A Review of Lightweight Self-Healing Concrete

Abstract

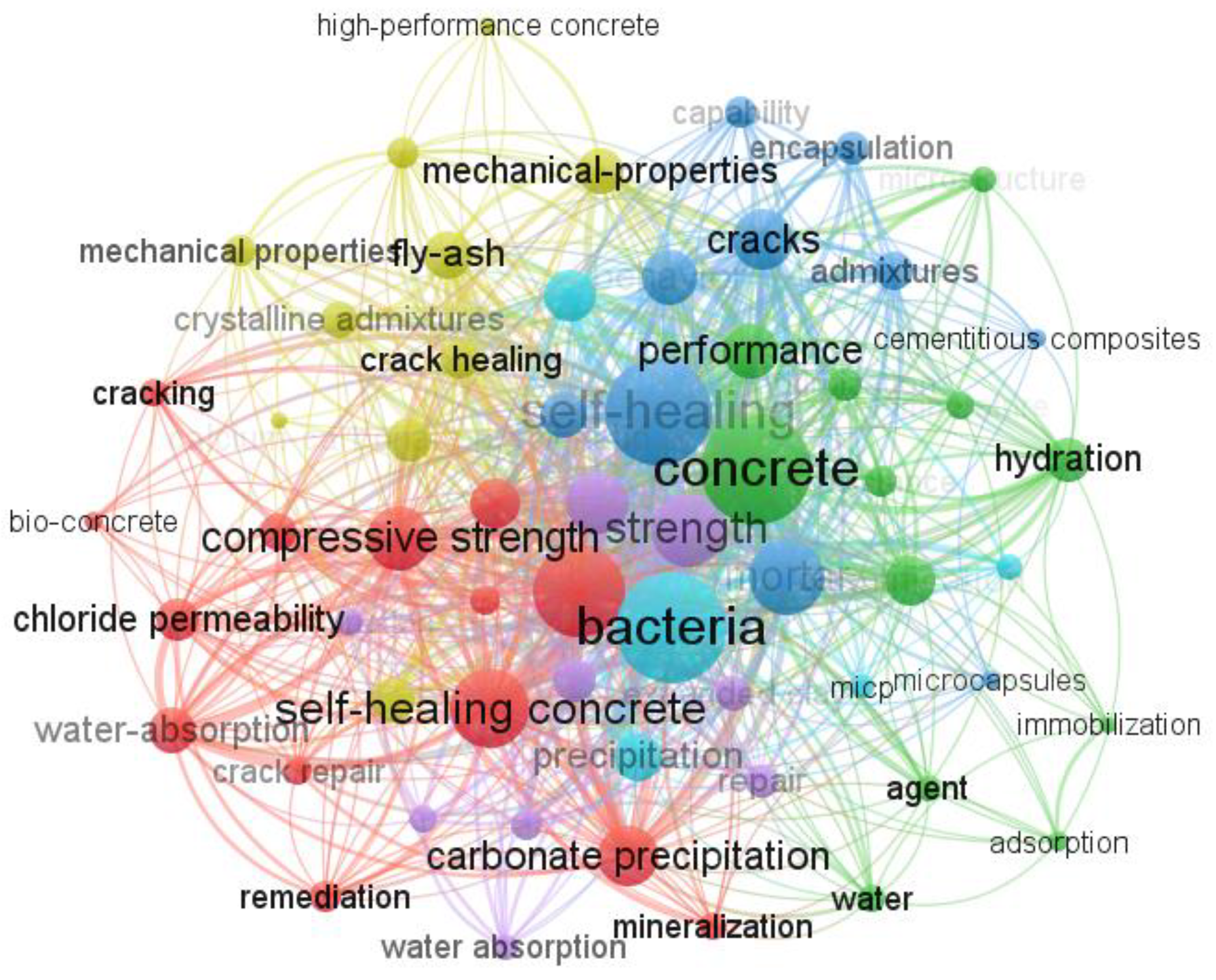

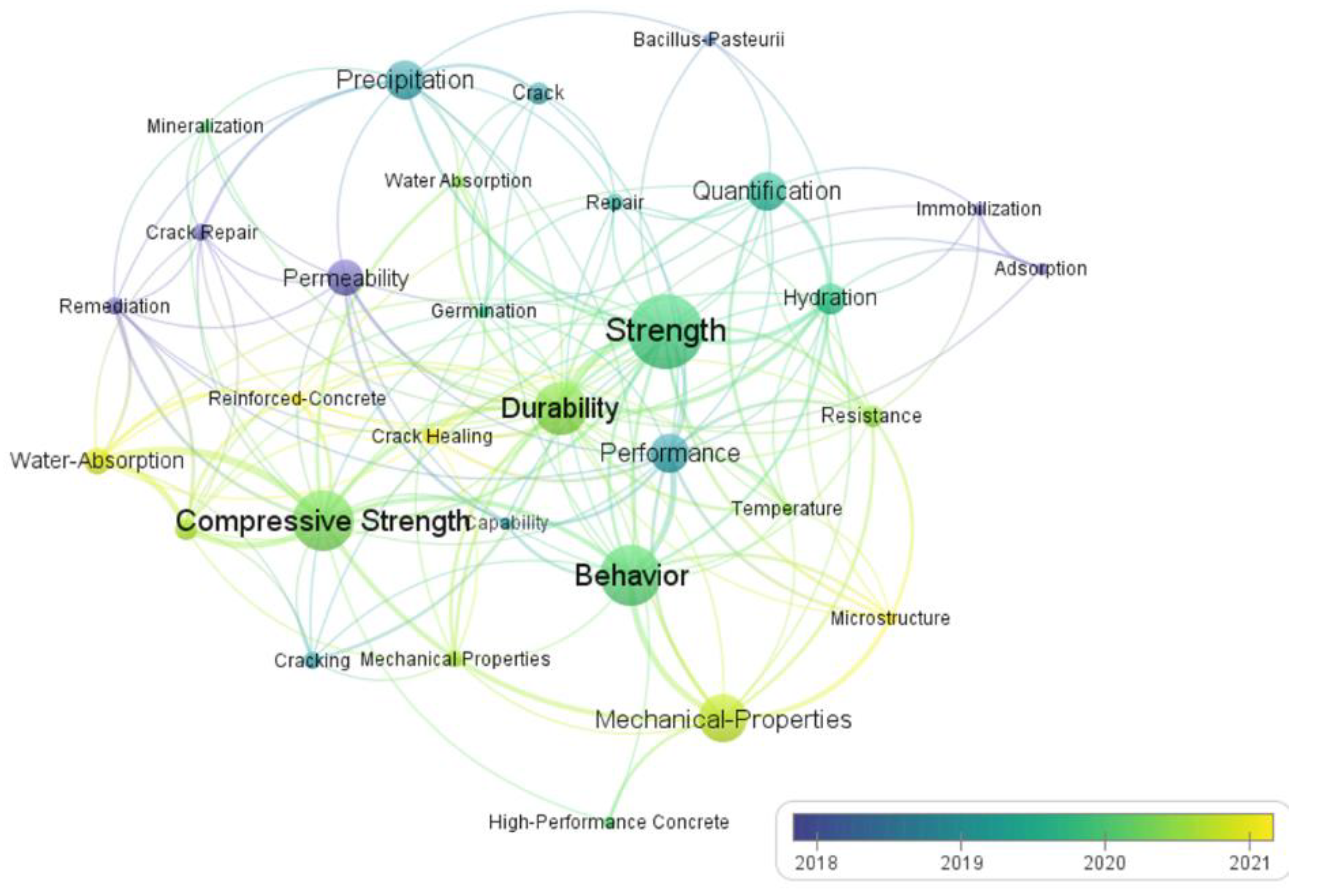

:1. Introduction

2. Components and Mechanisms of Lightweight Aggregate Self-Healing Concrete

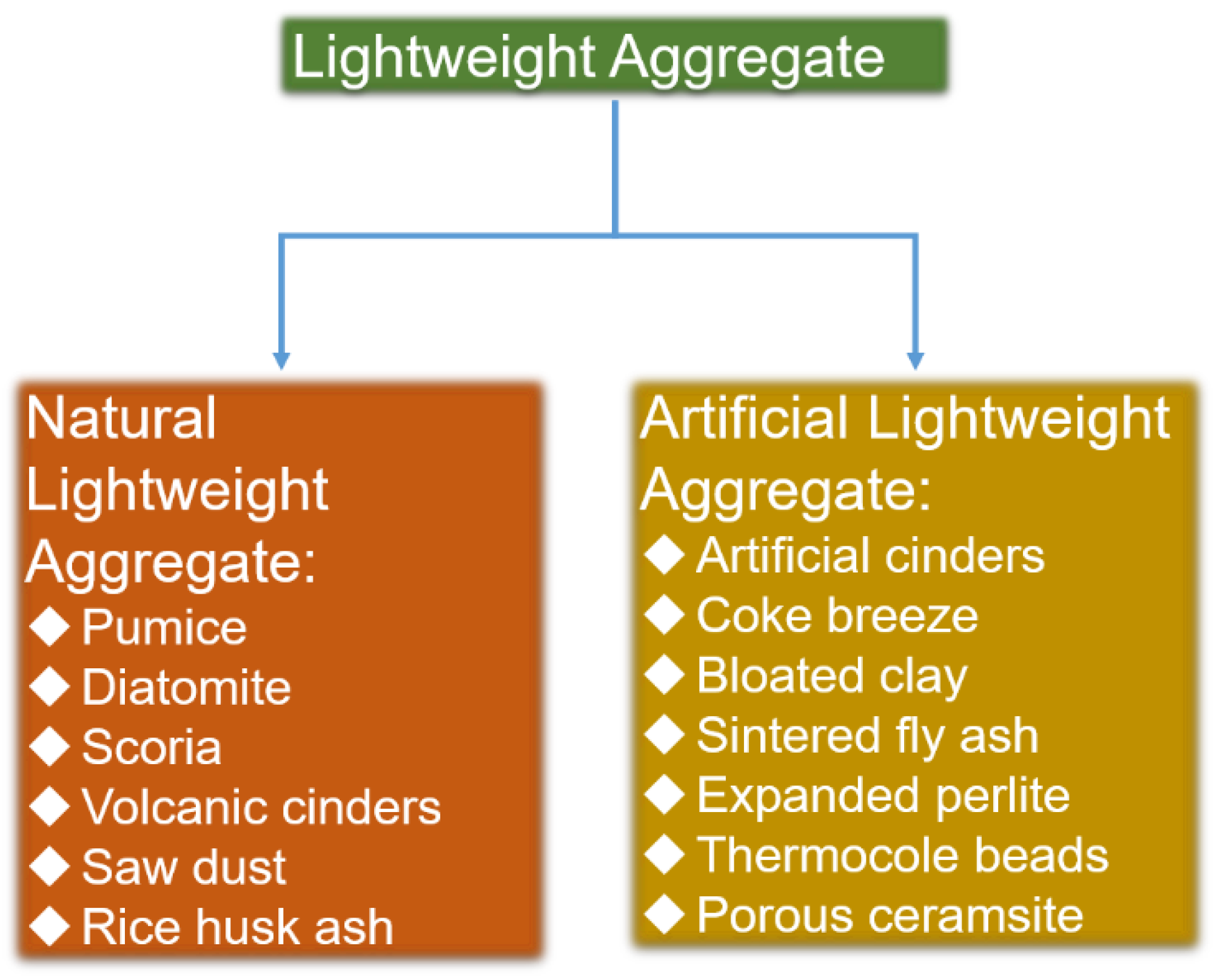

2.1. Lightweight Aggregate

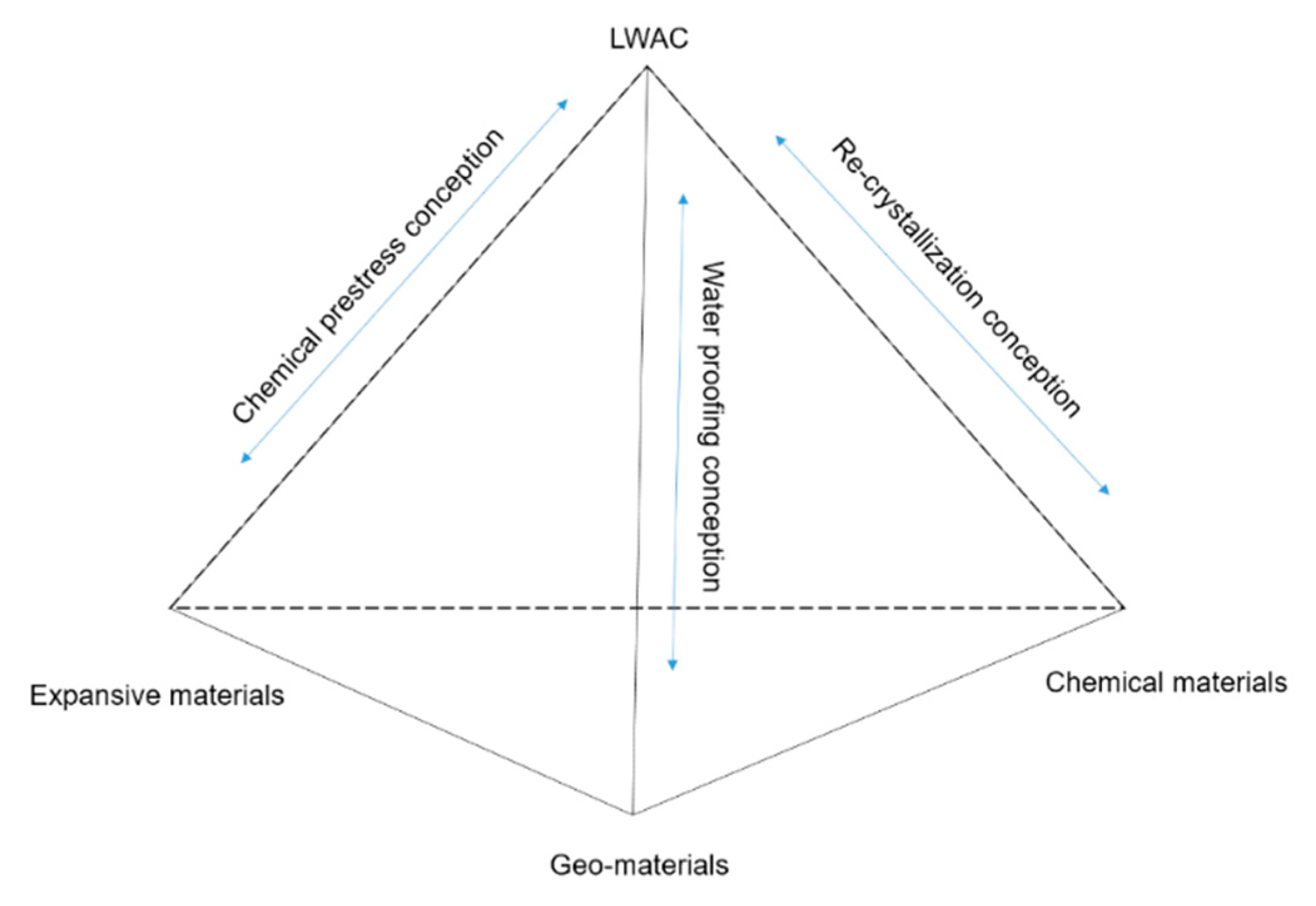

2.2. Chemical Healing Agents + LWA

2.2.1. Water as the Healing Agent

2.2.2. Sodium Silicate as the Healing Agent

2.2.3. Sodium Carbonate as the Healing Agent

2.3. Biological Healing Agents + LWA

2.3.1. Different Lightweight Aggregates

2.3.2. Different Microorganisms

3. Performance of Lightweight Aggregate Self-Healing Concrete

3.1. Workability

3.2. Crack Closure

3.3. Mechanical Properties

3.4. Durability

4. Theoretical Prediction of the Healing Behavior of Lightweight Aggregate Self-Healing Concrete

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, W.; Zheng, Q.F.; Ashraf, A.; Han, B.G. Self-healing cement concrete composites for resilient infrastructures: A review. Compos. Part B-Eng. 2020, 189, 107892. [Google Scholar] [CrossRef]

- Mashkoor, F.; Lee, S.J.; Yi, H.; Noh, S.M.; Jeong, C. Self-healing materials for electronics applications. Int. J. Mol. Sci. 2022, 23, 622. [Google Scholar] [CrossRef]

- Yin, P.F.; Liu, Y.; Huang, D.; Zhang, C. Highly tough, stretchable and self-healing polyampholyte elastomers with dual adhesiveness. Int. J. Mol. Sci. 2022, 23, 4548. [Google Scholar] [CrossRef]

- Utrera-Barrios, S.; Verdejo, R.; López-Manchado, M.; Santana, M.H. The final frontier of sustainable materials: Current developments in self-healing elastomers. Int. J. Mol. Sci. 2022, 23, 4757. [Google Scholar] [CrossRef]

- Zhou, S.; Jia, Y.; Wang, C. Global sensitivity analysis for the polymeric microcapsules in self-healing cementitious composites. Polymers 2020, 12, 2990. [Google Scholar] [CrossRef]

- Olivieri, C.; Angelillo, M.; Gesualdo, A.; Iannuzzo, A.; Fortunato, A. Parametric design of purely compressed shells. Mech. Mater. 2021, 155, 103782. [Google Scholar] [CrossRef]

- Deshpande, Y.S.; Hiller, J.E. Pore characterization of manufactured aggregates: Recycled concrete aggregates and lightweight aggregates. Mater. Struct. 2012, 45, 67–79. [Google Scholar] [CrossRef]

- Xiong, G.Q.; Wang, C.; Zhou, S.; Jia, X.L.; Luo, W.; Liu, J.; Peng, X. Preparation of high strength lightweight aggregate concrete with the vibration mixing process. Constr. Build. Mater. 2019, 229, 116936. [Google Scholar] [CrossRef]

- Elango, K.; Sanfeer, J.; Gopi, R.; Shalini, A.; Saravanakumar, R.; Prabhu, L. Properties of light weight concrete—A state of the art review. Mater. Today Proc. 2021, 46, 4059–4062. [Google Scholar] [CrossRef]

- Melby, K. Long-span bridges in Norway constructed in high-strength LWA concrete. Eng. Struct. 1996, 18, 845–849. [Google Scholar] [CrossRef]

- Pati, P.K.; Sahu, S.K. Structural performance of concrete containing fly ash based lightweight angular aggregates. Adv. Concr. Constr. 2022, 13, 291–305. [Google Scholar]

- Stuckrath, C.; Serpell, R.; Valenzuela, L.M.; Lopez, M. Quantification of chemical and biological calcium carbonate precipitation: Performance of self-healing in reinforced mortar containing chemical admixtures. Cem. Concr. Comp. 2014, 50, 10–15. [Google Scholar] [CrossRef]

- Wang, X.; Chen, S.; Yang, Z.; Ren, J.; Zhang, X.; Xing, F. Self-healing concrete incorporating mineral additives and encapsulated lightweight aggregates: Preparation and application. Constr. Build. Mater. 2021, 301, 124119. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Wang, R.W.; Ding, Z. Influence of crystalline admixtures and their synergetic combinations with other constituents on autonomous healing in cracked concrete—A Review. Materials 2022, 15, 440. [Google Scholar] [CrossRef]

- Huynh, N.N.T.; Imamoto, K.; Kiyohara, C. A study on biomineralization using bacillus subtilis natto for repeatability of self-Healing concrete and strength improvement. J. Adv. Concr. Technol. 2020, 17, 700–714. [Google Scholar] [CrossRef] [Green Version]

- Yu, K.Q.; Zhu, H.; Hou, M.J.; Li, V.C. Self-healing of PE-fiber reinforced lightweight high-strength engineered cementitious composite. Cem. Concr. Comp. 2021, 123, 104209. [Google Scholar] [CrossRef]

- Zhan, Q.; Zhou, J.; Wang, S.; Su, Y.; Liu, B.; Yu, X.; Pan, Z.; Qian, C. Crack self-healing of cement-based materials by microorganisms immobilized in expanded vermiculite. Constr. Build. Mater. 2021, 272, 121610. [Google Scholar] [CrossRef]

- Su, Y.F.; Huang, C.H.; Jeong, H.; Nantung, T.; Olek, J.; Baah, P.; Lu, N. Autogenous healing performance of internal curing agent-based self-healing cementitious composite. Cem. Concr. Compos. 2020, 114, 103825. [Google Scholar] [CrossRef]

- Wang, X.; Yang, Z.; Fang, C.; Wang, W.; Liu, J.; Xing, F. Effect of carbonate-containing self-healing system on properties of a cementitious composite: Fresh, mechanical, and durability properties. Constr. Build. Mater. 2020, 235, 117442. [Google Scholar] [CrossRef]

- Alghamri, R.; Kanellopoulos, A.; A-Tabbaa, A. Impregnation and encapsulation of lightweight aggregates for self-healing concrete. Constr. Build. Mater. 2016, 124, 910–921. [Google Scholar] [CrossRef]

- Rashid, M.; Haq, E.U.; Yousaf, S.; Javed, M.; Nadeem, M.; Aziz, U.; Abbas, A.Q. Light weight low thermal conductive fly ash foams through microwave irradiation for insulative, agricultural and self-healing purposes. Mater. Today Proc. 2021, 47, S38–S45. [Google Scholar] [CrossRef]

- Erşan, Y.Ç.; Da Silva, F.B.; Boon, N.; Verstraete, W.; De Belie, N. Screening of bacteria and concrete compatible protection materials. Constr. Build. Mater. 2015, 88, 196–203. [Google Scholar] [CrossRef]

- Khan, M.B.E.; Shen, L.M.; Dias-da-Costa, D. Crack healing performance of bacteria-based mortar under sustained tensile loading in marine environment. Cem. Concr. Comp. 2021, 120, 104055. [Google Scholar] [CrossRef]

- Zhang, L.V.; Suleiman, A.R.; Allaf, M.M.; Marani, A.; Tuyan, M.; Nehdi, M.L. Crack self-healing in alkali-activated slag composites incorporating immobilized bacteria. Constr. Build. Mater. 2022, 326, 126842. [Google Scholar] [CrossRef]

- Xu, J.; Wang, X.Z.; Zuo, J.Q.; Liu, X.Y. Self-healing of concrete cracks by ceramsite-loaded microorganisms. J. Mater. Civ. Eng. 2018, 2018, 5153041. [Google Scholar] [CrossRef] [Green Version]

- Dembovska, L.; Bajare, D.; Korjakins, A.; Toma, D.; Jakubovica, E. Preliminary research for long lasting self-healing effect of bacteria-based concrete with lightweight aggregates. IOP Conf. Ser. Mater. Sci. Eng. 2019, 660, 012034. [Google Scholar] [CrossRef]

- Tziviloglou, E.; Pan, Z.C.; Jonkers, H.M.; Schlangen, E. Bio-based self-healing mortar: An experimental and numerical study. J. Adv. Concr. Technol. 2017, 15, 536–543. [Google Scholar] [CrossRef] [Green Version]

- Han, S.; Choi, E.K.; Park, W.; Yi, C.; Chung, N. Effectiveness of expanded clay as a bacteria carrier for self-healing concrete. Appl. Biol. Chem. 2019, 62, 19. [Google Scholar] [CrossRef]

- Saridhe, S.P.; Selvaraj, T. Microbial precipitation of calcium carbonate in cementitious materials—A critical review. Mater. Today Proc. 2021, 43, 1232–1240. [Google Scholar] [CrossRef]

- Gilford, J.; Hassan, M.M.; Rupnow, T.; Barbato, M.; Okeil, A.M.; Asadi, S. Dicyclopentadiene and sodium silicate microencapsulation for self-Healing of concrete. J. Mater. Civ. Eng. 2014, 26, 886–896. [Google Scholar] [CrossRef]

- Kanellopoulos, A.; Qureshi, T.S.; Al-Tabbaa, A. Glass encapsulated minerals for self-healing in cement based composites. Constr. Build. Mater. 2015, 98, 780–791. [Google Scholar] [CrossRef]

- Han, S.; Jang, I.; Choi, E.K.; Park, W.; Yi, C.; Chung, N. Bacterial self-healing performance of coated expanded clay in concrete. J. Environ. Eng. 2020, 146, 04020072. [Google Scholar] [CrossRef]

- Balam, N.H.; Mostofinejad, D.; Eftekhar, M. Effects of bacterial remediation on compressive strength, water absorption, and chloride permeability of lightweight aggregate concrete. Constr. Build. Mater. 2017, 145, 107–116. [Google Scholar] [CrossRef]

- Fu, Q.; Wu, Y.; Liu, S.; Lu, L.; Wang, J. The adaptability of Sporosarcina pasteurii in marine environments and the feasibility of its application in mortar crack repair. Constr. Build. Mater. 2022, 332, 127371. [Google Scholar] [CrossRef]

- Salehi, P.; Dabbagh, H.; Ashengroph, M. Effects of microbial strains on the mechanical and durability properties of lightweight concrete reinforced with polypropylene fiber. Constr. Build. Mater. 2022, 322, 126519. [Google Scholar] [CrossRef]

- Meng, H.N.; Lu, X.J.; Hussain, S.; Shaheen, A.; Liu, G. Self-healing behaviors of core-shell-structured microcapsules cement-based materials immobilized with microbes by expanded perlite. J. Nanoelectron. Optoe. 2022, 16, 1828–1833. [Google Scholar]

- Wiktor, V.; Jonkers, H.M. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Comp. 2011, 33, 763–770. [Google Scholar] [CrossRef]

- Wiktor, V.; Jonkers, H.M. Determination of the crack self-healing capacity of bacterial concrete. Concr. Solut. 2012, 331–334. [Google Scholar] [CrossRef]

- Huynh, N.N.T.; Phuong, N.M.; Toan, N.P.A.; Son, N.K. Bacillus subtilis HU58 immobilized in micropores of diatomite for using in self-healing concrete. Procedia Eng. 2017, 171, 598–605. [Google Scholar] [CrossRef]

- Yazici, S.; Ayekin, B.; Mardani-Aghabaglou, A.; Guller, C. Assessment of mechanical properties of steel fiber reinforced mortar mixtures containing lightweight aggregates improved by bacteria. J. Sustain. Cem.-Based Mater. 2022, 1–19. [Google Scholar] [CrossRef]

- Chen, H.J.; Peng, C.F.; Tang, C.W.; Chen, Y.T. Self-healing concrete by biological substrate. Materials 2020, 12, 4099. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, J.; Tang, Y.H.; Wang, X.Z.; Wang, Z.P.; Yao, W. Application of ureolysis-based microbial CaCO3 precipitation in self-healing of concrete and inhibition of reinforcement corrosion. Constr. Build. Mater. 2020, 265, 120364. [Google Scholar] [CrossRef]

- Su, Y.L.; Li, F.; He, Z.Q.; Qian, C.X. Artificial aggregates could be a potential way to realize microbial self-healing concrete: An example based on modified ceramsite. J. Build. Eng. 2021, 35, 102082. [Google Scholar] [CrossRef]

- Chen, H.C.; Qian, C.X.; Huang, H.L. Self-healing cementitious materials based on bacteria and nutrients immobilized respectively. Constr. Build. Mater. 2016, 126, 297–303. [Google Scholar] [CrossRef]

- Rooij, M.D.; Tittelboom, K.V.; Belie, N.D.; Schlangen, E. State-of-the-art report of RILEM technical committee 221-SHC. In Self-Healing Phenomena in Cement-Based Materials; Springer: Dordrecht, The Netherlands, 2013. [Google Scholar]

- Li, V.C.; Yang, E. Self-healing in concrete materials. In Selfhealing Materials: An Alternative Approach to 20 Centuries of Materials Science; van der Zwaag, S., Ed.; Springer: Dordrecht, The Netherlands, 2007. [Google Scholar]

- De Belie, N.; Gruyaert, E.; Al-Tabbaa, A.; Antonaci, P.; Baera, C.; Bajare, D.; Darquennes, A.; Davies, R.; Ferrara, L.; Jefferson, T.; et al. A review of self-healing concrete for damage management of structures. Adv. Mater. Interfaces 2018, 5, 1800074. [Google Scholar] [CrossRef]

- Park, S.M.; Seo, J.H.; Lee, H.K. Thermal evolution of hydrates in carbonation-cured Portland cement. Mater. Struct. 2018, 51, 7. [Google Scholar] [CrossRef]

- Ahn, T.H.; Kishi, T. Crack self-healing behavior of cementitious composites incorporating various mineral admixtures. J. Adv. Concr. Technol. 2010, 8, 171–186. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.H. Experimental Study on Self-Healing Cement-Based Materials Based on Encapsulated Lightweight Aggregate-Admixture System. Master’s Thesis, Shenzhen University, Shenzhen, China, 2020. [Google Scholar]

- Yildirim, G.; Khiavi, A.H.; Yesilmen, S.; Sahmaran, M. Self-healing performance of aged cementitious composites. Cem. Concr. Compos. 2018, 87, 172–186. [Google Scholar] [CrossRef]

- Tomczak, K.; Jakubowski, J. The effects of age, cement content, and healing time on the self-healing ability of high-strength concrete. Constr. Build. Mater. 2018, 187, 149–159. [Google Scholar] [CrossRef]

- Huang, L.M.; Yu, L.; Zhang, H.; Yang, Z.H. Composition and microstructure of 50-year lightweight aggregate concrete (LWAC) from Nanjing Yangtze River bridge (NYRB). Constr. Build. Mater. 2019, 216, 390–404. [Google Scholar] [CrossRef]

- Bundur, Z.B.; Kirisits, M.J.; Ferron, R.D. Use of pre-wetted lightweight fine expanded shale aggregates as internal nutrient reservoirs for microorganisms in bio-mineralized mortar. Cem. Concr. Compos. 2017, 84, 167–174. [Google Scholar] [CrossRef]

- Sani, A.K.; Olawoore, I.O.; Singh, R.M. Assessment of impregnating phase change materials into lightweight aggregates for development of thermal energy storage aggregate composites. Constr. Build. Mater. 2021, 305, 124683. [Google Scholar] [CrossRef]

- Kheradmand, M.; Castro-Gomes, J.; Azenha, M.; Silva, P.D.; de Aguiar, J.L.B.; Zoorob, S.E. Assessing the feasibility of impregnating phase change materials in lightweight aggregate for development of thermal energy storage systems. Constr. Build. Mater. 2015, 89, 48–59. [Google Scholar] [CrossRef] [Green Version]

- Mostavi, E.; Asadi, S.; Hassan, M.M.; Alansari, M. Evaluation of self-healing mechanisms in concrete with double-walled sodium silicate microcapsules. J. Mater. Civ. Eng. 2015, 27, 04015035. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G.; Leung, C.; Wan, K.T. Application of Sodium Silicate Solution as Self-Healing Agent in Cementitious Materials. In Proceedings of the International RILEM Conference on Advances in Construction Materials through Science and Engineering, Hong Kong, China, 5 September 2011; pp. 530–536. [Google Scholar]

- Wang, Y.; Lin, Z.; Tang, C.; Hao, W. Influencing factors on the healing performance of microcapsule self-healing concrete. Materials 2021, 14, 4139. [Google Scholar] [CrossRef] [PubMed]

- Nakarai, K.; Shibata, M.; Sakamoto, H.; Owada, H.; Kosakowski, G. Calcite precipitation at cement-bentonite interface. Part 1: Effect of carbonate admixture in bentonite. J. Adv. Concr. Technol. 2021, 19, 433–446. [Google Scholar] [CrossRef]

- Yang, Z.H.; Gao, S.S.; Yu, L.; Li, T.T. Effect of curing temperature on migration of water from ceramsite to cement paste. J. Build. Mater. 2019, 23, 138–144. [Google Scholar]

- Roy, R.; Rossi, E.; Silfwerbrand, J.; Jonkers, H. Encapsulation techniques and test methods of evaluating the bacteria-based self-healing efficiency of concrete: A literature review. Nord. Concr. Res. 2020, 62, 63–85. [Google Scholar] [CrossRef]

- Anbu, P.; Kang, C.H.; Shin, Y.J.; So, J.S. Formations of calcium carbonate minerals by bacteria and its multiple applications. SpringerPlus 2016, 5, 250. [Google Scholar] [CrossRef] [Green Version]

- Alazhari, M.; Sharma, T.; Heath, A.; Cooper, R.; Paine, K. Application of expanded perlite encapsulated bacteria and growth media for self-healing concrete. Constr. Build. Mater. 2018, 160, 610–619. [Google Scholar] [CrossRef]

- Chu, J.; Stabnikov, V.; Ivanov, V. Microbially induced calcium carbonate precipitation on surface or in the bulk of soil. Geomicrobiol. J. 2012, 29, 544–549. [Google Scholar] [CrossRef]

- Jonkers, H.M.; Thijssen, A.; Muyzer, G.; Copuroglu, O.; Schlangena, E. Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol. Eng. 2010, 36, 230–235. [Google Scholar] [CrossRef]

- Nielsen, S.D.; Koren, K.; Löbmann, K.; Hinge, M.; Scoma, A.; Kjeldsen, K.U.; Røy, H. Constraints on CaCO3 precipitation in superabsorbent polymer by aerobic bacteria. Appl. Microbiol. Biot. 2020, 104, 365–375. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Bundur, Z.B.; Mondal, P.; Ferron, R.D. Use of biomineralisation in developing smart concrete inspired by nature. Int. J. Mater. Struct. Integr. 2015, 9, 39–60. [Google Scholar] [CrossRef]

- Bundur, Z.B.; Kirisits, M.J.; Ferron, R.D. Biomineralized cement-based materials: Impact of inoculating vegetative bacterial cells on hydration and strength. Cem. Concr. Res. 2015, 67, 237–245. [Google Scholar] [CrossRef]

- Buchanan, R.E.; Gibbons, N.E. Bergey’s Manual of Determinative Bacteriology, 8th ed.; The Williams& Wilkin Company: Baltimore, MD, USA, 1974. [Google Scholar]

- Jiang, L.; Jia, G.H.; Jiang, C.; Li, Z. Sugar-coated expanded perlite as a bacterial carrier for crack-healing concrete applications. Constr. Build. Mater. 2020, 232, 117222. [Google Scholar] [CrossRef]

- Purohit, R.; Gupta, N.K.; Purohit, M.R.; Patil, A.; Bharilya, R.; Singh, S.K. An Investigation on manufacturing of self-healing materials. Mater. Today Proc. 2016, 2, 3371–3377. [Google Scholar] [CrossRef]

- Singh, P.; Kaur, I.; Singh, N. A review of different bacteria carriers used in self-healing mechanism. Mater. Today Proc. 2020, 32, 955–960. [Google Scholar] [CrossRef]

- Wang, J.Y.; Snoeck, D.; Van Vlierberghe, S.; Verstraete, W.; De Belie, N. Application of hydrogel encapsulated carbonate precipitating bacteria for approaching a realistic self-healing in concrete. Constr. Build. Mater. 2014, 68, 110–119. [Google Scholar] [CrossRef]

- Pungrasmi, W.; Intarasoontron, J.; Jongvivatsakul, P.; Likitlersuang, S. Evaluation of microencapsulation techniques for MICP bacterial spores applied in self-healing concrete. Sci. Rep. 2019, 9, 12484. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zamani, M.; Nikafshar, S.; Mousa, A.; Behnia, A. Bacteria encapsulation using synthesized polyurea for self-healing of cement paste. Constr. Build. Mater. 2020, 249, 118556. [Google Scholar] [CrossRef]

- Ayati, B.; Ferrandiz-Mas, V.; Newport, D.; Cheeseman, C. Use of clay in the manufacture of lightweight aggregate. Constr. Build. Mater. 2008, 162, 124–131. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, C.; Zhou, A.; Yang, C.; Zhao, L.; Li, Z. Aragonite formation induced by open cultures of microbial consortia to heal cracks in concrete: Insights into healing mechanisms and crystal polymorphs. Constr. Build. Mater. 2019, 224, 815–822. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Y.; Feng, T.; Zhou, M.; Zhao, L.; Zhou, A.; Li, Z. Immobilizing bacteria in expanded perlite for the crack self-healing in concrete. Constr. Build. Mater. 2017, 148, 610–617. [Google Scholar] [CrossRef]

- Junusmin, K.I.; Manurung, B.S.; Darmayati, Y. Bioremediation of oil-contaminated sediment by hydrocarbonoclastic bacterial consortium immobilized in different types of carrier. In Proceedings of the 5th International Symposium on Applied Chemistry 2019, Tangerang, Indonesia, 23–24 October 2019; Volume 2175, p. 020056. [Google Scholar]

- Wang, J.Y.; De Belie, N.; Verstraete, W. Diatomaceous earth as a protective vehicle for bacteria applied for self-healing concrete. J. Ind. Microbiol. Biotechnol. 2013, 39, 567–577. [Google Scholar] [CrossRef] [PubMed]

- Kalinowska-Wichrowska, K.; Pawluczuk, E.; Bołtryk, M.; Nietupski, A. Geopolymer concrete with lightweight artificial aggregates. Materials 2022, 15, 3012. [Google Scholar] [CrossRef] [PubMed]

- Wasim, K.H.; Basit, E.M. Crack healing in concrete using various bio influenced self-healing techniques. Constr. Build. Mater. 2016, 102, 349–357. [Google Scholar]

- Domagala, L.; Podolska, A. Effect of lightweight aggregate impregnation on selected concrete properties. Materials 2022, 15, 198. [Google Scholar] [CrossRef]

- Chaurasia, L.; Bisht, V.; Singh, L.P.; Gupta, S. A novel approach of biomineralization for improving micro and macro-properties of concrete. Constr. Build. Mater. 2019, 195, 340–351. [Google Scholar] [CrossRef]

- Kim, H.; Son, H.M.; Park, S.; Lee, H.K. Effects of biological admixtures on hydration and mechanical properties of Portland cement paste. Constr. Build. Mater. 2020, 235, 117461. [Google Scholar] [CrossRef]

- Wang, X. Investigation of Effect of Sodium Carbonate on Properties of Alkali Activated Slag Cement. Master’s Thesis, Chongqing University, Chongqing, China, 2016. [Google Scholar]

- Luo, M.; Bai, J.Q.; Jing, K.; Ding, Z.Q.; Yang, D.Y.; Qian, C.X. Self-healing of early-age cracks in cement mortars with artificial functional aggregates. Constr. Build. Mater. 2021, 272, 121846. [Google Scholar] [CrossRef]

- Wang, X.; Fang, C.; Kuang, W.; Li, D.; Han, N.; Xing, F. Experimental study on early cracking sensitivity of lightweight aggregate concrete. Constr. Build. Mater. 2017, 136, 173–183. [Google Scholar] [CrossRef]

- Muhammad, N.Z.; Shafaghat, A.; Keyvanfar, A.; Majid, M.Z.A.; Ghoshal, S.K.; Yasouj, S.E.M.; Ganiyu, A.A.; Kouchaksaraei, M.S.; Kamyab, H.; Taheri, M.M.; et al. Tests and methods of evaluating the self-healing efficiency of concrete: A review. Constr. Build. Mater. 2016, 112, 1123–1132. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; Gruyaert, E.; Rahier, H.; De Belie, N. Influence of mix composition on the extent of autogenous crack healing by continued hydration or calcium carbonate formation. Constr. Build. Mater. 2012, 37, 349–359. [Google Scholar] [CrossRef]

- Palin, D.; Wiktor, V.; Jonkers, H.M. Autogenous healing of marine exposed concrete: Characterization and quantification through visual crack closure. Cem. Concr. Res. 2015, 73, 17–24. [Google Scholar] [CrossRef]

- Anand, K.; Goyal, S.; Reddy, M.S. Crack healing in concrete by microbially induced calcium carbonate precipitation as assessed through electromechanical impedance technique. Eur. J. Environ. Civ. Eng. 2022, 20, 411–418. [Google Scholar] [CrossRef]

- Maurya, K.K.; Sonker, T.; Rawat, A. Sustainable concrete construction by microorganism and monitoring using EMI technique: A review. Mater. Today Proc. 2020, 32, 670–676. [Google Scholar] [CrossRef]

- Grino, A.A.; Daly, M.K.M.; Ongpeng, J.M.C. Bio-influenced self-healing mechanism in concrete and its testing: A Review. Appl. Sci. 2020, 10, 5161. [Google Scholar] [CrossRef]

- Tziviloglou, E.; Wiktor, V.; Jonkers, H.M.; Schlangen, E. Bacteria-based self-healing concrete to increase liquid tightness of cracks. Constr. Build. Mater. 2016, 112, 118–125. [Google Scholar] [CrossRef]

- Mediyanto, A.; Safitri, E.; Wibowo; Widagdo, J.B.I.S. The minimum water curing recovery time after burning of aluminium fiber light weight concrete (with alwa as coarse aggregate) modulus elasticity. AIP Conf. Proc. 2019, 2114, 030018. [Google Scholar]

- Ji, T.; Zheng, D.-D.; Chen, X.-F.; Lin, X.-J.; Wu, H.-C. Effect of prewetting degree of ceramsite on the early-age autogenous shrinkage of lightweight aggregate concrete. Constr. Build. Mater. 2015, 98, 102–111. [Google Scholar] [CrossRef]

- Fernandez-Jimenez, A.; Palomo, J.G.; Puertas, F. Alkali-activated slag mortars—mechanical strength behavior. Cem. Concr. Res. 1999, 29, 1313–1321. [Google Scholar] [CrossRef]

- Nodehi, M.; Ozbakkaloglu, T.; Gholampour, A. A systematic review of bacteria-based self-healing concrete: Biomineralization, mechanical, and durability properties. J. Build. Eng. 2022, 49, 104038. [Google Scholar] [CrossRef]

- Nossoni, G.; Hussey, D.; Budziszewski, M. Efficacy of Bacteria Encapsulated Self-Healing Concrete Exposed to Salt Water and Freeze-Thaw Cycling. In Proceedings of the International Concrete Sustainability Conference, Washington, DC, USA, 15–18 May 2016; p. 10. [Google Scholar]

- Zemskov, S.V.; Ahmad, B.; Çopuroğlu, O.; Vermolen, F. Modeling of a self-healing process in blast furnace slag cement exposed to accelerated carbonation. J. Phys. Confer. Seri. 2013, 410, 012088. [Google Scholar] [CrossRef]

- Sisomphon, K.; Copuroglu, O.; Fraaij, A. Application of encapsulated lightweight aggregate impregnated with sodium monofluorophosphate as a self-healing agent in blast furnace slag mortar. Heron 2011, 56, 13–32. [Google Scholar]

- Zhuang, X.Y.; Zhou, S. The prediction of self-healing capacity of bacteria-based concrete using machine learning approaches. CMC-Comput. Mater. Contain. 2019, 59, 57–77. [Google Scholar] [CrossRef]

| Healing Agents | LWA | References |

|---|---|---|

| Bacillus pseudofirmus | Expanded clay | [12] |

| Na2CO3 solution | Porous ceramsite | [13] |

| Bacillus subtilis natto | Expanded clay granules | [15] |

| Paenibacillus mucilaginosus | Expanded vermiculite | [17] |

| Water | Clinoptilolite zeolite particles | [18] |

| Na2CO3 solution | Lightweight clay aggregate | [19] |

| Sodium silicate solution | Expanded clay | [20] |

| Sodium silicate solution | Fly ash-based geopolymer foam | [21] |

| Bacillus sphaericus | Diatomaceous earth, expanded clay, granular activated carbon, metakaolin, zeolite, and air entrainment | [22] |

| Sporosarcina Halophila | Expanded perlite aggregates | [23] |

| Bacterium S. pasteurii | Porous and superlight expanded glass | [24] |

| Alkaliphilic bacteria of the genus Bacillus | Expanded clay granules | [25,26,27] |

| Sporosarcina pasteurii | Expanded shale aggregate | [28] |

| Bacillus psuedofirms | Expanded perlite | [29] |

| Bacillus pseudofirmus | Expanded perlite | [30] |

| Alkaliphilic bacteria of the genus Bacillus | Expanded clay particles | [31] |

| Lysinibacillus boronitolerans | Expanded clay | [32] |

| Sporosarcina pasteurii | Lightweight aggregates of Leca | [33] |

| Sporosarcina pasteurii | Diatomite | [34] |

| Sporosarcina Pasteurii, Bacillus Megateterium, Sporosarcina Ureae, and Bacillus Licheniformis | Leca coarse LWA and Leca fine LWA | [35] |

| Bacillus mucilaginous | Expanded perlite | [36] |

| Bacillus alkalinitrilicus | Expanded clay particles | [37,38] |

| Bacillus subtilis | Diatomite pellet | [39] |

| Bacillus subtilis | Pumice | [40] |

| Sporosarcina pasteurii | Ceramsite particles | [41,42] |

| Bacillus alcalophilus | Modified ceramsite particles | [43] |

| Bacillus mucilaginous | Ceramsite | [44] |

| Microorganisms | Cell Concentration | References |

|---|---|---|

| Alkaliphilic bacteria of the genus Bacillus | 108 spores/L | [26] |

| Sporosarcina pasteurii | 106 cells/mL | [33] |

| Sporosarcina pasteurii | 2.36 × 108 cells/mL | [34] |

| Sporosarcina Pasteurii, Bacillus Megateterium, Sporosarcina Ureae, and Bacillus Licheniformis | 107 cells/mL | [35] |

| Bacillus subtilis | 109 cfu/g | [39] |

| Sporosarcina pasteurii | 109 spores/mL | [42] |

| Bacillus alcalophilus | 1010–1011 cells/mL | [43] |

| Bacillus mucilaginous | 108–109 cells/mL | [44] |

| References | Healing Agents | LWA | Crack Closure Rate | Width of Healed Cracks |

|---|---|---|---|---|

| [12] | Calcium lactate + Bacillus pseudofirmus | Expanded clay | - | 220 μm |

| [13] | Na2CO3 solution | Porous ceramsite | 69.32% | 240 μm |

| [13] | Na2CO3 solution | Porous ceramsite | 60.60% | 240 μm |

| [13] | Na2CO3 solution | Porous ceramsite | 41.74% | 240 μm |

| [13] | Na2CO3 solution | Porous ceramsite | 51.33% | 240 μm |

| [13] | Na2CO3 solution | Porous ceramsite | 64.58% | 240 μm |

| [17] | Paenibacillus mucilaginosus | Expanded vermiculite | 63.51% | 400 μm |

| [17] | Paenibacillus mucilaginosus | Expanded vermiculite | 98.87% | 400 μm |

| [20] | Sodium silicate | Expanded clay | 80% | 300 μm |

| [25] | Alkaliphilic bacteria of the genus Bacillus | Expanded clay granules | 86% | 300 μm |

| [34] | Sporosarcina pasteurii | Diatomite | 80% | 200 μm |

| [36] | Bacillus mucilaginous | Expanded perlite | 98% | 850 μm |

| [37] | Bacillus alkalinitrilicus | Expanded clay particles | 61% | 460 μm |

| [42] | Sporosarcina pasteurii | Ceramsite particles | 90% | 150 μm |

| [44] | Bacillus mucilaginous | Ceramsite | 87.5% | 50 μm |

| [96] | Alkaliphilic bacteria of the genus Bacillus | Expanded clay particles | 98% | 350 μm |

| Healing Agents | LWA | Strength (MPa) | Age | Healing Rate | References |

|---|---|---|---|---|---|

| Na2CO3 solution | Porous ceramsite | 24–25.7 | 3 days | - | [13] |

| Na2CO3 solution | Porous ceramsite | 29.3–30.9 | 7 days | - | [13] |

| Na2CO3 solution | Porous ceramsite | 36.4–38.9 | 14 days | - | [13] |

| Na2CO3 solution | Porous ceramsite | 41.2–43.9 | 28 days | - | [13] |

| Bacillus subtilis natto | Expanded clay | - | 7 days | 40% | [15] |

| Paenibacillus mucilaginosus | expanded vermiculite | 20–43 | 28 days | - | [17] |

| Water | Clinoptilolite zeolite particles | 69.2–80 | 28 days | - | [18] |

| Na2CO3 solution | Lightweight clay aggregate | 31.17–31.50 | 28 days | - | [19] |

| Sodium silicate | Expanded clay | - | 28 days | 16–80% | [20] |

| Diaphorobacter nitroreducens | Diatomaceous earth | 59.9 ± 1.4 | 28 days | - | [22] |

| Diaphorobacter nitroreducens | Expanded clay | 67.8 ± 1.8 | 28 days | - | [22] |

| Bacillus sphaericus | Metakaolin | 19.6 ± 1.1 | 28 days | - | [22] |

| Bacillus sphaericus | Zeolite | 49.0 ± 1.4 | 28 days | - | [22] |

| Bacterium S. pasteurii | Porous and superlight expanded glass | 20–22 | 7 days | - | [24] |

| Bacterium S. pasteurii | Porous and superlight expanded glass | 25–26 | 14 days | - | [24] |

| Bacterium S. pasteurii | Porous and superlight expanded glass | 30–32 | 28 days | - | [24] |

| Alkaliphilic bacteria of the genus Bacillus | Expanded clay granules | - | 28 days | 63% | [25] |

| Alkaliphilic bacteria of the genus Bacillus | Expanded clay aggregates | 21–22 | 28 days | - | [26] |

| Sporosarcina pasteurii | Lightweight aggregates of Leca | 24.70–34.86 | 28 days | - | [33] |

| Sporosarcina pasteurii | Lightweight aggregates of Leca | 24.80–34.53 | 14 days | - | [33] |

| Sporosarcina pasteurii | Lightweight aggregates of Leca | 24.29–40.05 | 90 days | - | [33] |

| Sporosarcina pasteurii | Lightweight aggregates of Leca | 23.91–42.00 | 180 days | - | [33] |

| Sporosarcina pasteurii | Lightweight aggregates of Leca | - | 28 days | 16.5–17.4% | [33] |

| Sporosarcina pasteurii | Lightweight aggregates of Leca | - | 90 days | 21.5% | [33] |

| Sporosarcina pasteurii | Lightweight aggregates of Leca | - | 150 days | 26.4% | [33] |

| Sporosarcina Pasteurii | Leca LWA | - | 28 days | 25.61% | [35] |

| Bacillus Megateterium | Leca LWA | - | 28 days | 20.13% | [35] |

| Sporosarcina Ureae | Leca LWA | - | 28 days | 16.80% | [35] |

| Bacillus Licheniformis | Leca LWA | - | 28 days | 13.98% | [35] |

| Bacillus subtilis | Diatomite pellet | 15 | 1 day | - | [39] |

| Bacillus subtilis | Diatomite pellet | 26 | 3 days | - | [39] |

| Bacillus subtilis | Diatomite pellet | 45 | 28 days | - | [39] |

| Bacillus subtilis | Diatomite pellet | 52 | 60 days | - | [39] |

| Bacillus subtilis | Diatomite pellet | 57 | 90 days | - | [39] |

| Bacillus subtilis | Diatomite pellet | 60 | 365 days | - | [39] |

| Bacillus subtilis | Diatomite pellet | 61 | 730 days | - | [39] |

| Bacillus subtilis | Pumice | 20–32.7 | 3 days | - | [40] |

| Bacillus subtilis | Pumice | 24.3–40.7 | 7 days | - | [40] |

| Bacillus subtilis | Pumice | 30.4–45.4 | 28 days | - | [40] |

| Sporosarcina pasteurii | Expanded shale aggregates | 43–44 | 21 days | - | [54] |

| Sporosarcina pasteurii | Expanded shale aggregates | 45–46 | 49 days | - | [54] |

| Sporosarcina pasteurii | Expanded shale aggregates | 43–44 | 83 days | - | [54] |

| Alkaliphilic bacteria of the genus Bacillus | Expanded clay particles | 25 | 28 days | - | [96] |

| Alkaliphilic bacteria of the genus Bacillus | Expanded clay particles | 22 | 7 d | - | [96] |

| Healing Agents | LWA | Strength (MPa) | Age | Healing Rate | References |

|---|---|---|---|---|---|

| Na2CO3 solution | Porous ceramsite | 5.07 | 3 days | - | [13] |

| Na2CO3 solution | Porous ceramsite | 5.23 | 3 days | - | [13] |

| Na2CO3 solution | Porous ceramsite | 5.5 | 7 days | - | [13] |

| Na2CO3 solution | Porous ceramsite | 5.73 | 7 days | - | [13] |

| Na2CO3 solution | Porous ceramsite | 6.3 | 14 days | - | [13] |

| Na2CO3 solution | Porous ceramsite | 6.57 | 14 days | - | [13] |

| Na2CO3 solution | Porous ceramsite | 6.97 | 28 days | - | [13] |

| Na2CO3 solution | Porous ceramsite | 7.23 | 28 days | - | [13] |

| Paenibacillus mucilaginosus | Expanded vermiculite | 8.1 | 28 days | - | [17] |

| Paenibacillus mucilaginosus | Expanded vermiculite | 7.8 | 28 days | - | [17] |

| Paenibacillus mucilaginosus | Expanded vermiculite | 7.7 | 28 days | - | [17] |

| Paenibacillus mucilaginosus | Expanded vermiculite | 7.5 | 28 days | - | [17] |

| Paenibacillus mucilaginosus | Expanded vermiculite | 7.4 | 28 days | - | [17] |

| Paenibacillus mucilaginosus | Expanded vermiculite | 7.3 | 28 days | - | [17] |

| Na2CO3 solution | Lightweight clay aggregate | 6.15 | 3 days | - | [19] |

| Na2CO3 solution | Lightweight clay aggregate | 6.04 | 3 days | - | [19] |

| Na2CO3 solution | Lightweight clay aggregate | 8.49 | 28 days | - | [19] |

| Na2CO3 solution | Lightweight clay aggregate | 8.62 | 28 days | - | [19] |

| Sodium silicate solution | Expanded clay | - | 28days | 80% | [20] |

| Bacillus subtilis | Diatomite pellet | 4 | 1 day | - | [39] |

| Bacillus subtilis | Diatomite pellet | 5 | 3 days | - | [39] |

| Bacillus subtilis | Diatomite pellet | 5 | 7 days | - | [39] |

| Bacillus subtilis | Diatomite pellet | 6 | 14 days | - | [39] |

| Bacillus subtilis | Diatomite pellet | 7 | 28 days | - | [39] |

| Bacillus subtilis | Diatomite pellet | 8 | 60 days | - | [39] |

| Bacillus subtilis | Diatomite pellet | 8 | 90 days | - | [39] |

| Bacillus subtilis | Diatomite pellet | 9 | 365 days | - | [39] |

| Bacillus subtilis | Diatomite pellet | 9 | 730 days | - | [39] |

| Bacillus subtilis | Pumice | 6.91 | 28 days | - | [40] |

| Bacillus subtilis | Pumice | 7.73 | 28 days | - | [40] |

| Bacillus subtilis | Pumice | 8.67 | 28 days | - | [40] |

| Bacillus subtilis | Pumice | 7.27 | 28 days | - | [40] |

| Bacillus subtilis | Pumice | 7.5 | 28 days | - | [40] |

| Bacillus subtilis | Pumice | 7.27 | 28 days | - | [40] |

| Bacillus subtilis | Pumice | 8.32 | 28 days | - | [40] |

| Bacillus subtilis | Pumice | 8.91 | 28 days | - | [40] |

| Bacillus subtilis | Pumice | 8.09 | 28 days | - | [40] |

| Bacillus subtilis | Pumice | 8.55 | 28 days | - | [40] |

| Sporosarcina pasteurii | Ceramsite particles | - | 120 days | 10% | [42] |

| Sporosarcina pasteurii | Ceramsite particles | - | 120 days | 5% | [42] |

| Sporosarcina pasteurii | Ceramsite particles | - | 120 days | 17% | [42] |

| Bacillus mucilaginous | Ceramsite | - | 28 days | 56% | [44] |

| Bacillus mucilaginous | Ceramsite | - | 28 days | 72% | [44] |

| Alkaliphilic bacteria of the genus Bacillus | Expanded clay particles | 5.5 | 28 days | - | [96] |

| Alkaliphilic bacteria of the genus Bacillus | Expanded clay particles | 5.7 | 7 days | - | [96] |

| Healing Agents | LWA | Strength (MPa) | Age | Healing Rate | References |

|---|---|---|---|---|---|

| Water | Clinoptilolite zeolite particles | 7.54 | 28 days | - | [18] |

| Water | Clinoptilolite zeolite particles | 7.56 | 28 days | - | [18] |

| Water | Clinoptilolite zeolite particles | 7.8 | 28 days | - | [18] |

| Water | Clinoptilolite zeolite particles | 7.7 | 28 days | - | [18] |

| Water | Clinoptilolite zeolite particles | 7.98 | 28 days | - | [18] |

| Water | Clinoptilolite zeolite particles | - | 28 days | 98% | [18] |

| Bacterium S. pasteurii | Porous and superlight expanded glass | 3 | 7 days | - | [24] |

| Bacterium S. pasteurii | Porous and superlight expanded glass | 3.1 | 7 days | - | [24] |

| Bacterium S. pasteurii | Porous and superlight expanded glass | 3.8 | 14 days | - | [24] |

| Bacterium S. pasteurii | Porous and superlight expanded glass | 3.9 | 14 days | - | [24] |

| Bacterium S. pasteurii | Porous and superlight expanded glass | 4.1 | 28 days | - | [24] |

| Bacterium S. pasteurii | Porous and superlight expanded glass | 4.2 | 28 days | - | [24] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, F.; Zhou, S. A Review of Lightweight Self-Healing Concrete. Materials 2022, 15, 7572. https://doi.org/10.3390/ma15217572

Huang F, Zhou S. A Review of Lightweight Self-Healing Concrete. Materials. 2022; 15(21):7572. https://doi.org/10.3390/ma15217572

Chicago/Turabian StyleHuang, Feng, and Shuai Zhou. 2022. "A Review of Lightweight Self-Healing Concrete" Materials 15, no. 21: 7572. https://doi.org/10.3390/ma15217572

APA StyleHuang, F., & Zhou, S. (2022). A Review of Lightweight Self-Healing Concrete. Materials, 15(21), 7572. https://doi.org/10.3390/ma15217572