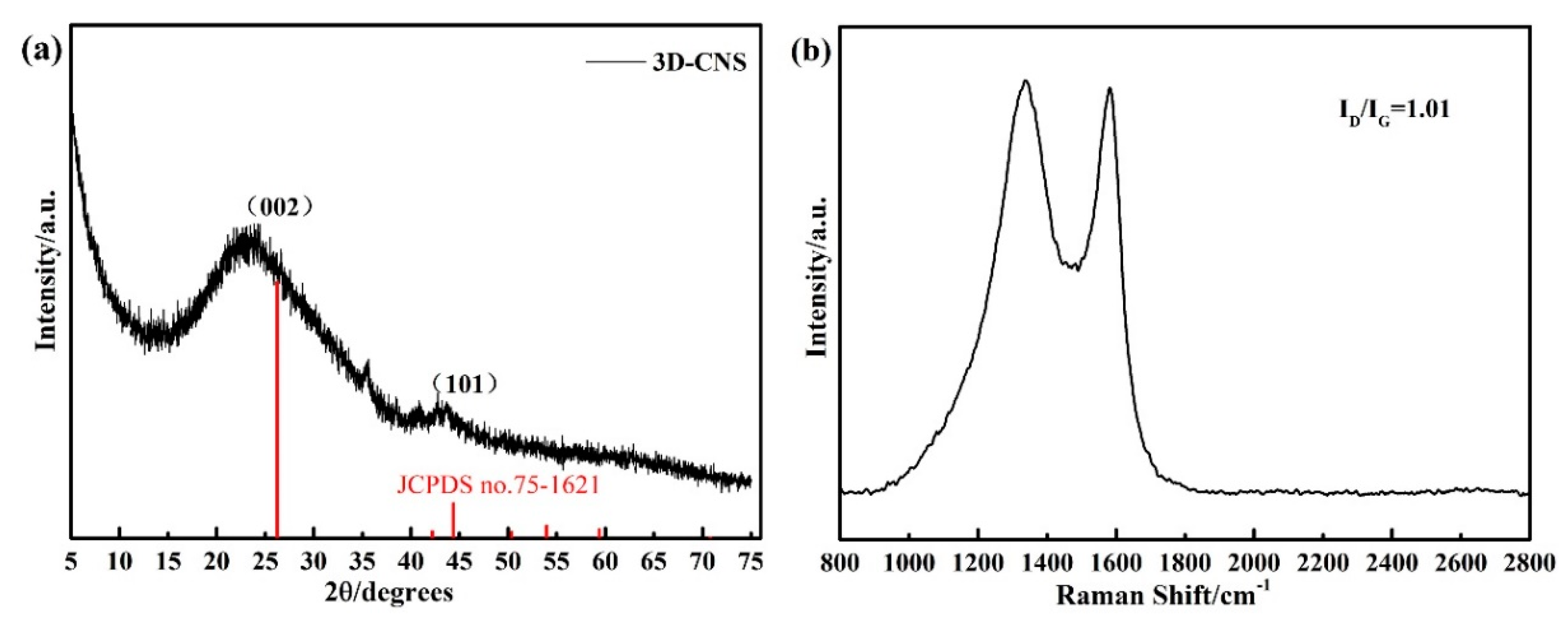

2. Experimental Procedure

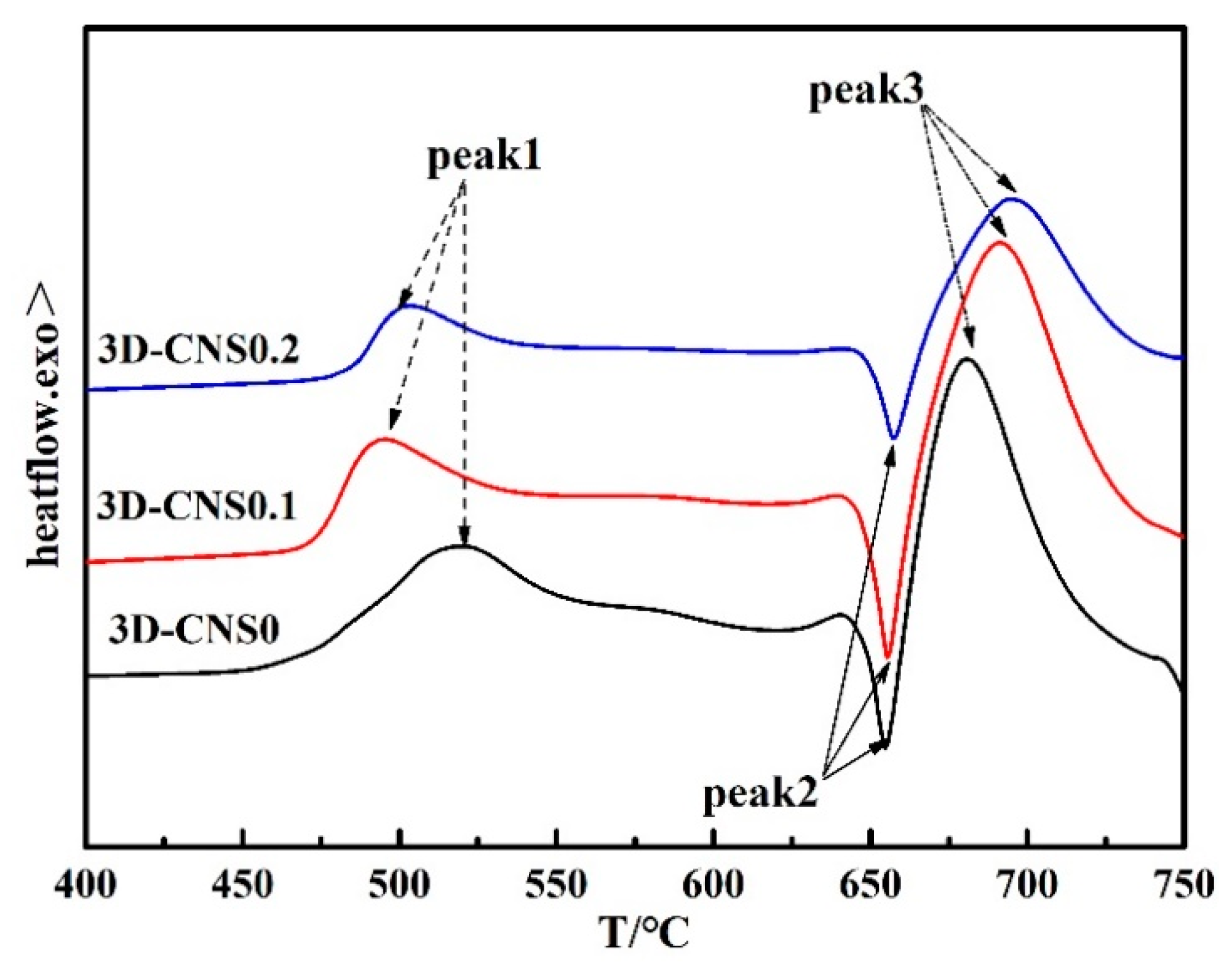

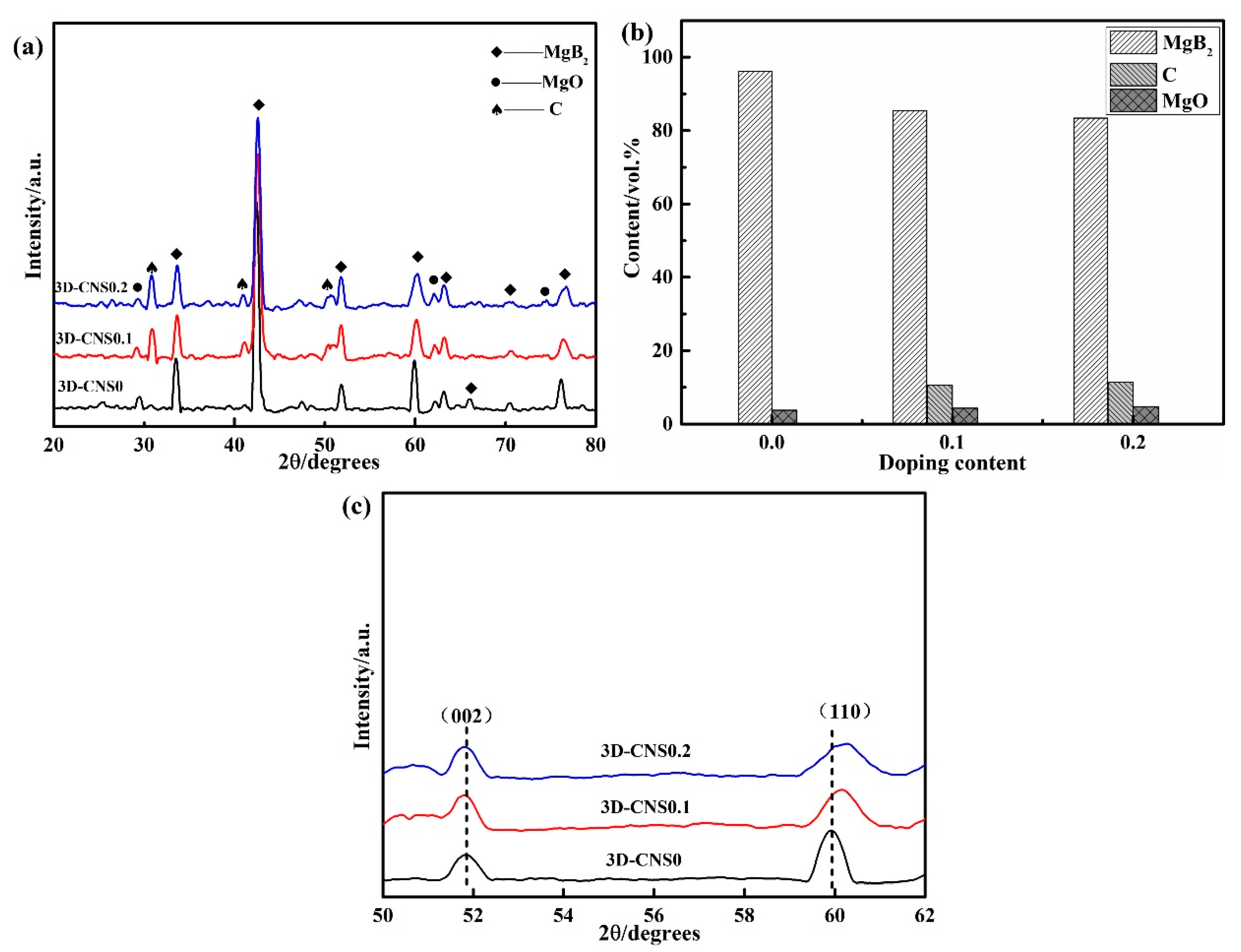

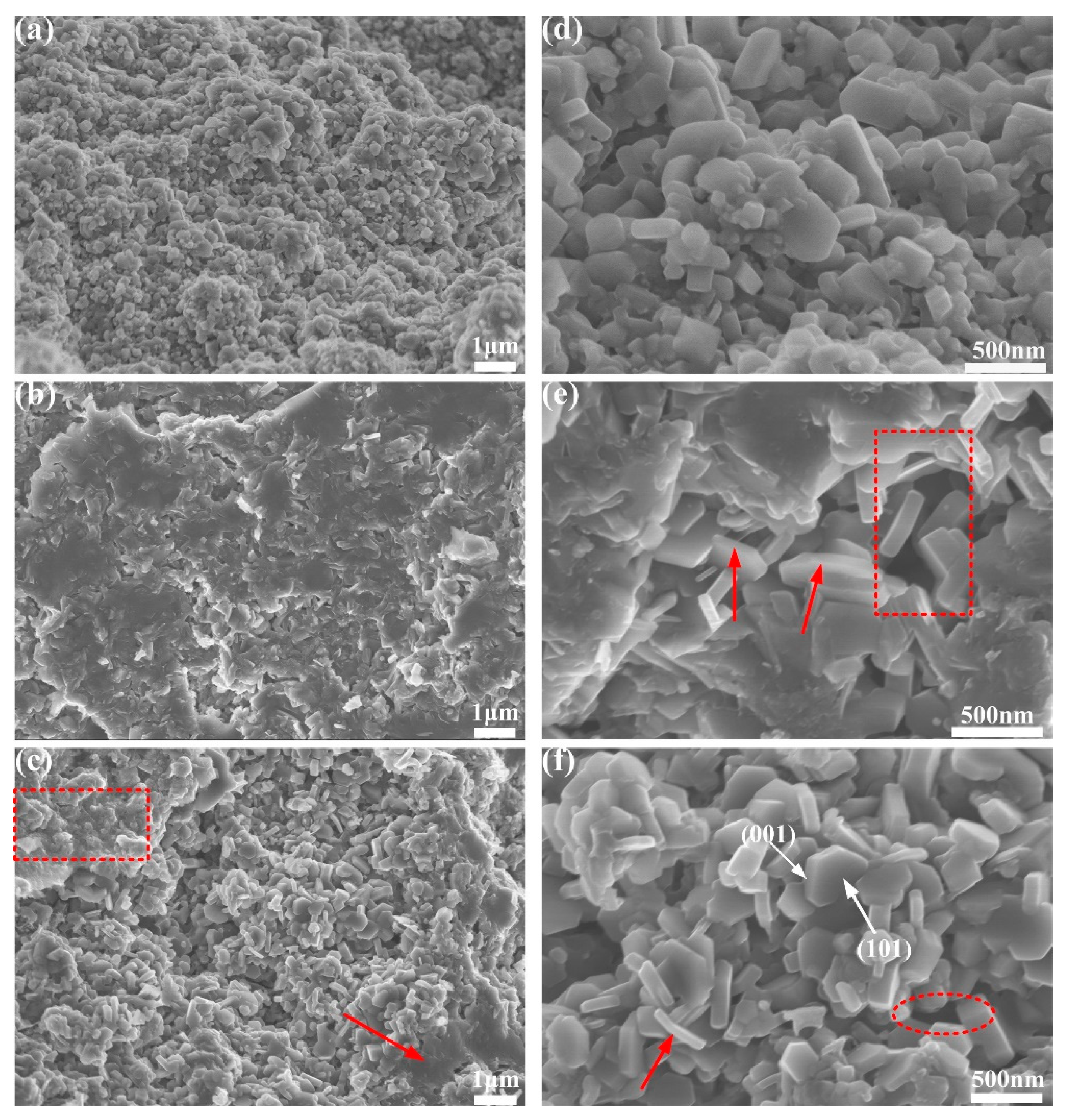

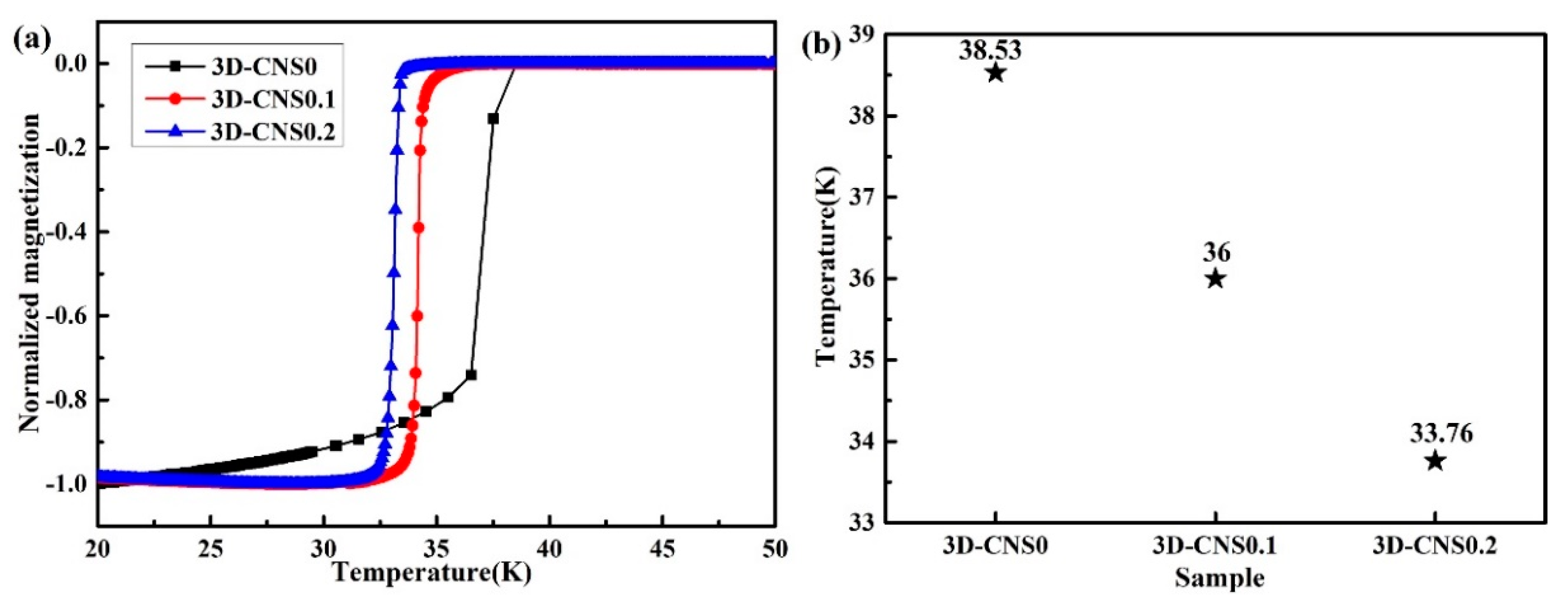

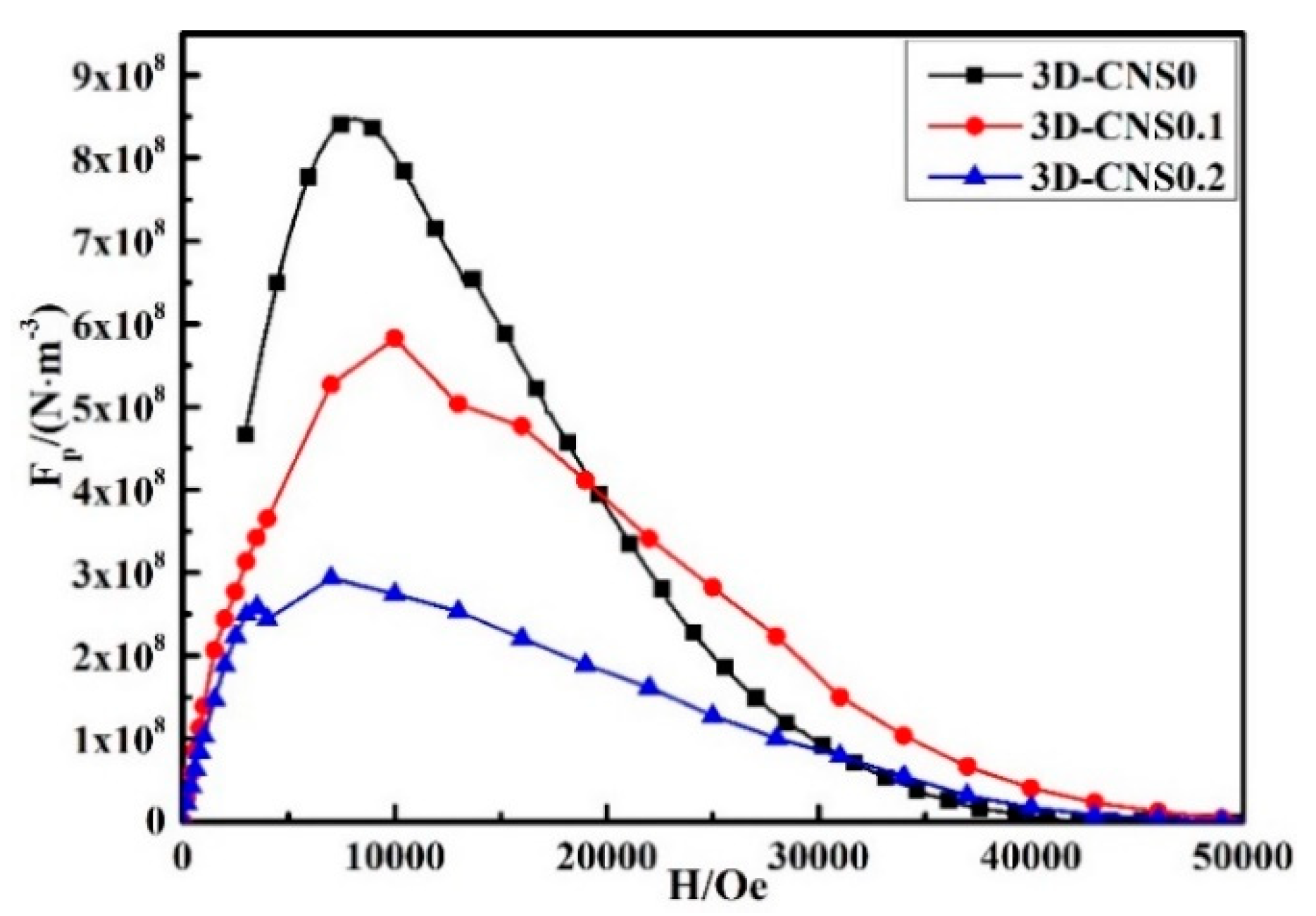

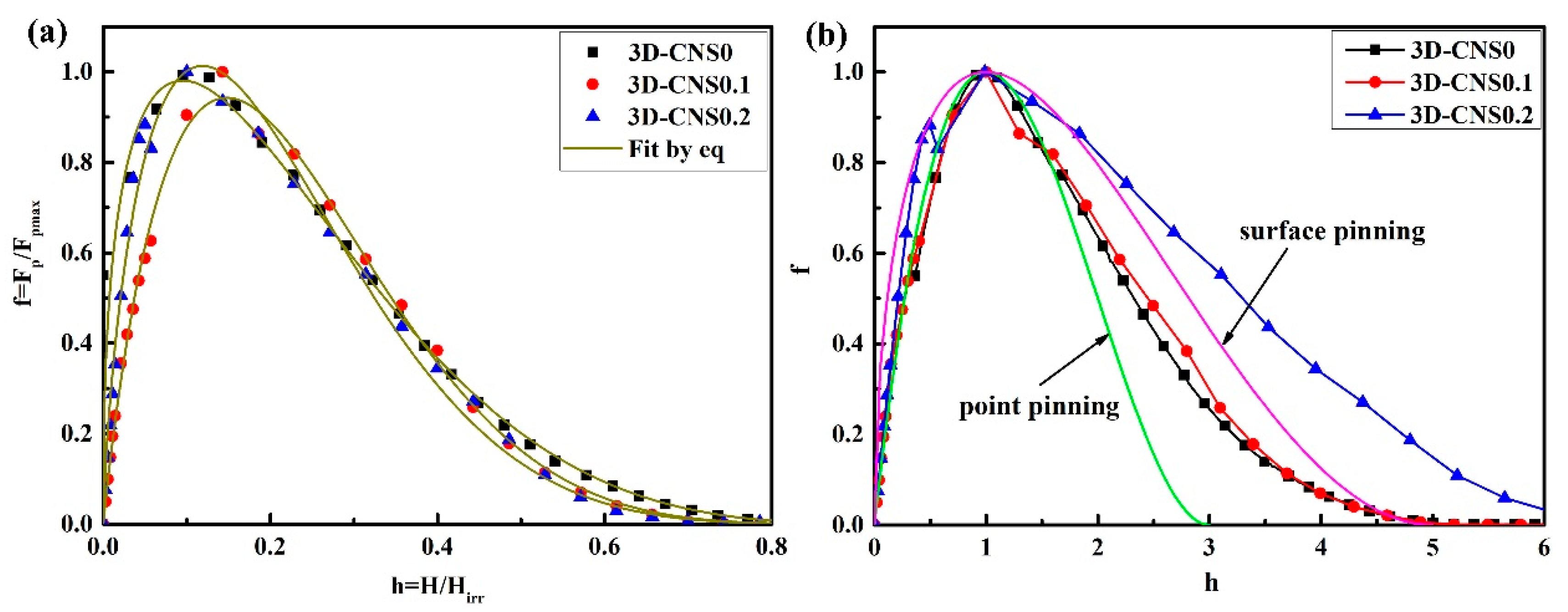

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pęczkowski, P.; Łuszczek, M.; Szostak, E.; Muniraju, N.K.C.; Krztoń-Maziopa, A.; Gondek, Ł. Superconductivity and appearance of negative magnetocaloric effect in Ba1–xKxBiO3 perovskites, doped by Y, La and Pr. Acta Mater. 2022, 222, 137437. [Google Scholar] [CrossRef]

- Nagamatsu, J.; Nakagawa, N.; Muranaka, T.; Zenitani, Y.; Akimitsu, J. Superconductivity at 39 K in magnesium diboride. Nature 2001, 410, 63–64. [Google Scholar] [CrossRef] [PubMed]

- Gurevich, A.; Patnaik, S.; Braccini, V.; Kim, K.H.; Mielke, C.; Song, X.; Cooley, L.D.; Bu, S.D.; Kim, D.M.; Choi, J.H.; et al. Very high upper critical fields in MgB2 produced by selective tuning of impurity scattering. Supercond. Sci. Technol. 2004, 17, 278–280. [Google Scholar] [CrossRef] [Green Version]

- Finnemore, D.K.; Ostenson, J.E.; Bud’ko, S.L.; Lapertot, G.; Canfield, P.C. Thermodynamic and transport properties of superconducting Mg10B2. Phys. Rev. Lett. 2001, 86, 2420. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dadiel, J.L.; Naik, S.P.K.; Pęczkowski, P.; Sugiyama, J.; Ogino, H.; Sakai, N.; Kazuya, Y.; Warski, T.; Wojcik, A.; Oka, T.; et al. Synthesis of Dense MgB2 Superconductor via In Situ and Ex Situ Spark Plasma Sintering Method. Materials 2021, 14, 7395. [Google Scholar] [CrossRef]

- Çiçek, Ö.; Yakinci, K. Enhanced superconducting properties of multi-wall carbon nanotubes added YBCO-123 Superconducting System. J. Mol. Struct. 2020, 1211, 1228089. [Google Scholar] [CrossRef]

- Patel, P.; Maeda, M.; Choi, S.; Kim, S.J.; Shahabuddin, M.; Parakandy, J.M.; Hossain, M.S.A.; Kim, J.H. Multiwalled carbon nanotube-derived superior electrical, mechanical and thermal properties in MgB2 wires. Scr. Mater. 2014, 88, 13–16. [Google Scholar] [CrossRef]

- Anas, M.; Ebrahim, S.; Eldeen, I.G.; Awad, R.; Abou-Aly, A.I. Effect of single and multi-wall carbon nanotubes on the mechanical properties of Gd-123 superconducting phase. Chem. Phys. Lett. 2017, 686, 34–43. [Google Scholar] [CrossRef]

- Dou, S.X.; Shcherbakova, O.; Yeoh, W.K.; Kim, J.H.; Soltanian, S.; Wang, X.L.; Senatore, C.; Flukiger, R.; Dhalle, M.; Husnjak, O.; et al. Mechanism of enhancement in electromagnetic properties of MgB2 by nano SiC doping. Phys. Rev. Lett. 2007, 98, 139902. [Google Scholar] [CrossRef]

- Yeoh, W.K.; Kim, J.H.; Horvat, J.; Xu, X.; Qin, M.J.; Dou, S.X.; Jiang, C.H.; Nakane, T.; Kumakura, H.; Munroe, P. Control of nano carbon substitution for enhancing the critical current density in MgB2. Supercond. Sci. Technol. 2006, 19, 596–599. [Google Scholar] [CrossRef]

- Dou, S.X.; Yeoh, W.K.; Horvat, J.; Ionescu, M. Effect of carbon nanotube doping on critical current density of MgB2 superconductor. Appl. Phys. Lett. 2003, 83, 4996–4998. [Google Scholar] [CrossRef] [Green Version]

- Gao, Z.S.; Ma, Y.W.; Zhang, X.P.; Wang, D.L. Influence of oxygen contents of carbohydrate dopants on connectivity and critical current density in MgB2 tapes. Appl. Phys. Lett. 2007, 91, 162504. [Google Scholar] [CrossRef]

- Zhang, X.P.; Wang, D.L.; Gao, Z.S.; Wang, L.; Qi, Y.P.; Zhang, Z.Y.; Ma, Y.W.; Awaji, S.; Nishijima, G.; Watanabe, K.; et al. Doping with a special carbohydrate, C9H11NO, to improve the J(c)-B properties of MgB2 tapes. Supercond. Sci. Technol. 2010, 23, 025024. [Google Scholar] [CrossRef]

- Kim, J.H.; Zhou, S.; Hossain, M.S.A.; Pan, A.V.; Dou, S.X. Carbohydrate doping to enhance electromagnetic properties of MgB2 superconductors. Appl. Phys. Lett. 2006, 89, 142505. [Google Scholar] [CrossRef] [Green Version]

- Zhou, S.; Pan, A.V.; Wexler, D.; Dou, S.X. Sugar coating of boron powder for efficient carbon doping of MgB2 with enhanced current-carrying performance. Adv. Mater. 2007, 19, 1373–1376. [Google Scholar] [CrossRef]

- Li, C.Y.; Suo, H.L.; Liu, M.; Ma, L.; Wang, Y.; Tian, M.; Wan, B.C.; Cui, J.; Ji, Y.T. Effect of malonic acid and of different doping methods on the superconducting properties of MgB2 superconductors. Phys. C Supercond. 2018, 555, 60–65. [Google Scholar] [CrossRef]

- Xu, X.; Dou, S.X.; Wang, X.L.; Kim, J.H.; Stride, J.A.; Choucair, M.; Yeoh, W.K.; Zheng, R.K.; Ringer, S.P. Graphene doping to enhance the flux pinning and supercurrent carrying ability of a magnesium diboride superconductor. Supercond. Sci. Technol. 2010, 23, 085003. [Google Scholar] [CrossRef] [Green Version]

- De Silva, K.S.B.; Xu, X.; Li, W.X.; Zhang, Y.; Rindfleisch, M.; Tomsic, M. Improving superconducting properties of MgB2 by graphene doping. IEEE Trans. Appl. Supercond. 2011, 21, 2686–2689. [Google Scholar] [CrossRef]

- Zhang, H.; Li, L.; Zhao, Y.; Zhang, Y. The Comparison of graphene and reduced graphene oxide added to MgB2 prepared by diffusion method. IEEE Trans. Appl. Supercond. 2019, 29, 6800605. [Google Scholar] [CrossRef]

- Savaskan, B.; Koparan, E.T.; Celik, S.; Ozturk, K.; Yanmaz, E. Investigation on the levitation force behaviour of malic acid added bulk MgB2 superconductors. Phys. C Supercond. 2014, 502, 63–69. [Google Scholar] [CrossRef]

- Çakır, B.; Taylan Koparan, E.; Savaşkan, B. Relationship between pinning mechanism and excess conductivity analysis of x wt% C4H6O5 (x = 0.0, 4.0, and 6.0)-added bulk MgB2. J. Mater. Sci: Mater. Electron. 2021, 32, 20317–20326. [Google Scholar] [CrossRef]

- Barua, S.; Hossain, M.S.; Ma, Z.Q.; Dipak, P.; Mustapic, M.; Somer, M.; Acar, S.; Kokal, I.; Morawski, A.; Cetner, T.; et al. Superior critical current density obtained in MgB2 bulks through low-cost carbon-encapsulated boron powder. Scr. Mater. 2015, 104, 37–40. [Google Scholar] [CrossRef]

- Kim, J.H.; Oh, S.J.; Kumakura, K.; Matsumoto, A.; Heo, Y.-U.; Song, K.-S.; Kang, Y.M.; Maeda, M.; Rindfleisch, M.; Tomsic, M.; et al. Tailored materials for high-performance MgB2 wire. Adv. Mater. 2011, 23, 4942–4946. [Google Scholar] [CrossRef] [PubMed]

- Cai, Q.; Liu, Y.C.; Ma, Z.Q.; Yu, L. Comparison of carbon-doped MgB2 bulks fabricated from pre-synthesized Mg/CNT and Mg/amorphous carbon composites. Appl. Phys. A 2001, 114, 919–924. [Google Scholar] [CrossRef]

- Li, W.X.; Kang, J.X.; Liu, Y.; Zhu, M.Y.; Li, Y.; Qu, J.T.; Zhang, R.K.; Xu, J.Y.; Liu, B. Extrinsic two-dimensional flux pinning centers in MgB2 superconductors induced by graphene-coated boron. ACS Appl. Mater. Interfaces 2019, 11, 10818–10828. [Google Scholar] [CrossRef]

- Zhao, Q.; Jiao, C.J.; Zhu, Z.; Chen, Z.; Cui, S.H. In-situ synthesis of carbon capsulated Ni nanoparticles and their cooperative doping effects on superconducting properties of MgB2. J. Alloys Compd. 2016, 682, 441–446. [Google Scholar] [CrossRef]

- Sandu, V.; Aldica, G.; Popa, S.; Badica, P.; Cimpoiasu, E.; Dumitrache, F.; Sandu, E. Transport properties of superconducting MgB2 composites with carbon-encapsulated Fe nanospheres. J. Appl. Phys. 2011, 110, 123921. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, C.S.; Liu, E.Z.; He, F.; Ma, L.Y.; Li, Q.Y.; Li, J.J.; Bacsa, W.; Zhao, N.Q.; He, C.N. Achieving high strength and high ductility in metal matrix composites reinforced with a discontinuous three-dimensional graphene-like network. Nanoscale 2017, 9, 11929–11938. [Google Scholar] [CrossRef]

- Qin, J.; Wang, T.S.; Liu, D.Y.; Liu, E.Z.; Zhao, N.Q.; Shi, C.S.; He, F.; Ma, L.Y.; He, C.N. A Top-Down strategy toward SnSb In-Plane nanoconfined 3D N-Doped porous graphene composite microspheres for high performance Na-Ion battery anode. Adv. Mater. 2018, 30, 1704670. [Google Scholar] [CrossRef]

- Liu, Z.N.; He, F.; Shi, C.S. Synthesis of interconnected carbon nanosheets anchored with Fe3O4 nanoparticles as broadband electromagnetic wave absorber. Chem. Phys. Lett. 2019, 716, 221–226. [Google Scholar] [CrossRef]

- Bean, C.P. Magnetization of hard superconductors. Phys. Rev. Lett. 1962, 8, 250–253. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Meyer, J.C.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.S.; Roth, S. Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rietveld, H.M. A profile refinement method for nuclear and magnetic structures. J. Appl. Cryst. 1969, 2, 65–71. [Google Scholar] [CrossRef]

- Avdeev, M.; Jorgensen, J.D.; Ribeiro, R.A.; Budko, S.L.; Canfield, P.C. Crystal chemistry of carbon-substituted MgB2. Phys. C Supercond. 2003, 387, 301. [Google Scholar] [CrossRef] [Green Version]

- Cai, Q.; Liu, Y.C.; Ma, Z.Q.; Cardwell, D.A. Fishtail effects and improved critical current density in polycrystalline bulk MgB2 containing carbon nanotubes. Phys. C Supercond. 2013, 492, 6–10. [Google Scholar] [CrossRef]

- Cai, Q.; Ma, Z.Q.; Liu, Y.C.; Yu, L.M. Enhancement of critical current density in glycine-doped MgB2 bulks. Mater. Chem. Phys. 2012, 136, 778–782. [Google Scholar] [CrossRef]

- Cai, Q.; Liu, Y.C.; Ma, Z.Q.; Yu, L.M. Superconducting properties and growth mechanism of layered structure in MgB2 bulks with Cu/Y2O3 co-doping. J. Mater.Sci. Mater. Electron. 2013, 24, 1452–1457. [Google Scholar] [CrossRef]

- Jiao, C.J.; Zhao, Q.; Wang, L. Effect of graphene doping on the microstructure and properties of MgB2 bulk. J. Fun. Mater. 2017, 48, 11138–11140, 11146. [Google Scholar] [CrossRef]

- Martínez, E.; Mikheenko, P.; Martínez-López, M.; Millán, A.; Bevan, A.; Abell, J.S. Flux pinning force in bulk MgB2 with variable grain size. Phys. Rev. B 2007, 75, 134515. [Google Scholar] [CrossRef] [Green Version]

- Dew-Hughes, D. The role of grain boundaries in determining Jc in high-field high current superconductors. Philos. Mag. Part B 1987, 55, 459–479. [Google Scholar] [CrossRef]

- Higuchi, T.; Yoo, S.I.; Murakami, M. Comparative study of critical current densities and flux pinning among a flux-grown NdBa2Cu3Oy single crystal, melt-textured Nd-Ba-Cu-O, and Y-Ba-Cu-O bulks. Phys. Rev. B 1999, 59, 1514–1527. [Google Scholar] [CrossRef]

| Sample | n(Mg): n(B): n(3D-CNS) | Temperature/°C | Duration/h | Size/mm |

|---|---|---|---|---|

| 3D-CNS0 | 1:2:0 | 750 | 0.5 | Φ5 × 1.5 |

| 3D-CNS0.1 | 1:1.9:0.1 | |||

| 3D-CNS0.2 | 1:1.8:0.2 |

| Sample | 2θ of (002) Peak | 2θ of (110) Peak | FWHM of (002) Peak | FWHM of (110) Peak | a/Å | c/Å | y in Mg(B1−yCy)2 |

|---|---|---|---|---|---|---|---|

| 3D-CNS0 | 51.879 | 59.938 | 0.324 | 0.266 | 3.0859 | 3.5230 | / |

| 3D-CNS0.1 | 51.859 | 60.143 | 0.318 | 0.698 | 3.0777 | 3.5192 | 0.017 |

| 3D-CNS0.2 | 51.852 | 60.289 | 0.341 | 0.854 | 3.0581 | 3.5255 | 0.021 |

| Sample | m | n | hpeak | R2 |

|---|---|---|---|---|

| Point pinning | 1 | 2 | 0.33 | / |

| Surface pinning | 0.5 | 2 | 0.2 | / |

| 3D-CNS0 | 0.40 | 3.78 | 0.11 | 0.9913 |

| 3D-CNS0.1 | 0.95 | 5.45 | 0.15 | 0.9961 |

| 3D-CNS0.2 | 0.73 | 5.40 | 0.12 | 0.9856 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Q.; Chen, Y.; Qin, B.; Hu, C.; Xia, G.; Hao, L.; Ping, X. Synthesis of Three-Dimensional Carbon Nanosheets and Its Flux Pinning Mechanisms in C-Doped MgB2 Superconductors. Materials 2022, 15, 7530. https://doi.org/10.3390/ma15217530

Zhao Q, Chen Y, Qin B, Hu C, Xia G, Hao L, Ping X. Synthesis of Three-Dimensional Carbon Nanosheets and Its Flux Pinning Mechanisms in C-Doped MgB2 Superconductors. Materials. 2022; 15(21):7530. https://doi.org/10.3390/ma15217530

Chicago/Turabian StyleZhao, Qian, Yun Chen, Baojun Qin, Chunhao Hu, Guoqing Xia, Liang Hao, and Xuecheng Ping. 2022. "Synthesis of Three-Dimensional Carbon Nanosheets and Its Flux Pinning Mechanisms in C-Doped MgB2 Superconductors" Materials 15, no. 21: 7530. https://doi.org/10.3390/ma15217530

APA StyleZhao, Q., Chen, Y., Qin, B., Hu, C., Xia, G., Hao, L., & Ping, X. (2022). Synthesis of Three-Dimensional Carbon Nanosheets and Its Flux Pinning Mechanisms in C-Doped MgB2 Superconductors. Materials, 15(21), 7530. https://doi.org/10.3390/ma15217530