Dry Wear Behaviour of the New ZK60/AlN/SiC Particle Reinforced Composites

Abstract

:1. Introduction

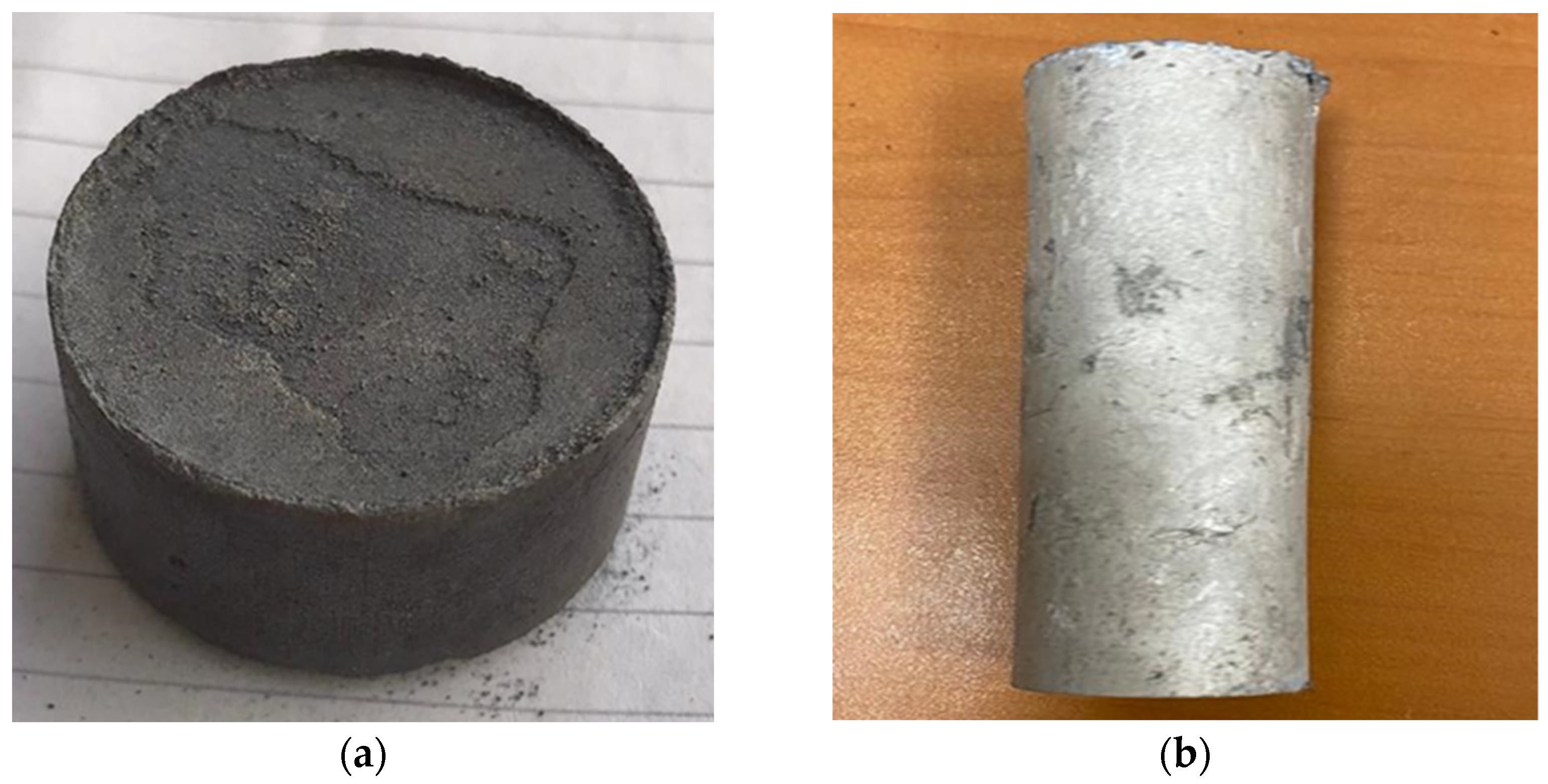

2. Experimental Procedure

3. Results and Discussion

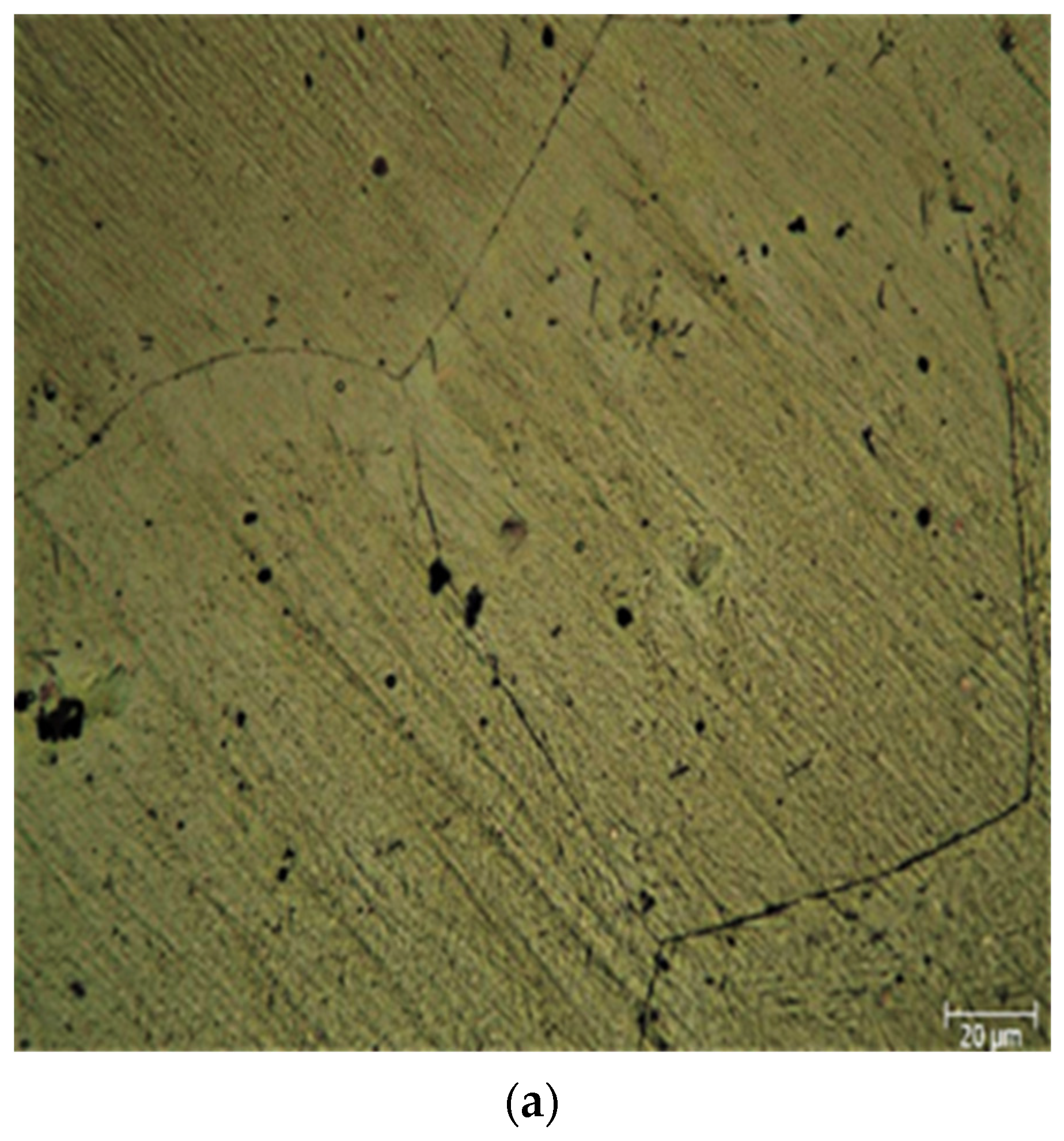

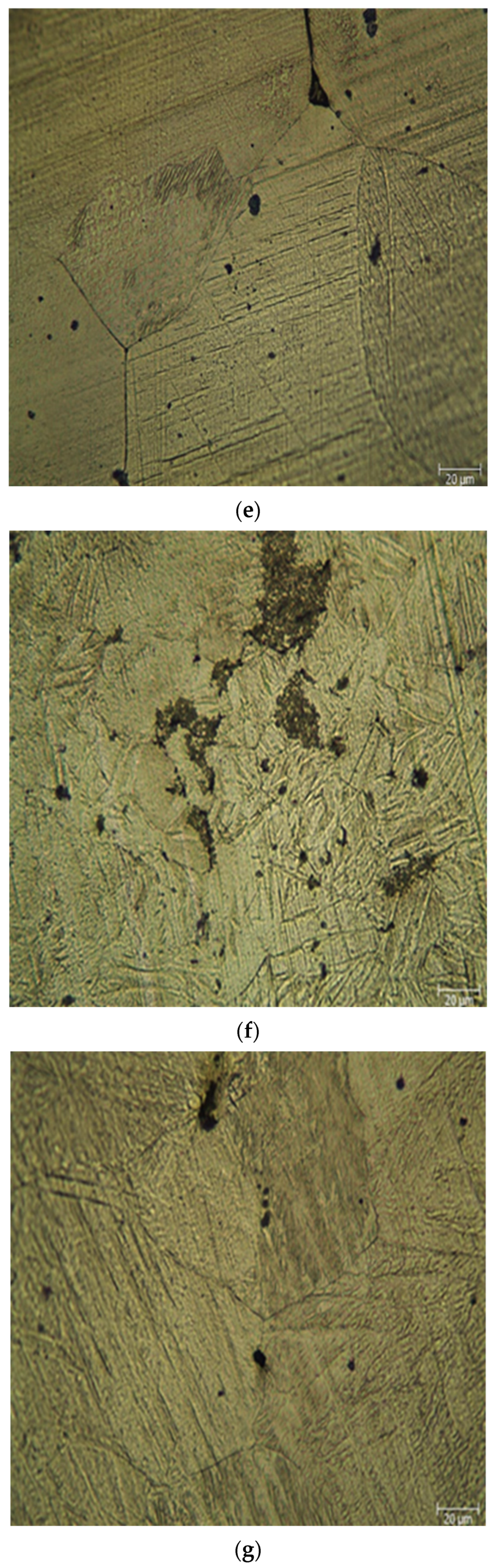

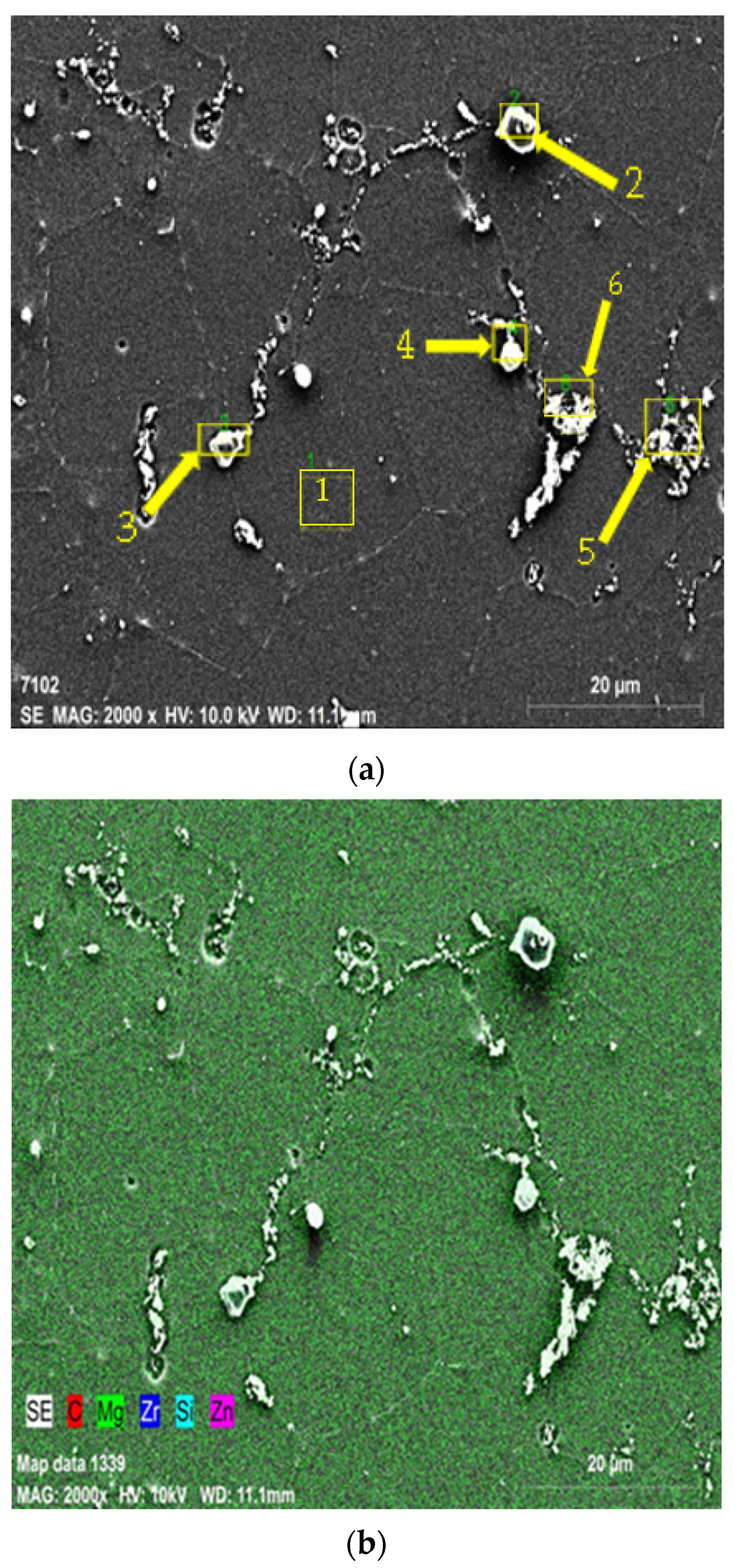

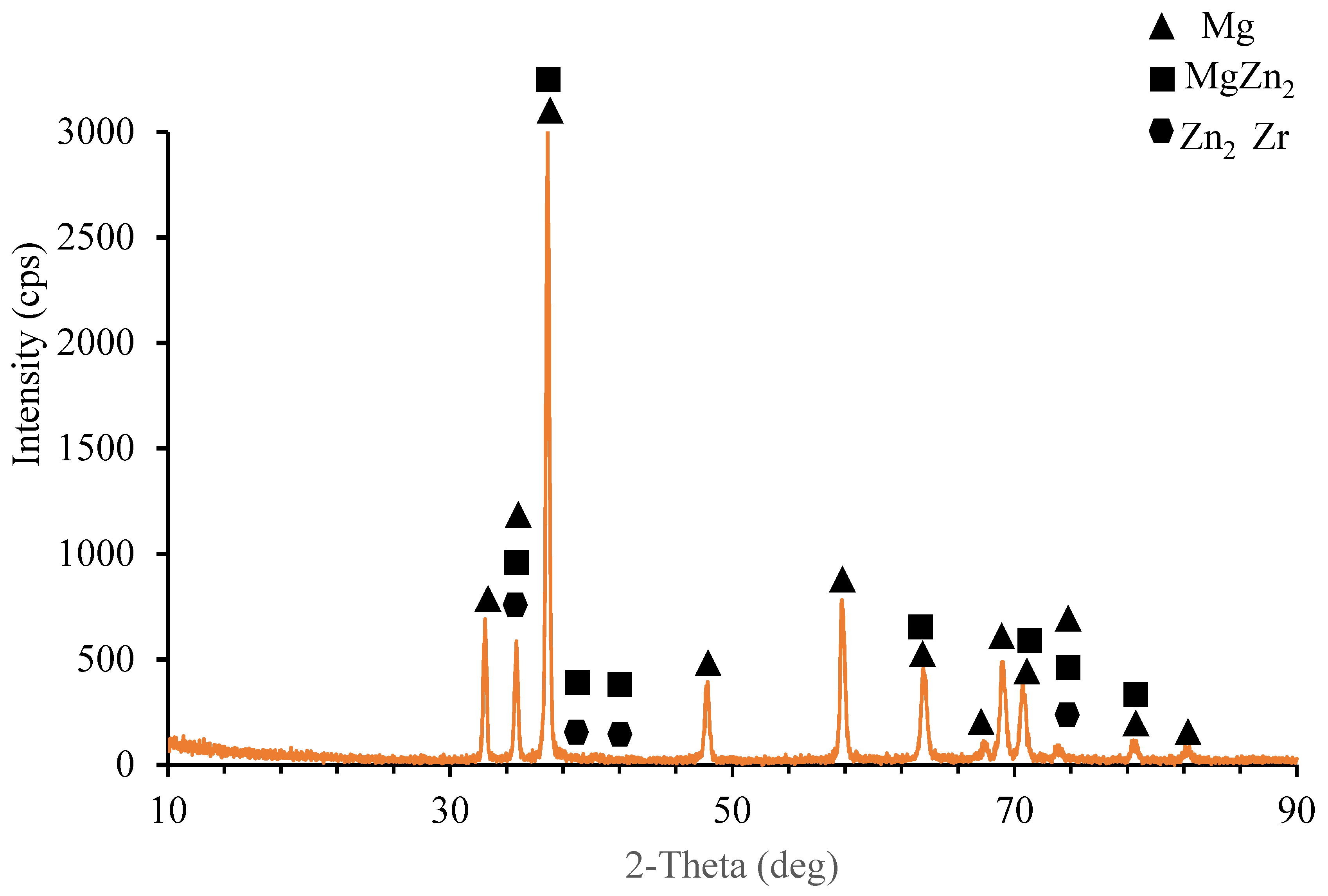

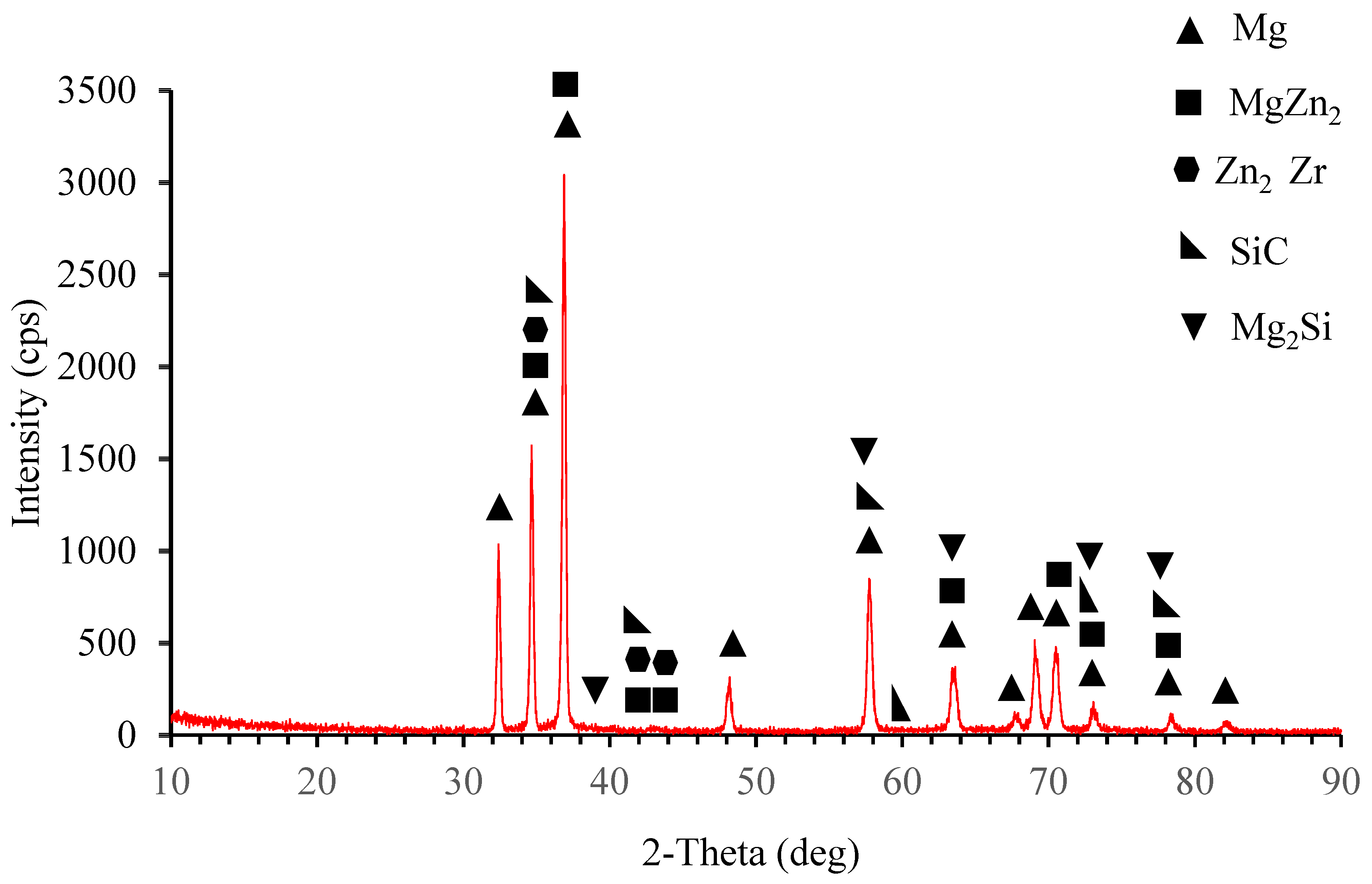

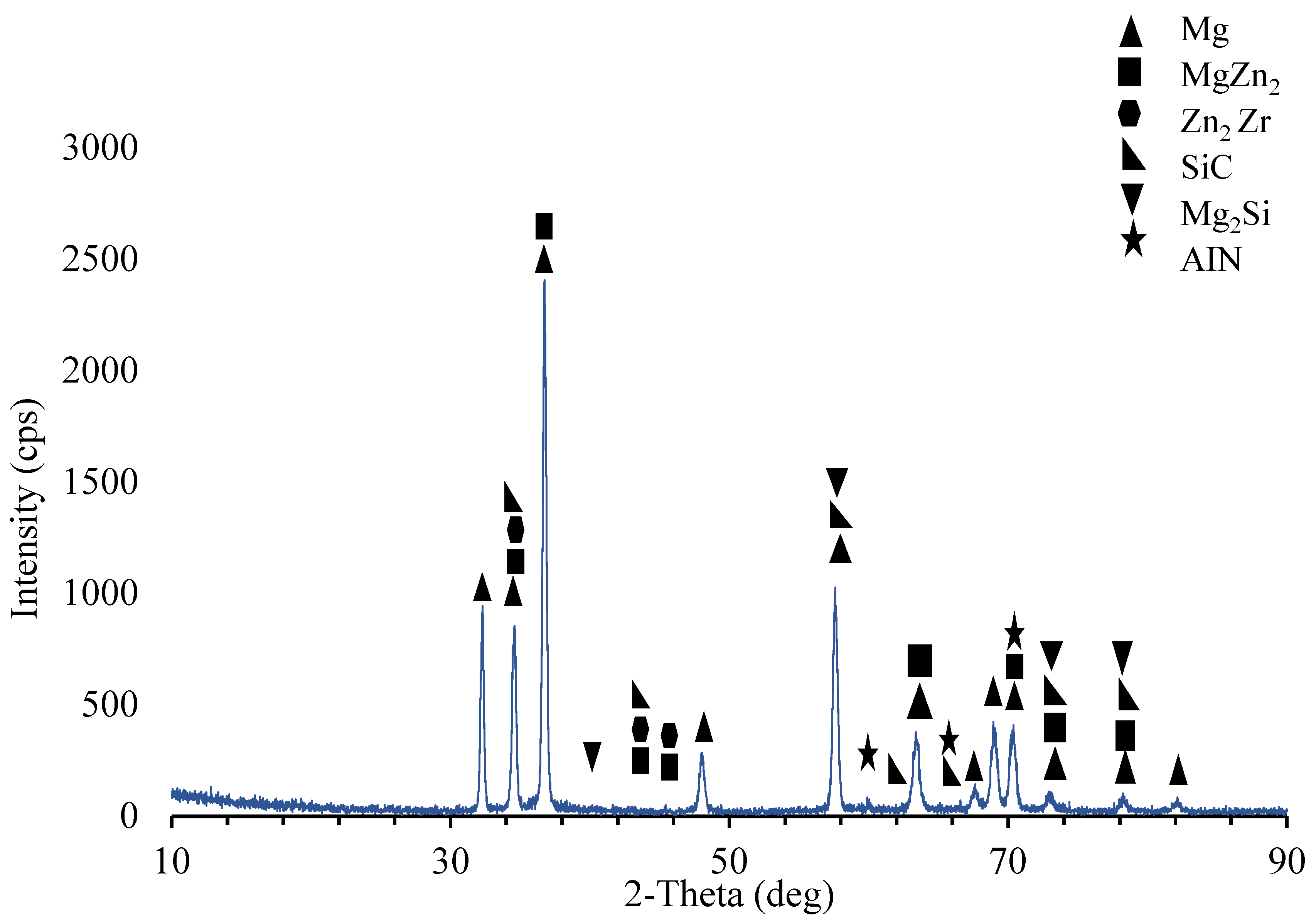

3.1. Microstructural Characterisation

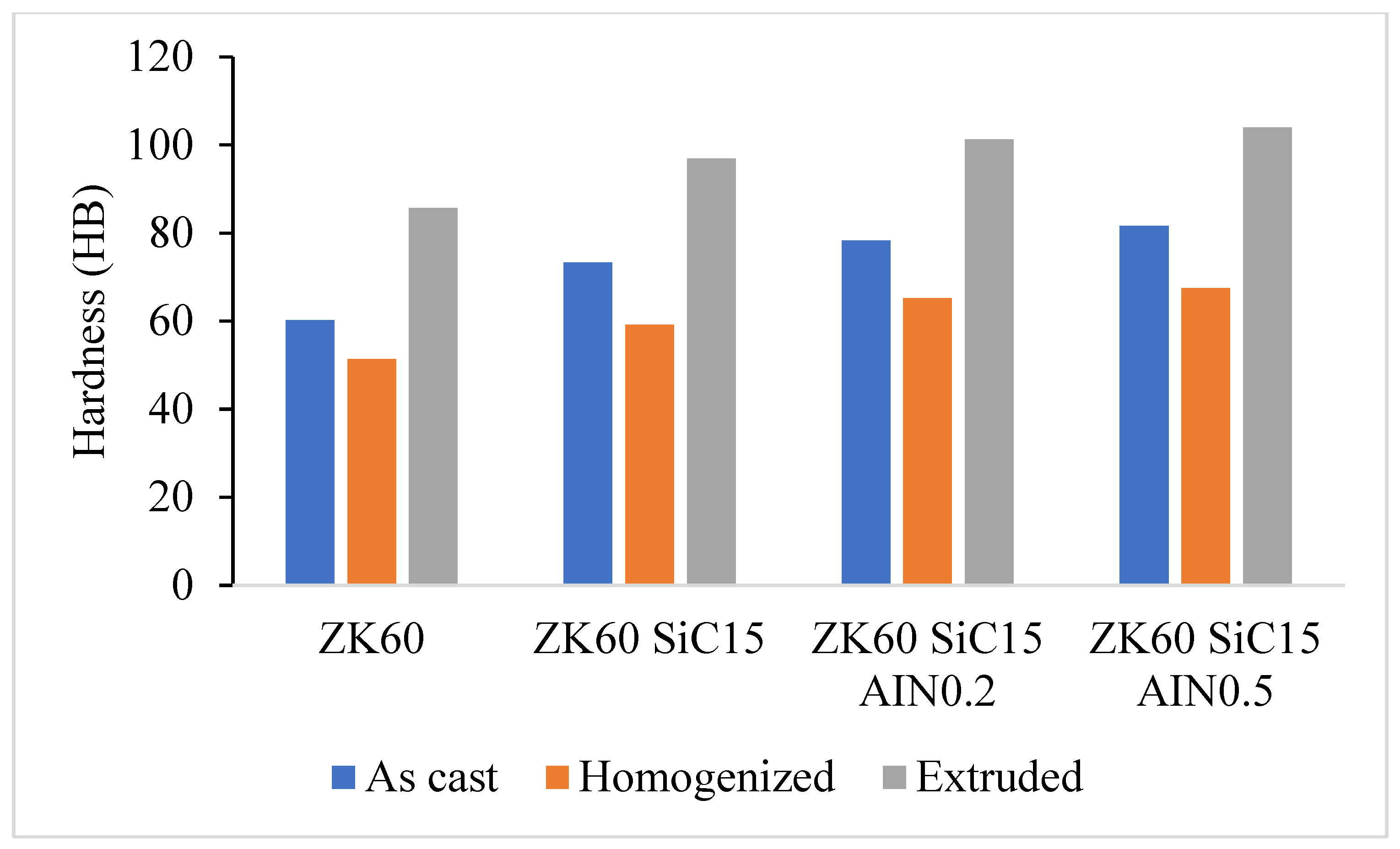

3.2. Hardness Test Results

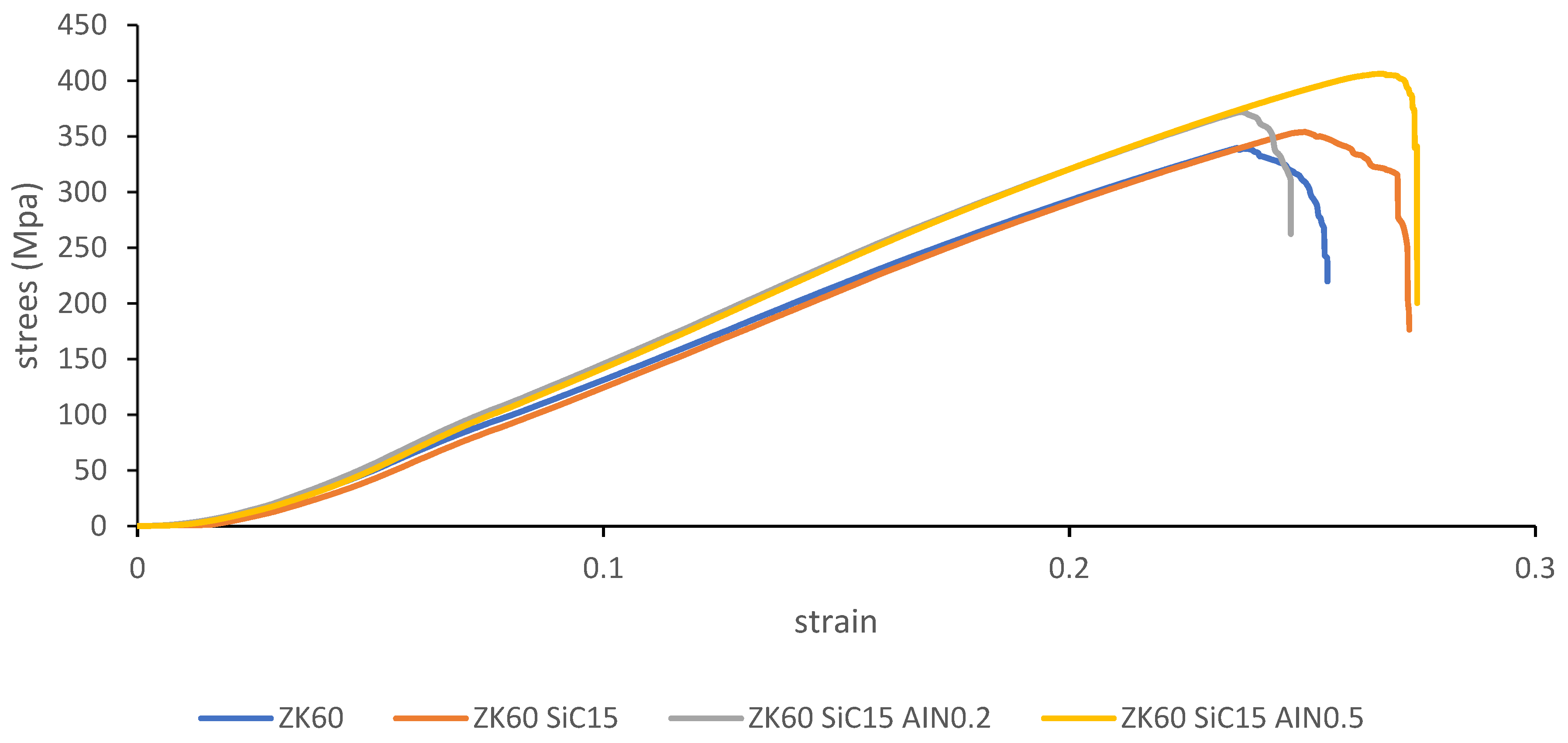

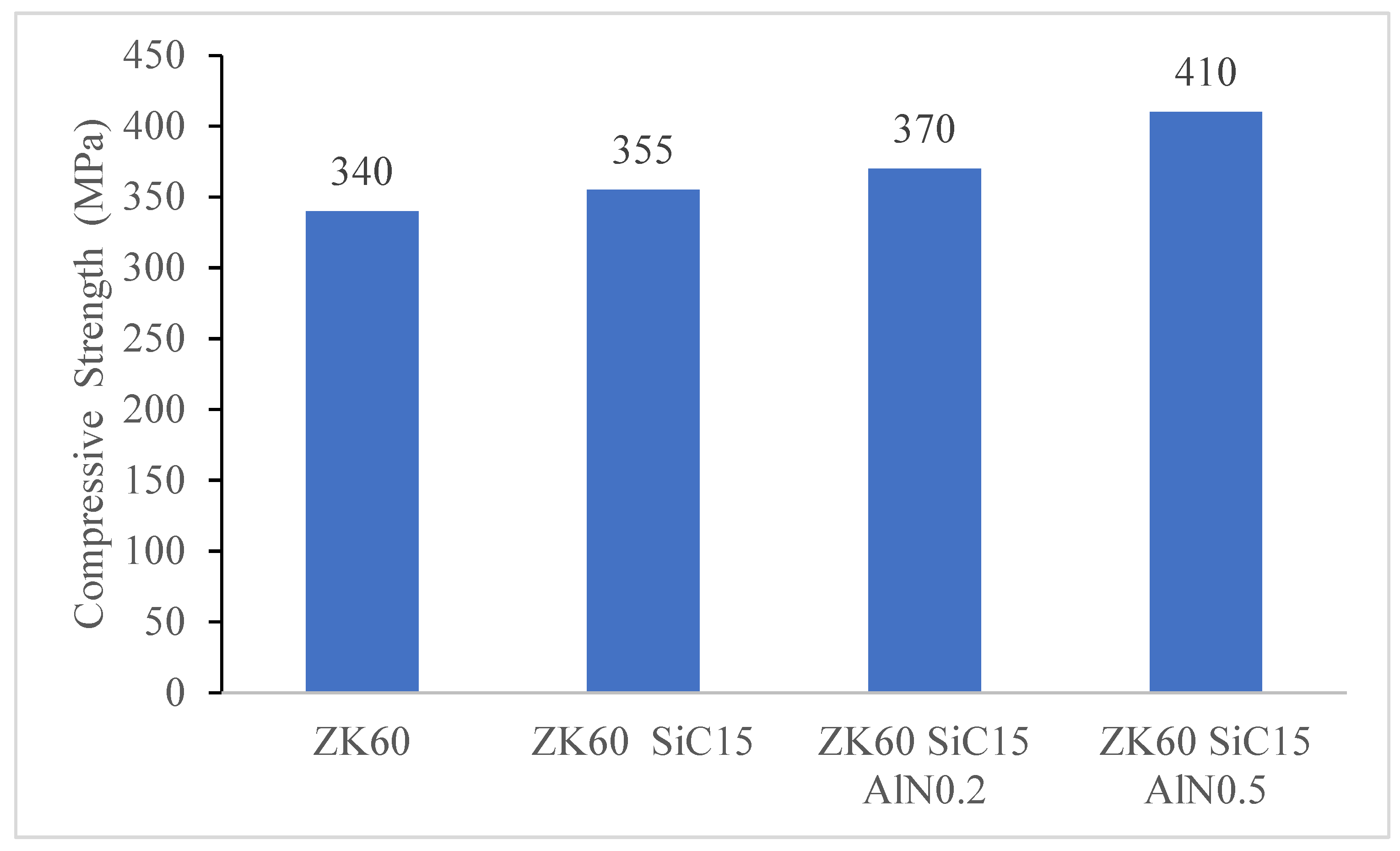

3.3. Compression Test Results

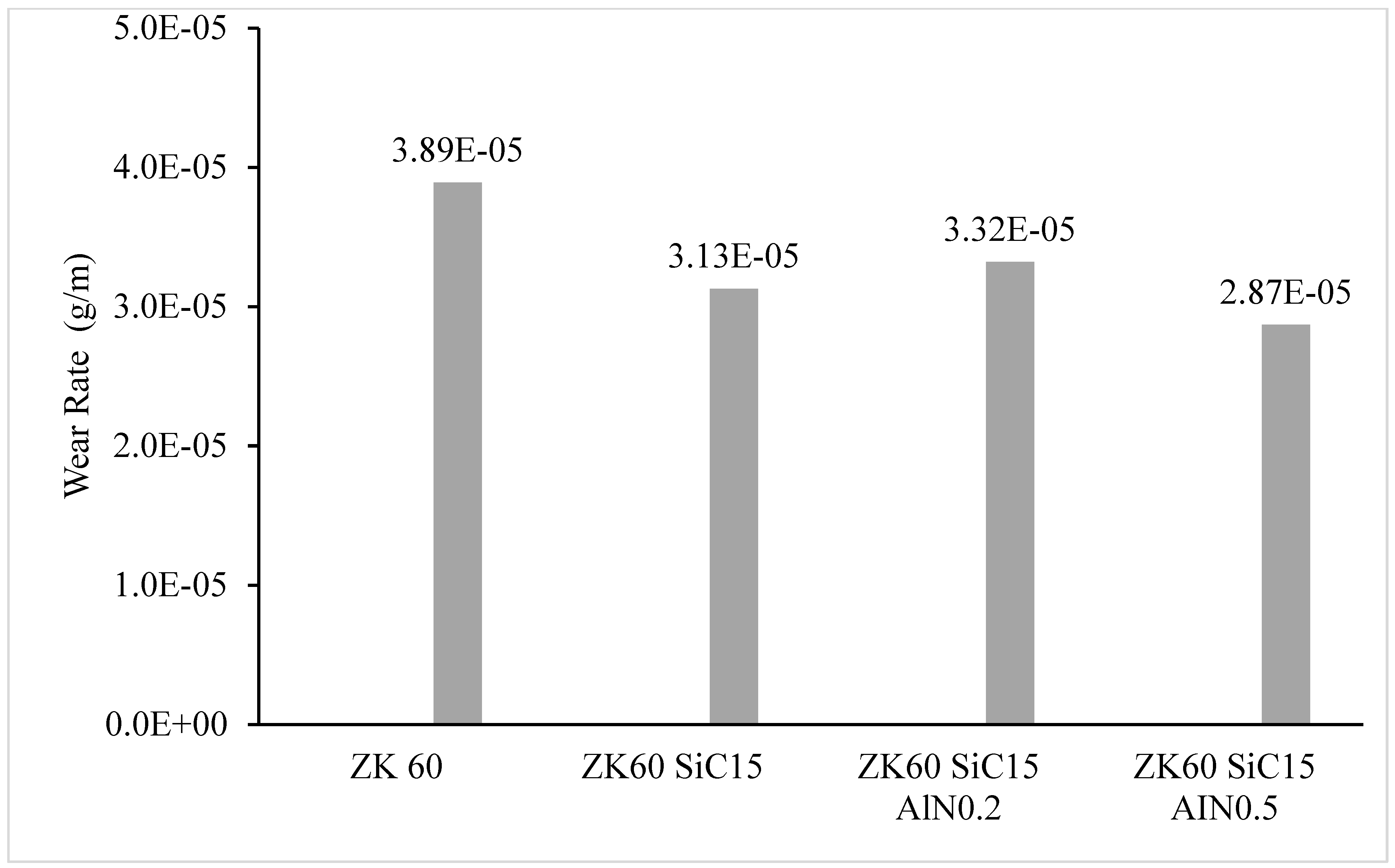

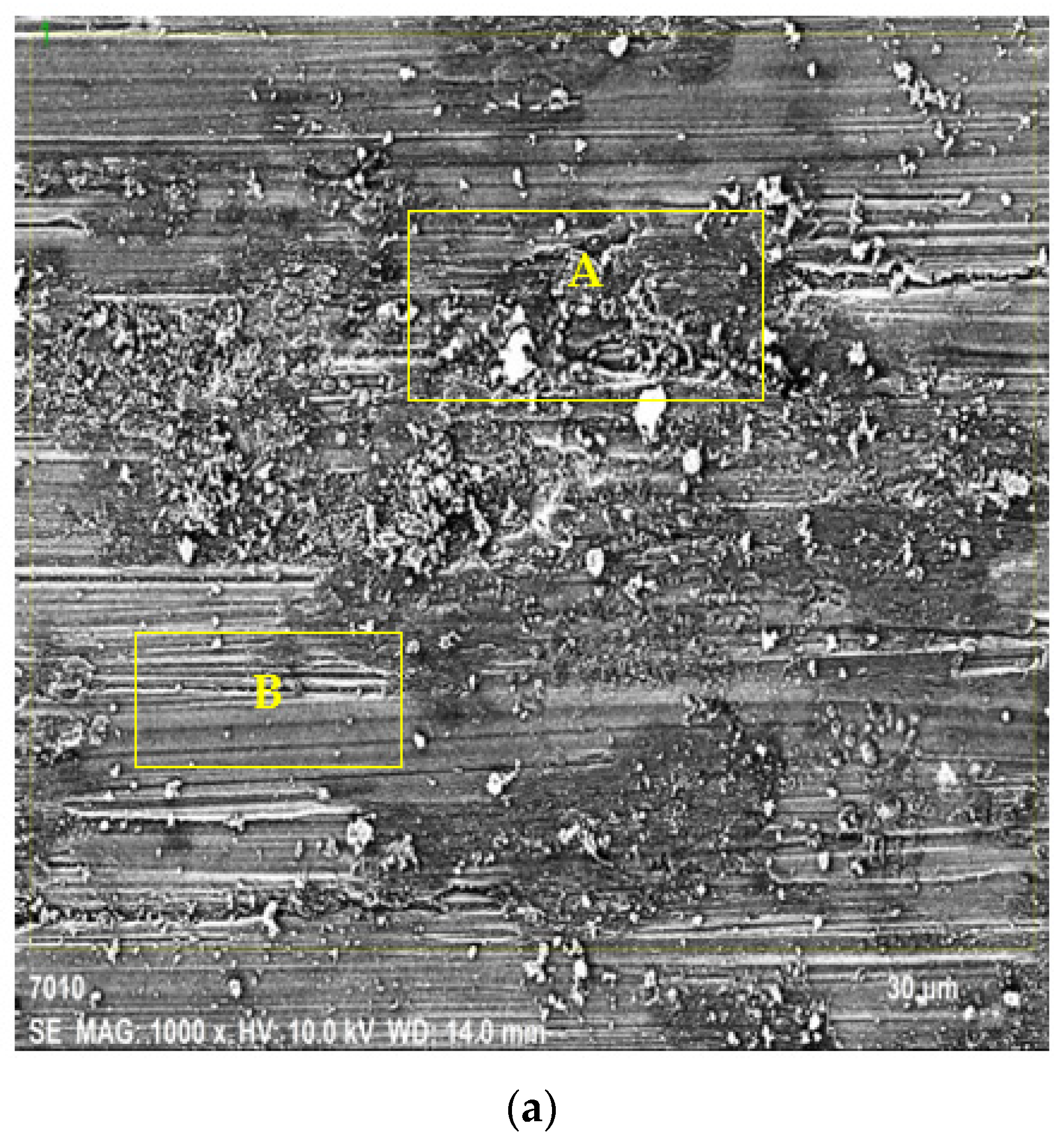

3.4. Wear Test Results

4. Conclusions

- The ZK60 alloy’s as-cast microstructure is composed of coarse α-Mg. It was seen that for the as cast samples the average grain sizes of the unreinforced ZK60, ZK60 SiC15 and, ZK60 SiC15 AIN0.2 15 and ZK60 SiC15 AIN0.5 are 65 µm, 60 µm, 62 µm and 48 µm, respectively. But, for the extruded samples the average grain sizes of unreinforced ZK60, ZK60 SiC15 and, ZK60 SiC15 AIN0.2 and ZK60 SiC15 AIN0.5 are 32 µm, 28 µm, 25 µm and 23 µm, respectively.

- The hardness test results, respectively, are 60.23, 73.33, 78.29 and 81.61 HB for the as cast unreinforced ZK60, ZK60 SiC15, ZK60 SiC15 AIN0.2 and ZK60 SiC15 AIN0.5. After the extrusion, the hardness values measured as 85.65, 96.86, 101.23 and 103.94 for the ZK60, ZK60 SiC15, ZK60 SiC15 AIN0.2 and ZK60 SiC15 AIN0.5.

- The compression test result of the unreinforced ZK60 is 340 MPa, with the reinforcement of SiC15 it raised to 355 MPa and for the reinforcement of SiC15 AlN0.2 it raised to 370 MPa. Finally, for SiC15 AlN0.5 it raised to 410 MPa.

- The wear test results of the ZK60, ZK60 SiC15, ZK60 SiC15 AIN0.2 and ZK60 SiC15 AIN0.5 are 3.89 × 10−5, 3.13 × 10−5, 3.32 × 10−5 and 2.87 × 10−5 g/m respectively. The average friction coefficients of the samples, respectively, are 0.1268, 0.1262, 0.0994 and 0.0684 for ZK60, ZK60 SiC15, ZK60 SiC15 AIN0.2 and ZK60 SiC15 AIN0.5.

- ZK60 alloys with 45 µm, 15% silicon carbide particle (SiC) and 760 nm, 0.2–0.5% aluminium nitride (AlN) nanoparticle reinforcements the compressive strength and hardness of the composites increased, and the friction coefficient decreased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Atrens, A.; Shi, Z.; Mehreen, S.U.; Johnston, S.; Song, G.L.; Chen, X.; Pan, F. Review of Mg Alloy Corrosion Rates. J. Magnes. Alloy. 2020, 8, 989–998. [Google Scholar] [CrossRef]

- Li, Y.; Lu, X.; Wu, K.; Yang, L.; Zhang, T.; Wang, F. Exploration the Inhibition Mechanism of Sodium Dodecyl Sulfate on Mg Alloy. Corros. Sci. 2020, 168, 108559. [Google Scholar] [CrossRef]

- Fakhar, N.; Sabbaghian, M. A Good Combination of Ductility, Strength, and Corrosion Resistance of Fine-Grained ZK60 Magnesium Alloy Produced by Repeated Upsetting Process for Biodegradable Applications. J. Alloys Compd. 2021, 862, 158334. [Google Scholar] [CrossRef]

- Xiong, Y.; Yu, Y.; Hu, X. Fatigue Behavior of Modified ZK60 Magnesium Alloy after Pre-Corrosion under Stress-Controlled Loading. Eng. Fract. Mech. 2022, 260, 108187. [Google Scholar] [CrossRef]

- Wei, X.; Liu, P.; Ma, S.; Li, Z.; Peng, X.; Deng, R.; Zhao, Q. Improvement on Corrosion Resistance and Biocompability of ZK60 Magnesium Alloy by Carboxyl Ion Implantation. Corros. Sci. 2020, 173, 108729. [Google Scholar] [CrossRef]

- Wei, X.; Ma, J.; Ma, S.; Liu, P.; Qing, H.; Zhao, Q. Enhanced Anti-Corrosion and Biocompatibility of a Functionalized Layer Formed on ZK60 Mg Alloy via Hydroxyl (OH-) Ion Implantation. Colloids Surf. B Biointerfaces 2022, 216, 112533. [Google Scholar] [CrossRef]

- Ma, H.; Wang, J.; Wang, H.; Dong, N.; Zhang, J.; Jin, P.; Peng, Y. Influence of Nano-Diamond Content on the Microstructure, Mechanical and Thermal Properties of the ZK60 Composites. J. Magnes. Alloy. 2022, 10, 440–448. [Google Scholar] [CrossRef]

- Zengin, H.; Turen, Y.; Turan, M.E. Tensile and Wear Properties of As-Cast and as-Extruded ZK60 Magnesium Alloys Containing Minor Nd Additions. Mater. Res. Express 2019, 6, 086528. [Google Scholar] [CrossRef]

- Yu, H.; Hyuk Park, S.; Sun You, B.; Min Kim, Y.; Shun Yu, H.; Soo Park, S. Effects of Extrusion Speed on the Microstructure and Mechanical Properties of ZK60 Alloys with and without 1wt% Cerium Addition. Mater. Sci. Eng. A 2013, 583, 25–35. [Google Scholar] [CrossRef]

- Liang, J.; Lei, Z.; Chen, Y.; Fu, W.; Wu, S.; Chen, X.; Yang, Y. Microstructure Evolution of Laser Powder Bed Fusion ZK60 Mg Alloy after Different Heat Treatment. J. Alloys Compd. 2022, 898, 163046. [Google Scholar] [CrossRef]

- Yin, D.S.; Zhang, E.L.; Zeng, S.Y. Effect of Zn on Mechanical Property and Corrosion Property of Extruded Mg-Zn-Mn Alloy. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 2008, 18, 763–768. [Google Scholar] [CrossRef]

- Tayebi, M.; Nategh, S.; Najafi, H.; Khodabandeh, A. Tensile Properties and Microstructure of ZK60/SiCw Composite after Extrusion and Aging. J. Alloys Compd. 2020, 830, 154709. [Google Scholar] [CrossRef]

- Cho, J.H.; Han, S.H.; Jeong, H.T.; Choi, S.H. The Effect of Aging on Mechanical Properties and Texture Evolution of ZK60 Alloys during Warm Compression. J. Alloys Compd. 2018, 743, 553–563. [Google Scholar] [CrossRef]

- Xu, Y.; Liang, Y.; Peng, G. Effect of a Compound Modification Process on the Microstructure and Mechanical Properties of ZK60 Magnesium Alloys. Mater. Sci. Eng. A 2020, 778, 139117. [Google Scholar] [CrossRef]

- Park, S.H.; Yu, H.; Bae, J.H.; Yim, C.D.; You, B.S. Microstructural Evolution of Indirect-Extruded ZK60 Alloy by Adding Ce. J. Alloys Compd. 2012, 545, 139–143. [Google Scholar] [CrossRef]

- Yu, H.; Kim, Y.M.; You, B.S.; Yu, H.S.; Park, S.H. Effects of Cerium Addition on the Microstructure, Mechanical Properties and Hot Workability of ZK60 Alloy. Mater. Sci. Eng. A 2013, 559, 798–807. [Google Scholar] [CrossRef]

- Silva, E.P.; Marques, F.; Nossa, T.S.; Alfaro, U.; Pinto, H.C. Impact of Ce-Base Mischmetal on the Microstructure and Mechanical Behavior of ZK60 Magnesium Casting Alloys. Mater. Sci. Eng. A 2018, 723, 306–313. [Google Scholar] [CrossRef]

- Banijamali, S.M.; Palizdar, Y.; Najafi, S.; Sheikhani, A.; Soltan Ali Nezhad, M.; Valizadeh Moghaddam, P.; Torkamani, H. Effect of Ce Addition on the Tribological Behavior of ZK60 Mg-Alloy. Met. Mater. Int. 2021, 27, 2732–2742. [Google Scholar] [CrossRef]

- Wu, H.; Yan, T.; Wang, L.; Li, X.; Wei, Y.; Li, S.; Wang, X.; Wu, R. Effect of Yb Addition on the Microstructure and Mechanical Properties of ZK60 Alloy during Extrusion. Mater. Sci. Eng. A 2020, 777, 139033. [Google Scholar] [CrossRef]

- Zhang, T.; Cui, H.; Cui, X.; Chen, H.; Zhao, E.; Chang, L.; Pan, Y.; Feng, R.; Zhai, S.; Chai, S. Effect of Addition of Small Amounts of Samarium on Microstructural Evolution and Mechanical Properties Enhancement of an As-Extruded ZK60 Magnesium Alloy Sheet. J. Mater. Res. Technol. 2020, 9, 133–141. [Google Scholar] [CrossRef]

- Abbas, A.; Hu, K.C.; Lin, H.C.; Lin, K.M. Influence of Severe Plastic Deformation and Some Additives on Hydrogenation of ZK60 Alloy. J. Phys. Chem. Solids 2021, 151, 109927. [Google Scholar] [CrossRef]

- Huang, Z.; Liu, W.; Qi, W.; Xu, J.; Zhou, N. Effects of Bi on the Microstructure and Mechanical Property of ZK60 Alloy. J. Magnes. Alloy. 2015, 3, 29–35. [Google Scholar] [CrossRef] [Green Version]

- Labib, F.; Ghasemi, H.M.; Mahmudi, R. Dry Tribological Behavior of Mg/SiCp Composites at Room and Elevated Temperatures. Wear 2016, 348–349, 69–79. [Google Scholar] [CrossRef]

- Sabbaghian, M.; Fakhar, N.; Nagy, P.; Fekete, K.; Gubicza, J. Investigation of Shear and Tensile Mechanical Properties of ZK60 Mg Alloy Sheet Processed by Rolling and Sheet Extrusion. Mater. Sci. Eng. A 2021, 828, 142098. [Google Scholar] [CrossRef]

- Banijamali, S.M.; Shariat Razavi, M.; Palizdar, Y.; Najafi, S.; Sheikhani, A.; Torkamani, H. Experimental and Simulation Study on Wear Behavior of ZK60 Alloy with 3 Wt.% Yttrium Addition. J. Mater. Eng. Perform. 2022, 31, 4721–4734. [Google Scholar] [CrossRef]

- Behnamian, Y.; Serate, D.; Aghaie, E.; Zahiri, R.; Tolentino, Z.; Niazi, H.; Mostafaei, A. Tribological Behavior of ZK60 Magnesium Matrix Composite Reinforced by Hybrid MWCNTs/B4C Prepared by Stir Casting Method. Tribol. Int. 2022, 165, 107299. [Google Scholar] [CrossRef]

- Huan, Z.G.; Leeflang, M.A.; Zhou, J.; Fratila-Apachitei, L.E.; Duszczyk, J. In Vitro Degradation Behavior and Cytocompatibility of Mg-Zn-Zr Alloys. J. Mater. Sci. Mater. Med. 2010, 21, 2623–2635. [Google Scholar] [CrossRef] [Green Version]

- García-Rodríguez, S.; Torres, B.; Maroto, A.; López, A.J.; Otero, E.; Rams, J. Dry Sliding Wear Behavior of Globular AZ91 Magnesium Alloy and AZ91/SiCp Composites. Wear 2017, 390–391, 1–10. [Google Scholar] [CrossRef]

- Dong, N.; Li, M.; Sun, L.; Wang, J.; Jin, P.; Wei, Y.; Ma, H. Effect of Nanodiamond Content on the Hot Deformation Behaviors of ND/ZK60 Composites. Diam. Relat. Mater. 2022, 125, 108983. [Google Scholar] [CrossRef]

- Stanford, N.; Sha, G.; Xia, J.H.; Ringer, S.P.; Barnett, M.R. Solute Segregation and Texture Modification in an Extruded Magnesium Alloy Containing Gadolinium. Scr. Mater. 2011, 65, 919–921. [Google Scholar] [CrossRef]

- Caceres, C.H.; Mann, G.E.; Griffiths, J.R. Grain Size Hardening in Mg and Mg-Zn Solid Solutions. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2011, 42, 1950–1959. [Google Scholar] [CrossRef] [Green Version]

- Sandlöbes, S.; Zaefferer, S.; Schestakow, I.; Yi, S.; Gonzalez-Martinez, R. On the Role of Non-Basal Deformation Mechanisms for the Ductility of Mg and Mg-Y Alloys. Acta Mater. 2011, 59, 429–439. [Google Scholar] [CrossRef]

| Alloy | Nominal Composition | Elongation at Fracture (%) | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|---|---|

| ZK 60 | Mg-6Zn-0.6Zr | 8 | 315 | 235 |

| Alloy and Composites | SiC (g) | AlN (g) | Mg (g) | Zn (g) | Zr (g) | Mg (g) |

|---|---|---|---|---|---|---|

| ZK60 | 0 | 0 | 0 | 60 | 5 | 935 |

| ZK60 + 15% SiC | 150 | 0 | 114 | 60 | 5 | 735 |

| ZK60 + 15% SiC + 0.2% AlN nano. | 150 | 2 | 114 | 60 | 5 | 733 |

| ZK60 + 15% SiC + 0.5% AlN nano. | 150 | 5 | 114 | 60 | 5 | 730 |

| Spectrum | C | Mg | Si | Zn | Zr |

|---|---|---|---|---|---|

| 1 | 4.46 | 87.15 | 0.00 | 8.40 | 0.00 |

| 2 | 13.22 | 47.16 | 36.19 | 2.18 | 1.25 |

| 3 | 7.23 | 57.79 | 32.97 | 1.75 | 0.27 |

| 4 | 11.90 | 55.60 | 29.59 | 2.89 | 0.02 |

| 5 | 8.58 | 83.64 | 0.09 | 7.43 | 0.25 |

| 6 | 12.27 | 80.20 | 0.43 | 7.10 | 0.00 |

| Mean value | 9.61 | 68.59 | 16.55 | 4.96 | 0.30 |

| Sigma | 3.42 | 17.03 | 18.06 | 3.00 | 0.48 |

| Sigma mean | 1.40 | 6.95 | 7.37 | 1.22 | 0.20 |

| Spectrum | C | N | Mg | Al | Si | Zn |

|---|---|---|---|---|---|---|

| 1 | 6.53 | 1.81 | 82.86 | 1.06 | 0.19 | 7.55 |

| 2 | 3.13 | 31.35 | 1.52 | 62.65 | 0.08 | 1.27 |

| 3 | 11.63 | 20.18 | 0.94 | 60.78 | 6.21 | 0.27 |

| 4 | 28.82 | 3.19 | 7.18 | 5.66 | 53.86 | 1.28 |

| 5 | 2.92 | 0.00 | 83.89 | 11.70 | 0.00 | 1.49 |

| 6 | 15.14 | 2.68 | 71.06 | 2.65 | 1.44 | 7.04 |

| 7 | 2.75 | 36.72 | 0.79 | 58.82 | 0.13 | 0.79 |

| Mean value | 10.13 | 13.70 | 35.46 | 29.05 | 8.84 | 2.81 |

| Sigma: | 9.53 | 15.52 | 41.24 | 29.86 | 19.98 | 3.09 |

| Sigma mean: | 3.60 | 5.86 | 15.59 | 11.29 | 7.55 | 1.17 |

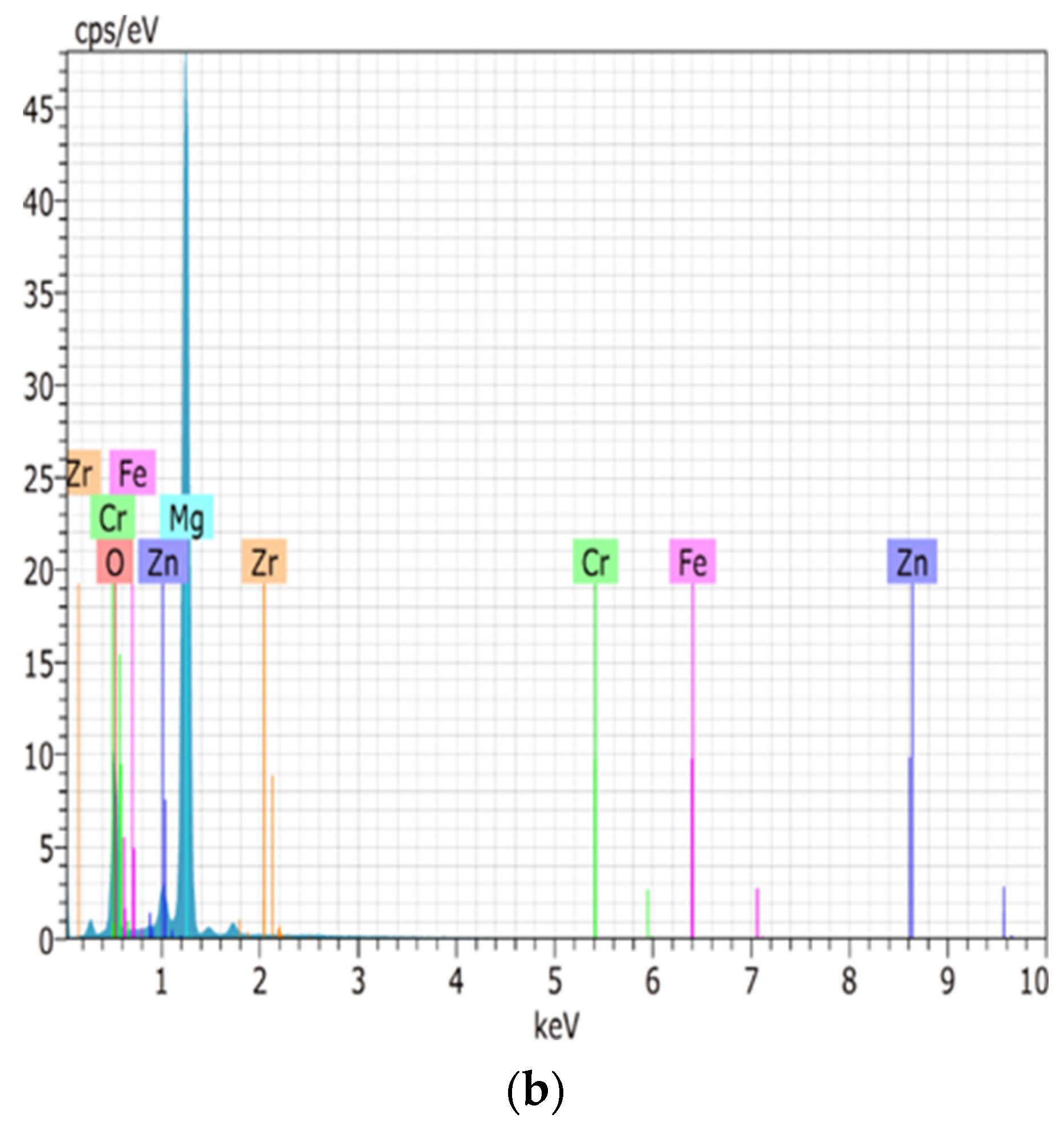

| Elements | Atomic Compound [%] |

|---|---|

| O | 32.55 |

| Mg | 64.73 |

| Cr | 0.02 |

| Fe | 0.01 |

| Zn | 2.66 |

| Zr | 0.03 |

| Total | 100.00 |

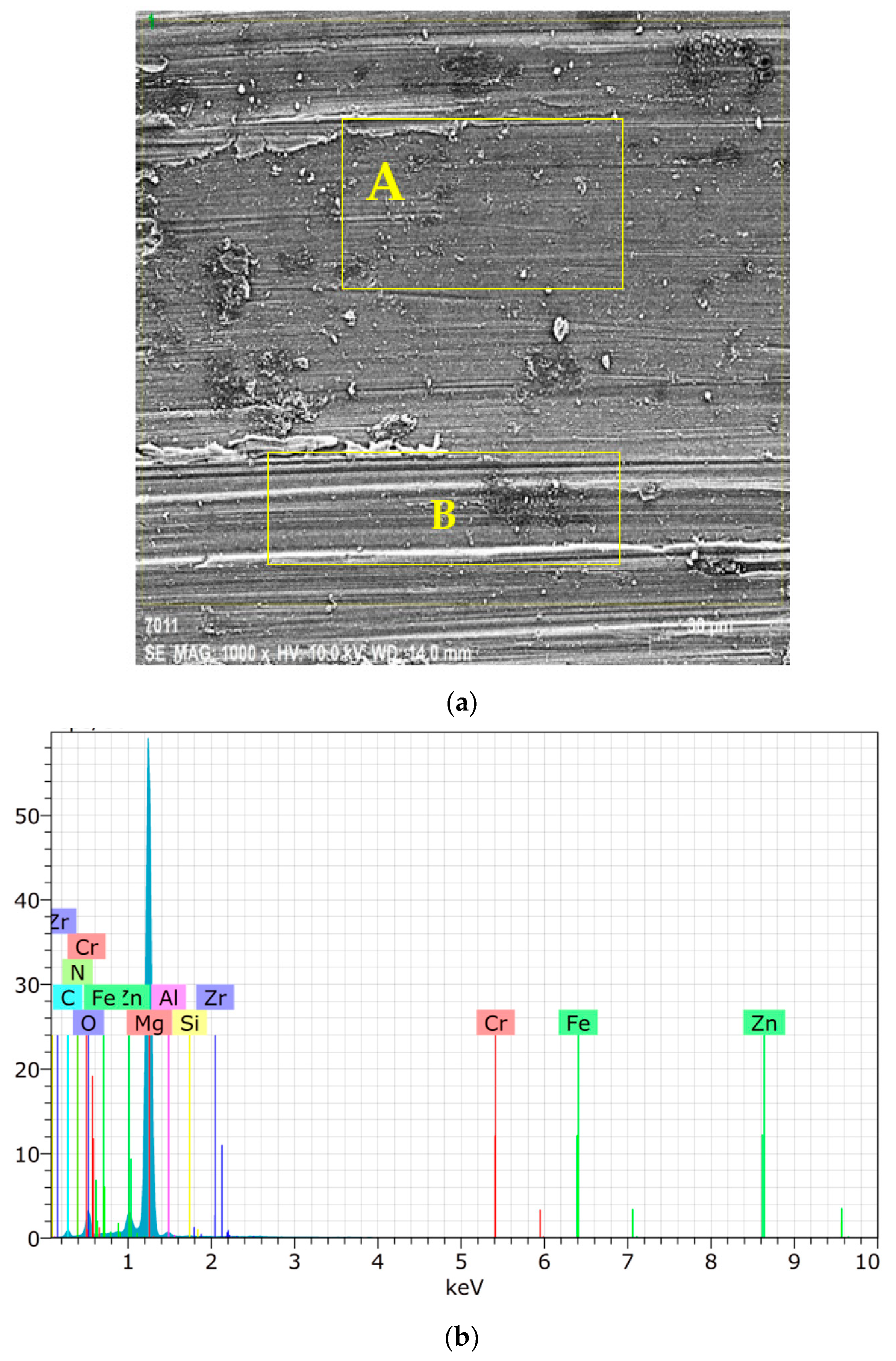

| Elements | Atomic Compound [%] |

|---|---|

| C | 12.12 |

| N | 1.83 |

| O | 10.91 |

| Mg | 71.67 |

| Al | 0.87 |

| Si | 0.08 |

| Cr | 0.05 |

| Fe | 0.06 |

| Zn | 2.39 |

| Zr | 0.00 |

| Total | 100.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sager, A.; Esen, I.; Ahlatçi, H.; Turen, Y. Dry Wear Behaviour of the New ZK60/AlN/SiC Particle Reinforced Composites. Materials 2022, 15, 8582. https://doi.org/10.3390/ma15238582

Sager A, Esen I, Ahlatçi H, Turen Y. Dry Wear Behaviour of the New ZK60/AlN/SiC Particle Reinforced Composites. Materials. 2022; 15(23):8582. https://doi.org/10.3390/ma15238582

Chicago/Turabian StyleSager, Abdulmuaen, Ismail Esen, Hayrettin Ahlatçi, and Yunus Turen. 2022. "Dry Wear Behaviour of the New ZK60/AlN/SiC Particle Reinforced Composites" Materials 15, no. 23: 8582. https://doi.org/10.3390/ma15238582

APA StyleSager, A., Esen, I., Ahlatçi, H., & Turen, Y. (2022). Dry Wear Behaviour of the New ZK60/AlN/SiC Particle Reinforced Composites. Materials, 15(23), 8582. https://doi.org/10.3390/ma15238582