Preparation and Properties of New Thermal Reflective Coating for Asphalt Pavement

Abstract

:Highlights

- A new heat reflective coating material for asphalt pavement was obtained.

- The inorganic filler with lipophilicity after surface modification was obtained.

- A double coating structure with better cooling effect is obtained.

- A heat reflective coating with excellent road performance was obtained.

- Compared with the traditional heat reflection coating, it has better physical and chemical properties and lower cost.

- Make the inorganic filler better dispersed in the matrix.

- The higher the temperature, the better the cooling effect of the coating.

- After the heat-reflective coating is laid, its skid resistance, wear resistance and impermeability meet the requirements of the specification, and the performance is improved.

Abstract

1. Introduction

2. Coating Material

2.1. Composition of Raw Materials

- (1)

- Elementary body

- (2)

- Functional fillers

- (3)

- Pigment

- (4)

- Additive

- (5)

- Anti-slip pellet

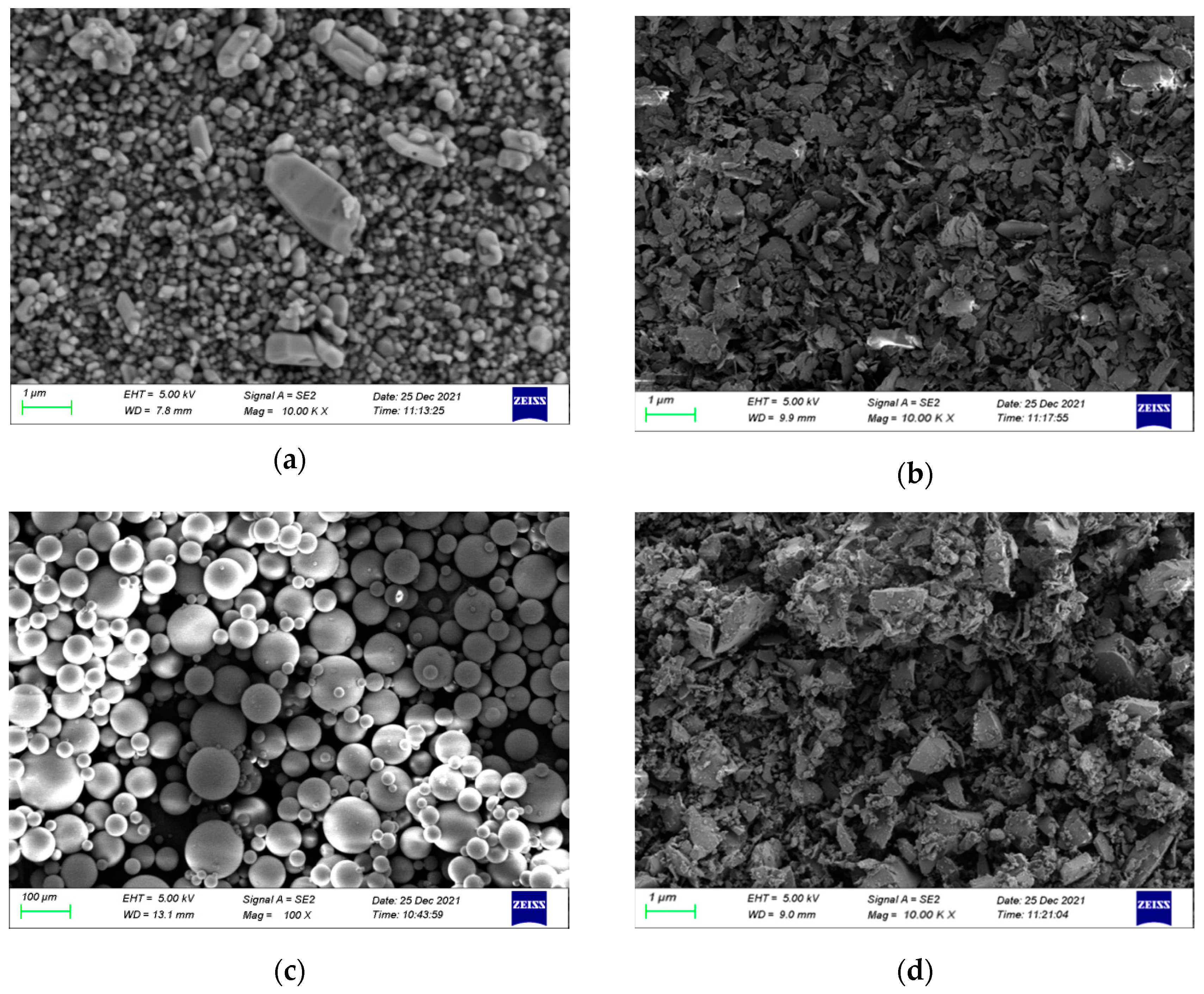

2.2. Surface Modification of Functional Filler

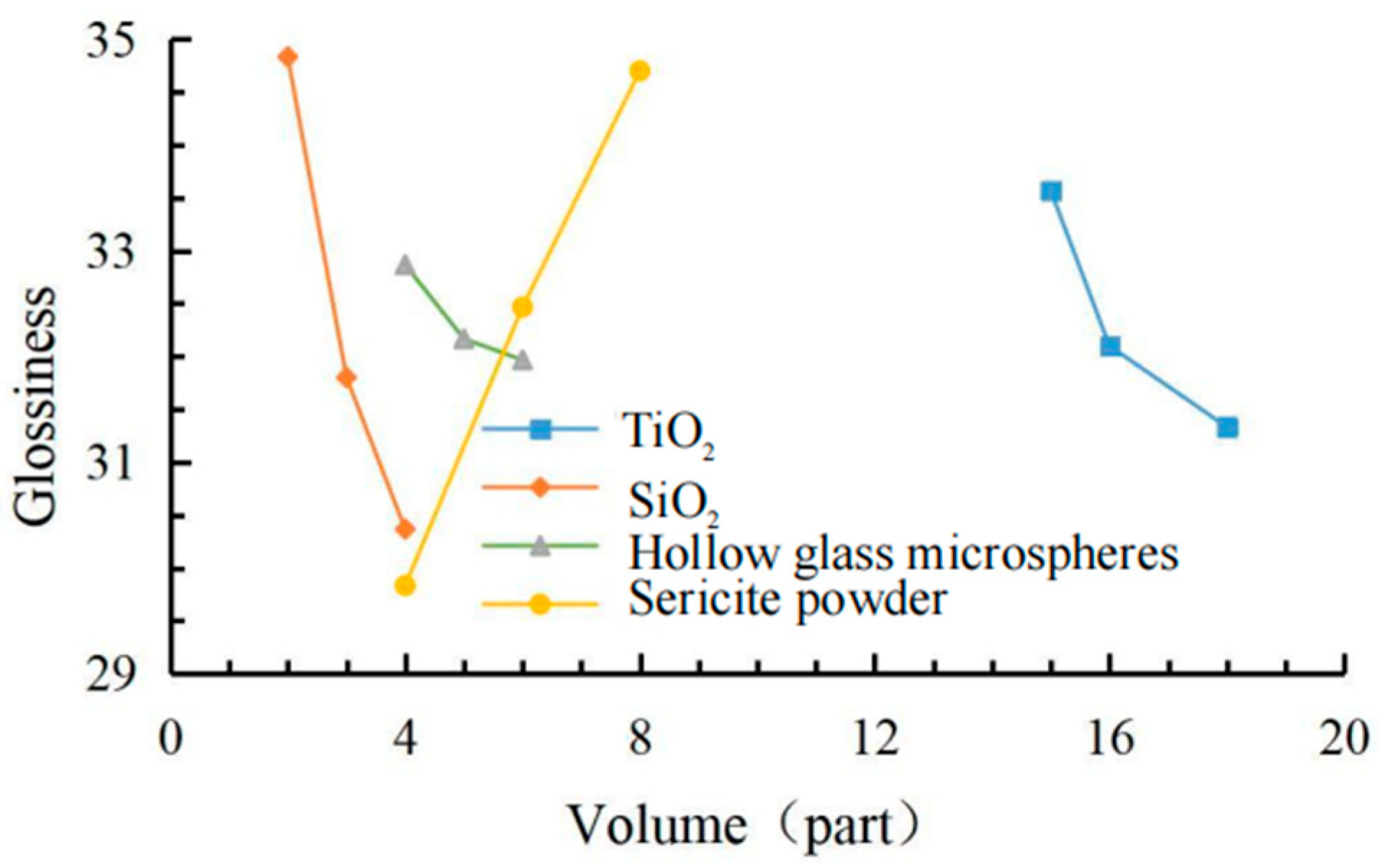

2.3. Determination of Filler Content

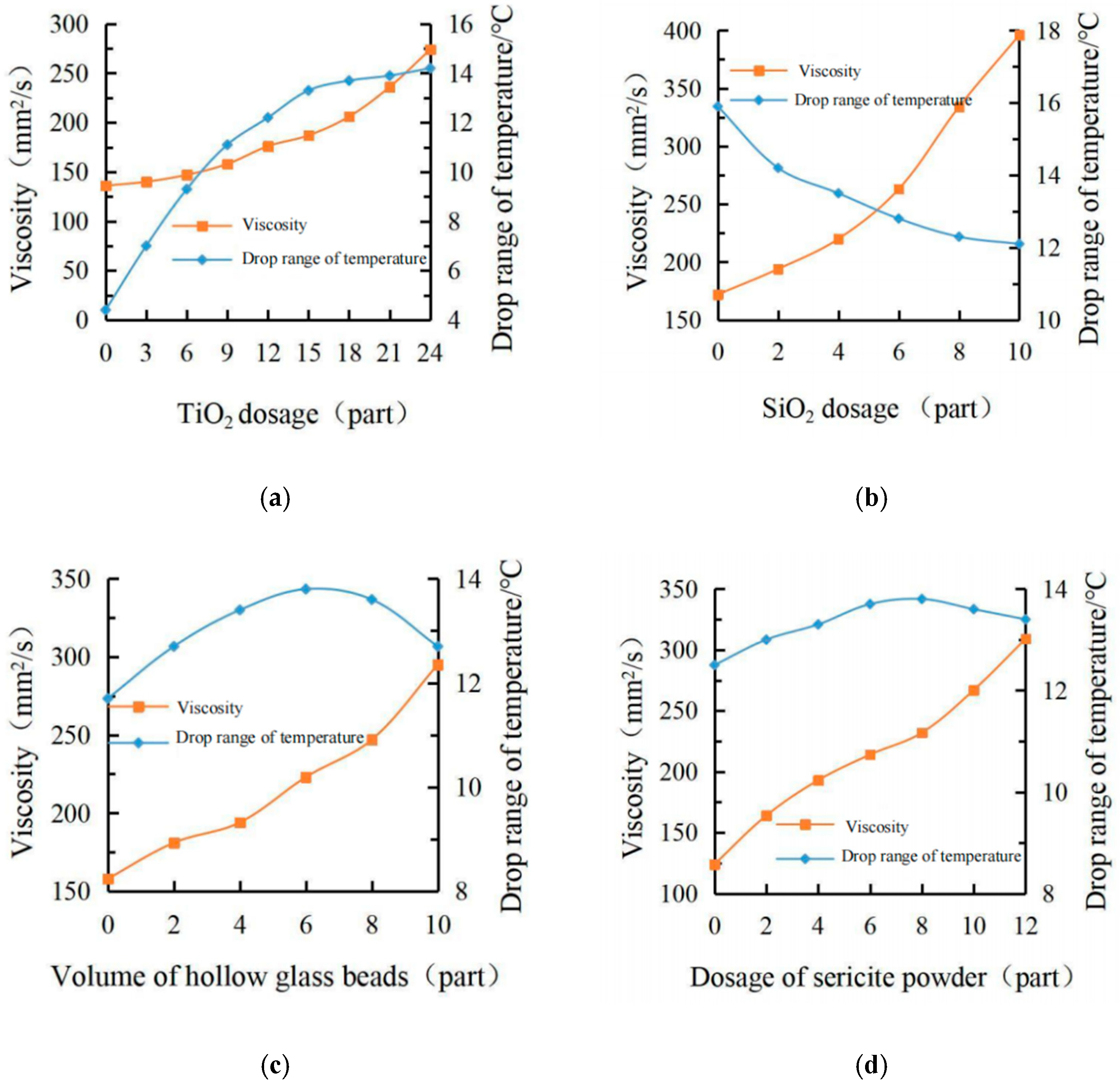

- (1)

- TiO2 dosage

- (2)

- SiO2 dosage

- (3)

- The volume of hollow glass beads

- (4)

- Dosage of sericite powder

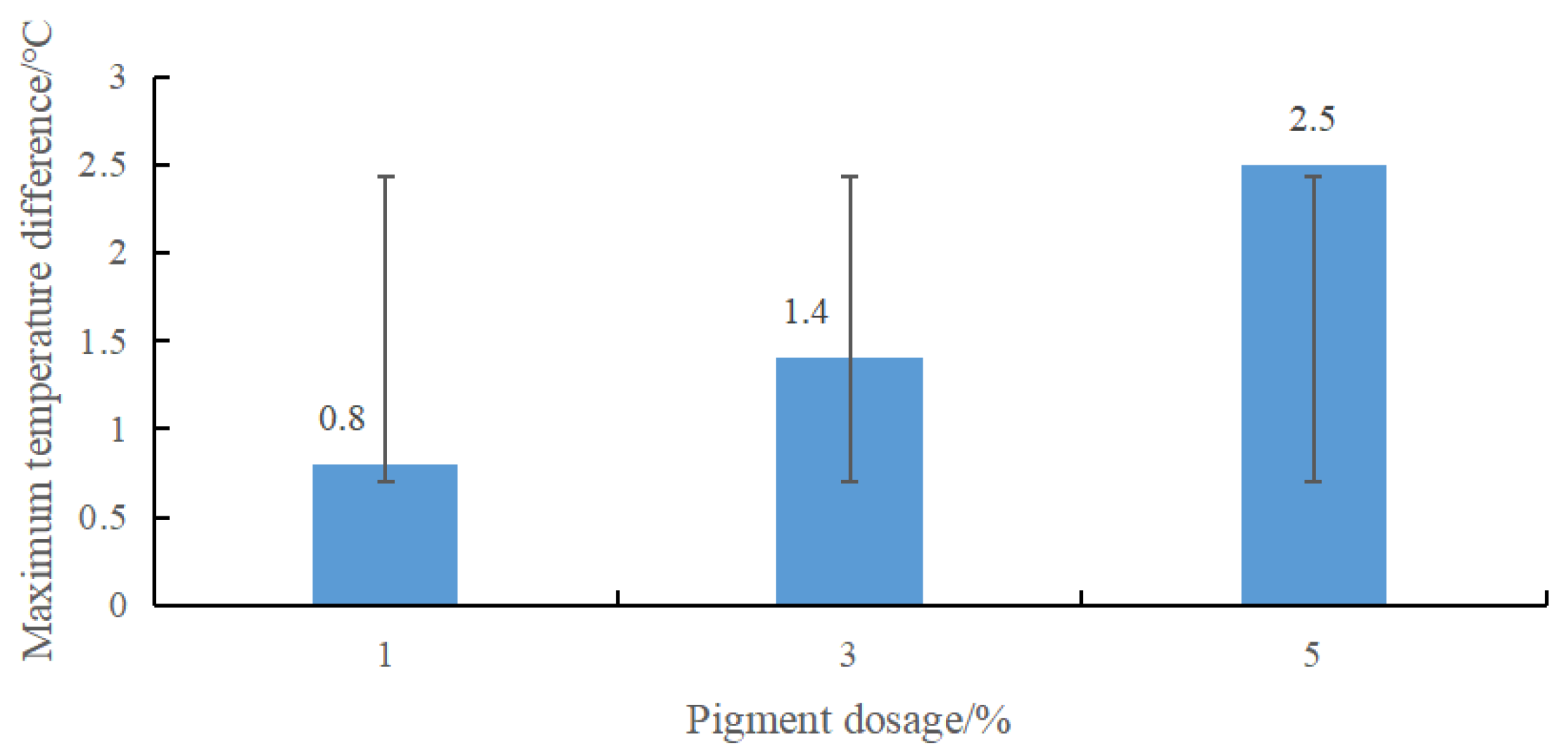

2.4. Determination of Pigment Content

2.5. Material Dosage of Each Component

3. Test Scheme

3.1. Indoor Cooling Test

- (1)

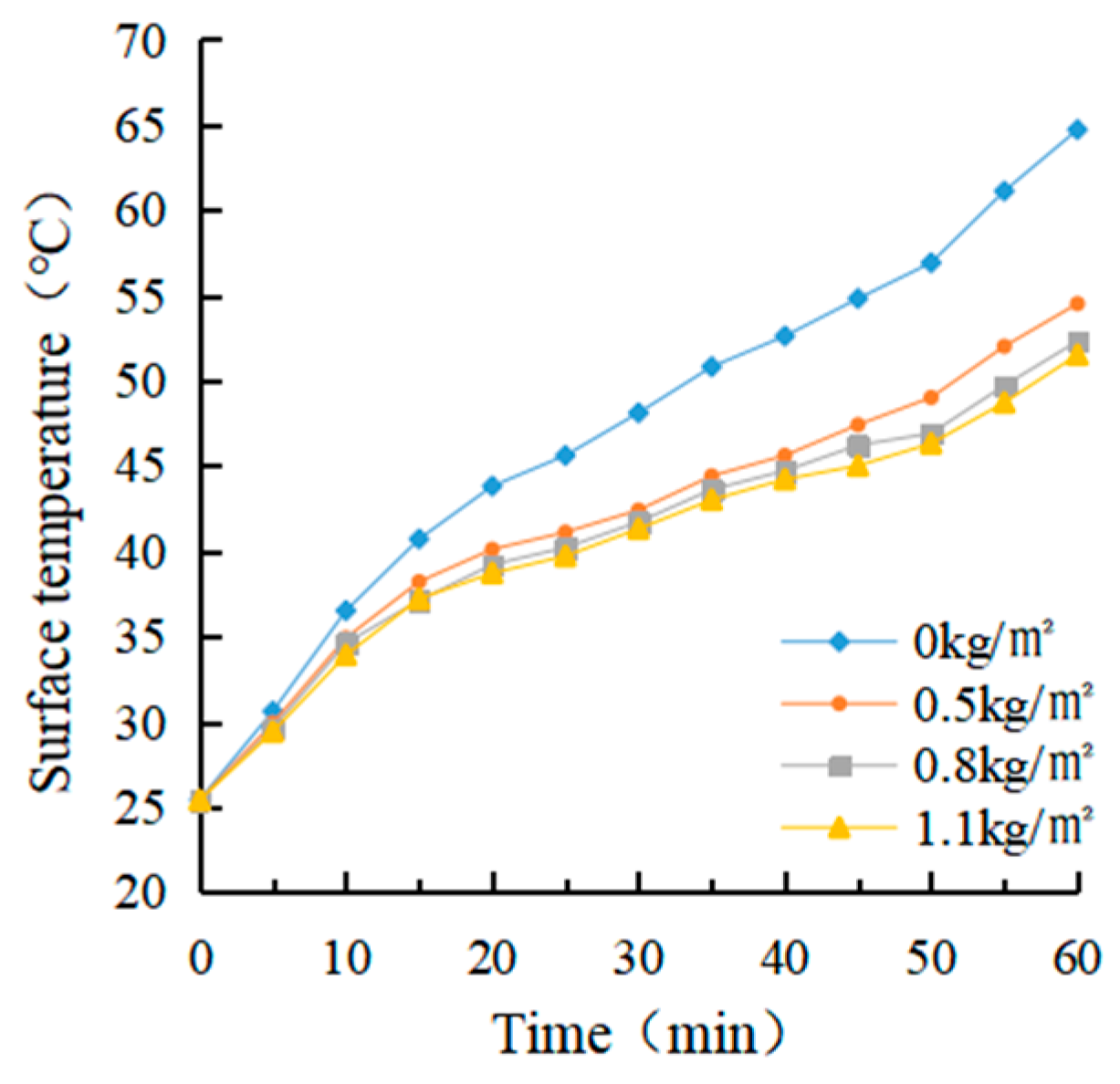

- Determination of coating amount

- (2)

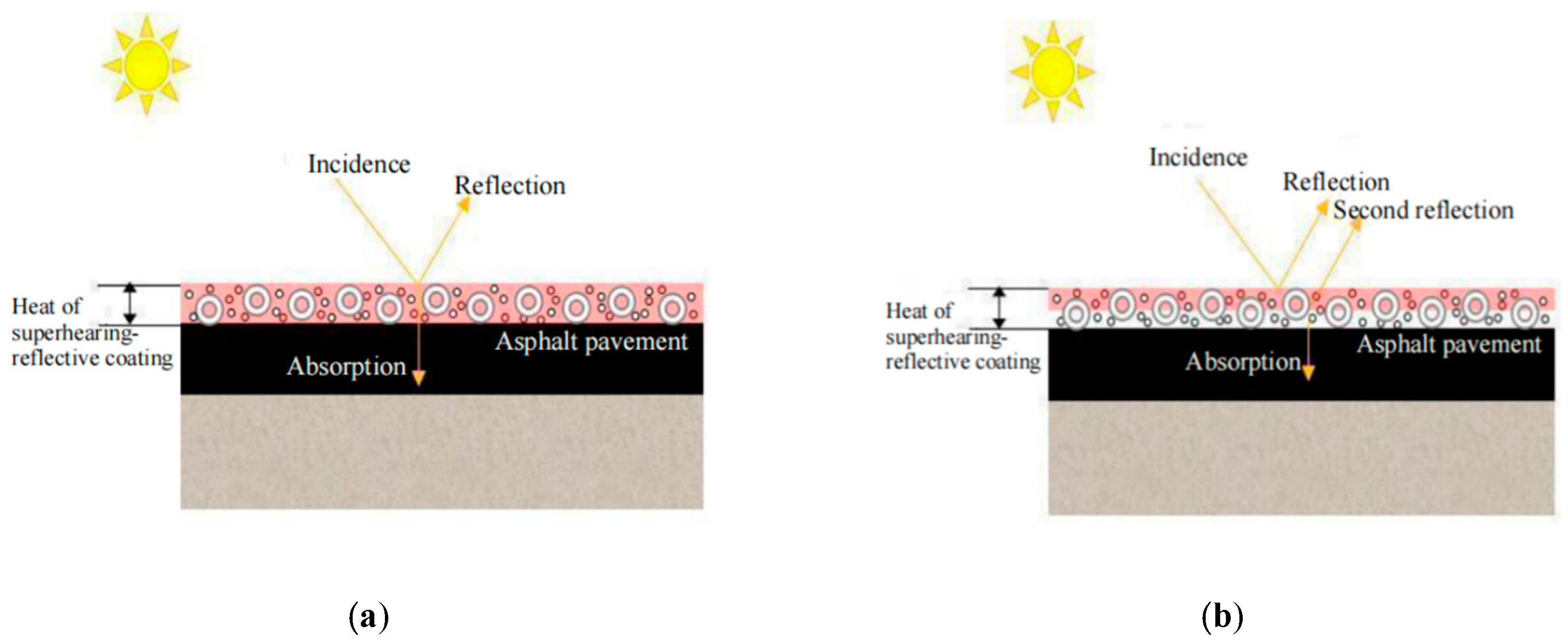

- Determination of coating structure

3.2. Outdoor Cooling Test

3.3. Anti-Skid Test

3.4. Structural Depth Test

3.5. Wear Resistance Test

3.6. Water Impermeability Test

4. Results Analysis and Discussion

4.1. Evaluation of Indoor Cooling Effect

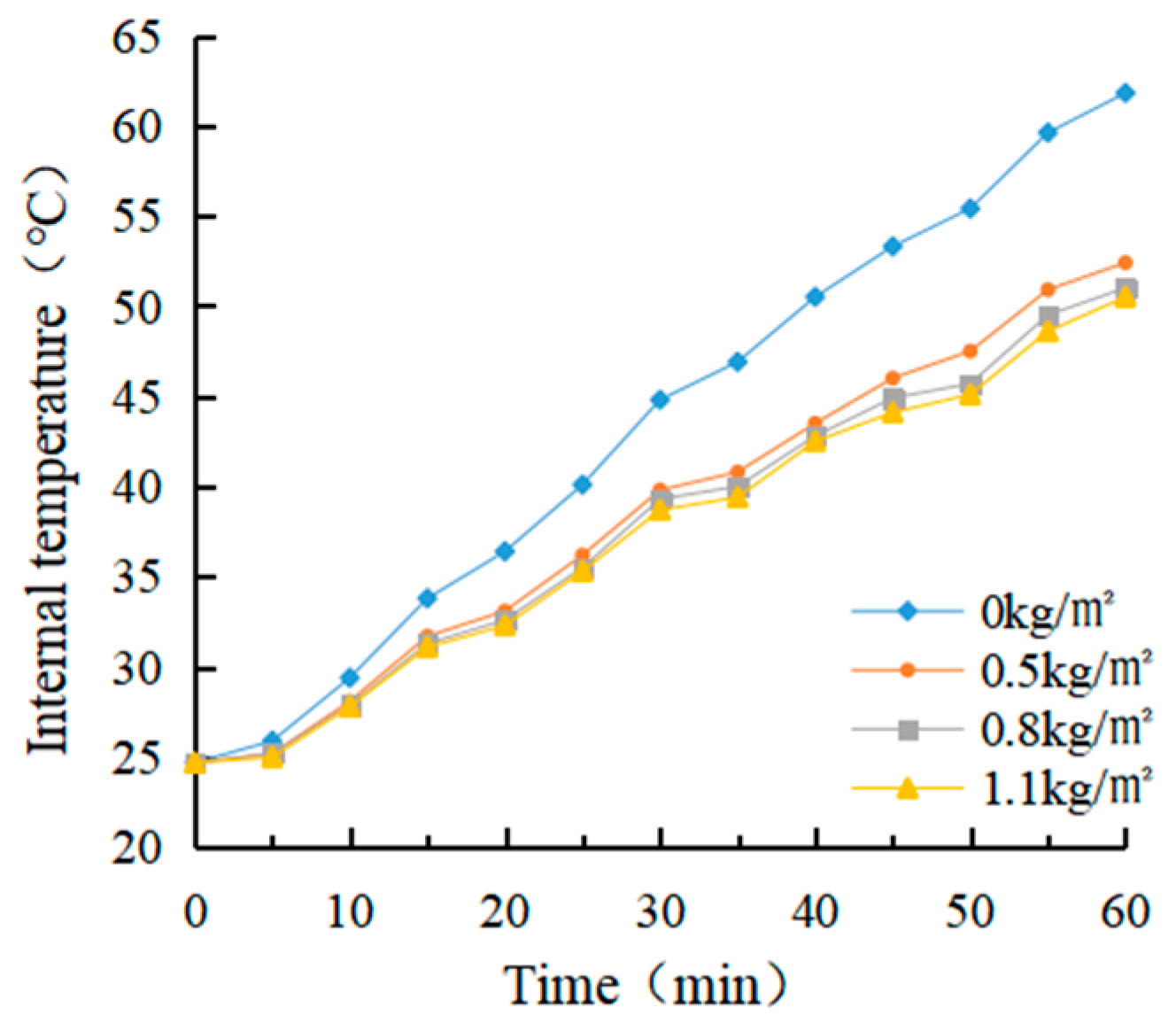

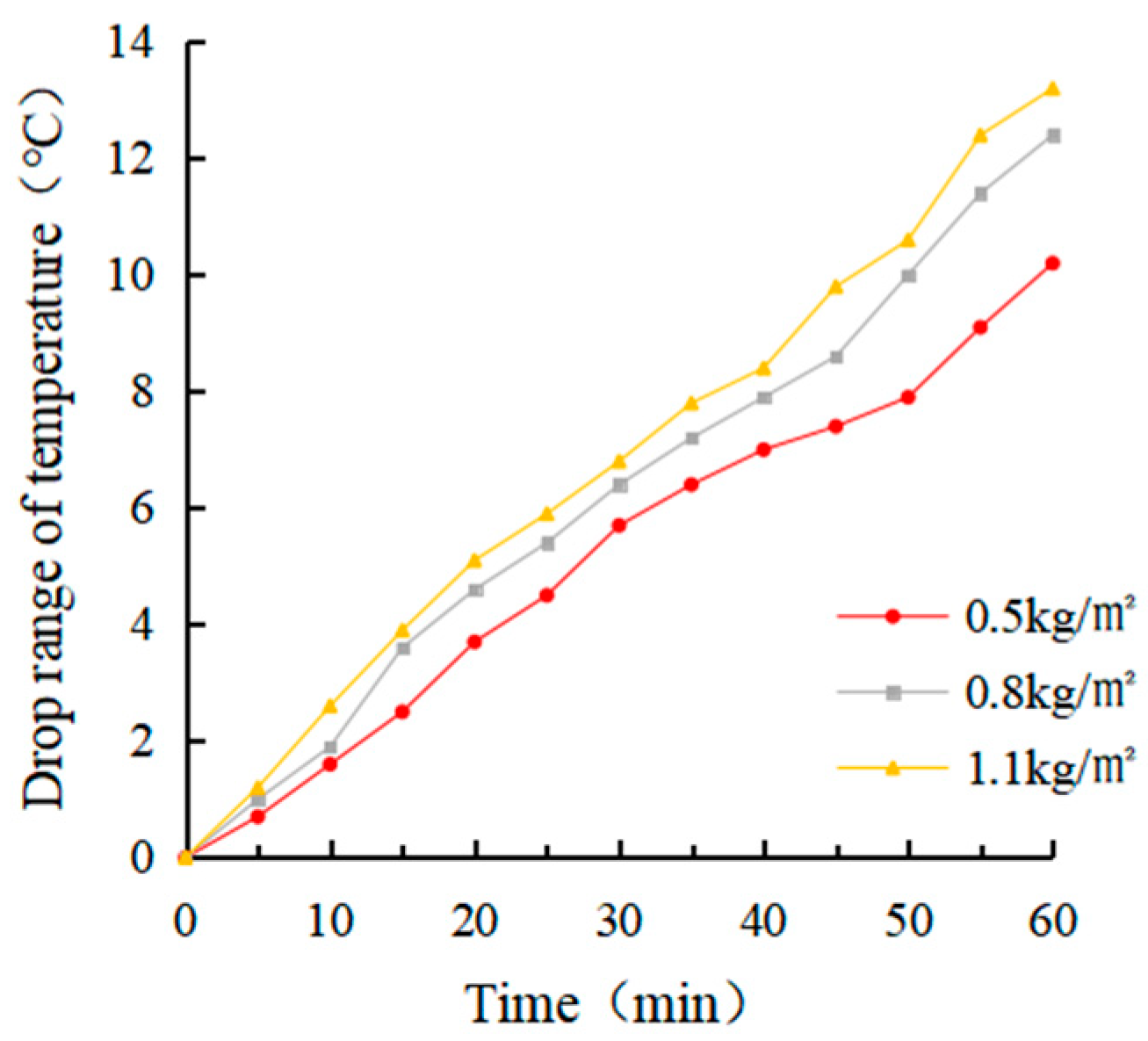

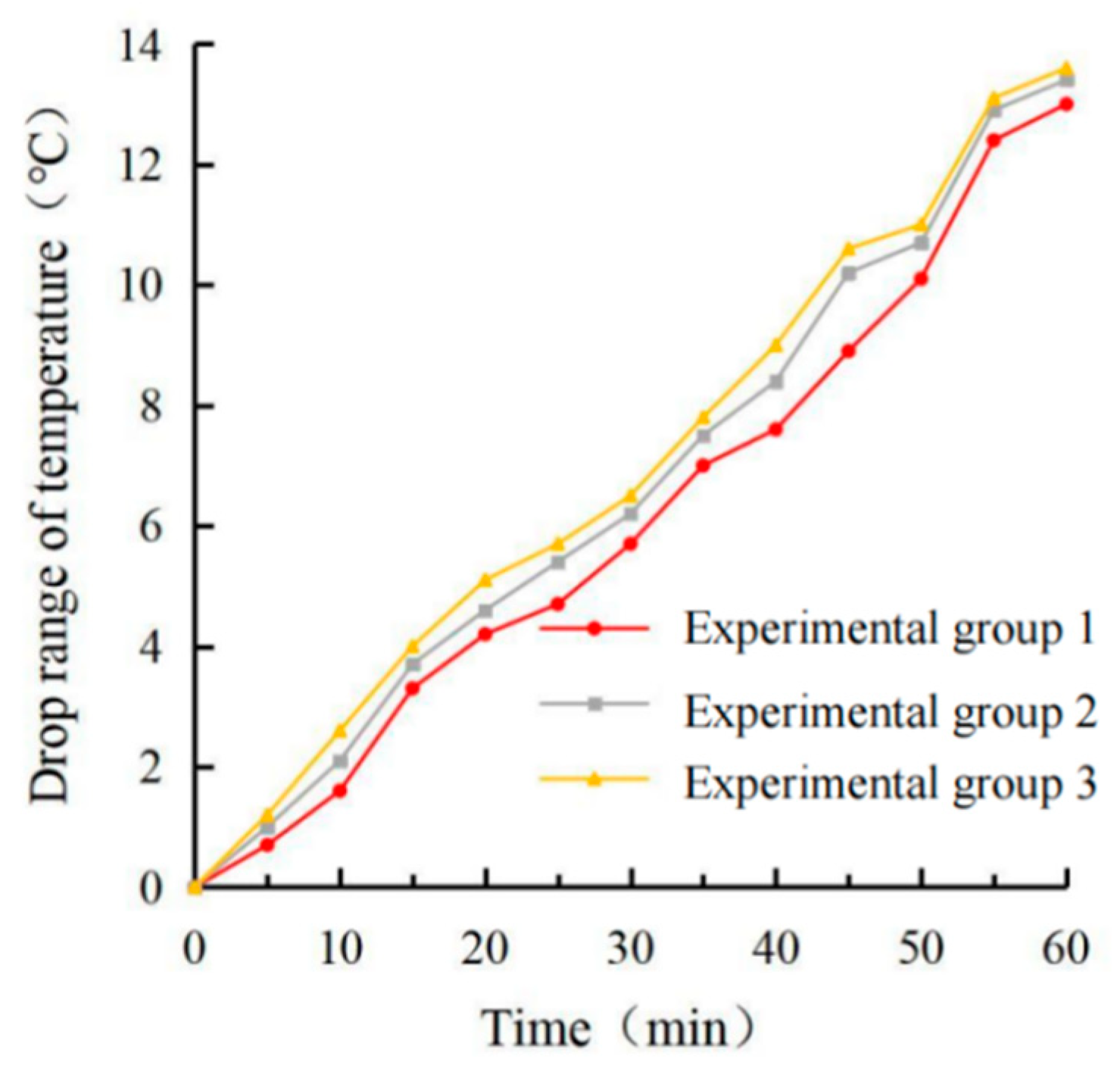

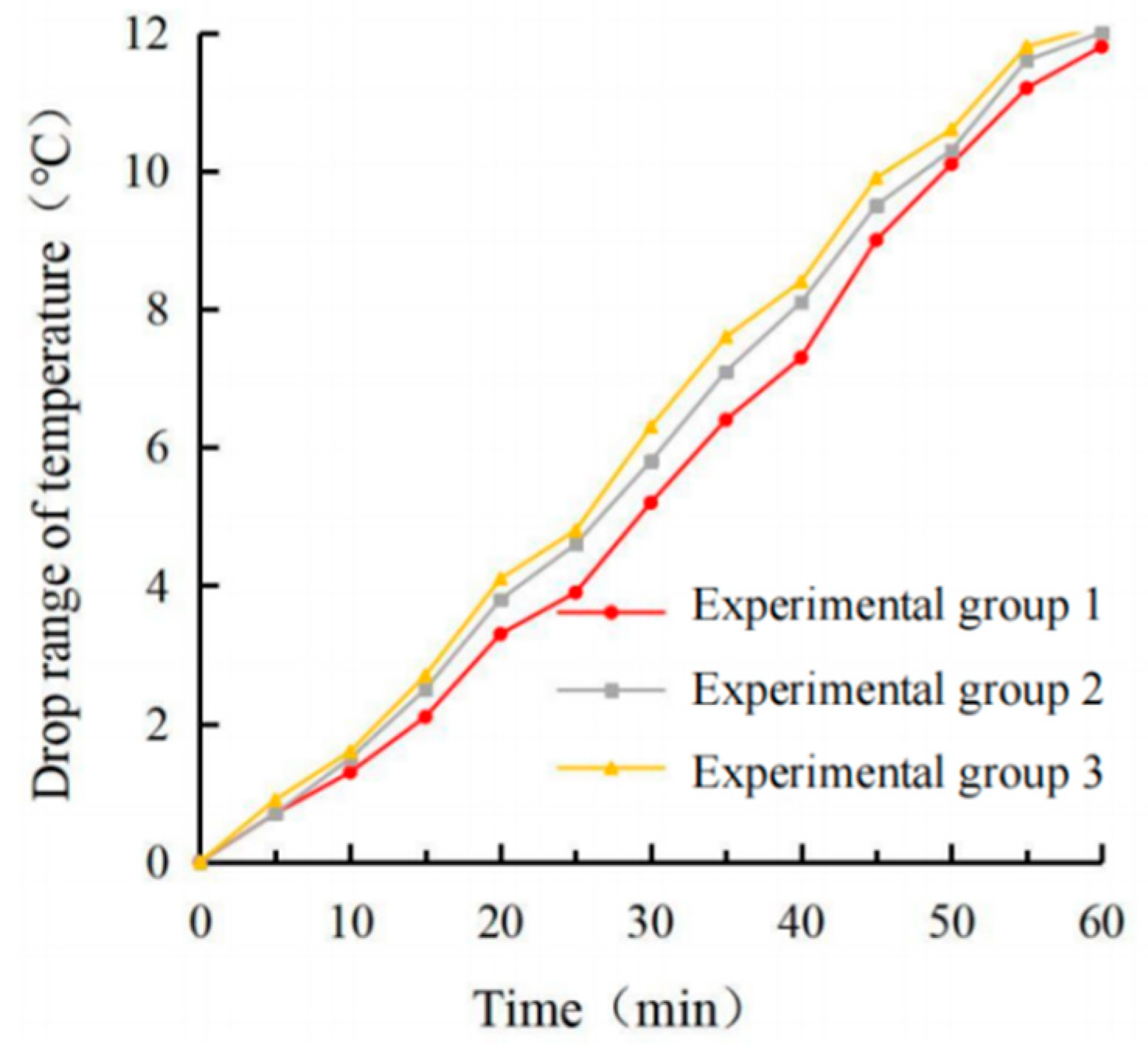

- (1)

- Determination of coating amount

- (2)

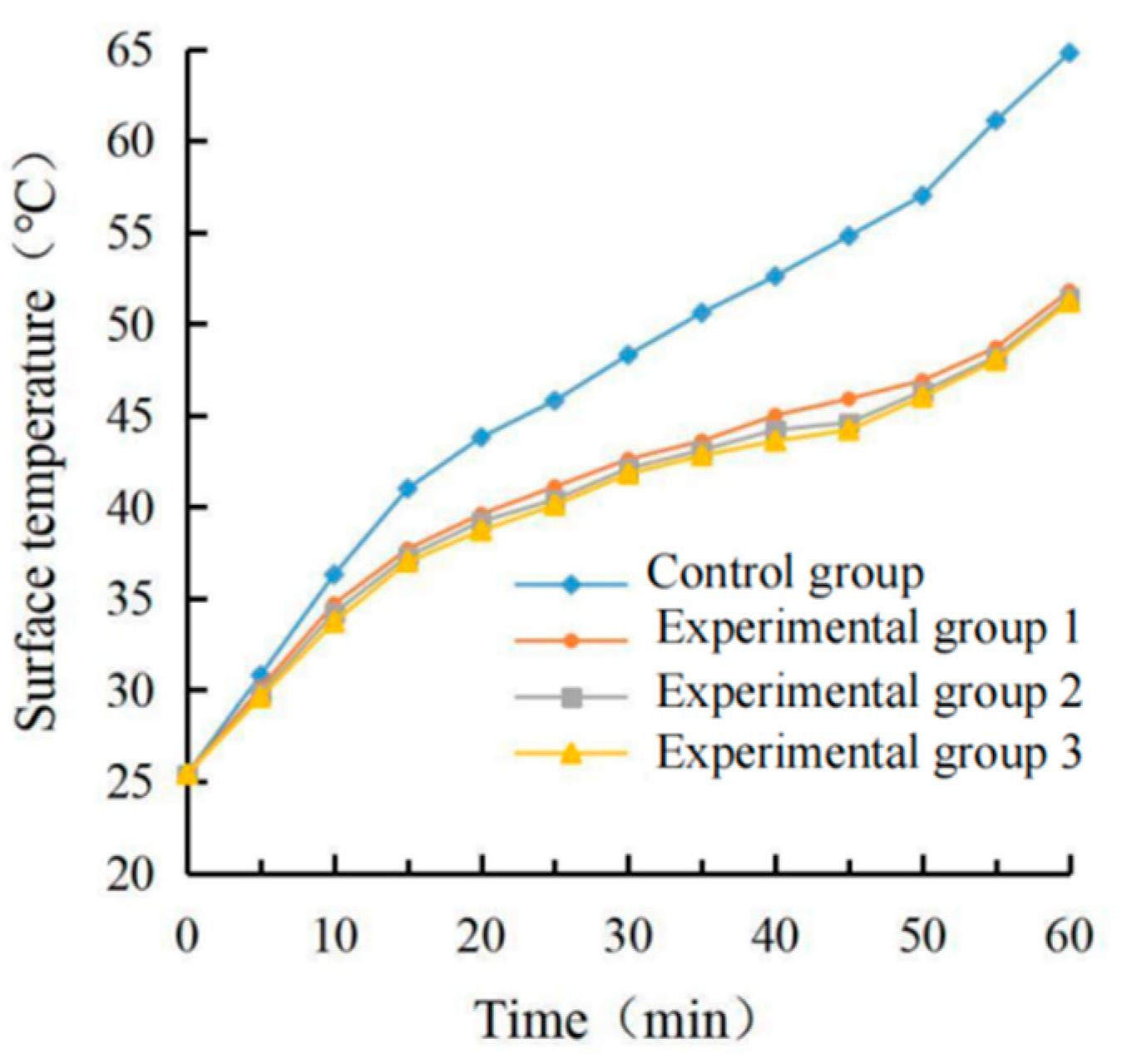

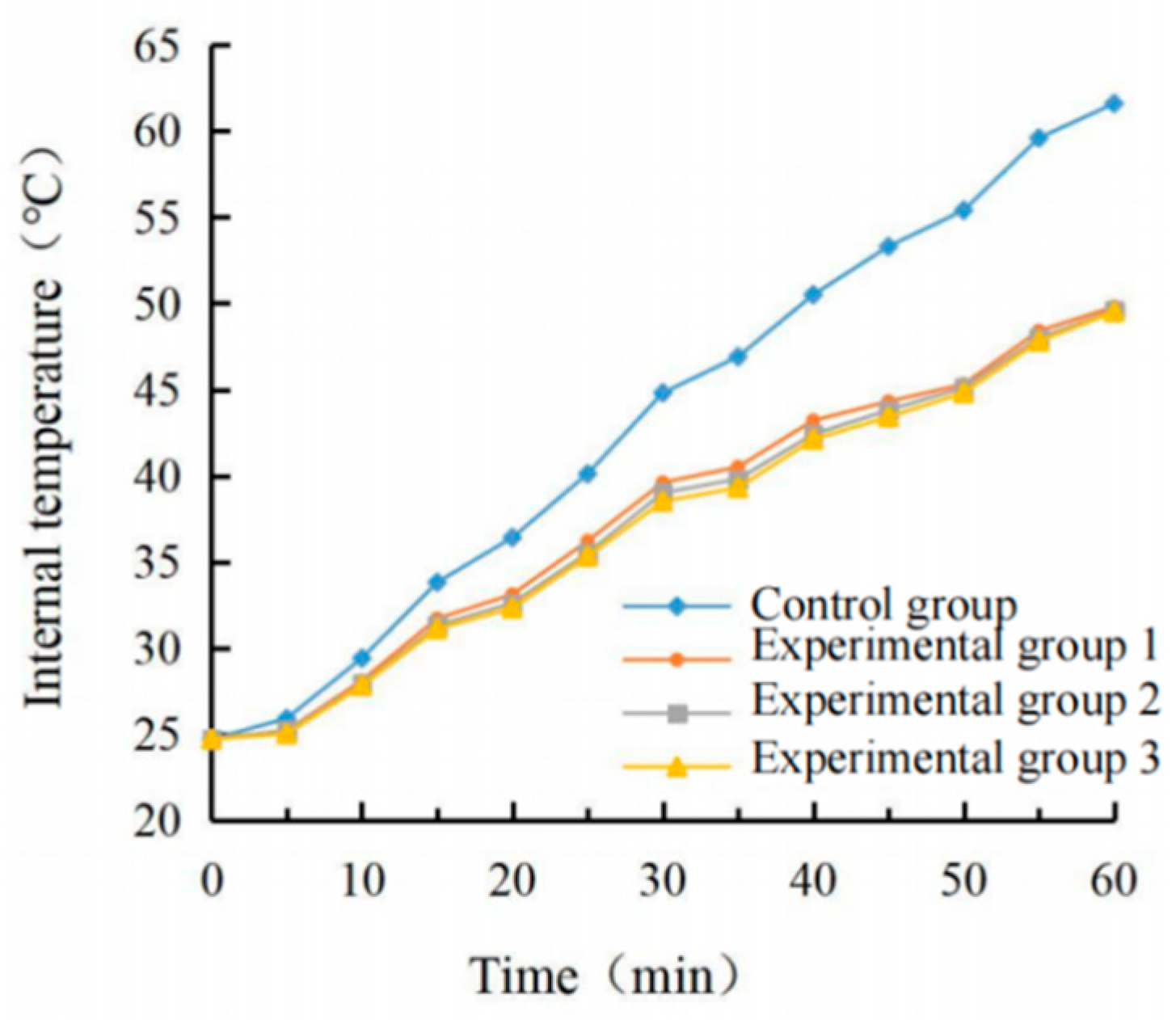

- Determination of coating structure

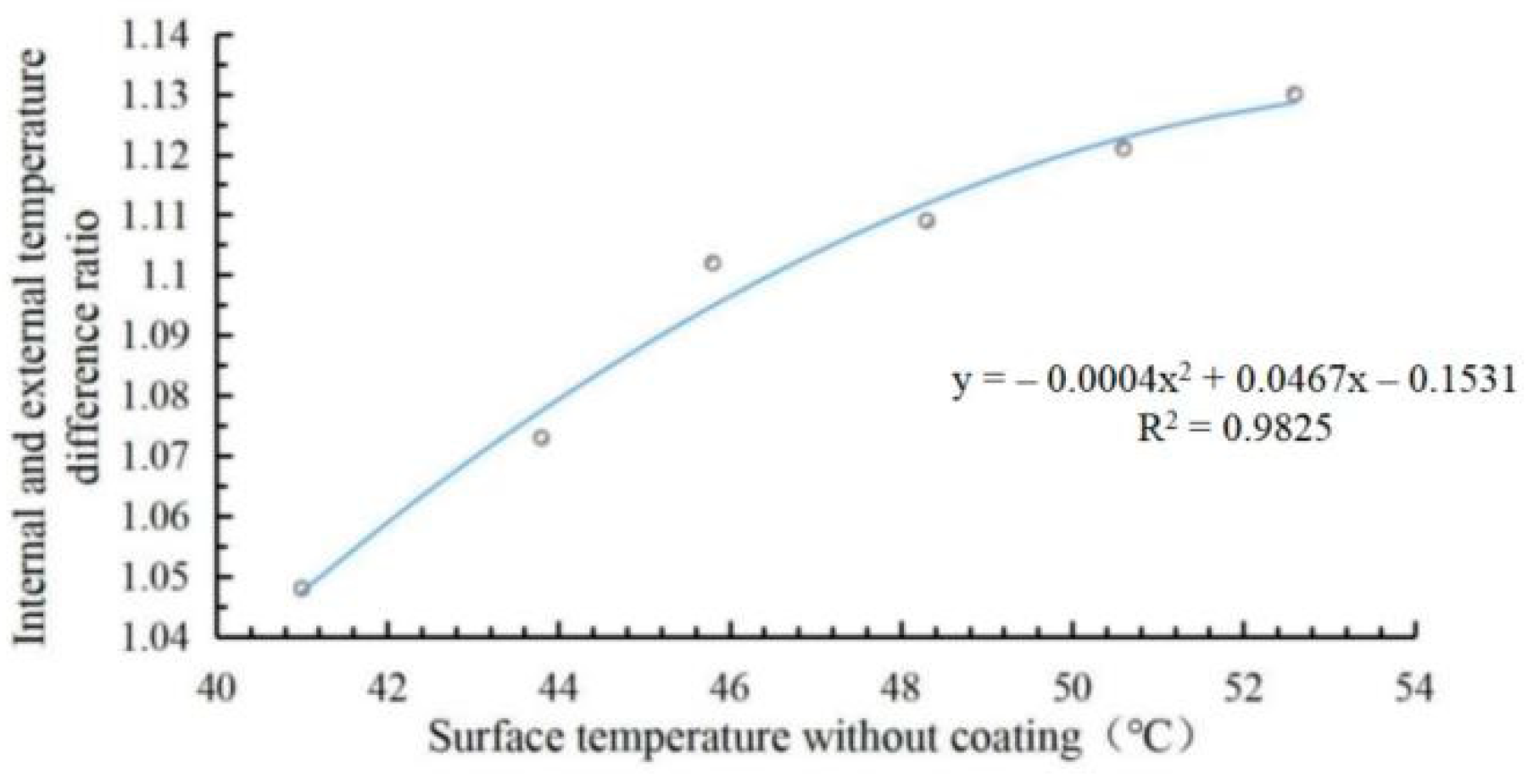

4.2. Evaluation of Outdoor Cooling Effect

4.3. Anti-Slip Performance

4.4. Wear Resistance Evaluation

4.5. Evaluation of Impermeability

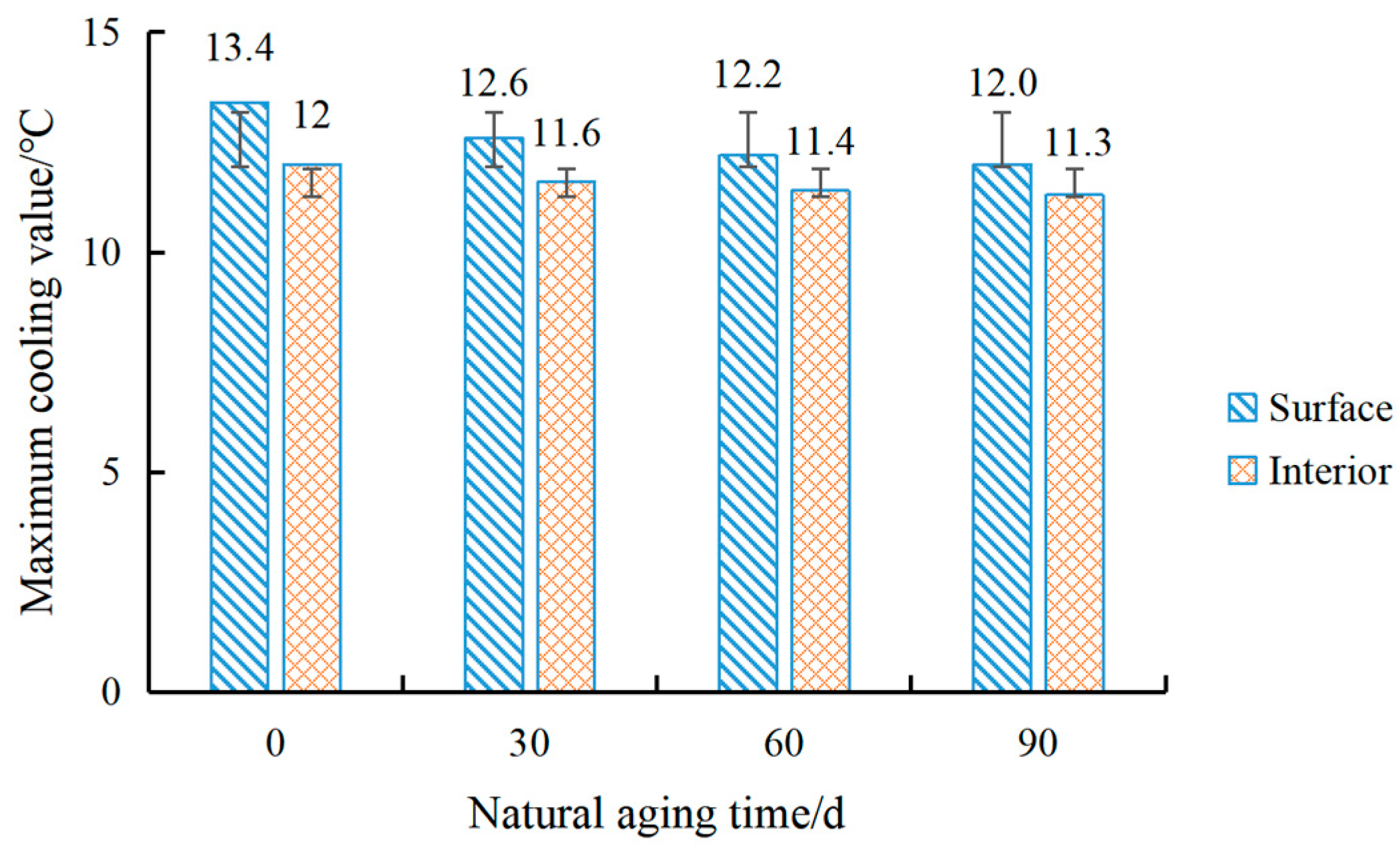

4.6. Anti-Aging Performance Evaluation

5. Conclusions

- (1)

- A new type of asphalt pavement thermal reflective coating was developed. The emulsion mixed with epoxy resin and liquid phenolic resin was used as the matrix resin, and silica, hollow glass beads and sericite powder were used to replace part of titanium dioxide as the functional filler of the thermal reflection coating. Compared with all titanium dioxide as the functional filler, it was more economical, and the physical and chemical properties were more prominent.

- (2)

- After surface modification of functional fillers, it was found that the particles were hydrophobic and lipophilic, which could be stably and uniformly dispersed in the thermal reflection coating of asphalt pavement and displays the cooling effect of the coating.

- (3)

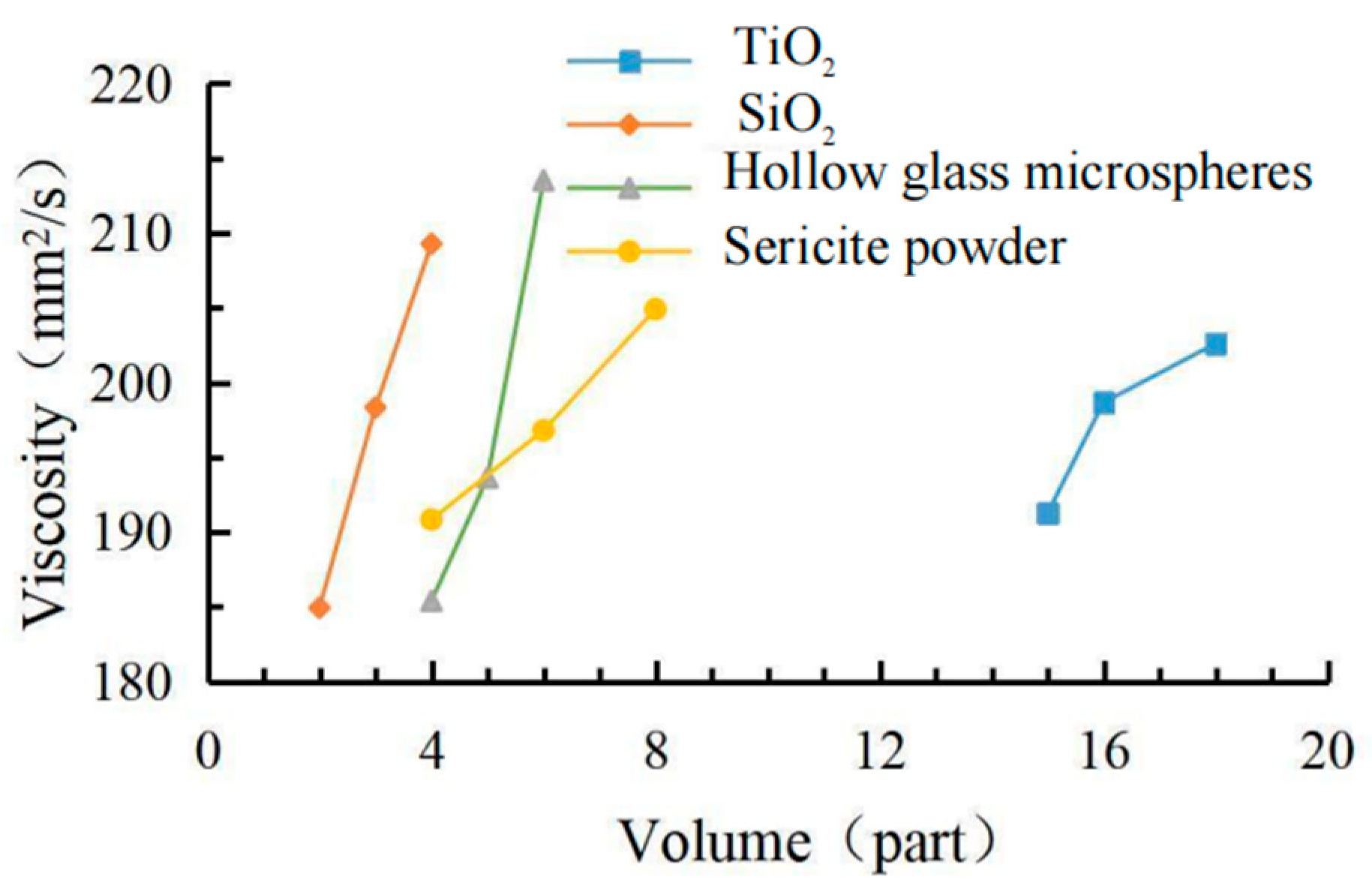

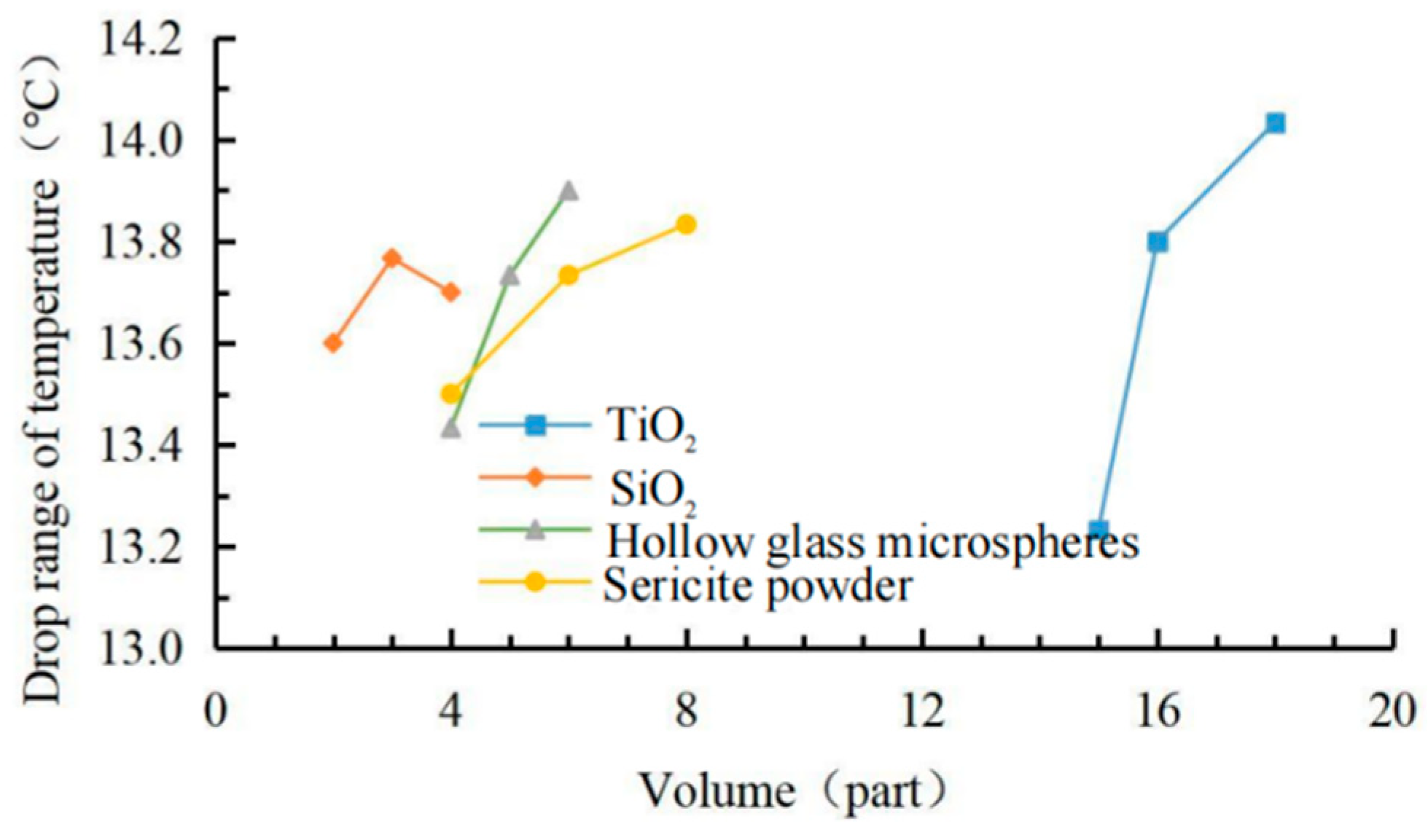

- With the cooling value, viscosity and gloss as the evaluation indexes, the orthogonal experimental design analysis was used to optimize the distribution ratio of each filler group that could best balance the three indexes as follows: 18 portions of modified TiO2, 3 portions of modified SiO2, 5 portions of modified hollow glass microspheres and 6 portions of modified sericite powder were added to each 100 mass portion of the mixed matrix resin, and the amount of pigment was determined to be 3% of the matrix mass after testing.

- (4)

- The indoor cooling test showed that the optimal coating amount was 0.8 kg/m2, and the double-layer coating structure was adopted, i.e., the bottom layer was white pigment-free coating, and the upper layer was colored layer. The test results showed that when the coating amount of the bottom layer and the surface layer was 0.4 kg/m2, the coating structure could make the internal and external cooling values of the mixture reach 12.0 °C and 13.4 °C, respectively, and the cooling capacity increased by 11.1% and 8.1%, respectively, compared with the single coating structure. Due to the limitations of the external environmental conditions, the maximum cooling value of the outdoor cooling test is 8.5 °C, which is somewhat different from that of the indoor test. However, according to the fitting calculation of the indoor cooling test value, it can be seen that the outdoor asphalt pavement surface cooling value will be close to 11.23 °C when the ambient temperature is consistent, which has progressive achievements.

- (5)

- The new asphalt pavement heat-reflective coating has good skid resistance, wear resistance, impermeability and aging resistance, indicating that the heat-reflective coating has good excellent prospects for application.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jarnette, V.D.; McCarthy, L.M.; Bennert, T.; Guercio, M.C. Use of Mechanistic-Empirical Pavement Design Principles to Assign Asphalt Pavement Pay Factor Adjustments. J. Constr. Eng. Manag. 2013, 139, 04013024. [Google Scholar] [CrossRef]

- Zhu, S.S.; Mai, X.M. A Review of Using Reflective Pavement Materials as Mitigation Tactics to Counter the Effects of Urban Heat Island. Adv. Compos. Hybrid Mater. 2019, 2, 381–388. [Google Scholar] [CrossRef]

- Feng, D.C.; Yi, J.Y.; Wang, D.S. Performance and Thermal Evaluation of Incorporating Waste Ceramic Aggregates in Wearing Layer of Asphalt Pavement. J. Mater. Civ. Eng. 2013, 25, 857–863. [Google Scholar] [CrossRef]

- Qin, Y. A Review on the Development of Cool Pavements to Mitigate Urban Heat Island Effect. Renew. Sustain. Energy Rev. 2015, 52, 445–459. [Google Scholar] [CrossRef]

- Anna, L.P.; Franco, C.; Andrea, N.; Brinchi, L. Development of Clay Tile Coatings for Steep-Sloped Cool Roofs. Energies 2013, 6, 3637–3653. [Google Scholar]

- Xie, N.; Li, H.; Zhang, H.J.; Zhang, X.; Jia, M. Effects of Accelerated Weathering on the Optical Characteristics of Reflective Coatings for Cool Pavement. Sol. Energy Mater. Sol. Cells 2020, 215, 110698. [Google Scholar] [CrossRef]

- Kyriakodis, G.E.; Santamouris, M. Using Reflective Pavements to Mmitigate Urban Heat Island in Warm Climates-Results From a Large Scale Urban Mitigation Project. Urban Clim. 2018, 24, 326–339. [Google Scholar] [CrossRef]

- Carnielo, E.; Zinzi, M. Optical and Thermal Characterisation of Cool Asphalts to Mitigate Urban Temperatures and Building Cooling Demand. Build. Environ. 2013, 60, 56–65. [Google Scholar] [CrossRef]

- Rossi, F.; Castellani, B.; Presciutti, A.; Morini, E.; Anderini, E.; Filipponi, M.; Nicolini, A. Experimental Evaluation of Urban Heat Island Mitigation Potential of Retro-Reflective Pavement in Urban Canyons. Energy Build. 2016, 126, 340–352. [Google Scholar] [CrossRef]

- Uemoto, K.L.; Neide, M.N.S.; John, V.M. Estimating Thermal Performance of Cool Colored Paints. Energy Build. 2010, 42, 17–22. [Google Scholar] [CrossRef]

- Synnefa, A.; Karlessi, T.; Gaitani, N.; Santamouris, M.; Assimakopoulos, D.N.; Papakatsikas, C. Experimental Testing of Cool Colored Thin Layer Asphalt and Estimation of Its Potential to Improve the Urban Microclimate. Build. Environ. 2011, 46, 38–44. [Google Scholar] [CrossRef]

- Tukiran, J.M.; Ariffin, J.; Ghani, A.N.A. Comparison on Colored Coating for Asphalt and Concrete Pavement Based on Thermal Performance and Cooling Effect. J. Teknol. 2016, 78, 63–70. [Google Scholar] [CrossRef] [Green Version]

- Du, Y.F.; Shi, Q.; Wang, S.Y. Bidirectional Heat Induced Structure of Asphalt Pavement for Reducing Pavement Temperature. Appl. Therm. Eng. 2015, 75, 298–306. [Google Scholar]

- Du, Y.F.; Shi, Q.; Wang, S.Y. Highly Oriented Heat-Induced Structure of Asphalt Pavement for Reducing Pavement Temperature. Energy Build. 2014, 85, 23–31. [Google Scholar]

- Du, Y.F.; Wang, S.Y.; Zhang, J. Cooling Asphalt Pavement by a Highly Oriented Heat Conduction structure. Energy Build. 2015, 102, 187–196. [Google Scholar]

- Zheng, M.L.; Tian, Y.J.; He, L.T. Analysis on Environmental Thermal Effect of Functionally Graded Nanocomposite Heat Reflective Coatings for Asphalt Pavement. Coatings 2019, 9, 178. [Google Scholar] [CrossRef] [Green Version]

- Chen, Q.; Wang, C.H.; Fu, H. Durability Evaluation of Road Cooling Coating. Constr. Build. Mater. 2018, 190, 13–23. [Google Scholar] [CrossRef]

- Shen, A.; Kong, T.; Guo, Y.; Qian, Y.; Li, P. Optimal Design and Road Performance of Waterborne Acrylic Heat Reflective Coating on Asphalt Pavement. Bull. Chin. Ceram. Soc. 2021, 40, 3829–3836. [Google Scholar]

- Morini, E.; Castellani, B.; Anderini, E.; Presciutti, A.; Nicolini, A.; Rossi, F. Optimized Retro-Reflective Tiles for Exterior Building Element. Sustain. Cities Soc. 2018, 37, 146–153. [Google Scholar] [CrossRef]

- Gao, P.; Yu, C.; Du, L.; Luo, H.; Li, Y.; Wei, C. Preparation and research progress of hollow mesoporous silica microsphere. New Chem. Mater. 2019, 47, 31–34+38. [Google Scholar]

- Dong, J.; Lu, P.; Ding, Y. Thermal Insulation Performance of High Reflection Hollow Glass Beads in Heat Reflecting Coatings. Bull. Chin. Ceram. Soc. 2019, 38, 2191–2195. [Google Scholar]

- Yu, X.; Xu, C. Influence of Hight-Performance Hollow Class Microsphere on Thermal Insulation of Coatings. Paint. Coat. Ind. 2014, 44, 1–5. [Google Scholar]

- Sha, A.M.; Liu, Z.Z.; Li, P. Solar Heating Reflective Coating Layer (SHRCL) to Cool the Asphalt Pavement Surface. Constr. Build. Mater. 2017, 139, 355–364. [Google Scholar] [CrossRef]

- Pan, L. Preparation of Waterborne Epoxy Heat-Reflective Coating for Asphalt Pavement. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2017. [Google Scholar]

- GB/T 1766-2008; Rating Method for Aging of Paint and Varnish Coatings. China Standards Press: Beijing, China, 2008.

| Resin Category | Epoxide Equivalent (g/EP) | Chromaticity (Platinum–Cobalt color) | Viscosity at 25 °C (mPa·S) | Hydrolyzable Chlorine (%) | Volatile Matter (%) |

|---|---|---|---|---|---|

| E51 epoxy resin | 186.6 | 23 | 12,380 | 0.0623 | 0.087 |

| Category of Curing Agents | Appearance | Amine Value (mgKOH/g) | Density (g/cm3) | Active Hydrogen Equivalent | Viscosity at 25 °C (mPa·S) |

|---|---|---|---|---|---|

| 593 epoxy curing agent | Colorless transparent liquid | 500~600 | 0.985 | 45~48 | 150 ± 25 |

| Category of Curing Agents | Appearance | Amine Value (mgKOH/g) | Density (g/cm3) | Active Hydrogen Equivalent | Viscosity at 25 °C (mPa·S) |

|---|---|---|---|---|---|

| 593 epoxy curing agent | Colorless transparent liquid | 500~600 | 0.985 | 45~48 | 150 ± 25 |

| Name | Main Feature |

|---|---|

| Rutile titanium dioxide | It has strong light scattering ability, anti-ultraviolet ability, stability and refraction ability, high density, low photochemical activity, high refractive index and reflection ratio to near-infrared radiation, and can obviously shield solar thermal radiation energy. |

| Hollow glass microspheres | The coating has low density, low thermal conductivity, high reflection ratio, good thermal insulation, sound insulation, stability and flow smoothness. The addition of small doses of the coating has a low effect on the viscosity of the coating, so it can reduce the amount of solvent, reduce the emission of VOCs, and enhance the elasticity of the coating, which greatly reduces the possible cracks and shedding phenomena [20,21,22]. |

| Silicon dioxide | It has porosity, heat insulation, high-temperature resistance, strong dispersion, high reflection and barrier ability to light and heat, and strong weather resistance. It can improve the viscosity and stability of the coating and also has a certain effect on the extinction of the coating. |

| Sericite powder | The lamellar structure can form the ‘maze effect‘ of heat transfer due to its large aspect ratio and significantly improve the UV shielding ability, impermeability, surface hardness and corrosion resistance of the coating. Moreover, due to the polarization effect of mineral crystals and the intervention effect of interlayer water molecules, the ability of the coating to shield ultraviolet, microwave and infrared rays is higher than that of all other inorganic fillers, so it can greatly improve the aging resistance and high-temperature resistance of the coating. |

| Level | Factor Dosage (Part) | |||

|---|---|---|---|---|

| TiO2 | SiO2 | Hollow Glass Microsphere | Sericite Powder | |

| 1 | 15 | 2 | 4 | 4 |

| 2 | 15 | 3 | 5 | 6 |

| 3 | 15 | 4 | 6 | 8 |

| 4 | 16.5 | 2 | 5 | 8 |

| 5 | 16.5 | 3 | 6 | 4 |

| 6 | 16.5 | 4 | 4 | 6 |

| 7 | 18 | 2 | 6 | 6 |

| 8 | 18 | 3 | 4 | 8 |

| 9 | 18 | 4 | 5 | 4 |

| Test Number | Filler/ (Fill + Base) | Drop Range of Temperature (°C) | Kinematic Viscosity (mm2/s) | Glossiness |

|---|---|---|---|---|

| 1 | 20.0% | 12.7 | 159.9 | 34.1 |

| 2 | 22.5% | 13.4 | 187.5 | 33.0 |

| 3 | 24.8% | 13.6 | 226.4 | 33.6 |

| 4 | 23.9% | 13.9 | 189.6 | 36.8 |

| 5 | 22.8% | 13.9 | 208.8 | 28.7 |

| 6 | 23.4% | 13.6 | 197.6 | 30.8 |

| 7 | 24.2% | 14.2 | 205.3 | 33.6 |

| 8 | 24.8% | 14.0 | 198.7 | 33.7 |

| 9 | 23.7% | 13.9 | 203.8 | 26.7 |

| Category | Name of the Material | Content (Mass Fraction) |

|---|---|---|

| Basal body | Solvent-free epoxy resin | 97 |

| Liquid phenolic resin | 3 | |

| 593 curing agent | 25 | |

| Functional fillers | Modified rutile titanium dioxide | 18 |

| Modified silica | 3 | |

| Modified hollow glass beads | 5 | |

| Modified sericite powder | 6 | |

| Pigment | Iron oxide red powder | 3 |

| Assistant | 692 epoxy active diluent | 8 |

| Gas phase silica | 0.5 | |

| Propylene glycol | 2.5 | |

| Anti-slip pellet | Quartz sand | 5 |

| Surface Temperature of Indoor Rut Plate (°C) | The Cooling Value of Indoor Test T1 (°C) | The Calculated Outdoor Cooling Value T2 (°C) | Internal and External Cooling Value Ratio (T1/T2) |

|---|---|---|---|

| 36.3 | 2.1 | - | - |

| 41.0 | 3.6 | 3.435 | 1.048 |

| 43.8 | 4.6 | 4.288 | 1.073 |

| 45.8 | 6.1 | 5.533 | 1.102 |

| 48.3 | 7.1 | 6.400 | 1.109 |

| 50.6 | 7.8 | 6.961 | 1.121 |

| 52.6 | 9.0 | 7.962 | 1.130 |

| 54.8 | 10.4 | - | - |

| 57.0 | 11.7 | - | - |

| 61.1 | 13.2 | - | - |

| 64.8 | 13.4 | - | - |

| Surface Condition | Pendulum Value (BPN) | Average Value (BPN) | Average Value Difference (BPN) |

|---|---|---|---|

| >No coating | 70 | 67 | 7 |

| 63 | |||

| 68 | |||

| Coated | 61 | 60 | |

| 60 | |||

| 58 |

| Surface Condition | Measuring Points | Tectonic Depth TD (mm) | Average Tectonic Depth (mm) | Average Difference (mm) |

|---|---|---|---|---|

| No coating | Point 1 | 0.79 | 0.80 | 0.14 |

| Point 2 | 0.82 | |||

| Point 3 | 0.80 | |||

| Coated | Point 1 | 0.66 | 0.66 | |

| Point 2 | 0.64 | |||

| Point 3 | 0.67 |

| Groups | Surface State | Wear Mass Loss (g·m−2) | Mass Loss Difference (g·m−2) |

|---|---|---|---|

| Group 1 | Coated | 0.166 | 0.073 |

| No coating | 0.093 | ||

| Group 2 | Coated | 0.163 | 0.076 |

| No coating | 0.087 | ||

| Group 3 | Coated | 0.162 | 0.071 |

| No coating | 0.091 | ||

| Average value | Coated | 0.164 | 0.074 |

| No coating | 0.090 |

| Surface State | Tectonic Depth (mm) | Mean Value of Tectonic Depth (mm) | Mean Difference (mm) | ||

|---|---|---|---|---|---|

| When just painting | 0.66 | 0.64 | 0.67 | 0.66 | - |

| Two months later | 0.67 | 0.68 | 0.67 | 0.67 | +0.01 |

| Four months later | 0.65 | 0.63 | 0.64 | 0.64 | −0.03 |

| Half a year later | 0.63 | 0.62 | 0.63 | 0.63 | −0.01 |

| Surface State | Anti-Skid Value (BPN) | Anti-Skid Average Value (BPN) | Average Difference (BPN) |

|---|---|---|---|

| When just painting | 61 | 60 | - |

| 60 | |||

| 58 | |||

| Two months later | 62 | 61 | +1 |

| 60 | |||

| 62 | |||

| Four months later | 58 | 58 | −3 |

| 59 | |||

| 58 | |||

| Half a year later | 57 | 57 | −1 |

| 57 | |||

| 56 |

| Groups | Surface State | Permeability Coefficient CW (mL/min) | CW Difference (mL/min) | Average Difference (mL/min) |

|---|---|---|---|---|

| Group 1 | Coated | 138 | 138 | 147 |

| No coating | 0 | |||

| Group 2 | Coated | 156 | 156 | |

| No coating | 0 | |||

| Group 3 | Coated | 143 | 143 | |

| No coating | 0 | |||

| Group 4 | Coated | 147 | 147 | |

| No coating | 0 | |||

| Group 5 | Coated | 151 | 151 | |

| No coating | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Guo, T.; Chen, Y.; Wang, C.; Chen, Q.; Ding, S.; Chen, Q.; Chen, H. Preparation and Properties of New Thermal Reflective Coating for Asphalt Pavement. Materials 2022, 15, 8087. https://doi.org/10.3390/ma15228087

Li Z, Guo T, Chen Y, Wang C, Chen Q, Ding S, Chen Q, Chen H. Preparation and Properties of New Thermal Reflective Coating for Asphalt Pavement. Materials. 2022; 15(22):8087. https://doi.org/10.3390/ma15228087

Chicago/Turabian StyleLi, Zhenxia, Tengteng Guo, Yuanzhao Chen, Chaohui Wang, Qian Chen, Siqing Ding, Qi Chen, and Haijun Chen. 2022. "Preparation and Properties of New Thermal Reflective Coating for Asphalt Pavement" Materials 15, no. 22: 8087. https://doi.org/10.3390/ma15228087

APA StyleLi, Z., Guo, T., Chen, Y., Wang, C., Chen, Q., Ding, S., Chen, Q., & Chen, H. (2022). Preparation and Properties of New Thermal Reflective Coating for Asphalt Pavement. Materials, 15(22), 8087. https://doi.org/10.3390/ma15228087