Comparative Investigation of the Influence of Ultrafine-Grained State on Deformation and Temperature Behavior and Microstructure Formed during Quasi-Static Tension of Pure Titanium and Ti-45Nb Alloy by Means of Infrared Thermography

Abstract

:1. Introduction

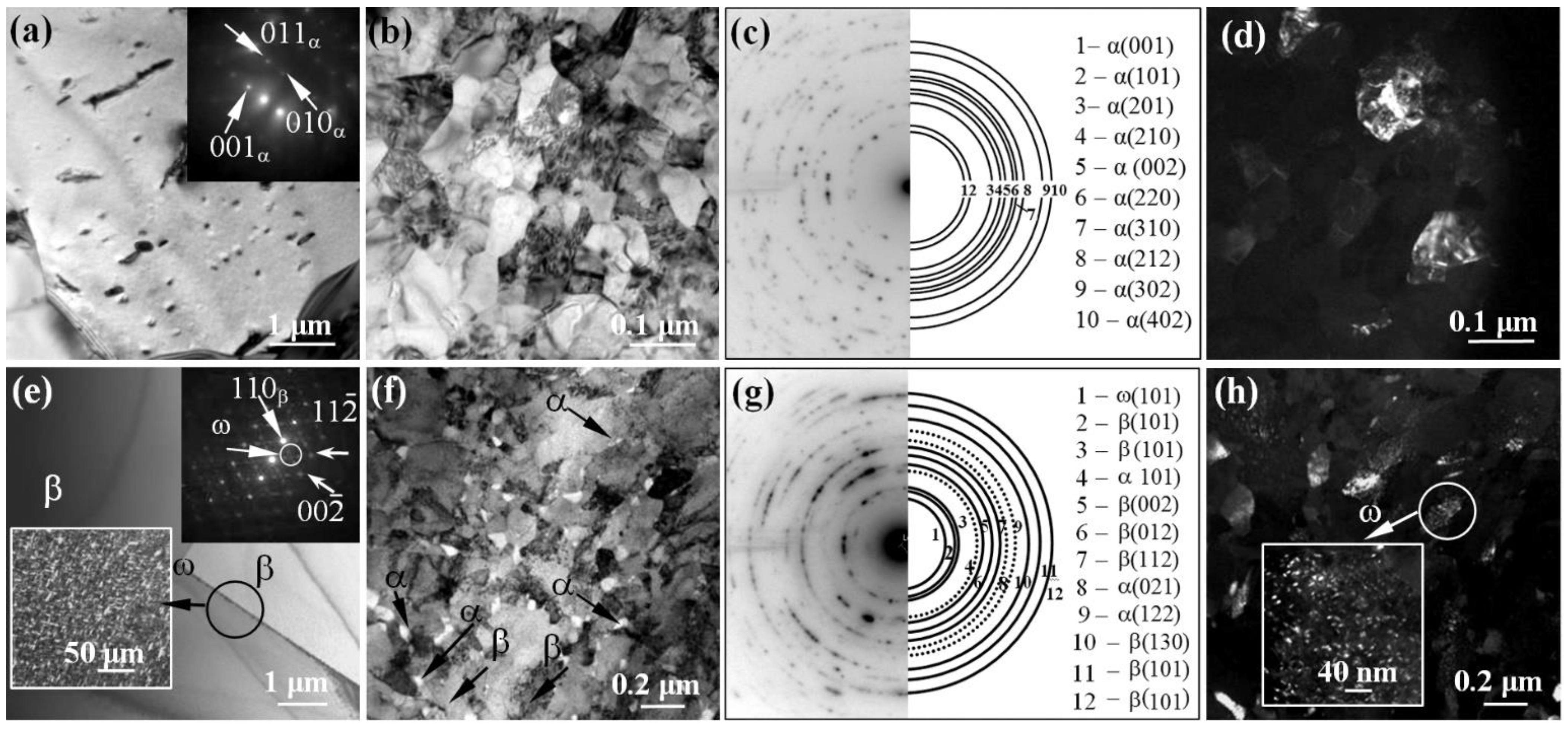

2. Materials and Research Methods

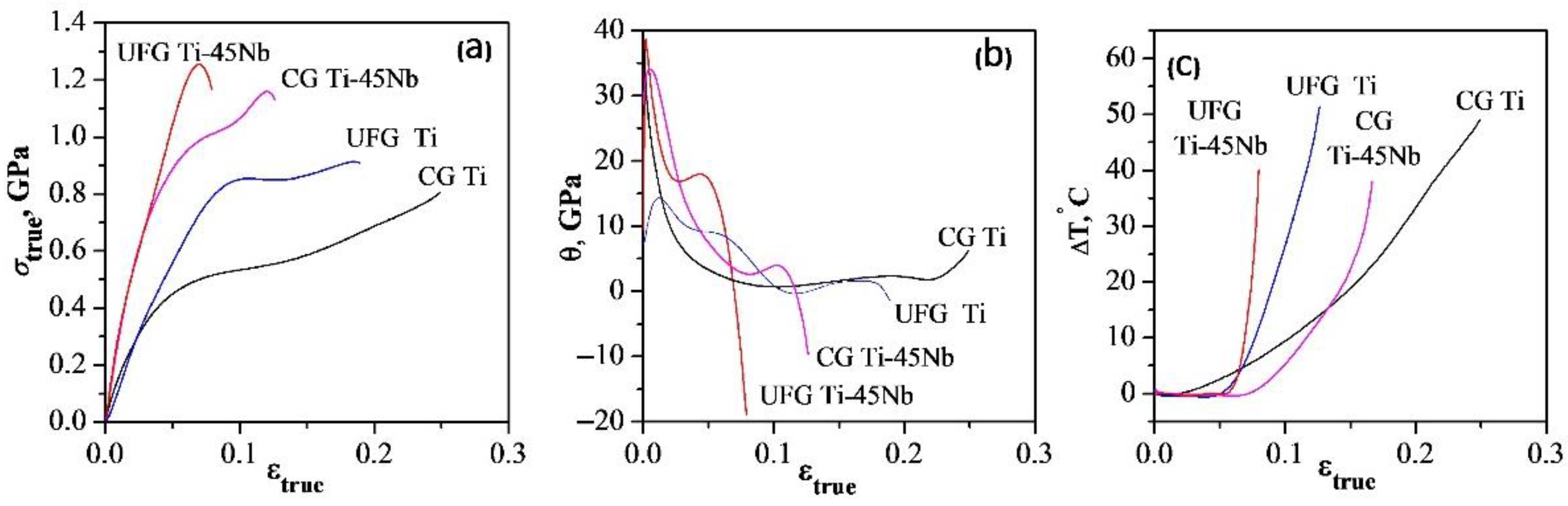

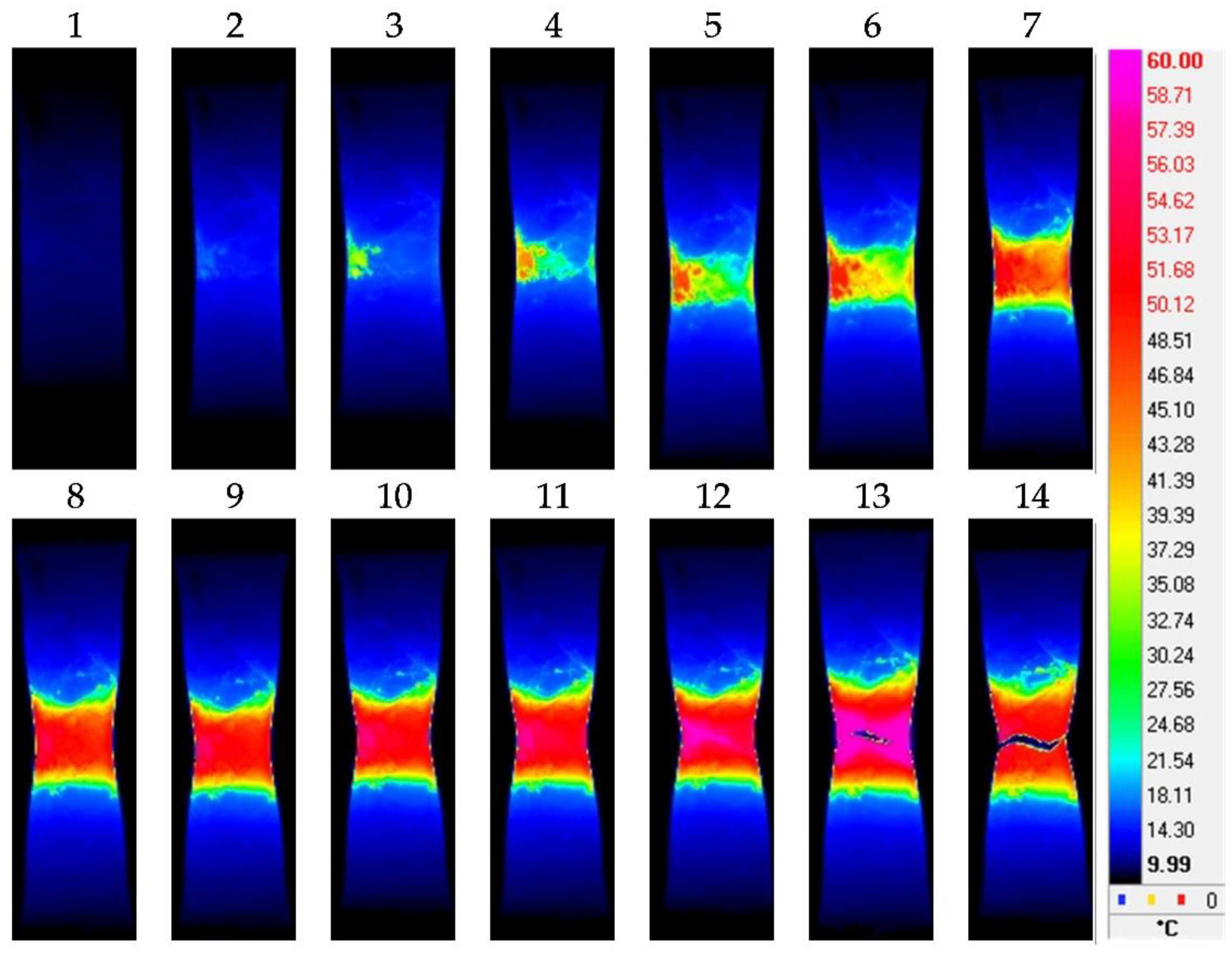

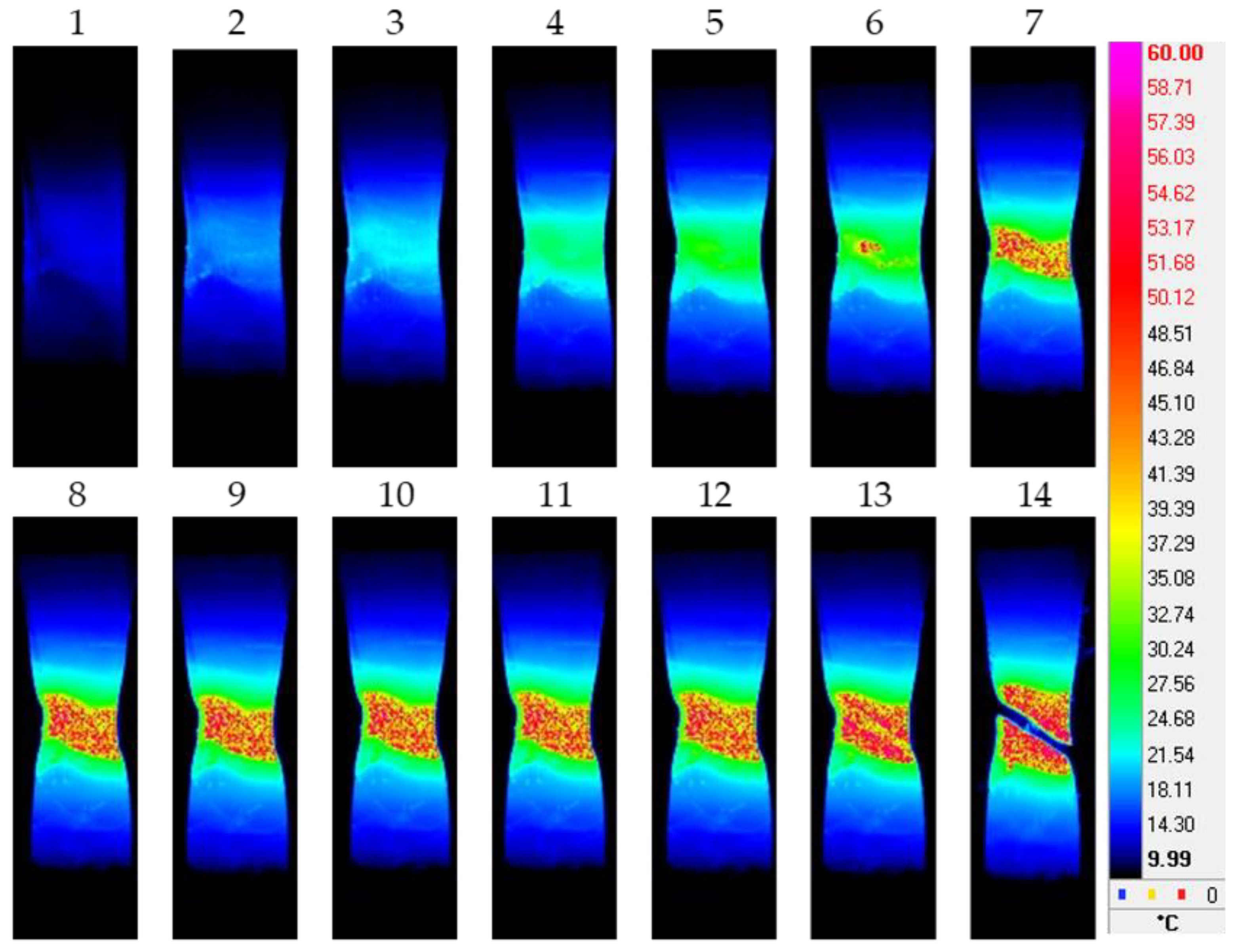

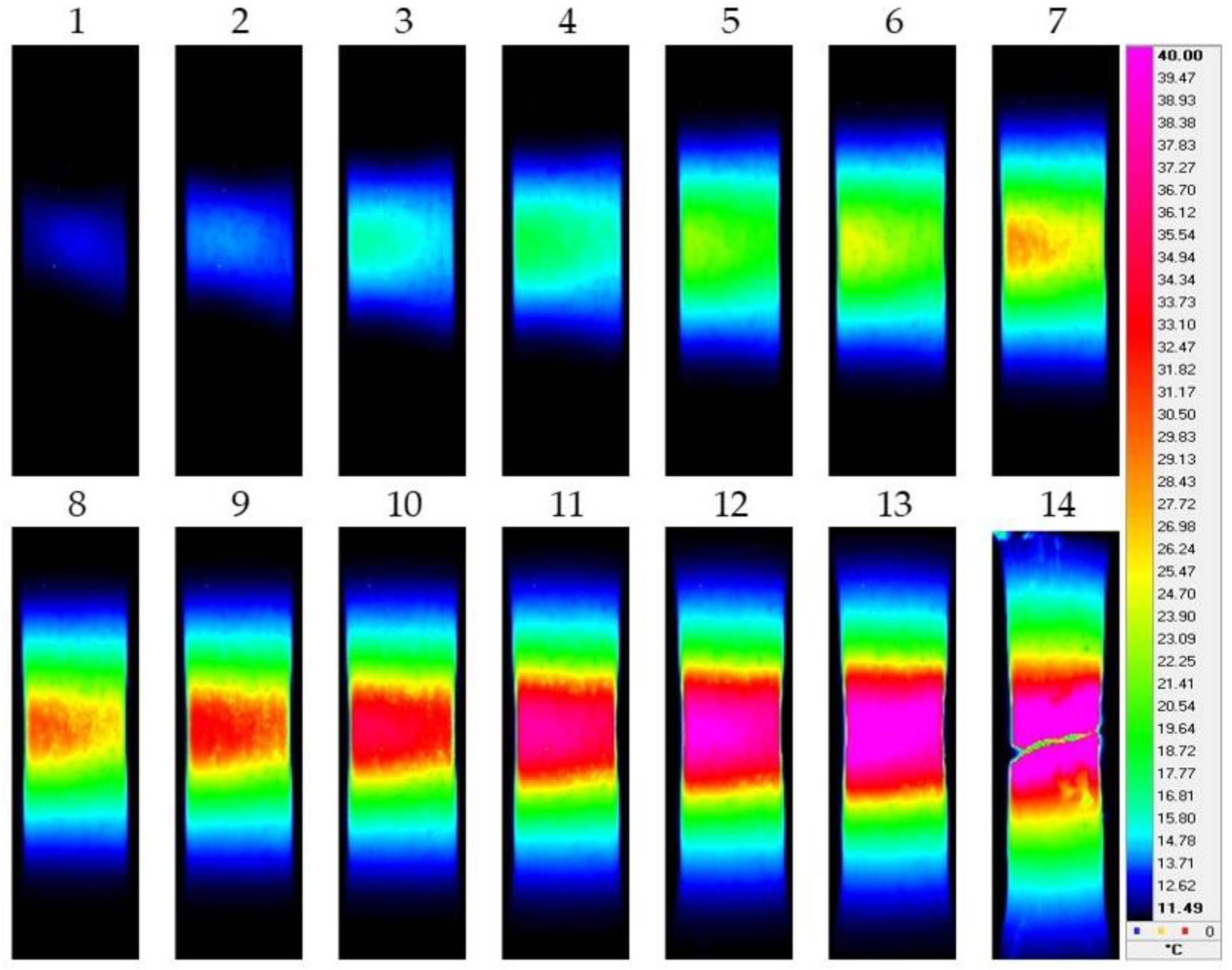

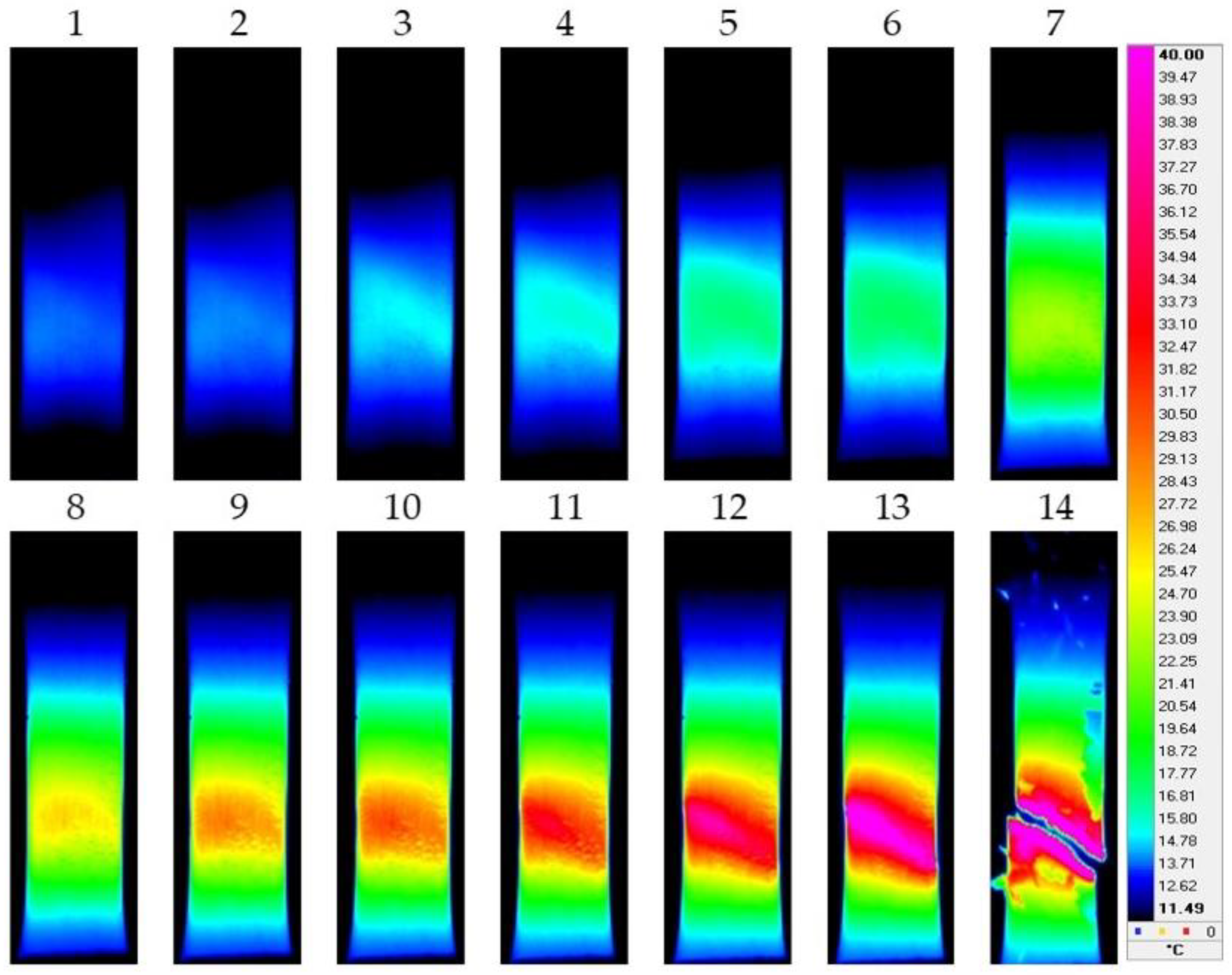

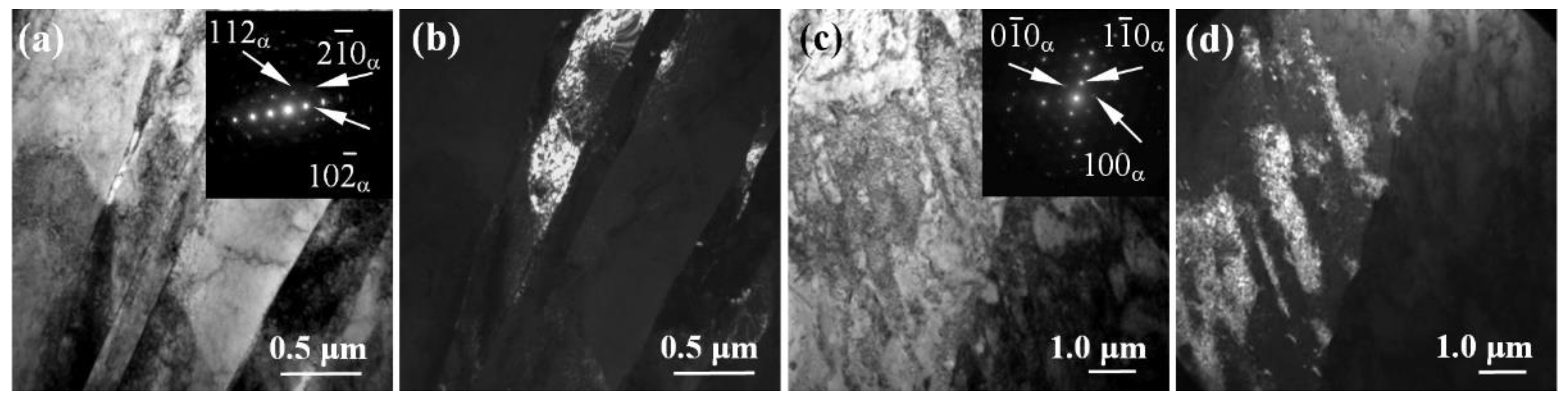

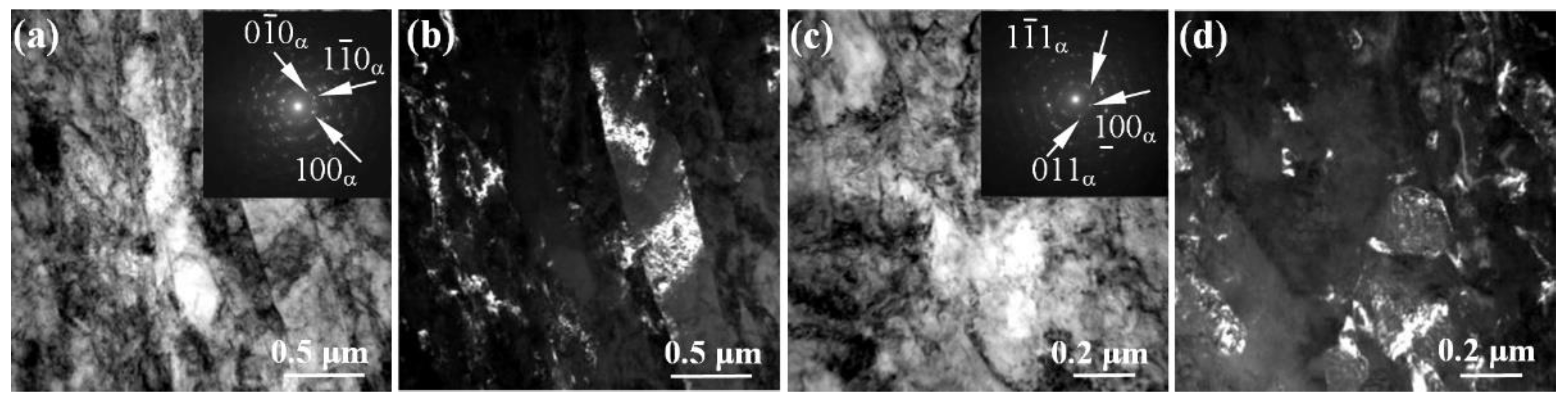

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leyens, C.; Peters, M. (Eds.) Titanium and Titanium Alloys: Fundamentals and Applications; Wiley-VCH Verlag GmbH & Co. KgaA: Weinheim, Germany, 2003; 532p, Available online: https://onlinelibrary.wiley.com/doi/book/10.1002/3527602119 (accessed on 26 September 2022).

- Li, Y.; Yang, C.; Zhao, H.; Qu, S.; Li, X.; Li, Y. New Developments of Ti-Based Alloys for Biomedical Applications. Materials 2014, 7, 1709–1800. [Google Scholar] [CrossRef] [Green Version]

- Patel, D.; Kim, S.-H.; Qiu, W.; Maeda, M.; Matsumoto, A.; Nishijima, G.; Kumakura, H.; Choi, S.; Kim, J.H. Niobium-titanium (Nb-Ti) superconducting joints for persistent-mode operation. Sci. Rep. 2019, 9, 14287. [Google Scholar] [CrossRef] [Green Version]

- Niinomi, M.; Liu, Y.; Nakai, M.; Liu, H.; Li, H. Biomedical titanium alloys with Young’s moduli close to that of cortical bone. Regen. Biomater. 2016, 3, 173–185. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Niinomi, M.; Nakai, M. Titanium-based biomaterials for preventing stress shielding between implant devices and bone. Int. J. Biomater. 2011, 1, 836587–836596. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Q.; Thouas, G.A. Metallic implant biomaterials. Mater. Sci. Eng. R. Rep. 2015, 87, 1–57. [Google Scholar] [CrossRef]

- Khorasani, A.M.; Goldberg, M.; Doeven, E.H.; Littlefair, G. Titanium in Biomedical Applications—Properties and Fabrication: A Review. J. Biomater. Tissue Eng. 2015, 5, 593–619. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, K. Review on titanium and titanium based alloys as biomaterials for orthopaedic applications. Mater. Sci. Eng. C 2019, 102, 844–862. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.C.; Chen, L.Y. A review on biomedical titanium alloys: Recent progress and prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef] [Green Version]

- Hussein, M.A.; Mohammed, A.S.; Al-Aqeeli, N. Wear Characteristics of Metallic Biomaterials: A Review. Materials 2015, 8, 2749–2768. [Google Scholar] [CrossRef] [Green Version]

- Ozaki, T.; Matsumoto, H.; Watanabe, S.; Hanada, S. Beta Ti alloys with low Young’s modulus. Mater. Transac. 2004, 45, 2776–2779. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, J.; Cheng, X.; Zhao, X. A metastable β-type Ti-Nb binery alloy with low modulus and high strength. J. Alloys Compd. 2015, 644, 411–415. [Google Scholar] [CrossRef]

- Helth, A.; Gostin, P.F.; Oswald, S.; Wendrock, H.; Wolff, U.; Hempel, U.; Arnhold, S.; Calin, M.; Eckert, J.; Gebert, A. Chemical nanoroughening of Ti40Nb surfaces and its effect on human mesenchymal stromal cell response. J. Biomed. Mater. Res. Part B 2014, 102, 31–41. [Google Scholar] [CrossRef] [PubMed]

- Helth, A.; Pilz, S.; Kirsten, T.; Giebeler, L.; Freudenberger, J.; Calin, M.; Eckert, J.; Gebert, A. Effect of thermomechanical processing on the mechanical biofunctionality of a low modulus Ti-40Nb alloy. J. Mech. Behav. Biomed. Mater. 2017, 65, 137–150. [Google Scholar] [CrossRef]

- Reck, A.; Pilz, S.; Thormann, U.; Alt, V.; Gebert, A.; Călin, M.; Heiß, C.; Zimmermann, M. Effects of thermomechanical history and environment on the fatigue behavior of (β)-Ti-Nb implant alloys. MATEC Web Conf. 2018, 165, 06001. [Google Scholar] [CrossRef]

- Bonisch, M.; Calin, M.; Humbeeck, J.; Skrotzki, W.; Eckert, J. Factors influencing the elastic moduli, reversible strains and hysteresis loops in martensitic Ti–Nb alloys. Mater. Sci. Eng. C 2015, 48, 511–520. [Google Scholar] [CrossRef] [PubMed]

- Valiev, R.Z.; Zhilyaev, A.P.; Langdon, T.G. Bulk Nanostructured Materials: Fundamentals and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; 456p. [Google Scholar] [CrossRef] [Green Version]

- Rosochowski, A. (Ed.) Severe Plastic Deformation Technology; Whittles Publishing: Edinburgh, UK, 2017; 264p. [Google Scholar]

- Valiev, R.Z.; Semenova, I.P.; Latysh, V.V.; Shcherbakov, A.V.; Yakushina, E.B. Nanostructured titanium for biomedical applications: New developments and challenges for commercialization. Nanotechnol. Russ. 2008, 3, 593–601. [Google Scholar] [CrossRef]

- Zhao, X.; Fu, W.; Yang, X.; Langdon, T.G. Microstructure and properties of pure titanium processed by equal-channel angular pressing at room temperature. Scr. Mater. 2008, 59, 542–545. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Huang, J.Y.; Gubicza, J.; Ungár, T.; Wang, Y.M.; Ma, E.; Valiev, R.Z. Nanostructures in Ti processed by severe plastic deformation. J. Mater. Res. 2003, 18, 1908–1917. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Figueiredo, R.B.; Alhajeri, S.N.; Wang, J.T.; Gao, N.; Langdon, T.G. Structure and mechanical properties of commercial purity titanium processed by ECAP at room temperature. Mater. Sci. Eng. A 2011, 528, 7708–7714. [Google Scholar] [CrossRef]

- Elias, C.N.; Meyers, M.A.; Valiev, R.Z.; Monteiro, S.N. Ultrafine grained titanium for biomedical applications: An overview of performance. J. Mater. Res. Technol. 2013, 2, 340–350. [Google Scholar] [CrossRef] [Green Version]

- Mohammed, M.T. Mechanical and wear properties of HPT-biomedical titanium: A review, J. Biomimetics. Biomater. Biomed. Eng. 2015, 2, 185–196. [Google Scholar] [CrossRef]

- Eroshenko, A.Y.; Sharkeev, Y.P.; Glukhov, I.A.; Uvarkin, P.V.; Mairambekova, A.M.; Tolmachev, A.I. The Influence of Dimesions and Phase State of Structural Elements on Mechanical Properties of Binary Alloys of the Ti-Nb and Zr-Nb Systems. Russ. Phys. J. 2019, 61, 1899–1907. [Google Scholar] [CrossRef]

- Sharkeev, Y.P.; Skripnyak, V.A.; Vavilov, V.P.; Legostaeva, E.V.; Kozulin, A.A.; Chulkov, A.O.; Eroshenko, A.Y.; Belyavskaya, O.A.; Skripnyak, V.V.; Glukhov, I.A. Special Aspects of Microstructure, Deformation and Fracture of Bioinert Zirconium and Titanium-Niobium Alloys in Different Structural States. Russ. Phys. J. 2019, 61, 1718–1725. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Salishchev, G.; Łojkowsk, W. Strengthening of a Ti–6Al–4V titanium alloy by means of hydrostatic extrusion and other methods. Mater. Sci. Eng. A 2009, 515, 43–48. [Google Scholar] [CrossRef]

- Dimić, I.; Cvijović-Alagić, I.; Völker, B.; Hohenwarter, A.; Pippan, R.; Veljović, D.; Rakin, M.; Bugarski, B. Microstructure and metallic ion release of pure titanium and Ti–13Nb–13Zr alloy processed by high pressure torsion. Mater. Des. 2016, 91, 340–347. [Google Scholar] [CrossRef]

- Dinda, G.P.; Rösner, H.; Wilde, G. Synthesis of bulk nanostructured Ni, Ti and Zr by repeated cold—Rolling. Scr. Mater. 2005, 52, 577–582. [Google Scholar] [CrossRef]

- Sharkeev, Y.; Eroshenko, A.; Legostaeva, E.; Kovalevskaya, Z.; Belyavskaya, O.; Khimich, M.; Epple, M.; Prymak, O.; Sokolova, V.; Zhu, Q.; et al. Development of Ultrafine–Grained and Nanostructured Bioinert Alloys Based on Titanium, Zirconium and Niobium and their Microstructure, Mechanical and Biological Properties. Metals 2022, 12, 1136–1158. [Google Scholar] [CrossRef]

- Glezer, A.M.; Kozlov, E.V.; Koneva, N.A.; Popova, N.A.; Kurzina, I.A. Plastic Deformation of Nanostructured Materials; CRC Press: Boca Raton, FL, USA, 2017; 334p. [Google Scholar] [CrossRef]

- Ozaltin, K.; Chrominski, W.; Kulczyk, M.; Panigrahi, A.; Horky, J.; Zehetbauer, M.; Lewandowska, M. Enhancement of mechanical properties of biocompatible Ti–45Nb alloy by hydrostatic extrusion. J. Mater. Sci. 2014, 49, 6930–6936. [Google Scholar] [CrossRef]

- Völker, B.; Jäger, N.; Calin, M.; Zehetbauer, M.; Eckert, J.; Hohenwarter, A. Influence of testing orientation on mechanical properties of Ti45Nb deformed by high pressure torsion. Mater. Des. 2017, 114, 40–46. [Google Scholar] [CrossRef]

- Panigrahi, A.; Bönisch, M.; Waitz, T.; Schafler, E.; Calin, M.; Eckert, J.; Skrotzki, W.; Zehetbauer, M. Phase transformations and mechanical properties of biocompatible Ti–16.1Nb processed by severe plastic deformation. J. Alloys Compd. 2015, 628, 434–441. [Google Scholar] [CrossRef]

- Ma, J.; Karaman, I.; Kockar, B.; Maier, H.J.; Chumlyakov, Y.I. Severe plastic deformation of Ti74Nb26 shape memory alloys. Mater. Sci. Eng. A 2011, 528, 7628–7635. [Google Scholar] [CrossRef]

- Hilarov, V.L.; Slutsker, A.I. Description of the thermoelastic effect in solids in a wide temperature range. Phys. Solid State 2014, 56, 2493–2495. [Google Scholar] [CrossRef]

- Oliferuk, W.; Maj, M.; Zembrzycki, K. Determination of the energy storage rate distribution in the area of strain localization using infrared and visible imaging. Exp. Mech. 2015, 55, 753–760. [Google Scholar] [CrossRef] [Green Version]

- Maj, M.; Oliferuk, W. Analysis of plastic strain localization on the basis of strain and temperature fields. Arch. Metall. Mater. 2012, 57, 1111–1116. [Google Scholar] [CrossRef] [Green Version]

- Vavilov, V. Thermal NDT: Historical milestones, state-of-the-art and trends. J. Quant. InfraRed Therm. 2014, 11, 66–83. [Google Scholar] [CrossRef]

- Plekhov, O.A.; Uvarov, S.V.; Naimark, O.B.; Saintier, N.; Palin-Luc, T. Theoretical analysis, infrared and structural investigation of dissipation energy in metals under cyclic loading. Mater. Sci. Eng. A 2007, 462, 367–369. [Google Scholar] [CrossRef] [Green Version]

- Bagavathiappan, S.; Lahiri, B.B.; Saravanan, T.; Philip, J.; Jayakumar, T. Infrared Thermography for Condition Monitoring—A review. Infrared Phys. Tech. 2013, 60, 35–55. [Google Scholar] [CrossRef]

- Meola, C.; Carlomagno, G.M. Recent advances in the use of infrared thermography—A review. Meas. Sci. Technol. 2004, 15, 27–58. [Google Scholar] [CrossRef]

- Moyseychik, E.A. Heat generation and fracture initiation in stretched steel plate with a process-induced structural defects. J. Appl. Mech. Techn. Phys. 2013, 54, 116–123. [Google Scholar] [CrossRef]

- Pieczyska, E.A.; Maj, M.; Golasiński, K.; Staszczak, M.; Furuta, T.; Kuramoto, S. Thermomechanical studies of yielding and strain localization phenomena of gum metal under tension. Materials 2018, 11, 567–579. [Google Scholar] [CrossRef] [Green Version]

- Plekhov, O.; Naimark, O.; Chudinov, V.; Leont’ev, V. Experimental investigations of the laws of energy dissipation during dynamic deformation of nanocrystalline titanium. Techn. Phys. Lett. 2009, 35, 92–95. [Google Scholar] [CrossRef]

- Oborin, V.A.; Bannikov, M.V.; Naimark, O.B.; Palin-Luc, T. Scaling invariance of fatigue crack growth in gigacycle loading regime. Tech. Phys. Lett. 2010, 36, 1061–1063. [Google Scholar] [CrossRef] [Green Version]

- Naimark, O.B.; Sharkeev, Y.P.; Mairambekova, A.M.; Bannikov, M.V.; Eroshenko, A.Y.; Vedernikova, A.I. Failure mechanisms of titanium VT1−0 and zirconium alloy E110 in ultrafine-grained, fine-grained and coarse-grained states under cyclic loading in gigacycle regime. Lett. Mater. 2018, 8, 317–322. (In Russian) [Google Scholar] [CrossRef] [Green Version]

- Plekhov, O.A.; Panteleev, I.A.; Naimark, O.B. Energy accumulation and dissipation in metals as a result of structural-scaling transitions in a mesodefect ensemble. Phys. Mesomech. 2007, 10, 294–301. [Google Scholar] [CrossRef]

- Moyseychik, E.A.; Vavilov, V.P. Analyzing patterns of heat generated by the tensile loading of steel rods containing discontinuity-like defects. Intern. J. Damage Mech. 2018, 27, 950–960. [Google Scholar] [CrossRef]

- Zhang, H.X.; Wu, G.H.; Yan, Z.F.; Guo, S.F.; Chen, P.D.; Wang, W.X. An experimental analysis of fatigue behavior of AZ31B magnesium alloy welded joint based on infrared thermography. Mater. Des. 2014, 55, 785–791. [Google Scholar] [CrossRef]

- Wang, X.G.; Crupi, V.; Guo, X.L.; Zhao, Y.G. Quantitative thermographic methodology forfatigue assessment and stress measurement. Int. J. Fatigue 2010, 32, 1970–1976. [Google Scholar] [CrossRef]

- Williams, P.; Liakat, M.; Khonsari, M.M.; Kabir, O.M. A thermographic method forremaining fatigue life prediction of welded joints. Mater. Des. 2013, 51, 916–923. [Google Scholar] [CrossRef]

- Fan, J.; Guo, X.; Wu, C. A new application of the infrared thermography for fatigue evaluation and damage assessment. Int. J. Fatigue 2012, 44, 1–7. [Google Scholar] [CrossRef]

- Yan, Z.F.; Xia, Z.H.; Wang, W.X.; Wang, K.; Pei, F.F. Temperature evolution and fatigue life evaluation of AZ31B magnesium alloy based on infrared thermography. PEI Trans. Nonferr. Met. Soc. 2013, 23, 1942–1948. [Google Scholar] [CrossRef]

- Nowak, M.; Maj, M. Determination of coupled mechanical and thermal fields using 2D digital image correlation and infrared thermography. Numerical procedures and results. Arch. Civ. Mech. Eng. 2018, 18, 630–644. [Google Scholar] [CrossRef]

- Sharkeev, Y.; Vavilov, V.; Skripnyak, V.; Belyavskaya, O.; Legostaeva, E.; Kozulin, A.; Sorokoletov, A.; Skripnyak, V.V.; Eroshenko, A.; Kuimova, M. Analyzing the deformation and fracture of bioinert titanium, zirconium and niobium alloys in different structural states by the use of infrared thermography. Metals 2018, 8, 703–717. [Google Scholar] [CrossRef] [Green Version]

- Sharkeev, Y.; Vavilov, V.; Skrypnyak, V.; Legostaeva, E.; Eroshenko, A.Y.; Belyavskaya, O.; Ustinov, A.; Klopotov, A.; Chulkov, A.; Kozulin, A.; et al. Research on the processes of deformation and failure in coarse- and ultrafine-grain states of Zr1–Nb alloys by digital image correlation and infrared thermography. Mater. Sci. Eng. A 2020, 784, 139203. [Google Scholar] [CrossRef]

- ASTM E1382-97; Standard Test Methods for Determining Average Grain Size Using Semiautomatic and Automatic Image Analysis. ANSI: New York, NY, USA, 2010. [CrossRef]

- Colings, E.W. (Ed.) Physical Metallurgy of Titanium Alloys; American Society for Metals: Metals Park, OH, USA, 1984; 261p. [Google Scholar]

- Lai, M.J.; Li, T.; Raabea, D. ω phase acts as a switch between dislocation channeling and joint twinning- and transformation-induced plasticity in a metastable β titanium alloy. Acta Mater. 2018, 151, 67–77. [Google Scholar] [CrossRef]

- Prima, F.; Vermaut, P.; Ansel, D.; Debuigne, J. Omega—Precipitation in a beta metastable titanium alloy, resistometric study. Mater. Trans. JIM 2000, 41, 1092–1097. [Google Scholar] [CrossRef] [Green Version]

- Takemoto, Y.; Hida, M.; Sakakibara, A. Mechanism of omega-alpha transformation in beta-Ti alloy. Trans. Jpn. Inst. Met. 1993, 57, 261–267. [Google Scholar] [CrossRef]

- Prima, F.; Vermaut, P.; Texier, G.; Ansel, D.; Gloriant, T. Evidence of α-nanophase heterogeneous nucleation from ω particles in a β-metastable Ti based alloy by high-resolution electron microscopy. Scr. Mater. 2006, 54, 645–648. [Google Scholar] [CrossRef]

- Koneva, N.A.; Kozlov, E.V.; Trishkina, L.I.; Pekarskaya, E.E. Thermodynamics of substructure transformations under plastic deformation of metals and alloys. Mater. Sci. Eng. A 1997, 234–236, 614–616. [Google Scholar] [CrossRef]

- Murayama, M.; Howe, J.M.; Hidaka, H.; Takaki, S. Atomic-Level Observation of Disclination Dipoles in Mechanically Milled, Nanocrystalline Fe. Science 2002, 29, 2433–2435. [Google Scholar] [CrossRef] [PubMed]

| Materials/State | D, μm | Phase Composition, Type Lattice |

|---|---|---|

| pure Ti (CG state) | 20 | α- phase Ti (hcp-lattice) |

| pure Ti (UFG state) | 0.2 | α- phase Ti (hcp-lattice) |

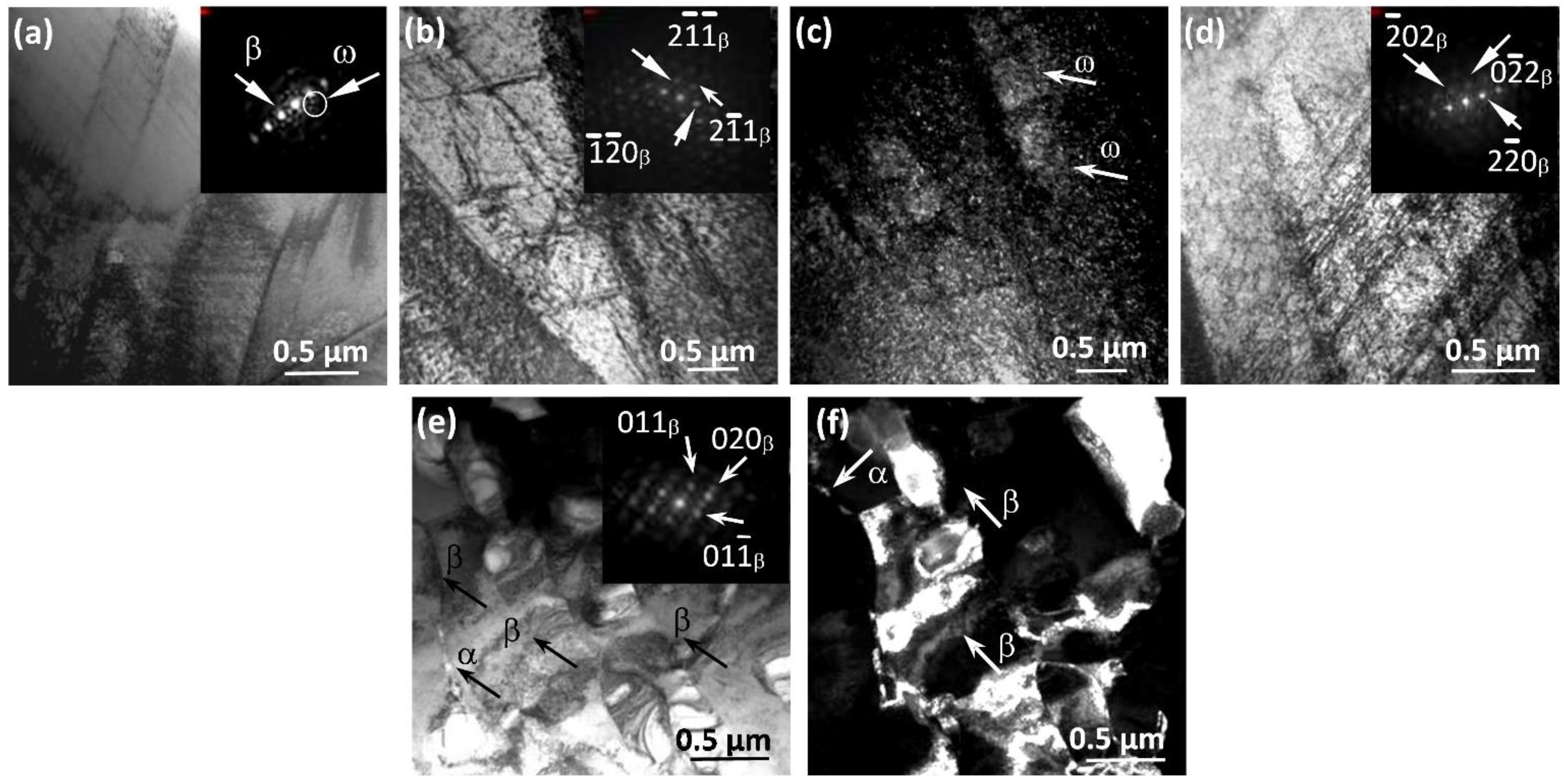

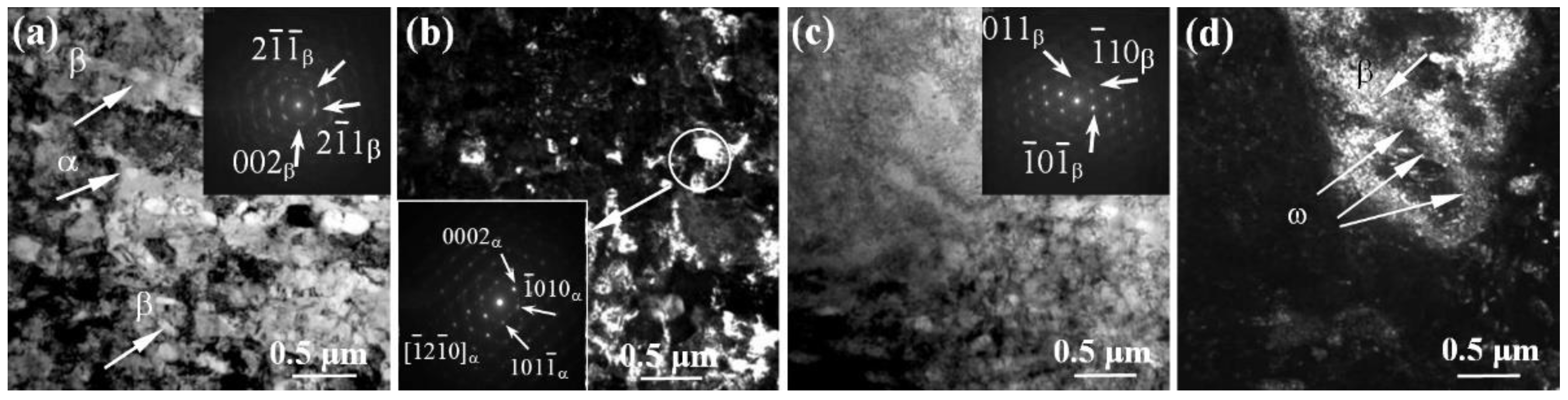

| Ti-45Nb alloy (CG state) | 45 0.015 | β-phase (Ti,Nb) (bcc-lattice) ω-phase Ti (hp-lattice) |

| Ti-45Nb alloy (UFG state) | 0.2 0.015 0.05 | β-phase (Ti,Nb) (bcc-lattice) ω-phase Ti (hp-lattice) α-phase Ti (hcp-lattice) |

| Materials | Ap, MJ/m3 | Q, MJ/m3 | Es, MJ/m3 |

|---|---|---|---|

| pure Ti (CG state) | 110 | 57 | 53 |

| pure Ti (UFG state) | 85 | 60 | 25 |

| Ti-45Nb alloy (CG state) | 95 | 40 | 55 |

| Ti-45Nb alloy (UFG state) | 48 | 32 | 16 |

| Materials/State | Pure Ti CG State | Ti UFG State | Ti-45Nb Alloy CG State | Ti-45Nb Alloy UFG State |

|---|---|---|---|---|

| Type of substructure | band structure cellular-network dislocation substructure | band structure cellular-network dislocation substructure anisotropic fragments | band structure cellular-network dislocation substructure fragmented structure | fragmented structure cellular-network dislocation substructure anisotropic fragments |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Legostaeva, E.; Eroshenko, A.; Vavilov, V.; Skripnyak, V.A.; Chulkov, A.; Kozulin, A.; Skripnyak, V.V.; Glukhov, I.; Sharkeev, Y. Comparative Investigation of the Influence of Ultrafine-Grained State on Deformation and Temperature Behavior and Microstructure Formed during Quasi-Static Tension of Pure Titanium and Ti-45Nb Alloy by Means of Infrared Thermography. Materials 2022, 15, 8480. https://doi.org/10.3390/ma15238480

Legostaeva E, Eroshenko A, Vavilov V, Skripnyak VA, Chulkov A, Kozulin A, Skripnyak VV, Glukhov I, Sharkeev Y. Comparative Investigation of the Influence of Ultrafine-Grained State on Deformation and Temperature Behavior and Microstructure Formed during Quasi-Static Tension of Pure Titanium and Ti-45Nb Alloy by Means of Infrared Thermography. Materials. 2022; 15(23):8480. https://doi.org/10.3390/ma15238480

Chicago/Turabian StyleLegostaeva, Elena, Anna Eroshenko, Vladimir Vavilov, Vladimir A. Skripnyak, Arsenii Chulkov, Alexander Kozulin, Vladimir V. Skripnyak, Ivan Glukhov, and Yurii Sharkeev. 2022. "Comparative Investigation of the Influence of Ultrafine-Grained State on Deformation and Temperature Behavior and Microstructure Formed during Quasi-Static Tension of Pure Titanium and Ti-45Nb Alloy by Means of Infrared Thermography" Materials 15, no. 23: 8480. https://doi.org/10.3390/ma15238480

APA StyleLegostaeva, E., Eroshenko, A., Vavilov, V., Skripnyak, V. A., Chulkov, A., Kozulin, A., Skripnyak, V. V., Glukhov, I., & Sharkeev, Y. (2022). Comparative Investigation of the Influence of Ultrafine-Grained State on Deformation and Temperature Behavior and Microstructure Formed during Quasi-Static Tension of Pure Titanium and Ti-45Nb Alloy by Means of Infrared Thermography. Materials, 15(23), 8480. https://doi.org/10.3390/ma15238480