Evaluation of Prediction Models of the Microwire EDM Process of Inconel 718 Using ANN and RSM Methods

Abstract

:1. Introduction

2. Materials and Methods

2.1. Workpiece Material

2.2. Experimental Setup

- U—average discharge voltage,

- I—the height of the peak current during discharging,

- ton—pulse time.

3. Results and Discussion

3.1. Analysis of the Surface Topography

3.2. Predictive Models

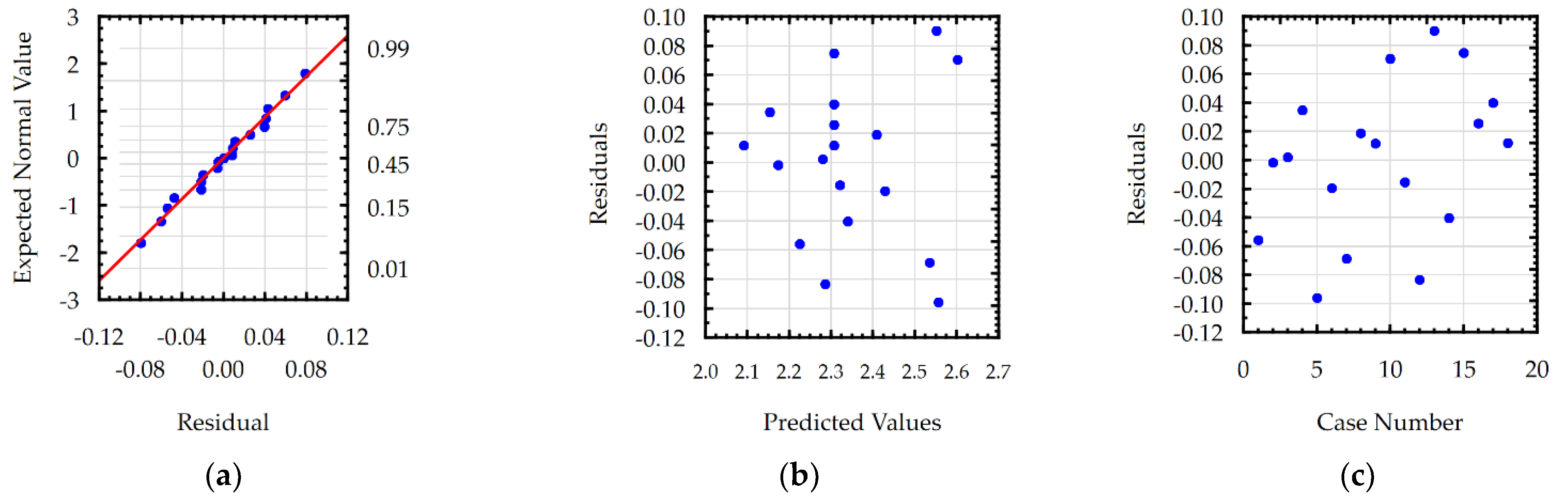

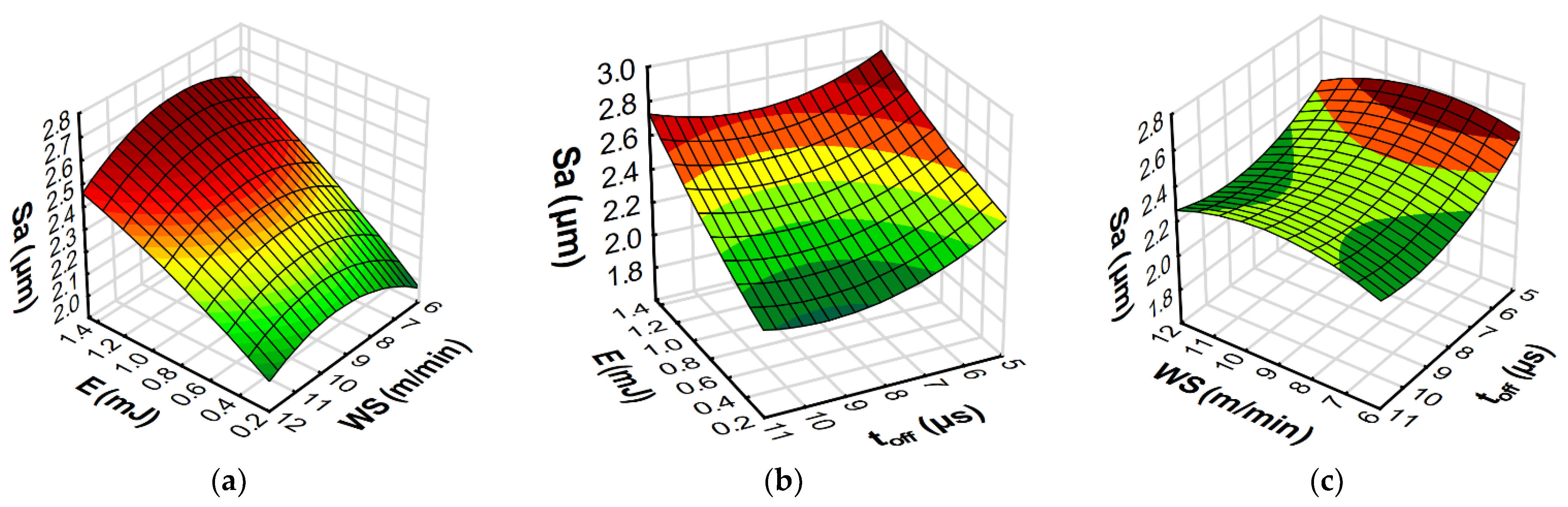

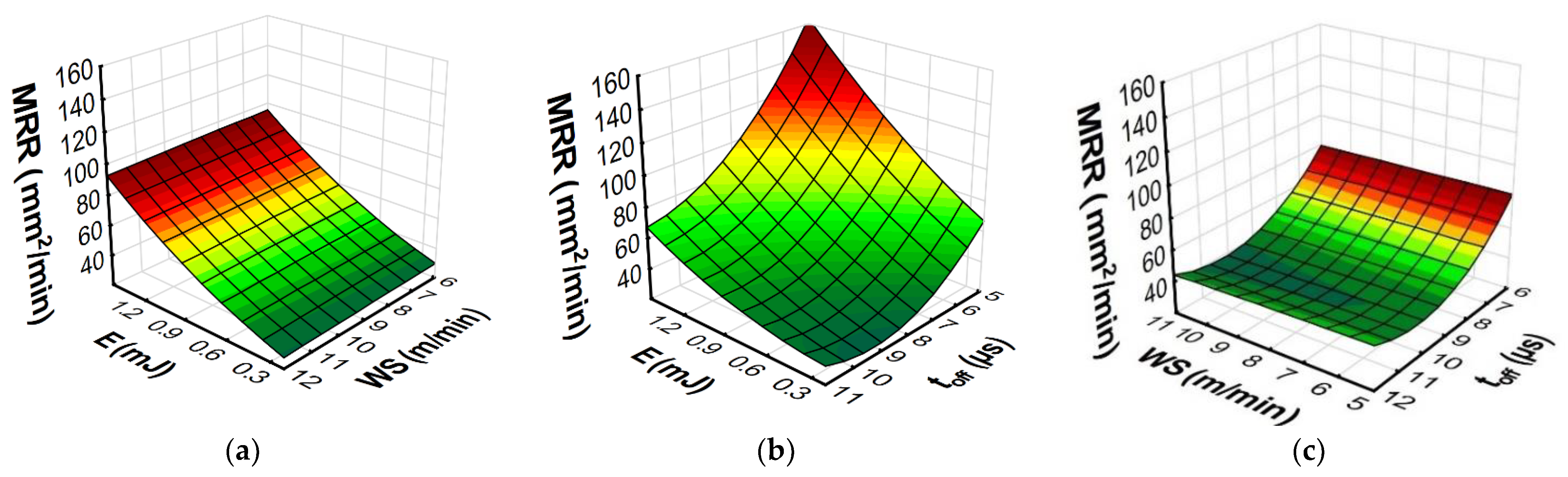

3.2.1. Response Surface Methodology

3.2.2. Artificial Neural Network

3.3. Evalutaion of the Predcitve Models

4. Conclusions

- Discharge energy made the main contribution to the surface roughness (Sa, Spk, Sv, and Svk) and the MRR during micro-WEDM of Inconel 718.

- The time interval made the main contribution to the MRR, as the decrease in the time interval increased the frequency of the discharge. Furthermore, for the adopted range, the time interval had the least influence on the parameters describing the surface topography’s properties.

- Wire-speed had the least influence on the parameters describing the surface topography’s properties (Sa, Spk, Sv, and Svk) and MRR. Furthermore, for the lowest wire speed, it was possible to obtain a high MRR and a low value of surface roughness. A decrease in the wire speed led to a decrease in the consumption of the electrode, which would have a significant impact on the environment and sustainability.

- The predictive models based on RSM and ANN for the micro-WEDM of Inconel 718 can be applied to construct technological tables for the investigated process.

- The models developed with ANN had a lower value for the relative error compared with the RSM models. The maximum relative error for the ANN models did not exceed 4%.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Sánchez, J.A.; Izquierdo, B.; Ayesta, I. Experimental and Numerical Study of Crater Volume in Wire Electrical Discharge Machining. Materials 2020, 13, 577. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Straka, Ľ.; Čorný, I. Identification of geometric errors of circular profiles at WEDM caused by the wire tool electrode vibrations and their reduction with support of acoustic emission method. Eng. Fail. Anal. 2022, 134, 106040. [Google Scholar] [CrossRef]

- Ma, J.; Yin, C.; Li, X.; Han, X.; Wuyi, M.; Chen, S.; Cao, Y.; Liu, K. Optimization of EDM process parameters based on variable-fidelity surrogate model. Int. J. Adv. Manuf. Technol. 2022, 122, 2031–2041. [Google Scholar] [CrossRef]

- Qiu, J. Fundamental research on machining performance of diamond wire sawing and diamond wire electrical discharge sawing quartz glass. Ceram. Int. 2022, 48, 24332–24345. [Google Scholar] [CrossRef]

- Oniszczuk-Swiercz, D.; Swiercz, R.; Chmielewski, T.; Salacinski, T. Experimental investigation of influence WEDM parameters on surface roughness and flatness deviation. Metal 2020, 29, 611–617. [Google Scholar] [CrossRef]

- Kowalczyk, M.; Tomczyk, K. Assessment of measurement uncertainties for energy signals stimulating the selected NiTi alloys during the wire electrical discharge machining. Precis. Eng. 2022, 76, 133–140. [Google Scholar] [CrossRef]

- Straka, L.; Kuchta, P. Dynamic Control of Discharge Energy during WEDM for the Purpose of Eliminating Vibrations of the Wire Tool Electrode. Manag. Syst. Prod. Eng. 2021, 29, 260–265. [Google Scholar] [CrossRef]

- Dodun, O.; Slătineanu, L.; Nagîț, G.; Hrițuc, A.; Mihalache, A.M.; Beșliu-Băncescu, I. WEDM-Generated Slot Width Variation Modeling. Micromachines 2022, 13, 1231. [Google Scholar] [CrossRef]

- Chen, X.; Wang, Z.; Wang, Y.; Chi, G. Investigation on MRR and Machining Gap of Micro Reciprocated Wire-EDM for SKD11. Int. J. Precis. Eng. Manuf. 2020, 21, 11–22. [Google Scholar] [CrossRef]

- Ishfaq, K.; Ahmad, N.; Jawad, M.; Ali, M.A.; Al-Ahmari, A.M. Evaluating Material’s Interaction in Wire Electrical Discharge Machining of Stainless Steel (304) for Simultaneous Optimization of Conflicting Responses. Materials 2019, 12, 1940. [Google Scholar] [CrossRef] [PubMed]

- Ilkhchi, R.N.; Akar, S.; Meshri, H.A.M.; Seyedzavvar, M. Prediction of white layer formation in μ-WEDM process of NiTi shape memory superalloy: FEM with experimental verification. Int. J. Adv. Manuf. Technol. 2021, 113, 2805–2817. [Google Scholar] [CrossRef]

- Vijayakumar, R.; Srirangarajalu, N.; Santhanakumar, M.; Adalarasan, R. Investigation in µ-WEDM of Inconel 625 superalloy using RSM-CCD technique. Mater. Manuf. Process. 2022, 37, 1–12. [Google Scholar] [CrossRef]

- Abhilash, P.M.; Chakradhar, D. Effect of wire material and discharge energy on productivity and surface integrity of WEDM-processed Inconel 718. Adv. Mater. Process. Technol. 2022, 0, 1–22. [Google Scholar] [CrossRef]

- Sharma, P.; Chakradhar, D.; Narendranath, S. Precision manufacturing of turbine wheel slots by trim-offset approach of WEDM. Precis. Eng. 2021, 71, 293–303. [Google Scholar] [CrossRef]

- Burek, J.; Babiarz, R.; Buk, J.; Sułkowicz, P.; Krupa, K. The Accuracy of Finishing WEDM of Inconel 718 Turbine Disc Fir Tree Slots. Materials 2021, 14, 562. [Google Scholar] [CrossRef]

- Ali, M.Y.; Banu, A.; Al Hazza, M.H. Analysis of kerf accuracy in dry micro-wire EDM. Int. J. Adv. Manuf. Technol. 2020, 111, 597–608. [Google Scholar] [CrossRef]

- Franczyk, E.; Machno, M.; Zębala, W. Investigation and Optimization of the SLM and WEDM Processes’ Parameters for the AlSi10Mg-Sintered Part. Materials 2021, 14, 410. [Google Scholar] [CrossRef] [PubMed]

- Świercz, R.; Oniszczuk-Świercz, D. Investigation of the Influence of Reduced Graphene Oxide Flakes in the Dielectric on Surface Characteristics and Material Removal Rate in EDM. Materials 2019, 16, 943. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Le, V. An investigation on machined performance and recast layer properties of AISI H13 steel by Powder Mixed-EDM in fine-finishing process. Mater. Chem. Phys. 2021, 276, 125362. [Google Scholar] [CrossRef]

- Naik, S.; Das, S.R.; Dhupal, D. Experimental Investigation, Predictive Modeling, Parametric Optimization and Cost Analysis in Electrical Discharge Machining of Al-SiC Metal Matrix Composite. Silicon 2021, 13, 1017–1040. [Google Scholar] [CrossRef]

- Nowicki, R.; Świercz, R.; Oniszczuk-Świercz, D.; Rozenek, M. Experimental Investigation of Technological Indicators and Surface Roughness of Hastelloy C-22 after Electrical Discharge Machining Using POCO Graphite Electrodes. Materials 2022, 15, 5631. [Google Scholar] [CrossRef]

- Kundu, P.; Luo, X.; Qin, Y.; Cai, Y.; Liu, Z. A machine learning-based framework for automatic identification of process and product fingerprints for smart manufacturing systems. J. Manuf. Process. 2022, 73, 128–138. [Google Scholar] [CrossRef]

- Machno, M.; Matras, A.; Szkoda, M. Modelling and Analysis of the Effect of EDM-Drilling Parameters on the Machining Performance of Inconel 718 Using the RSM and ANNs Methods. Materials 2022, 15, 1152. [Google Scholar] [CrossRef] [PubMed]

- Thakur, S.S.; Pradhan, S.K.; Sehgal, S.; Saxena, K.K. Experimental investigations on silicon carbide mixed electric discharge machining. Silicon 2022, 1–19. [Google Scholar] [CrossRef]

- Van, D.-N.; Van, B.-P.; Huu, P.-N. Application of Deng’s similarity-based analytic hierarchy process approach in parametric optimization of the electrical discharge machining process of SDK11 die steel. Trans. Can. Soc. Mech. Eng. 2020, 44, 294–310. [Google Scholar] [CrossRef]

- Sivalingam, V.; Poogavanam, G.; Natarajan, Y.; Sun, J. Optimization of atomized spray cutting fluid eco-friendly turning of Inconel 718 alloy using ARAS and CODAS methods. Int. J. Adv. Manuf. Technol. 2022, 120, 4551–4564. [Google Scholar] [CrossRef]

- Vagaská, A.; Gombár, M.; Straka, Ľ. Selected Mathematical Optimization Methods for Solving Problems of Engineering Practice. Energies 2022, 15, 2205. [Google Scholar] [CrossRef]

- Wang, C.; Yan, X.; Liao, H.; Chai, L.; Zou, L.; Huang, Y. Process parameter optimization and anisotropy sensitivity study for abrasive belt grinding of nickel-based single-crystal superalloy. Arch. Civ. Mech. Eng. 2021, 21, 1–8. [Google Scholar] [CrossRef]

- Gholizadeh, H.; Fathollahi-Fard, A.M.; Fazlollahtabar, H.; Charles, V. Fuzzy data-driven scenario-based robust data envelopment analysis for prediction and optimisation of an electrical discharge machine’s parameters. Expert Syst. Appl. 2022, 193, 116419. [Google Scholar] [CrossRef]

- Sameer, M.D.; Sai Kartheek Reddy, B.; Amrutha, N.; Srishma, K.; Samantha, K. Selection of Optimal EDM Process Parameters for Machining Maraging Steel Using Grey-Fuzzy Relational analysis—An Experimental Approach. In Recent Advances in Manufacturing Processes and Systems; Dave, H.K., Dixit, U.S., Nedelcu, D., Eds.; Springer Nature: Singapore, 2022; pp. 905–918. [Google Scholar]

- Joshi, A.Y.; Joshi, A.Y. Multi response optimization of PMEDM of Ti6Al4V using Al2O3 and SiC powder added de-ionized water as dielectric medium using grey relational analysis. SN Appl. Sci. 2021, 3, 718. [Google Scholar] [CrossRef]

- Das, P.P.; Chakraborty, S. Application of grey correlation-based EDAS method for parametric optimization of non-traditional machining processes. Sci. Iran. 2022, 29, 864–882. [Google Scholar] [CrossRef]

- Kouahla, I.; Yallese, M.A.; Belhadi, S.; Safi, K.; Nouioua, M. Tool vibration, surface roughness, cutting power, and productivity assessment using RSM and GRA approach during machining of Inconel 718 with PVD-coated carbide tool. Int. J. Adv. Manuf. Technol. 2022, 122, 1835–1856. [Google Scholar] [CrossRef]

- Jatakar, K.H.; Mulgund, G.; Patange, A.D.; Deshmukh, B.B.; Rambhada, K.S. Multi-Point Face Milling Tool Condition Monitoring through Vibration Spectrogram and LSTM-Autoencoder. Int. J. Perform. Eng. 2022, 18, 570–579. [Google Scholar] [CrossRef]

- Patil, S.S.; Pardeshi, S.S.; Pradhan, N.; Patange, A.D. Cutting Tool Condition Monitoring using a Deep Learning-based Artificial Neural Network. Int. J. Perform. Eng. 2022, 18, 37–46. [Google Scholar]

- Machno, M.; Franczyk, E.; Bogucki, R.; Matras, A.; Zębala, W. A Comparative Study on the Structure and Quality of SLM and Cast AISI 316L Samples Subjected to WEDM Processing. Materials 2022, 15, 701. [Google Scholar] [CrossRef] [PubMed]

- Song, L.; Wang, Y.; Wang, H.; Sun, S.; Guo, Q.; Yang, Y.; Zhu, X. A Triangulation-Based Method for Complex Mold Parts Surface Wear Assessment. IEEE Sens. J. 2022, 22, 15306–15315. [Google Scholar] [CrossRef]

- Maruda, R.W.; Wojciechowski, S.; Szczotkarz, N.; Legutko, S.; Mia, M.; Gupta, M.K.; Nieslony, P.; Krolczyk, G.M. Metrological analysis of surface quality aspects in minimum quantity cooling lubrication. Meas. J. Int. Meas. Confed. 2021, 171, 108847. [Google Scholar] [CrossRef]

- Teimouri, R.; Grabowski, M.; Bogucki, R.; Ślusarczyk, Ł.; Skoczypiec, S. Modeling of strengthening mechanisms of surface layers in burnishing process. Mater. Des. 2022, 223, 111114. [Google Scholar] [CrossRef]

- Żyra, A.; Bogucki, R.; Podolak-Lejtas, A.; Skoczypiec, S. Research on influence of heat treatment scheme of Ti10V2Fe3Al alloy on technological surface integrity after electrodischarge machining. J. Manuf. Process. 2021, 62, 47–57. [Google Scholar] [CrossRef]

- Wróbel, N.; Rejek, M.; Królczyk, J.; Franka, M.; Gupta, M.K.; Śliwiński, M.; Królczyk, G. Parametric Assessment of Surface Topography and Its Influence on Joint Tightness of Non-Separable Joints for Thin Wall Applications. Appl. Sci. Switz. 2022, 12, 8917. [Google Scholar] [CrossRef]

- Krolczyk, J.B.; Maruda, R.W.; Krolczyk, G.M.; Wojciechowski, S.; Gupta, M.K.; Korkmaz, M.E. Investigations on surface induced tribological characteristics in MQCL assisted machining of duplex stainless steel. J. Mater. Res. Technol. 2022, 18, 2754–2769. [Google Scholar] [CrossRef]

- Joshi, A.Y.; Banker, V.J.; Patel, K.K.; Patel, K.S.; Joshi, D.M.; Purohit, M.R. Experimental Investigation in Wire Cut EDM of Inconel 718 Superalloy. In Recent Advances in Manufacturing Processes and Systems; Dave, H.K., Dixit, U.S., Nedelcu, D., Eds.; Springer Nature: Singapore, 2022; pp. 445–455. [Google Scholar]

- Buk, J. Surface Topography of Inconel 718 Alloy in Finishing WEDM. Adv. Sci. Technol. Res. J. 2022, 16, 47–61. [Google Scholar] [CrossRef]

- Jithin, S.; Joshi, S.S. Surface topography generation and simulation in electrical discharge texturing: A review. J. Mater. Process. Technol. 2021, 298, 117297. [Google Scholar] [CrossRef]

- Basak, A.; Pramanik, A.; Prakash, C.; Shankar, S.; Debnath, S. Understanding the Micro-Mechanical Behaviour of Recast Layer Formed during WEDM of Titanium Alloy. Metals 2022, 12, 188. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, G.; Zhang, Z.; Zhang, Y.; Huang, Y. Effect of assisted transverse magnetic field on distortion behavior of thin-walled components in WEDM process. Chin. J. Aeronaut. 2022, 35, 291–307. [Google Scholar] [CrossRef]

- Sun, Y.; Jin, L.; Liu, M.; Gong, Y.; Wen, X.; Yin, G.; Wen, Q. A comprehensive review on fabrication of ultra small micro tools via electrical discharge machining-based methods. Int. J. Adv. Manuf. Technol. 2022, 118, 703–735. [Google Scholar] [CrossRef]

- Welschof, L.; Schäfer, N.; Herrig, T.; Klink, A.; Bergs, T. Effect of electrode material on removal efficiency regarding single discharges in wire EDM. Int. J. Adv. Manuf. Technol. 2022, 120, 1583–1589. [Google Scholar] [CrossRef]

- Wu, N.-J. Predicting the Compressive Strength of Concrete Using an RBF-ANN Model. Appl. Sci. 2021, 11, 6382. [Google Scholar] [CrossRef]

- Shen, Z.; Yang, H.; Zhang, S. Neural network approximation: Three hidden layers are enough. Neural Netw. 2021, 141, 160–173. [Google Scholar] [CrossRef]

- Chu, J.; Liu, X.; Zhang, Z.; Zhang, Y.; He, M. A novel method overcomeing overfitting of artificial neural network for accurate prediction: Application on thermophysical property of natural gas. Case Stud. Therm. Eng. 2021, 28, 101406. [Google Scholar] [CrossRef]

- Al Bataineh, A.; Kaur, D.; Jalali, S.M.J. Multi-Layer Perceptron Training Optimization Using Nature Inspired Computing. IEEE Access 2022, 10, 36963–36977. [Google Scholar] [CrossRef]

- Bajaj, N.S.; Patange, A.D.; Jegadeeshwaran, R.; Kulkarni, K.A.; Ghatpande, R.S.; Kapadnis, A.M. A Bayesian Optimized Discriminant Analysis Model for Condition Monitoring of Face Milling Cutter Using Vibration Datasets. J. Nondestruct. Eval. Diagn. Progn. Eng. Syst. 2021, 5, 021002. [Google Scholar] [CrossRef]

- Zhao, W. A Broyden–Fletcher–Goldfarb–Shanno algorithm for reliability-based design optimization. Appl. Math. Model. 2021, 92, 447–465. [Google Scholar] [CrossRef]

- Esteves, P.M.B.; Wiessner, M.; Costa, J.V.M.R.; Sikora, M.; Wegener, K. WEDM single crater asymmetry. Int. J. Adv. Manuf. Technol. 2021, 117, 2421–2427. [Google Scholar] [CrossRef]

| Ni | Cr | Nb | Mo | Ti | Al | Co | C | Mn | Si | P | S | B | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50–55 | 17–21 | 4.75–5.5 | 2.8–3.3 | 0.65–1.15 | 0.2–0.8 | <1.0 | <0.015 | <0.5 | <0.35 | <0.015 | <0.015 | <0.06 | Balance |

| Electrode | Brass wire, diameter 0.1 mm |

| Workpiece material | Inconel 718 |

| Height of specimen | 5 mm |

| Discharge energy | 0.21–1.46 mJ |

| Time interval toff | 5–11 μs |

| Open voltage U0 | 220 V |

| Dielectric | Deionized water |

| Wire mechanical tension | 0.2 daN |

| Level | Parameter | ||

|---|---|---|---|

| Discharge Energy E (mJ) | Wire Speed (m/min) | Time Interval toff (µm) | |

| −1.68 | 0.21 | 6 | 5 |

| −1 | 0.42 | 7 | 6 |

| 0 | 0.70 | 9 | 8 |

| 1 | 1.04 | 11 | 10 |

| 1.68 | 1.46 | 12 | 11 |

| Exp. No. | WEDM Input | Observed Values | ||||||

|---|---|---|---|---|---|---|---|---|

| Discharge Energy E (mJ) | Wire Speed WS (m/min) | Time Interval toff (μs) | Sa (μm) | Spk (μm) | Sk (μm) | Svk (μm) | MRR (mm2/min) | |

| 1. | 0.42 | 7 | 7 | 2.169 | 3.11 | 6.987 | 1.984 | 45.74 |

| 2. | 0.42 | 7 | 10 | 2.172 | 2.967 | 6.792 | 1.923 | 34.4 |

| 3. | 0.426 | 11 | 6 | 2.282 | 3.085 | 6.645 | 1.94 | 55.12 |

| 4. | 0.42 | 11 | 10 | 2.188 | 3.183 | 6.806 | 1.796 | 32.56 |

| 5. | 1.05 | 7 | 6 | 2.46 | 3.619 | 7.717 | 2.296 | 100.7 |

| 6. | 1.05 | 7 | 10 | 2.41 | 3.271 | 7.793 | 2.181 | 58.18 |

| 7. | 1.05 | 11 | 6 | 2.467 | 3.599 | 7.852 | 2.257 | 97.02 |

| 8. | 1.05 | 11 | 10 | 2.428 | 3.804 | 7.616 | 2.271 | 56.72 |

| 9. | 0.21 | 9 | 8 | 2.103 | 3.178 | 6.594 | 1.719 | 27.88 |

| 10. | 1.46 | 9 | 8 | 2.673 | 4.116 | 8.435 | 2.508 | 91.62 |

| 11. | 0.74 | 6 | 8 | 2.305 | 3.223 | 7.589 | 2.129 | 58.64 |

| 12. | 0.74 | 12 | 8 | 2.203 | 3.28 | 6.967 | 2.012 | 55.42 |

| 13. | 0.74 | 9 | 5 | 2.642 | 3.853 | 8.401 | 2.364 | 101.94 |

| 14. | 0.74 | 9 | 11 | 2.299 | 3.511 | 7.277 | 2.058 | 31.2 |

| 15. | 0.74 | 9 | 8 | 2.381 | 3.64 | 7.648 | 2.021 | 44.1 |

| 16. | 0.74 | 9 | 8 | 2.332 | 3.473 | 7.498 | 1.938 | 43.81 |

| 17. | 0.74 | 9 | 8 | 2.346 | 3.574 | 7.541 | 1.982 | 43.2 |

| 18. | 0.74 | 9 | 8 | 2.318 | 3.574 | 7.567 | 1.968 | 44.31 |

| Source | Sum of Squares | Degrees of Freedom | Mean Square | F-Value | Prob > f | Contribution % |

|---|---|---|---|---|---|---|

| Model | 0.3506 | 4 | 0.0876 | 39.96 | ||

| E | 0.2599 | 1 | 0.2599 | 355.59 | 0.0003 | 74.14 |

| WS2 | 0.0174 | 1 | 0.0174 | 23.93 | 0.0163 | 4.99 |

| toff | 0.0493 | 1 | 0.0493 | 67.54 | 0.0037 | 14.08 |

| toff2 | 0.0237 | 1 | 0.0237 | 32.52 | 0.0106 | 6.78 |

| Error | 0.0021 | 13 | ||||

| Total SS | 0.3527 | 17 | R-sqr = 0.92 | R-Adj = 0.90 | ||

| Source | Sum of Squares | Degrees of Freedom | Mean Square | F-Value | Prob > f | Contribution % |

|---|---|---|---|---|---|---|

| Model | 1.2631 | 3 | 0.4210 | 16.31 | ||

| E | 0.8963 | 1 | 0.8963 | 48.73 | <0.0001 | 70.96 |

| WS2 | 0.2717 | 1 | 0.2717 | 14.77 | 0.0017 | 21.51 |

| toff | 0.0950 | 1 | 0.0950 | 5.16 | 0.0392 | 7.53 |

| Error | 0.0142 | 14 | ||||

| Total SS | 1.5206 | 17 | R-sqr = 0.84 | R-Adj = 0.81 | ||

| Source | Sum of Squares | Degrees of Freedom | Mean Square | F-Value | Prob > f | Contribution % |

|---|---|---|---|---|---|---|

| Model | 4.1954 | 6 | 0.6992 | 58.51 | ||

| E | 3.2785 | 1 | 3.2785 | 823.14 | <0.0001 | 78.15 |

| E2 | 0.0988 | 1 | 0.0988 | 24.80 | 0.0155 | 2.36 |

| WS | 0.1761 | 1 | 0.1761 | 44.21 | 0.0069 | 4.20 |

| WS2 | 0.2511 | 1 | 0.2511 | 63.04 | 0.0041 | 5.99 |

| toff | 0.3491 | 1 | 0.3491 | 87.65 | 0.0025 | 8.32 |

| toff2 | 0.0416 | 1 | 0.0416 | 10.44 | 0.0481 | 0.99 |

| Error | 0.0119 | 11 | ||||

| Total SS | 4.2073 | 17 | R-sqr = 0.87 | R-Adj = 0.85 | ||

| Source | Sum of Squares | Degrees of Freedom | Mean Square | F-Value | Prob > f | Contribution % |

|---|---|---|---|---|---|---|

| Model | 0.6621 | 5 | 0.1317 | 36.96 | ||

| E | 0.5196 | 1 | 0.5196 | 437.61 | 0.0002 | 78.92 |

| WS | 0.0120 | 1 | 0.0120 | 10.15 | 0.0498 | 1.83 |

| toff | 0.0545 | 1 | 0.0545 | 45.90 | 0.0065 | 8.28 |

| toff2 | 0.0601 | 1 | 0.0601 | 50.66 | 0.0057 | 9.14 |

| E WS | 0.0120 | 1 | 0.0120 | 10.16 | 0.0497 | 1.83 |

| Error | 0.0035 | 12 | ||||

| Total SS | 0.6585 | 17 | R-sqr = 0.95 | R-Adj = 0.92 | ||

| Source | Sum of Squares | Degrees of Freedom | Mean Square | F-Value | Prob > f | Contribution % |

|---|---|---|---|---|---|---|

| Model | 9016.25 | 6 | 1502.70 | 10.52 | ||

| E | 3285.90 | 1 | 3285.90 | 253.14 | <0.0001 | 36.44 |

| E2 | 175.54 | 1 | 175.54 | 13.52 | 0.0036 | 1.95 |

| WS2 | 318.09 | 1 | 318.09 | 24.50 | 0.0004 | 3.53 |

| toff | 4234.76 | 1 | 4234.76 | 326.24 | <0.0001 | 46.97 |

| toff2 | 867.89 | 1 | 867.89 | 66.86 | <0.0001 | 9.63 |

| E WS | 134.07 | 1 | 134.07 | 10.32 | 0.0082 | 1.49 |

| Error | 142.78 | 11 | ||||

| Total SS | 9159.03 | 17 | R-sqr = 0.98 | R-Adj = 0.98 | ||

| Model | Number of Neurons in the Hidden Layer | Activation Function in the Hidden Layer | Activation Function in the Output Layer | Optimization Algorithm |

|---|---|---|---|---|

| Sa | 3 | Exponential | Logistic | BFGS 0 |

| Spk | 2 | Tanh | Tanh | BFGS 45 |

| Sk | 4 | Identity | Tanh | BFGS 3 |

| Svk | 2 | Exponential | Exponential | BFGS 10 |

| MRR | 3 | Logistic | Tanh | BFGS 50 |

| Model | Values of Sensitivity | ||

|---|---|---|---|

| E | WS | toff | |

| Sa | 3.05 | 1.28 | 1.16 |

| Spk | 6.35 | 5.43 | 1.91 |

| Sk | 7.19 | 1.57 | 1.75 |

| Svk | 5.14 | 1.08 | 1.40 |

| MRR | 335.87 | 22.68 | 360.77 |

| Model | Correlation Coefficient R | |||

|---|---|---|---|---|

| RSM | ANN | |||

| Train | Test | Validation | ||

| Sa | 0.96 | 0.97 | 0.98 | 0.99 |

| Spk | 0.92 | 0.96 | 0.99 | 0.99 |

| Sk | 0.93 | 0.95 | 0.97 | 0.98 |

| Svk | 0.97 | 0.97 | 0.98 | 0.99 |

| MRR | 0.99 | 0.99 | 0.99 | 0.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oniszczuk-Świercz, D.; Świercz, R.; Michna, Š. Evaluation of Prediction Models of the Microwire EDM Process of Inconel 718 Using ANN and RSM Methods. Materials 2022, 15, 8317. https://doi.org/10.3390/ma15238317

Oniszczuk-Świercz D, Świercz R, Michna Š. Evaluation of Prediction Models of the Microwire EDM Process of Inconel 718 Using ANN and RSM Methods. Materials. 2022; 15(23):8317. https://doi.org/10.3390/ma15238317

Chicago/Turabian StyleOniszczuk-Świercz, Dorota, Rafał Świercz, and Štefan Michna. 2022. "Evaluation of Prediction Models of the Microwire EDM Process of Inconel 718 Using ANN and RSM Methods" Materials 15, no. 23: 8317. https://doi.org/10.3390/ma15238317

APA StyleOniszczuk-Świercz, D., Świercz, R., & Michna, Š. (2022). Evaluation of Prediction Models of the Microwire EDM Process of Inconel 718 Using ANN and RSM Methods. Materials, 15(23), 8317. https://doi.org/10.3390/ma15238317