Microstructure Sensitivity on Environmental Embrittlement of a High Nb Containing TiAl Alloy under Different Atmospheres

Abstract

1. Introduction

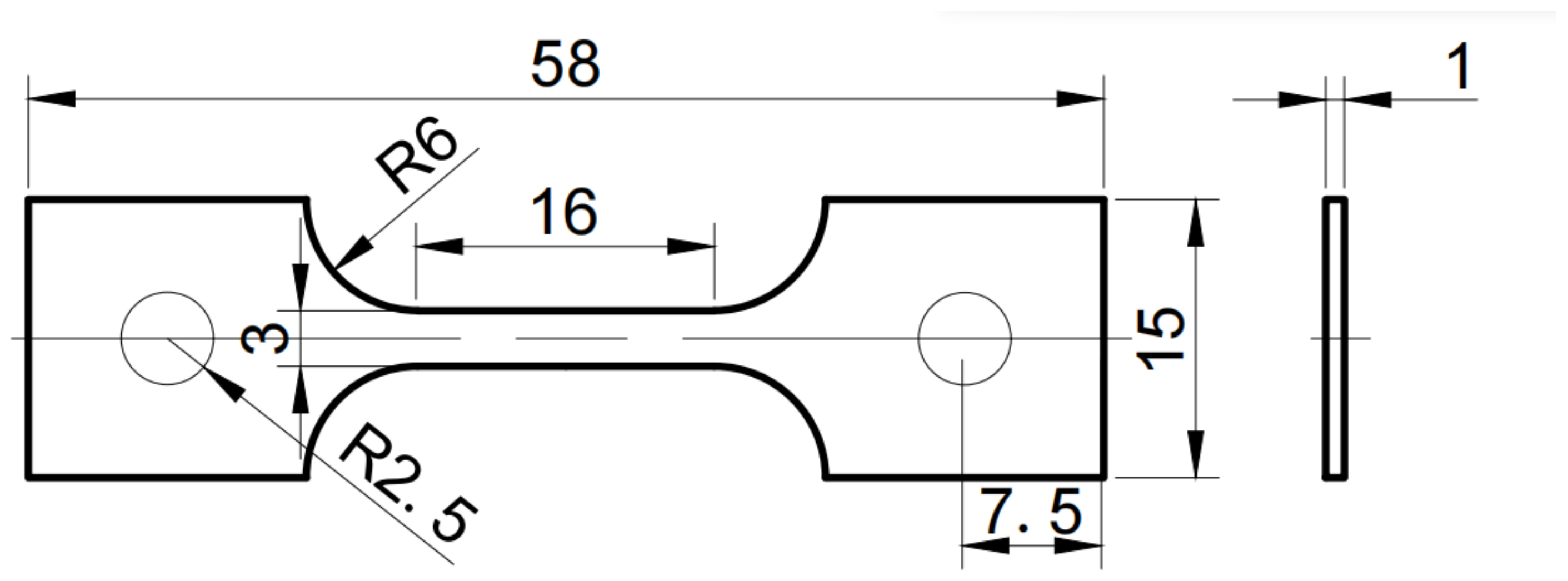

2. Experimental Procedures

3. Results

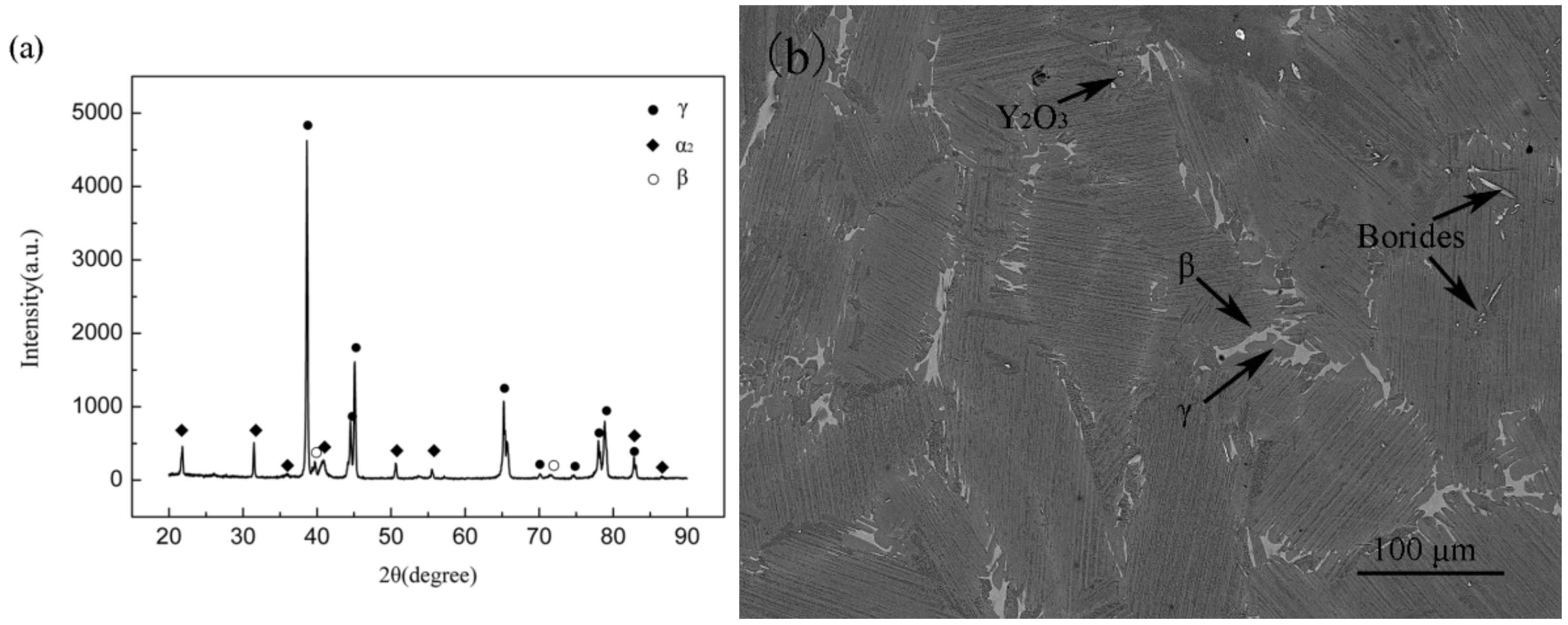

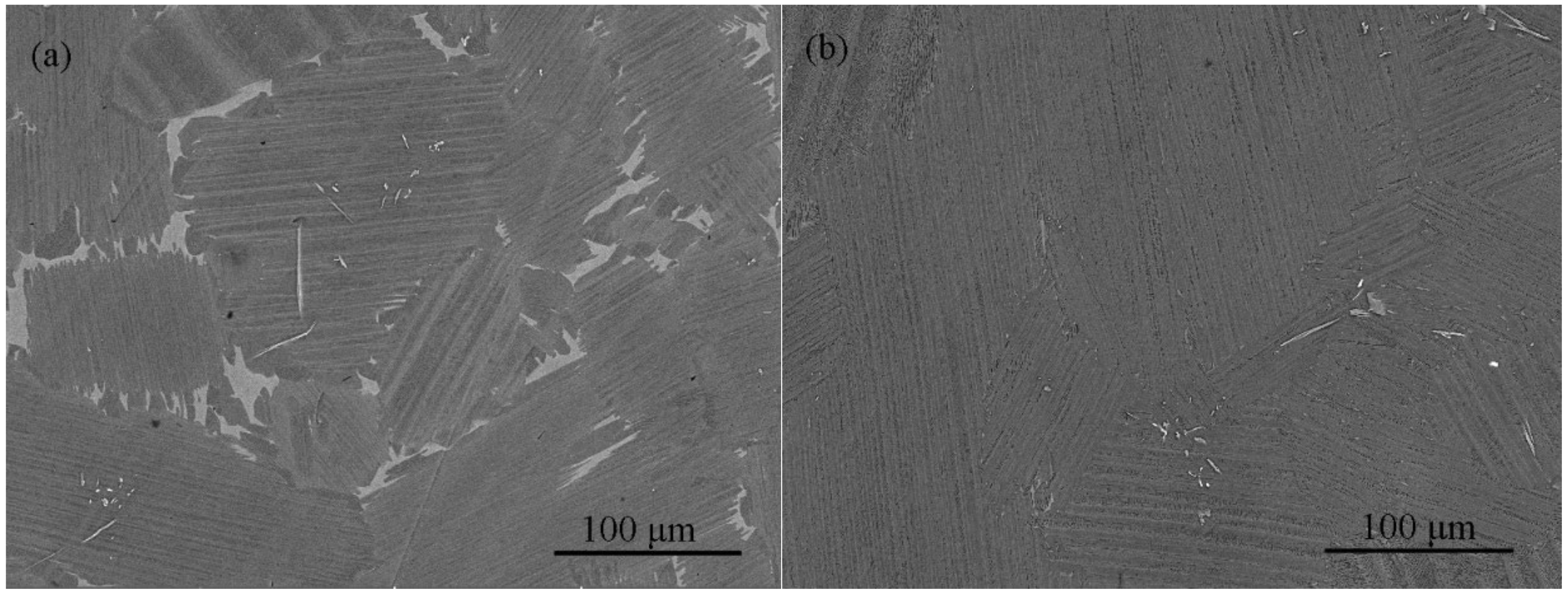

3.1. Phase Composition and Microstructure Evolution

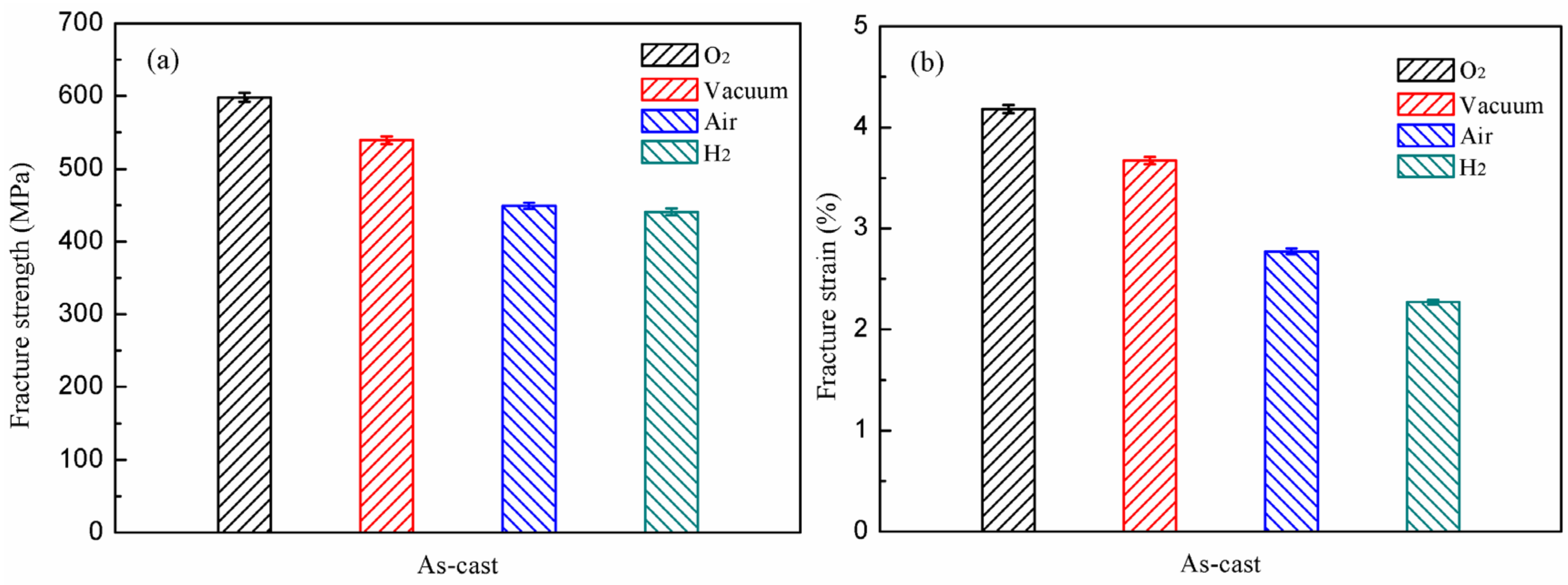

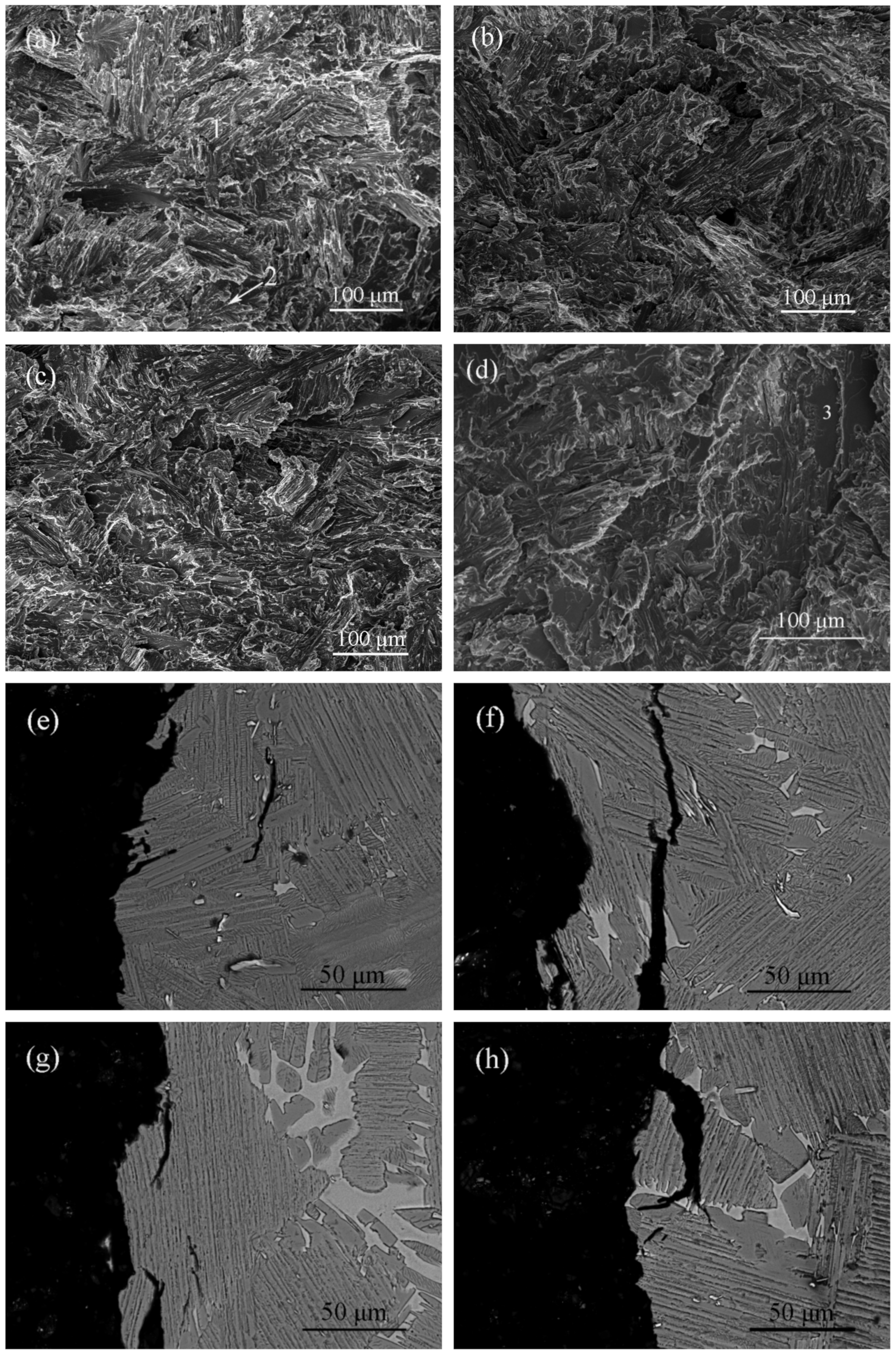

3.2. Mechanical Properties and Fracture Feature of the As–Cast Alloy

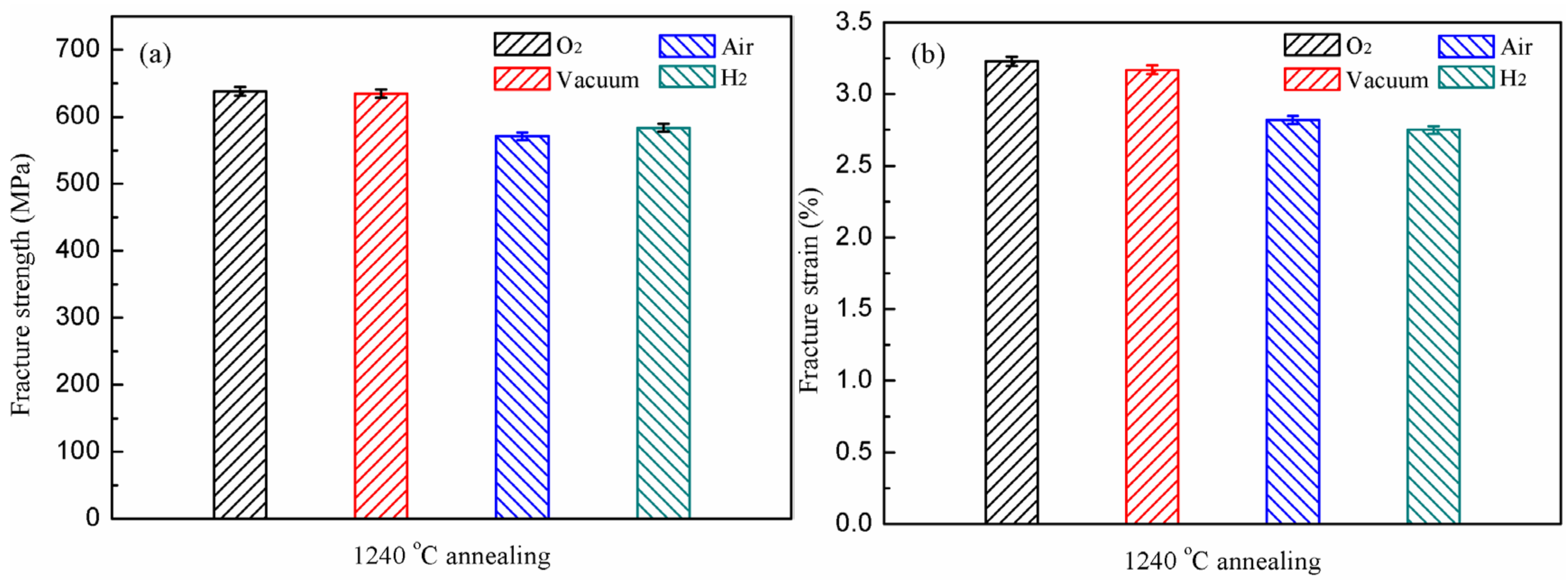

3.3. Mechanical Properties and Fracture Feature of the Alloy Annealed at 1240 °C

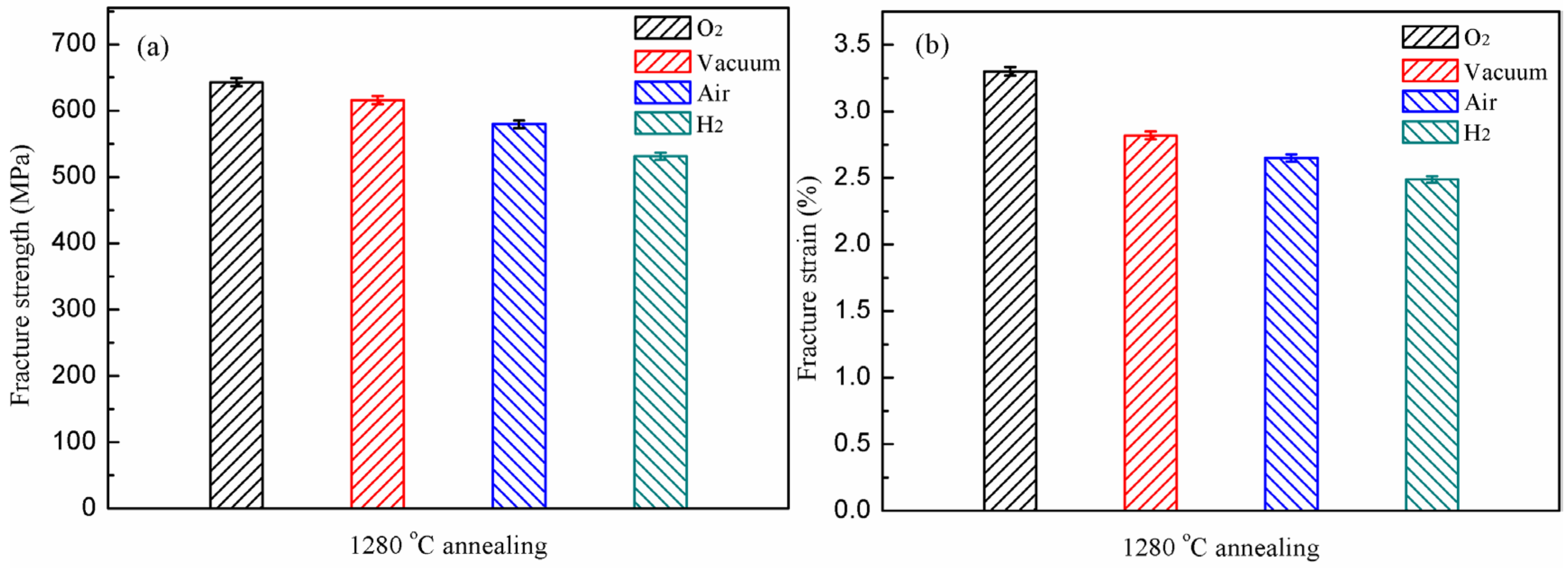

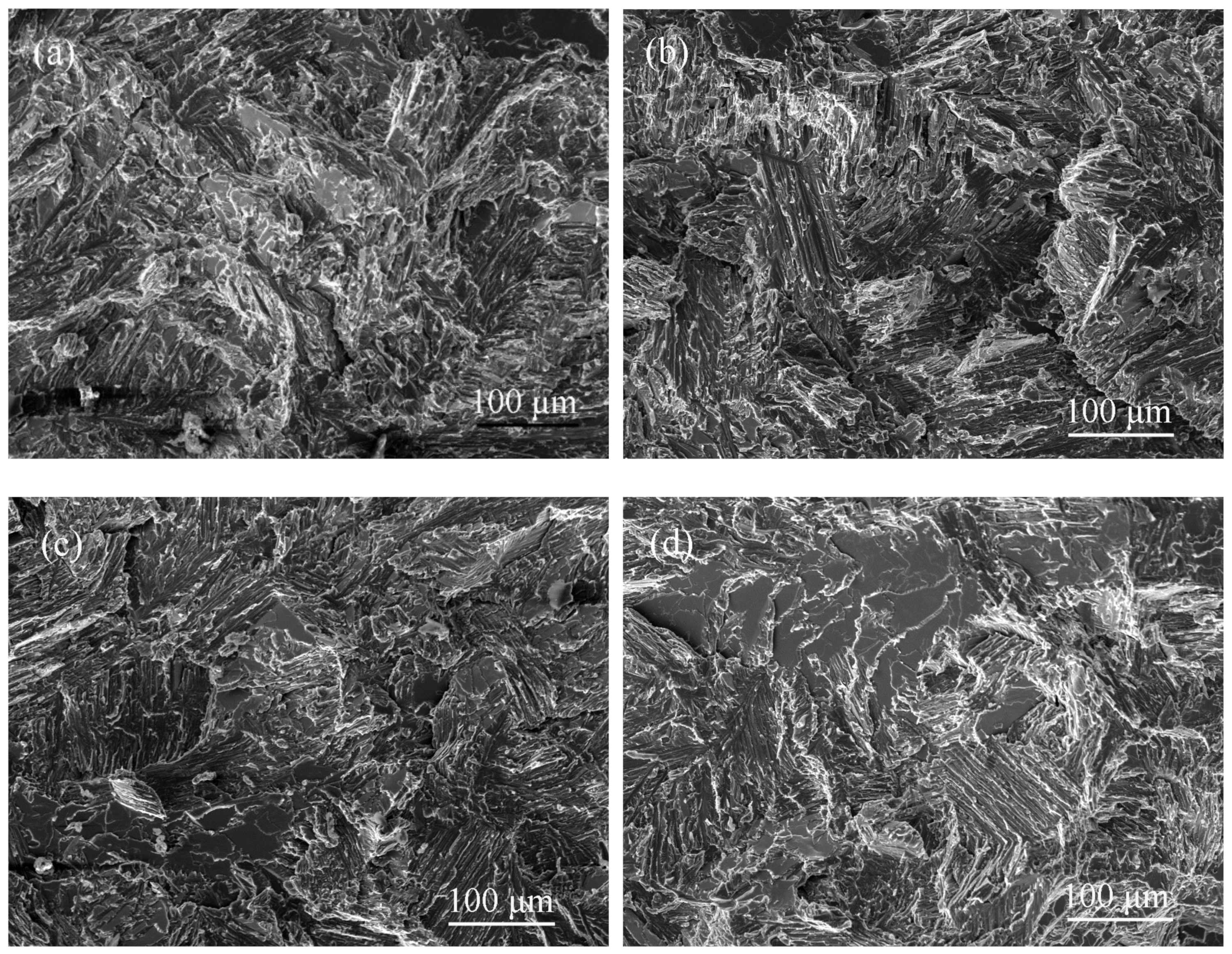

3.4. Mechanical Properties and Fracture Features of the Alloy Annealed at 1280 °C

4. Discussion

5. Conclusions

- (1)

- The mechanical properties of all the three microstructure types show a gradual declining trend in the four environmental atmospheres, indicating that each microstructure can be affected by environmental embrittlement. The γ phase increased nearly lamellar microstructure is the most resistant to hydrogen–induced environmental embrittlement. The as–cast alloy is the most susceptible to environmental embrittlement. In addition, the fully lamellar microstructure results in moderate susceptibility to hydrogen–induced environmental embrittlement.

- (2)

- The fracture modes of the three microstructure types in the four atmospheres have not changed. However, although the transgranular fracture is dominant, the proportion of intergranular fractures increases in air and hydrogen. It indicates that hydrogen embrittlement mainly acts on the intergranular fracture, which reduces the bonding force between the lamellar colonies, resulting in the low ductility of the alloy.

- (3)

- Hydrogen–induced environmental embrittlement is very sensitive to γ and β phases existing at the interface of the lamellar colonies for the experimental alloy. The γ phase can inhibit the hydrogen–induced environmental embrittlement, while β phase is just the opposite. It is disclosed in the present study that an appropriate amount of blockish shape γ phase and as little β phase as possible in high Nb containing TiAl alloy is one of the key factors for creating the alloy with maximum environmental embrittlement resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Petrik, M.; Razumov, I.; Gornostyrev, Y.; Naschetnikova, I.; Popov, A. Kinetics of ordering and decomposition in Ti-Al-X (X = Si, Zr) alloys: Monte Carlo Modeling. Materials 2022, 15, 5722. [Google Scholar] [CrossRef]

- Lim, H.; Liew, W.; Melvin, G.; Jiang, Z. A short review on the phase structures, oxidation kinetics, and mechanical properties of complex Ti-Al Alloys. Materials 2021, 14, 1677. [Google Scholar] [CrossRef]

- Saha, M. A brief discussion on the tensile creep deformation behaviour of wrought single-phase γ-TiAl. Mater. Today Proc. 2021, 46, 3187–3192. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, D.; Zhu, J.; Xiao, H.; Liu, C.; Wang, Y. Non-conventional transformation pathways and ultrafine lamellar structures in γ-TiAl alloys. Acta Mater. 2020, 189, 25–34. [Google Scholar] [CrossRef]

- Lasalmonie, A. Intermetallics: Why is it so difficult to introduce them in gas turbine engines? Intermetallics 2006, 14, 1123–1129. [Google Scholar] [CrossRef]

- Kothari, K.; Radhakrishnan, R.; Wereley, N. Advances in gamma titanium aluminides and their manufacturing techniques. Prog. Aerosp. Sci. 2012, 55, 1–16. [Google Scholar] [CrossRef]

- Loria, E. Gamma titanium aluminides as prospective structural materials. Intermetallics 2000, 8, 1339–1345. [Google Scholar] [CrossRef]

- Hamada, S.; Hamada, H.; Suzuki, H. Microstructure and environment—Dependent fatigue crack propagation properties of Ti-48Al intermetallics. J. Mater. Sci 2002, 37, 1107–1113. [Google Scholar] [CrossRef]

- Youn, S.; Kim, Y.; Kim, S.; Lee, K. Elevated temperature compressive deformation behaviors of γ-TiAl-based Ti-48Al-2Cr-2Nb alloy additively manufactured by electron beam melting. Intermetallics 2020, 124, 106859. [Google Scholar] [CrossRef]

- Zhou, H.; Kong, F.; Wang, Y.; Hou, X.; Cui, N.; Sun, J. Deformation and Phase Transformation of Disordered α Phase in the (α + γ) Two-Phase Region of a High-Nb TiAl Alloy. Materials 2021, 14, 4817. [Google Scholar] [CrossRef]

- Knaislová, A.; Novák, P.; Linhart, J.; Szurman, I.; Skotnicová, K.; Juřica, J.; Čegan, T. Structure and Properties of Cast Ti-Al-Si Alloys. Materials 2021, 14, 813. [Google Scholar] [CrossRef] [PubMed]

- Małecka, J. Resistance to High-Temperature Oxidation of Ti-Al-Nb Alloys. Materials 2022, 15, 2137. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Xu, X.; Teng, Z.; Wang, Y.; Lin, J. Microsegregation in high Nb containing TiAl alloy ingots beyond laboratory scale. Intermetallics 2007, 15, 625–631. [Google Scholar] [CrossRef]

- Song, L.; Appel, F.; Wang, L.; Oehring, M.; Hu, X.; Stark, A.; He, J.; Lorenz, U.; Zhang, T.; Lin, J. New insights into high-temperature deformation and phase transformation mechanisms of lamellar structures in high Nb-containing TiAl alloys. Acta Mater. 2020, 186, 575–586. [Google Scholar] [CrossRef]

- Appel, F.; Clemens, H.; Fischer, F. Modeling concepts for intermetallic titanium aluminides. Prog. Mater. Sci. 2016, 81, 55–124. [Google Scholar] [CrossRef]

- Huang, Z.; Cong, T. Microstructural instability and embrittlement behaviour of an Al-lean, high-Nb γ-TiAl-based alloy subjected to a long-term thermal exposure in air. Intermetallics 2010, 18, 161–172. [Google Scholar] [CrossRef]

- Wu, Z.; Hu, R.; Zhang, T.; Zhou, H.; Li, J. Moisture induced environmental embrittlement of a high Nb containing TiAl alloy. Mater. Sci. Eng. A 2017, 701, 214–220. [Google Scholar] [CrossRef]

- Hotta, Y.; Kaneno, Y.; Takasugi, T.; Tetsui, T. High-temperature environmental embrittlement of thermomechanically processed TiAl-based intermetallic alloys. Metall. Mater. Trans. A 2006, 37, 361–369. [Google Scholar] [CrossRef]

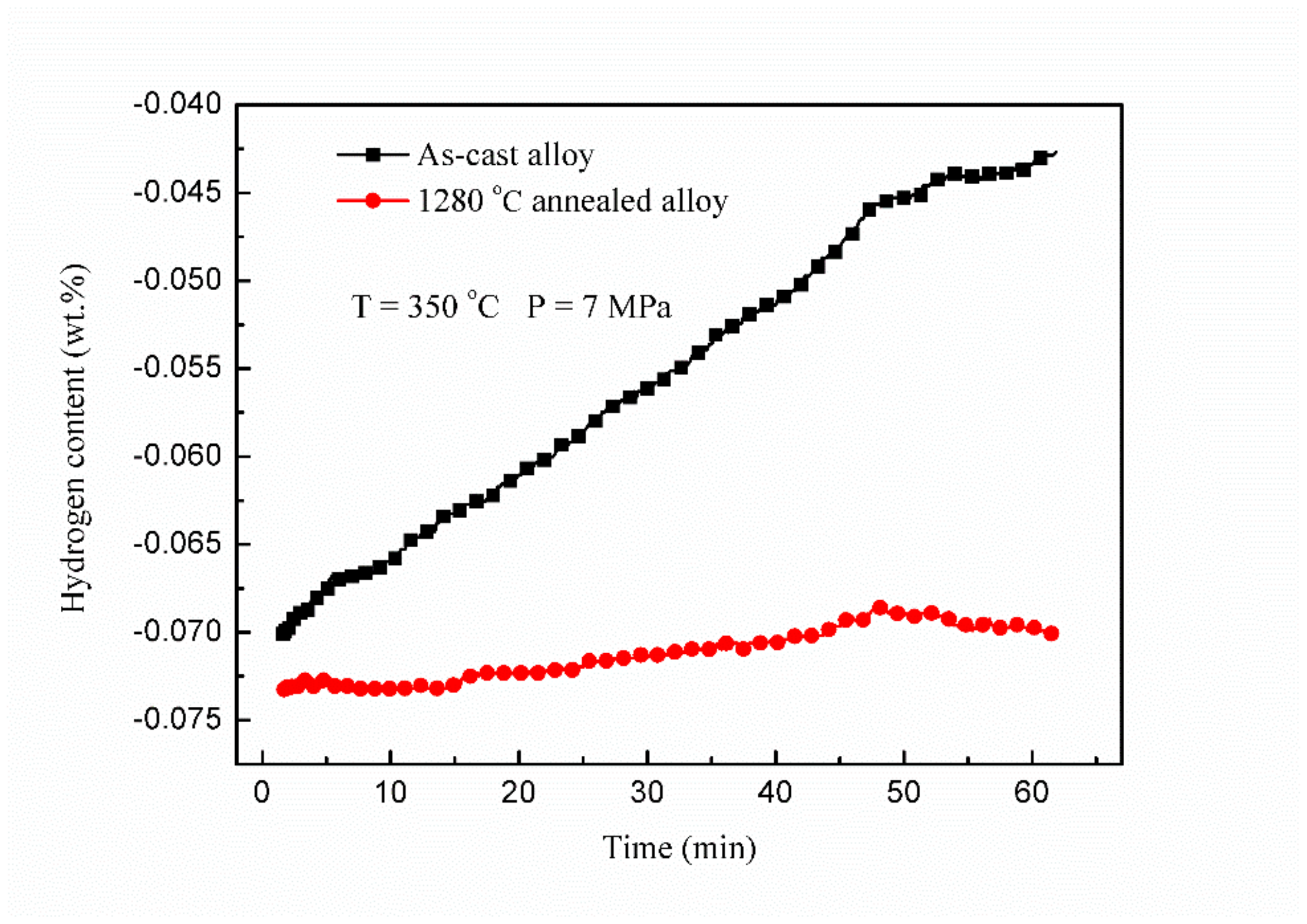

- Chen, R.; Ma, T.; Sun, Z.; Guo, J.; Ding, H.; Su, Y.; Fu, H. The hydrogen absorption behavior of high Nb contained titanium aluminides under high pressure and temperature. Int. J. Hydrogen Energy 2016, 41, 13254–13260. [Google Scholar] [CrossRef]

- Gao, K.; Nakamura, M. Effect of hydrogen on tensile properties of Ti-49at.%Al alloy. Scr. Mater. 2000, 43, 135–140. [Google Scholar] [CrossRef]

- Tsuyumu, T.; Kaneno, Y.; Inoue, H.; Takasugi, T. Microstructural effects on moisture-induced embrittlement of isothermally forged TiAl-based intermetallic alloys. Metall. Mater. Trans. A 2003, 34, 645–655. [Google Scholar] [CrossRef]

- Liu, C.; George, E. Environmental embrittlement in boron-free and boron-doped FeAl (40 at. % Al) alloys. Scr. Metall. Mater. 1990, 24, 1285–1290. [Google Scholar] [CrossRef]

- McKamey, C.; Liu, C. Chromium addition and environmental embrittlement in Fe3Al. Scr. Metall. Mater. 1990, 24, 2119–2122. [Google Scholar] [CrossRef]

- Chen, Y.; Haley, D.; Gerstl, S.; London, A.; Sweeney, F.; Wepf, R.; Rainforth, W.; Bagot, P.; Moody, M. Direct observation of individual hydrogen atoms at trapping sites in a ferritic steel. Science 2017, 355, 1196. [Google Scholar] [CrossRef]

- Witusiewicz, V.; Bondar, A.; Hecht, U.; Velikanova, T. The Al-B-Nb-Ti system: IV. Experimental study and thermodynamic re-evaluation of the binary Al-Nb and ternary Al-Nb-Ti systems. J. Alloy. Compd. 2009, 472, 133–161. [Google Scholar] [CrossRef]

- McCusker, L.; Von Dreele, R.; Cox, D.; Louer, D.; Scardi, P. Rietveld refinement guidelines. J. Appl. Crystallogr. 1999, 32, 36–50. [Google Scholar] [CrossRef]

- Hao, Y.; Yang, R.; Cui, Y.; Li, D. The effect of Ti/Al ratio on the site occupancies of alloying elements in γ-TiAl. Intermetallics 2000, 8, 633–636. [Google Scholar] [CrossRef]

- Jin, Y.; Wang, J.; Yang, J.; Wang, Y. Microstructure refinement of cast TiAl alloys by [beta] solidification. Scr. Mater. 2004, 51, 113–117. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, Processing, Microstructure, Properties, and Applications of Advanced Intermetallic TiAl Alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Takasugi, T.; Misawa, T.; Saitoh, H. Effect of hydrogen—Solute interaction on the environmental embrittlement of ordered intermetallics. Mater. Sci. Eng. A 1995, 192–193, 413–419. [Google Scholar] [CrossRef]

- Lee, K.; Lukowski, J.; White, C. Effects of gaseous hydrogen and water vapor pressure on environmental embrittlement of Ni3Al. Intermetallics 1997, 5, 483–490. [Google Scholar] [CrossRef]

- Maurice, V.; Noumet, A.; Zanna, S.; Josso, P.; Bacos, M.; Marcus, P. Dual surface and bulk control by Nb of the penetration of environmental elements in TiAl intermetallic alloys. Act. Mater. 2008, 56, 3963–3968. [Google Scholar] [CrossRef]

- Barnoush, A.; Vehoff, H. Recent developments in the study of hydrogen embrittlement: Hydrogen effect on dislocation nucleation. Acta Mater. 2010, 58, 5274–5285. [Google Scholar] [CrossRef]

- Takasaki, A.; Furuya, Y. Mechanical alloying of the Ti-Al system in atmosphere of hydrogen and argon. Nanostructured Mater. 1999, 11, 1205–1217. [Google Scholar] [CrossRef]

- Yoshioka, M.; Ueno, A.; Kishimoto, H. Analysis of hydrogen behaviour in crack growth tests of γ-TiAl by means of the hydrogen microprint technique. Intermetallics 2004, 12, 23–31. [Google Scholar] [CrossRef]

- Hénaff, G.; Odemer, G.; Tonneau-Morel, A. Environmentally-assisted fatigue crack growth mechanisms in advanced materials for aerospace applications. Int. J. Fatigue 2007, 29, 1927–1940. [Google Scholar] [CrossRef]

- Nakamura, M.; Abe, E.; Gao, K.; Qiao, L.; Chu, W. Tensile Properties of TiAl Based Alloy in a Gaseous Hydrogen Atmosphere in a Temperature Range from Room Temperature to 973 K. ISIJ Int. 2003, 43, 489–495. [Google Scholar] [CrossRef]

- Iino, Y.; Gao, K.; Okamura, K.; Qiao, L.; Chu, W. Effects of high-temperature hydrogen exposure on room temperature tensile properties and fatigue crack growth behaviour of TiAl base alloy. Mater. Sci. Eng. A 2002, 338, 54–59. [Google Scholar] [CrossRef]

- Kim, S.; Lee, Y. Effect of microstructure on environmental embrittlement in a TiAl base alloy. Met. Mater. 1998, 4, 47–51. [Google Scholar] [CrossRef]

- Wang, J.; Gong, H. Adsorption and diffusion of hydrogen on Ti, Al, and TiAl surfaces. Int. J. Hydrogen Energy 2014, 39, 6068–6075. [Google Scholar] [CrossRef]

| Phases | Ti | Al | Nb | W | B | Y | O |

|---|---|---|---|---|---|---|---|

| β | 51.85 | 33.98 | 13.41 | 0.75 | _ | _ | _ |

| Boride | 24.53 | 7.12 | 9.24 | 0.54 | 58.58 | _ | _ |

| Yttrium oxide | 20.9 | 17.08 | _ | _ | _ | 14.65 | 47.37 |

| Specimen | Heat Treatment | Tested Environment | Tensile Properties | Main Metallografic Findings | ||

|---|---|---|---|---|---|---|

| Fracture Strength (MPa) | εf (%) | Fracture Type | Fracture Mode | |||

| 1, 2, 3 | As-cast | O2 | 598.4 | 4.18 | Cleavage fracture | Transgranular fracture (predominant) Intergranular fracture (secondary feature) |

| 4, 5, 6 | As-cast | Vacuum | 539.6 | 3.67 | Cleavage fracture | Transgranular fracture (predominant) Intergranular fracture (slightly increased) |

| 7, 8, 9 | As-cast | Air | 499.1 | 2.77 | Cleavage fracture | Transgranular fracture (predominant) Intergranular fracture (increase in proportion) |

| 10, 11, 12 | As-cast | H2 | 441.0 | 2.27 | Cleavage fracture | Mix of inter–and trans–lamellar fracture |

| Specimen | Heat Treatment | Tested Environment | Tensile Properties | Main Metallografic Findings | ||

|---|---|---|---|---|---|---|

| Fracture Strength (MPa) | εf (%) | Fracture Type | Fracture Mode | |||

| 1, 2, 3 | Annealed at 1240 °C | O2 | 637.8 | 3.23 | Cleavage fracture | Transgranular fracture (predominant) Intergranular fracture (secondary feature) |

| 4, 5, 6 | Annealed at 1240 °C | Vacuum | 634.7 | 3.17 | Cleavage fracture | Transgranular fracture (predominant) Intergranular fracture (secondary feature) |

| 7, 8, 9 | Annealed at 1240 °C | Air | 571.2 | 2.82 | Cleavage fracture | Transgranular fracture (predominant) Intergranular fracture (slightly increased) |

| 10, 11, 12 | Annealed at 1240 °C | H2 | 583.8 | 2.75 | Cleavage fracture | Transgranular fracture (predominant) Intergranular fracture (slightly increased) |

| Specimen | Heat Treatment | Tested Environment | Tensile Properties | Main Metallografic Findings | ||

|---|---|---|---|---|---|---|

| Fracture Strength (MPa) | εf (%) | Fracture Type | Fracture Mode | |||

| 1, 2, 3 | Annealed at 1280 °C | O2 | 642.8 | 3.30 | Cleavage fracture | Transgranular fracture (predominant) Intergranular fracture (secondary feature) |

| 4, 5, 6 | Annealed at 1280 °C | Vacuum | 616.1 | 2.82 | Cleavage fracture | Transgranular fracture (predominant) Intergranular fracture (slightly increased) |

| 7, 8, 9 | Annealed at 1280 °C | Air | 579.5 | 2.65 | Cleavage fracture | Transgranular fracture (predominant) Intergranular fracture (increase in proportion) |

| 10, 11, 12 | Annealed at 1280 °C | H2 | 531.1 | 2.49 | Cleavage fracture | Mix of inter–and trans–lamellar fracture |

| Material Condition | The Performance Degradation of Fracture Strength (%) | The Performance Degradation of εf (%) |

|---|---|---|

| As-cast | 26.3 | 45.7 |

| 1240 °C | 8.5 | 14.9 |

| 1280 °C | 17.4 | 24.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, F.; Wu, Z.; Zhang, T.; Hu, R.; Wang, X. Microstructure Sensitivity on Environmental Embrittlement of a High Nb Containing TiAl Alloy under Different Atmospheres. Materials 2022, 15, 8508. https://doi.org/10.3390/ma15238508

Zhang F, Wu Z, Zhang T, Hu R, Wang X. Microstructure Sensitivity on Environmental Embrittlement of a High Nb Containing TiAl Alloy under Different Atmospheres. Materials. 2022; 15(23):8508. https://doi.org/10.3390/ma15238508

Chicago/Turabian StyleZhang, Fan, Zeen Wu, Tiebang Zhang, Rui Hu, and Xiaoye Wang. 2022. "Microstructure Sensitivity on Environmental Embrittlement of a High Nb Containing TiAl Alloy under Different Atmospheres" Materials 15, no. 23: 8508. https://doi.org/10.3390/ma15238508

APA StyleZhang, F., Wu, Z., Zhang, T., Hu, R., & Wang, X. (2022). Microstructure Sensitivity on Environmental Embrittlement of a High Nb Containing TiAl Alloy under Different Atmospheres. Materials, 15(23), 8508. https://doi.org/10.3390/ma15238508