Influence of the Welding Degree on the Strength and Failure Modes of Tuff

Abstract

1. Introduction

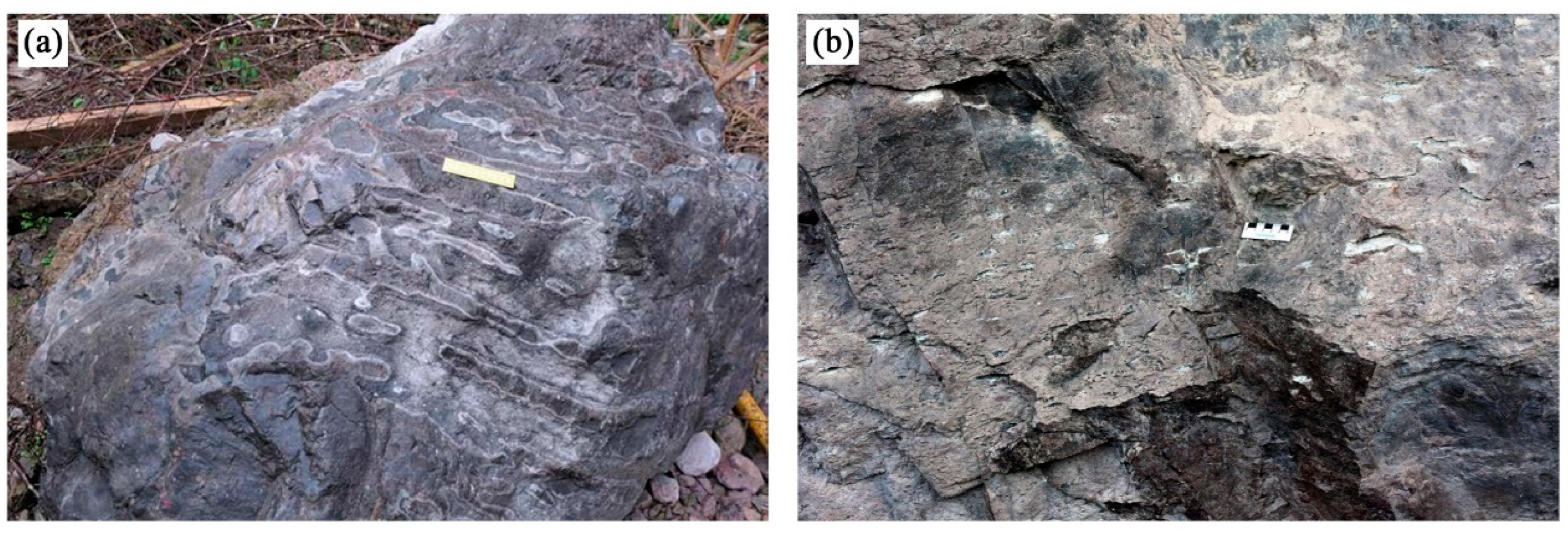

2. Geological Background

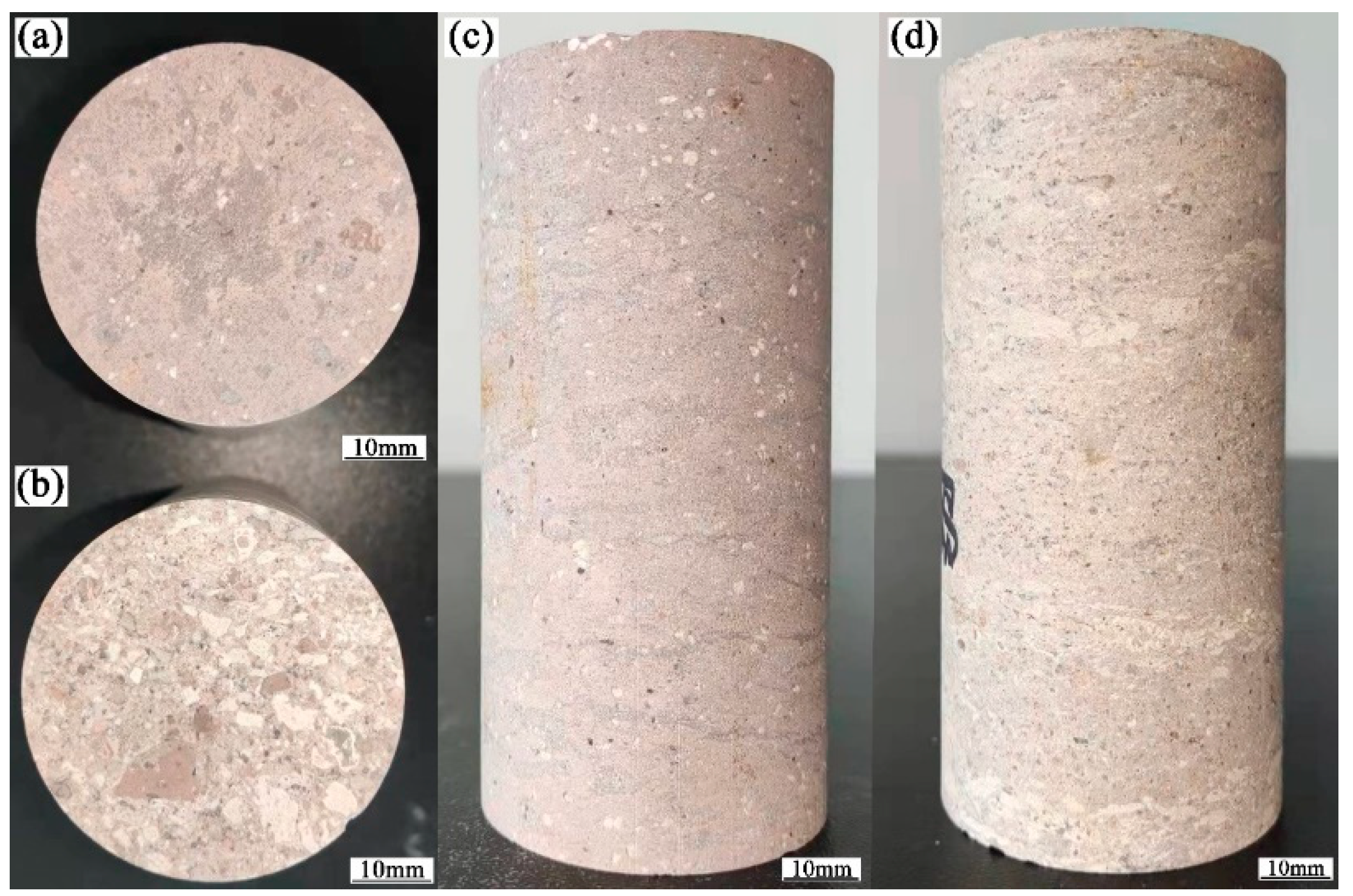

3. Samples and Methods

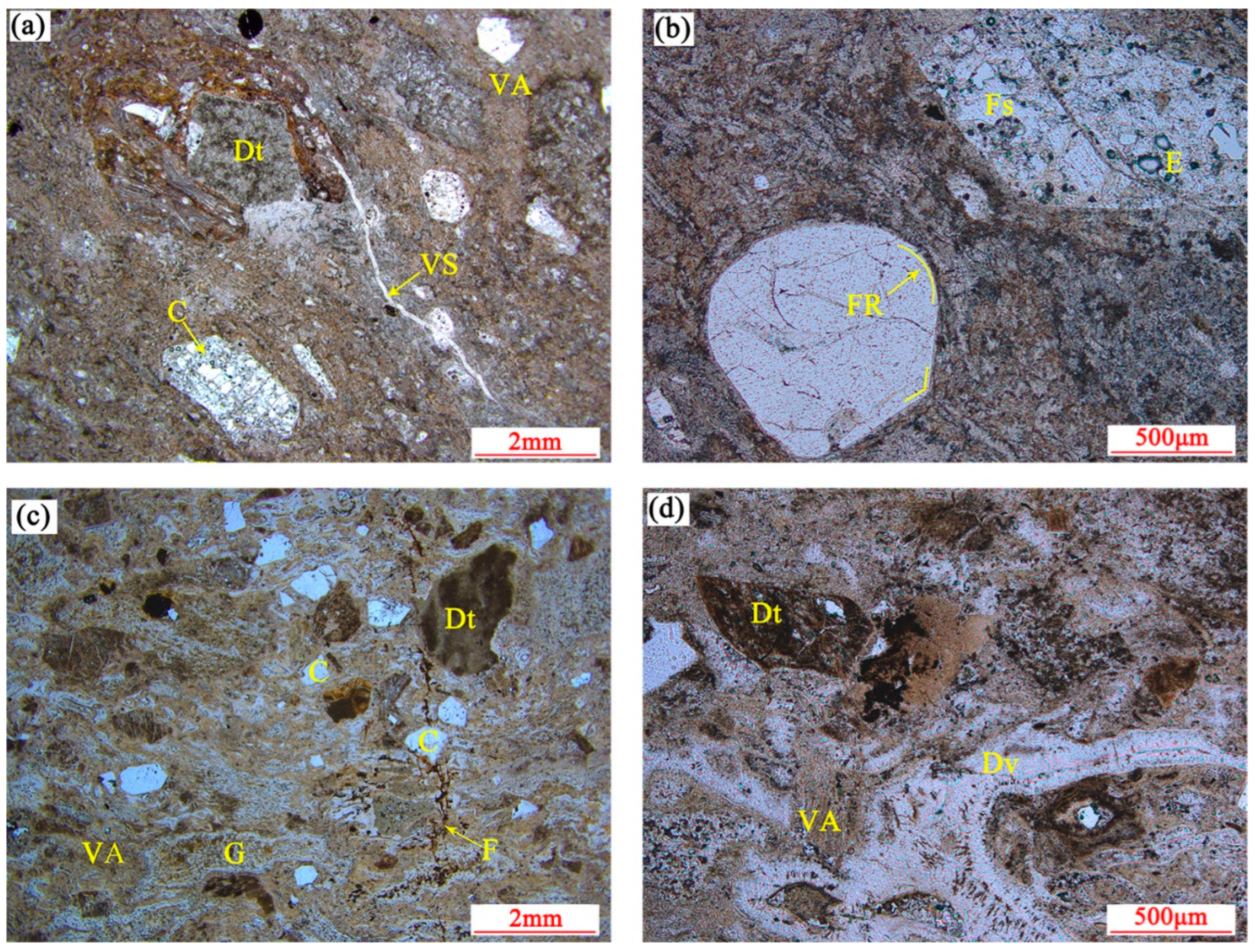

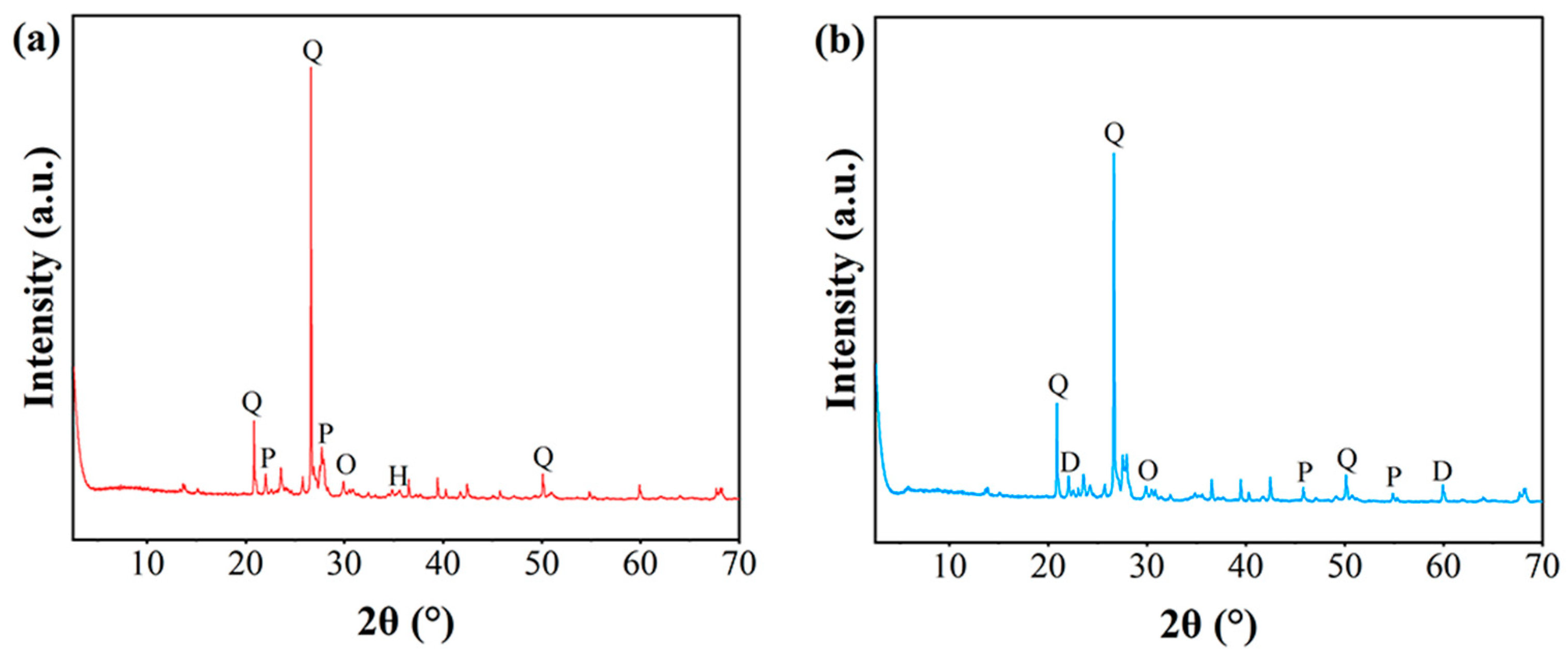

3.1. Petrographic and Mineralogical Identification

3.2. Pore Measurements and Calculations

3.3. Mechanical Tests

4. Mineralogical, Petrological, and Porosity Characteristics of the Samples

4.1. Petrographic Identification Characteristics

4.2. Mineralogical Compositions

4.3. Pore Structures

5. Mechanical Properties of the Welded Tuffs with Different Welding Degrees

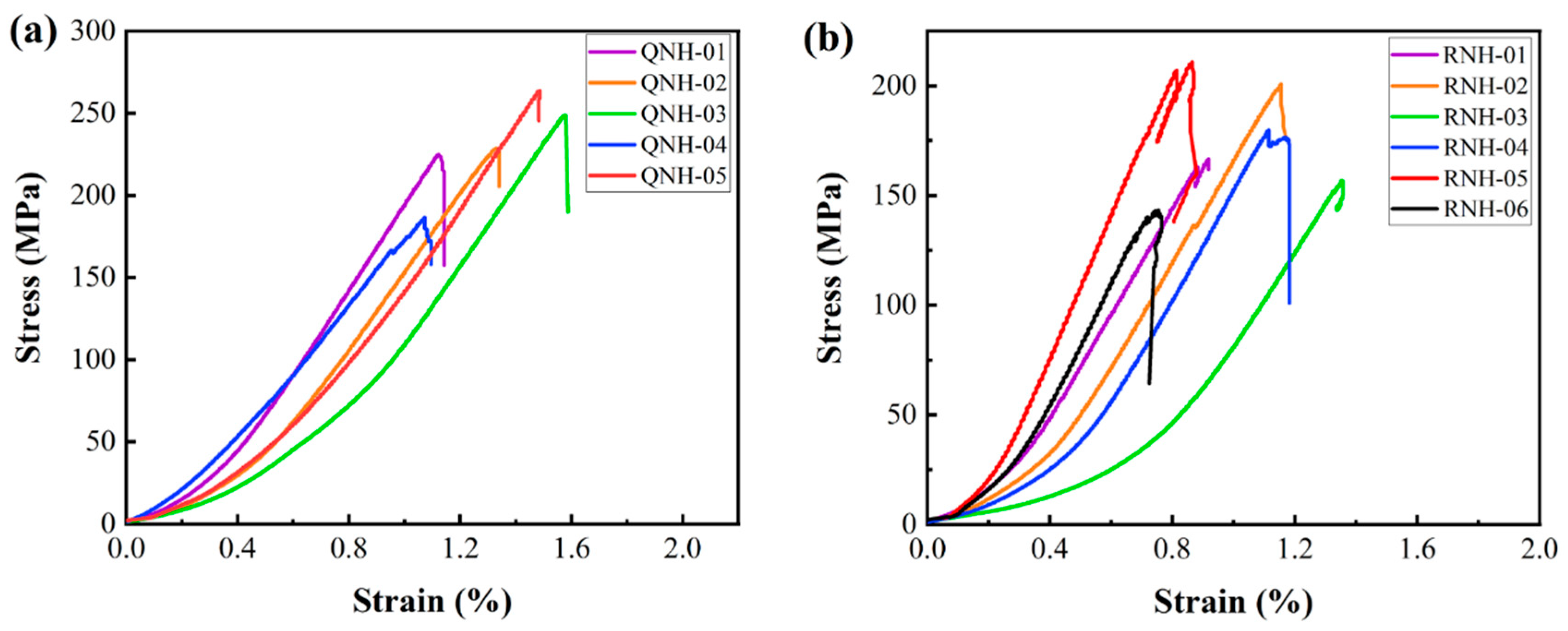

5.1. Strength of the Welded Tuffs

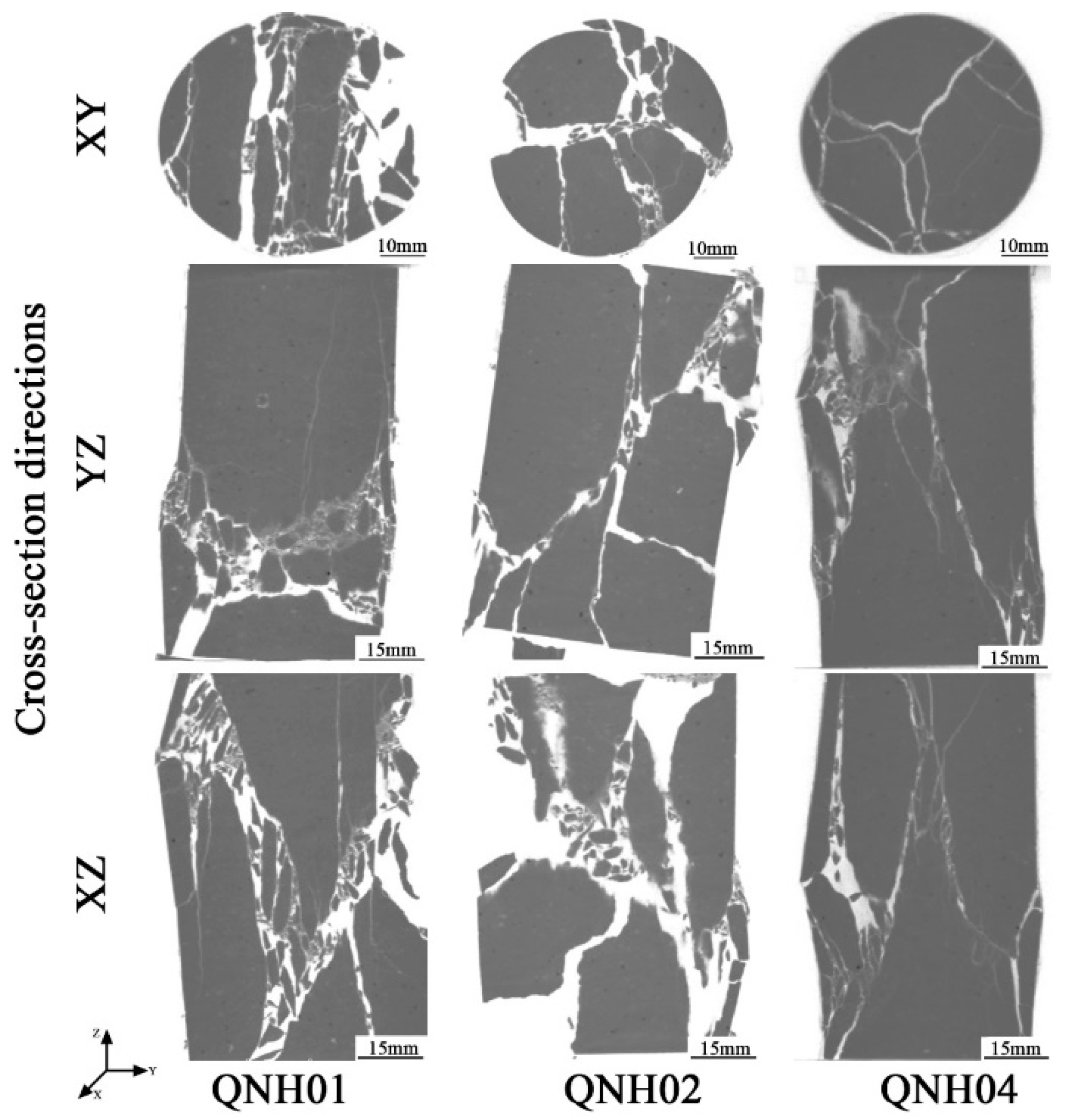

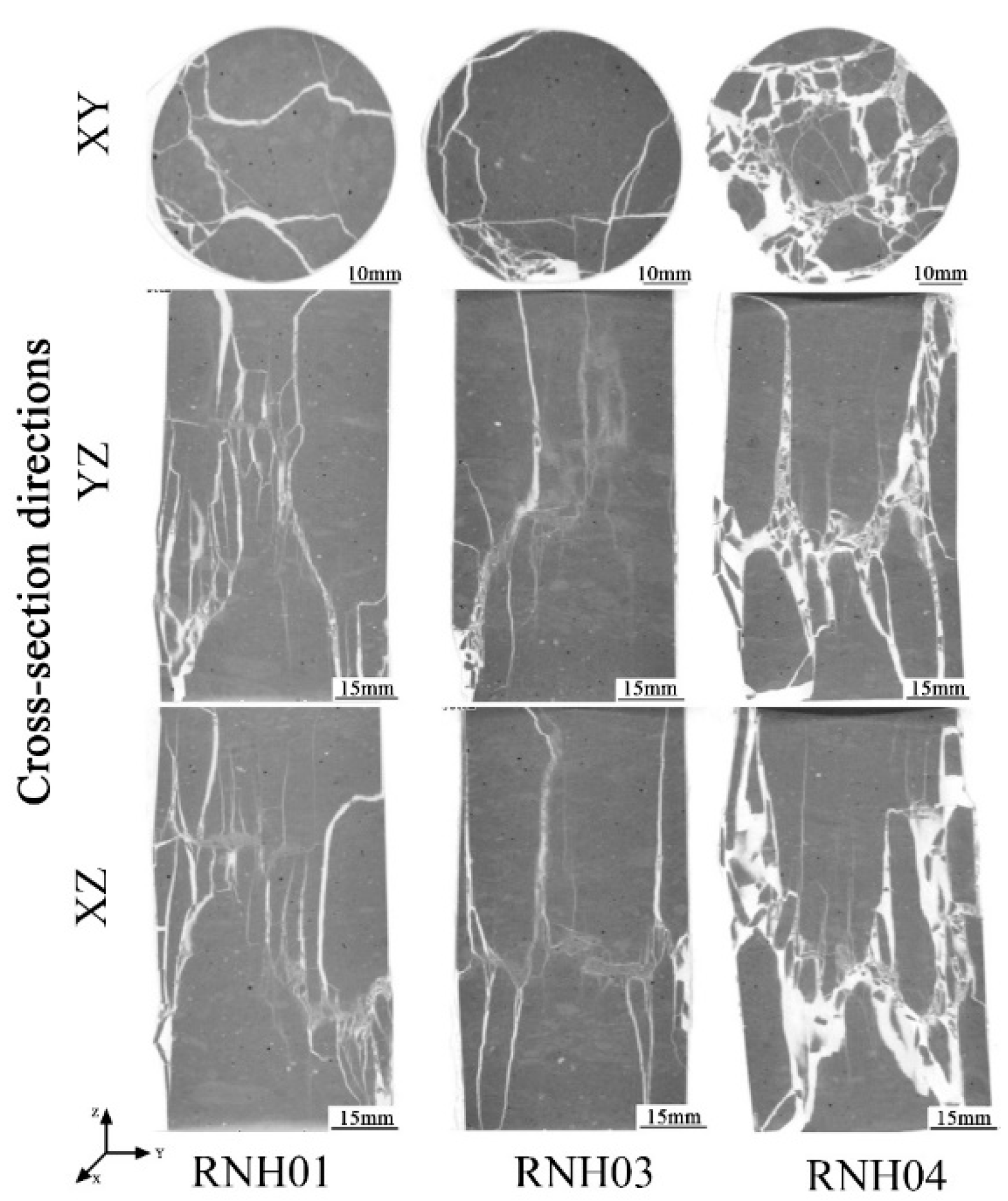

5.2. Failure Modes of the Welded Tuffs

6. Discussion

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Watson, D.; Schofield, N.; Jolley, D.; Archer, S.; Finlay, A.J.; Mark, N.; Hardman, J.; Watton, T. Stratigraphic overview of Palaeogene tuffs in the Faroe–Shetland Basin, NE Atlantic Margin. J. Geol. Soc. 2017, 174, 627–645. [Google Scholar] [CrossRef]

- Xie, J. Identification of magma fragments and pumice fragments in welded tuff. Volcanol. Miner. Resour. 1994, 15, 62–63. [Google Scholar]

- Aslan, Z. UPb zircon SHRIMP age, geochemical and petrographical characteristics of tuffs within calc-alkaline Eocene volcanics around Gumushane (NE Turkey), Eastern Pontides. Neues Jahrb. Mineral. Abh. 2010, 187, 329–346. [Google Scholar] [CrossRef]

- Pal, T.; Gupta, T.D.; Das Gupta, S.C. Vitric tuff from Archipelago Group (Mio-Pliocene), South Andaman. J. Geol. Soc. India 2002, 59, 111–114. [Google Scholar]

- Zheng, M.; Li, B. Characteristics and anti-collapse of tuff in Dapingzhang Copper Mine in Western Yunnan. Geotech. Investig. Surv. 2020, 48, 6–11. [Google Scholar]

- Bao, Y. Characterics of ignimbrites in Zhejiang province. Reg. Geol. China 1986, 3, 228–238. [Google Scholar]

- Jin, L. Petrological and petrochemical characteristics of Mesozoic glassy volcanic rocks in Shandong Province. Shandong Land Resour. 1992, 8, 53–67. [Google Scholar]

- Henry, C.D.; Faulds, J.E. Ash-flow tuffs in the Nine Hill, Nevada, paleovalley and implications for tectonism and volcanism of the western Great Basin, USA. Geosphere 2010, 6, 339–369. [Google Scholar] [CrossRef]

- Xie, J. Identification of the degree of welded pyroclastic rocks. Volcanol. Miner. Resour. 1995, 16, 51–52. [Google Scholar]

- Zhu, S.; Zhu, X.; Liu, J.; Yao, Y.; Xian, B.; Niu, H.; Zhao, C. Genesis and hydrocarbon significance of vesicular welded tuffs: A case study from the Fengcheng Formation, Wu-Xia area, Junggar Basin, NW China. Pet. Explor. Dev. 2012, 39, 173–183. [Google Scholar] [CrossRef]

- Kaçmaz, H.; Köktürk, U. Geochemistry and mineralogy of zeolitic tuffs from the Alaçatı (Çeşme) area, Turkey. Clays Clay Miner. 2004, 52, 705–713. [Google Scholar] [CrossRef]

- Freundt, A. The formation of high-grade ignimbrites, I: Experiments on high- and low-concentration transport systems containing sticky particles. Bull. Volcanol. 1998, 59, 414–435. [Google Scholar] [CrossRef]

- Branney, M.J.; Kokelaar, P. A reappraisal of ignimbrite emplacement: Progressive aggradation and changes from particulate to non-particulate flow during emplacement of high-grade ignimbrite. Bull. Volcanol. 1992, 54, 504–520. [Google Scholar] [CrossRef]

- Branney, M.J.; Kokelaar, B.P.; McConnell, B.J. The Bad Step Tuff: A lava-like rheomorphic ignimbrite in a calc-alkaline piecemeal caldera, English Lake District. Bull. Volcanol. 1992, 54, 187–199. [Google Scholar] [CrossRef]

- Akın, M.; Özvan, A.; Dinçer, I.; Topal, T. Evaluation of the physico-mechanical parameters affecting the deterioration rate of Ahlat ignimbrites (Bitlis, Turkey). Environ. Earth Sci. 2017, 76, 827. [Google Scholar] [CrossRef]

- Geissman, J.W.; Holm, D.; Harlan, S.S.; Embree, G.F. Rapid, high-temperature formation of large-scale rheomorphic structures in the 2.06 Ma Huckleberry Ridge Tuff, Idaho, USA. Geology 2010, 38, 263–266. [Google Scholar] [CrossRef]

- Branney, M.J.; Sparks, R.S.J. Fiamme formed by diagenesis and burial-compaction in soils and subaqeuous sediments. J. Geol. Soc. 1990, 147, 919–922. [Google Scholar] [CrossRef]

- Crawford, B.R.; DeDontney, N.L.; Alramahi, B.; Ottesen, S. Shear strength anisotropy in fine-grained rocks. In Proceedings of the 46th US Rock Mechanics/Geomechanics Symposium 2012, Chicago, IL, USA, 24–27 June 2012; pp. 425–436. [Google Scholar]

- Erarslan, N.; Alehossein, H.; Williams, D.J. Tensile Fracture Strength of Brisbane Tuff by Static and Cyclic Loading Tests. Rock Mech. Rock Eng. 2013, 47, 1135–1151. [Google Scholar] [CrossRef]

- Erarslan, N.; Williams, D. Mechanism of rock fatigue damage in terms of fracturing modes. Int. J. Fatigue 2012, 43, 76–89. [Google Scholar] [CrossRef]

- Sandeep, C.S.; Todisco, M.C.; Nardelli, V.; Senetakis, K.; Coop, M.R.; Lourenco, S.D.N. A micromechanical experimental study of highly/completely decomposed tuff granules. Acta Geotech. 2018, 13, 1355–1367. [Google Scholar] [CrossRef]

- Price, R.H.; Bauer, S.J. Analysis of the elastic and strength properties of Yucca Mountain tuff, Nevada. In Proceedings of the 26th US Symposium on Rock Mechanics, Rapid City, SD, USA, 26–28 June 1985; pp. 89–96. [Google Scholar]

- Price, R.H. Analysis of the Rock Mechanics Properties of Volcanic Tuff Units from Yucca Mountain, Nevada Test Site; Sandia National Lab. (SNL-NM): Albuquerque, NM, USA, 1983. [Google Scholar] [CrossRef]

- Glover, P.W.J.; Baud, P.; Darot, M.; Meredith, P.G.; Boon, S.A.; LeRavalec, M.; Zoussi, S.; Reuschlé, T. α/β phase transition in quartz monitored using acoustic emissions. Geophys. J. Int. 1995, 120, 775–782. [Google Scholar] [CrossRef]

- Yong, C.; Wang, C.-Y. Thermally induced acoustic emission in westerly granite. Geophys. Res. Lett. 1980, 7, 1089–1092. [Google Scholar] [CrossRef]

- Yang, S.-Q.; Ranjith, P.; Jing, H.-W.; Tian, W.-L.; Ju, Y. An experimental investigation on thermal damage and failure mechanical behavior of granite after exposure to different high temperature treatments. Geothermics 2017, 65, 180–197. [Google Scholar] [CrossRef]

- Griffiths, L.; Heap, M.; Baud, P.; Schmittbuhl, J. Quantification of microcrack characteristics and implications for stiffness and strength of granite. Int. J. Rock Mech. Min. Sci. 2017, 100, 138–150. [Google Scholar] [CrossRef]

- Li, M.; Mao, X.; Cao, L.; Pu, H.; Mao, R.; Lu, A. Effects of Thermal Treatment on the Dynamic Mechanical Properties of Coal Measures Sandstone. Rock Mech. Rock Eng. 2016, 49, 3525–3539. [Google Scholar] [CrossRef]

- Fredrich, J.T.; Wong, T.-F. Micromechanics of thermally induced cracking in three crustal rocks. J. Geophys. Res. Solid Earth 1986, 91, 12743–12764. [Google Scholar] [CrossRef]

- Dwivedi, R.; Goel, R.; Prasad, V.; Sinha, A. Thermo-mechanical properties of Indian and other granites. Int. J. Rock Mech. Min. Sci. 2007, 45, 303–315. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, J. Triaxial test study of the depth effect on the mechanical properties of porous sandstone. Prog. Geophys. 1993, 8, 90–96. [Google Scholar]

- Zhou, Y.; Geng, Y.; Wang, G.; Tang, H.; Li, Z. Testing and analyzing rock mechanical characteristics for deep formation. Rock Soil Mech. 2011, 32, 1625–1630. [Google Scholar] [CrossRef]

- Fang, H.; Wu, X. The mechanical properties and velocities of rocks pre-and post-failure under pressure and temperature. Prog. Geophys. 1999, 14, 73–78. [Google Scholar]

- Zhu, H.; Yan, Z.; Deng, T.; Yao, J.; Zeng, L.; Qiang, J. Testing study on mechanical properties of tuff, granite and breccia after high temperatures. Chin. J. Rock Mech. Eng. 2006, 25, 1945–1950. [Google Scholar]

- Yan, Z.; Zhu, H.; Deng, T.; Zeng, L.; Yao, J.; Qiang, J. Experimental study on longitudinal wave characteristics of tuff, granite and breccia after high temperature. Chin. J. Geotech. Eng. 2006, 28, 2010–2014. [Google Scholar]

- Rutqvist, J.; Tsang, C.-F. Multiphysics processes in partially saturated fractured rock: Experiments and models from Yucca Mountain. Rev. Geophys. 2012, 50, RG3006. [Google Scholar] [CrossRef]

- Heap, M.J.; Lavallée, Y.; Laumann, A.; Hess, K.-U.; Meredith, P.; Dingwell, D.B. How tough is tuff in the event of fire? Geology 2012, 40, 311–314. [Google Scholar] [CrossRef]

- Wang, X.; Frattini, P.; Stead, D.; Sun, J.; Liu, H.; Valagussa, A.; Li, L. Dynamic rockfall risk analysis. Eng. Geol. 2020, 272, 105622. [Google Scholar] [CrossRef]

- Wang, X.; Frattini, P.; Crosta, G.B.; Zhang, L.; Agliardi, F.; Lari, S.; Yang, Z. Uncertainty assessment in quantitative rockfall risk assessment. Landslides 2013, 11, 711–722. [Google Scholar] [CrossRef]

- SY/T 5163-2018; Analysis Method for Clay Minerals and Ordinary Non-Clay Minerals in Sedimentary Rocks by the X-ray Diffraction. National Energy Administration of the People’s Republic of China: Beijing, China, 2018.

- Washburn, E.W. The dynamics of capillary flow. Phys. Rev. 1921, 17, 273. [Google Scholar] [CrossRef]

- Li, L.; Tan, Y.; Huang, B.; Deng, X. Pore property as an indicator of macro-deterioration in slightly weathered tuffs. Eng. Geol. 2020, 267, 105492. [Google Scholar] [CrossRef]

- Tan, X.; Konietzky, H. Brazilian split tests and numerical simulation by discrete element method for heterogeneous gneiss with bedding structure. Chin. J. Rock Mech. Eng. 2014, 33, 938–0946. [Google Scholar]

- Keller, J.U.; Staudt, R. Gas Adsorption Equilibria—Experimental Methods and Adsorptive Isotherms; Springer Science & Business Media: Berlin, Germany, 2005. [Google Scholar]

| Lithology | Mineral Contents (%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q | O | P | D | H | CM | Relative Content of Clay Minerals (%) | ||||||

| S | I/S | I | K | C | C/S | |||||||

| Strongly welded tuff | 68.5 | 8.2 | 18.7 | / | 1.7 | 2.9 | / | 87 | 13 | / | / | / |

| Weakly welded tuff | 69.1 | 11.5 | 12.8 | 2.8 | / | 3.8 | 88 | / | 12 | / | / | / |

| Sample | No. | Uniaxial Compressive Strength (MPa) | Average | Elastic Modulus (GPa) | Average | Tensile Strength (MPa) | Average |

|---|---|---|---|---|---|---|---|

| Strongly welded tuff | QNH01 | 224.89 | 230.57 | 1.64 | 1.41 | 12.00 | 11.64 |

| QNH02 | 228.75 | 1.37 | 11.72 | ||||

| QNH03 | 248.68 | 1.16 | 11.53 | ||||

| QNH04 | 186.76 | 1.52 | 10.82 | ||||

| QNH05 | 263.75 | 1.38 | 12.14 | ||||

| Weakly welded tuff | RNH01 | 166.81 | 176.42 | 1.52 | 1.43 | 10.99 | 10.98 |

| RNH02 | 200.95 | 1.39 | 14.33 | ||||

| RNH03 | 156.78 | 0.79 | 9.46 | ||||

| RNH04 | 179.74 | 1.2 | 11.79 | ||||

| RNH05 | 210.92 | 2.13 | 8.35 | ||||

| RNH06 | 143.33 | 1.54 | / |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Li, C.; Huang, B.; Wang, M.; Bai, Z.; Qi, S. Influence of the Welding Degree on the Strength and Failure Modes of Tuff. Materials 2022, 15, 8757. https://doi.org/10.3390/ma15248757

Li L, Li C, Huang B, Wang M, Bai Z, Qi S. Influence of the Welding Degree on the Strength and Failure Modes of Tuff. Materials. 2022; 15(24):8757. https://doi.org/10.3390/ma15248757

Chicago/Turabian StyleLi, Lihui, Chenglong Li, Beixiu Huang, Ming Wang, Zhida Bai, and Shengwen Qi. 2022. "Influence of the Welding Degree on the Strength and Failure Modes of Tuff" Materials 15, no. 24: 8757. https://doi.org/10.3390/ma15248757

APA StyleLi, L., Li, C., Huang, B., Wang, M., Bai, Z., & Qi, S. (2022). Influence of the Welding Degree on the Strength and Failure Modes of Tuff. Materials, 15(24), 8757. https://doi.org/10.3390/ma15248757