Using Response Surface for Searching the Nearly Optimal Parameters Combination of the Foam Concrete Muffler

Abstract

1. Introduction

1.1. Background

1.2. Objectives

2. Literature Review

2.1. On Muffler

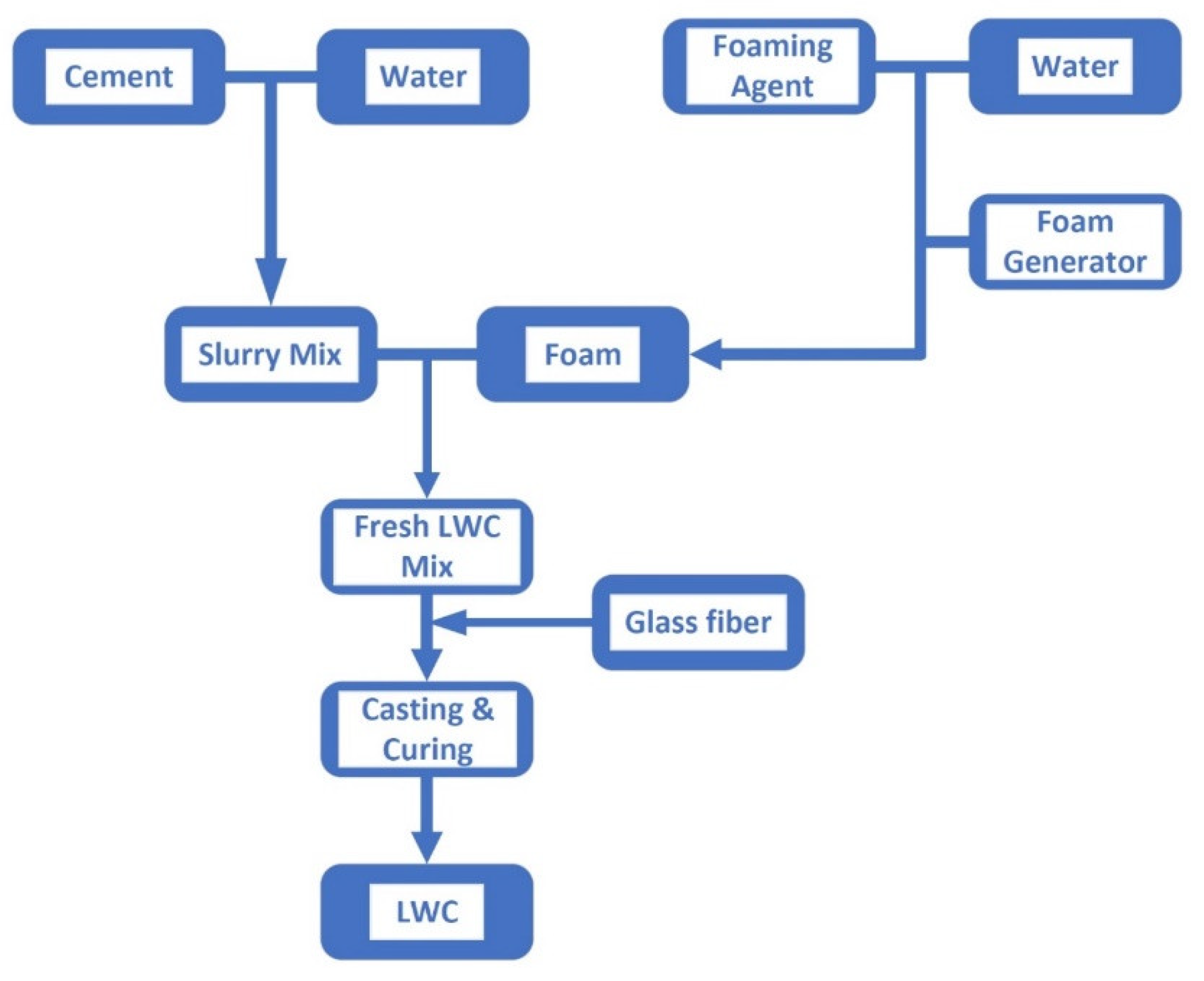

2.2. On Foam Concrete

2.3. On Sound Absorption

2.4. On Response Surface Methodology

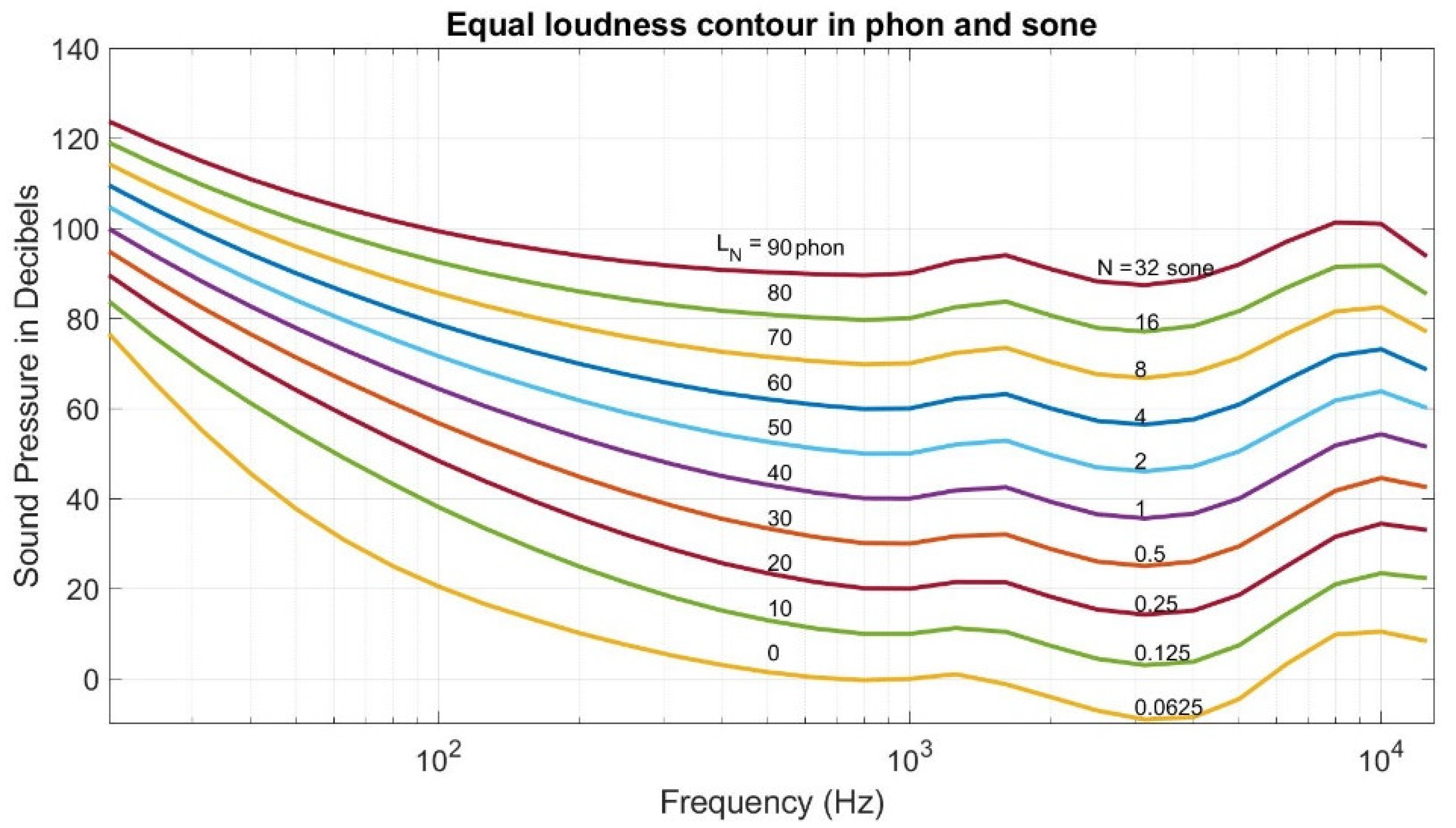

2.5. On Sone

3. Method and Result

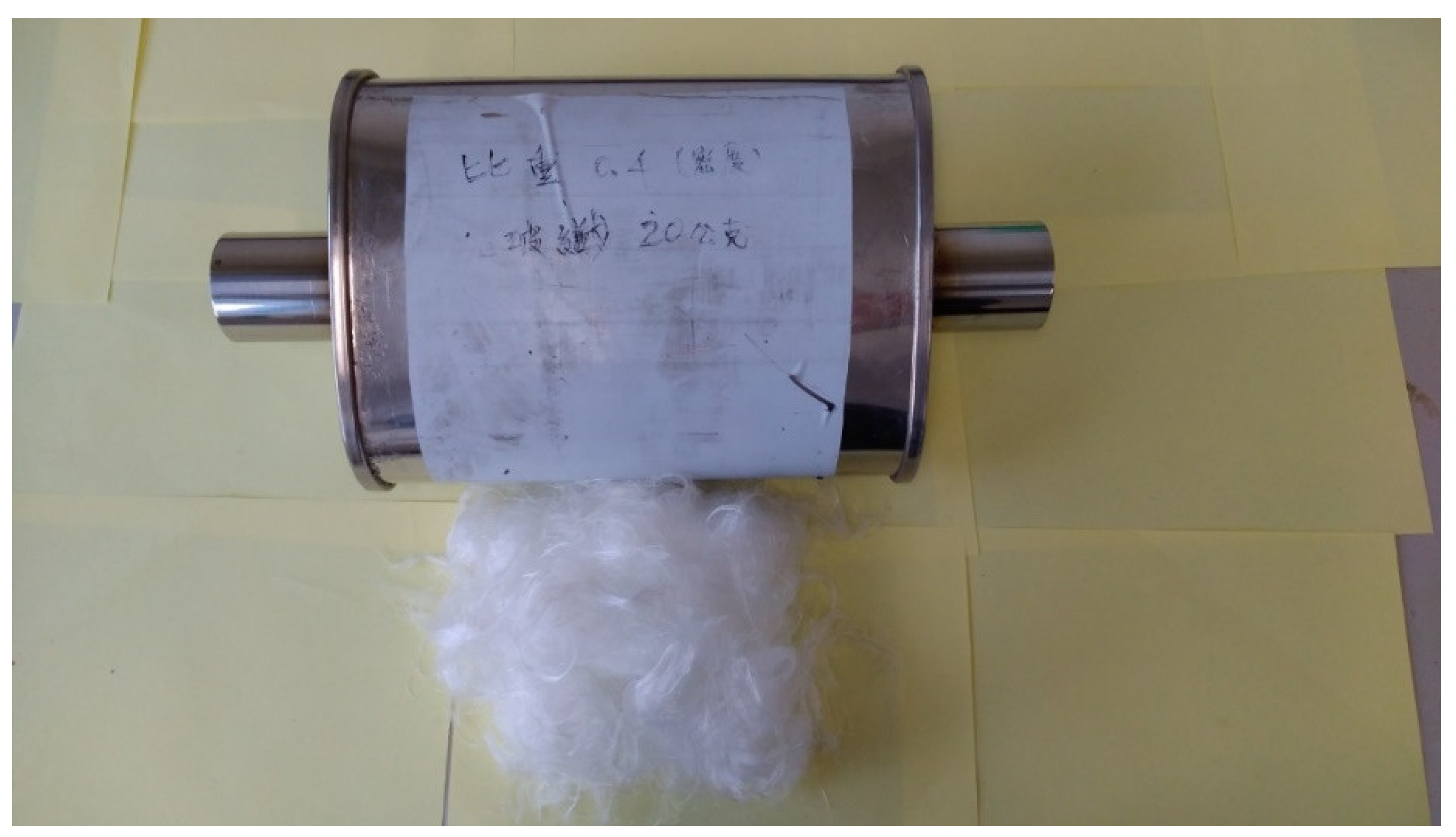

3.1. Two-Way Factorial Design

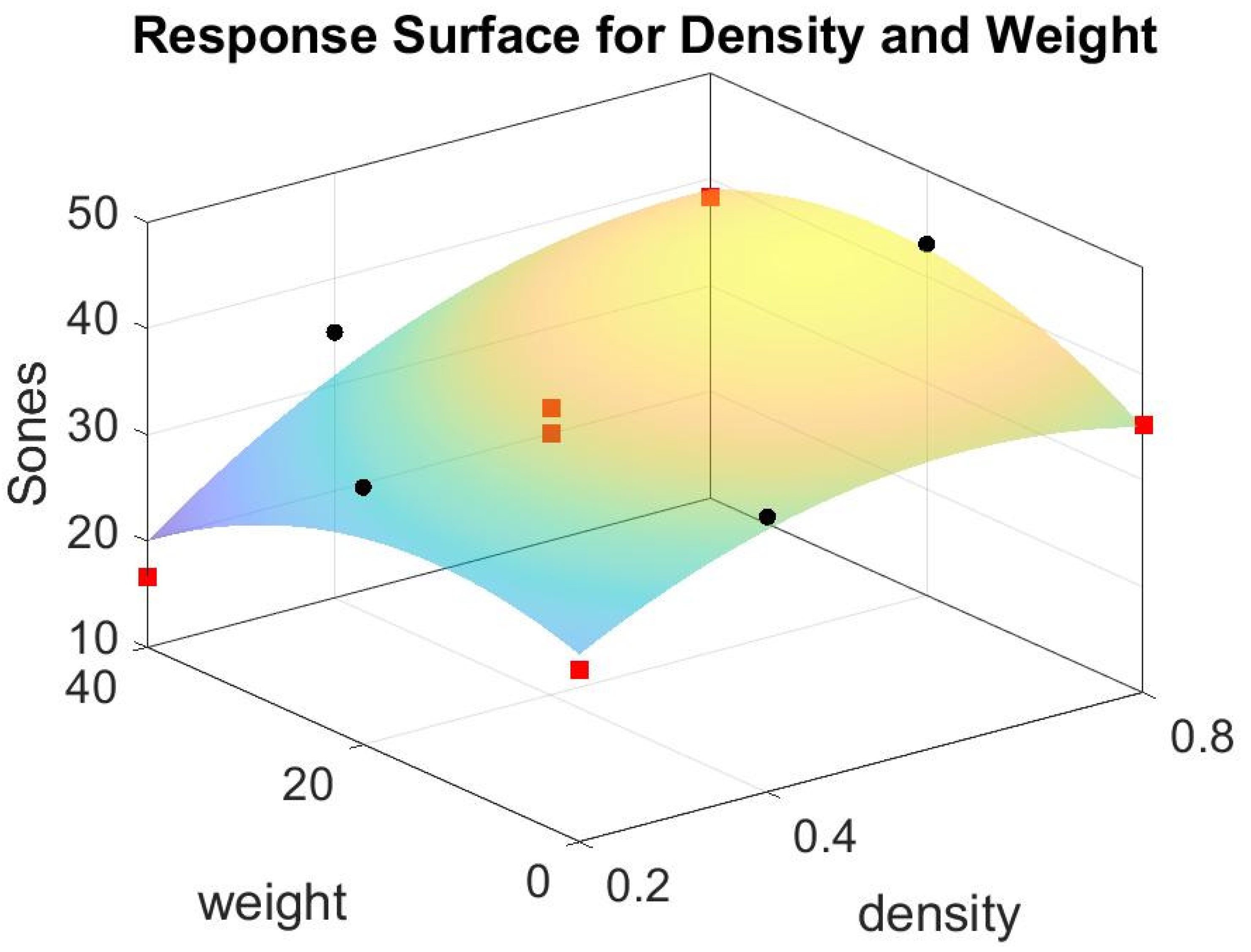

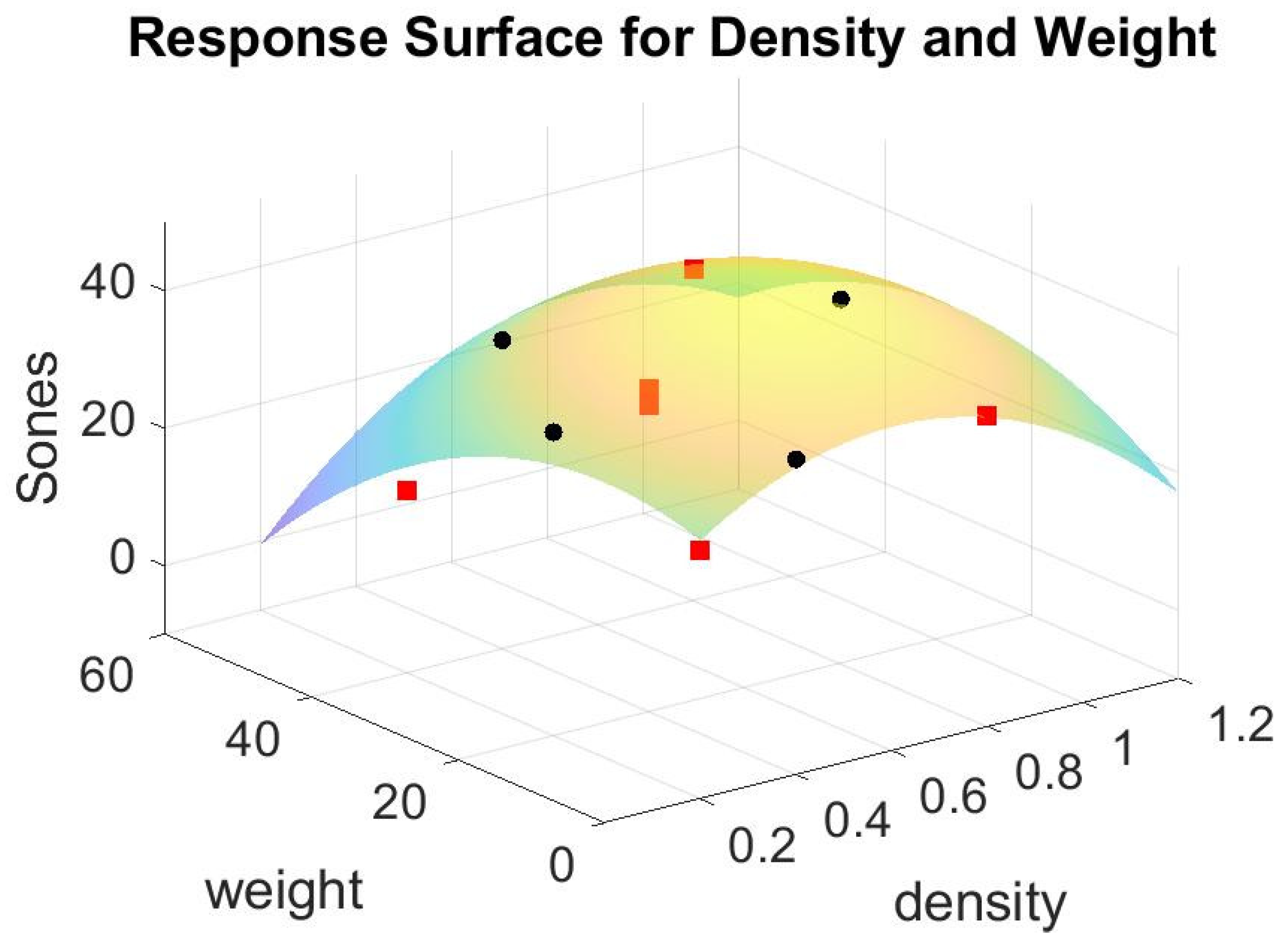

3.2. Patch Formula and ANOVA

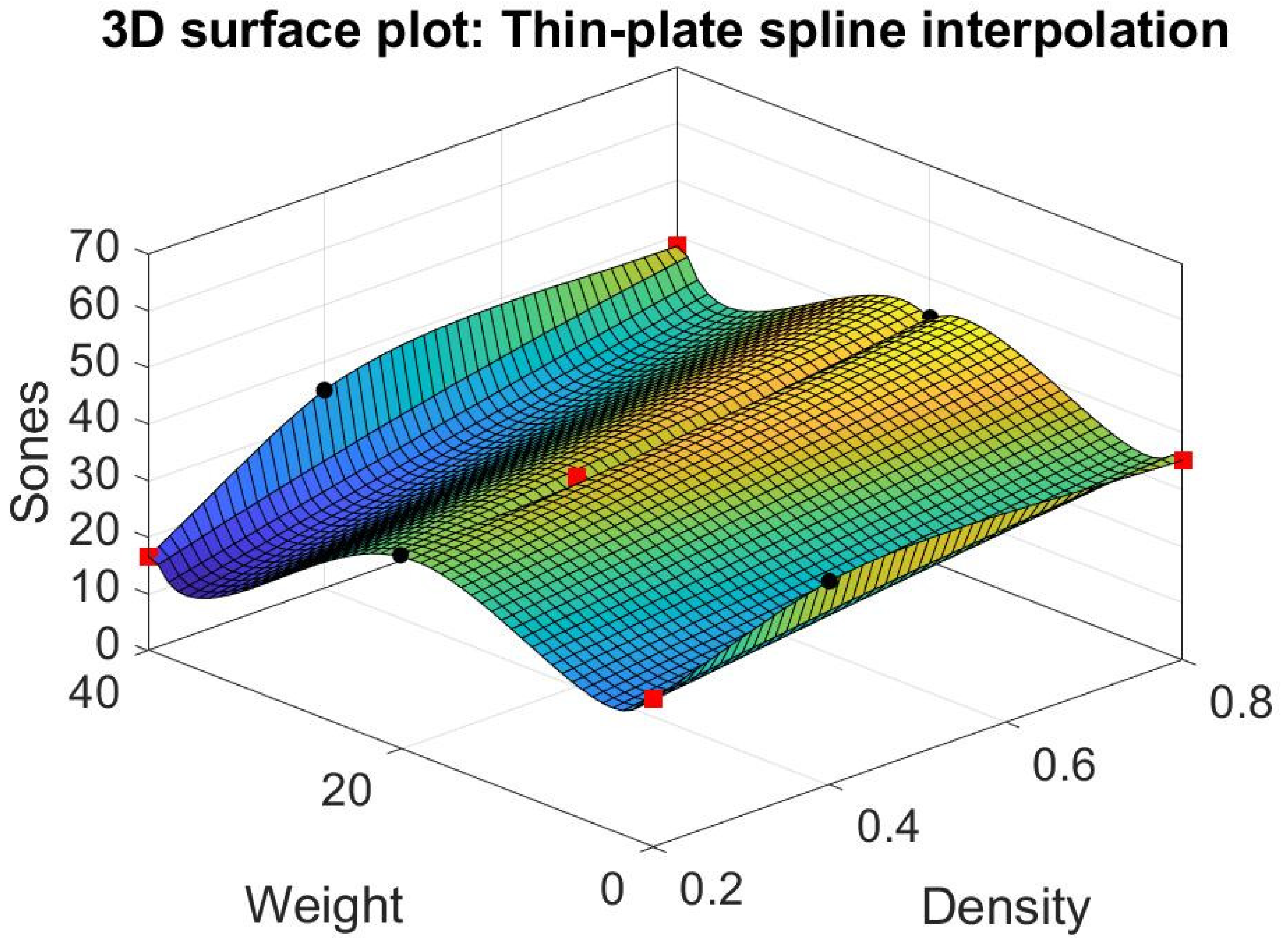

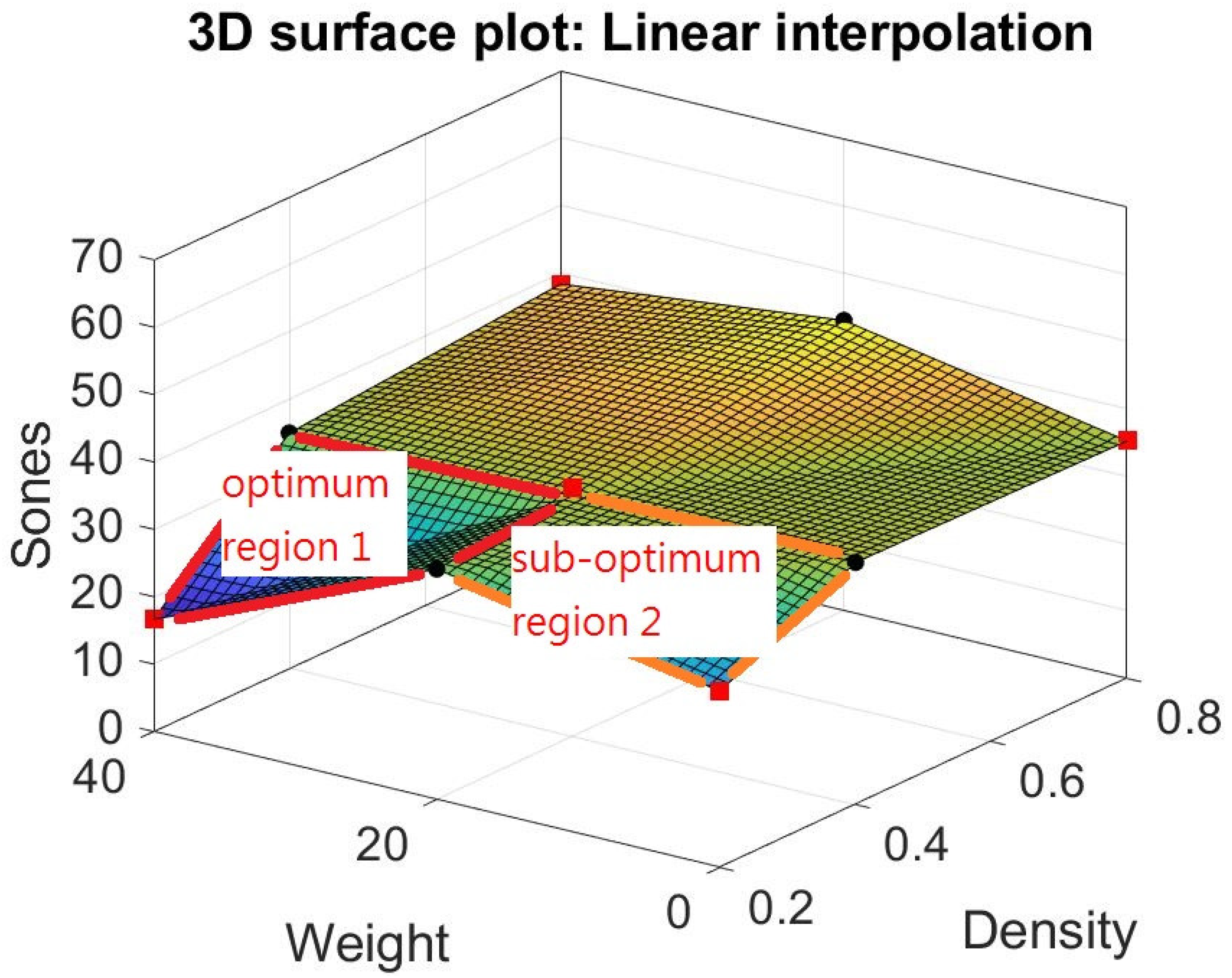

3.3. Matlab’s Interpolation

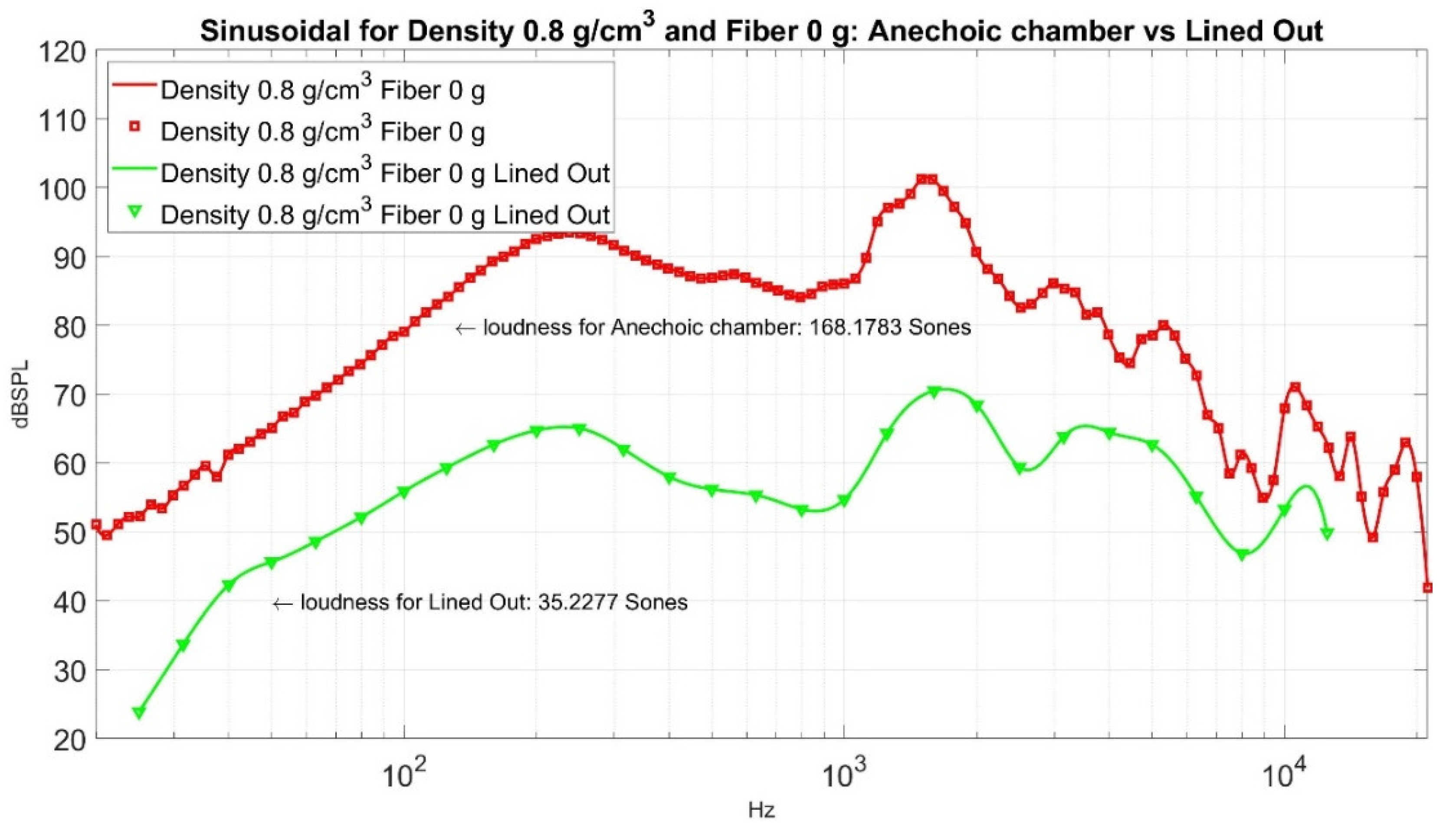

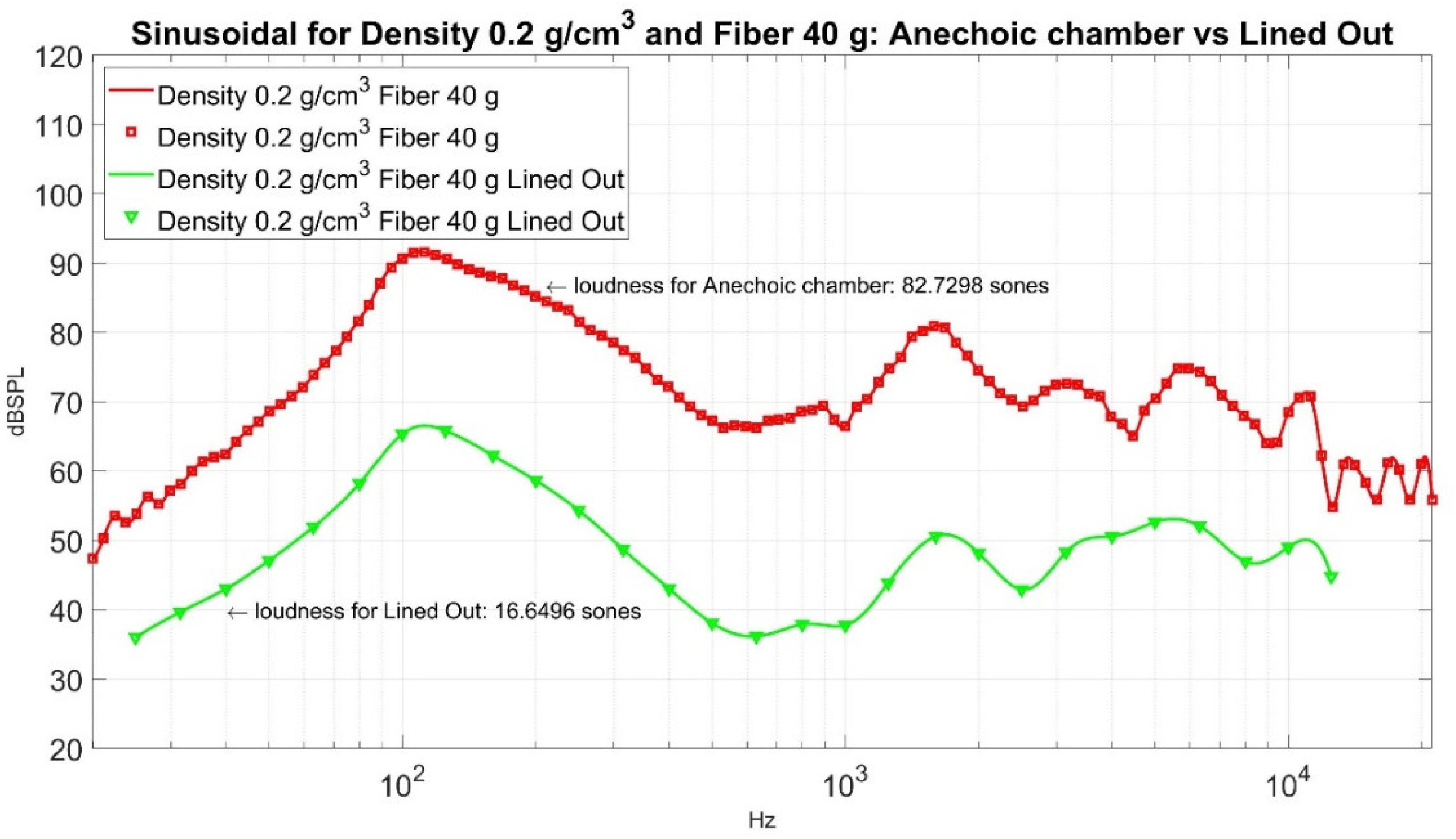

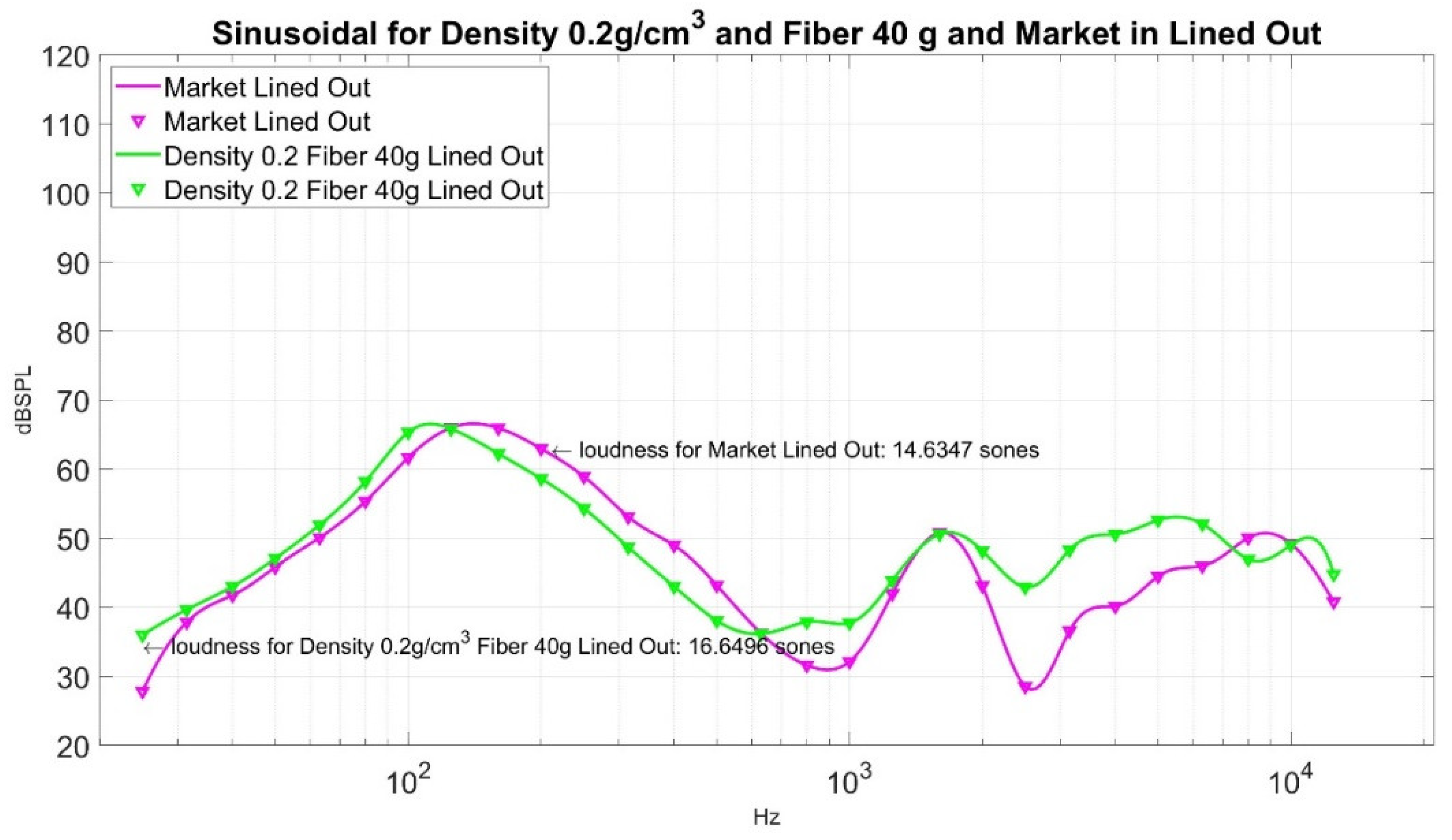

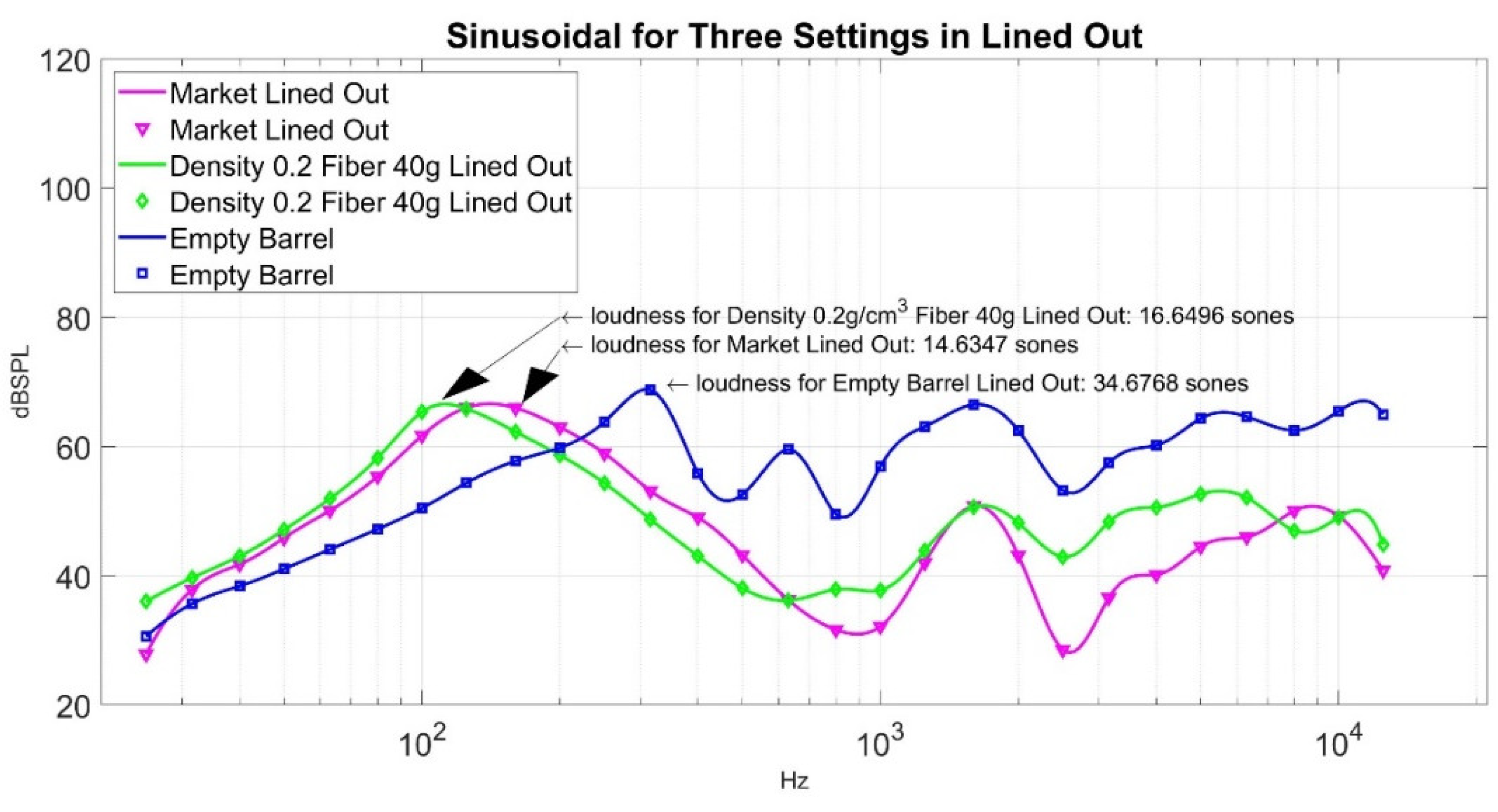

3.4. Comparison among Three Mufflers

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ferguson, D. A study of neurosis and occupation. Br. J. Ind. Med. 1973, 30, 187–198. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Belojevic, G.; Jakovljevic, B.; Slepcevic, V. Noise and mental performance: Personality attributes and noise sensitivity. Noise Health 2003, 6, 77–89. [Google Scholar] [PubMed]

- Committee on Environmental Health. Noise: A hazard for the fetus and newborn. Pediatrics 1997, 100, 724–727. [Google Scholar] [CrossRef]

- Prajapati, V.D.; Desai, A.J. Design and analysis of automotive muffler. Int. J. Eng. Res. Technol. 2016, 5, 384–389. [Google Scholar]

- Oh, J.E.; Cha, K.J. Noise reduction of muffler by optimal design. KSME Int. J. 2000, 14, 947–955. [Google Scholar] [CrossRef]

- Selamet, A.; Lee, I.J.; Ji, Z.L.; Huff, N.T. Acoustic attenuation performance of perforated absorbing silencers. In Proceedings of the 2001 Noise and Vibration Conference (NOISE2001CD), Traverse City, MI, USA, 30 April 2001. [Google Scholar] [CrossRef]

- Cofer, C.G.; Bielert, F.; Kullmann, T. Durability, acoustic performance and process efficiencies of absorbent fibers for muffler filling. In Proceedings of the 1999 Noise and Vibration Conference (P-342), Grand Rapids, MI, USA, 17 May 1999. [Google Scholar] [CrossRef]

- Potente, D. General design principles for an automotive muffler. In Proceedings of the ACOUSTICS 2005, Busselton, Australia, 9–11 November 2005. [Google Scholar]

- Kashikar, A.; Suryawanshi, R.; Sonone, N.; Thorat, R.; Savant, S. Development of muffler design and its validation. Appl. Acoust. 2021, 180, 108132. [Google Scholar] [CrossRef]

- Yu, X.Y.; Cheng, L.; You, X. Hybrid silencers with micro-perforated panels and internal partitions. J. Acoust. Soc. Am. 2015, 137, 951–962. [Google Scholar] [CrossRef]

- Yang, T.; Tsai, S.S. Design optimization of an industrial muffler by Taguchi method. Adv. Mater. Res. 2014, 871, 277–282. [Google Scholar] [CrossRef]

- Maa, D.Y. Potential of microperforated panel absorber. J. Acoust. Soc. Am. 1998, 104, 2851–2866. [Google Scholar] [CrossRef]

- Allam, S.; Abom, M. A new type of muffler based on microperforated tubes. J. Vib. Acoust. 2011, 133, 031005. [Google Scholar] [CrossRef]

- Zhang, X.; Cheng, L. Acoustic silencing in a flow duct with micro-perforated panel liners. Appl. Acoust. 2020, 167, 107382. [Google Scholar] [CrossRef]

- Calleri, C.; Astolfi, A.; Shtrepi, L.; Prato, A.; Schiavi, A.; Zampini, D.; Volpatti, G. Characterization of the sound insulation properties of a two-layers lightweight concrete innovative façade. Appl. Acoust. 2019, 145, 267–277. [Google Scholar] [CrossRef]

- Zhang, B.; Poon, C.S. Sound insulation properties of rubberized lightweight aggregate concrete. J. Clean. Prod. 2018, 172, 3176–3185. [Google Scholar] [CrossRef]

- Krzywon, R.; Dawczynski, S. Strength parameters of foamed geopolymer reinforced with GRFP mesh. Materials 2021, 14, 689. [Google Scholar] [CrossRef]

- Laukaitis, A.; Fiks, B. Acoustical properties of aerated autoclaved concrete. Appl. Acoust. 2006, 67, 284–296. [Google Scholar] [CrossRef]

- Kim, H.K.; Jeon, J.H.; Lee, H.K. Workability, and mechanical, acoustic and thermal properties of lightweight aggregate concrete with a high volume of entrained air. Constr. Build. Mater. 2012, 29, 193–200. [Google Scholar] [CrossRef]

- Kumar, G.S.; Mishra, A.K. Influence of granite fine powder on the performance of cellular light weight concrete. J. Build. Eng. 2021, 40, 102707. [Google Scholar] [CrossRef]

- Kim, H.; Hong, J.; Pyo, S. Acoustic characteristics of sound absorbable high performance concrete. Appl. Acoust. 2018, 138, 171–178. [Google Scholar] [CrossRef]

- Myers, R.H.; Khuri, A.I.; Carter, W.H. Response surface methodology: 1966–1988. Technometrics 1989, 31, 137–157. [Google Scholar] [CrossRef]

- Kim, H.K.; Lee, H.K. Acoustic absorption modeling of porous concrete considering the gradation and shape of aggregates and void ratio. J. Sound Vib. 2010, 329, 866–879. [Google Scholar] [CrossRef]

- Forouharmajd, F.; Mohammadi, Z. Assessment of normal incidence absorption performance of sound absorbing materials. Int. J. Environ. Health Eng. 2016, 5, 10. [Google Scholar]

- Zarastvand, M.; Ghassabi, M.; Talebitooti, R. Prediction of acoustic wave transmission features of the multi-layered plate constructions: A review. J. Sandw. Struct. Mater. 2022, 24, 218–293. [Google Scholar] [CrossRef]

- Fastl, H.; Zwicker, E. Psycho-Acoustic: Facts and Models, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Omran, S. Create Equal Loudness Contours and Convert Phons to Sons, MathWorks File Exchange. 2018. Available online: https://www.mathworks.com/matlabcentral/fileexchange/69110-create-equal-loudness-contours-and-convert-phons-to-sons (accessed on 21 April 2021).

- Kook, J.; Koo, K.; Hyun, J.; Jensen, J.S.; Wang, S. Acoustical topology optimization for Zwicker’s loudness model—Application to noise barriers. Comput. Methods Appl. Mech. Eng. 2012, 237–240, 130–151. [Google Scholar] [CrossRef]

- Vardeman, S. Statistics for Engineering Problem Solving; PWS Publishing Company: Boston, MA, USA, 1994. [Google Scholar]

- Tang, X.; Yan, X. Acoustics energy absorption properties of fibrous materials: A review. Compos. Part A 2017, 101, 360–380. [Google Scholar] [CrossRef]

- Zhao, C.Y.; Wang, P.; Wang, L.; Liu, D. Reducing railway noise with porous sound-absorbing concrete slabs. Adv. Mater. Sci. Eng. 2014, 2014, 206549. [Google Scholar] [CrossRef]

- Matlab. AcousticLoudness. 2021. Available online: https://www.mathworks.com/help/audio/ref/acousticloudness.html (accessed on 12 April 2021).

- Jones, M.R.; Ozlutas, K.; Zheng, L. High-volume, ultra-low-density fly ash foamed concrete. Mag. Concr. Res. 2017, 69, 1146–1156. [Google Scholar] [CrossRef]

| Car Muffler Device | Strength | Weakness |

|---|---|---|

| Reactive muffler | No fiber/wool filling, environmentally friendly, suitable for low-frequency noise reduction; commercially available. | There are multiple partitions in the chamber structure. Complexity is induced. |

| Absorptive muffler | A simple chamber structure is suitable for high-frequency reduction; it is commercially available. | With fiber/wool filling could cause environmental hazards. |

| Hybrid muffler | It could reduce both low and high-frequency noise and is commercially available. | Manufacturing is costly. |

| MPP muffler | The theory of MPP on sound reduction has been established. No fiber/wool filling, environmentally friendly, and could reduce both low and high-frequency noise. | No mockup is available. The demonstration of the MPP muffler is too large to be used in the car muffler. |

| SiO2 | Al2O3 | CaO | B2O3 | MgO | Na2O + K2O | Fe2O3 |

|---|---|---|---|---|---|---|

| 52–56 | 12–16 | 15–25 | 5–10 | 0–6 | 0–1 | 0.05–0.4 |

| Fiber Diameter | Temperature Duration |

|---|---|

| 650 °C |

| Experiment No. | Density (g/cm3) | Weight (g) | Loudness Sensation (Sones) |

|---|---|---|---|

| 1 | 0.2 | 0 | 26.1455 |

| 2 | 0.2 | 20 | 34.2075 |

| 3 | 0.2 | 40 | 16.6496 |

| 4 | 0.4 | 0 | 35.9190 |

| 5 (A) | 0.4 | 20 | 36.9825 |

| 6 (B) | 0.4 | 20 | 34.5275 |

| 7 | 0.4 | 40 | 34.9396 |

| 8 | 0.8 | 0 | 35.2277 |

| 9 | 0.8 | 20 | 43.0220 |

| 10 | 0.8 | 40 | 38.3396 |

| Analysis of Variance | |||||

|---|---|---|---|---|---|

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

| Model | 5 | 404.876 | 80.975 | 4.51 | 0.085 |

| Linear | 2 | 265.988 | 132.994 | 7.42 | 0.045 |

| Density | 1 | 261.184 | 261.184 | 14.56 | 0.019 |

| Fiber | 1 | 4.803 | 4.803 | 0.27 | 0.632 |

| Square | 2 | 142.874 | 71.437 | 3.98 | 0.112 |

| Density × Density | 1 | 47.241 | 47.241 | 2.63 | 0.180 |

| Fiber × Fiber | 1 | 72.703 | 72.703 | 4.05 | 0.114 |

| 2-Way Interaction | 1 | 35.389 | 35.389 | 1.97 | 0.233 |

| Density × Fiber | 1 | 35.389 | 35.389 | 1.97 | 0.233 |

| Error | 4 | 71.740 | 17.935 | ||

| Lack-of-Fit | 3 | 78.726 | 22.909 | 7.60 | 0.259 |

| Pure Error | 1 | 3.014 | 3.014 | ||

| Total | 9 | 476.616 | |||

| Sound Reduction Conditions | Empty Barrel * | Market Muffler * | Green Muffler with Density of 0.2 g/cm3 and Fiber 40 g * |

|---|---|---|---|

| Sound wave from lined out |  |  |  |

| Mixture | Items | Weight (g) |

|---|---|---|

| 1 | Lime | 231 |

| Portland cement | 807 | |

| Calcium sulfoaluminate (CSA) | 115 | |

| Water 1 | 540 | |

| 2 | Foaming agent | 38 |

| Water 2 | 657 | |

| 3 | Calcium chloride anhydrous | 30 |

| Water 3 | 25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, T.-H.; Deng, J.; Chen, Y.-C. Using Response Surface for Searching the Nearly Optimal Parameters Combination of the Foam Concrete Muffler. Materials 2022, 15, 8128. https://doi.org/10.3390/ma15228128

Lin T-H, Deng J, Chen Y-C. Using Response Surface for Searching the Nearly Optimal Parameters Combination of the Foam Concrete Muffler. Materials. 2022; 15(22):8128. https://doi.org/10.3390/ma15228128

Chicago/Turabian StyleLin, Teng-Hsuan, Jyhjeng Deng, and Yi-Ching Chen. 2022. "Using Response Surface for Searching the Nearly Optimal Parameters Combination of the Foam Concrete Muffler" Materials 15, no. 22: 8128. https://doi.org/10.3390/ma15228128

APA StyleLin, T.-H., Deng, J., & Chen, Y.-C. (2022). Using Response Surface for Searching the Nearly Optimal Parameters Combination of the Foam Concrete Muffler. Materials, 15(22), 8128. https://doi.org/10.3390/ma15228128