Polycrystalline PbTe:In Films on Amorphous Substrate: Structure and Physical Properties

Abstract

:1. Introduction

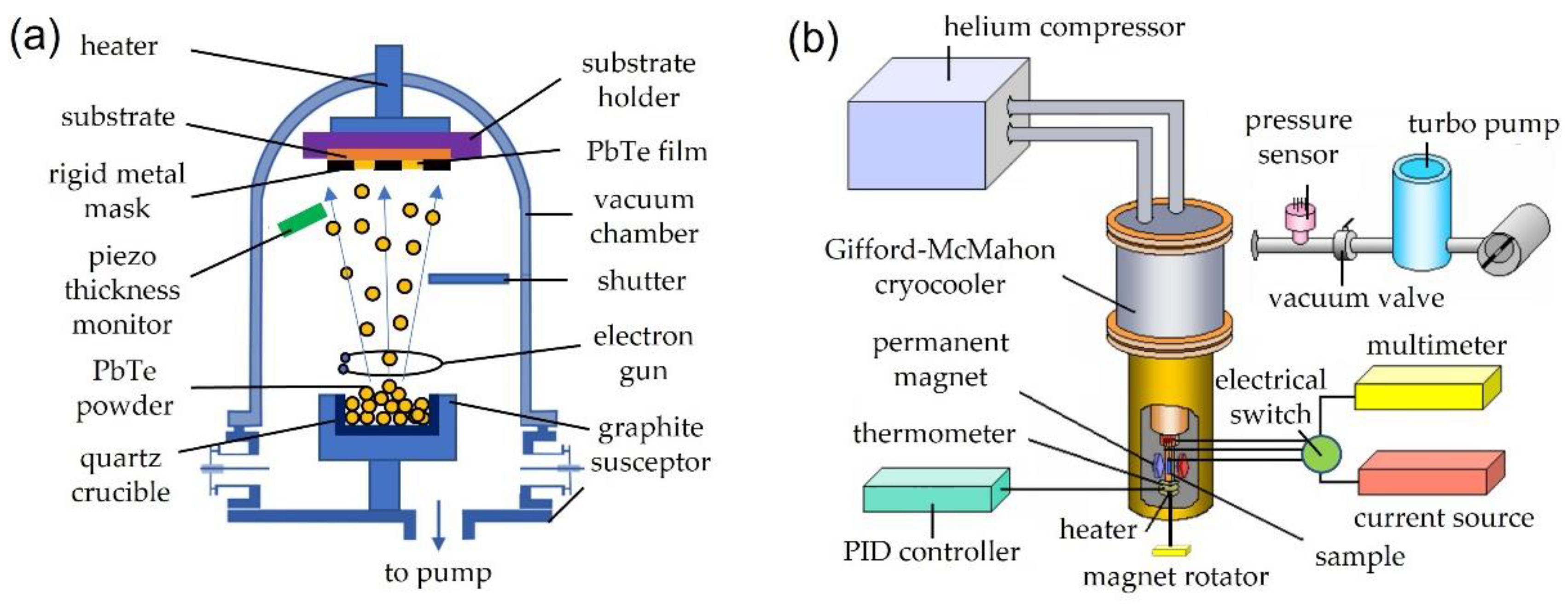

2. Materials and Methods

3. Results

3.1. Structural Properties

3.2. XRD

3.3. Seebeck Coefficient

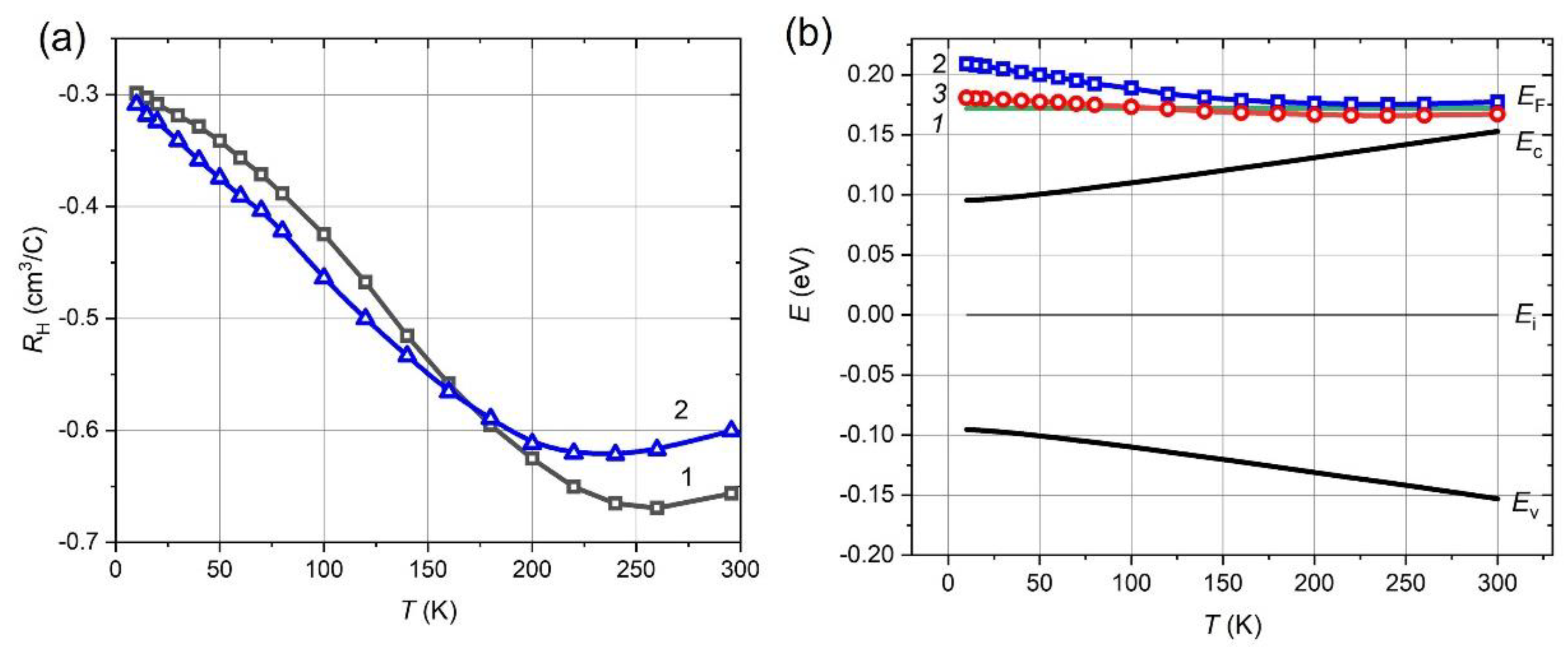

3.4. Hall Coefficient and Energy Bands Diagram Reconstruction

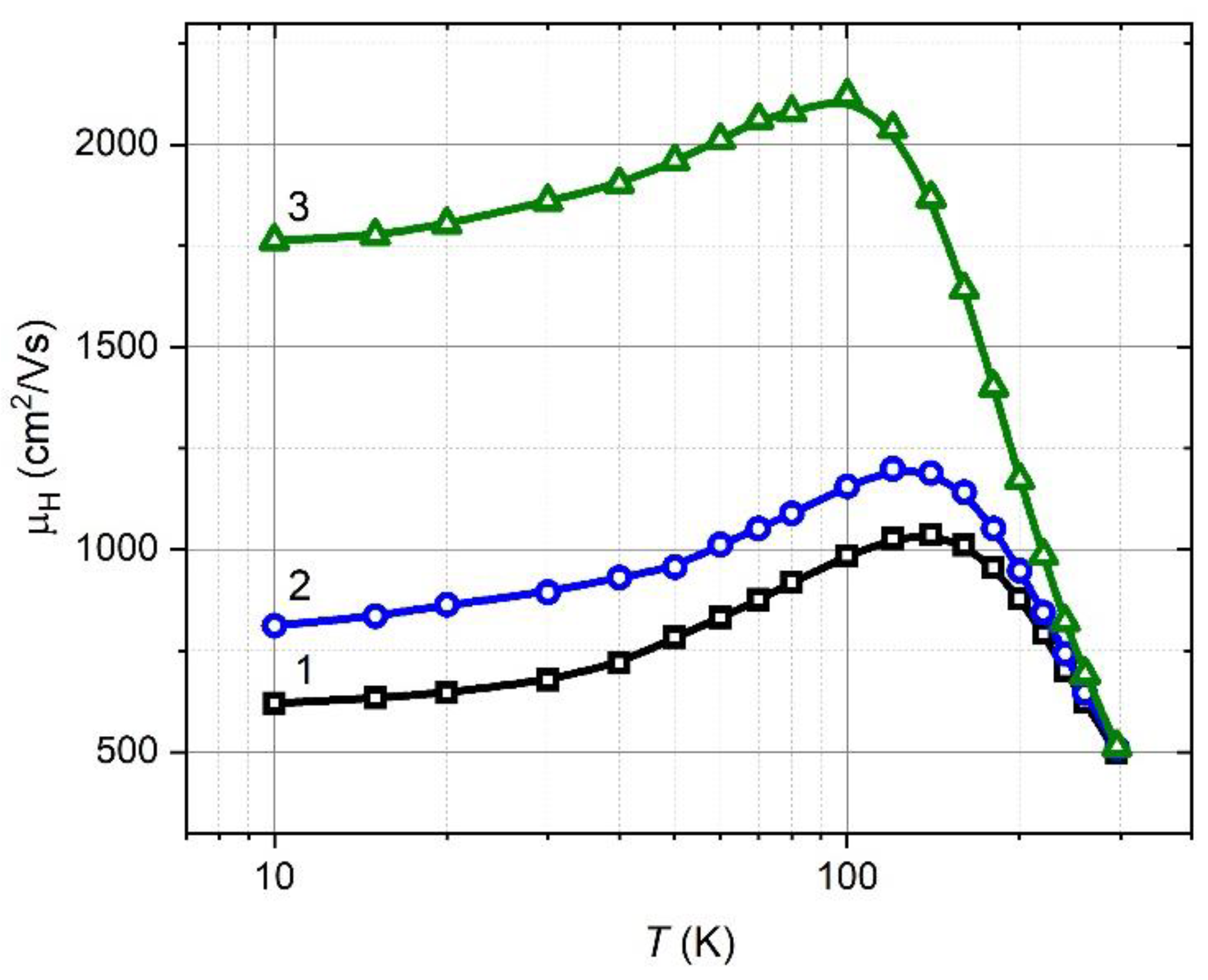

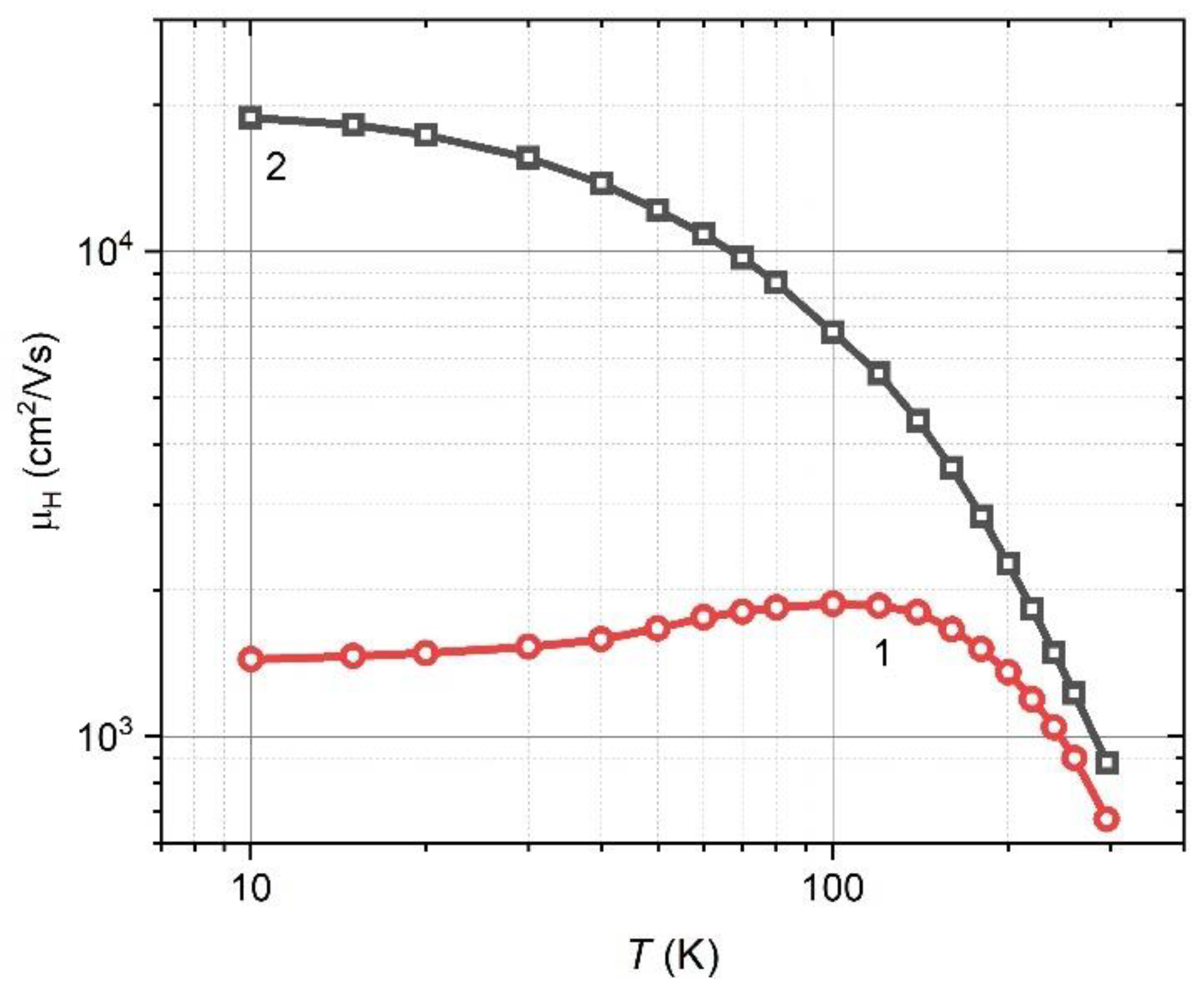

3.5. Mobility

4. Discussion

- Scattering on the free surface;

- Scattering on crystalline boundaries;

- Scattering on defects and dislocations.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Rogalski, A. Infrared detectors: Status and trends. Prog. Quantum Electron. 2003, 27, 59–210. [Google Scholar] [CrossRef]

- Rahim, M.; Khiar, A.; Felder, F.; Fill, M.; Zogg, H. 4.5 µm wavelength vertical external cavity surface emitting laser operating above room temperature. Appl. Phys. Lett. 2009, 94, 201112. [Google Scholar] [CrossRef]

- Fill, M.; Debernardi, P.; Felder, F.; Zogg, H. Lead-chalcogenide mid-infrared vertical external cavity surface emitting lasers with improved threshold: Theory and experiment. Appl. Phys. Lett. 2013, 103, 201120. [Google Scholar] [CrossRef]

- Barros, A.S.; Abramof, E.; Rappl, P.H.O. Electrical and optical properties of PbTe p-n junction infrared sensors. J. Appl. Phys. 2006, 99, 024904. [Google Scholar] [CrossRef] [Green Version]

- Yasuda, A.; Suto, K.; Takahashi, Y.; Nishizawa, J.-I. Mid-infrared photoconductive properties of heavily Bi-doped PbTe p-n homojunction diode grown by liquid-phase epitaxy. Infrared Phys. Technol. 2014, 67, 609–612. [Google Scholar] [CrossRef]

- Fill, M.; Felder, F.; Rahim, M.; Zogg, H.; Ishida, A. AIV-BVI mid-infrared VECSEL on Si-substrate. Proc. SPIE 2012, 8242, 0H-1–0H-11. [Google Scholar]

- Zogg, H.; Arnold, M.; Felder, F.; Rahim, M.; Ebneter, C.; Zasavitskiy, I.; Quack, N.; Blunier, S.; Dual, J. Epitaxial lead chalco-genides on Si for mid-IR detectors and emitters including cavities. J. Electron. Mater. 2008, 37, 1497–1503. [Google Scholar] [CrossRef] [Green Version]

- Gradauskas, J.; Dzundza, B.; Chernyak, L.; Dashevsky, Z. Two-color infrared sensors on the PbTe: In p-n junction. Sensors 2021, 21, 1195. [Google Scholar] [CrossRef] [PubMed]

- Jost, S. Identifying the physical mechanisms of polycrystalline lead salt photoconductors. J. Appl. Phys. 2022, 132, 064503. [Google Scholar] [CrossRef]

- Springholz, G. Molecular Beam Epitaxy of IV-VI Semiconductors, Low Dimensional Structures and Device Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2018; pp. 211–276. [Google Scholar] [CrossRef]

- Dashevsky, Z.; Belenchuk, A.; Gartstein, E.; Shapoval, O. PbTe films grown by hot wall epitaxy on sapphire substrates. Thin Solid Films 2004, 461, 256–265. [Google Scholar] [CrossRef]

- Shandalov, M.; Dashevsky, Z.; Golan, Y. Microstructure related transport phenomena in chemically deposited PbSe films. Mater. Chem. Phys. 2008, 112, 132–135. [Google Scholar] [CrossRef]

- Dzundza, B.; Nykyruy, L.; Parashchuk, T.; Ivakin, E.; Yavorsky, Y.; Chernyak, L.; Dashevsky, Z. Transport and thermoelectric performance of n-type PbTe films. Phys. B Condens. Matter 2020, 588, 412178. [Google Scholar] [CrossRef]

- Lalonge, A.D.; Pei, Y.; Wang, H.; Snyder, J. Lead telluride alloy thermoelectrics. Mater. Today 2011, 14, 526–532. [Google Scholar] [CrossRef]

- Dashevsky, Z.; Jarashneli, A.; Unigovski, Y.; Dzundza, B.; Gao, F.; Shneck, R.Z. Development of a High Performance Gas Thermoelectric Generator 3 (TEG) with Possible use of Waste Heat. Energies 2022, 15, 3960. [Google Scholar] [CrossRef]

- Goltsman, B.M.; Dashevskii, Z.M.; Kaidanov, V.I.; Kolomoets, N.V. Film Thermoelements: Physics and Application; Nauka: Moscow, Russia, 1985. (In Russian) [Google Scholar]

- Dariel, M.P.; Dashevsky, Z.; Jarashnely, A.; Shusterman, S.; Horowitz, A. Carrier concentration gradient generated in p-type PbTe crystals by unidirection solidification. J. Cryst. Growth 2002, 234, 164–170. [Google Scholar] [CrossRef]

- Humphrey, J.N.; Petritz, R.L. Photoconductivity in lead selenide: Theory of the mechanism of sensitization. Phys. Rev. 1957, 105, 1736–1740. [Google Scholar] [CrossRef]

- Atakulov, S.B.; Zaynolobidinova, S.M.; Nabiev, G.A.; Nabiyev, M.B.; Yuldashev, A.A. Theory of Transport Phenomena in Polycrystalline Lead Chalcogenide Films. Mobility. Nondegenerate Statistics. Semiconductors 2013, 47, 879–883. [Google Scholar] [CrossRef]

- Kaidanov, V.I.; Ravich, Y.I. Deep and resonance states in AIV BVI semiconductors. Sov. Phys. Uspekhi 1985, 28, 31–53. [Google Scholar] [CrossRef]

- Volkov, B.A.; Ryabova, L.I.; Khokhlov, D.P. Mixed-valence impurities in lead telluride-based solid solutions. Phys. Uspekhi 2002, 45, 819. [Google Scholar] [CrossRef]

- Kaidanov, V.I. Resonance (Quasilocal) States in AIVBVI Semiconductors. Defect Diffus. Forum 1993, 103–105, 387–406. [Google Scholar] [CrossRef]

- Ravich, Y.I.; Efimova, B.A.; Smirnov, I.A. Semiconducting Lead Chalcogenides; Plenum Press: New York, NY, USA, 1970. [Google Scholar]

- Parashchuk, T.; Dashevsky, Z.; Wojciechowski, K. Feasibility of a high stable PbTe: In semiconductor for thermoelectric energy applications. J. Appl. Phys. 2019, 125, 245103. [Google Scholar] [CrossRef]

- Wojciechowski, K.; Parashchuk, T.; Wiendlocha, B.; Cherniushok, O.; Dashevsky, Z. Highly efficient n-type PbTe developed by advanced electronic structure engineering. J. Mater. Chem. C 2020, 38, 13270. [Google Scholar] [CrossRef]

- Park, S.-J.; Cho, K.-S.; Kim, S.-H. A study on dielectric characteristics of fluorinated polyimide thin film. J. Colloid Interface Sci. 2004, 272, 384. [Google Scholar] [CrossRef] [PubMed]

- Averkin, A.A.; Kaidanov, V.I.; Mel’nik, R.B. On the nature of impurity states of indium in-telluride lead. Fiz. Tekh. Poluprovodn. 1971, 5, 91–95. [Google Scholar]

- Skipetrov, P.; Golubev, A.V.; Dmitriev, N.N.; Slyn’ko, V.E. Chapter: Gallium-Induced Resonant States in Pb1−xSnxTe:Ga under Pressure; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar] [CrossRef]

- Parashchuk, T.; Chernyak, L.; Nemov, S.; Dashevsky, Z. Influence of Deformation on Pb1−xInxTe1−yIy and Pb1−x−ySnxInyTe Films; PSS: London, UK, 2020; Volume 257, p. 2000304. [Google Scholar] [CrossRef]

- Kane, E.O. Band structure of indium antimonide. J. Phys. Chem. Solids 1957, 1, 249–261. [Google Scholar] [CrossRef]

- Cohen, M.H. Energy Bands in the Bismuth Structure. I. A Nonellipsoidal Model for Electrons in Bi. Phys. Rev. 1961, 121, 387–395. [Google Scholar] [CrossRef]

- Allgaier, R.S.; Scanlon, W.W. Mobility of Electrons and Holes in PbS, PbSe, and PbTe between Room Temperature and 4.2 K. Phys. Rev. 1958, 111, 1029. [Google Scholar] [CrossRef]

| Composition | Thickness, d (µm) | Substrate Temperature, TS (K) | Average Grain Size (nm) | Mean Free Path at 10 K (nm) | Seebeck Coefficient S, (µV/K) |

|---|---|---|---|---|---|

| Pb0.99In0.01Te | 523 | 114 ± 11 | 6 | −160 | |

| 548 | 145 ± 20 | 9 | −150 | ||

| 2 ± 0.1 | 573 | 180 ± 30 | 11 | −160 | |

| 598 | 300 ± 35 | 18 | −150 | ||

| 638 | 510 ± 54 | 29 | −150 | ||

| 3 ± 0.2 | 598 | 586 ± 62 | 25 | −160 | |

| 4 ± 0.3 | 598 | 640 ± 70 | 44 | −150 | |

| Pb0.995In0.005Te | 2 ± 0.1 | 573 | 180 ± 30 | 34 | −150 |

| 3 ± 0.2 | 623 | 641± 70 | 42 | −160 | |

| Pb0.995In0.005Te (heat treatment) | 3 ± 0.2 | 623 | 656± 50 | 515 | −160 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kovalyuk, V.; Sheveleva, E.; Auslender, M.; Goltsman, G.; Shneck, R.; Dashevsky, Z. Polycrystalline PbTe:In Films on Amorphous Substrate: Structure and Physical Properties. Materials 2022, 15, 8383. https://doi.org/10.3390/ma15238383

Kovalyuk V, Sheveleva E, Auslender M, Goltsman G, Shneck R, Dashevsky Z. Polycrystalline PbTe:In Films on Amorphous Substrate: Structure and Physical Properties. Materials. 2022; 15(23):8383. https://doi.org/10.3390/ma15238383

Chicago/Turabian StyleKovalyuk, Vadim, Evgeniia Sheveleva, Mark Auslender, Gregory Goltsman, Roni Shneck, and Zinovi Dashevsky. 2022. "Polycrystalline PbTe:In Films on Amorphous Substrate: Structure and Physical Properties" Materials 15, no. 23: 8383. https://doi.org/10.3390/ma15238383