A Study of Hydrogen Embrittlement of SA-372 J Class High Pressure Hydrogen Storage Seamless Cylinder (≥100 MPA)

Abstract

:1. Introduction

2. Test Method and Sample Preparation

2.1. Summary of the Test Method

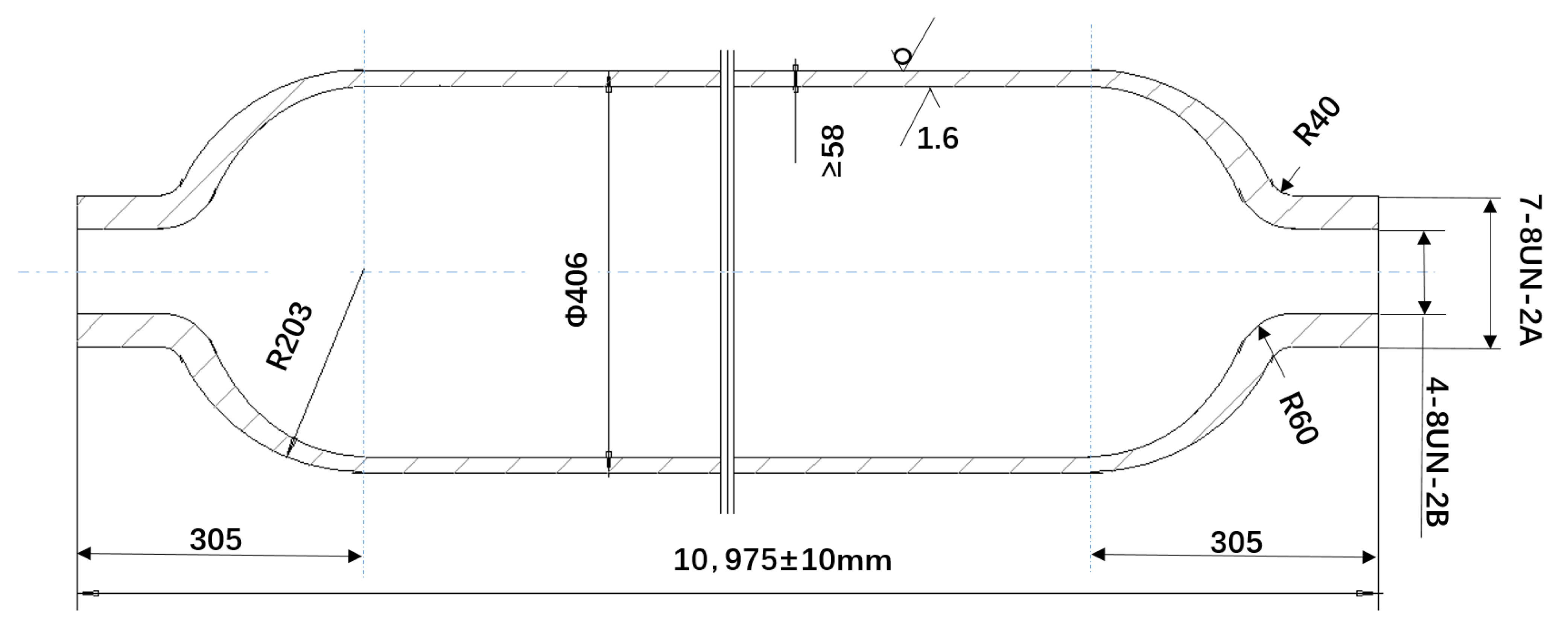

2.2. High-Pressure Hydrogen Storage Cylinder Manufacturing

2.3. Sampling Location and Numbers

2.3.1. Disc Sampling (A, B, and C)

2.3.2. Sampling Disc

- Diameter: 58 ± 0.05 mm;

- Thickness: 0.75 mm ± 0.005 mm;

- Flatness: less than 1/10 mm deflection.

2.3.3. Number of Samples

2.4. Test Method

3. Test Results and Discussion

3.1. Helium Rupture

3.2. H2 Rupture Pressure Test

3.2.1. Three Cylinder Body Pr′He/Pr′H2 Ratio

3.2.2. The Pr′He/Pr′H2 Ratio of Three Cylinders at the Body-Shoulder Junction

3.2.3. The Pr′He/Pr′H2 Ratio of the Shoulder of the Three Cylinders

3.3. Analysis of Experimental Results

3.3.1. The Relationship between the Strength and the Sensitivity to Hydrogen Embrittlement Index

3.3.2. The Relationship between Different Microstructures and the Hydrogen Embrittlement Index

4. Conclusions

- The experimental results show the hydrogen embrittlement index is cylinder body > the junction of body and shoulder > cylinder shoulder > 2;

- The experimental results show an increase in the strength of SA372 Grade J steel will lead to an increase in hydrogen embrittlement sensitivity;

- The experimental results show that different microstructures have different hydrogen embrittlement sensitivity. The hydrogen embrittlement sensitivity of balance sorbite is better than that of pearlite.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, J.Y.; Kai, F.M.; Liu, Z.Q.; Chen, R.; Chen, C.P. High pressure hydrogen storage and transportation equipment and its risk assessment. J. Sol. Energy 2006, 27, 1168–1174. [Google Scholar]

- Chen, R.; Zheng, J.Y.; Xu, P.; Kai, F.M.; Liu, P.F. Research progress of hydrogen embrittlement of metal materials at room temperature and high pressure. Sun Chin. J. Energy 2008, 29, 502–508. [Google Scholar]

- Zheng, J.; Liu, X.; Xu, P.; Liu, P.; Zhao, Y.; Yang, J. Development of high pressure gaseous hydrogen storage technologies. Int. J. Hydrog. Energy 2012, 37, 1048–1057. [Google Scholar] [CrossRef]

- Mostafaeipour, A.; Khayyami, M.; Sedaghat, A.; Mohammadi, K.; Shamshirband, S.; Sehati, M.; Gorakifard, E. Evaluating the wind energy potential for hydrogen production: A case study. Int. J. Hydrog. Energy 2016, 41, 6200–6210. [Google Scholar] [CrossRef]

- Ni, M.; Leung, D.; Leung, M.; Leung, M.K.H.; Sumathy, K. An overview of hydrogen production from biomass. Fuel Process. Technol. 2006, 87, 461–472. [Google Scholar] [CrossRef]

- Veziroglu, T.N.; Sahi, N.S. 21st Century energy: Hydrogen energy system. Energy Convers. Manag. 2008, 49, 1820–1831. [Google Scholar] [CrossRef]

- Barreto, L.; Makihira, A.; Riahi, K. The hydrogen economy in the 21st century: A sustainable development scenario. Int. J. Hydrog. Energy 2003, 28, 267–284. [Google Scholar] [CrossRef] [Green Version]

- ASTM F1624-17; Standard Test Method for Hydrogen embrittlement Threshold in Steel by Incremental Step Loading Technique. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM F1459-06 (Reapproved 2017); Standard Test Method for Determining Sensitivity of metallic materials to Hydrogen embrittlement (HGE). ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM G142-98 (Reapproved 2016); Standard Test Method for Determination of embrittlement Sensitivity of metals Containing Hydrogen at High pressure, high temperature, or both. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM STP 543; Hydrogen embrittlement test. ASTM International: West Conshohocken, PA, USA, 1974.

- ISO 11114-4:2005; Transport-gas cylinder compatibility Test method of ME-Hydrogen embrittlement resistant metallic material. International Organization for Standardization: Geneva, Switzerland, 2005.

- ASME VIII-3; Article KD—10 Service for special requirements of hydrogen vessels. ASTM International: West Conshohocken, PA, USA, 2021.

- NACE TM0284-2003; Evaluation of hydrogen induced cracking resistance of pipeline and pressure vessel steel. NACE International: Houston, TX, USA, 2003.

- ANSI/CSA CHMC1-2014; Test method for Material Compatibility Assessment in Compressed Hydrogen Applications. We ANSI: New York, NY, USA, 2014.

- SAE J2579 JAN2009; Fuel technical information report. SAE International: Warrendale, PA, USA, 2009.

- Somerday, B.P.; Marchi, C.S.; Nibur, K. Measurement of fatigue crack growth rates for SA-372 Gr. J steel in 100 MPA hydrogen gas following article KD-10 (PVP2013-97455). In Proceedings of the ASME Pressure Vessels and Piping Division Conference, Paris, France, 14–18 July 2013. [Google Scholar]

- Somerday, B.P.; Marchi, C.S.; Nibur, K. Measurement of fatigue crack growth rates for steels in hydrogen containment components. In Proceedings of the International Conference on Hydrogen Safety (ICHS), Ajaccio, Corsica, France, 16–18 September 2009. [Google Scholar]

- Wada, Y.; Ishigaki, R.; Tanaka, Y.; Iwadate, T.; Ohnishi, K. Effect of Hydrogen Gas Pressure on The Mechanical Properties of Low Alloy Steel for Hydrogen Pressure Vessels. In Proceedings of the 2007 ASME Pressure Vessels and Piping Division Conference, San Antonio, TX, USA, 22–26 July 2007. [Google Scholar]

- Sehefer, R.W.; Hour, W.G.; Williams, T.C.; Bourne, B.; Colton, J. Characterization of high-pressure, under expanded hydrogen-jet flames. Int. J. Hydrog. Energy 2007, 32, 2081–2093. [Google Scholar] [CrossRef]

- Liang, B.X.; Yang, M.H.; Yang, Y.H.; Xia, Q. Cylinder Spinning Forming Technology. Electromechanical Eng. Technol. 2004, 33, 12–13. [Google Scholar]

- Makhviladze, G.M.; Yakush, S.E. Large-seal unconfined fires and explosion. Proc. Combust. Inst. 2002, 29, 195–210. [Google Scholar] [CrossRef]

- Zhang, X. Hydrogen Embrittlement Test and Crack Tolerance Evaluation of 4130X Steel for High Pressure Hydrogen Storage Cylinder. Master’s Dissertation, Zhejiang University, Hangzhou, China, 2019. [Google Scholar]

- Nelson, H.G.; Williams, D.P. Quantitative Observations of Hydrogen-Induced, Slow Crack Growth in a Low Alloy Steel; NASA Ames Research Center: Moffett field, CA, USA, 1973. [Google Scholar]

- Loginow, A.W.; Phelps, E.H. Steels for seamless hydrogen pressure vessels. Corrosion 1975, 31, 404–412. [Google Scholar] [CrossRef]

- Hinotani, S.; Terasaki, F.; Takahashi, K. Hydrogen embrittlement of high strength steels in high pressure hydrogen gas at ambient temperature. Tetsu Hagane 1978, 64, 899–905. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.K. Hydrogen embrittlement of steel. Mach. Chem. Ind. Oil Refin. 1984, 13, 5–14. [Google Scholar]

- Westphal, D.A.; Worzala, F.J.; Bernstein, I.M.; Thompson, A.W. (Eds.) Hydrogen in Metals; ASM: Metals Park, OH, USA, 1974; p. 79. [Google Scholar]

- Tien, J.; Thompson, A.W.; Bernstein, I.M.; Richards, R.J. Hydrogen transport by dislocations. Metall. Mater. Trans. A 1976, 7, 821–829. [Google Scholar] [CrossRef]

- Ji, S.K.; You, H.L.; Lee, D.L.; Park, K.-T.; Lee, C.S. Microstructural influences on hydrogen delayed fracture of high strength steels. Mater. Sci. Eng. A 2009, 505, 105–110. [Google Scholar] [CrossRef]

- Nagao, A.; Kuramoto, S.; Ichitani, K.; Kanno, M. Visualization of hydrogen transport in high strength steels affected by stress fields and hydrogen trapping. Scr. Mater. 2001, 45, 1227–1232. [Google Scholar] [CrossRef]

| Chemical Element | C | Mn | P | S | Si | Cr | Mo |

|---|---|---|---|---|---|---|---|

| Mass fraction % | 0.39 | 0.90 | 0.010 | 0.002 | 0.31 | 1.07 | 0.22 |

| Sampling Location | Disc Test Sample No. | Tensile Test Sample No. |

|---|---|---|

| Cylinder body | Cylinder 1: A11, A12, A31–A33 Cylinder 2: A21, A22, A34–A36 Cylinder 3: A31, A32, A37–A39 | Cylinder 1: D1–D3 Cylinder 2: D4–D6 Cylinder 3: D7–D9 |

| Shoulder | Cylinder 1: B11, B12, B31–B33 Cylinder 2: B21, B22, B34–B36 Cylinder 3: B31, B32, B37–B39 | Cylinder 1: E1–E3 Cylinder 2: E4–E6 Cylinder 3: E7–E9 |

| The junction of body and shoulder | Cylinder 1: C11, C12, C31–C33 Cylinder 2: C21, C22, C34–C36 Cylinder 3: C31, C32, C37–C39 | Cylinder 1: F1–F3 Cylinder 2: F4–F6 Cylinder 3: F7–F9 |

| Sample No. | A1 | A2 | B1 | B2 | C1 | C2 |

|---|---|---|---|---|---|---|

| Pressure rise rate (bar/min) | 20.8 | 369.7 | 10.1 | 5.1 | 62.8 | 30.5 |

| Rupture pressure PHe (bar) | 569.6 | 640.8 | 607.7 | 616.6 | 640.3 | 615.9 |

| Corrected hydrogen rupture pressure Pr′He (bar) | 567.7 | 643.8 | 610.3 | 618.2 | 641.8 | 620.0 |

| Cylinder No: 1. | A31 | A32 | A33 | A34 | A35 | A36 | A37 | A38 | A39 |

|---|---|---|---|---|---|---|---|---|---|

| Pressure rise rate (bar/min) | 62.2 | 30.1 | 3.7 | 355.4 | 239.2 | 20.0 | 15.1 | 6.0 | 157.4 |

| Corrected helium rupture pressure Pr′He (bar) | 531.2 | 614.6 | 680.5 | 839.7 | 654.4 | 491.4 | 562.7 | 514.8 | 699.1 |

| Corrected hydrogen rupture pressure Pr′H2 (bar) | 384.9 | 399.1 | 456.7 | 556.1 | 448.2 | 348.5 | 367.8 | 352.6 | 488.9 |

| Pr′He/Pr′H2 | 1.38 | 1.54 | 1.49 | 1.51 | 1.46 | 1.41 | 1.53 | 1.46 | 1.43 |

| The average value | Hydrogen embrittlement index = 1.47 | ||||||||

| Cylinder No: 2. | B31 | B32 | B33 | B34 | B35 | B36 | B37 | B38 | B39 |

|---|---|---|---|---|---|---|---|---|---|

| Pressure rise rate (bar/min) | 62.2 | 30.1 | 3.7 | 355.4 | 239.2 | 20.0 | 15.1 | 6.0 | 157.4 |

| Corrected helium rupture pressure Pr′He (bar) | 587.1 | 659.0 | 761.4 | 845.3 | 680.8 | 602.3 | 580.5 | 490.0 | 739.2 |

| Corrected hydrogen rupture pressure Pr′H2 (bar) | 360.2 | 399.4 | 440.1 | 556.1 | 428.2 | 356.4 | 367.4 | 312.1 | 453.5 |

| Pr′He/Pr′H2 | 1.63 | 1.65 | 1.73 | 1.52 | 1.59 | 1.69 | 1.58 | 1.57 | 1.63 |

| The average value | Hydrogen embrittlement index = 1.62 | ||||||||

| Cylinder No: 3. | C31 | C32 | C33 | C34 | C35 | C36 | C37 | C38 | C39 |

|---|---|---|---|---|---|---|---|---|---|

| Pressure rise rate (bar/min) | 62.2 | 30.1 | 3.7 | 355.4 | 239.2 | 20.0 | 15.1 | 6.0 | 157.4 |

| Corrected helium rupture pressures Pr′He (bar) | 695.2 | 706.9 | 850.2 | 925.1 | 848.6 | 588.6 | 662.0 | 643.3 | 911.5 |

| Corrected hydrogen rupture pressure Pr′H2 (bar) | 377.8 | 399.4 | 440.5 | 486.9 | 458.7 | 328.8 | 359.8 | 342.2 | 498.1 |

| Pr′He/Pr′H2 | 1.84 | 1.77 | 1.93 | 1.90 | 1.85 | 1.79 | 1.84 | 1.88 | 1.83 |

| The average value | Hydrogen embrittlement index = 1.85 | ||||||||

| Cylinder Body | D2 | D3 | D4 | D5 | D6 | D7 | D8 | D9 |

|---|---|---|---|---|---|---|---|---|

| Tensile test value | 843 | 827 | 839 | 832 | 829 | 832 | 833 | 828 |

| Yield strength | 684 | 692 | 687 | 664 | 710 | 707 | 692 | 693 |

| Elongation | 29 | 30 | 26 | 27 | 31 | 30 | 26 | 32 |

| Hydrogen embrittlement index | 1.54 | 1.49 | 1.51 | 1.46 | 1.41 | 1.53 | 1.46 | 1.43 |

| The junction (body and shoulder) | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 |

| Tensile test value | 852 | 851 | 842 | 861 | 858 | 847 | 849 | 851 |

| Yield strength | 723 | 679 | 712 | 706 | 721 | 724 | 690 | 702 |

| Elongation | 31 | 30 | 32 | 28 | 27 | 33 | 29 | 31 |

| Hydrogen embrittlement index | 1.65 | 1.73 | 1.52 | 1.59 | 1.69 | 1.58 | 1.57 | 1.63 |

| Shoulder | E2 | E3 | E4 | E5 | E6 | E7 | E8 | E9 |

| Tensile test value | 890 | 908 | 896 | 858 | 867 | 860 | 851 | 867 |

| Yield strength | 727 | 735 | 708 | 667 | 679 | 701 | 699 | 710 |

| Elongation | 33 | 32 | 28 | 31 | 26 | 34 | 27 | 29 |

| Hydrogen embrittlement index | 1.77 | 1.93 | 1.9 | 1.85 | 1.79 | 1.84 | 1.88 | 1.83 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, R.; Fu, R.; Gu, N.; Liu, Y. A Study of Hydrogen Embrittlement of SA-372 J Class High Pressure Hydrogen Storage Seamless Cylinder (≥100 MPA). Materials 2022, 15, 7714. https://doi.org/10.3390/ma15217714

Yin R, Fu R, Gu N, Liu Y. A Study of Hydrogen Embrittlement of SA-372 J Class High Pressure Hydrogen Storage Seamless Cylinder (≥100 MPA). Materials. 2022; 15(21):7714. https://doi.org/10.3390/ma15217714

Chicago/Turabian StyleYin, Ruifeng, Ruidong Fu, Ningning Gu, and Yongjiu Liu. 2022. "A Study of Hydrogen Embrittlement of SA-372 J Class High Pressure Hydrogen Storage Seamless Cylinder (≥100 MPA)" Materials 15, no. 21: 7714. https://doi.org/10.3390/ma15217714

APA StyleYin, R., Fu, R., Gu, N., & Liu, Y. (2022). A Study of Hydrogen Embrittlement of SA-372 J Class High Pressure Hydrogen Storage Seamless Cylinder (≥100 MPA). Materials, 15(21), 7714. https://doi.org/10.3390/ma15217714