Effect of Sn Addition on Microstructure, Aging Properties and Softening Resistance of Cu-Cr Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

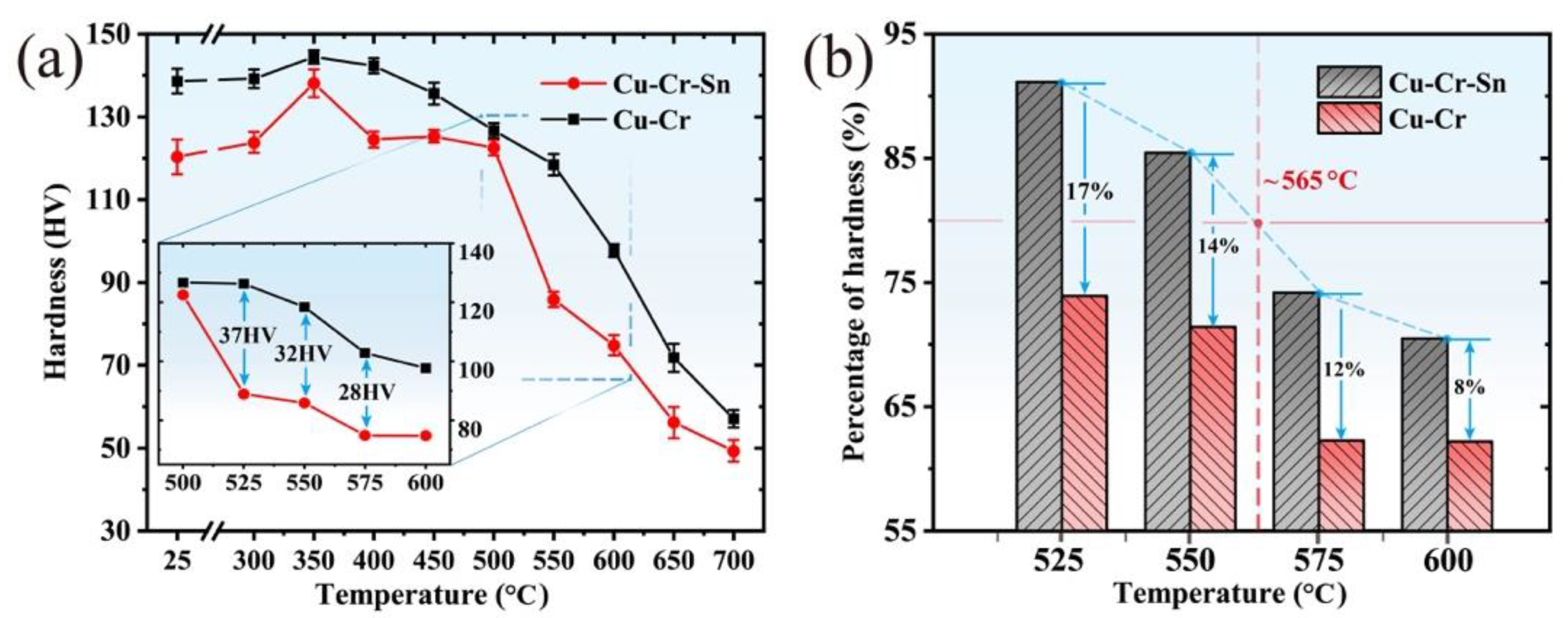

3.1. Properties

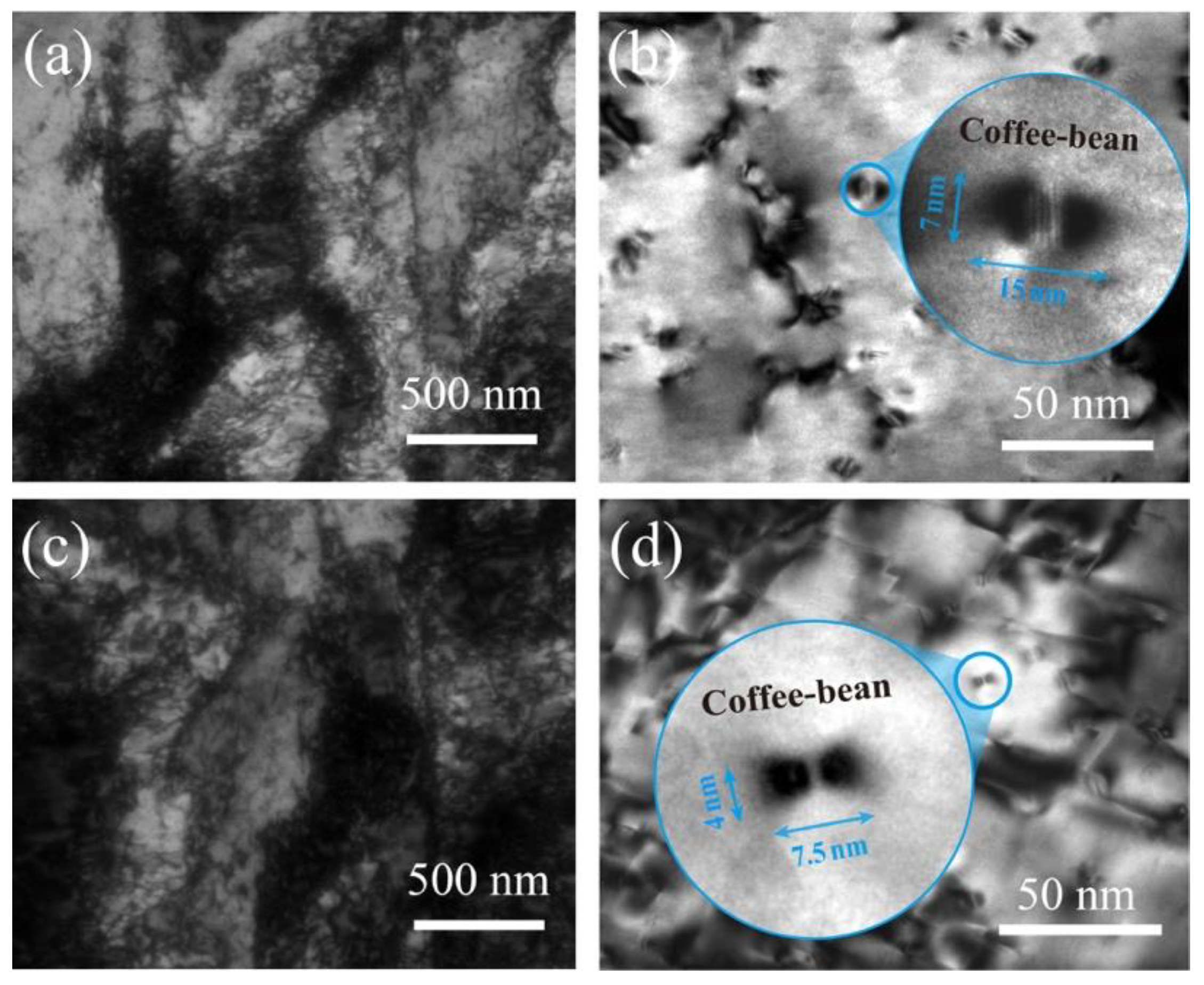

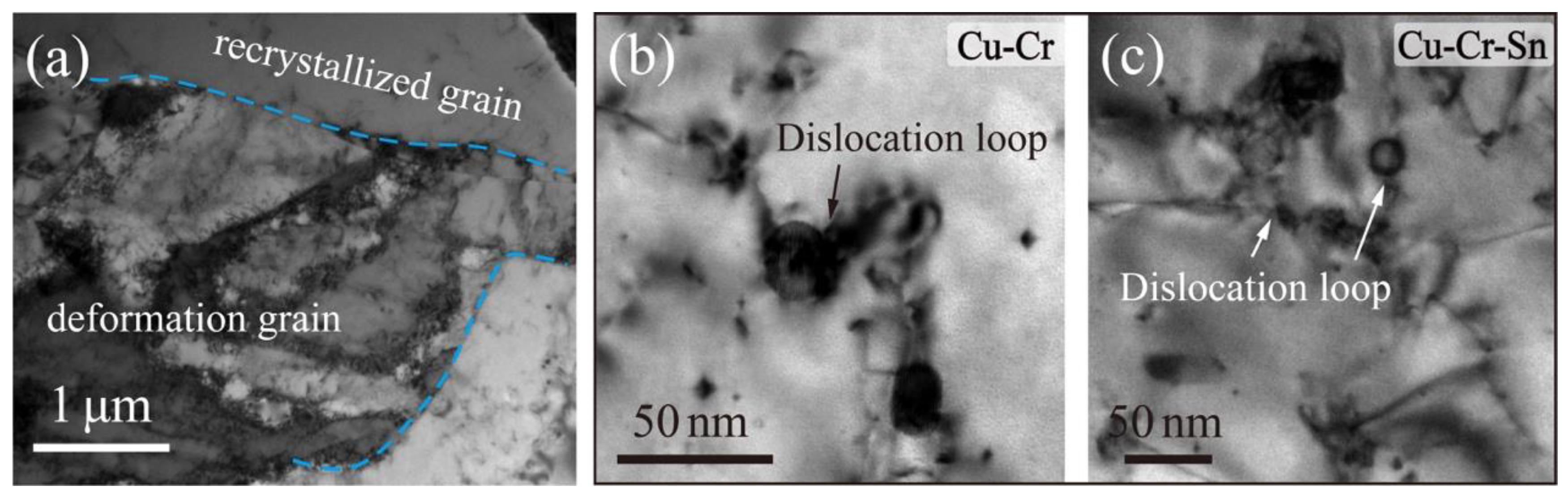

3.2. Microstructure Evolution

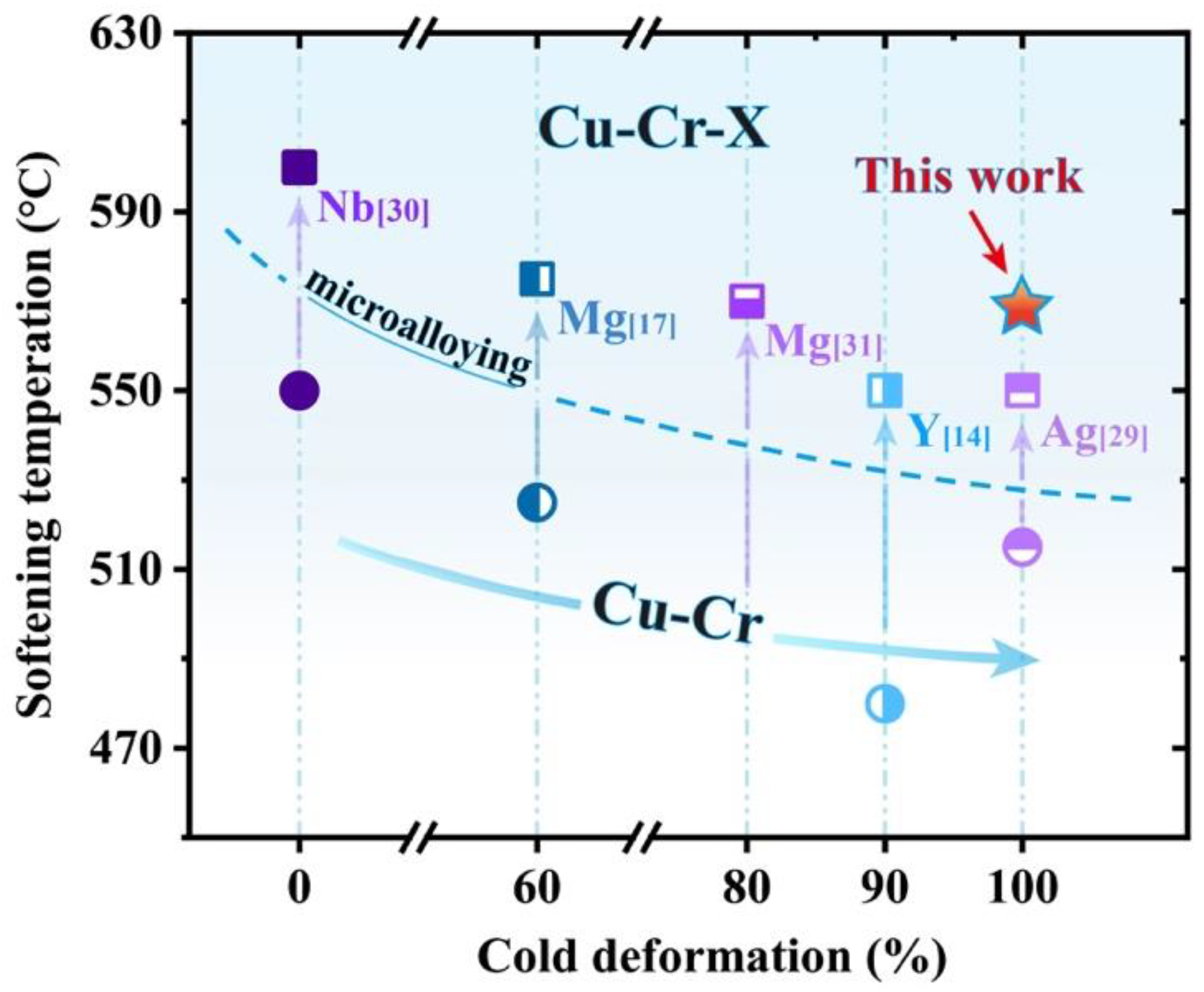

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.H.; Zhang, Y.; Tian, B.H.; Song, K.X.; Liu, P.; Jia, Y.L.; Chen, X.H.; An, J.C.; Zhao, Z.; Liu, Y.; et al. Review of nano-phase effects in high strength and conductivity copper alloys. Nanotechnol. Rev. 2019, 8, 383–395. [Google Scholar] [CrossRef]

- Geng, Y.F.; Ban, Y.J.; Wang, B.J.; Li, X.; Song, K.X.; Zhang, Y.; Jia, Y.L.; Tian, B.H.; Liu, Y.; Volinsky, A.A. A review of microstructure and texture evolution with nanoscale precipitates for copper alloys. J. Mater. Res. Technol. 2020, 9, 11918–11934. [Google Scholar] [CrossRef]

- Ma, M.Z.; Xiao, Z.; Meng, X.P.; Li, Z.; Gong, S.; Dai, J.; Jiang, H.Y.; Jiang, Y.B.; Lei, Q.; Wei, H.G. Effects of trace calcium and strontium on microstructure and properties of Cu-Cr alloys. J. Mater. Sci. Technol. 2022, 112, 11–23. [Google Scholar] [CrossRef]

- Li, R.G.; Guo, E.Y.; Chen, Z.N.; Kang, H.J.; Wang, W.; Zou, C.L.; Li, T.J.; Wang, T.M. Optimization of the balance between high strength and high electrical conductivity in CuCrZr alloys through two-step cryorolling and aging. J. Alloys Compd. 2019, 771, 1044–1051. [Google Scholar]

- Zhang, S.J.; Li, R.G.; Kang, H.J.; Chen, Z.N.; Wang, W.; Zou, C.L.; Li, T.J.; Wang, T.M. A high strength and high electrical conductivity Cu-Cr-Zr alloy fabricated by cryorolling and intermediate aging treatment. Mater. Sci. Eng. A 2017, 680, 108–114. [Google Scholar] [CrossRef]

- Wang, K.; Liu, K.F.; Zhang, J.B. Microstructure and properties of aging Cu-Cr-Zr alloy. Rare Met. 2014, 33, 134–138. [Google Scholar] [CrossRef]

- Fu, H.D.; Xu, S.; Li, W.; Xie, J.X.; Zhao, H.B.; Pan, Z.J. Effect of rolling and aging processes on microstructure and properties of Cu-Cr-Zr alloy. Mater. Sci. Eng. A 2017, 700, 107–115. [Google Scholar] [CrossRef]

- Xu, S.; Fu, H.D.; Wang, Y.T.; Xie, J.X. Effect of Ag addition on the microstructure and mechanical properties of Cu-Cr alloy. Mater. Sci. Eng. A 2018, 726, 208–214. [Google Scholar] [CrossRef]

- Zhang, K.; Yang, J.J.; Li, J.Y.; Chen, X.H.; Zhou, H.L.; Liu, P. Effect of deformation and aging treatment on the microstructure and properties of Cu-0.45Cr-0.14Ti (wt.%) alloy. J. Alloys Compd. 2021, 851, 8. [Google Scholar] [CrossRef]

- Zeng, H.; Sui, H.; Wu, S.J.; Liu, J.P.; Wang, H.; Zhang, J.B.; Yang, B. Evolution of the microstructure and properties of a Cu-Cr-(Mg) Alloy upon thermomechanical treatment. J. Alloys Compd. 2021, 857, 157582. [Google Scholar]

- Yuan, D.W.; Wang, J.F.; Chen, H.M.; Xie, W.B.; Wang, H.; Yang, B. Mechanical properties and microstructural evolution of a Cu-Cr-Ag alloy during thermomechanical treatment. Mater. Sci. Technol. 2018, 34, 1433–1440. [Google Scholar] [CrossRef]

- Peng, H.C.; Xie, W.B.; Chen, H.M.; Wang, H.; Yang, B. Effect of micro-alloying element Ti on mechanical properties of Cu-Cr alloy. J. Alloys Compd. 2021, 852, 157004. [Google Scholar] [CrossRef]

- Wang, H.; Gong, L.K.; Liao, J.F.; Chen, H.M.; Xie, W.B.; Yang, B. Retaining meta-stable fcc-Cr phase by restraining nucleation of equilibrium bcc-Cr phase in CuCrZrTi alloys during ageing. J. Alloys Compd. 2018, 749, 140–145. [Google Scholar] [CrossRef]

- Wang, Y.J.; Qu, J.P.; Wang, X.L.; Jie, J.C.; Li, T.J. Effects of Y addition on the microstructure, properties and softening resistance of Cu-Cr alloy. J. Alloys Compd. 2022, 902, 12. [Google Scholar] [CrossRef]

- Wang, W.Y.; Zhu, J.L.; Qin, N.N.; Zhang, Y.F.; Li, S.Y.; Xiao, Z.; Lei, Q.; Li, Z. Effects of minor rare earths on the microstructure and properties of Cu-Cr-Zr alloy. J. Alloys Compd. 2020, 847, 13. [Google Scholar] [CrossRef]

- Zhao, Z.Q.; Xiao, Z.; Li, Z.; Ma, M.Z.; Dai, J. Effect of magnesium on microstructure and properties of Cu-Cr alloy. J. Alloys Compd. 2018, 752, 191–197. [Google Scholar] [CrossRef]

- Sun, Y.Q.; Peng, L.J.; Huang, G.J.; Xie, H.F.; Mi, X.J.; Liu, X.H. Effects of Mg addition on the microstructure and softening resistance of Cu-Cr alloys. Mater. Sci. Eng. A 2020, 776, 139009. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Z.; Jiang, Y.X.; Zhang, Y.; Zhou, Z.Y.; Lei, Q. The microstructure evolution and properties of a Cu-Cr-Ag alloy during thermal-mechanical treatment. J. Mater. Res. 2017, 32, 1324–1332. [Google Scholar] [CrossRef]

- Luo, Z.Y.; Luo, F.X.; Xie, W.B.; Chen, H.M.; Wang, H.; Yang, B. The Effect of Precipitation Characteristics on Hardening Behavior in Cu-Cr-Sn Alloy with Sn Variation. Powder Metall. Met. Ceram. 2020, 58, 657–666. [Google Scholar] [CrossRef]

- Li, J.Z.; Ding, H.; Li, B.M.; Gao, W.L.; Bai, J.; Sha, G. Effect of Cr and Sn additions on microstructure, mechanical-electrical properties and softening resistance of Cu-Cr-Sn alloy. Mater. Sci. Eng. A 2021, 802, 140628. [Google Scholar] [CrossRef]

- Luo, Z.; Luo, F.; Xie, W.; Chen, H.; Wang, H.; Yang, B. A study on annealing-induced softening in cold drawn Cu-Cr-Sn alloy. Materialwiss. Werkstofftech. 2018, 49, 1325–1334. [Google Scholar] [CrossRef]

- Peng, L.J.; Xie, H.F.; Huang, G.J.; Xu, G.L.; Yin, X.Q.; Feng, X.; Mi, X.J.; Yang, Z. The phase transformation and strengthening of a Cu-0.71 wt% Cr alloy. J. Alloys Compd. 2017, 708, 1096–1102. [Google Scholar] [CrossRef]

- Chbihi, A.; Sauvage, X.; Blavette, D. Atomic scale investigation of Cr precipitation in copper. Acta Mater. 2012, 60, 4575–4585. [Google Scholar] [CrossRef] [Green Version]

- Fujii, T.; Nakazawa, H.; Kato, M.; Dahmen, U. Crystallography and morphology of nanosized Cr particles in a Cu-0.2% Cr alloy. Acta Mater. 2000, 48, 1033–1045. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, S.; Mukhopadhyay, N.K.; Yadav, A.; Kumar, V.; Winczek, J. Effect of Variation of SiC Reinforcement on Wear Behaviour of AZ91 Alloy Composites. Materials 2021, 14, 990. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, S.; Mukhopadhyay, N.K.; Yadav, A.; Sinha, D.K. Effect of TiC Reinforcement on Mechanical and Wear Properties of AZ91 Matrix Composites. Int. J. Metalcast. 2022, 16, 2128–2143. [Google Scholar] [CrossRef]

- Wang, Y.T.; Fu, H.D.; Wang, J.; Zhang, H.T.; Li, W.D.; Xie, J.X. Enhanced combination properties of Cu-0.8Cr alloy by Fe and P additions. J. Nucl. Mater. 2019, 526, 9. [Google Scholar] [CrossRef]

- Guo, X.L.; Xiao, Z.; Qiu, W.T.; Li, Z.; Zhao, Z.Q.; Wang, X.; Jiang, Y.B. Microstructure and properties of Cu-Cr-Nb alloy with high strength, high electrical conductivity and good softening resistance performance at elevated temperature. Mater. Sci. Eng. A 2019, 749, 281–290. [Google Scholar] [CrossRef]

- Yang, X.H.; Zhao, B.W.; Zhang, B.C.; Cao, F.; Xiao, P. Evolution of the Microstructures and Properties of Cu-xCr-0.4Nb Alloys. Adv. Eng. Mater. 2022, 24, 2101403. [Google Scholar] [CrossRef]

- Dai, J.; Ma, M.Z.; Xiao, Z.; Meng, X.P.; Sun, G.; Zhang, T.Y.; Zhou, T.; Li, L.H.; Zhu, Y.X. Effect of trace silicon addition on microstructure and properties of a Cu-0.26Cr-0.14Mg alloy. Mater. Sci. Eng. A 2022, 833, 11. [Google Scholar] [CrossRef]

- Sun, Y.Q.; Xu, G.L.; Feng, X.; Peng, L.J.; Huang, G.J.; Xie, H.F.; Mi, X.J.; Liu, X.H. Effect of Ag on Properties, Microstructure, and Thermostability of Cu-Cr Alloy. Materials 2020, 13, 5386. [Google Scholar] [CrossRef] [PubMed]

| Elements | Cr | Sn | Cu | |

|---|---|---|---|---|

| Measured composition | Cu-Cr | 0.20 | — | Bal. |

| Cu-Cr-Sn | 0.20 | 0.12 | Bal. | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, G.; Zhu, Y.; Peng, L.; Xie, H.; Li, Z.; Huang, S.; Yang, Z.; Zhang, W.; Mi, X. Effect of Sn Addition on Microstructure, Aging Properties and Softening Resistance of Cu-Cr Alloy. Materials 2022, 15, 8441. https://doi.org/10.3390/ma15238441

Xu G, Zhu Y, Peng L, Xie H, Li Z, Huang S, Yang Z, Zhang W, Mi X. Effect of Sn Addition on Microstructure, Aging Properties and Softening Resistance of Cu-Cr Alloy. Materials. 2022; 15(23):8441. https://doi.org/10.3390/ma15238441

Chicago/Turabian StyleXu, Gaolei, Yunqing Zhu, Lijun Peng, Haofeng Xie, Zengde Li, Shuhui Huang, Zhen Yang, Wenjing Zhang, and Xujun Mi. 2022. "Effect of Sn Addition on Microstructure, Aging Properties and Softening Resistance of Cu-Cr Alloy" Materials 15, no. 23: 8441. https://doi.org/10.3390/ma15238441

APA StyleXu, G., Zhu, Y., Peng, L., Xie, H., Li, Z., Huang, S., Yang, Z., Zhang, W., & Mi, X. (2022). Effect of Sn Addition on Microstructure, Aging Properties and Softening Resistance of Cu-Cr Alloy. Materials, 15(23), 8441. https://doi.org/10.3390/ma15238441