Decay Resistance of Surface Carbonized Wood

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

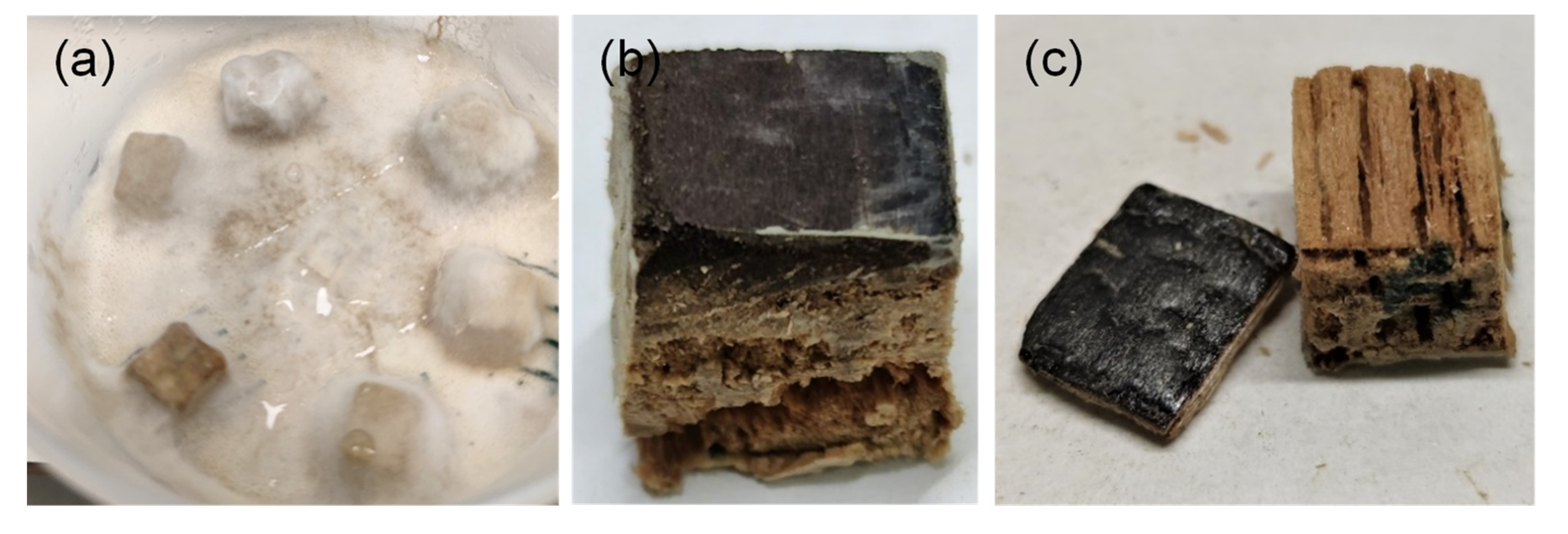

2.2. Decay Test

2.3. Elemental Analysis

2.4. Determination of Chemical Composition

2.5. Microscopy

3. Results

3.1. Elemental and Chemical Analysis of Undegraded Spruce and Birch

3.2. Mass Loss Due to Decay

3.3. Chemical Analysis of Decayed Spruce and Birch

3.4. Quantification of Fungal Biomass

3.5. Microscopical Examination

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Okamura, K.; Yasui, N.; Kaku, C.; Koshihara, M.; Imamoto, K.; Oshima, K. A research on Yakisugi—Performance evaluation and feasibility study for dissemination. SRI Res. Pap. Pract. Res. Rep. 2017, 44, 13–23. [Google Scholar]

- Hasburgh, L.E.; Zelinka, S.L.; Bishell, A.B.; Kirker, G.T. Durability and fire performance of charred wood siding (shou sugi ban). Forests 2021, 12, 1262. [Google Scholar] [CrossRef]

- Ebner, D.H.; Barbu, M.-C.; Čermák, P. Surface modification of spruce and fir sawn-timber by charring on the traditional Japanese method—Yakisugi. Polymers 2021, 13, 1662. [Google Scholar] [CrossRef] [PubMed]

- Ebner, D.H.; Barbu, M.-C.; Gryc, V.; Čermák, P. Surface charring of silver fir wood cladding using an enhanced traditional Japanese yakisugi method. Bioresources 2022, 17, 2031–2042. [Google Scholar] [CrossRef]

- Kampe, A.; Pfriem, A. A note on artificial weathering of spruce (Picea abies) with a carbonised layer. Int. Wood Prod. J. 2018, 9, 86–89. [Google Scholar] [CrossRef]

- Kymäläinen, M.; Lourençon, T.V.; Lillqvist, K. Natural weathering of soft- and hardwoods modified by contact and flame charring methods. Eur. J. Wood Prod. 2022, 80, 1309–1320. [Google Scholar] [CrossRef]

- Kymäläinen, M.; Dömény, J.; Rautkari, L. Moisture sorption of wood surfaces modified by one-sided carbonization as an alternative to traditional façade coatings. Coatings 2022, 12, 1273. [Google Scholar] [CrossRef]

- Kymäläinen, M.; Hautamäki, S.; Lillqvist, K.; Segerholm, K.; Rautkari, L. Surface modification of solid wood by charring. J. Mater. Sci. 2017, 52, 6111–6119. [Google Scholar] [CrossRef]

- Kymäläinen, M.; Turunen, H.; Čermák, P.; Hautamäki, S.; Rautkari, L. Sorption-related characteristics of surface charred spruce wood. Materials 2018, 11, 2083. [Google Scholar] [CrossRef] [Green Version]

- Čermák, P.; Dejmal, A.; Paschová, Z.; Kymäläinen, M.; Dömény, J.; Brabec, M.; Hess, D.; Rautkari, L. One-sided surface charring of beech wood. J. Mater. Sci. 2019, 54, 9497–9506. [Google Scholar] [CrossRef]

- Kymäläinen, M.; Turunen, H.; Rautkari, L. Effect of weathering on surface functional groups of charred norway spruce cladding panels. Forests 2020, 11, 1373. [Google Scholar] [CrossRef]

- Machová, D.; Oberle, A.; Zárybnická, L.; Dohnal, J.; Šeda, V.; Dömény, J.; Vacenovská, V.; Kloiber, M.; Pěnčík, J.; Tippner, J.; et al. Surface characteristics of one-sided charred beech wood. Polymers 2021, 13, 1551. [Google Scholar] [CrossRef] [PubMed]

- Šeda, V.; Machová, D.; Dohnal, J.; Dömény, J.; Zárybnická, L.; Oberle, A.; Vacenovská, V.; Čermák, P. Effect of one-sided surface charring of beech wood on density profile and surface wettability. Appl. Sci. 2021, 11, 4086. [Google Scholar] [CrossRef]

- Kymäläinen, M.; Sjökvist, T.; Dömény, J.; Rautkari, L. Artificial weathering of contact-charred wood—The effect of modification duration, wood species and material density. Materials 2022, 15, 3951. [Google Scholar] [CrossRef]

- Knicker, H.; Hilscher, A.; González-Vila, F.J.; Almendros, G. A new conceptual model for the structural properties of char produced during vegetation fires. Org. Geochem. 2008, 39, 935–939. [Google Scholar] [CrossRef] [Green Version]

- Prosen, E.M.; Radlein, D.; Piskorz, J.; Scott, D.S.; Legge, R.L. Microbial utilization of levoglucosan in wood pyrolysate as a carbon and energy source. Biotechnol. Bioeng. 1993, 42, 538–541. [Google Scholar] [CrossRef]

- Graham, R.D. Service Life of Treated and Untreated Fence Posts: 1952 Progress Report on the TJ Starker Post Farm; Oregon State University: Corvallis, OR, USA, 1952. [Google Scholar]

- Kymäläinen, M.; Havimo, M.; Louhelainen, J. Sorption properties of torrefied wood and charcoal. Wood Mater. Sci. Eng. 2014, 9, 170–178. [Google Scholar] [CrossRef]

- Zelinka, S.L.; Altgen, M.; Emmerich, L.; Guigo, N.; Keplinger, T.; Kymäläinen, M.; Thybring, E.E.; Thygesen, L.G. Review of wood modification and wood functionalization technologies. Forests 2022, 13, 1004. [Google Scholar] [CrossRef]

- SCAN-CM 49:03. Content of Acetone Soluble Matter; Scandinavian Pulp, Paper and Board Testing Committee: Stockholm, Sweden, 2003. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D.L.A.P. Determination of Structural Carbohydrates and Lignin in Biomass; Technical Report NREL/TP-510-42618; National Renewable Energy Laboratory: Denver, Colorado, USA, 2012. [Google Scholar]

- Jones, H.L.; Worral, J.J. Fungal biomass in decayed wood. Mycologia 1995, 97, 459–466. [Google Scholar] [CrossRef]

- Raveendran, K.; Ganesh, A.; Khilar, K.C. Pyrolysis characteristics of biomass and biomass components. Fuel 1996, 75, 987–998. [Google Scholar] [CrossRef]

- Antal, M.J.J.; Grønli, M. The art, science, and technology of charcoal production. Ind. Eng. Chem. Res. 2003, 42, 1619–1640. [Google Scholar] [CrossRef]

- Shen, D.K.; Gu, S.; Bridgwater, A.V. The thermal performance of the polysaccharides extracted from hardwood: Cellulose and hemicellulose. Carbohyd. Polym. 2010, 82, 39–45. [Google Scholar] [CrossRef]

- Zicherman, J.B.; Williamson, R.B. Microstructure of wood char. Wood Sci. Technol. 1981, 15, 237–249. [Google Scholar] [CrossRef]

- Chaouch, M.; Pétrissans, M.; Pétrissans, A.; Gérardin, P. Use of wood elemental composition to predict heat treatment intensity and decay resistance of different softwood and hardwood species. Polym. Degr. Stabil. 2010, 95, 2255–2259. [Google Scholar] [CrossRef]

- Wannapeera, J.; Fungtammasan, B.; Worasuwannarak, N. Effects of temperature and holding time during torrefaction on the pyrolysis behaviors of woody biomass. J. Anal. Appl. Pyrol. 2011, 92, 99–105. [Google Scholar] [CrossRef]

- Bryden, K.M.; Ragland, K.W.; Rutland, C.J. Modeling thermally thick pyrolysis of wood. Biom. Bioenerg. 2002, 22, 41–53. [Google Scholar] [CrossRef]

- Knicker, H.; Hilscher, A.; de la Rosa, J.M.; González-Pérez, J.A.; González-Vila, F.J. Modification of biomarkers in pyrogenic organic matter during the initial phase of charcoal biodegradation in soils. Geoderma 2013, 197–198, 43–50. [Google Scholar] [CrossRef] [Green Version]

- Wengel, M.; Kothe, E.; Schmidt, C.M.; Heide, K.; Gleixner, G. Degradation of organic matter from black shales and charcoal by the wood-rotting fungus Schizophyllum commune and release of DOC and heavy metals in the aquous phase. Sci. Total Environ. 2006, 367, 383–393. [Google Scholar] [CrossRef] [PubMed]

- Ascough, P.L.; Sturrock, C.J.; Bird, M.I. Investigation of growth responses in saprophytic fungi to charred biomass. Isot. Environ. Health Stud. 2010, 46, 64–77. [Google Scholar] [CrossRef] [Green Version]

- Kwon, S.-M.; Kim, N.-H.; Cha, D.-S. An investigation on the transition characteristics of the wood cell walls during carbonization. Wood Sci. Technol. 2009, 43, 487–498. [Google Scholar] [CrossRef]

- Nishimiya, K.; Hata, T.; Imamura, Y.; Ishihara, S. Mechanism and clarification of electrical conduction through wood charcoal. Wood Res. 1995, 82, 34–36. [Google Scholar]

- Nishimiya, K.; Hata, T.; Imamura, Y.; Ishihara, S. Analysis of chemical structure of wood charcoal by X-ray photoelectron spectroscopy. J. Wood Sci. 1998, 44, 56–61. [Google Scholar] [CrossRef]

- Curling, S.F.; Clausen, C.A.; Winandy, J.E. Relationships between mechanical properties, weight loss, and chemical composition of wood during incipient brown-rot decay. Forest Prod. J. 2002, 52, 34–39. [Google Scholar]

- Goodell, B.; Winandy, J.E.; Morrell, J.J. Fungal degradation of wood: Emerging data, new insights and changing perceptions. Coatings 2020, 10, 1210. [Google Scholar] [CrossRef]

- Ringman, R.; Pilgård, A.; Brischke, C.; Richter, K. Mode of action of brown rot decay resistance in modified wood: A review. Holzforschung 2014, 68, 239–246. [Google Scholar] [CrossRef]

- Kymäläinen, M.; Rautkari, L.; Hill, C.A.S. Sorption behaviour of torrefied wood and charcoal determined by dynamic vapour sorption. J. Mater. Sci. 2015, 50, 7673–7680. [Google Scholar] [CrossRef]

- Carll, C.G.; Highley, T.L. Decay of wood and wood-based products above ground in buildings. J. Test Eval. 1999, 27, 150–158. [Google Scholar]

- Rautkari, L.; Kutnar, A.; Hughes, M.; Kamke, F.A. Wood surface densification using different methods. In Proceedings of the 11th World Conference on Timber Engineering, Riva del Garda, Italy, 20–24 June 2010. [Google Scholar]

- Rautkari, L.; Hänninen, T.; Johansson, L.S.; Hughes, M. A study by X-ray photoelectron spectroscopy (XPS) of the chemistry of the surface of Scots pine (Pinus sylvestris L.) modified by friction. Holzfoschung 2012, 66, 93–96. [Google Scholar] [CrossRef]

| Species | Modification | Code |

|---|---|---|

| Spruce | Unmodified | SR |

| Contact charred | SC | |

| Flame charred | SF | |

| Birch | Unmodified | BR |

| Contact charred | BC | |

| Flame charred | BF |

| Species | Sample | C, % | H, % |

|---|---|---|---|

| Spruce | SR | 46.9 (0.2) | 5.9 (0.0) |

| SC | 57.2 (0.3) | 5.2 (0.1) | |

| SF | 70.5 (0.2) | 3.6 (0.1) | |

| Birch | BR | 45.8 (0.1) | 5.8 (0.0) |

| BC | 54.2 (0.2) | 5.3 (0.0) | |

| BF | 71.8 (1.0) | 3.4 (0.0) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kymäläinen, M.; Belt, T.; Seppäläinen, H.; Rautkari, L. Decay Resistance of Surface Carbonized Wood. Materials 2022, 15, 8410. https://doi.org/10.3390/ma15238410

Kymäläinen M, Belt T, Seppäläinen H, Rautkari L. Decay Resistance of Surface Carbonized Wood. Materials. 2022; 15(23):8410. https://doi.org/10.3390/ma15238410

Chicago/Turabian StyleKymäläinen, Maija, Tiina Belt, Hanna Seppäläinen, and Lauri Rautkari. 2022. "Decay Resistance of Surface Carbonized Wood" Materials 15, no. 23: 8410. https://doi.org/10.3390/ma15238410

APA StyleKymäläinen, M., Belt, T., Seppäläinen, H., & Rautkari, L. (2022). Decay Resistance of Surface Carbonized Wood. Materials, 15(23), 8410. https://doi.org/10.3390/ma15238410