An Investigation of Non-Linear Strength Characteristics of Solidified Saline Soils in Cold Regions

Abstract

1. Introduction

2. Test Materials and Methods

2.1. Test Materials

2.2. Experimental Program

2.3. Experimental Methods

3. Test Results and Analysis

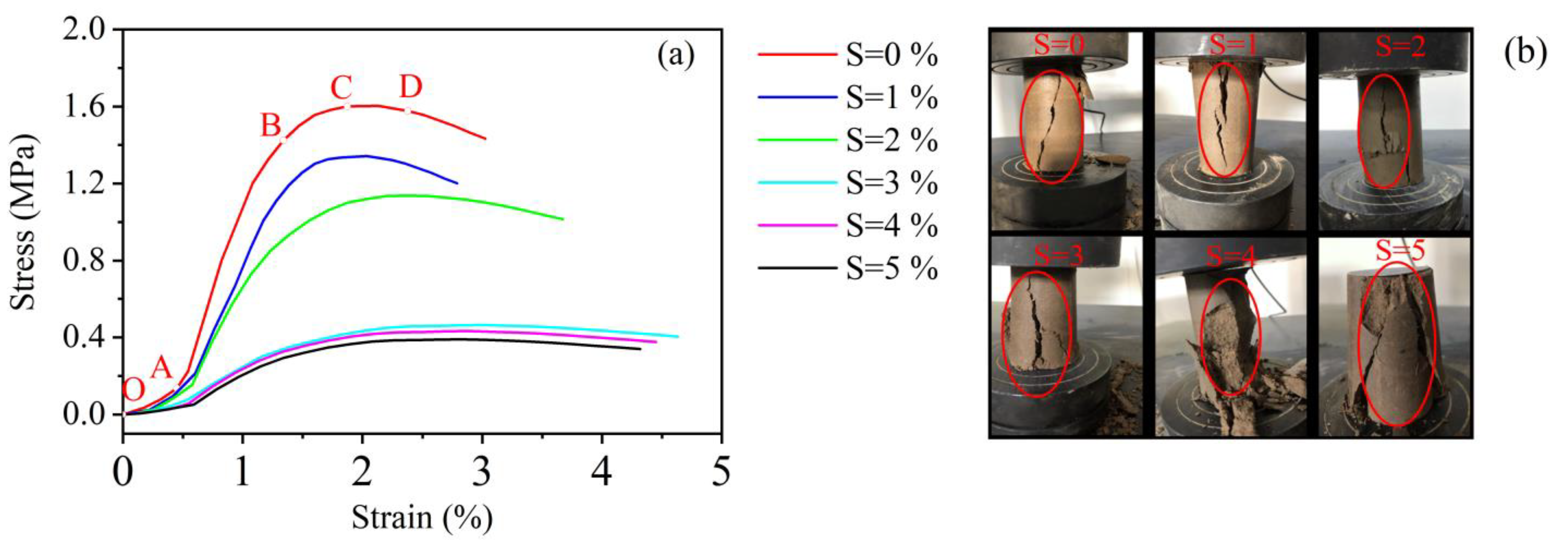

3.1. UCST Results

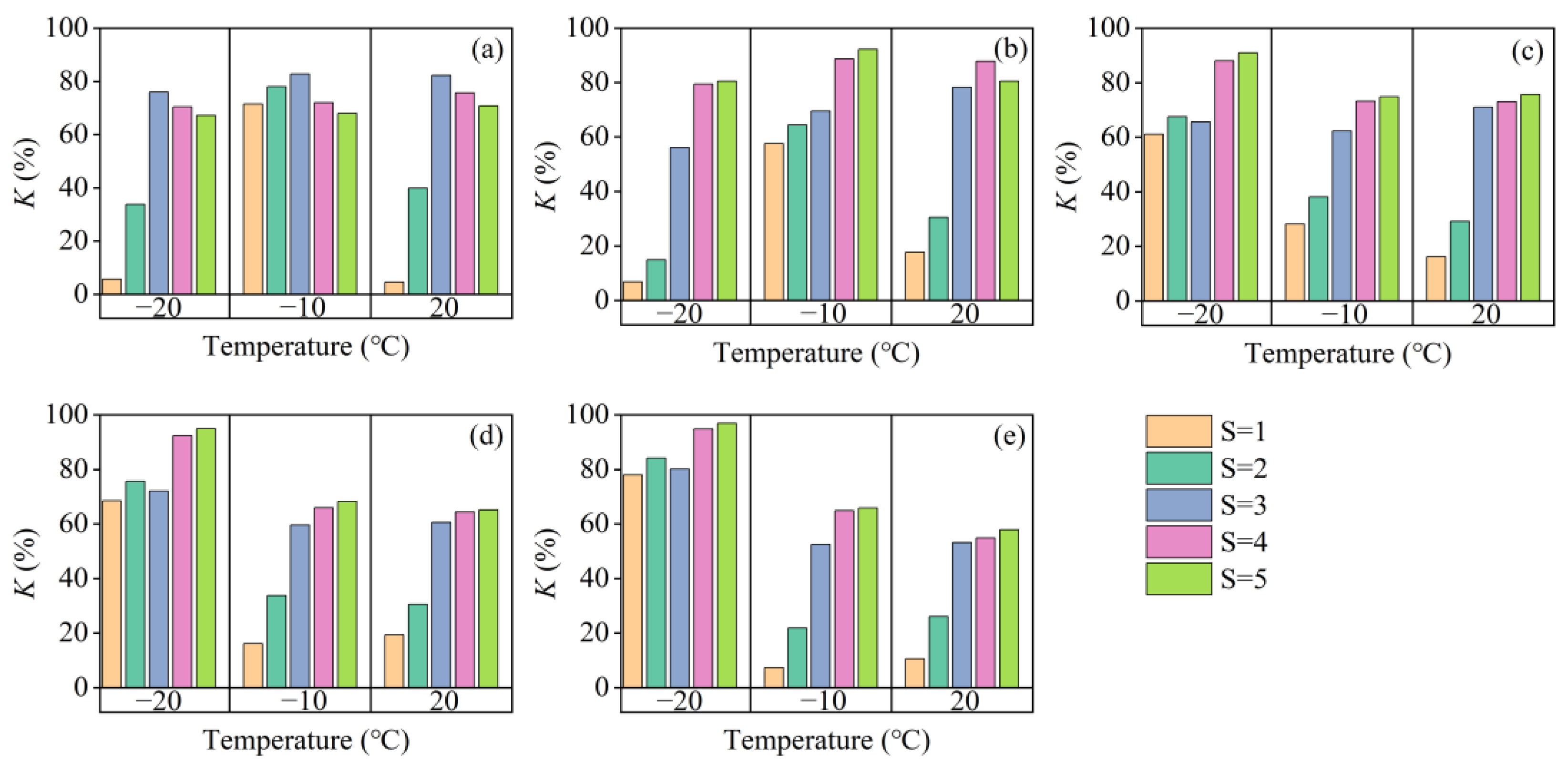

3.2. The Rate of Strength Loss

3.3. Age–Strength Relationships

4. Non-Linear Strength Characterization

4.1. Changes in the Stress–Strain Relationship for Improved Soils for Different FTCs and Salinities

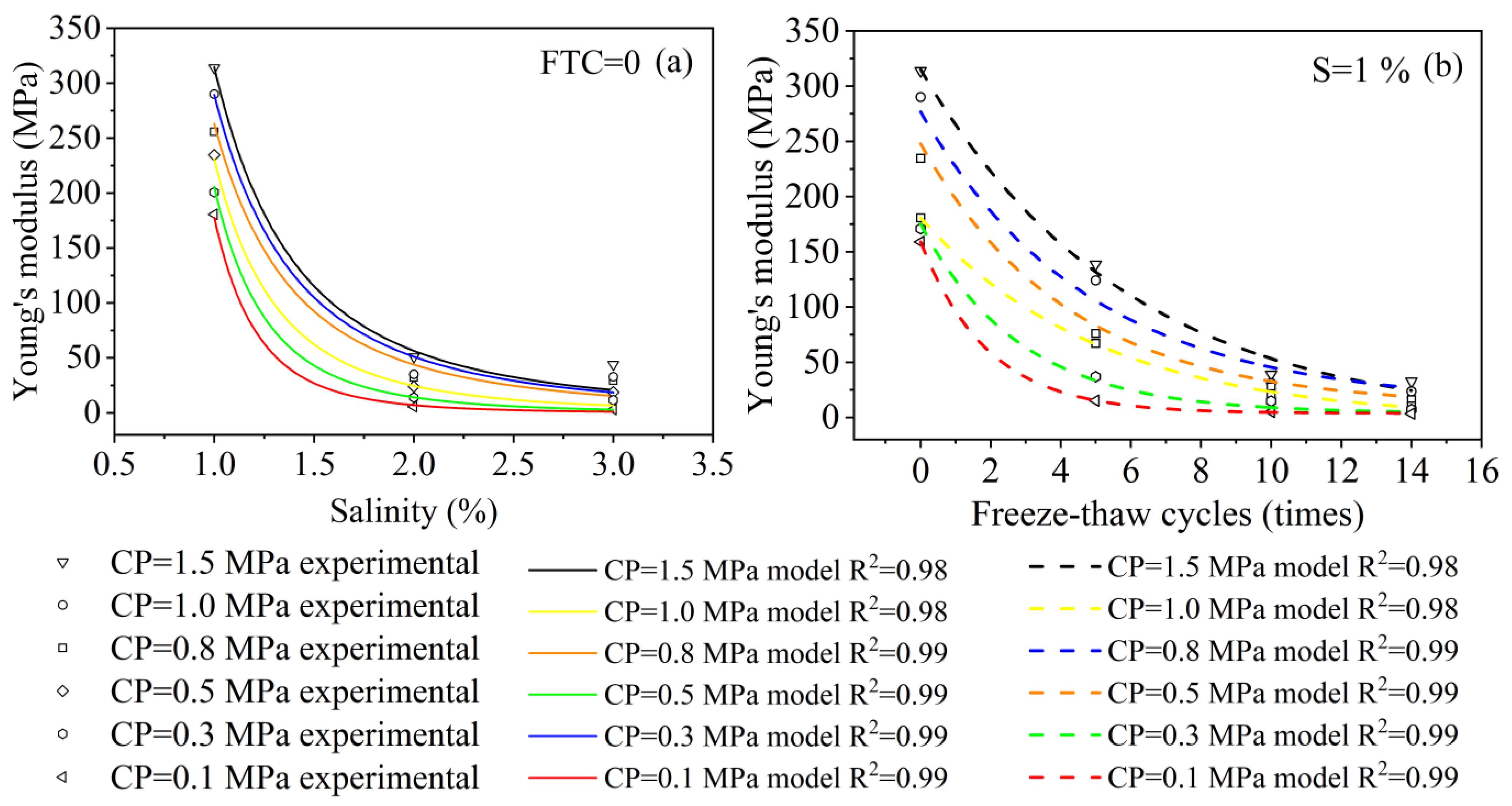

4.2. Effect of FTCs and Salt Erosion on the Tangent Modulus of Solidified Soils

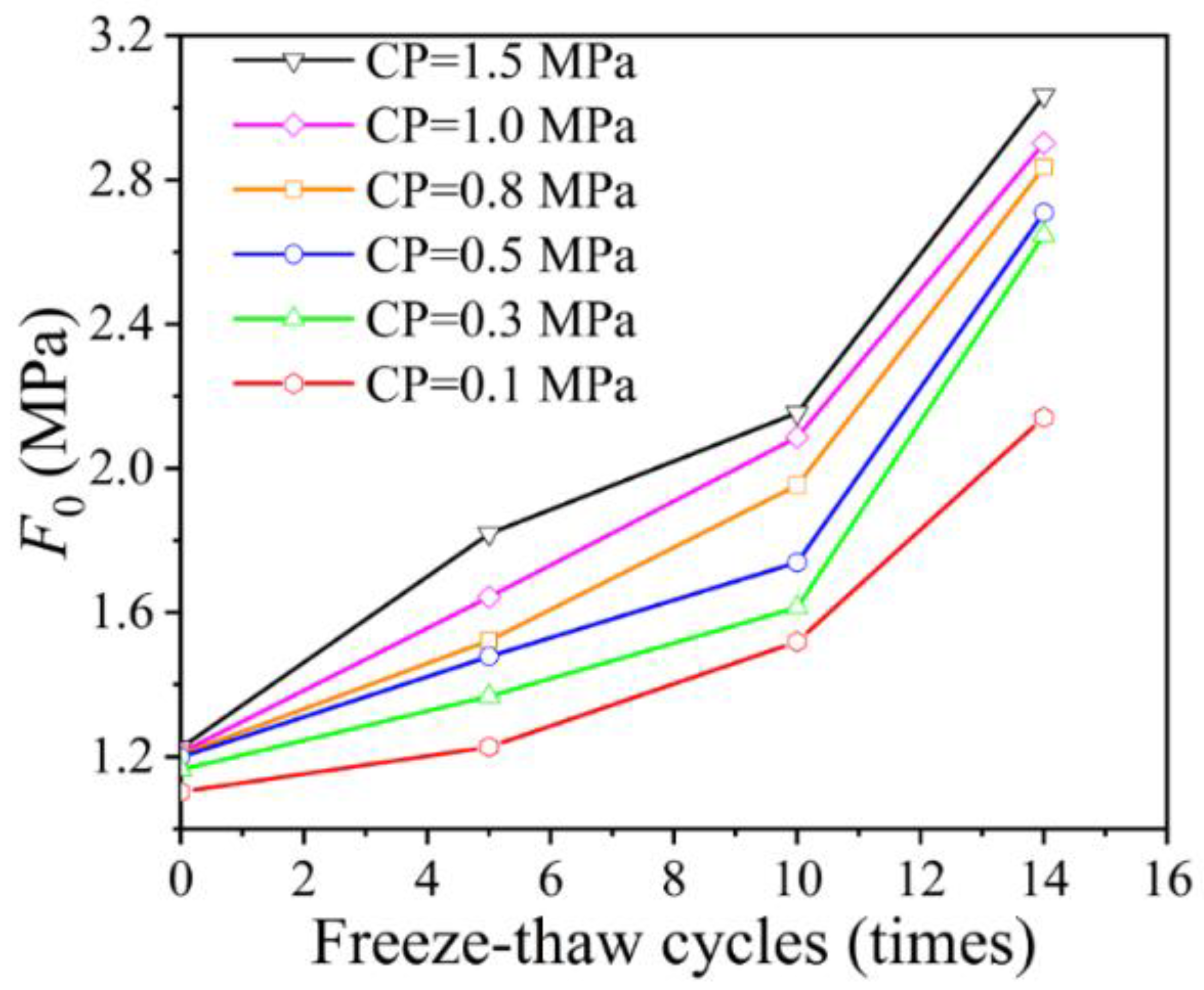

4.3. Damage Evolution Equations and Intrinsic Structure Modelling

5. Conclusions

- After using lime, fly ash, and cement to cure saline soils in cold regions, the UCS is greatly improved, and the solidified saline soils with a salinity of less than 3% can meet the requirements of the sub-base filler for secondary and lower roads with medium and light traffic at the age of 14 d. Both frost heave and salt erosion could cause irreversible damage in soil, and the coupling effect of freezing-salt will amplify the rate of strength loss.

- After curing the saline soils in cold regions, the freeze–thaw resistance of the solidified saline soils is remarkably enhanced, and the stress–strain curve of the solidified saline soils does not show rapid strain softening after FTCs. The effect of FTCs and salt erosion causes peak stress to shift backward at the appearance of Young’s modulus, which indicates that, with increased FTCs and salinity, the resistance to deformation of the solidified saline soil was reduced.

- Considering the damage threshold of FTCs on solidified saline soil, Weibull distribution is used to describe its damage evolution regulation. The simulation results of modelling show that the damage constitutive model is more suitable than the traditional constitutive model for solidified saline soil under the effect of FTCs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, Y.W.; Guo, D.X.; Qiu, G.Q.; Zhang, T.J. Geocryology in China; Science Press: Beijing, China, 2000. [Google Scholar]

- Ran, Y.H.; Li, X.; Cheng, G.D.; Zhang, T.J.; Wu, Q.B.; Jin, H.J.; Jin, R. Distribution of Permafrost in China: An Overview of Existing Permafrost Maps. Permafr. Periglac. Process. 2012, 23, 322–333. [Google Scholar] [CrossRef]

- Wang, L.; Wang, H.; Tian, Z.; Lu, Y.; Gao, W.; Ren, T. Structural Changes of Compacted Soil Layers in Northeast China due to Freezing-Thawing Processes. Sustainability 2020, 12, 1587. [Google Scholar] [CrossRef]

- Ma, Q.; Zhang, K.; Jabro, J.D. Freeze–thaw cycles effects on soil physical properties under different degraded conditions in Northeast China. Environ. Earth Sci. 2019, 78, 321. [Google Scholar] [CrossRef]

- Wang, L.; Zuo, X.F.; Zheng, F.L.; Wilson, G.V.; Zhang, X.C.; Wang, Y.F.; Han, F. The effects of freeze-thaw cycles at different initial soil water contents on soil erodibility in Chinese Mollisol region. Catena 2020, 193, 104615. [Google Scholar] [CrossRef]

- Wang, S.; Ding, J.; Xu, J.; Ren, J.; Yang, Y. Shear Strength Behavior of Coarse-Grained Saline Soils after Freeze-Thaw. KSCE J. Civ. Eng. 2019, 23, 2437–2452. [Google Scholar] [CrossRef]

- Bureau JPLA. Land Resources in Jilin Province; Geological Publishing House: Beijing, China, 1994. [Google Scholar]

- Wang, Z.Q. Saline Soil in China; Science Press: Beijing, China, 1993. [Google Scholar]

- Li, G.Y.; Wang, F.; Ma, W.; Fortier, R.; Mu, Y.H.; Zhou, Z.W. Field observations of cooling performance of thermosyphons on permafrost under the China-Russia Crude Oil Pipeline. Appl. Therm. Eng. 2018, 141, 688–696. [Google Scholar] [CrossRef]

- Wang, F.; Li, G.Y.; Ma, W.; Mu, Y.H.; Zhou, Z.W.; Mao, Y.C. Permafrost thawing along the China-Russia Crude Oil Pipeline and countermeasures: A case study in Jagdaqi, Northeast China. Cold Reg. Sci. Technol. 2018, 155, 308–313. [Google Scholar] [CrossRef]

- Yang, S.Z.; Wen, X.; Zhao, L.; Shi, Y.L.; Jin, H.J. Crude Oil Treatment Leads to Shift of Bacterial Communities in Soils from the Deep Active Layer and Upper Permafrost along the China-Russia Crude Oil Pipeline Route. PLoS ONE 2014, 9, e96552. [Google Scholar] [CrossRef]

- Lyu, C.; Nishimura, S.; Amiri, S.A.G. Pore-water pressure development in a frozen saline clay under isotropic loading and undrained shearing. Acta Geotech. 2021, 16, 3831–3847. [Google Scholar] [CrossRef]

- Ma, Q.G.; Lai, Y.M.; Zhang, M.Y. Freezing-thawing behavior of saline soil with various anti-saline measures. Eur. J. Environ. Civ. Eng. 2019, 23, 1178–1202. [Google Scholar]

- Wang, J.; Wang, Q.; Kong, Y. Analysis of the pore structure characteristics of freeze-thawed saline soil with different salinities based on mercury intrusion porosimetry. Environ. Earth Sci. 2020, 79, 161. [Google Scholar] [CrossRef]

- Peng, W.; Wang, Q.; Zhang, X.D. Prediction of the structural yield strength of saline soil in western jilin province, China: A comparison of the back-propagation neural network and support vector machine models. Symmetry 2020, 12, 1163. [Google Scholar] [CrossRef]

- Li, G.Y.; Yu, W.B.; Ma, W.; Qi, J.L.; Jin, H.J.; Sheng, Y. Experimental study of characteristics of frost and salt heaves of saline highway foundation soils in seasonally frozen regions in Gansu Province. Rock Soil Mech. 2009, 38, 2276–2280. [Google Scholar]

- Wardeh, G.; Mohamed, M.A.; Ghorbel, E. Analysis of concrete internal deterioration due to frost action. J. Build. Phys. 2011, 35, 54–82. [Google Scholar] [CrossRef]

- Zhang, Y.; Fan, J.H.; Liu, J.K.; Xu, A.H. Field tests on reinforcement effects of ground treatment of composite foundation in saline soils by dynamic compaction replacement. Chin. J. Geotech. Eng. 2011, 33, 251–254. [Google Scholar]

- Virkutyte, J.; Sillanpää, M.; Latostenmaa, P. Electrokinetic soil remediation—Critical overview. Sci. Total Environ. 2002, 289, 97–121. [Google Scholar] [CrossRef]

- Estabragh, A.R.; Naseh, M.; Javadi, A.A. Improvement of clay soil by electro-osmosis technique. Appl. Clay Sci. 2014, 95, 32–36. [Google Scholar] [CrossRef]

- Flora, A.; Gargano, S.; Lirer, S.; Mele, L. Effect of electro-kinetic consolidation on fine grained dredged sediments. Procedia Eng. 2016, 158, 3–8. [Google Scholar] [CrossRef]

- Eskisar, T.; Altun, S.; Kalipcilar, I. Assessment of strength development and freeze-thaw performance of cement treated clays at different water contents. Cold Reg. Sci. Technol. 2015, 111, 50–59. [Google Scholar] [CrossRef]

- Lv, Q.F.; Jiang, L.S.; Ma, B.; Zhao, B.H. A study on the effect of the salinities on the solidification of sulfate saline soil solidified with an alkali-activated geopolymer. Constr. Build. Mater. 2018, 176, 68–74. [Google Scholar] [CrossRef]

- Li, M.; Chai, S.X.; Du, H.P.; Wang, C. Effect of chlorine salt on the physical and mechanical properties of inshore saline soil treated with lime. Soils Found. 2016, 56, 327–335. [Google Scholar] [CrossRef]

- Yu, H.Y.; Zhao, J.; Yang, J.J.; Li, Y.Q. Research on the mechanical properties and mechanism of alkali-activated saline soil composite materials. Ferroelectrics 2018, 529, 49–58. [Google Scholar]

- Janoo, V.C.; Firicano, A.J.; Barna, L.A. Field testing of stabilized soil. J. Cold Reg. Eng. 1999, 13, 37–53. [Google Scholar] [CrossRef]

- Arasan, S.; Nasirpur, O. The effects of polymers and fly ash on unconfined compressive strength and freeze-thaw behavior of loose saturated sand. Geomech. Eng. 2015, 8, 361–375. [Google Scholar] [CrossRef]

- Gullu, H.; Hazirbaba, K. Unconfined compressive strength and post-freeze-thaw behavior of fine-grained soils treated with geofiber and synthetic fluid. Cold Reg. Sci. Technol. 2010, 62, 142–150. [Google Scholar] [CrossRef]

- Yang, Z.J.; Still, B.; Ge, X. Mechanical properties of seasonally frozen and permafrost soils at high strain rate. Cold Reg. Sci. Technol. 2015, 113, 12–19. [Google Scholar] [CrossRef]

- Ying, Z.; Cui, Y.-J.; Benahmed, N.; Duc, M. Changes in microstructure and water retention property of a lime-treated saline soil during curing. Acta Geotech. 2022, 17, 319–326. [Google Scholar] [CrossRef]

- Tang, A.M.; Vu, M.-N.; Cui, Y.-J. Effects of the maximum soil aggregates size and cyclic wetting-drying on the stiffness of a lime-treated clayey soil. Géotechnique 2011, 61, 421–429. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, Y.J.; Benahmed, N.; Tang, A.M.; Duc, M. Changes of small strain shear modulus and suction for a lime-treated silt during curing. Géotechnique 2020, 70, 276–280. [Google Scholar] [CrossRef]

- Muzahim, A.L.; Jean-Francois, A. Behaviour and mineralogy changes in lime-treated expansive soil at 50 °C. Appl. Clay Sci. 2010, 50, 199–203. [Google Scholar]

- Bell, F.G. Lime stabilization of clay minerals and soils. Eng. Geol. 1996, 42, 223–237. [Google Scholar] [CrossRef]

- Gautam, S.; Hoyos, L.R.; He, S.; Prabakar, S.; Yu, X.B. Chemical Treatment of a Highly Expansive Clay Using a Liquid Ionic Soil Stabilizer. Geotech. Geol. Eng. 2020, 38, 4981–4993. [Google Scholar] [CrossRef]

- Xiang, W.; Cui, D.S.; Liu, Q.B.; Lu, X.S.; Cao, L.J. Theory and practice of ionic soil stabilizer reinforcing special clay. J. Asian Earth Sci. 2010, 21, 882–887. [Google Scholar] [CrossRef]

- Luo, X.H.; Xu, W.Y.; Qiu, X.; Yang, Q.; Xiao, S.L. Exploring the microstructure characteristics and mechanical behavior of the ionic soil stabilizer-treated clay. Arab. J. Geosci. 2020, 13, 729. [Google Scholar] [CrossRef]

- He, S.; Yu, X.B.; Banerjee, A.; Puppala, A.J. Expansive Soil Treatment with Liquid Ionic Soil Stabilizer. Transp. Res. Rec. 2018, 2672, 185–194. [Google Scholar] [CrossRef]

- Wu, X.T.; Sun, J.S.; Qi, Y.; Chen, B. Pore and compression characteristics of clay solidified by ionic soil stabilizer Influence of soil initial state on clay solidification effect. Bull. Eng. Geol. Environ. 2021, 80, 5003–5019. [Google Scholar] [CrossRef]

- Gong, X.; Niu, J.G.; Liang, S.H.; Feng, D.L.; Luo, Q.Z. Solidification of Nansha soft clay using cement-based composite curing agents. Adv. Cem. Res. 2020, 32, 66–77. [Google Scholar] [CrossRef]

- Chen, N.; Wei, Y.Q.; Lu, J.F.; Li, G. Environmentally friendly solidifying agent for soft silty soil and its application in green foundation treatment. Fresenius Environ. Bull. 2020, 29, 6898–6905. [Google Scholar]

- Liu, C.B.; Ji, H.G.; Liu, J.H. Anti-seawater corrosion performance of coastal saline soil solidified by slag composite cementitious material. Emerg. Mater. Res. 2014, 3, 292–298. [Google Scholar] [CrossRef]

- Ma, C.; Qin, Z.H.; Zhuang, Y.C.; Chen, L.Z.; Chen, B. Influence of sodium silicate and promoters on unconfined compressive strength of Portland cement-stabilized clay. Soils Found. 2015, 55, 1222–1232. [Google Scholar] [CrossRef]

- Koliji, A.; Laloui, L.; Vulliet, L. Constitutive modeling of unsaturated aggregated soils. Int. J. Numer. Anal. Methods Geomech. 2010, 34, 1846–1876. [Google Scholar] [CrossRef]

- Liu, W.Z.; Shi, M.L.; Miao, L.C. Constitutive modeling of the destructuration and anisotropy of natural soft clay. Comput. Geotech. 2013, 51, 24–41. [Google Scholar] [CrossRef]

- Pham, H.Q.; Fredlund, D.G. Volume-mass unsaturated soil constitutive model for drying-wetting under isotropic loading-unloading conditions. Can. Geotech. J. 2011, 48, 280–313. [Google Scholar] [CrossRef]

- Anandarajah, A. Multi-mechanism anisotropic model for granular materials. Int. J. Plast. 2008, 24, 804–846. [Google Scholar] [CrossRef]

- Viyalov, S.S. The Strength and Creep of Frozen Soils; U.S. Army CRREL: Hanover, NH, USA, 1962; Volume 74. [Google Scholar]

- Lai, Y.; Xu, X.; Yu, W.; Qi, J. An experimental investigation of the mechanical behavior and a hyperplastic constitutive model of frozen loess. Int. J. Eng. Sci. 2014, 84, 29–53. [Google Scholar] [CrossRef]

- Xu, G.F.; Wu, W.; Qi, J.L. Modeling the viscous behavior of frozen soil with hypoplasticity. Int. J. Numer. Anal. Methods Geomech. 2016, 40, 2061–2075. [Google Scholar] [CrossRef]

- De Maeijer, P.K.; Craeye, B.; Snellings, R.; Kazemi-Kamyab, H.; Loots, M.; Janssens, K.; Nuyts, G. Effect of ultra-fine fly ash on concrete performance and durability. Constr. Build. Mater. 2020, 263, 120493. [Google Scholar] [CrossRef]

- Ouhadi, V.R.; Yong, R.N. The role of clay fractions of marly soils on their post stabilization failure. Eng. Geol. 2003, 70, 365–375. [Google Scholar] [CrossRef]

- Chen, K.Z.; Huang, S.; Liu, Y.J. Improving Carbonate Saline Soil in a Seasonally Frozen Region Using Lime and Fly Ash. Geofluids 2022, 2022, 7472284. [Google Scholar] [CrossRef]

- Liao, M.; Lai, Y.M.; Wang, C. A strength criterion for frozen sodium sulfate saline soil. Can. Geotech. J. 2016, 53, 1176–1185. [Google Scholar] [CrossRef]

- Sun, D.Y. Mechanical Properties and Mechanism of Unsaturated Saline Soils and Lime Consolidated Soils in Zhenlai Area under Freeze-thaw Cycles; Jilin University: Changchun, China, 2017. [Google Scholar]

- Zheng, T.Y.; Zheng, Y. A review of earthquake disaster losses in mainland China in 2013. J. Nat. Hazards 2015, 24, 239–246. [Google Scholar]

- Hu, T.F.; Liu, J.K.; Wang, Q.Z.; Fang, J.H. Experimental study on the undrained shear properties of powdered clay under freeze-thaw cycles. J. Cent. South Univ. 2018, 49, 1481–1490. [Google Scholar]

- Niu, J.Y.; Jin, P.W.; Li, D.W. Study of the uniaxial compressive strength of frozen saline sandy soil. J. Glaciol. Geocryol. 2015, 2, 428–433. [Google Scholar]

- Liu, Y.W.; Wang, Q.; Liu, S.W. Experimental investigation of the geotechnical properties and microstructure of lime-stabilized saline soils under freeze-thaw cycling. Cold Reg. Sci. Technol. 2019, 161, 32–42. [Google Scholar] [CrossRef]

- Jean, L. How to use damage mechanics. Nucl. Eng. Des. 1984, 80, 233–245. [Google Scholar]

- Zhang, Q.S.; Yang, Q.S.; Ren, J.X. A new approach to rock damage variables and intrinsic constitutive equations. J. Rock Mech. Geotech. 2003, 1, 30–34. [Google Scholar]

| Specific Gravity (g/cm3) | Optimum Moisture Content (%) | Dry Density (g/cm3) | Liquid Limit (%) | Plastic Limit (%) | Plastic Limit Index | Uniformity Coefficient | Coefficient of Curvature |

|---|---|---|---|---|---|---|---|

| 1.8 | 16.6 | 1.7 | 33 | 21 | 12 | 6.04 | 1.4 |

| Chemical Composition | SiO2 | CaO | MgO | SO3 | Loss on Burn | Al2O3 | Fe2O3 |

|---|---|---|---|---|---|---|---|

| Lime | 3.5 | 82.4 | 7.3 | 0.6 | 2.0 | / | / |

| Fly ash | 51 | 3.87 | 0.93 | 0.60 | 1.44 | 32.30 | 7.56 |

| Cement | 21 | 59 | ≤1.5 | ≤0.3 | ≤0.5 | 15.1 | 4.2 |

| Factor | Levels | |

|---|---|---|

| Stage 1 | Temperature (°C) | 20/−10/−20 |

| Age (d) | 3/7/14/28/90 | |

| Salinity (%) | 0/1/2/3/4/5 | |

| Stage 2 | Freeze–thaw cycles (times) | 0/5/10/14 |

| Salinity (%) | 1/2/3 | |

| Confining pressure (MPa) | 0.1/0.3/0.5/0.8/1.0/1.5 |

| CP/Mpa | a | b | R2 |

|---|---|---|---|

| 0.1 | 1806.7 | −4.9 | 1.00 |

| 0.3 | 2007.3 | −3.6 | 0.99 |

| 0.5 | 2344.1 | −3.0 | 0.99 |

| 0.8 | 2552.2 | −2.6 | 0.98 |

| 1.0 | 2895.5 | −2.5 | 0.98 |

| 1.5 | 3130.4 | −2.3 | 0.94 |

| CP (MPa) | a | b | c | R2 |

|---|---|---|---|---|

| 0.1 | 26.5 | 1552.1 | 1.9 | 1.00 |

| 0.3 | 44.2 | 1635.4 | 3.0 | 0.99 |

| 0.5 | 54.7 | 1834.9 | 3.7 | 0.98 |

| 0.8 | 90.6 | 2268.4 | 4.2 | 1.00 |

| 1.0 | 117.7 | 2964.4 | 5.2 | 0.98 |

| 1.5 | 202.2 | 3203.9 | 5.9 | 0.98 |

| Parameter | k | H | R2 |

|---|---|---|---|

| a | 124.3 | 2.3 | 0.96 |

| b | 1328.3 | 1313.3 | 0.93 |

| c | 2.8 | 2.0 | 0.94 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Q.; Hu, Z.; Huang, S.; Chen, K.; Liu, Y.; Ding, L. An Investigation of Non-Linear Strength Characteristics of Solidified Saline Soils in Cold Regions. Materials 2022, 15, 7594. https://doi.org/10.3390/ma15217594

Ding Q, Hu Z, Huang S, Chen K, Liu Y, Ding L. An Investigation of Non-Linear Strength Characteristics of Solidified Saline Soils in Cold Regions. Materials. 2022; 15(21):7594. https://doi.org/10.3390/ma15217594

Chicago/Turabian StyleDing, Qian, Zheng Hu, Shuai Huang, Kezheng Chen, Yanjie Liu, and Lin Ding. 2022. "An Investigation of Non-Linear Strength Characteristics of Solidified Saline Soils in Cold Regions" Materials 15, no. 21: 7594. https://doi.org/10.3390/ma15217594

APA StyleDing, Q., Hu, Z., Huang, S., Chen, K., Liu, Y., & Ding, L. (2022). An Investigation of Non-Linear Strength Characteristics of Solidified Saline Soils in Cold Regions. Materials, 15(21), 7594. https://doi.org/10.3390/ma15217594