Parameter Study of Interfacial Capacities for FRP–Steel Bonded Joints Based on 3D FE Modeling

Abstract

:1. Introduction

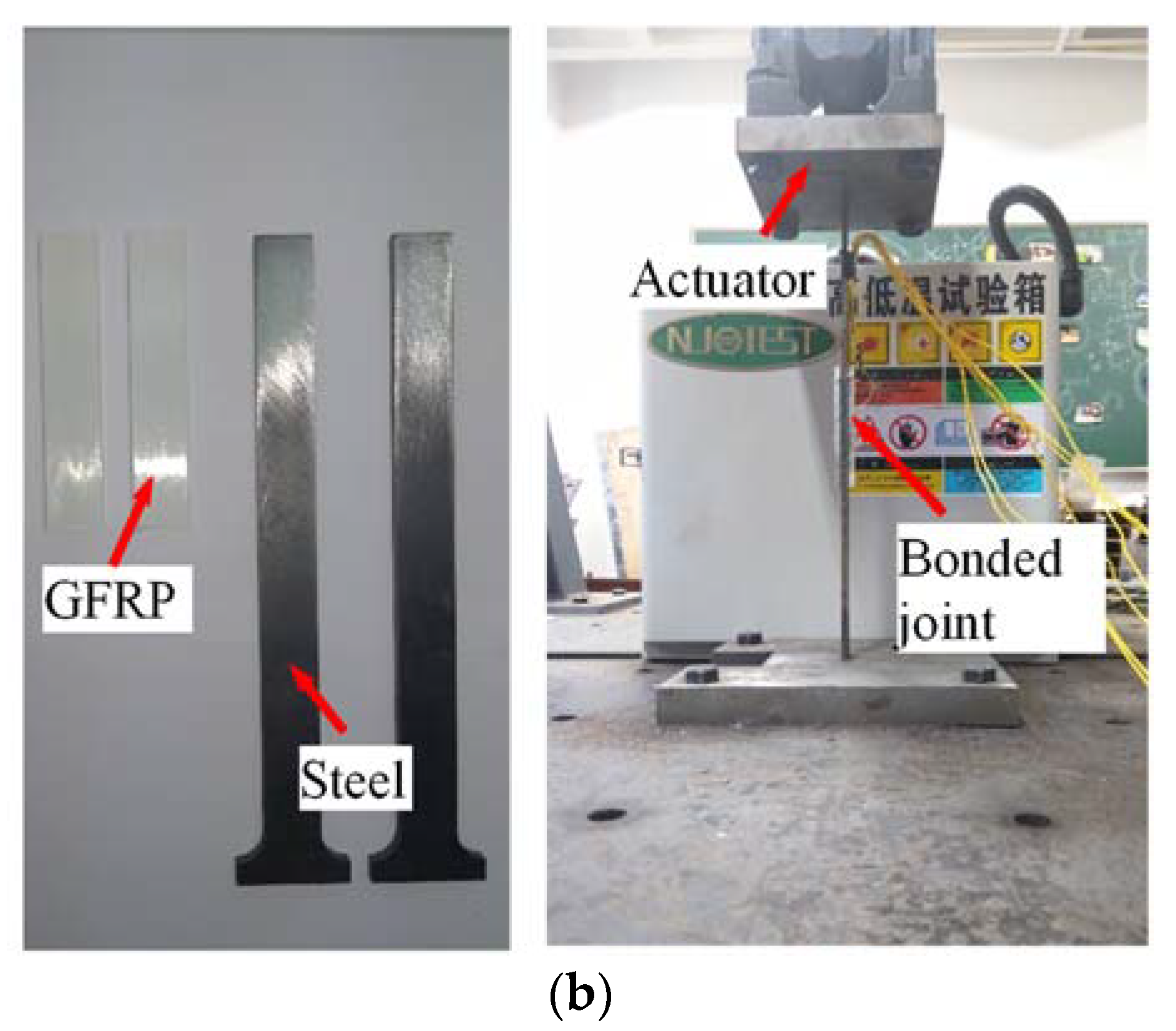

2. Bonding Materials

2.1. Material Properties of GFRP and Steel

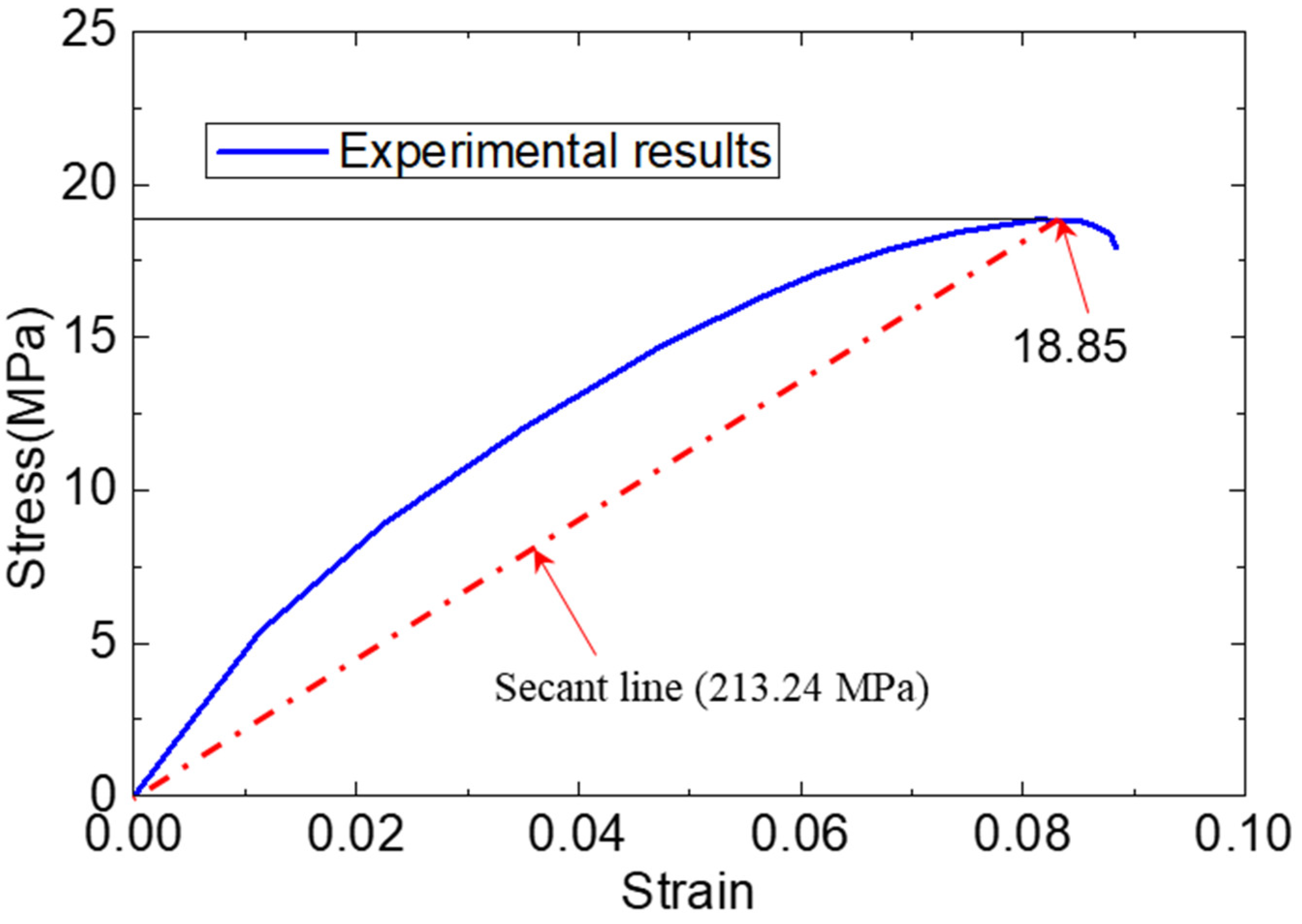

2.2. Tensile Test of the Adhesive Specimen

3. Tensile Property of GFRP–Steel Specimen

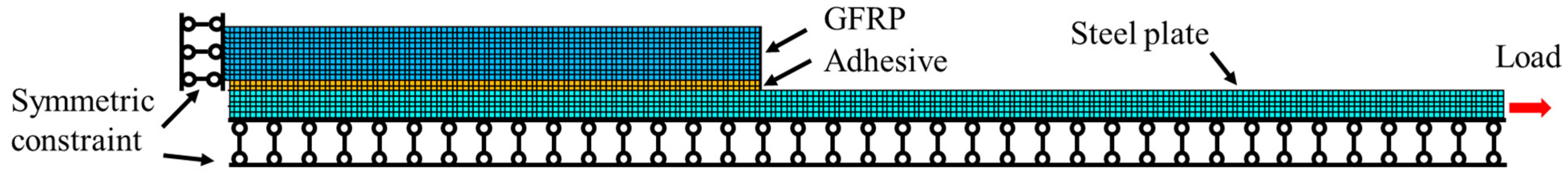

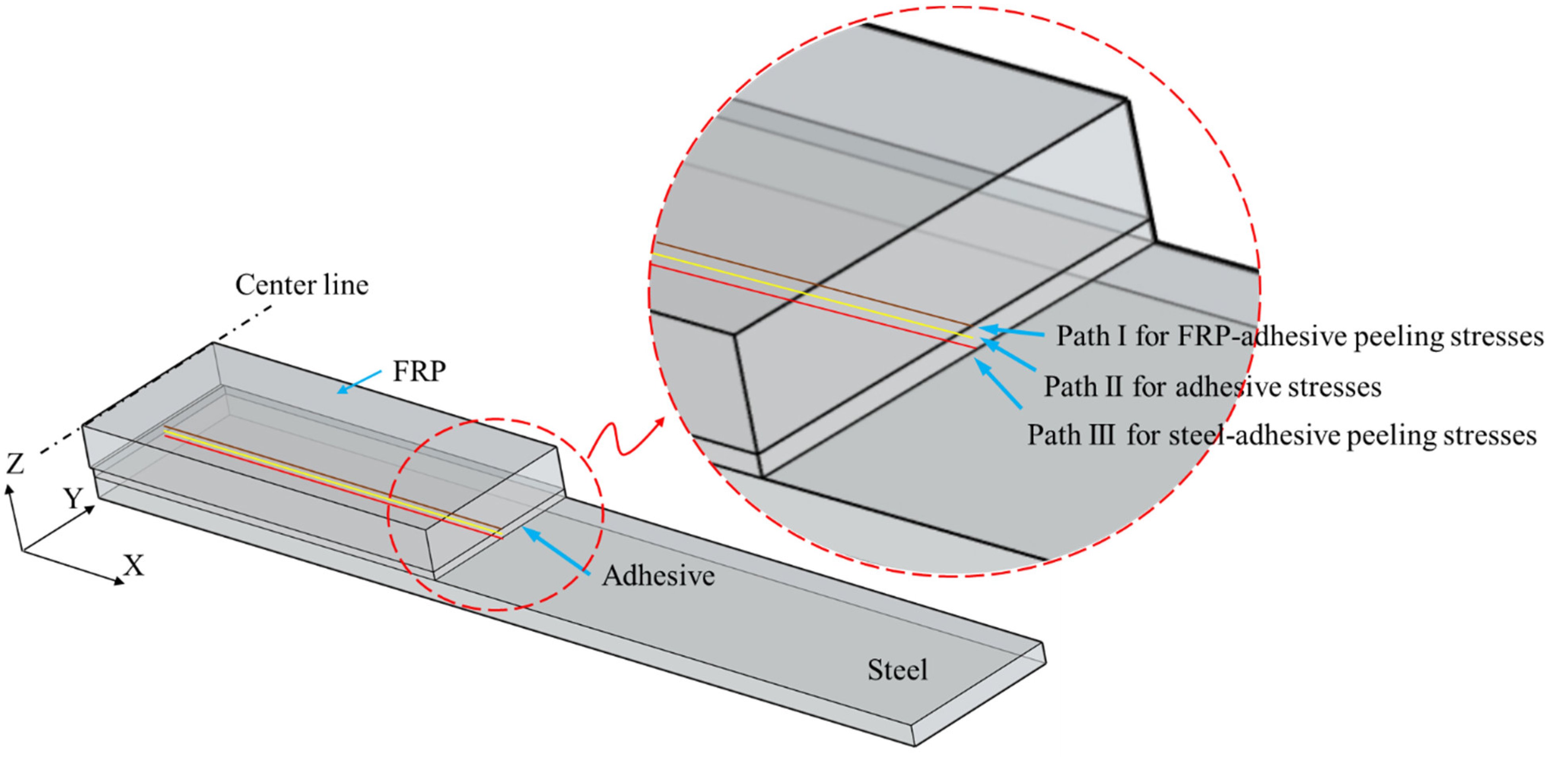

4. Finite Element Model

4.1. The Geometry of the Finite Elements

4.2. Validation of the FE Model

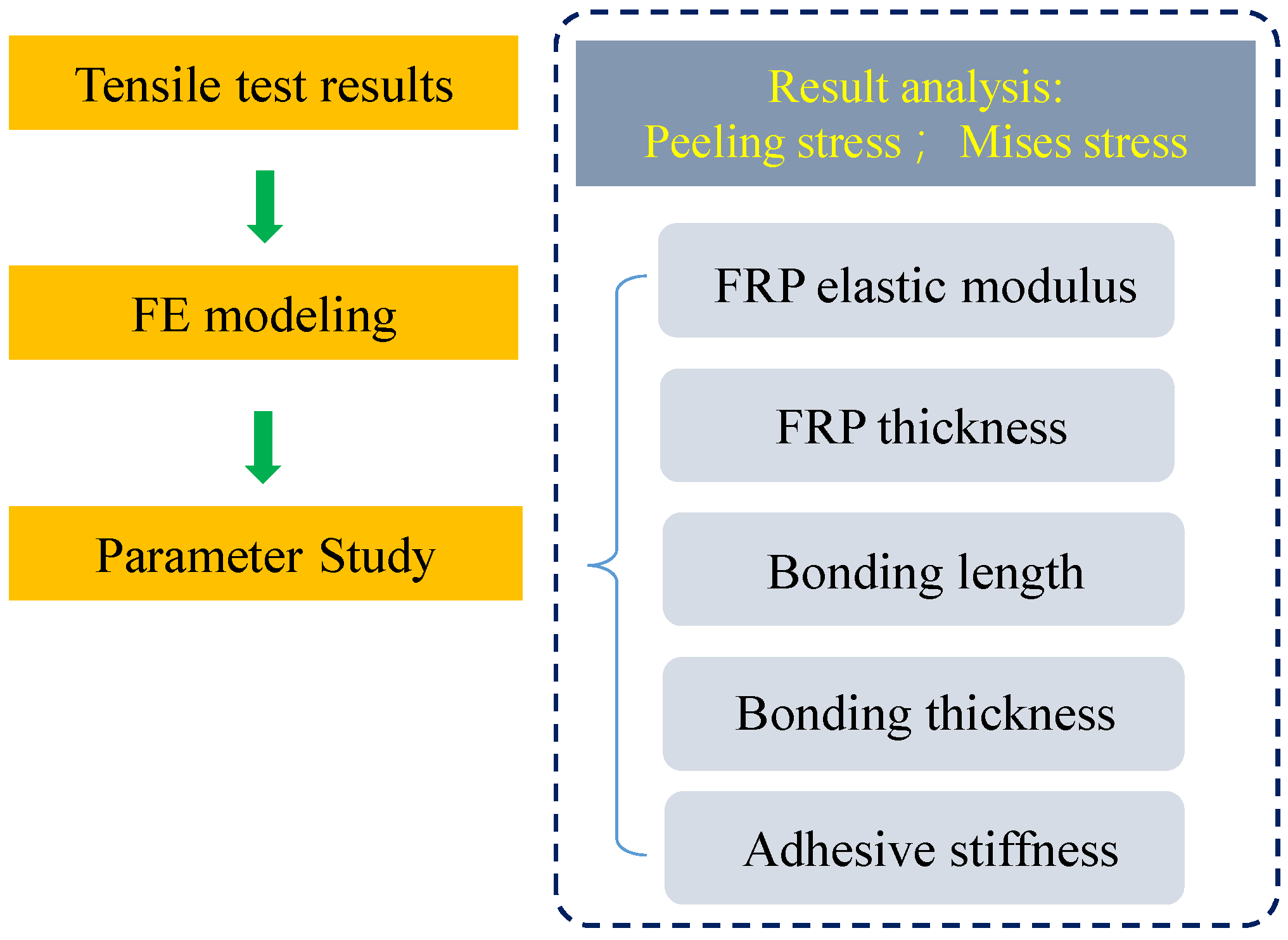

5. Parametric Studies

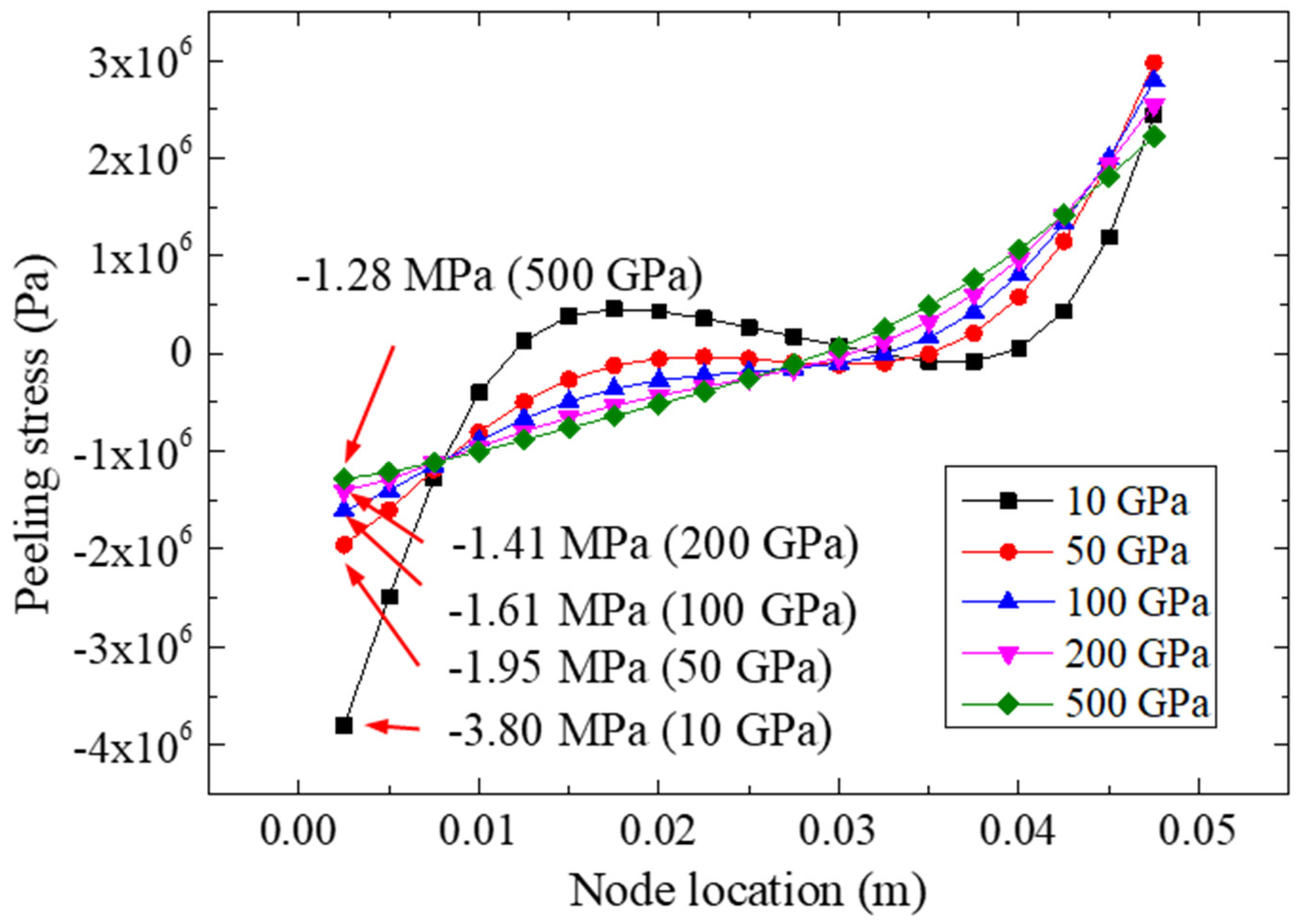

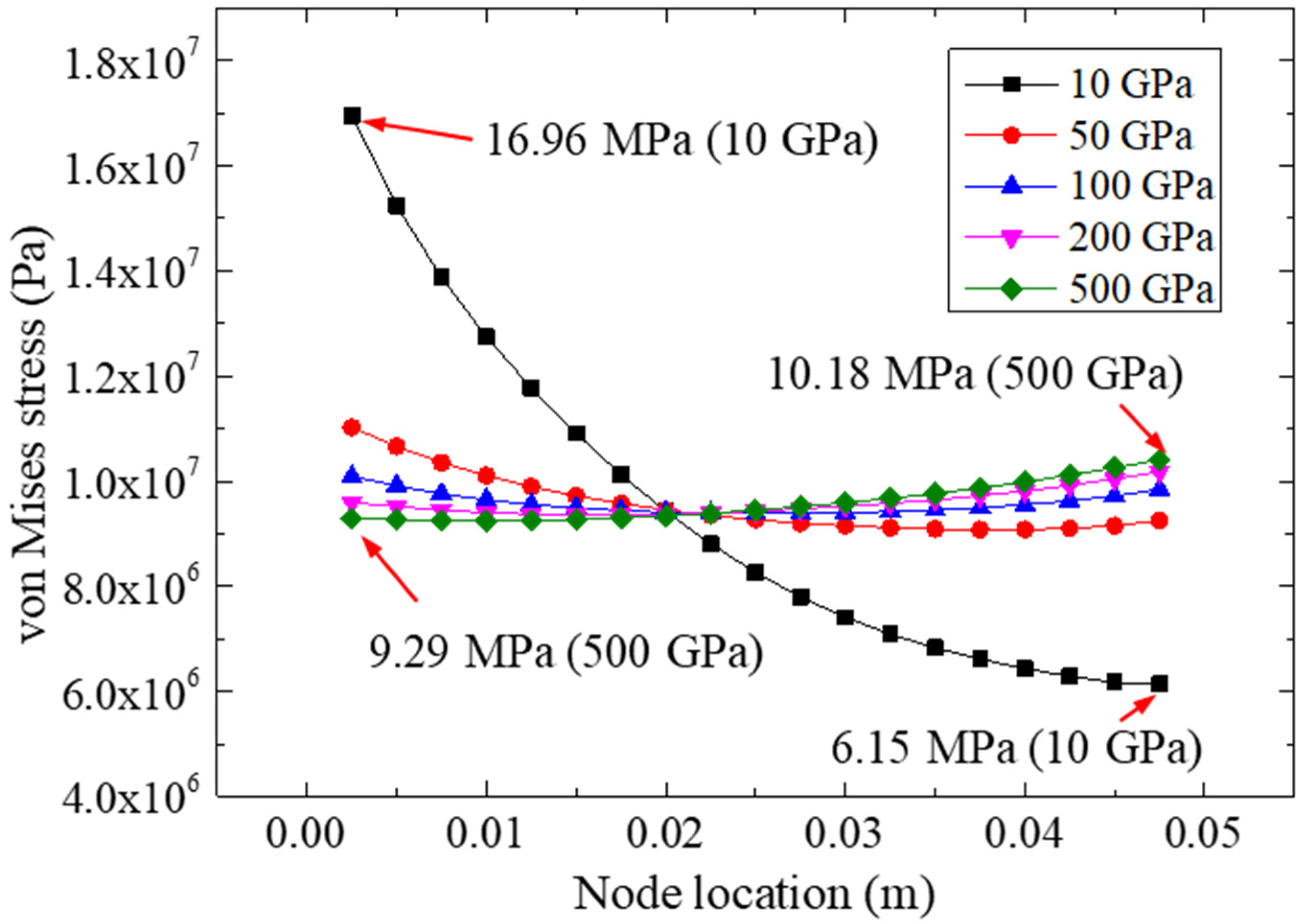

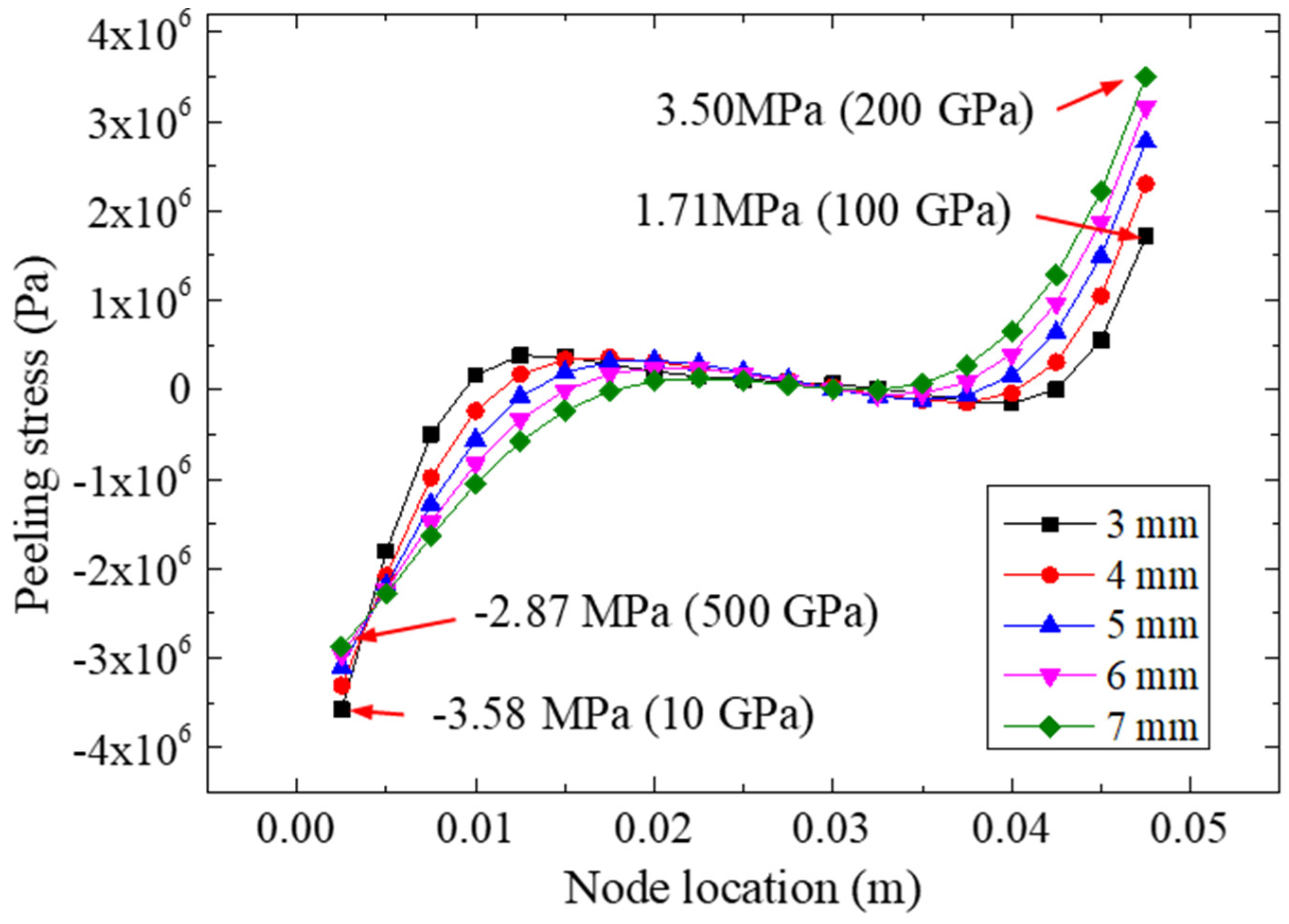

5.1. Effect of FRP Elastic Modulus

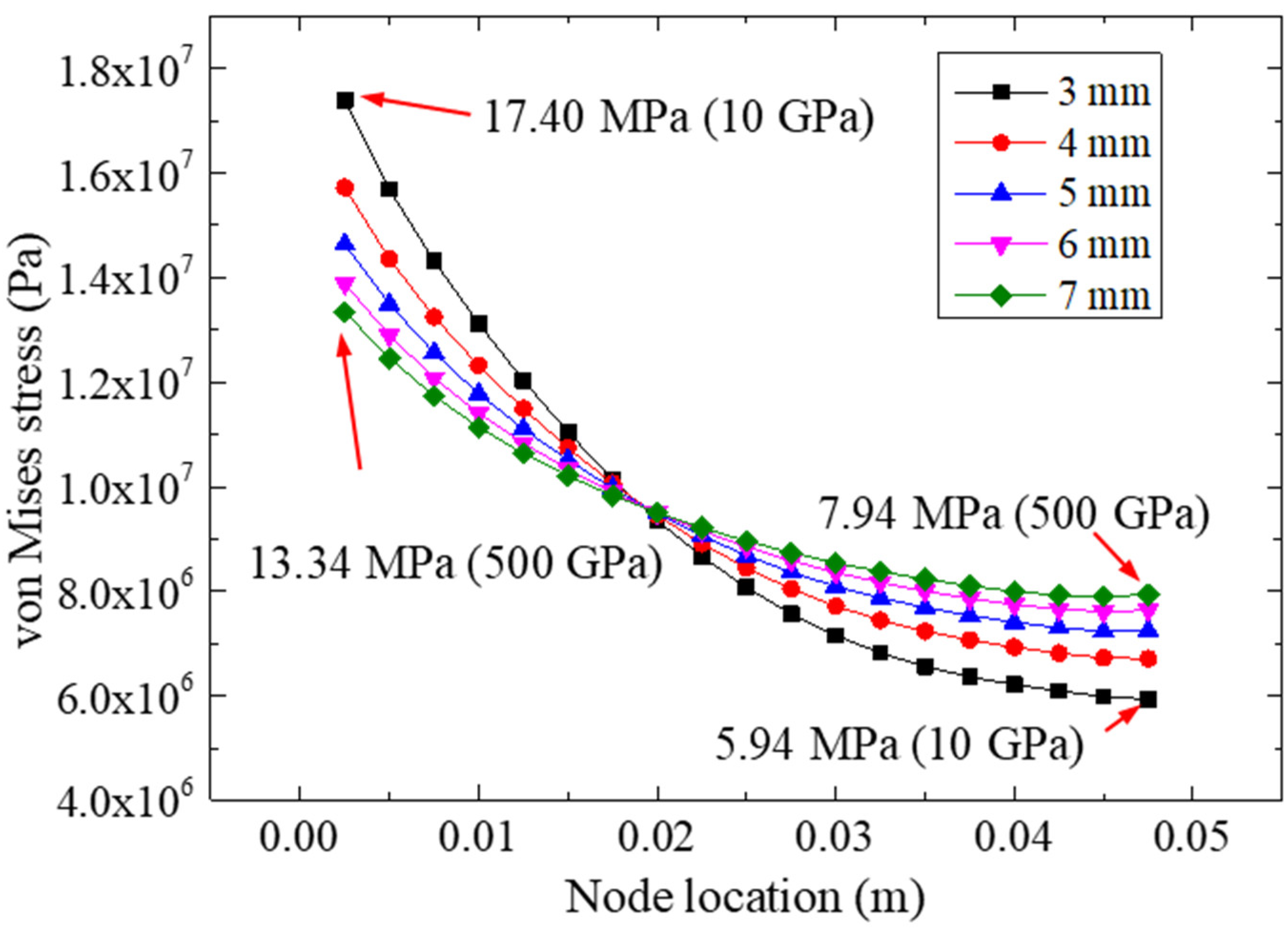

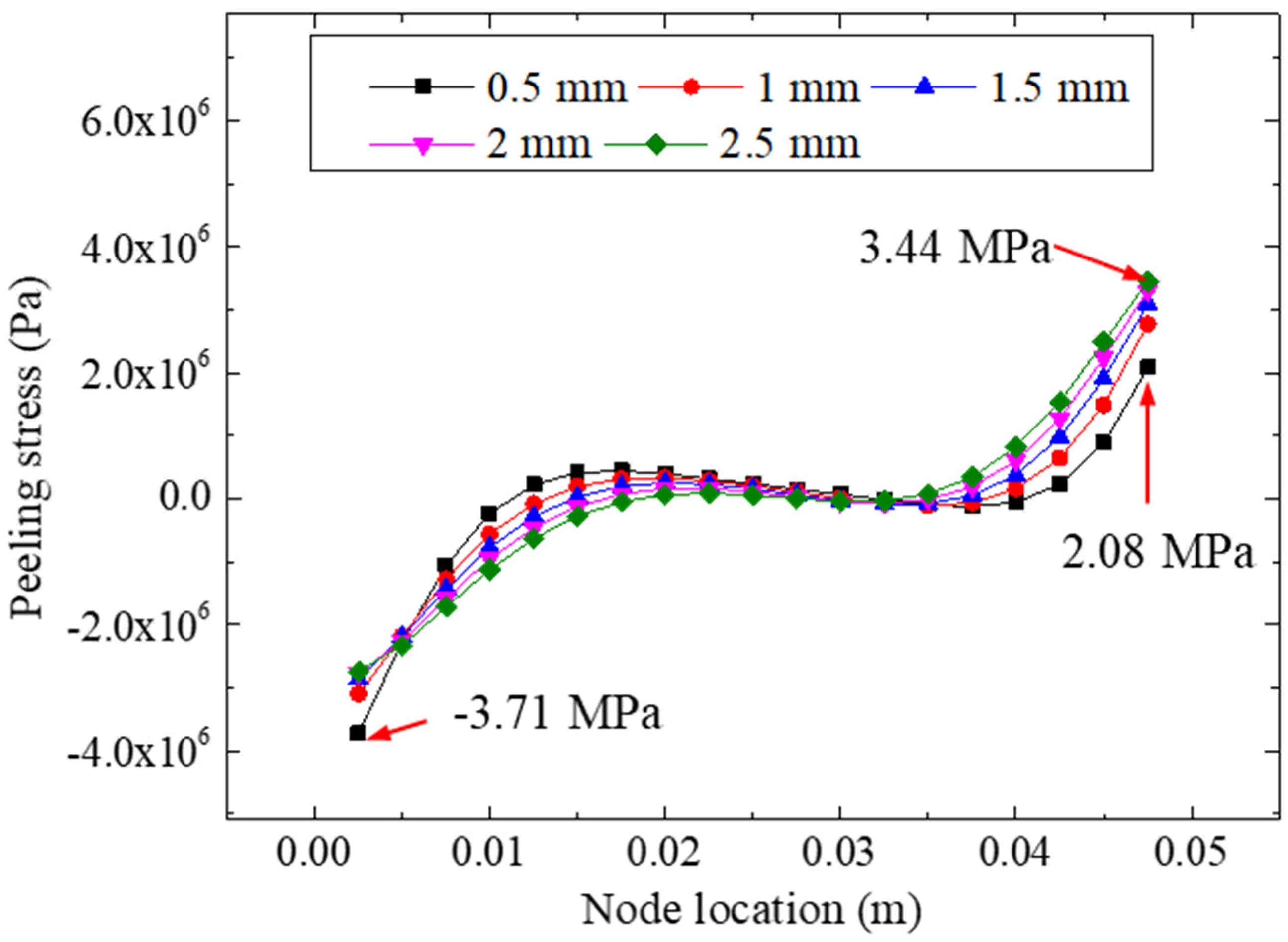

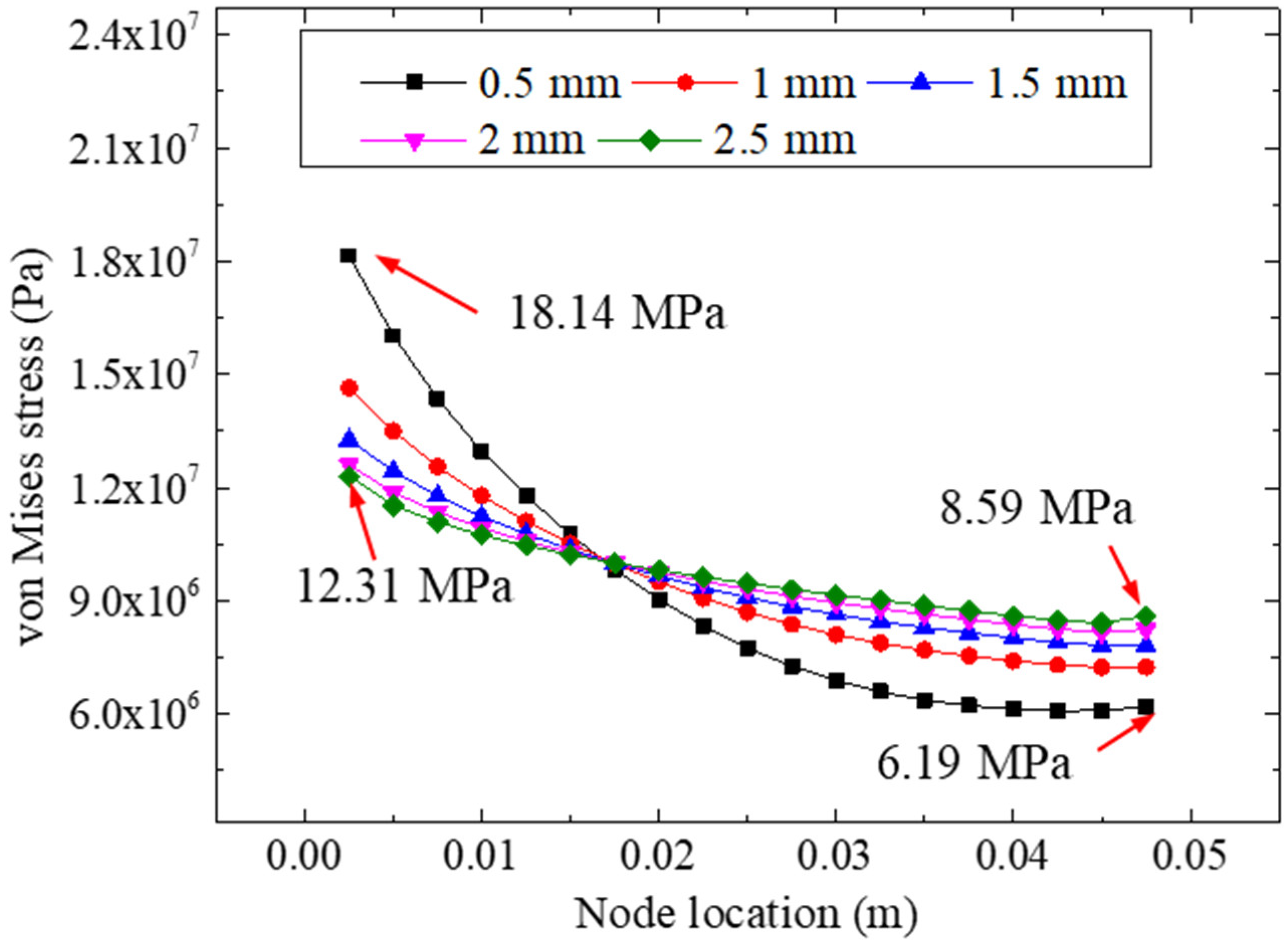

5.2. Effect of FRP Thickness

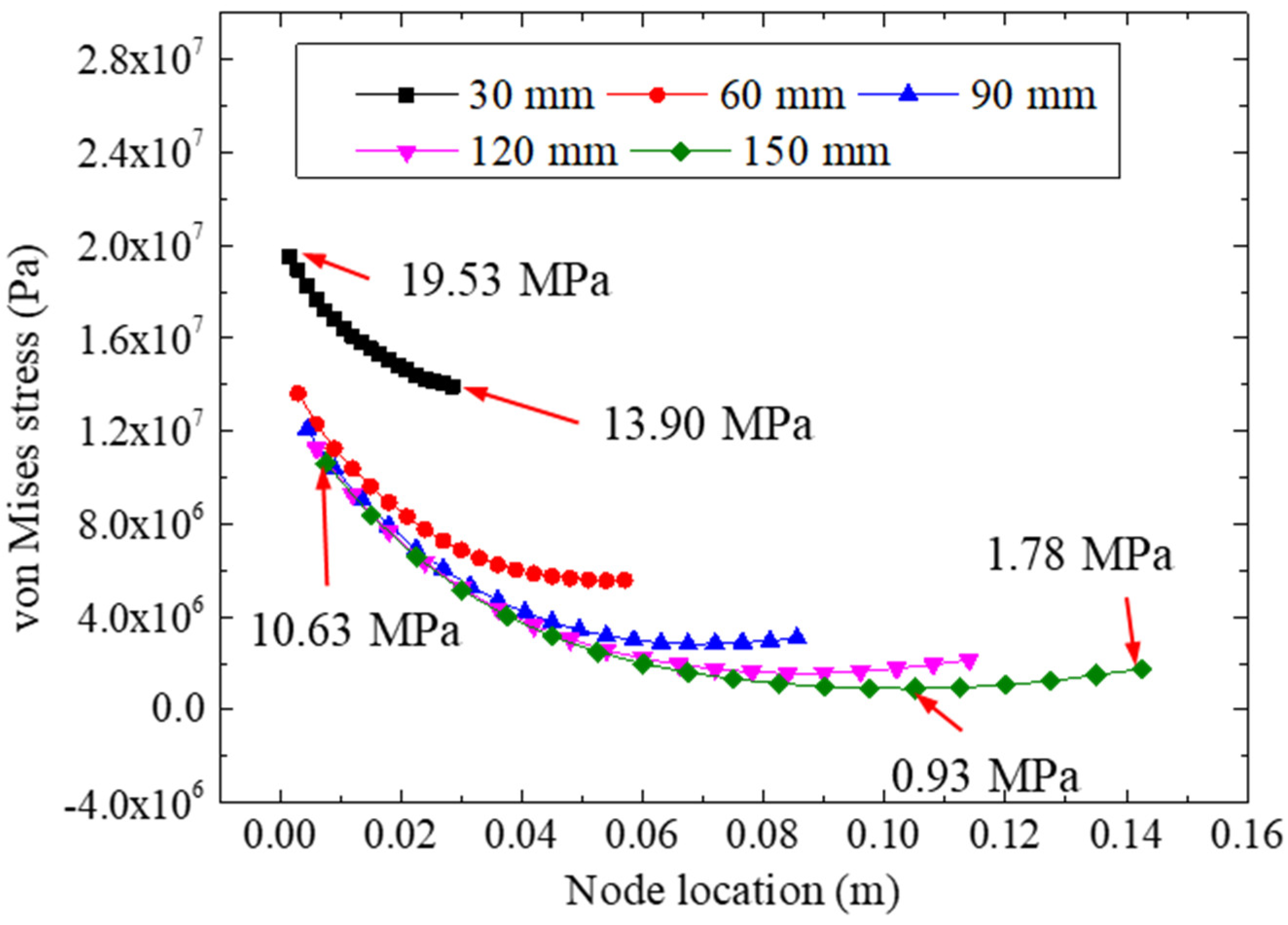

5.3. Effect of Bonding Length

5.4. Effect of Bonding Thickness

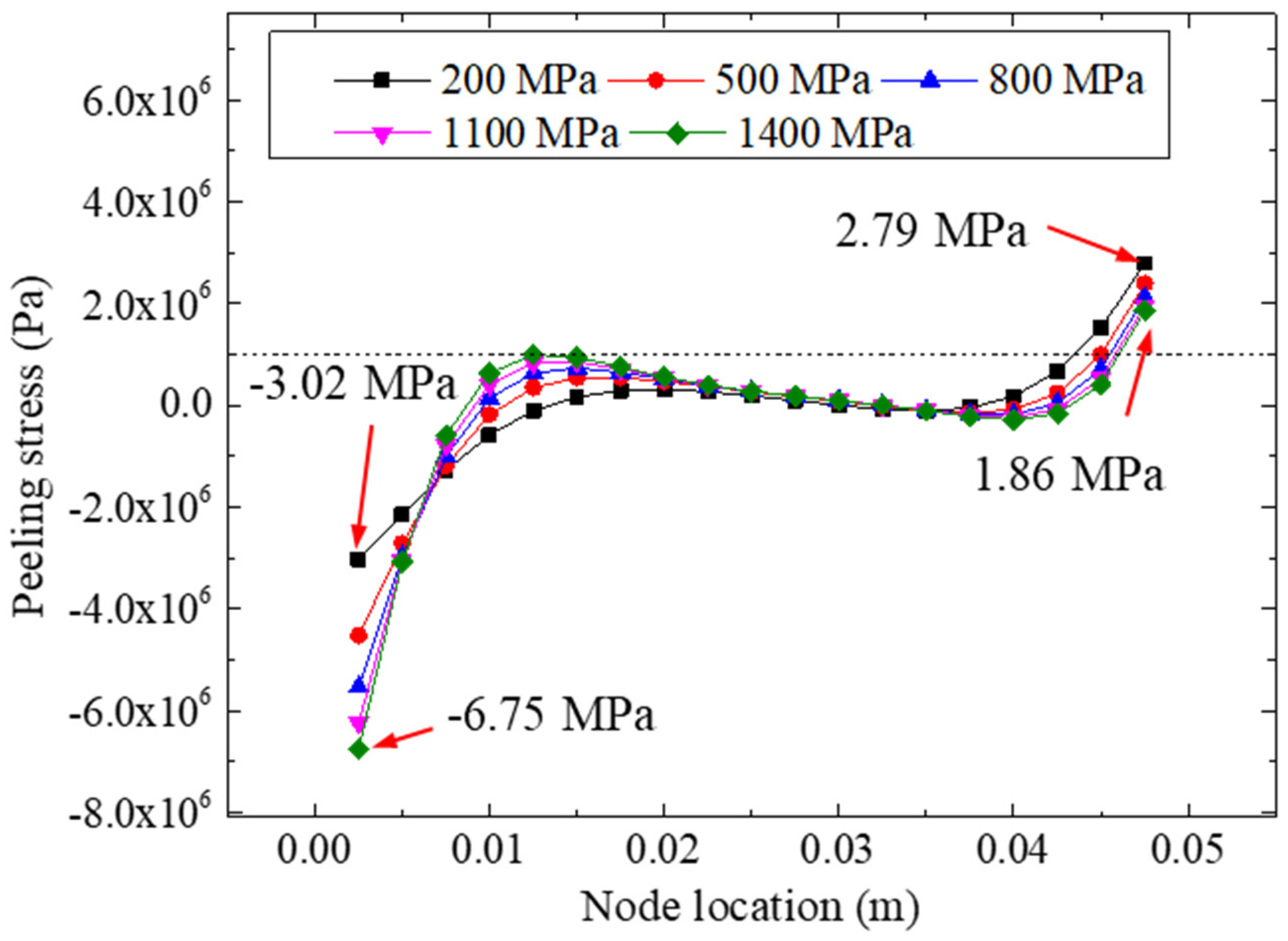

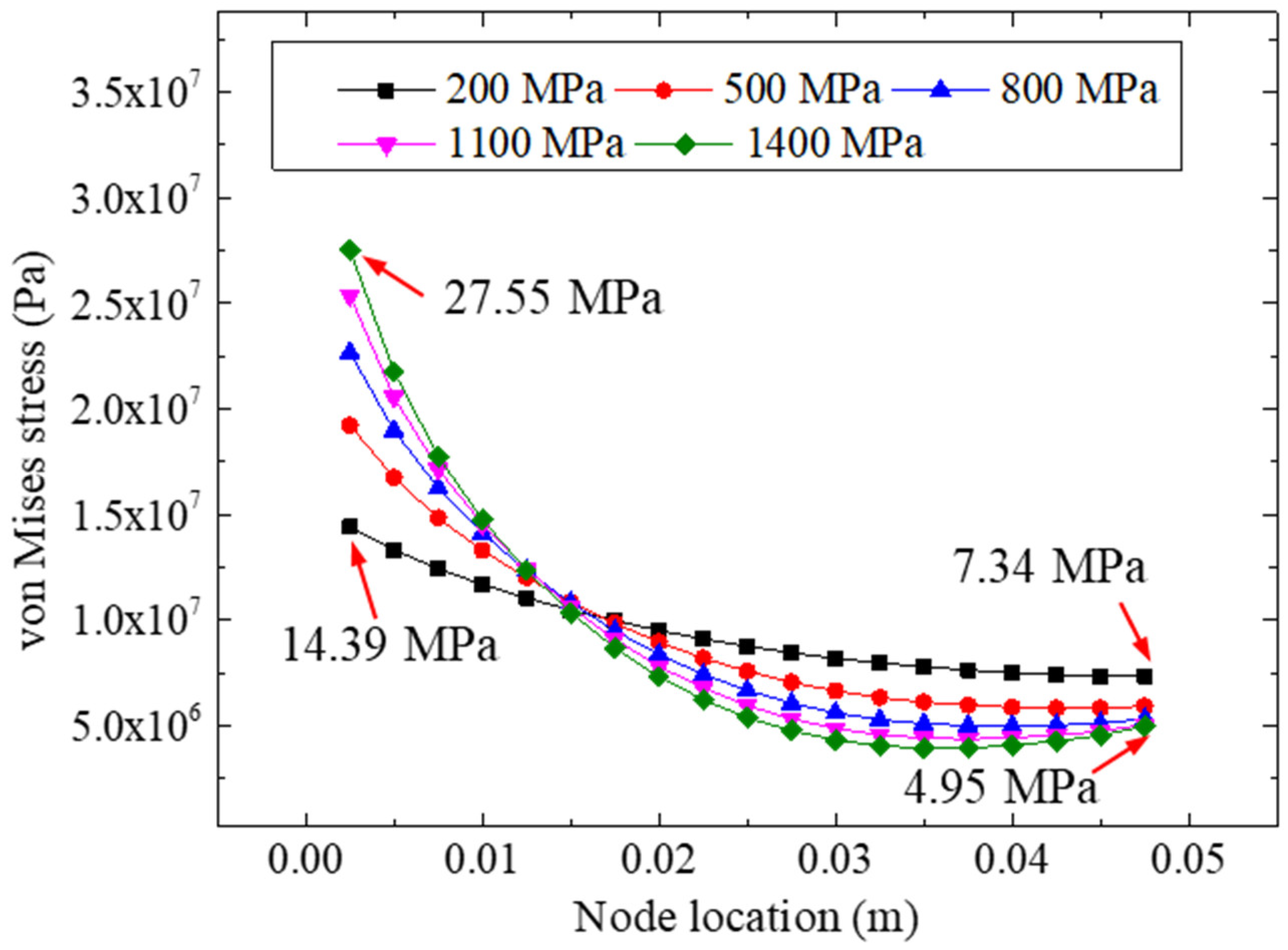

5.5. Effect of Adhesive Stiffness

6. Conclusions

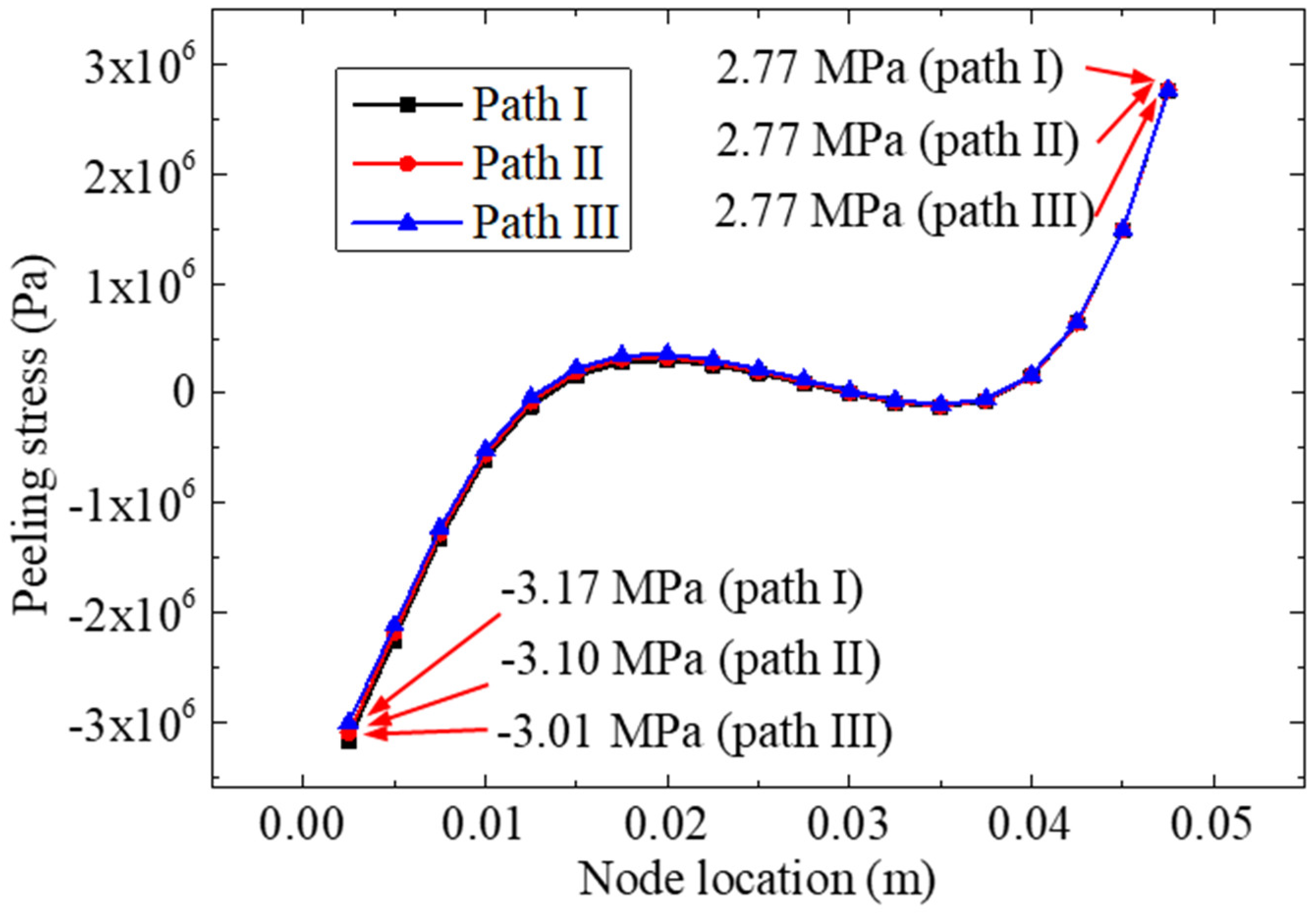

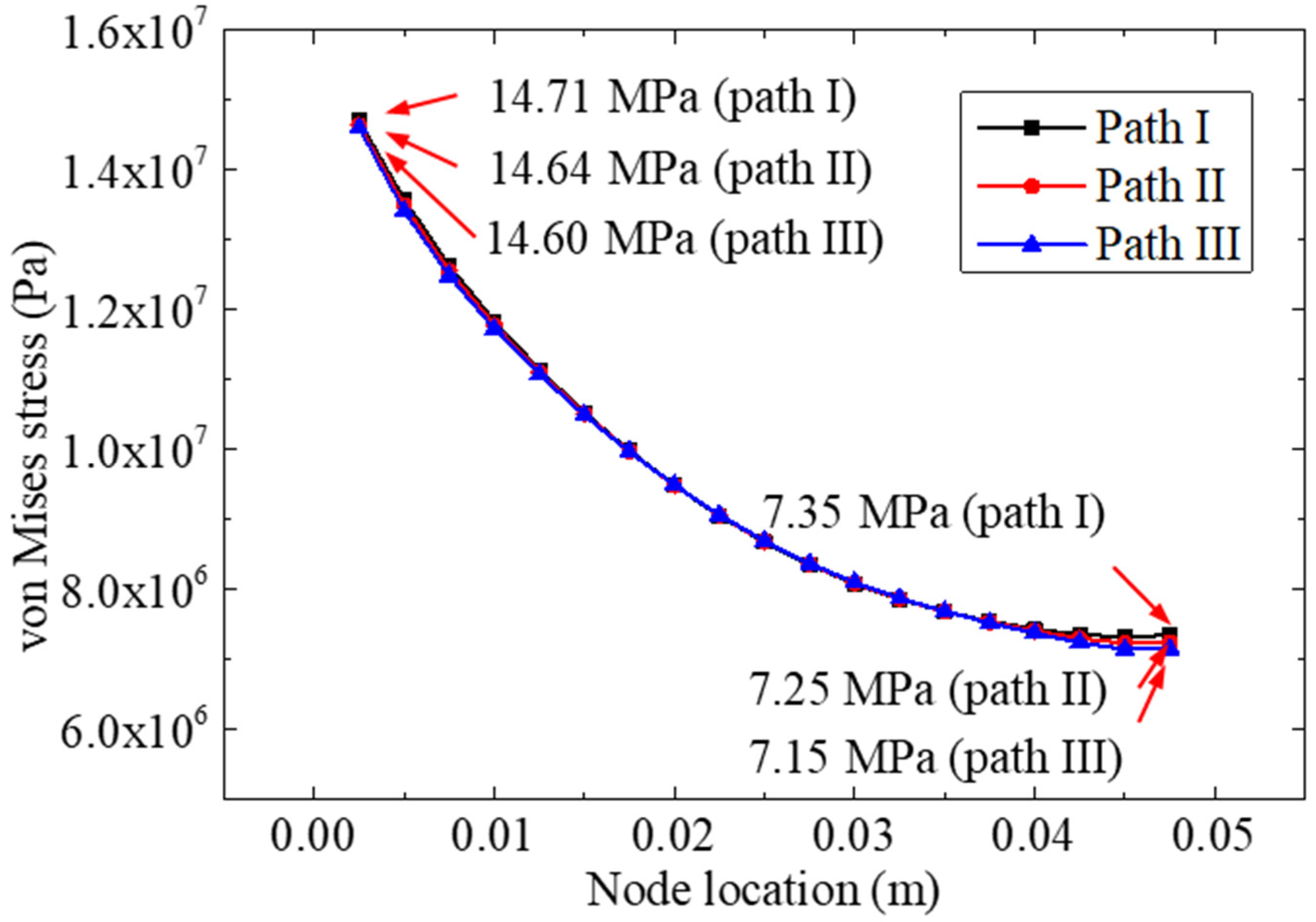

- When taking into account that the thickness of the bonding layer of the bonded specimen was relatively small, the stress results (for the interface peeling stress and the von Mises stress) of different calculating paths of the bonding material were very close. Therefore, path II (through the middle layer of the bonding layer) was used as the subsequent stress analysis path.

- The study of different FRP stiffnesses (elastic modulus and thickness) showed that the normal peeling stress and von Mises stress distributions in the bonding layer were more uniform in the specimens bonded with more rigid FRP materials, while the FRP with a higher stiffness was more conducive to eliminating the stress concentration in the adhesive layer.

- An increase in the bonding length could effectively reduce the stress concentration in the adhesive layer. When considering the manufacturing costs, we recommend a bonding length of 90 mm for double-strap bonded specimens.

- A difference in bonding thickness likely may not affect the nonuniformity of the interface peeling stress. However, a change in the bonding thickness can affect the equivalent stress remarkably; with an increase in the bonding thickness (from 0.5 mm to 2.5 mm), the extreme value of the bonding layer stress decreased gradually.

- The elastic modulus of the adhesive layer had a significant influence on the peeling stress of the bonded specimen. The peeling stress on the left side of the bonding layer was more sensitive to the stiffness of the adhesives; bonding materials with a higher elastic modulus were more likely to cause stress concentration in the bonding zone. This research included a detailed analysis of the influence of various bonding parameters on the tensile behaviors of FRP–steel double-strap bonded structures; however, when considering the relatively complex failure mechanisms of bonded composite structures, a more profound experimental analysis (including different bonding parameters and conditions) is required. It is worth noting that this study was aimed at the bonding stresses of FRP–steel double-strap bonded joints based on a linear elastic assumption and cohesive failure mode; therefore, the failure mechanisms of FRP–steel composite specimens composed of nonlinear materials with other failure modes (except for cohesive failure) require further research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, X.L.; Zhang, L. State-of-the-art review on FRP strengthened steel structures. Eng. Struct. 2007, 29, 1808–1823. [Google Scholar] [CrossRef]

- Liu, J.; Guo, T.; Feng, D.M.; Liu, Z.X. Fatigue performance of rib-to-deck joints strengthened with FRP angles. J. Bridg. Eng. 2018, 23, 04018060. [Google Scholar] [CrossRef]

- He, J.; Xian, G.J.; Zhang, Y.X. Numerical modelling of bond behaviour between steel and CFRP laminates with a ductile adhesive. Int. J. Adhes. Adhes. 2021, 104, 102753. [Google Scholar] [CrossRef]

- Wei, Y.; Bai, J.W.; Zhang, Y.R.; Miao, K.T.; Zheng, K.Q. Compressive performance of high-strength seawater and sea sand concrete filled circular FRP-steel composite tube columns. Eng. Struct. 2021, 240, 112357. [Google Scholar] [CrossRef]

- Tang, Y.; Sun, Z.; Wu, G.; Wei, Y. Compressive Behavior of Steel-FRP Composite Bars Confined with Low Elastic Modulus FRP Spirals in Concrete Columns. J. Compos. Constr. 2022, 26, 04022058. [Google Scholar] [CrossRef]

- Tang, Y.; Sun, Z.; Wei, Y.; Zou, X. Compressive behavior and design method of BFRP bars constrained with a BFRP spiral with different spacings in concrete members. Eng. Struct. 2022, 268, 114757. [Google Scholar] [CrossRef]

- Guo, T.; Liu, J.; Deng, Y.; Zhang, Z.L. Fatigue performance of orthotropic steel decks with FRP angles: Field measurement and numerical analysis. J. Perform. Constr. Facil. 2019, 33, 04019042. [Google Scholar] [CrossRef]

- Zheng, Z.H.; Du, Y.S.; Chen, Z.H.; Li, S.Y.; Niu, J.Q. Experimental and theoretical studies of FRP-Steel composite plate under static tensile loading. Constr. Build. Mater. 2021, 271, 121501. [Google Scholar] [CrossRef]

- Harries, K.A.; Peck, A.J.; Abraham, E.J. Enhancing stability of structural steel sections using FRP. Thin Wall Struct. 2009, 47, 1092–1101. [Google Scholar] [CrossRef]

- Su, P.; Dai, Q.; Li, M.; Ma, Y.; Wang, J. Investigation of the mechanical and shrinkage properties of plastic-rubber compound modified cement mortar with recycled tire steel fiber. Constr. Build. Mater. 2022, 334, 127391. [Google Scholar] [CrossRef]

- Wang, J.; Li, Q.; Song, G.; Luo, S.; Ge, D. Investigation on the comprehensive durability and interface properties of coloured ultra-thin pavement overlay. Case Stud. Constr. Mater. 2022, 17, 01341. [Google Scholar] [CrossRef]

- Miller, T.C.; Chajes, M.J.; Mertz, D.R.; Hastings, J.N. Strengthening of a steel bridge girder using CFRP plates. J. Bridg. Eng. 2001, 6, 514–522. [Google Scholar] [CrossRef]

- Fawzia, S.; Zhao, X.L.; Al-Mahaidi, R.; Rizkalla, S. Bond characteristics between CFRP and steel plates in double strap joints. Adv. Steel. Constr. 2005, 1, 17–27. [Google Scholar]

- Yu, T.; Fernando, D.; Teng, J.G.; Zhao, X.L. Experimental study on CFRP-to-steel bonded interfaces. Compos. Part B Eng. 2012, 43, 2279–2289. [Google Scholar] [CrossRef]

- Neto, J.A.B.P.; Campilho, R.D.S.G.; da Silva, L.F.M. Parametric study of adhesive joints with composites. Int. J. Adhes. Adhes. 2012, 37, 96–101. [Google Scholar] [CrossRef]

- Wang, H.T.; Wu, G.; Dai, Y.T.; He, X.Y. Experimental study on bond behavior between CFRP plates and steel substrates using digital image correlation. J. Compos. Constr. 2016, 20, 04016054. [Google Scholar] [CrossRef]

- Duc, N.D.; Trinh, T.D.; Do, T.V.; Doan, D.H. On the Buckling Behavior of Multi-Cracked FGM Plates. In International Conference on Advances in Computational Mechanics; Springer: Singapore, 2017; pp. 29–45. [Google Scholar]

- Nam, V.H.; Nam, N.H.; Vinh, P.V.; Khoa, D.N.; Thom, D.V.; Minh, P.V. A new efficient modified first-order shear model for static bending and vibration behaviors of two-layer composite plate. Adv. Civ. Eng. 2019, 2019, 6814367. [Google Scholar]

- Nguyen, H.N.; Nguyen, T.Y.; Tran, K.V.; Tran, T.T.; Nguyen, T.T.; Phan, V.D.; Do, T.V. A finite element model for dynamic analysis of triple-layer composite plates with layers connected by shear connectors subjected to moving load. Materials 2019, 12, 598. [Google Scholar] [CrossRef] [Green Version]

- Castagnetti, D.; Spaggiari, A.; Dragoni, E. Assessment of the Cohesive Contact method for the analysis of thin-walled bonded structures. Int. J. Adhes. Adhes. 2012, 37, 112–120. [Google Scholar] [CrossRef]

- Castagnetti, D.; Dragoni, E.; Spaggiari, A. Efficient post-elastic analysis of bonded joints by standard finite element techniques. J. Adhes. Sci. Technol. 2009, 23, 1459–1476. [Google Scholar] [CrossRef]

- Liu, J.; Guo, T.; Hebdon, M.H.; Liu, Z.X.; Wang, L.B. Bonding Behaviors of GFRP/Steel Bonded Joints after Wet–Dry Cyclic and Hygrothermal Curing. Appl. Sci. 2020, 10, 5411. [Google Scholar] [CrossRef]

- Ammarullah, M.I.; Santoso, G.; Sugiharto, S.; Supriyono, T.; Kurdi, O.; Tauviqirrahman, M.; Winarni, T.I.; Jamari, J. Tresca stress study of CoCrMo-on-CoCrMo bearings based on body mass index using 2D computational model. J. Tribol. 2022, 33, 31–38. [Google Scholar]

- Wang, J.; Dai, Q.; Lautala, P.; Yao, H.; Si, R. Rail Sample Laboratory Evaluation of Eddy Current Rail Inspection Sustainable System. Sustainability 2022, 14, 11568. [Google Scholar] [CrossRef]

- Chen, S.; Wang, J.; Li, Q.; Zhang, W.; Yan, C. The Investigation of Volatile Organic Compounds (VOCs) Emissions in Environmentally Friendly Modified Asphalt. Polymers 2022, 14, 3459. [Google Scholar] [CrossRef]

- Yang, J.Q.; Smith, S.T.; Feng, P. Effect of FRP-to-steel bonded joint configuration on interfacial stresses: Finite element investigation. Thin Wall. Struct. 2012, 62, 215–228. [Google Scholar] [CrossRef]

- Ammarullah, M.I.; Santoso, G.; Sugiharto, S.; Supriyono, T.; Wibowo, D.B.; Kurdi, O.; Tauviqirrahman, M.; Jamari, J. Minimizing Risk of Failure from Ceramic-on-Ceramic Total Hip Prosthesis by Selecting Ceramic Materials Based on Tresca Stress. Sustainability 2022, 14, 13413. [Google Scholar] [CrossRef]

- Mukhtar, F.M.; Faysal, R.M. A review of test methods for studying the FRP-concrete interfacial bond behavior. Constr. Build. Mater. 2018, 169, 877–887. [Google Scholar] [CrossRef]

- Razaqpur, A.G.; Lamberti, M.; Ascione, F. A nonlinear semi-analytical model for predicting debonding of FRP laminates from RC beams subjected to uniform or concentrated load. Constr. Build. Mater. 2020, 233, 117838. [Google Scholar] [CrossRef]

- Chiew, S.P.; Yu, Y.; Lee, C.K. Bond failure of steel beams strengthened with FRP laminates–Part 1: Model development. Compos. Part B Eng. 2011, 42, 1114–1121. [Google Scholar] [CrossRef]

- Robinson, M.J.; Adams, T.C. Performance of FRP composite strap joints utilizing fiber tow steering. Compos. Part B Eng. 2020, 190, 107910. [Google Scholar] [CrossRef]

- Wei, Y.; Zhu, C.; Miao, K.T.; Chai, J.L.; Zheng, K.Q. Compressive behavior of rectangular concrete-filled fiber-reinforced polymer and steel composite tube columns with stress-release grooves. Compos. Struct. 2021, 281, 114984. [Google Scholar] [CrossRef]

- Tang, Y.; Sun, Z.; Wu, G.; Wei, Y. Experimental Study on Cyclic Behavior of SFCBs with Different Slenderness Ratios. J. Mater Civ. Eng. 2021, 33, 04021204. [Google Scholar] [CrossRef]

- Hu, B.; Li, Y.; Jiang, Y.T.; Tang, H.Z. Bond behavior of hybrid FRP-to-steel joints. Compos. Struct. 2020, 237, 111936. [Google Scholar] [CrossRef]

| Mechanical Parameter | GFRP | Adhesive * | Steel |

|---|---|---|---|

| Young’s modulus, Mpa | 15,400 (longitudinal direction) 6850 (transverse direction) 7630 (thickness direction) | 213.24 * (Secant Young’s modulus) | 204,000 |

| Strength, Mpa | 291.1 (longitudinal direction) 125.3 (transverse direction) 144.6 (thickness direction) | 18.85 * | 291.3 (Yield stress) |

| Poisson’s ratio | 0.37 | 0.40 (According to product manual) | 0.3 |

| Elastic Modulus of FRP Plates/Gpa | Ultimate Peeling Stresses for Path II/Mpa | Von Mises Stresses for Path II/Mpa |

|---|---|---|

| 10 | −3.80 | 16.96 (left)/6.15 (right) |

| 50 | −1.95 | 11.02 (left)/9.25 (right) |

| 100 | −1.61 | 10.09 (left)/9.84 (right) |

| 200 | −1.41 | 9.59 (left)/10.18 (right) |

| 500 | −1.28 | 9.29 (left)/10.41 (right) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Yuan, Y.; Wang, L.; Liu, Z.; Yang, J. Parameter Study of Interfacial Capacities for FRP–Steel Bonded Joints Based on 3D FE Modeling. Materials 2022, 15, 7787. https://doi.org/10.3390/ma15217787

Liu J, Yuan Y, Wang L, Liu Z, Yang J. Parameter Study of Interfacial Capacities for FRP–Steel Bonded Joints Based on 3D FE Modeling. Materials. 2022; 15(21):7787. https://doi.org/10.3390/ma15217787

Chicago/Turabian StyleLiu, Jie, Yu Yuan, Libin Wang, Zhongxiang Liu, and Jun Yang. 2022. "Parameter Study of Interfacial Capacities for FRP–Steel Bonded Joints Based on 3D FE Modeling" Materials 15, no. 21: 7787. https://doi.org/10.3390/ma15217787

APA StyleLiu, J., Yuan, Y., Wang, L., Liu, Z., & Yang, J. (2022). Parameter Study of Interfacial Capacities for FRP–Steel Bonded Joints Based on 3D FE Modeling. Materials, 15(21), 7787. https://doi.org/10.3390/ma15217787