Multiscale Analysis of Bi-Layer Lattice-Filled Sandwich Structure Based on NIAH Method

Abstract

:1. Introduction

2. Analysis of Structural Equivalent Stiffness

2.1. Calculation of Equivalent Stiffness Using NIAH Method

2.2. Calculation of Shear Stiffness Using NIAH Method

3. Numerical Examples of the Effect of Unit Cell Parameters on Equivalent Analysis

3.1. Calculation of Equivalent Stiffness of Single Bi-layer Lattice Cell

3.1.1. Effects of Unit Cell Parameters on Tensile Stiffness

3.1.2. Effects of Unit Cell Parameters on Bending Stiffness

3.1.3. Effects of Unit Cell Parameters on Shear Stiffness

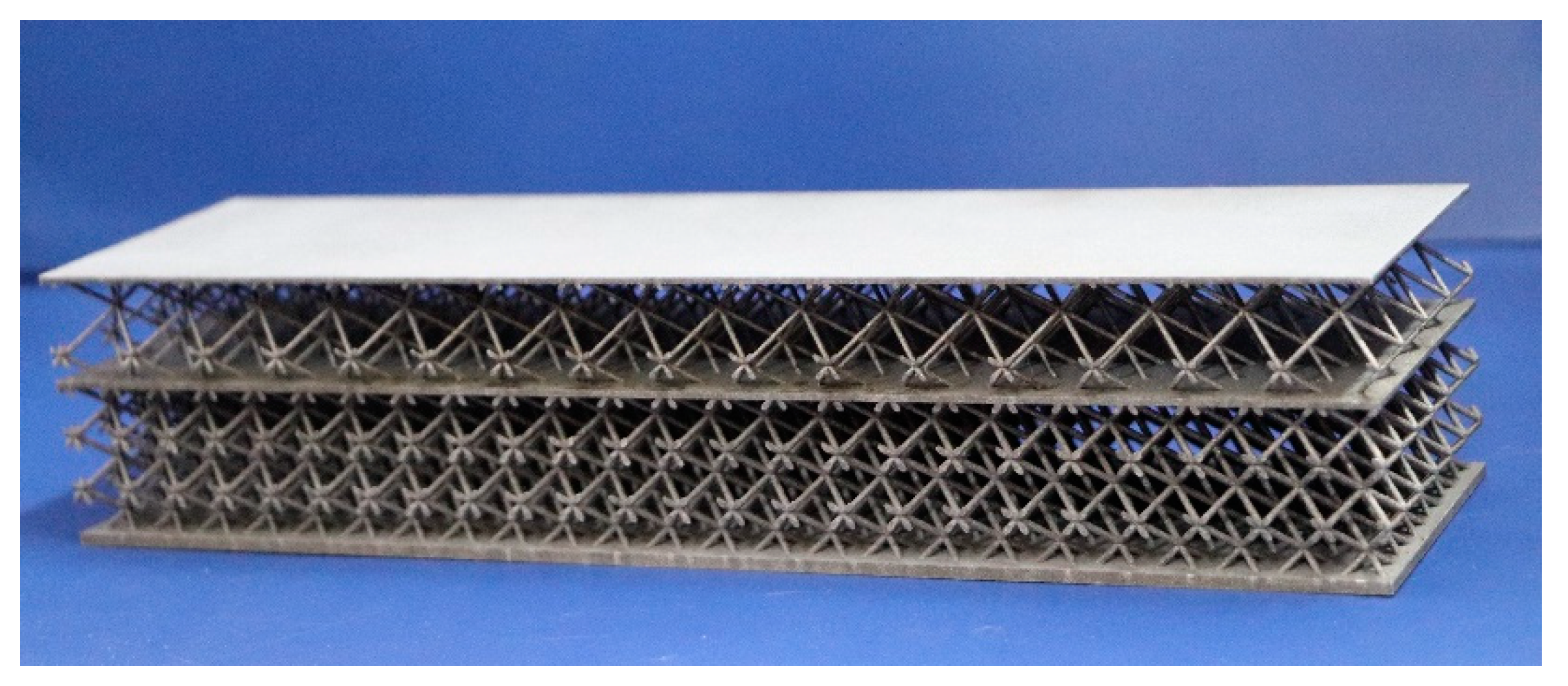

3.2. Bi-Layer Lattice-Filled Sandwich Plate

3.2.1. Deformation Analysis of Bi-Layer Lattice-Filled Sandwich Plate

3.2.2. Effects of Lattice Parameters on Accuracy of Results

4. A Bi-Layer Lattice Filled Cylinder

4.1. The Equivalent Stiffness of Four Bi-Layer Lattice Cells

4.2. Bi-Layer Lattice-Filled Cylinder

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wadley, H.N.G.; Fleck, N.A.; Evans, A.G. Fabrication and structural performance of periodic cellular metal sandwich structures. Compos. Sci. Technol. 2003, 63, 2331–2343. [Google Scholar] [CrossRef]

- Ashby, M.F.; Evans, A.; Fleck, N.A.; Gibson, L.J.; Hutchinson, W.J.; Wadley, H.N.G. Metal foams: A design guide. Appl. Mech. Rev. 2012, 23, 119. [Google Scholar]

- Gibson, L.J. Cellular solids. Mrs. Bull. 2003, 28, 270–274. [Google Scholar] [CrossRef] [Green Version]

- Zheng, J.; Qin, Q.; Wang, T.J. Impact plastic crushing and design of density-graded cellular materials. Mech. Mater. 2016, 94, 66–78. [Google Scholar] [CrossRef]

- Nasirov, A.; Fidan, I. Prediction of mechanical properties of fused filament fabricated structures via asymptotic homogenization. Mech. Mater. 2020, 145, 103372. [Google Scholar] [CrossRef]

- Silva, E.; Walters, M.C.; Paulino, G.H. Modeling bamboo as a functionally graded material: Lessons for the analysis of affordable materials. J. Mater. Sci. 2006, 41, 6991–7004. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, W.; Quan, D.; Shi, G.H.; Gao, T. Correction to: From Topology Optimization Design to Additive Manufacturing: Today’s Success and Tomorrow’s Roadmap. Arch. Comput. Methods E 2021, 28, 269. [Google Scholar] [CrossRef]

- Hu, J.; Luo, Y.; Liu, S. Two-scale concurrent topology optimization method of hierarchical structures with self-connected multiple lattice-material domains. Compos. Struct. 2021, 272, 114224. [Google Scholar] [CrossRef]

- Li, Q.H.; Xu, R.; Wu, Q.B.; Liu, S.T. Topology optimization design of quasi-periodic cellular structures based on erode–dilate operators. Comput. Method. Appl. Mech. Eng. 2021, 377, 113720. [Google Scholar] [CrossRef]

- Yan, J.; Zhang, C.G.; Huo, S.X.; Chai, X.H.; Liu, Z.H.; Yan, K. Experimental and numerical simulation of bird-strike performance of lattice-material-infilled curved plate. Chin. J. Aeronaut. 2021, 34, 245–257. [Google Scholar] [CrossRef]

- Sun, Y.; Guo, L.C.; Wang, T.S.; Zhong, S.Y.; Pan, H.Z. Bending behavior of composite sandwich structures with graded corrugated truss cores. Compos. Struct. 2017, 185, 446–454. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; Zhao, L. Dynamic response of functionally graded cellular materials based on the Voronoi model. Compos. Part B 2016, 85, 176–187. [Google Scholar] [CrossRef]

- Lefebvre, J.E.; Zhang, V.; Gazalet, J.; Gryba, T.; Sadaune, V. Acoustic wave propagation in continuous functionally graded plates: An extension of the Legendre polynomial approach. IEEE T Ultrason. Ferroelectr. Freq. Control 2001, 48, 1332–1340. [Google Scholar] [CrossRef] [PubMed]

- Sun, G.; Wang, E.; Wang, H.; Xiao, Z.; Li, Q. Low-velocity impact behaviour of sandwich panels with homogeneous and stepwise graded foam cores. Mater. Design. 2018, 160, 1117–1136. [Google Scholar] [CrossRef]

- Zhou, J.; Guan, Z.W.; Cantwell, W.J. The impact response of graded foam sandwich structures. Compos. Struct. 2013, 97, 370–377. [Google Scholar] [CrossRef]

- Woodward, B.; Kashtalyan, M. 3D elasticity analysis of sandwich plates with graded core under distributed and concentrated loadings. Int. J. Mech. Sci. 2011, 53, 872–885. [Google Scholar] [CrossRef]

- Liu, X.R.; Tian, X.G.; Lu, T.J.; Liang, B. Sandwich plates with functionally graded metallic foam cores subjected to air blast loading. Int. J. Mech. Sci. 2014, 84, 61–72. [Google Scholar] [CrossRef]

- Xu, G.D.; Zhai, J.J.; Tao, Z.; Wang, Z.H.; Fang, D.N. Response of composite sandwich beams with graded lattice core. Compos. Struct. 2015, 119, 666–676. [Google Scholar] [CrossRef]

- Guo, L.C.; Noda, N. Modeling method for a crack problem of functionally graded materials with arbitrary properties—Piecewise-exponential model. Int. J. Solids Struct. 2007, 44, 6768–6790. [Google Scholar] [CrossRef] [Green Version]

- Ajdari, A.; Nayeb-Hashemi, H.; Vaziri, A. Dynamic crushing and energy absorption of regular, irregular and functionally graded cellular structures. Int. J. Solids Struct. 2011, 48, 506–516. [Google Scholar] [CrossRef]

- Cheng, L.; Bai, J.; To, A.C. Functionally graded lattice structure topology optimization for the design of additive manufactured components with stress constraints—ScienceDirect. Comput. Method. Appl. Mech. Eng. 2019, 344, 334–359. [Google Scholar] [CrossRef]

- Li, H.; Luo, Z.; Zhang, N.; Gao, L.; Brown, T. Integrated design of cellular composites using a level-set topology optimization method. Comput. Method. Appl. Mech. Eng. 2016, 309, 453–475. [Google Scholar] [CrossRef]

- Cheng, G.D.; Cai, Y.W.; Xu, L. Novel implementation of homogenization method to predict effective properties of periodic materials. Acta Mech. Sinica 2013, 29, 550–556. [Google Scholar] [CrossRef]

- Wang, B.; Tian, K.; Hao, P.; Zheng, Y.; Ma, Y.; Wang, J. Numerical-based smeared stiffener method for global buckling analysis of grid-stiffened composite cylindrical shells. Compos. Struct. 2016, 9, 807–815. [Google Scholar] [CrossRef]

- Kalamkarov, A.L.; Kolpakov, A.G. Analysis, Design, and Optimization of Composite Structures, 2nd ed.; Prentice Hall: Hoboken, NJ, USA, 1997. [Google Scholar]

- Cai, Y.; Xu, L.; Cheng, G.D. Novel numerical implementation of asymptotic homogenization method for periodic plate structures. Int. J. Solids Struct. 2014, 51, 284–292. [Google Scholar] [CrossRef] [Green Version]

- Xu, L.; Cheng, G.D. Shear stiffness prediction of reissner-mindlin plates with periodic microstructures. Mech. Adv. Mater. Struc. 2017, 24, 271–286. [Google Scholar] [CrossRef]

- Yan, J.; Jiang, C.C.; Fan, Z.R.; Xu, Q.; Du, H.Z.; Sun, W.; Wang, G.Y.; Niu, B. Compression Experiment and Failure Analysis of Additive Manufactured Multi-Layer Lattice Sandwich Structure. Int. J. Appl. Mech. 2021, 13, 2150077. [Google Scholar] [CrossRef]

| n | wFEM (mm) | wS-NIAH (mm) | Error | wNIAH (mm) | Error |

|---|---|---|---|---|---|

| 10 | 0.019 | 0.020 | 1.23% | 0.007 | 65.91% |

| 20 | 0.100 | 0.101 | 0.01% | 0.047 | 53.48% |

| 30 | 0.301 | 0.302 | 0.30% | 0.178 | 41.17% |

| 40 | 0.719 | 0.721 | 0.34% | 0.494 | 31.46% |

| 50 | 1.462 | 1.468 | 0.44% | 1.107 | 24.57% |

| 60 | 2.734 | 2.744 | 0.37% | 2.214 | 19.31% |

| 70 | 4.728 | 4.742 | 0.30% | 4.009 | 15.46% |

| 80 | 7.689 | 7.708 | 0.25% | 6.738 | 12.58% |

| h (mm) | wFEM (mm) | wS-NIAH (mm) | Error |

|---|---|---|---|

| 10 | 2.449 | 2.456 | 0.29% |

| 15 | 1.169 | 1.170 | 0.09% |

| 20 | 0.719 | 0.721 | 0.28% |

| 25 | 0.513 | 0.516 | 0.58% |

| 30 | 0.405 | 0.408 | 0.74% |

| t (mm) | wFEM (mm) | wS-NIAH (mm) | Error |

|---|---|---|---|

| 1.0 | 1.140 | 1.152 | 1.04% |

| 2.0 | 0.719 | 0.721 | 0.28% |

| 3.0 | 0.571 | 0.575 | 0.70% |

| 4.0 | 0.493 | 0.501 | 1.62% |

| 5.0 | 0.443 | 0.456 | 2.93% |

| tm (mm) | wFEM (mm) | wS-NIAH (mm) | Error |

|---|---|---|---|

| 1.0 | 0.728 | 0.729 | 0.14% |

| 2.0 | 0.719 | 0.721 | 0.28% |

| 3.0 | 0.715 | 0.717 | 0.28% |

| 4.0 | 0.711 | 0.712 | 0.14% |

| 5.0 | 0.706 | 0.707 | 0.14% |

| r1 (mm) | wFEM (mm) | wS-NIAH (mm) | Error |

|---|---|---|---|

| 0.8 | 0.794 | 0.798 | 0.50% |

| 0.9 | 0.752 | 0.753 | 0.13% |

| 1.0 | 0.719 | 0.721 | 0.28% |

| 1.1 | 0.694 | 0.696 | 0.29% |

| 1.2 | 0.675 | 0.677 | 0.30% |

| r2 (mm) | wFEM (mm) | wS-NIAH (mm) | Error |

|---|---|---|---|

| 0.40 | 0.796 | 0.799 | 0.37% |

| 0.45 | 0.752 | 0.754 | 0.27% |

| 0.50 | 0.719 | 0.721 | 0.28% |

| 0.55 | 0.694 | 0.696 | 0.29% |

| 0.60 | 0.675 | 0.675 | 0.09% |

| Mass Ratio | Dimensions (mm) | Shear Stiffness (102 N/mm) | wFEM (mm) | wS-NIAH (mm) | Error | ||

|---|---|---|---|---|---|---|---|

| r1 | r2 | r1 | r2 | ||||

| 90:10 | 1.342 | 0.224 | 30.280 | 0.891 | 1.015 | 1.215 | 19.70% |

| 70:30 | 1.183 | 0.387 | 18.550 | 7.128 | 0.762 | 0.773 | 1.44% |

| 50:50 | 1.000 | 0.500 | 9.587 | 17.872 | 0.719 | 0.721 | 0.28% |

| 30:70 | 0.775 | 0.592 | 3.796 | 31.952 | 0.758 | 0.772 | 1.85% |

| 10:90 | 0.447 | 0.671 | 0.394 | 48.596 | 0.999 | 1.213 | 21.42% |

| Configuration | (105 N/mm) | (105 N/mm) | (105 N/mm) | (105 N/mm) | (107 N•mm) |

|---|---|---|---|---|---|

| BCC | 4.791 | 1.583 | 4.791 | 1.774 | 12.778 |

| BCCZ | 4.847 | 1.640 | 4.847 | 1.752 | 12.847 |

| FCC | 4.979 | 1.643 | 4.979 | 1.731 | 12.990 |

| FCCZ | 4.981 | 1.659 | 4.981 | 1.717 | 12.991 |

| Configuration | (107N•mm) | (107N•mm) | (107N•mm) | (104N/mm) | (104N/mm) |

| BCC | 4.219 | 12.778 | 4.497 | 1.603 | 1.603 |

| BCCZ | 4.290 | 12.847 | 4.469 | 1.441 | 1.441 |

| FCC | 4.285 | 12.990 | 4.422 | 1.208 | 1.208 |

| FCCZ | 4.303 | 12.991 | 4.407 | 1.093 | 1.093 |

| Lattice Cell | m | wFEM (10−2 mm) | wS-NIAH (10−2 mm) | Error | wNIAH (10−2 mm) | Error |

|---|---|---|---|---|---|---|

| BCC | 50 | 0.455 | 0.478 | 5.02% | 0.332 | 27.00% |

| 60 | 0.682 | 0.704 | 3.21% | 0.522 | 23.44% | |

| 70 | 0.911 | 0.943 | 3.54% | 0.694 | 23.85% | |

| 80 | 1.229 | 1.259 | 2.51% | 0.983 | 19.97% | |

| 90 | 1.543 | 1.579 | 2.32% | 1.234 | 20.05% | |

| 100 | 1.957 | 1.991 | 1.70% | 1.637 | 16.33% | |

| 110 | 2.421 | 2.452 | 1.27% | 2.106 | 13.03% | |

| 120 | 2.878 | 2.907 | 0.99% | 2.506 | 12.91% | |

| 130 | 3.443 | 3.471 | 0.78% | 3.099 | 9.99% | |

| 140 | 3.995 | 4.017 | 0.56% | 3.604 | 9.80% | |

| 150 | 4.664 | 4.684 | 0.44% | 4.321 | 7.35% | |

| BCCZ | 50 | 0.435 | 0.482 | 10.93% | 0.330 | 24.19% |

| 60 | 0.655 | 0.708 | 8.21% | 0.518 | 20.85% | |

| 70 | 0.888 | 0.950 | 7.04% | 0.688 | 22.50% | |

| 80 | 1.196 | 1.265 | 5.75% | 0.975 | 18.49% | |

| 90 | 1.516 | 1.587 | 4.67% | 1.223 | 19.33% | |

| 100 | 1.917 | 1.994 | 4.04% | 1.623 | 15.35% | |

| 110 | 2.367 | 2.451 | 3.56% | 2.086 | 11.84% | |

| 120 | 2.815 | 2.906 | 3.25% | 2.484 | 11.76% | |

| 130 | 3.363 | 3.461 | 2.92% | 3.070 | 8.71% | |

| 140 | 3.905 | 4.008 | 2.64% | 3.571 | 8.57% | |

| 150 | 4.553 | 4.664 | 2.43% | 4.280 | 6.00% | |

| FCC | 50 | 0.426 | 0.483 | 13.32% | 0.322 | 24.27% |

| 60 | 0.643 | 0.705 | 9.71% | 0.507 | 21.19% | |

| 70 | 0.884 | 0.949 | 7.38% | 0.673 | 23.84% | |

| 80 | 1.186 | 1.257 | 5.96% | 0.953 | 19.66% | |

| 90 | 1.505 | 1.581 | 4.96% | 1.196 | 20.52% | |

| 100 | 1.897 | 1.977 | 4.25% | 1.586 | 16.35% | |

| 110 | 2.334 | 2.420 | 3.71% | 2.039 | 12.65% | |

| 120 | 2.782 | 2.872 | 3.22% | 2.427 | 12.76% | |

| 130 | 3.312 | 3.408 | 2.90% | 2.998 | 9.48% | |

| 140 | 3.846 | 3.947 | 2.63% | 3.487 | 9.34% | |

| 150 | 4.471 | 4.579 | 2.42% | 4.178 | 6.56% | |

| FCCZ | 50 | 0.426 | 0.488 | 24.27% | 0.323 | 24.31% |

| 60 | 0.642 | 0.712 | 21.19% | 0.507 | 21.03% | |

| 70 | 0.883 | 0.959 | 23.84% | 0.673 | 23.76% | |

| 80 | 1.184 | 1.268 | 19.66% | 0.954 | 19.47% | |

| 90 | 1.504 | 1.595 | 20.52% | 1.197 | 20.42% | |

| 100 | 1.893 | 1.993 | 16.35% | 1.587 | 16.15% | |

| 110 | 2.327 | 2.436 | 12.65% | 2.039 | 12.36% | |

| 120 | 2.776 | 2.891 | 12.76% | 2.428 | 12.54% | |

| 130 | 3.302 | 3.426 | 9.48% | 2.999 | 9.17% | |

| 140 | 3.836 | 3.968 | 9.34% | 3.488 | 9.07% | |

| 150 | 4.456 | 4.597 | 6.56% | 4.180 | 6.20% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, J.; Zhang, C.; Li, X.; Xu, L.; Fan, Z.; Sun, W.; Wang, G.; Yan, K. Multiscale Analysis of Bi-Layer Lattice-Filled Sandwich Structure Based on NIAH Method. Materials 2022, 15, 7710. https://doi.org/10.3390/ma15217710

Yan J, Zhang C, Li X, Xu L, Fan Z, Sun W, Wang G, Yan K. Multiscale Analysis of Bi-Layer Lattice-Filled Sandwich Structure Based on NIAH Method. Materials. 2022; 15(21):7710. https://doi.org/10.3390/ma15217710

Chicago/Turabian StyleYan, Jun, Chenguang Zhang, Xin Li, Liang Xu, Zhirui Fan, Wei Sun, Guangyuan Wang, and Kun Yan. 2022. "Multiscale Analysis of Bi-Layer Lattice-Filled Sandwich Structure Based on NIAH Method" Materials 15, no. 21: 7710. https://doi.org/10.3390/ma15217710