Study of the Effect of the Use of Asphalt Binders Modified with Polymer Fibres from End-of-Life Tyres (ELT) on the Mechanical Properties of Hot Mix Asphalt at Different Operating Temperatures

Abstract

:1. Introduction

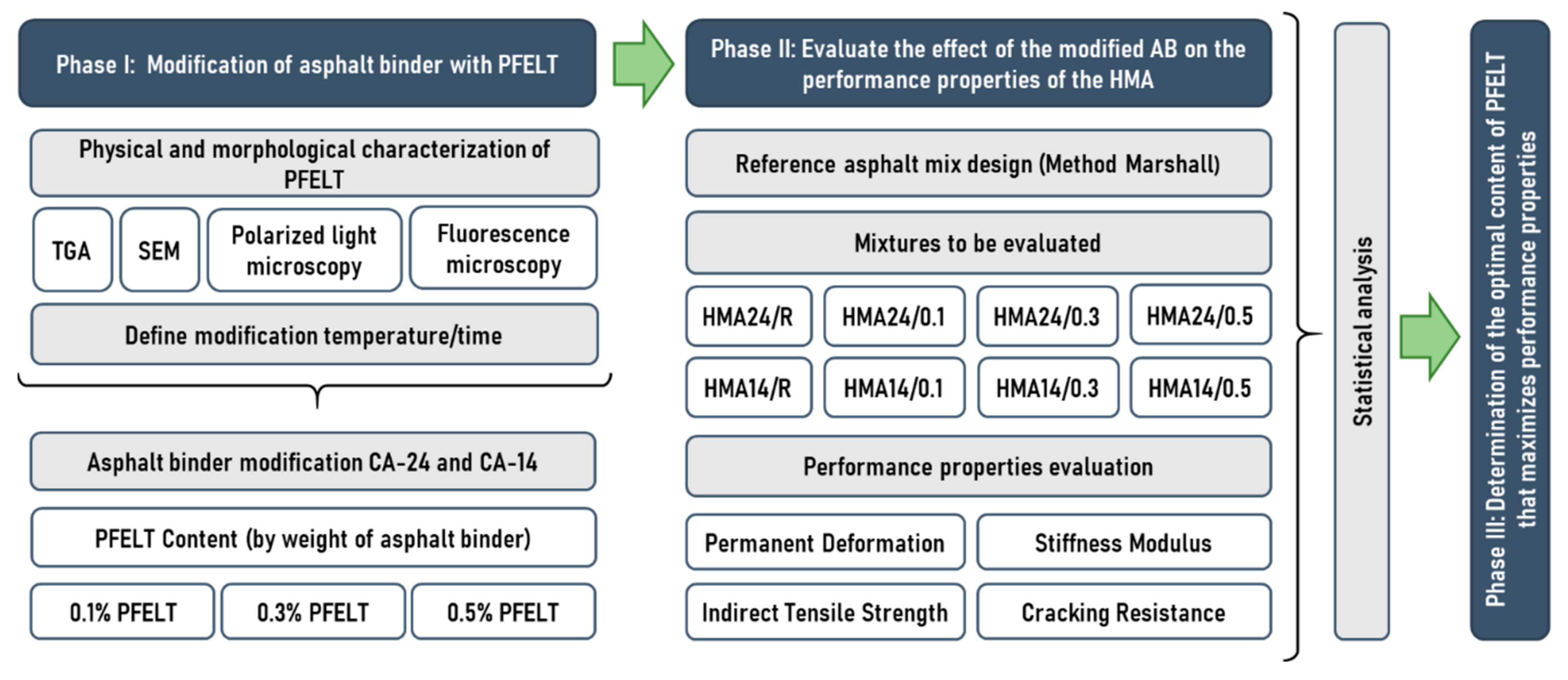

2. Materials and Methods

2.1. Raw Materials

2.1.1. Asphalt Binder Modifier Additive

2.1.2. Asphalt Binder

2.1.3. Stone Aggregates

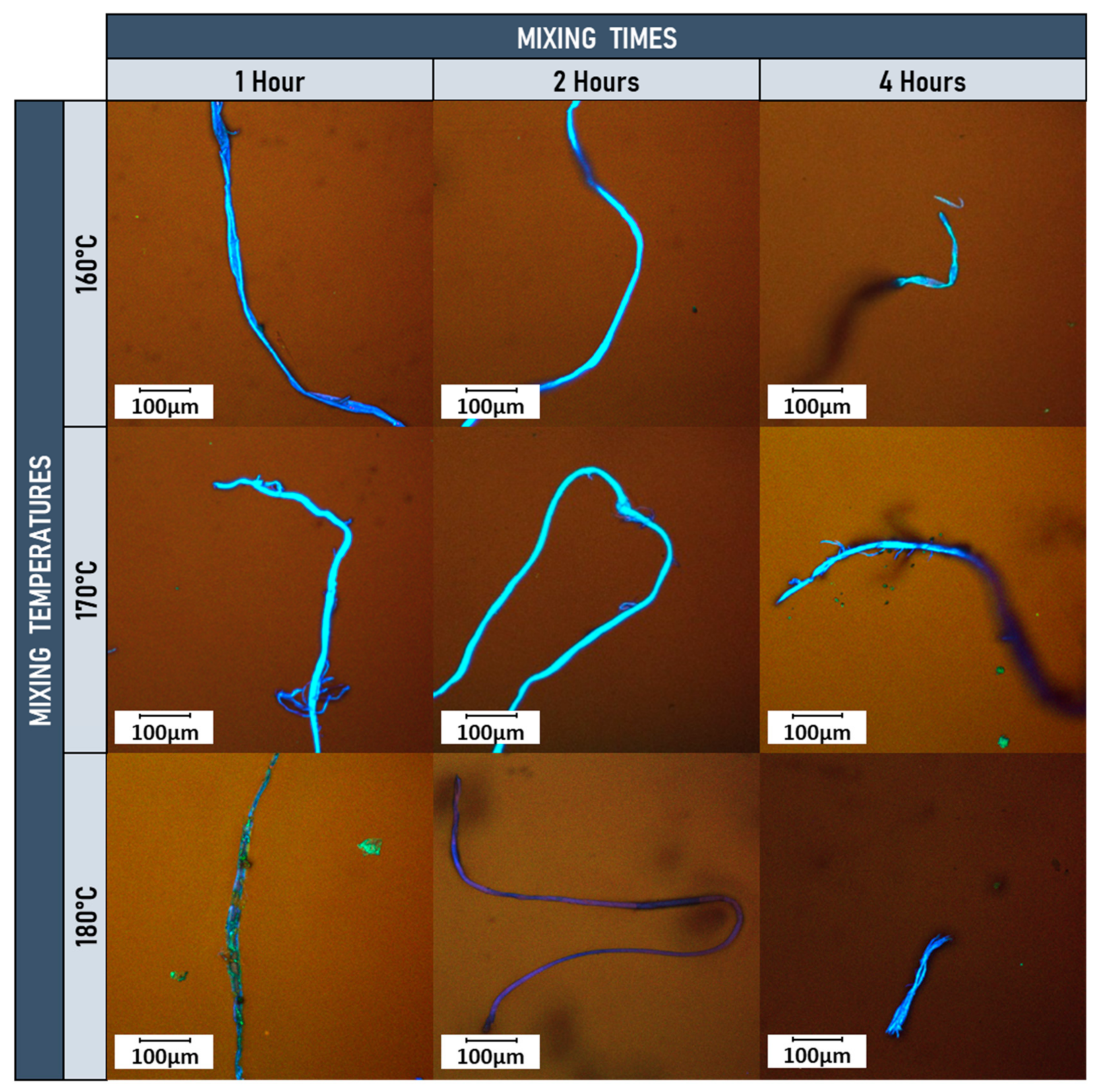

2.2. Modification of Asphalt Binder

2.3. Mix Design

2.4. Testing Methods

2.4.1. Phase I

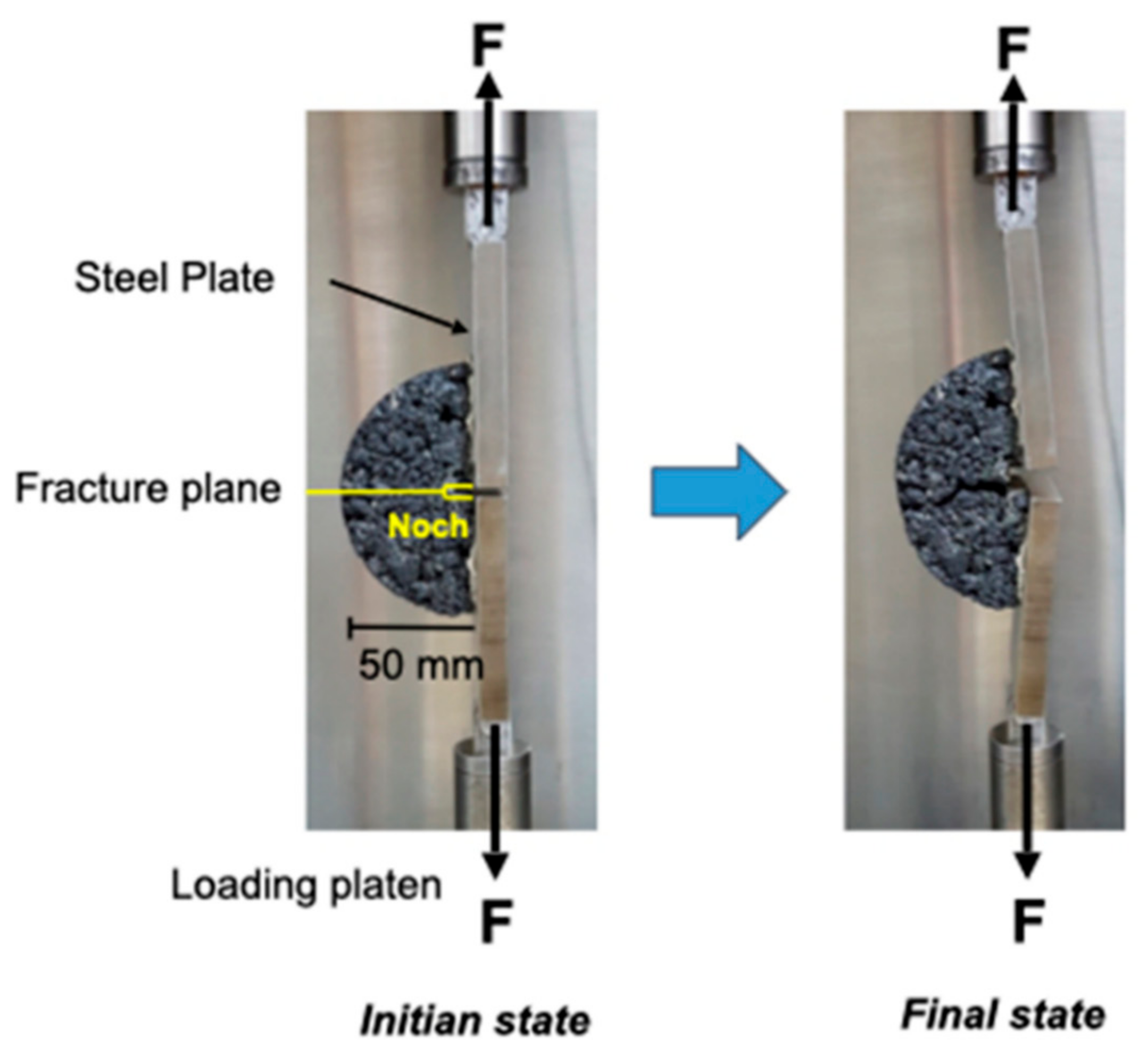

2.4.2. Phase II

2.4.3. Phase III

3. Results and Discussion

3.1. Characterisation of the Addition of Asphalt Binder Modifier

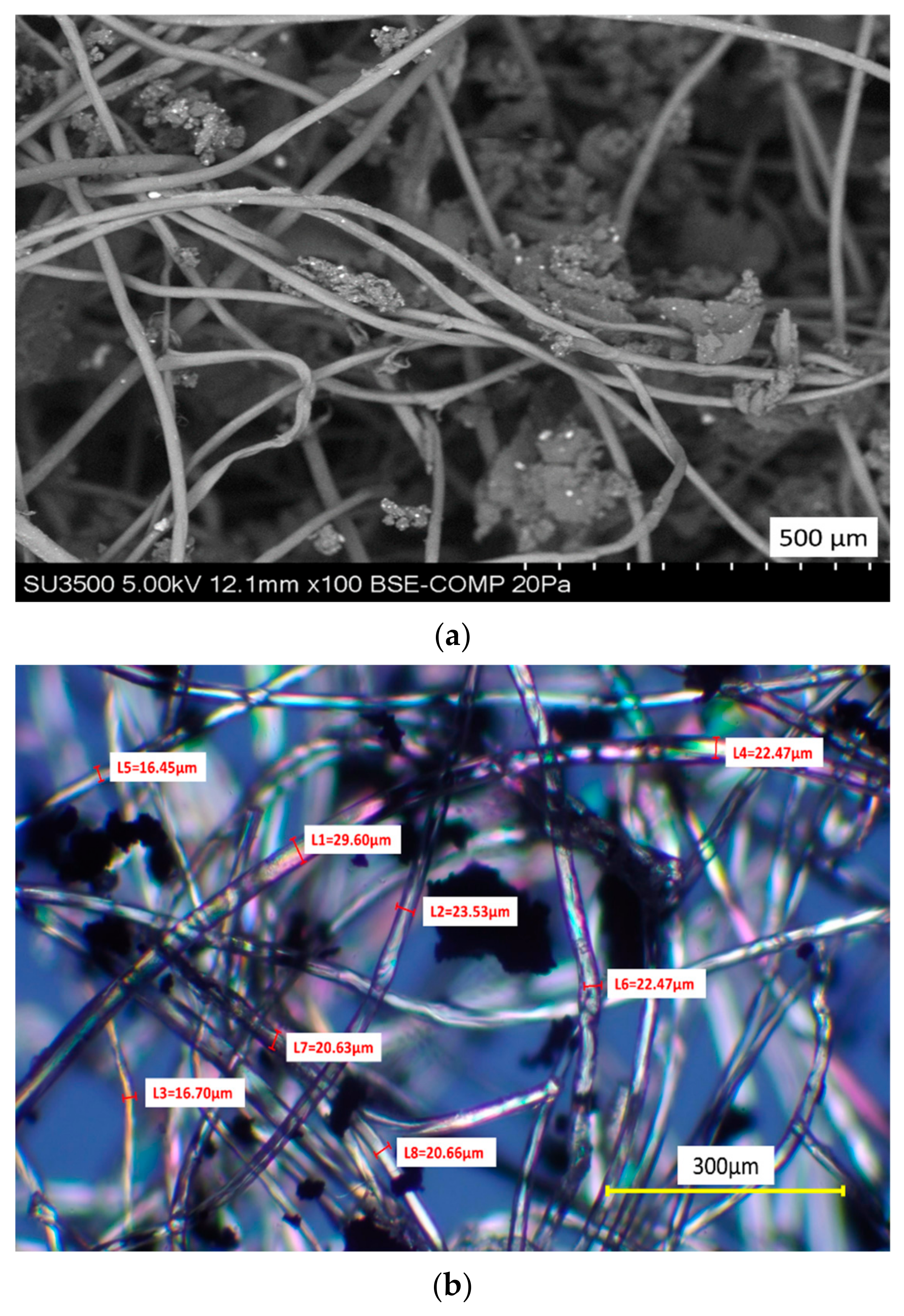

Thermogravimetric and Microscope Analysis of the PFELT

3.2. Analysis of the Effect of the Asphalt Binder Modified with PFELT on the Mechanical Performance of the HMA

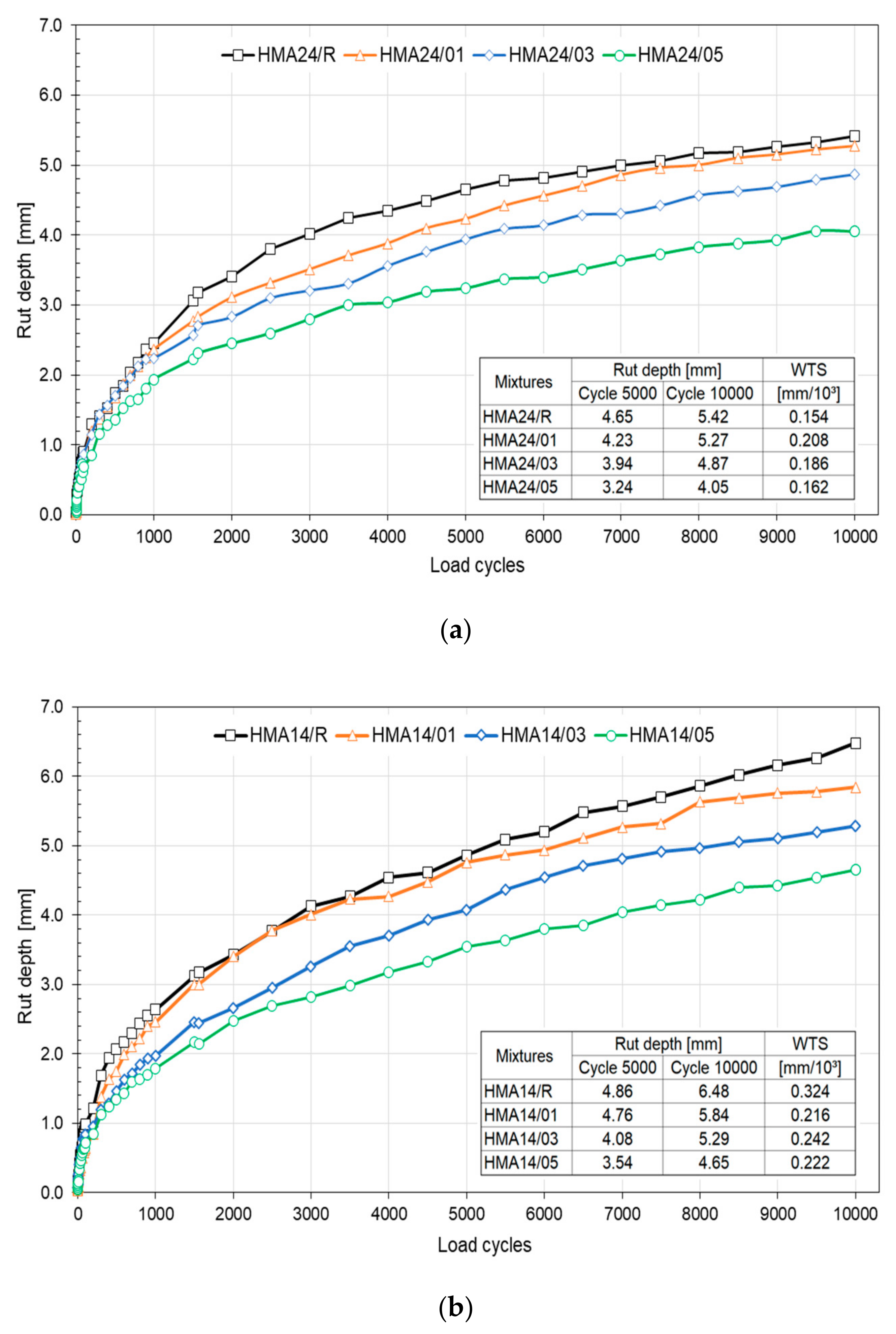

3.2.1. Evaluation of the Effects of PFELT on the Mechanical Properties of HMA at High Temperature

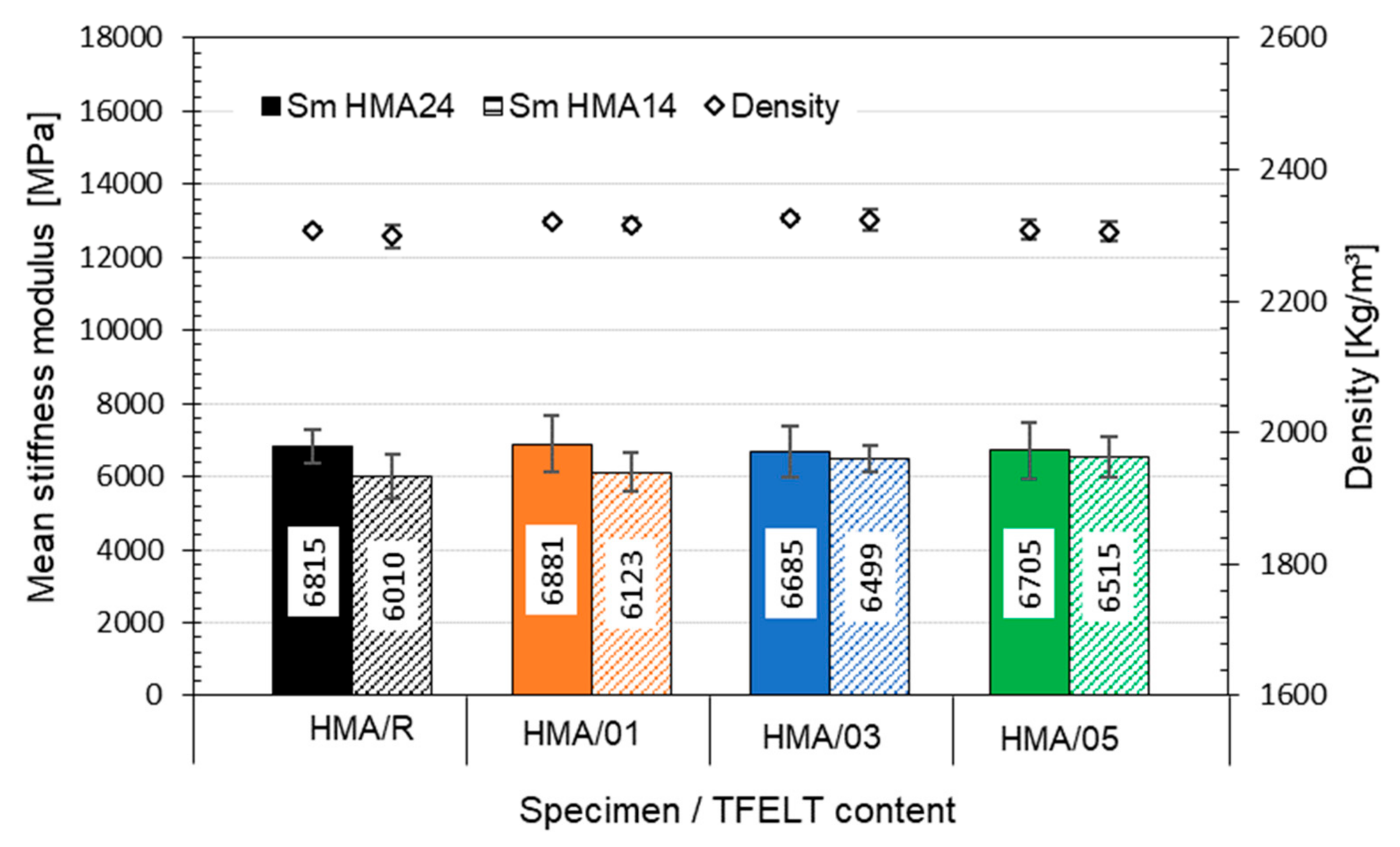

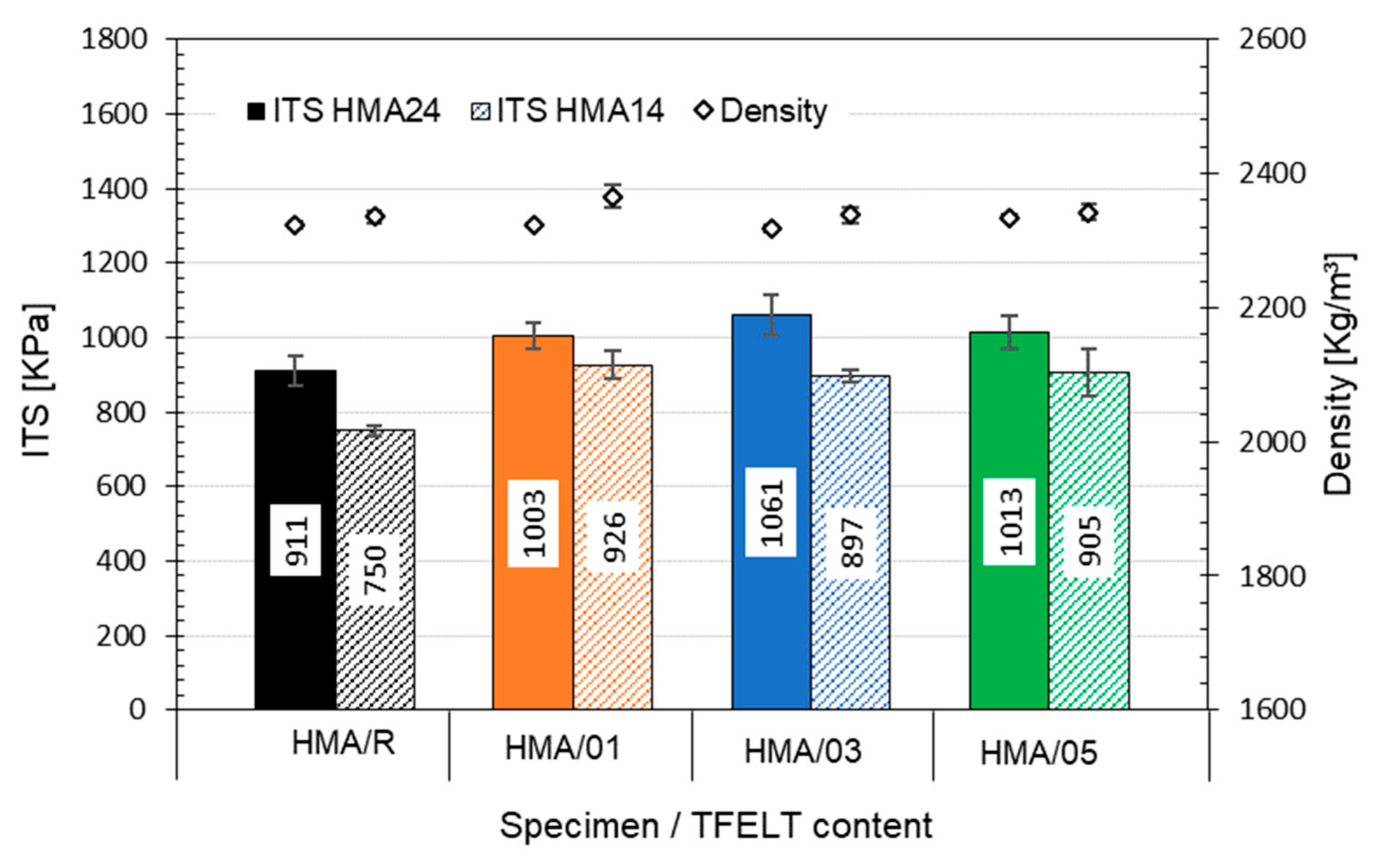

3.2.2. Evaluation of the Effects of PFELT on the Mechanical Properties of HMA at Intermediate Temperature

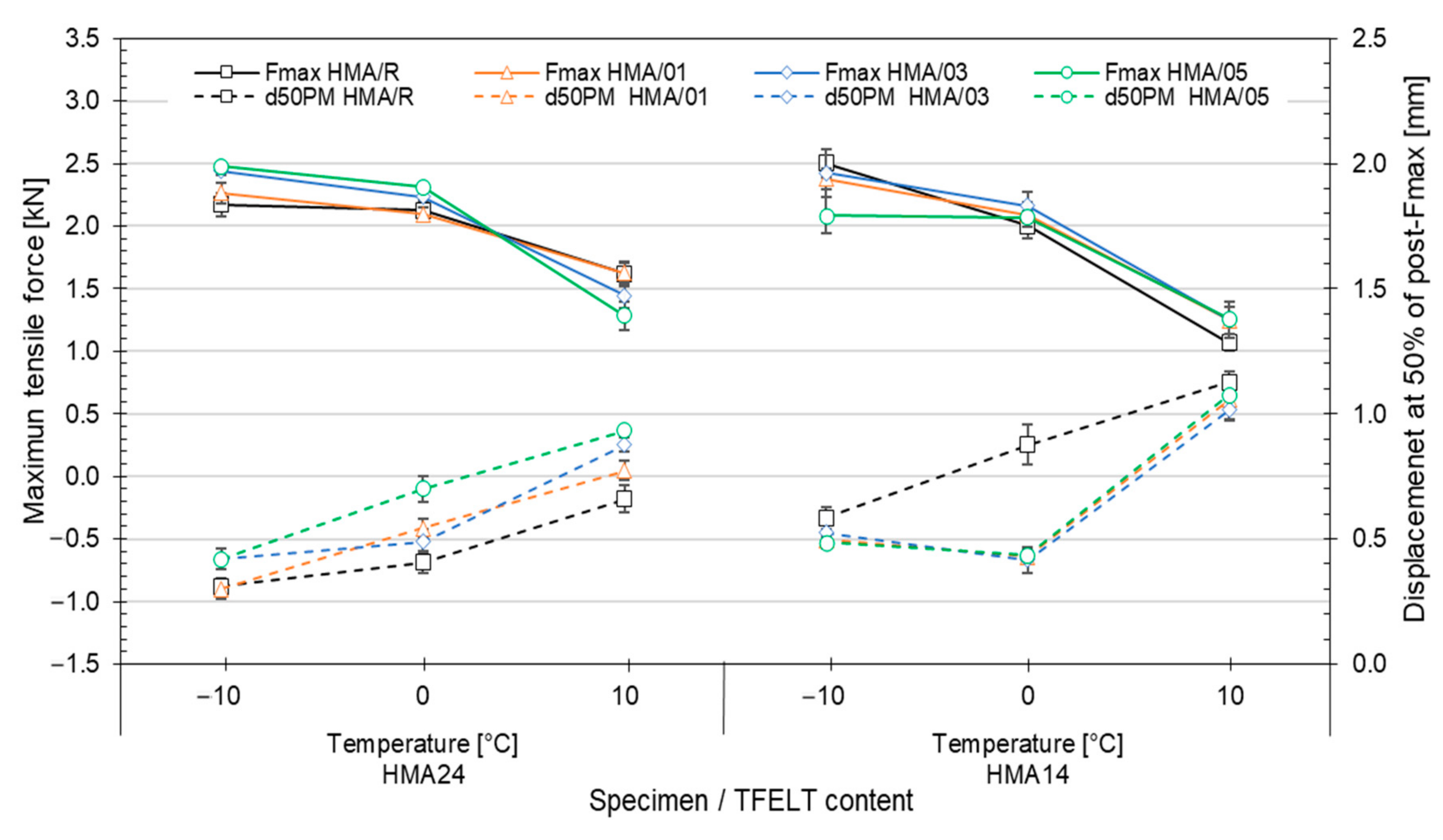

3.2.3. Evaluation the Effects of PFELT on the Mechanical Properties of HMA at Low Temperature

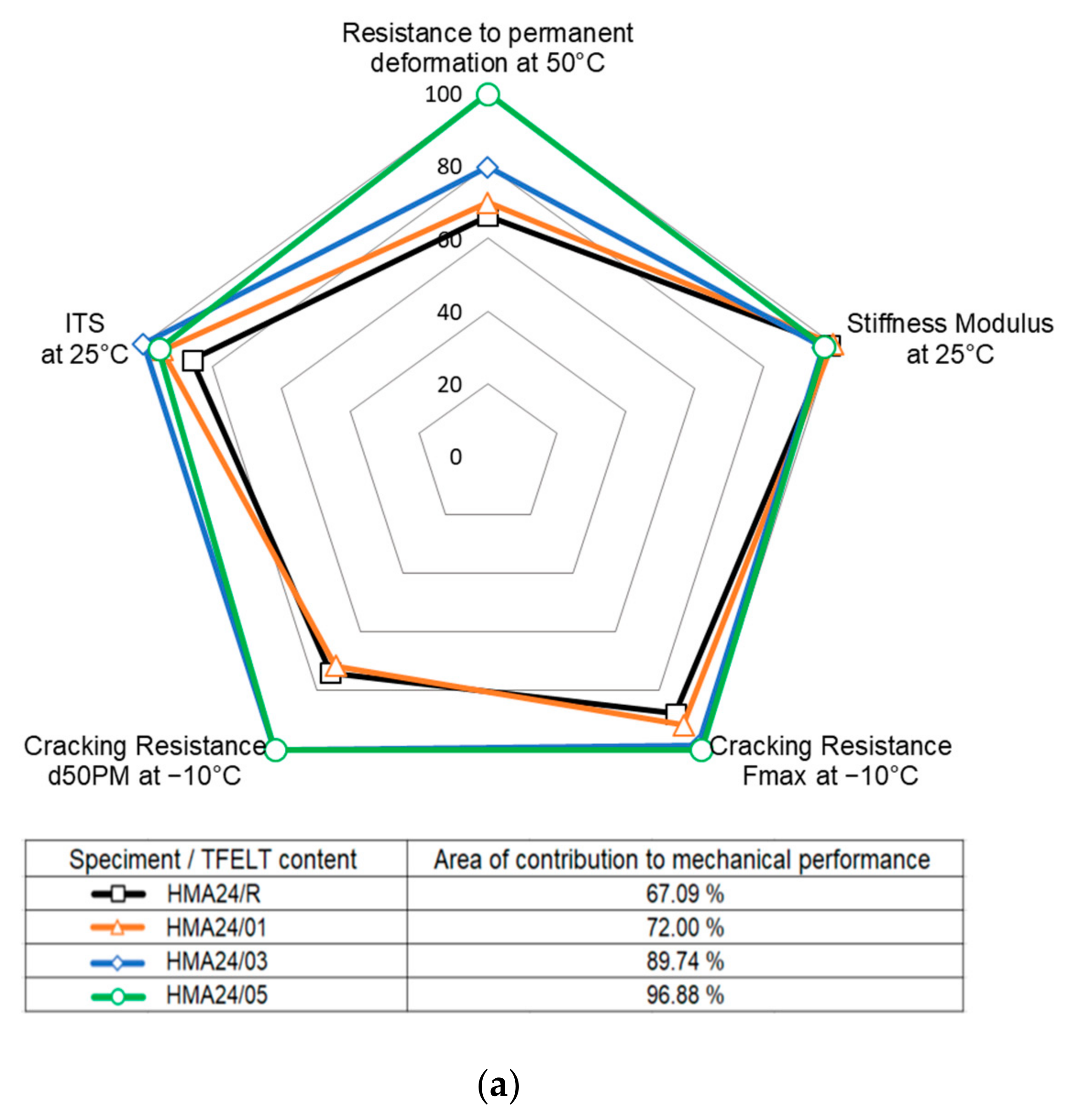

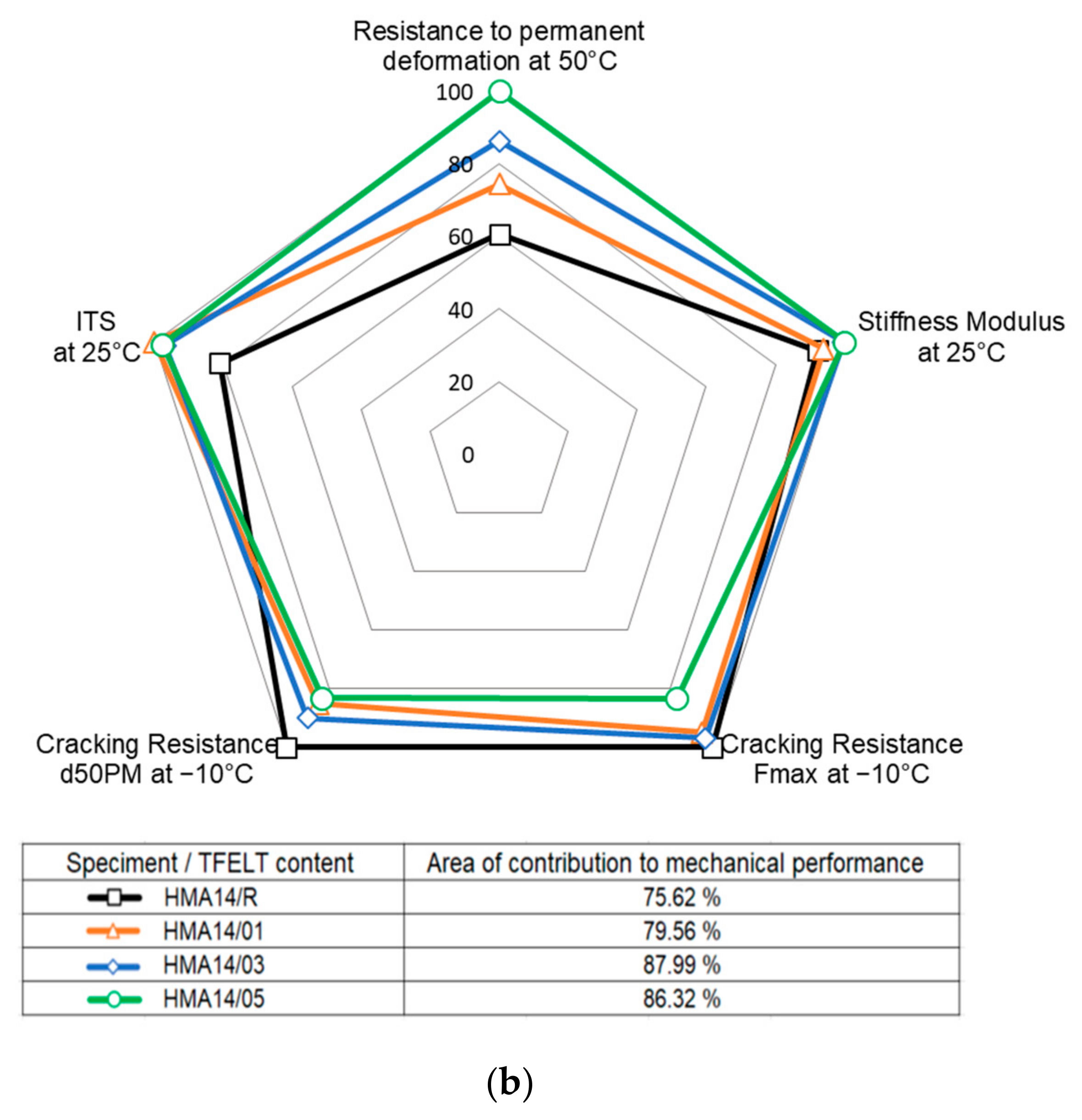

3.3. Determination of the Optimum AB-PFELT Content

4. Conclusions

- The physical and chemical analyses showed that polymer fibre from ELT (PFELT) consists of filaments of a mean diameter 22.5 μm, with particles of rubber waste from ELT recycling adhering to the fibres. The results of the TGA curves showed that the melting point of the PFELT was 241.7 °C, with devolatilization temperature around 347 °C.

- The best modification condition of the asphalt binder with TFELT was determined as a modification temperature of 170 °C for a period of 2 h at 350 rpm revolutions per minute.

- In the evaluation of thermal cracking, it was found that, in general, the maximum resistance (Fmax) of the HMA mixes manufactured with AB-PFELT presented no significant differences at −10, 0, and 10 °C. However, the HMA24/03 and HMA24/05 mixes presented greater tensile strength, indicating an increase in the Fmax of around 5–14% at 10 and 0 °C. In the evaluation of bending capacity (d50PM), the HMA24 mixes manufactured with AB-PFELT showed a greater capacity to admit deformation at lower temperatures, with a significant improvement in the values of the d50PM parameter, while the HMA14 mixes manufactured with AB-PFELT showed a significant diminution in the d50PM parameter, and the mixes had a faster fracture velocity.

- In the evaluation of the properties at intermediate temperature, the HMA mixes manufactured with AB-PFELT showed no significant effect on the stiffness modulus values at 25 °C; their performance was similar to that of HMA/R. On the other hand, it was observed that the AB-PFELT added to the asphalt mixes absorbed part of the traction forces, thus leading to a significant increase of up to 19% in the ITS values at 25 °C.

- The results for the capacity of the mixes to resist permanent deformation at high temperature showed that HMA manufactured with AB-PFELT presented a significant increase in resistance to rutting, which is attributed to strengthening of the asphalt binder matrix by the addition of PFELT. This effect was most significant at higher addition rates, thus reducing the rut depth recorded for conventional mixes by up to 34% in the case of HMA24/05 and 39% in case of HMA14/05. None of the mixes evaluated presented loss of adhesion between the stone aggregates and asphalt binder (stripping), indicating that the HMA mixes modified with AB-PFELT are not susceptible to moisture damage.

- It was determined that the greatest effects of the use of AB-PFELT were shown for the HMA24/05 and HMA14/03 mixes, with areas of contribution to mechanical performance 30% and 12% higher than the reference mixture, respectively.

- PFELT is currently a massive residue from the ELT recycling process. This study demonstrates that PFELT can be used to produce modified AB to improve the performance of asphalt mixes. However, future studies may be conducted with other ways of incorporating PFELT into the asphalt mix to improve its performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Araujo-Morera, J.; Verdejo, R.; López-Manchado, M.A.; Santana, M.H. Sustainable mobility: The route of tires through the circular economy model. Waste Manag. 2021, 126, 309–322. [Google Scholar] [CrossRef] [PubMed]

- Fiksel, J.; Bakshi, B.R.; Baral, A.; Guerra, E.; Dequervain, B. Comparative life cycle assessment of beneficial applications for scrap tires. Clean Technol. Environ. Policy 2011, 13, 19–35. [Google Scholar] [CrossRef]

- Gheni, A.A.; Alghazali, H.H.; ElGawady, M.A.; Myers, J.J.; Feys, D. Durability properties of cleaner cement mortar with by-products of tire recycling. J. Clean. Prod. 2019, 213, 1135–1146. [Google Scholar] [CrossRef]

- Abbaspour, M.; Aflaki, E.; Nejad, F.M. Reuse of waste tire textile fibers as soil reinforcement. J. Clean. Prod. 2019, 207, 1059–1071. [Google Scholar] [CrossRef]

- Dong, Y.; Zhao, Y.; Hossain, M.U.; He, Y.; Liu, P. Life cycle assessment of vehicle tires: A systematic review. Clean. Environ. Syst. 2021, 2, 100033. [Google Scholar] [CrossRef]

- World Business Council For Sustainable Development (WBCSD). Global ELT Management—A Global State of Knowledge on Regulation, Management Systems, Impacts of Recovery and Technologies. 2019. Available online: https://www.wbcsd.org/Sector-Projects/Tire-Industry-Project/End-of-Life-Tires-ELTs (accessed on 2 June 2022).

- Scott, E. End-of-Life Tyre Report ETRMA 2015; European Tyre & Rubber Manufacturers Association: Bruxelles, Belgium, 2016; p. 36. [Google Scholar]

- ETRMA. Statistics—Edition 2022; European Tyre & Rubber Manufacturers Association (ETRMA): Bruxelles, Belgium, 2022; Available online: https://www.etrma.org/ (accessed on 14 June 2022).

- Shulman, V.L. Chapter 26—Tire Recycling. In Waste, 2nd ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 489–515. [Google Scholar]

- Landi, D.; Gigli, S.; Germani, M.; Marconi, M. Investigating the feasibility of a reuse scenario for textile fibres recovered from end-of-life tyres. Waste Manag. 2018, 75, 187–204. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Recycling waste tires into ground tire rubber (Gtr)/rubber compounds: A review. J. Compos. Sci. 2020, 4, 103. [Google Scholar] [CrossRef]

- Polambiente, Polambiente Recicla & Innova. 2022. Available online: https://www.polambiente.com/ (accessed on 14 June 2022).

- Ghofrani, M.; Ashori, A.; Rezvani, M.H.; Ghamsari, F.A. Acoustical properties of plywood/waste tire rubber composite panels. Meas. J. Int. Meas. Confed. 2016, 94, 382–387. [Google Scholar] [CrossRef]

- Pan, R.; Li, Y. Effect of warm mix rubber modified asphalt mixture as stress absorbing layer on anti-crack performance in cold region. Constr. Build. Mater. 2020, 251, 118985. [Google Scholar] [CrossRef]

- Sol-Sánchez, M.; Carrión, A.J.d.; Hidalgo-Arroyo, A.; Moreno-Navarro, F.; Saiz, L.; Rubio-Gámez, M.d. Viability of producing sustainable asphalt mixtures with crumb rubber bitumen at reduced temperatures. Constr. Build. Mater. 2020, 265, 120154. [Google Scholar] [CrossRef]

- Herrero, S.; Mayor, P.; Hernández-Olivares, F. Influence of proportion and particle size gradation of rubber from end-of-life tires on mechanical, thermal and acoustic properties of plaster-rubber mortars. Mater. Des. 2013, 47, 633–642. [Google Scholar] [CrossRef] [Green Version]

- Medina, N.F.; Medina, D.F.; Hernández-Olivares, F.; Navacerrada, M.A. Mechanical and thermal properties of concrete incorporating rubber and fibres from tyre recycling. Constr. Build. Mater. 2017, 144, 563–573. [Google Scholar] [CrossRef]

- Acevedo, B.; Fernandez, A.M.; Barriocanal, C. Identification of polymers in waste tyre reinforcing fibre by thermal analysis and pyrolysis. J. Anal. Appl. Pyrolysis 2015, 111, 224–232. [Google Scholar] [CrossRef] [Green Version]

- Nasir, S.; Abebe, D.; Nebiyu, K. Synthesis and Characterization of Pyrolised Recycled Steel Fibers for Use in Reinforced Concrete. Int. J. Eng. Sci. Manag. Res. 2017, 4, 21–32. [Google Scholar]

- Liew, K.M.; Akbar, A. The recent progress of recycled steel fiber reinforced concrete. Constr. Build. Mater. 2020, 232, 117232. [Google Scholar] [CrossRef]

- Bocci, E.; Prosperi, E. Recycling of reclaimed fibers from end-of-life tires in hot mix asphalt. J. Traffic Transp. Eng. 2020, 7, 678–687. [Google Scholar] [CrossRef]

- Thai, Q.B.; Le-Cao, K.; Nguyen, P.T.T.; Le, P.K.; Phan-Thien, N.; Duong, H.M. Fabrication and optimization of multifunctional nanoporous aerogels using recycled textile fibers from car tire wastes for oil-spill cleaning, heat-insulating and sound absorbing applications. Colloids Surf. A Physicochem. Eng. Asp. 2021, 628, 127363. [Google Scholar] [CrossRef]

- Gama, D.A.; Rosa, J.M.; de Melo, T.J.A.; Rodrigues, J.K.G. Rheological studies of asphalt modified with elastomeric polymer. Constr. Build. Mater. 2016, 106, 290–295. [Google Scholar] [CrossRef]

- Polacco, G.; Stastna, J.; Biondi, D.; Antonelli, F.; Vlachovicova, Z.; Zanzotto, L. Rheology of asphalts modified with glycidylmethacrylate functionalized polymers. J. Colloid Interface Sci. 2004, 280, 366–373. [Google Scholar] [CrossRef]

- Behnood, A.; Gharehveran, M.M. Morphology, rheology, and physical properties of polymer-modified asphalt binders. Eur. Polym. J. 2019, 112, 766–791. [Google Scholar] [CrossRef]

- Abiola, O.S.; Kupolati, W.K.; Sadiku, E.R.; Ndambuki, J.M. Utilisation of natural fibre as modifier in bituminous mixes: A review. Constr. Build. Mater. 2014, 54, 305–312. [Google Scholar] [CrossRef]

- Mohammed, M.; Parry, T.; Grenfell, J. Influence of fibres on rheological properties and toughness of bituminous binder. Constr. Build. Mater. 2018, 163, 901–911. [Google Scholar] [CrossRef]

- Mohammed, M.; Parry, T.; Thom, N.; Grenfell, J. Microstructure and mechanical properties of fibre reinforced asphalt mixtures. Constr. Build. Mater. 2020, 240, 117932. [Google Scholar] [CrossRef]

- Klinsky, L.M.G.; Kaloush, K.E.; Faria, V.C.; Bardini, V.S.S. Performance characteristics of fiber modified hot mix asphalt. Constr. Build. Mater. 2018, 176, 747–752. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.; Kim, S.; Yoo, D.; Shin, H. Enhancing mechanical properties of asphalt concrete using synthetic fibers. Constr. Build. Mater. 2018, 178, 233–243. [Google Scholar] [CrossRef]

- Noorvand, H.; Salim, R.; Medina, J.; Stempihar, J.; Underwood, B.S. Effect of synthetic fiber state on mechanical performance of fiber reinforced asphalt concrete. Transp. Res. Rec. 2018, 2672, 42–51. [Google Scholar] [CrossRef]

- Landi, D.; Marconi, M.; Meo, I.; Germani, M. Reuse scenarios of tires textile fibers: An environmental evaluation. Procedia Manuf. 2018, 21, 329–336. [Google Scholar] [CrossRef]

- Narani, S.S.; Abbaspour, M.; Hosseini, S.M.M.M.; Aflaki, E.; Nejad, F.M. Sustainable reuse of Waste Tire Textile Fibers (WTTFs) as reinforcement materials for expansive soils: With a special focus on landfill liners/covers. J. Clean. Prod. 2020, 247, 119151. [Google Scholar] [CrossRef]

- Dirección de Vialidad de Chile. Especificaciones y métodos de muestreo, ensaye y control. In Manual de Carreteras; Ministerio de Obras Publicas de Chile, Ed.; Ministerio de Obras Públicas: Santiago, Chile, 2021; Volume 8. [Google Scholar]

- Dirección de Vialidad de Chile. Especificaciones técnicas generales de construcción. In Manual de Carreteras; Ministerio De Obras Publicas De Chile, Ed.; Ministerio de Obras Públicas: Santiago, Chile, 2021; Volume 5. [Google Scholar]

- Wu, S.; Ye, Q.; Li, N. Investigation of rheological and fatigue properties of asphalt mixtures containing polyester fibers. Constr. Build. Mater. 2008, 22, 2111–2115. [Google Scholar] [CrossRef]

- Hunter, R.N.; Self, A.; Read, J. The Shell Bitumen Handbook, 6th ed.; Shell Bitumen UK: Manchester, UK, 2015. [Google Scholar]

- AASHTO T 324; Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Asphalt Mixtures. AASHTO: Washington, DC, USA, 2019.

- EN 12697-26; Bituminous Mixtures-Test Methods—Part 26: Stiffness. Annex 3: Indirect Tensile Test on Cylindrical Specimens. AENOR: Madrid, Spain, 2019.

- EN 12697-23; Bituminous Mixtures-Test Methods—Part 23: Determination of the Indirect Tensile Strength of Bituminous Specimens. AENOR: Madrid, Spain, 2018.

- Pérez-Jiménez, F.; Valdés, G.; Miró, R.; Martínez, A.; Botella, R. Fénix test: Development of a new test procedure for evaluating cracking resistance in bituminous mixtures. Transp. Res. Rec. J. Transp. Res. Board 2010, 2181, 36–43. [Google Scholar] [CrossRef]

- NLT 383/20; Evaluación de la Resistencia, Tenacidad y Energía de Rotura de las Mezclas Bituminosas Mediante el Ensayo Fénix. Centro de Estudios y Experimentación de Obras Públicas: Madrid, Spain, 2020.

- Landi, D.; Vitali, S.; Germani, M. Environmental Analysis of Different End of Life Scenarios of Tires Textile Fibers. Procedia CIRP 2016, 48, 508–513. [Google Scholar] [CrossRef]

- Marconi, M.; Landi, D.; Meo, I.; Germani, M. Reuse of Tires Textile Fibers in Plastic Compounds: Is this Scenario Environmentally Sustainable? Procedia CIRP 2018, 69, 944–949. [Google Scholar] [CrossRef]

- Fang, C.; Zhang, M.; Yu, R.; Liu, X. Effect of Preparation Temperature on the Aging Properties of Waste Polyethylene Modified Asphalt. J. Mater. Sci. Technol. 2015, 31, 320–324. [Google Scholar] [CrossRef]

- Eskandarsefat, S.; Hofko, B.; Rossi, C.O.; Sangiorgi, C. Fundamental properties of bitumen binders containing novel cellulose-based poly-functional fibres. Compos. Part B Eng. 2019, 163, 339–350. [Google Scholar] [CrossRef]

- Mahrez, A.; Karim, M.R.; Katman, H.Y. Fatigue and Deformation Properties of Glass Fibre Reinforced Asphalt Mixes. East. Asia Soc. Transp. Stud. 2005, 6, 997–1007. [Google Scholar]

- Shukla, M.; Tirawi, D.; Sitaramanjaneyulu, K. Performance Characteristics of Asphalt Concrete Mix Modified With Glass Fibre. In Proceedings of the IJPC—International Journal of Pavements Conference, São Paulo, Brazil, 9–10 December 2013; pp. 1–10. [Google Scholar]

- Kumar, P.; Mehndiratta, H.C.; Immadi, S. Investigation of Fiber-Modified Bituminous Mixes. Transp. Res. Rec. J. Transp. Res. Board 2009, 2126, 91–99. [Google Scholar] [CrossRef]

- Chen, J.S.; Lin, K.Y.I. Mechanism and behavior of bitumen strength reinforcement using fibers. J. Mater. Sci. 2005, 40, 87–95. [Google Scholar] [CrossRef]

| Characteristic | Description | Reference | |

|---|---|---|---|

| Colour | Dark grey | |

| Form | Yarned | ||

| Single fibre diameter (μm) | 20–40 | [10,32] | |

| Length (mm) | 1.0–2.5 | [21] | |

| Density (gr/cm3) | 0.07–0.287 | [10] | |

| Thermal conductivity (W/m·K) | 0.05–0.06 | [10] | |

| Specific heat (J/kg·K) | 0.12–0.20 | [10] | |

| Diffusivity (m2/s) | 0.30–0.50 | [10] | |

| Tensile strength (MPa) | 300–2000 | [33] | |

| Melting point (°C) | 242–272 °C |

| Tests | CA-24 | CA-14 | Specs. [34] |

|---|---|---|---|

| Absolute viscosity at 60 °C, 300 mm Hg (P) | 2940 | 2226 | AB24: Min 2400 |

| AB14: Min 1400 | |||

| Penetration at 25 °C, 100 g. 5 s. (0.1 mm) | 63 | 70 | Min 40 |

| Ductility at 25 °C, (cm) | 100 | >150 | Min 100 |

| Spot test hep./xyl., (% xylene) | −30 | <25 | Max 30 |

| Trichloroethylene solubility (%) | 99.8 | 99.9 | Min 99 |

| Cleveland open cup flash point (°C) | 310 | 328 | Min 232 |

| Softening point R & B (°C) | 52.2 | 48.6 | To be reported |

| Penetration index | −0.1 | −0.8 | −1.5 a +1.0 |

| RTFOT | |||

| Mass loss (%). Absolute viscosity at 60 °C, 300 mm Hg (P) Ductility at 25 °C, 5 cm/min, (cm) Durability index | 0.08 7860 100 2.7 | 0.1 6019 150 2.7 | Max 0.8 To be reported Min 100 Max 4.0 |

| Tests | Results | Specifications [35] |

|---|---|---|

| Los Angeles abrasion loss (%) | 18.4 | Max. 25 (*)–35 |

| Sodium sulphate soundness (%) | 2.4 | Max 12 |

| Crushed aggregates (%) | 97.3 | Min. 90 (*)–70 |

| Flakiness index (%) | 0.1 | Max. 10 (*)–15 |

| Static method adhesion | >95 | Min. 95 |

| Dynamic method adhesion | >95 | Min. 95 |

| Soluble salts (%) | 0.5 | Max. 2 (*)–3 |

| Sand equivalent (%) | 81 | Min. 50 (*)–40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calabi-Floody, A.; Mignolet-Garrido, C.; Valdes-Vidal, G. Study of the Effect of the Use of Asphalt Binders Modified with Polymer Fibres from End-of-Life Tyres (ELT) on the Mechanical Properties of Hot Mix Asphalt at Different Operating Temperatures. Materials 2022, 15, 7578. https://doi.org/10.3390/ma15217578

Calabi-Floody A, Mignolet-Garrido C, Valdes-Vidal G. Study of the Effect of the Use of Asphalt Binders Modified with Polymer Fibres from End-of-Life Tyres (ELT) on the Mechanical Properties of Hot Mix Asphalt at Different Operating Temperatures. Materials. 2022; 15(21):7578. https://doi.org/10.3390/ma15217578

Chicago/Turabian StyleCalabi-Floody, Alejandra, Cristian Mignolet-Garrido, and Gonzalo Valdes-Vidal. 2022. "Study of the Effect of the Use of Asphalt Binders Modified with Polymer Fibres from End-of-Life Tyres (ELT) on the Mechanical Properties of Hot Mix Asphalt at Different Operating Temperatures" Materials 15, no. 21: 7578. https://doi.org/10.3390/ma15217578