Preparation and Characterization of In Situ (TiC-TiB2)/Al-Cu-Mg-Si Composites with High Strength and Wear Resistance

Abstract

1. Introduction

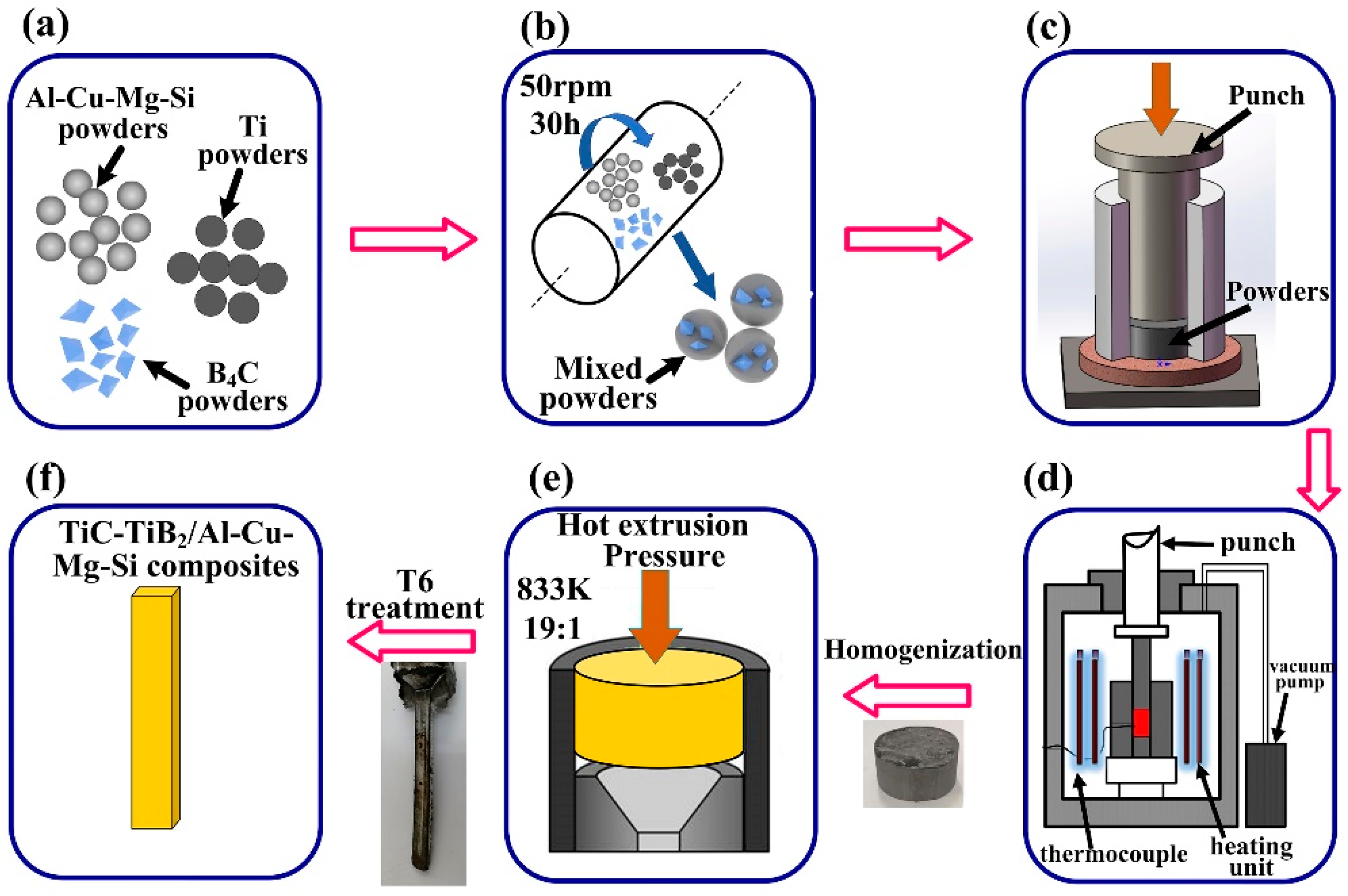

2. Experimental Procedure

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lakshmikanthan, A.; Angadi, S.; Malik, V.; Saxena, K.K.; Prakash, C.; Dixit, S.; Mohammed, K.A. Mechanical and Tribological Properties of Aluminum-Based Metal-Matrix Composites. Materials 2022, 15, 6111. [Google Scholar] [CrossRef]

- Sun, H.; Saba, F.; Fan, G.L.; Tian, Z.Q.; Li, Z.Q. Micro/nano-reinforcements in bimodal-grained matrix: A heterostructure strategy for toughening particulate reinforced metal matrix composites. Scr. Mater. 2022, 217, 114774. [Google Scholar] [CrossRef]

- Shankar, K.V.; Jezierski, J.; Ramalingam, V.V.; Padmakumar, D.; Leena, M.R.; Amal; Reghunath, G.; Krishnan, R. Investigating the Effect of Fly Ash Addition on the Metallurgical and Mechanical Behavior of Al-Si-Mg-Cu alloy for Engine Cylinder Head Application. Materials 2022, 15, 5462. [Google Scholar] [CrossRef] [PubMed]

- Pournaderi, S.; Akhlaghi, F. Wear behavior of Al6061-Al2O3 composites produced by in-situ powder metallurgy (IPM). Powder Technol. 2017, 313, 184–190. [Google Scholar] [CrossRef]

- Li, H.; Wang, X.M.; Chai, L.H.; Wang, H.J.; Chen, Z.Y.; Xiang, Z.L.; Jin, T. Microstructure and mechanical properties of an in-situ TiB2/Al-Zn-Mg-Cu-Zr composite fabricated by Melt-SHS process. Mater. Sci. Eng. A 2018, 720, 60–68. [Google Scholar] [CrossRef]

- Tian, W.S.; Zhao, Q.L.; Zhao, C.J.; Qiu, F.; Jiang, Q.C. The dry sliding wear properties of nano-sized TiCp/Al-Cu composites at elevated temperatures. Materials 2017, 10, 939. [Google Scholar] [CrossRef]

- Aydin, F. Investigation of Elevated Temperature Wear Behavior of Al 2024-BN Composites using Statistical Techniques. J. Mater. Eng. Perform. 2021, 30, 8560–8578. [Google Scholar] [CrossRef]

- Cabeza, M.; Feijoo, I.; Merino, P.; Pena, G.; Pérez, M.C.; Cruz, S.; Rey, P. Effect of high energy ball milling on the morphology, microstructure and properties of nano-sized TiC particle-reinforced 6005A aluminium alloy matrix composite. Powder Technol. 2017, 321, 31–43. [Google Scholar] [CrossRef]

- Li, Q.; Qiu, F.; Dong, B.X.; Gao, X.; Shu, S.L.; Yang, H.Y.; Jiang, Q.C. Processing, multiscale microstructure refinement and mechanical property enhancement of hypoeutectic Al–Si alloys via in situ bimodal-sized TiB2 particles. Mater. Sci. Eng. A 2020, 777, 139081. [Google Scholar] [CrossRef]

- Matus, K.; Matula, G.; Pawlyta, M.; Krzysteczko-Witek, J.; Tomiczek, B. TEM study of the microstructure of an Alumina/Al composite prepared by Gas-Pressure infiltration. Materials 2022, 15, 6112. [Google Scholar] [CrossRef]

- Liu, Z.W.; Cheng, N.; Zheng, Q.L.; Wu, J.H.; Han, Q.Y.; Huang, Z.F.; Xing, J.D.; Li, Y.F.; Gao, Y.M. Processing and tensile properties of A356 composites containing in situ small-sized Al3Ti particulates. Mater. Sci. Eng. A 2018, 710, 392–399. [Google Scholar] [CrossRef]

- Saba, F.; Haddad-Sabzevar, M.; Abdolkarim Sajjadi, S.; Zhang, F. The effect of TiC:CNT mixing ratio and CNT content on the mechanical and tribological behaviors of TiC modified CNT-reinforced Al-matrix nanocomposites. Powder Technol. 2018, 331, 107–120. [Google Scholar] [CrossRef]

- Zhang, D.; Wu, X.; Jia, B.; Jiang, H.; Liu, Y.; Wang, R.; Yang, Q.; Wu, H.; Wu, C. Effects of Preparation Methods on the Microstructure and Mechanical Properties of Graphene-Reinforced Alumina Matrix Composites. Materials 2022, 15, 5445. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Xu, E.Z.; Zhu, Z.F.; Liu, Q.; Yu, S.M.; Liu, J.W.; Zhong, H.H.; Jiang, Y. Mechanical and wear performances of aluminum/sintered-carbon composites produced by pressure infiltration for pantograph sliders. Powder Technol. 2018, 326, 54–61. [Google Scholar] [CrossRef]

- Zhao, Y.F.; Ma, X.; Chen, H.W.; Zhao, X.J.; Liu, X.F. Preferred orientation and interfacial structure in extruded nano-Al3BC/6061. Al. Mater. Des. 2017, 131, 23–31. [Google Scholar] [CrossRef]

- Kumar, A.; Mahapatra, M.M.; Jha, P.K. Effect of machining parameters on cutting force and surface roughness of in situ Al–4.5% Cu/TiC metal matrix composites. Measurement 2014, 48, 325–332. [Google Scholar] [CrossRef]

- Zhang, L.J.; Yang, D.L.; Qiu, F.; Wang, J.G.; Jiang, Q.C. Effects of reinforcement surface modification on the microstructures and tensile properties of SiCp/Al2014 composites. Mater. Sci. Eng. A 2015, 624, 102–109. [Google Scholar] [CrossRef]

- Moazami-Goudarzi, M.; Akhlaghi, F. Wear behavior of Al 5252 alloy reinforced with micrometric and nanometric SiC particles. Tribol. Int. 2016, 102, 28–37. [Google Scholar] [CrossRef]

- Yang, D.L.; Qiu, F.; Zhao, Q.L.; Wang, L.; Jiang, Q.C. The abrasive wear behavior of Al2014 composites reinforced with Ti5Si3-coated SiCP. Tribol. Int. 2017, 112, 33–41. [Google Scholar] [CrossRef]

- Zhou, D.S.; Qiu, F.; Jiang, Q.C. The nano-sized TiC particle reinforced Al–Cu matrix composite with superior tensile ductility. Mater. Sci. Eng. A 2015, 622, 189–193. [Google Scholar] [CrossRef]

- Tian, W.S.; Zhao, Q.L.; Geng, R.; Qiu, F.; Jiang, Q.C. Improved creep resistance of Al-Cu alloy matrix composite reinforced with bimodal-sized TiCp. Mater. Sci. Eng. A 2018, 713, 190–194. [Google Scholar] [CrossRef]

- Zhang, L.J.; Qiu, F.; Wang, J.G.; Wang, H.Y.; Jiang, Q.C. Microstructures and mechanical properties of the Al2014 composites reinforced with bimodal sized SiC particles. Mater. Sci. Eng. A 2015, 637, 70–74. [Google Scholar] [CrossRef]

- Li, Q.; Dong, B.X.; Liu, T.S.; Yang, H.Y.; Shu, S.L.; Qiu, F.; Jiang, Q.C. Insight into solidification microstructure control by trace TiCN–TiB2 particles for yielding fine-tuned nanoprecipitates in a hypoeutectic Al–Si–Mg alloy. Mater. Sci. Eng. A 2021, 827, 142093. [Google Scholar] [CrossRef]

- Kumar, S.; Panwar, R.S.; Pandey, O.P. Effect of dual reinforced ceramic particles on high temperature tribological properties of aluminum composites. Ceram. Int. 2013, 39, 6333–6342. [Google Scholar] [CrossRef]

- Xie, K.W.; Nie, J.F.; Ma, X.; Liu, X.F. Increasing the ductility of heat-resistant AlNp/Al composites by submicron Al2O3 particles. Mater. Charact. 2020, 170, 110672. [Google Scholar] [CrossRef]

- Gao, Q.; Wu, S.S.; Lü, S.L.; Duan, X.C.; Zhong, Z.Y. Preparation of in-situ TiB2 and Mg2Si hybrid particulates reinforced Al-matrix composites. J. Alloys Compd. 2015, 651, 521–527. [Google Scholar] [CrossRef]

- Guo, R.F.; Shen, P.; Guo, N.; Yang, L.K.; Jiang, Q.C. Al–7Si–5Cu/Al2O3–ZrO2 Laminated Composites with Excellent and Anisotropic Wear Resistance. Adv. Eng. Mater. 2018, 20, 1800540. [Google Scholar] [CrossRef]

- Zou, B.L.; Shen, P.; Cao, X.Q.; Jiang, Q.C. The mechanism of thermal explosion (TE) synthesis of TiC-TiB2 particulate locally reinforced steel matrix composites from an Al-Ti-B4C system via a TE-casting route. Mater. Chem. Phys. 2012, 132, 51–62. [Google Scholar] [CrossRef]

- Shen, P.; Zou, B.L.; Jin, S.B.; Jiang, Q.C. Reaction mechanism in self-propagating high temperature synthesis of TiC-TiB2/Al composites from an Al-Ti-B4C system. Mater. Sci. Eng. A 2007, 455, 300–309. [Google Scholar] [CrossRef]

- Duan, X.Z.; Xin, B.D.; Miao, T.J.; Xie, J.F.; Yang, H.Y.; Han, X.; Qiu, F.; Li, X.J. Microstructural and performance characterization of in-situ biphasic micro-nano scale (TiB2-TiCx)/Al-Cu-Mg composites with different ceramic and metal ratios designed for compact integration. J. Mater. Res. Technol. 2020, 9, 3418–3429. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, F.; Zhao, Q.L.; Zha, M.; Jiang, Q.C. Superior high creep resistance of in situ nano-sized TiCx/Al-Cu-Mg composite. Sci. Rep. 2017, 7, 4540. [Google Scholar] [CrossRef] [PubMed]

- Nieto, A.; Yang, H.; Jiang, L.; Schoenung, J.M. Reinforcement size effects on the abrasive wear of boron carbide reinforced aluminum composites. Wear 2017, 390, 228–235. [Google Scholar] [CrossRef]

- Yang, D.L.; Qiu, F.; Lei, Z.K.; Zhao, Q.L.; Jiang, Q.C. The interfacial structure and mechanical properties of Ti5Si3-coated SiCP/Al2014 composites fabricated by powder metallurgy with hot pressing. Mater. Sci. Eng. A 2016, 661, 217–221. [Google Scholar] [CrossRef]

- Gao, Y.Y.; Qiu, F.; Liu, T.S.; Chu, J.G.; Zhao, Q.L.; Jiang, Q.C. Effects of Carbon Source on TiC Particles’ Distribution, Tensile, and Abrasive Wear Properties of In Situ TiC/Al-Cu Nanocomposites Prepared in the Al-Ti-C System. Nanomaterials 2018, 8, 610. [Google Scholar] [CrossRef] [PubMed]

- Turan, M.E.; Aydin, F.; Sun, Y.; Zengin, H.; Akinay, Y. Wear resistance and tribological properties of GNPs and MWCNT reinforced AlSi18CuNiMg alloys produced by stir casting. Tribol. Int. 2021, 164, 107201. [Google Scholar] [CrossRef]

- Aydin, F. Effect of solid waste materials on properties of Magnesium matrix composites-A systematic review. J. Magnes. Alloys 2022, in press. [Google Scholar] [CrossRef]

- Shu, S.L.; Lu, J.B.; Qiu, F.; Xuan, Q.Q.; Jiang, Q.C. High volume fraction TiCx/Al composites with good comprehensive performance fabricated by combustion synthesis and hot press consolidation. Mater. Sci. Eng. A 2011, 528, 1931–1936. [Google Scholar] [CrossRef]

- Aydin, F. The investigation of the effect of particle size on wear performance of AA7075/Al2O3 composites using statistical analysis and different machine learning methods. Adv. Powder Technol. 2021, 32, 445–463. [Google Scholar] [CrossRef]

| Designed Composition | Used Powders (wt.%) | TiC Content | TiB2 Content |

|---|---|---|---|

| 10 wt.% (TiC-TiB2)/Al-4.7Cu-0.32Mg-0.44Si | 90% Al + 7.22% Ti + 2.78% B4C | 3.01 wt.% (1.78 vol.%) | 6.99 wt.% (4.50 vol.%) |

| 20 wt.% (TiC-TiB2)/Al-4.7Cu-0.32Mg-0.44Si | 80% Al + 14.44% Ti + 5.56% B4C | 6.02 wt.% (3.71 vol.%) | 13.98 wt.% (9.39 vol.%) |

| 30 wt.% (TiC-TiB2)/Al-4.7Cu-0.32Mg-0.44Si | 70% Al + 21.66% Ti + 8.4% B4C | 9.03 wt.% (5.81 vol.%) | 20.97 wt.% (14.71 vol.%) |

| 40 wt.% (TiC-TiB2)/Al-4.7Cu-0.32Mg-0.44Si | 60% Al + 28.88% Ti + 11.12% B4C | 12.05 wt.% (8.12 vol.%) | 27.95 wt.% (20.55 vol.%) |

| TiC-TiB2 Content | σ0.2/MPa | σUTS/MPa | εf/% | Hardness/HV | Actual Density/g·cm−3 |

|---|---|---|---|---|---|

| Al alloy | 136 ± 10 | 2.796 ± 0.001 | |||

| 10 wt.% | 192 ± 8 | 2.920 ± 0.003 | |||

| 20 wt.% | 210 ± 9 | 3.045 ± 0.002 | |||

| 30 wt.% | 268 ± 7 | 3.192 ± 0.002 | |||

| 40 wt.% | 286 ± 5 | 3.332 ± 0.004 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.-Y.; Liu, Y.; Li, Y.-L.; Zhang, A.; Teng, H.; Dong, Z.-H.; Li, T.; Jiang, B. Preparation and Characterization of In Situ (TiC-TiB2)/Al-Cu-Mg-Si Composites with High Strength and Wear Resistance. Materials 2022, 15, 8750. https://doi.org/10.3390/ma15248750

Gao Y-Y, Liu Y, Li Y-L, Zhang A, Teng H, Dong Z-H, Li T, Jiang B. Preparation and Characterization of In Situ (TiC-TiB2)/Al-Cu-Mg-Si Composites with High Strength and Wear Resistance. Materials. 2022; 15(24):8750. https://doi.org/10.3390/ma15248750

Chicago/Turabian StyleGao, Yu-Yang, Ying Liu, Yuan-Lin Li, Ang Zhang, Hang Teng, Zhi-Hua Dong, Tian Li, and Bin Jiang. 2022. "Preparation and Characterization of In Situ (TiC-TiB2)/Al-Cu-Mg-Si Composites with High Strength and Wear Resistance" Materials 15, no. 24: 8750. https://doi.org/10.3390/ma15248750

APA StyleGao, Y.-Y., Liu, Y., Li, Y.-L., Zhang, A., Teng, H., Dong, Z.-H., Li, T., & Jiang, B. (2022). Preparation and Characterization of In Situ (TiC-TiB2)/Al-Cu-Mg-Si Composites with High Strength and Wear Resistance. Materials, 15(24), 8750. https://doi.org/10.3390/ma15248750