Self-Propelled Rotary Tools in Hard Turning: Analysis and Optimization via Finite Element Models

Abstract

:1. Introduction

2. Materials and Methods

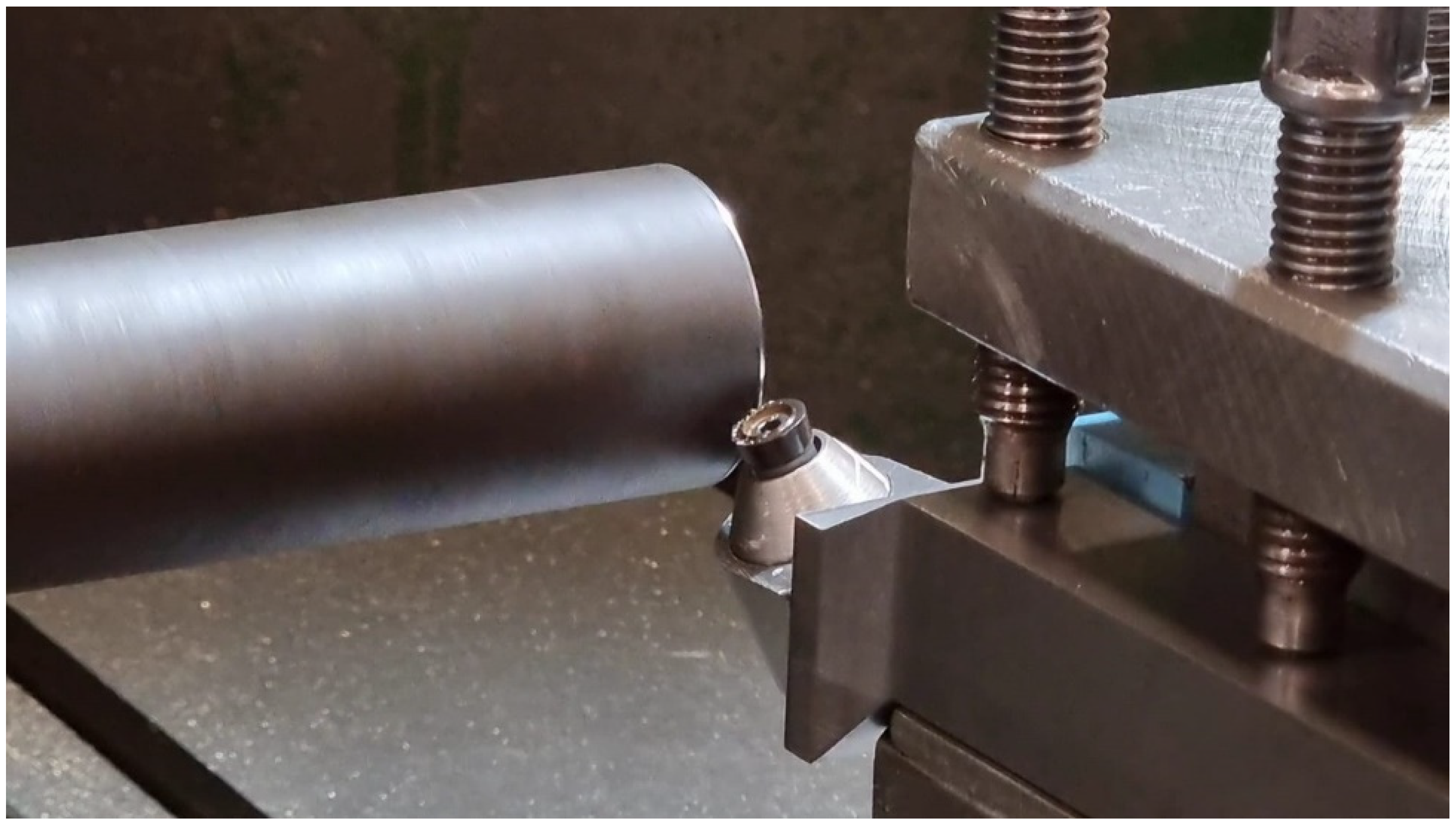

2.1. Experimental Setup

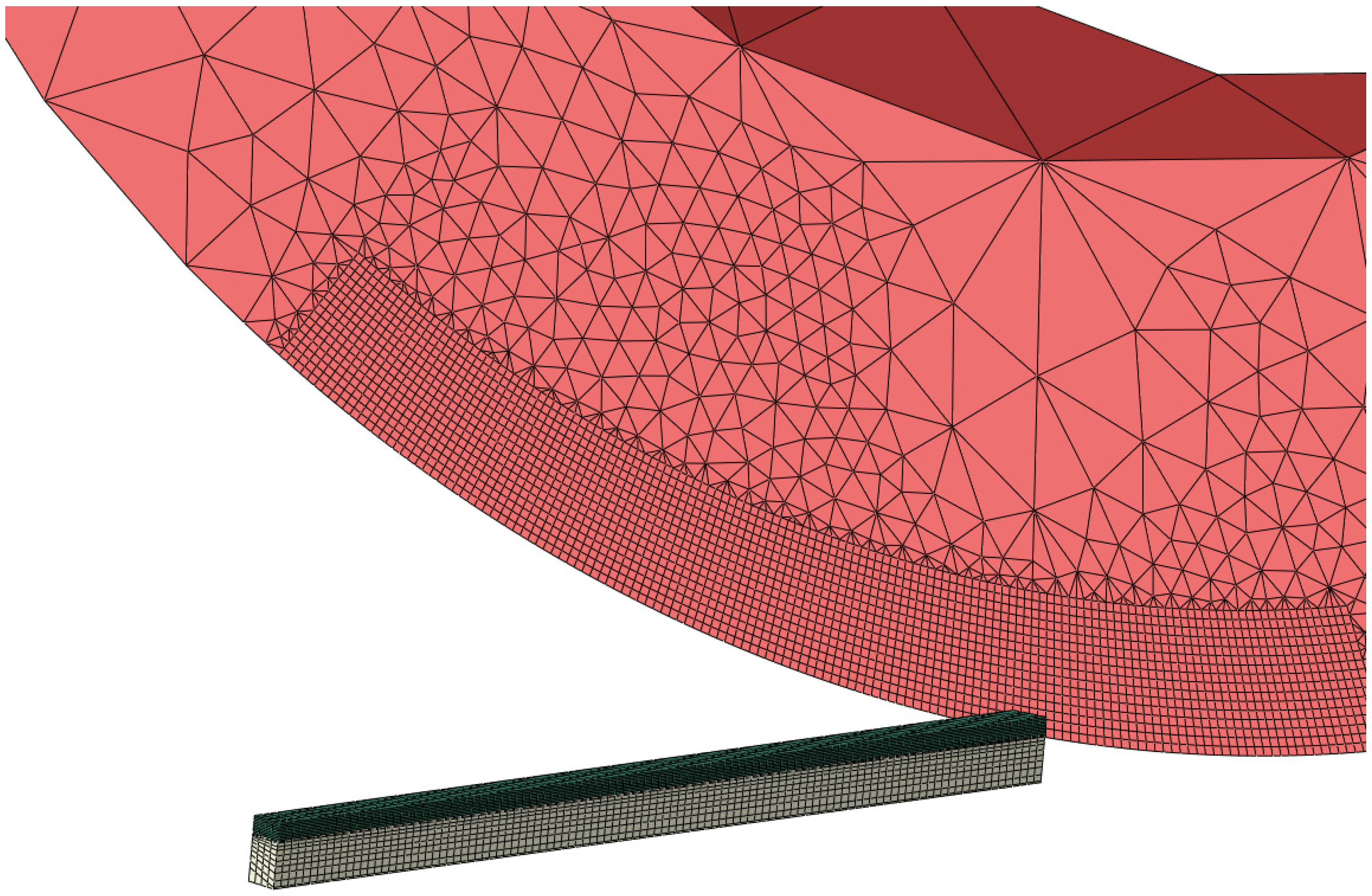

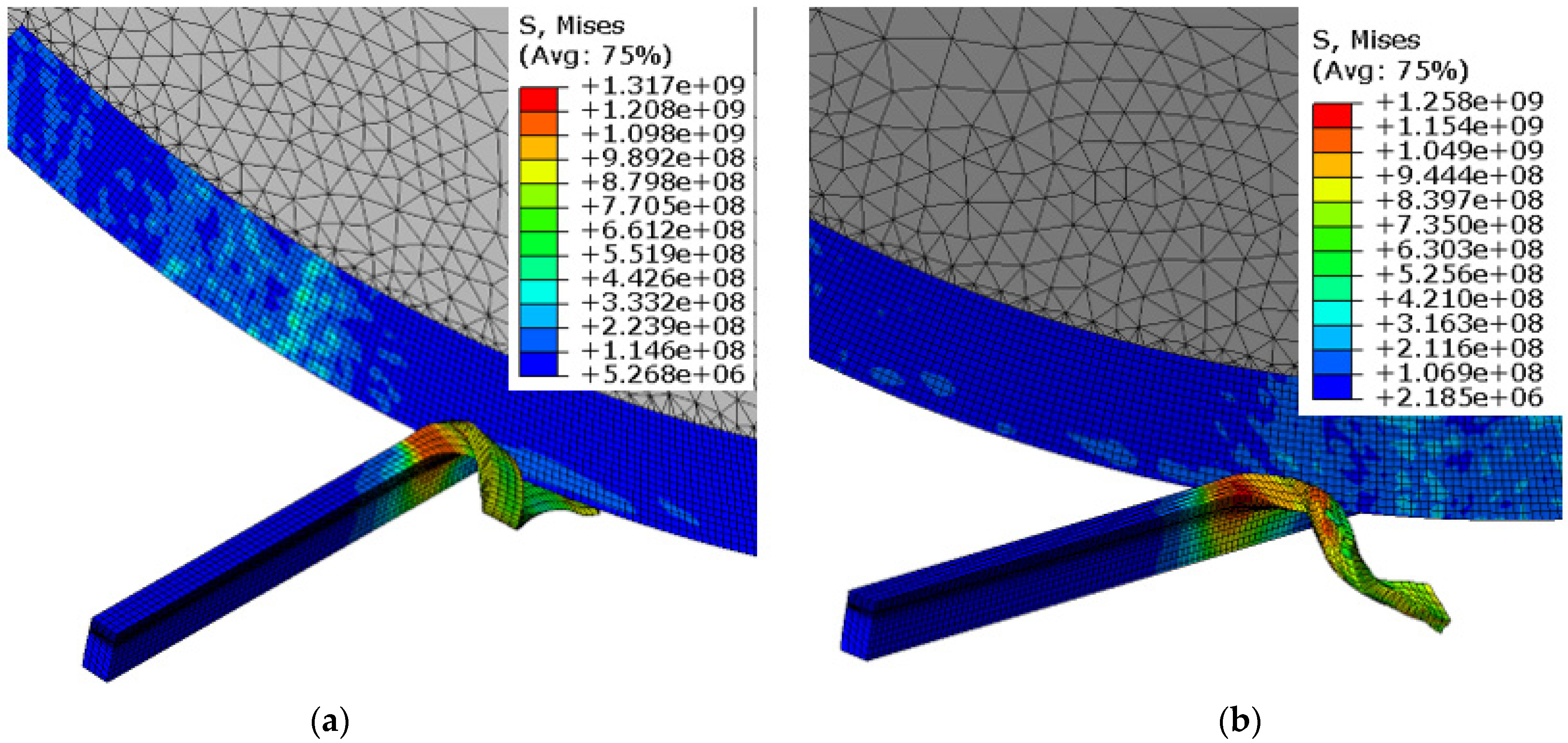

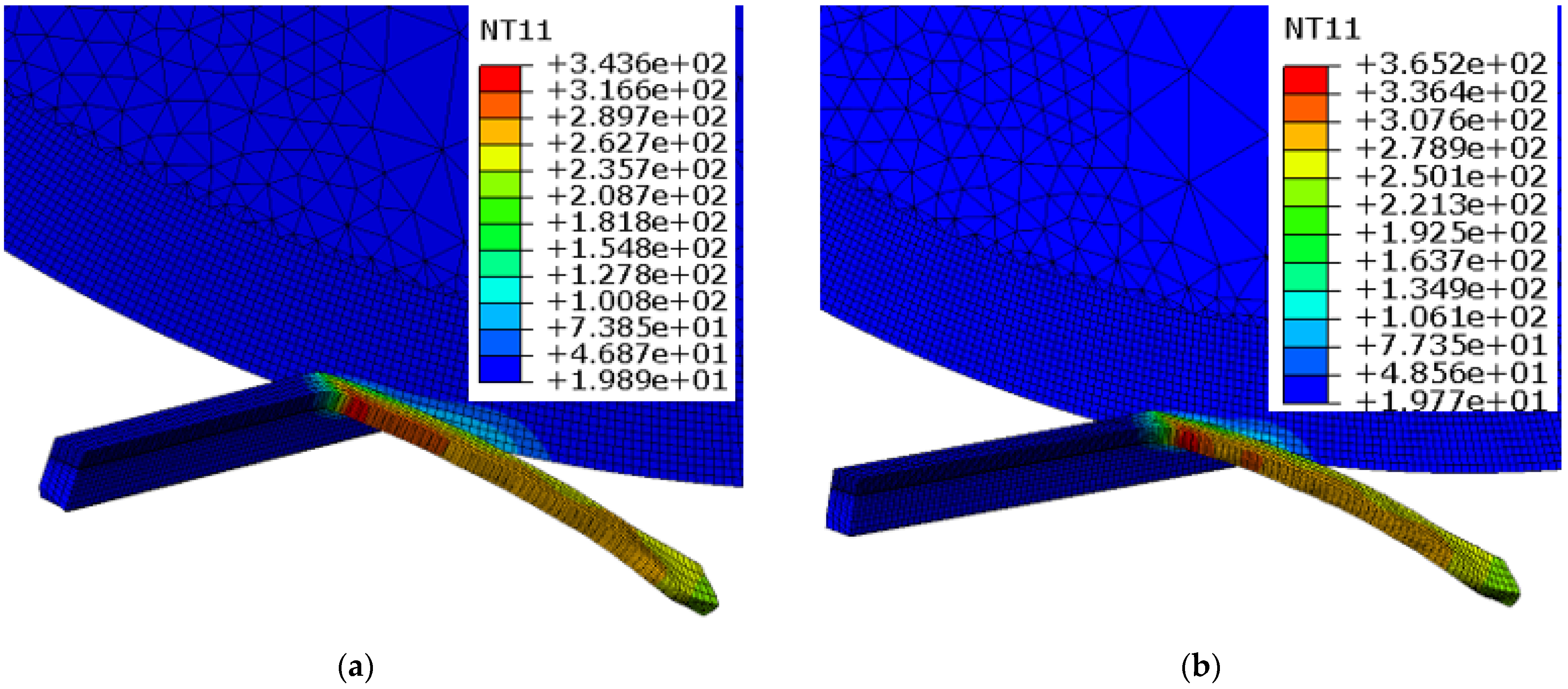

2.2. The Finite Element Model for SPRTs

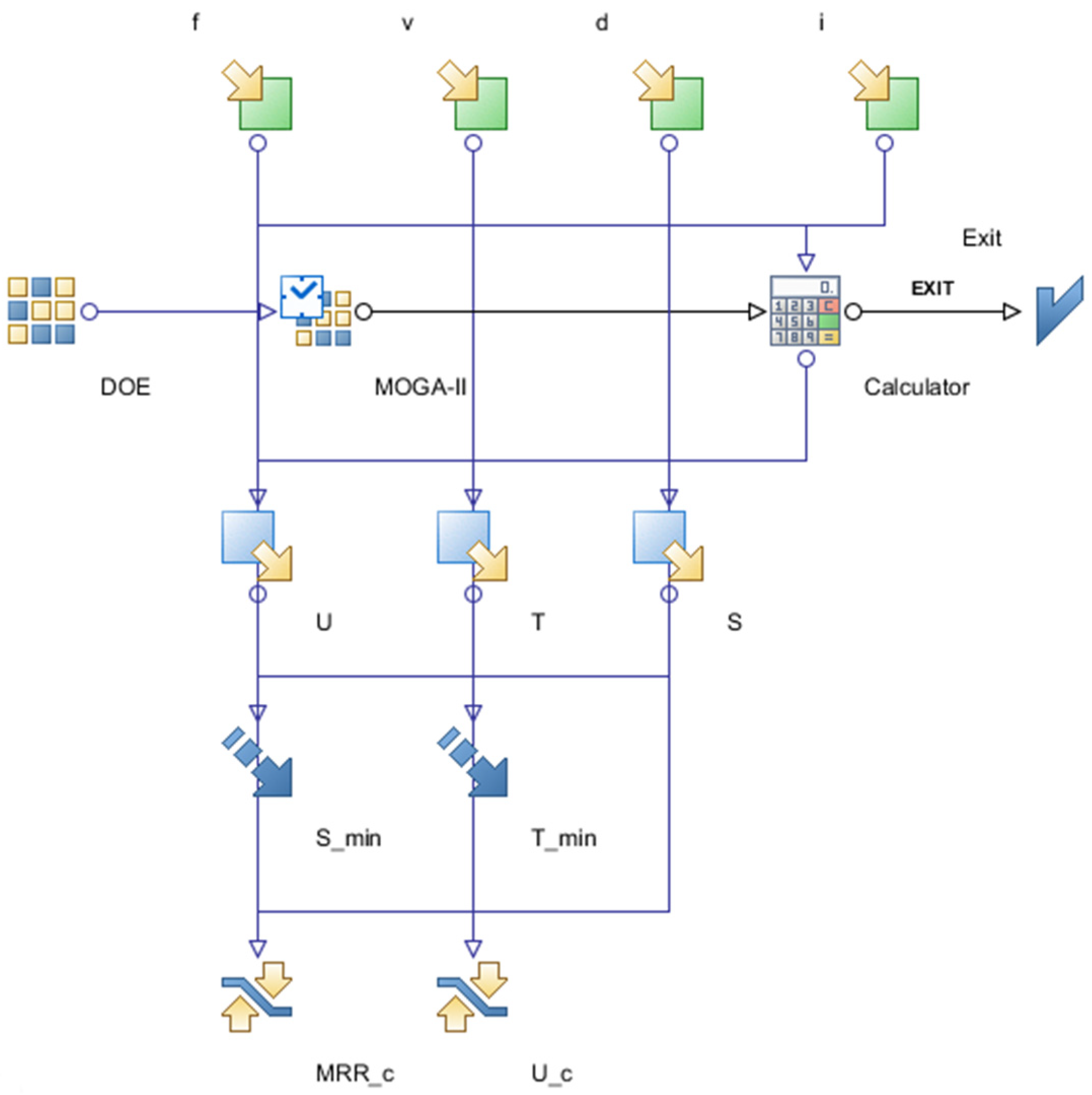

2.3. Optimization Problem

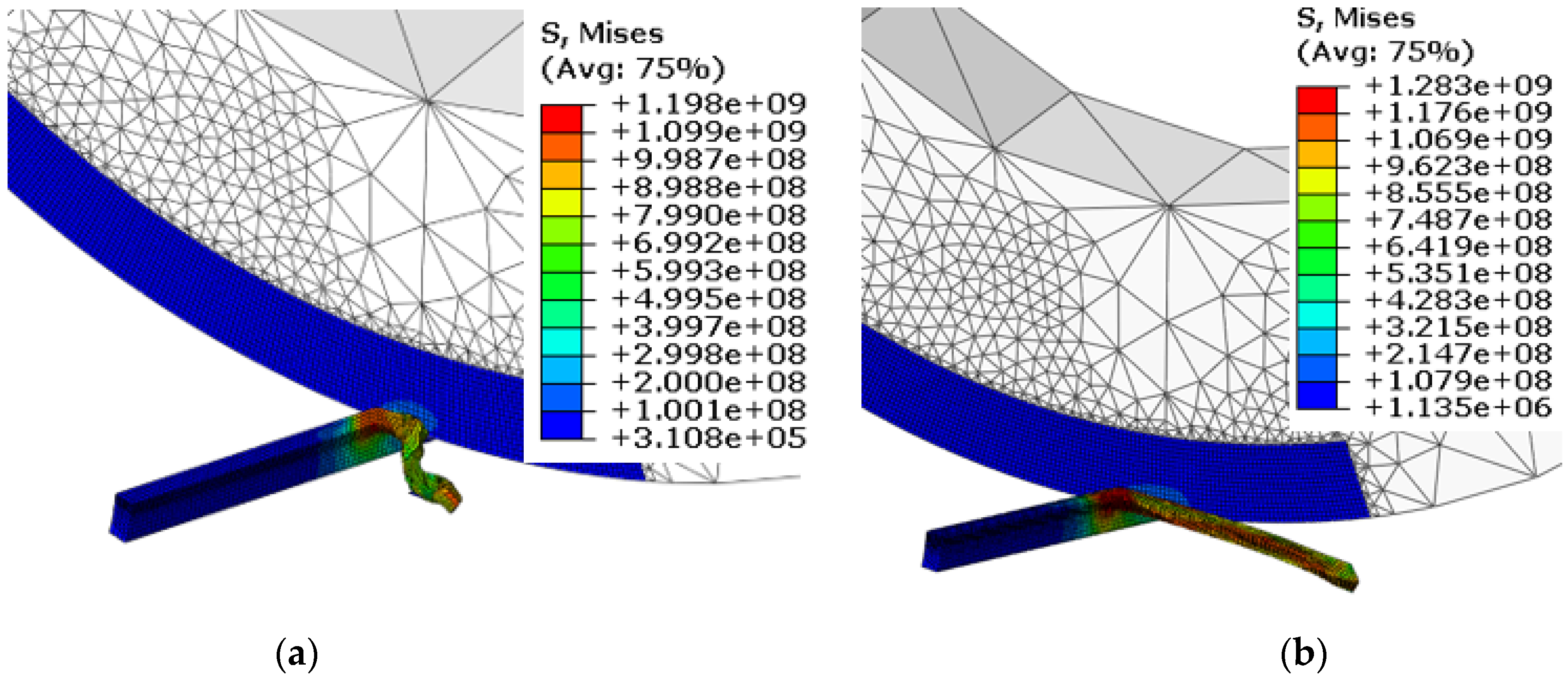

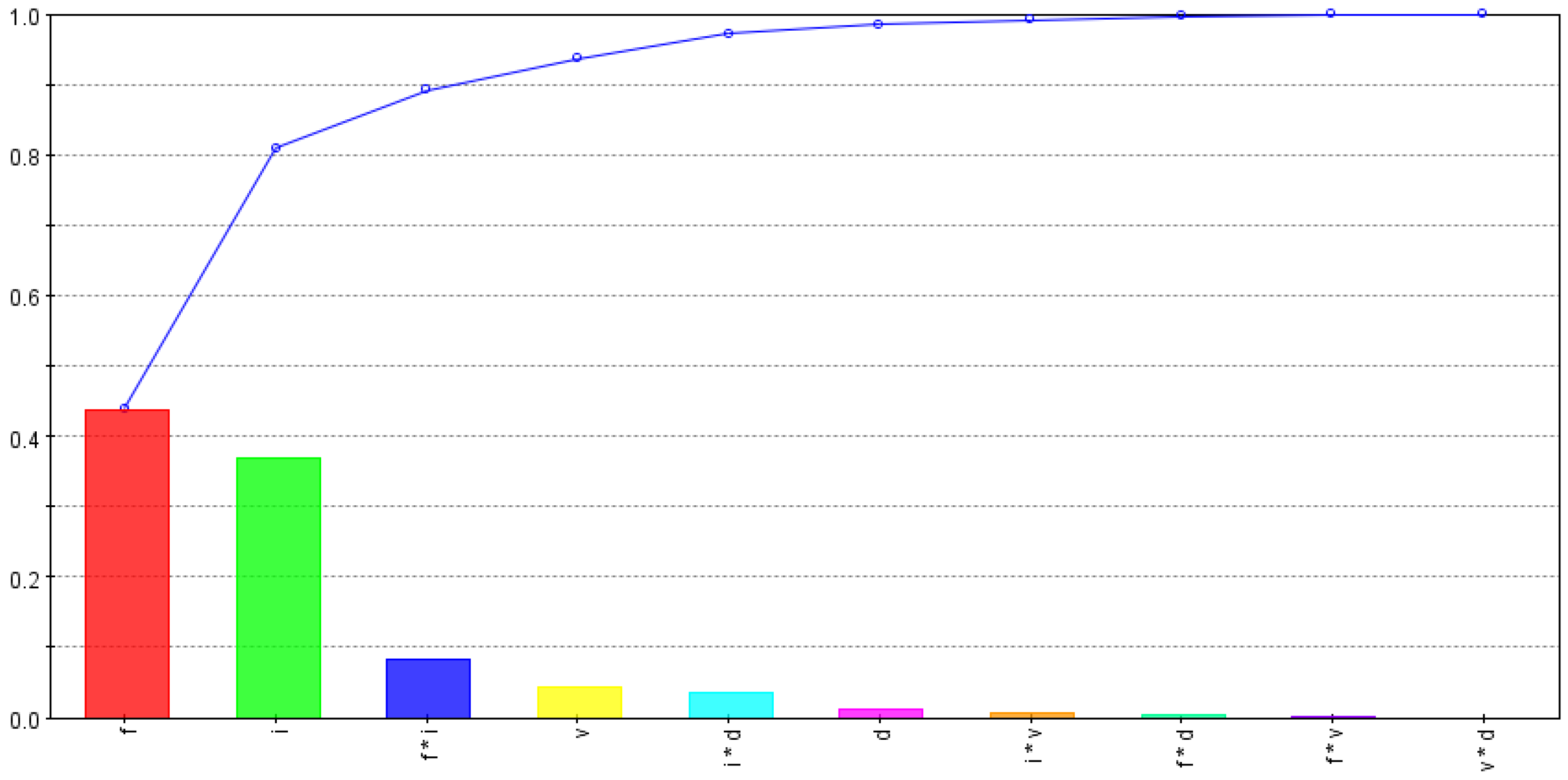

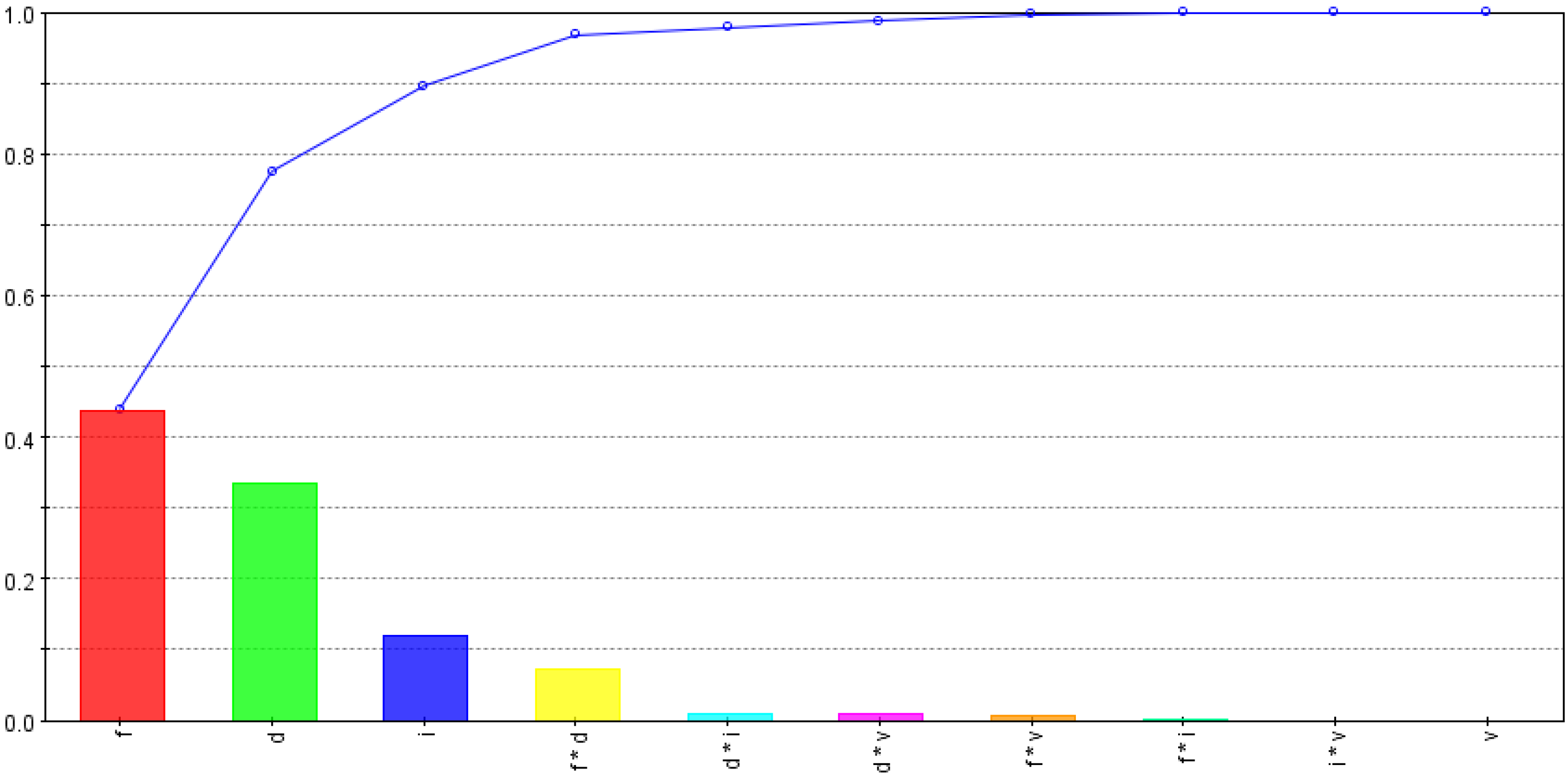

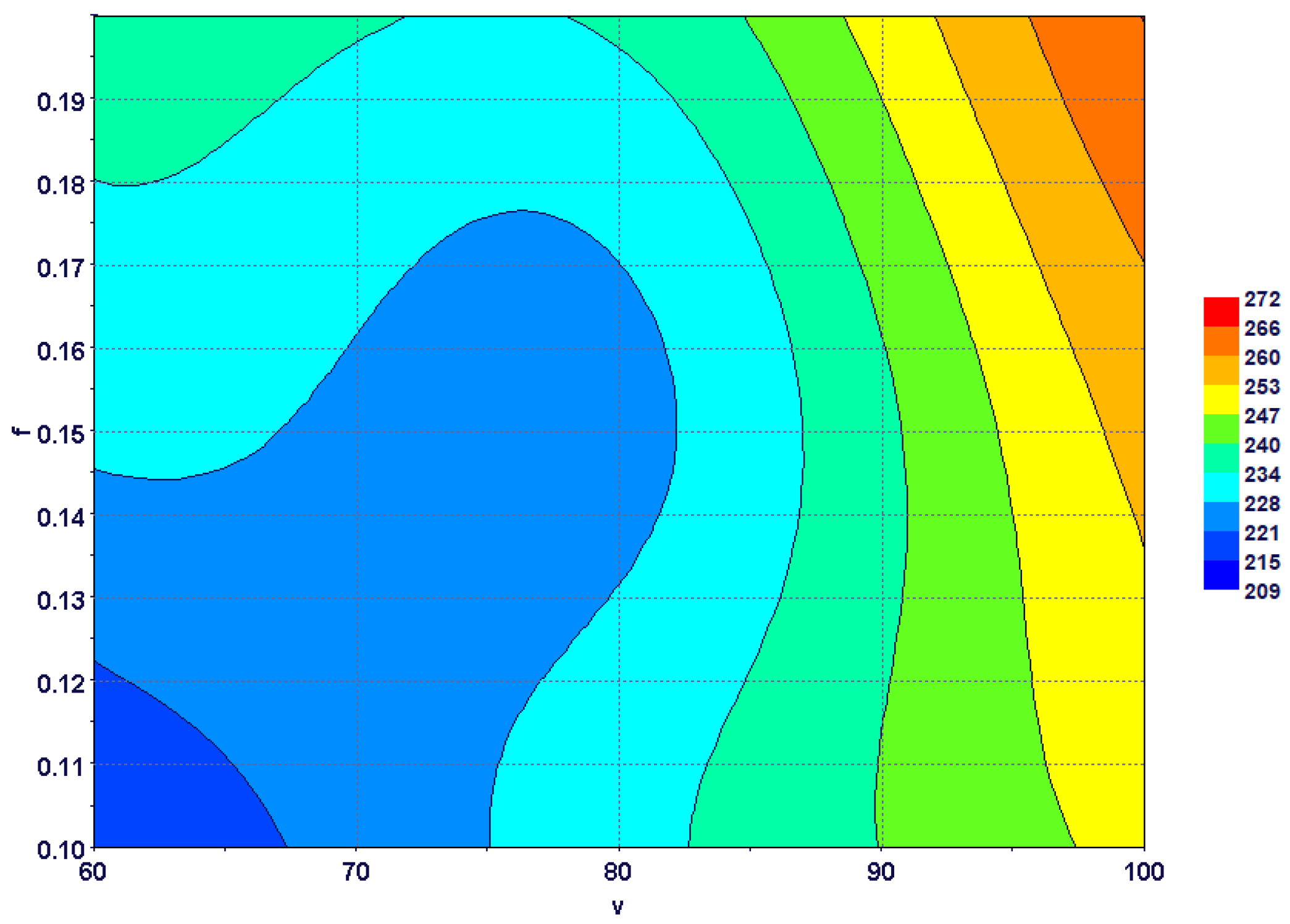

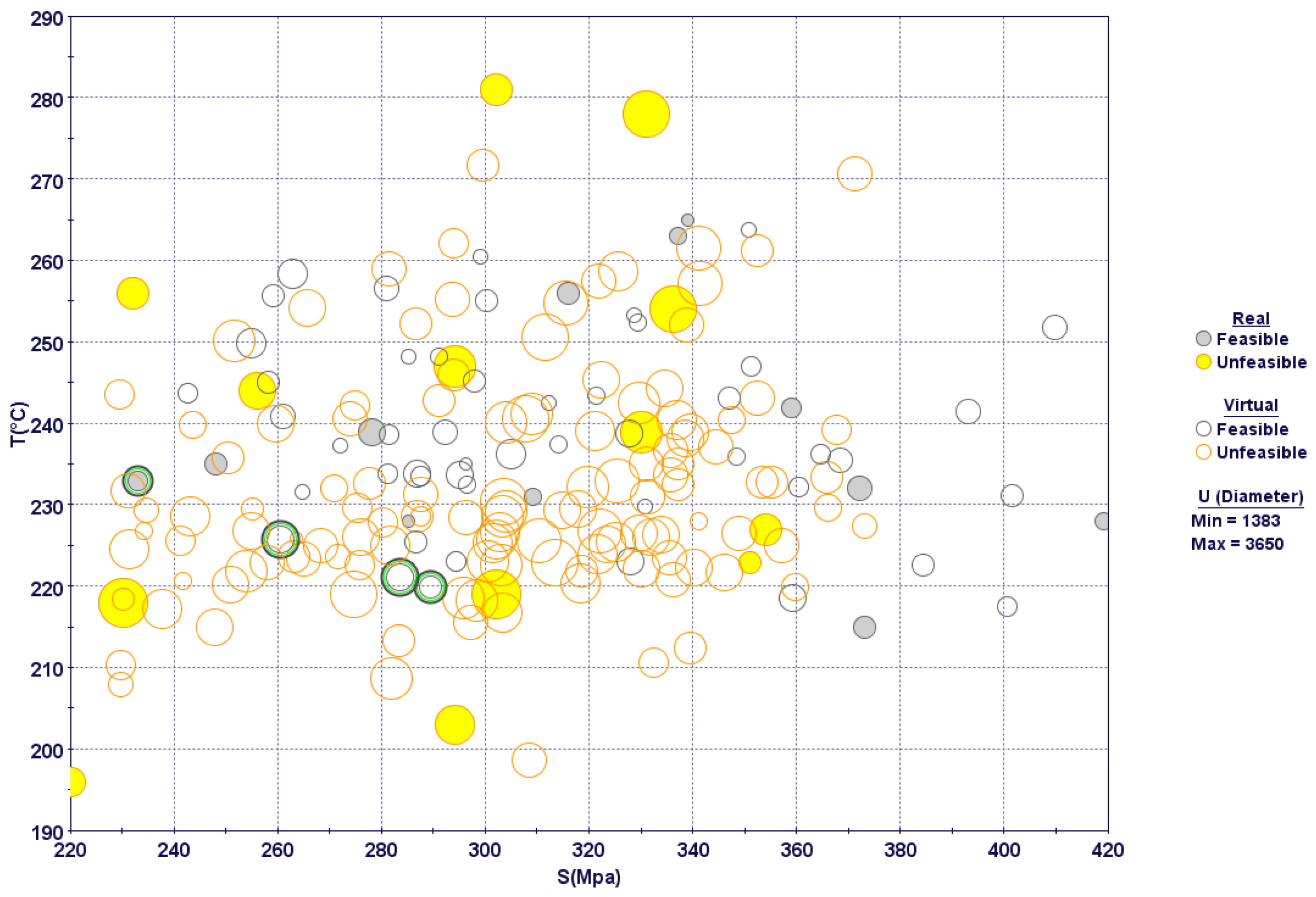

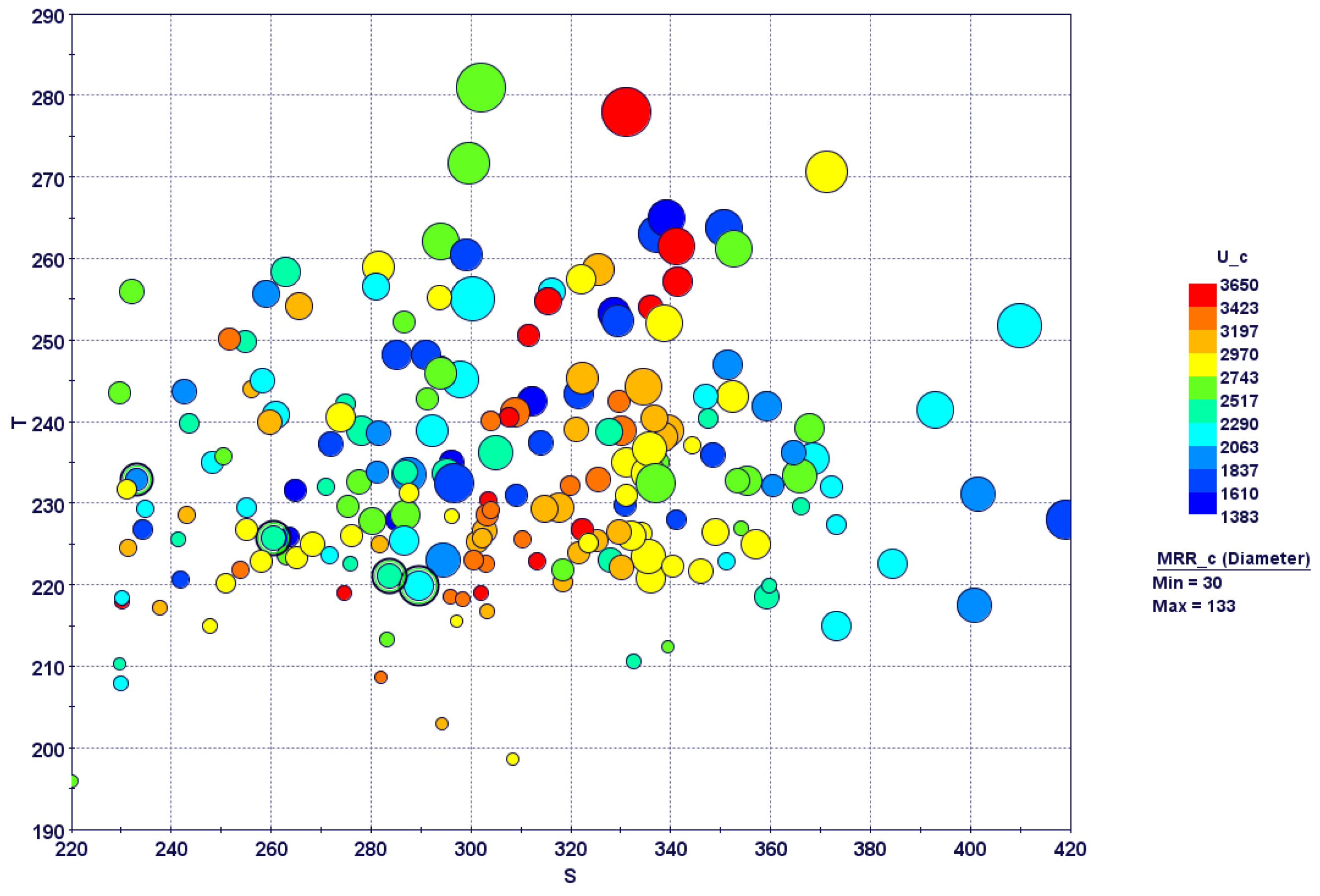

3. Results and Discussion

4. Conclusions

- The 3D FE models developed for the SPRT show good agreement with the experimental results, and the errors were 10% and 12% for cutting force and temperature, respectively.

- These models are able to predict changes in chip morphology with varying feed rates.

- Low feed rates result in higher chip flow angles, which leads to chip curling.

- Cutting force and von Mises stress fluctuate with the tool inclination angle. Low von Mises stress is found at higher inclination angles.

- Higher cutting speeds result in escalation of maximum tool–chip interface temperatures.

- Tool stress is found to be highly dependent on the feed rate and the inclination angle, whereas the effects of the cutting speed and the depth of the cut are found to be negligible.

- Optimized SPRT performance is found with moderate cutting speeds and moderate feed rates, with higher depths of cut and higher inclination angles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Batista, M.; Del Sol, I.; Gomez-Parra, A.; Ramirez-Peña, M.; Salguero, J. Study of the Tool Wear Process in the Dry Turning of Al–Cu Alloy. Metals 2019, 9, 1094. [Google Scholar] [CrossRef] [Green Version]

- Chuangwen, X.; Jianming, D.; Yuzhen, C.; Huaiyuan, L.; Zhicheng, S.; Jing, X. The Relationships between Cutting Parameters, Tool Wear, Cutting Force and Vibration. Adv. Mech. Eng. 2018, 10, 1687814017750434. [Google Scholar] [CrossRef]

- Machado, Á.R.; Diniz, A.E. Tool Wear Analysis in the Machining of Hardened Steels. Int. J. Adv. Manuf. Technol. 2017, 92, 4095–4109. [Google Scholar] [CrossRef]

- Bashir, M.A.; Mia, M.; Dhar, N.R. Investigations on Surface Milling of Hardened AISI 4140 Steel with Pulse Jet MQL Applicator. J. Inst. Eng. India Ser. C 2018, 99, 301–314. [Google Scholar] [CrossRef]

- Courbon, C.; Sajn, V.; Kramar, D.; Rech, J.; Kosel, F.; Kopac, J. Investigation of Machining Performance in High Pressure Jet Assisted Turning of Inconel 718: A Numerical Model. J. Mater. Process. Technol. 2011, 211, 1834–1851. [Google Scholar] [CrossRef]

- Mia, M.; Dhar, N.R. Effect of high pressure coolant jet on cutting temperature, tool wear and surface finish in turning hardened (HRC 48) steel. J. Mech. Eng. 2015, 45, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Dos Santos, F.A.; de Camargo Pinto, M.A.; dos Santos, R.O.B.; Bimestre, T.A.; Gama, R.P. Comparative Analysis of the Application of Lubricant Coolant by the MQF Technique in the Face Milling Machining Process of Hardened D2 Steel Alloy/Análise Comparativa Da Aplicação de Fluído Lubri-Refrigerante Pelo Método MQL No Processo de Usinagem Por Fresamento Frontal Do Aço D2 Endurecido. Braz. J. Dev. 2021, 7, 10349–10370. [Google Scholar] [CrossRef]

- Krolczyk, G.M.; Maruda, R.W.; Krolczyk, J.B.; Wojciechowski, S.; Mia, M.; Nieslony, P.; Budzik, G. Ecological Trends in Machining as a Key Factor in Sustainable Production—A Review. J. Clean. Prod. 2019, 218, 601–615. [Google Scholar] [CrossRef]

- Mia, M.; Dhar, N.R. Effects of Duplex Jets High-Pressure Coolant on Machining Temperature and Machinability of Ti-6Al-4V Superalloy. J. Mater. Process. Technol. 2018, 252, 688–696. [Google Scholar] [CrossRef]

- Ahmed, W.; Hegab, H.; Mohany, A.; Kishawy, H. Sustainability Assessment of Difficult-to-Cut Materials Using Rotary Tools: A Step towards Sustainable Machining Environment. Procedia Manuf. 2021, 53, 92–98. [Google Scholar] [CrossRef]

- Abbas, A.T.; El Rayes, M.M.; Luqman, M.; Naeim, N.; Hegab, H.; Elkaseer, A. On the Assessment of Surface Quality and Productivity Aspects in Precision Hard Turning of AISI 4340 Steel Alloy: Relative Performance of Wiper vs. Conventional Inserts. Materials 2020, 13, 2036. [Google Scholar] [CrossRef] [PubMed]

- Astakhov, V.P. Machining of Hard Materials—Definitions and Industrial Applications. In Machining of Hard Materials; Davim, J.P., Ed.; Springer: London, UK, 2011; pp. 1–32. ISBN 978-1-84996-450-0. [Google Scholar]

- Afteni, M.; Terecoasa, I.; Afteni, C.; Paunoiu, V. Study on Hard Turning Process Versus Grinding in Manufacturing Some Bearing Inner Rings. In NEWTECH 2017: Proceedings of 5th International Conference on Advanced Manufacturing Engineering and Technologies; Majstorovic, V., Jakovljevic, Z., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 95–111. [Google Scholar]

- Kishawy, H.A.; Pang, L.; Balazinski, M. Modeling of Tool Wear during Hard Turning with Self-Propelled Rotary Tools. Int. J. Mech. Sci. 2011, 53, 1015–1021. [Google Scholar] [CrossRef]

- Şap, E.; Usca, U.A.; Gupta, M.K.; Kuntoğlu, M. Tool Wear and Machinability Investigations in Dry Turning of Cu/Mo-SiCp Hybrid Composites. Int. J. Adv. Manuf. Technol. 2021, 114, 379–396. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z. Influences of Coating Thickness on Cutting Temperature for Dry Hard Turning Inconel 718 with PVD TiAlN Coated Carbide Tools in Initial Tool Wear Stage. J. Manuf. Process. 2020, 56, 1155–1165. [Google Scholar] [CrossRef]

- Olgun, U.; Budak, E. Machining of Difficult-to-Cut-Alloys Using Rotary Turning Tools. Procedia CIRP 2013, 8, 81–87. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, T.-T. An Energy-Efficient Optimization of the Hard Turning Using Rotary Tool. Neural Comput. Appl. 2021, 33, 2621–2644. [Google Scholar] [CrossRef]

- Singh, R.P.; Singhal, S. Rotary Ultrasonic Machining: A Review. Mater. Manuf. Process. 2016, 31, 1795–1824. [Google Scholar] [CrossRef]

- Amini, S.; Aghaei, M.; Lotfi, M.; Hakimi, E. Analysis of Linear Vibration in Rotary Turning of AISI 4140 Steel. Int. J. Adv. Manuf. Technol. 2017, 91, 4107–4116. [Google Scholar] [CrossRef]

- Armarego, E.J.A.; Karri, V.; Smith, A.J.R. Fundamental Studies of Driven and Self-Propelled Rotary Tool Cutting Processes—II. Experimental Investigation. Int. J. Mach. Tools Manuf. 1994, 34, 803–815. [Google Scholar] [CrossRef]

- Gurgen, S.; Sofuoglu, M.A.; Cakir, F.H.; Orak, S.; Kushan, M.C. Multi Response Optimization of Turning Operation with Self-Propelled Rotary Tool. Procedia—Soc. Behav. Sci. 2015, 195, 2592–2600. [Google Scholar] [CrossRef]

- Chen, P.; Hoshi, T. High-Performance Machining of SiC Whisker-Reinforced Aluminium Composite by Self-Propelled Rotary Tools. CIRP Ann. 1992, 41, 59–62. [Google Scholar] [CrossRef]

- Wang, Z.M.; Ezugwu, E.O.; Gupta, A. Evaluation of a Self-Propelled Rotary Tool in the Machining of Aerospace Materials. Tribol. Trans. 1998, 41, 289–295. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Wilcox, J. Tool Wear and Chip Formation during Hard Turning with Self-Propelled Rotary Tools. Int. J. Mach. Tools Manuf. 2003, 43, 433–439. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Becze, C.E.; McIntosh, D.G. Tool Performance and Attainable Surface Quality during the Machining of Aerospace Alloys Using Self-Propelled Rotary Tools. J. Mater. Process. Technol. 2004, 152, 266–271. [Google Scholar] [CrossRef]

- Elmounayri, H.; Razak, A.; Kessler, M. Investigating Turning of Hard-to-Cut Material Using Self-Propelled Rotary Tool. In Proceedings of the ASME 2011 International Manufacturing Science and Engineering Conference, Corvallis, OR, USA, 13–17 June 2011. [Google Scholar]

- Kossakowska, J.; Jemielniak, K. Application of Self-Propelled Rotary Tools for Turning of Difficult-to-Machine Materials. Procedia CIRP 2012, 1, 425–430. [Google Scholar] [CrossRef] [Green Version]

- Armarego, E.J.A.; Katta, R.K. Predictive Cutting Model for Forces and Power in Self-Propelled Rotary Tool Turning Operations. CIRP Ann. 1997, 46, 19–24. [Google Scholar] [CrossRef]

- Hao, W.; Zhu, X.; Li, X.; Turyagyenda, G. Prediction of Cutting Force for Self-Propelled Rotary Tool Using Artificial Neural Networks. J. Mater. Process. Technol. 2006, 180, 23–29. [Google Scholar] [CrossRef]

- Hao, W.S.; Zhu, X.S.; Tian, B.J.; Chi, M.R. Autoregressive Spectrum Analysis of Vibration and Condition Monitoring of Self-Propelled Rotary Tool. Key Eng. Mater. 2007, 329, 743–748. [Google Scholar] [CrossRef]

- Kishawy, H.A. Self-Propelled Rotary Tool. In CIRP Encyclopedia of Production Engineering; The International Academy for Production, Ed.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1–5. ISBN 978-3-642-35950-7. [Google Scholar]

- Ahmed, W.; Hussien, H.; Mohany, A.; Kishawy, H. Towards Analysis and Optimization during Machining Hardened Steel AISI 4140 with Self-Propelled Rotary Tools. Res. Sq. 2021. [Google Scholar]

- Różyło, P. Optimization of I-section profile design by the finite element method. Adv. Sci. Technol. Res. J. 2016, 10, 52–56. [Google Scholar] [CrossRef]

- Mabrouki, T.; Rigal, J.-F. A Contribution to a Qualitative Understanding of Thermo-Mechanical Effects during Chip Formation in Hard Turning. J. Mater. Process. Technol. 2006, 176, 214–221. [Google Scholar] [CrossRef]

- Umer, U.; Kishawy, H.; Abidi, M.H.; Mian, S.H.; Moiduddin, K. Evaluation of Self-Propelled Rotary Tool in the Machining of Hardened Steel Using Finite Element Models. Materials 2020, 13, 5092. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, W.; Hegab, H.; Kishawy, H.A.; Mohany, A. Estimation of Temperature in Machining with Self-Propelled Rotary Tools Using Finite Element Method. J. Manuf. Process. 2021, 61, 100–110. [Google Scholar] [CrossRef]

| Cutting Parameter | |

|---|---|

| Speed (V) | 60, 80 and 100 m/min |

| Feed rate (f) | 0.1, 0.15 and 0.2 mm/rev |

| Depth of cut (d) | 0.3 and 0.4 mm |

| Cutting-Tool Geometry | |

| Rake angle | −15° |

| Clearance angle | 5° |

| Inclination angle | 9°,17° and 25° |

| Diameter | 27 mm |

| Edge radius | 0.05 mm |

| J–C Flow Model | A (MPa) | B (MPa) | C | n | m |

|---|---|---|---|---|---|

| 792 | 510 | 0.26 | 0.014 | 1.03 | |

| J–C Damage Model | D1 | D2 | D3 | D4 | D5 |

| 0.05 | 3.44 | −2.12 | 0.002 | 0.61 |

| Objectives |

|

| Constraints |

|

| S. No. | V (m/min) | f (mm/rev) | d (mm) | i (°) | Fc_exp (N) | Fc_sim (N) | Tmax_exp (°C) | Tmax_sim (°C) |

|---|---|---|---|---|---|---|---|---|

| 1 | 60 | 0.1 | 0.3 | 9 | 105 | 94 | 363 | 313 |

| 2 | 60 | 0.1 | 0.3 | 25 | 85 | 77 | 336 | 298 |

| 3 | 60 | 0.15 | 0.3 | 17 | 109 | 95 | 381 | 332 |

| 4 | 80 | 0.15 | 0.3 | 17 | 108 | 97 | 393 | 343 |

| 5 | 80 | 0.15 | 0.4 | 17 | 141 | 124 | 364 | 325 |

| 6 | 80 | 0.2 | 0.4 | 17 | 159 | 146 | 393 | 337 |

| 7 | 100 | 0.2 | 0.4 | 9 | 308 | 280 | 488 | 425 |

| 8 | 100 | 0.2 | 0.4 | 25 | 234 | 216 | 476 | 427 |

| S. No. | V (m/min) | f (mm/rev) | d (mm) | i (°) | S (MPa) | T (°C) | U (J/mm3) | MRR (N/mm3) |

|---|---|---|---|---|---|---|---|---|

| 1 | 60 | 0.1 | 0.3 | 9 | 294 | 203 | 3133 | 30 |

| 2 | 60 | 0.1 | 0.3 | 25 | 220 | 196 | 2575 | 30 |

| 3 | 60 | 0.2 | 0.3 | 9 | 309 | 231 | 1800 | 60 |

| 4 | 60 | 0.2 | 0.3 | 25 | 285 | 228 | 1383 | 60 |

| 5 | 60 | 0.1 | 0.4 | 9 | 302 | 219 | 3650 | 40 |

| 6 | 60 | 0.1 | 0.4 | 25 | 230 | 218 | 3650 | 40 |

| 7 | 60 | 0.2 | 0.4 | 9 | 330 | 239 | 3310 | 80 |

| 8 | 60 | 0.2 | 0.4 | 25 | 278 | 239 | 2342 | 80 |

| 9 | 60 | 0.15 | 0.3 | 17 | 351 | 223 | 2089 | 45 |

| 10 | 80 | 0.15 | 0.3 | 17 | 372 | 232 | 2156 | 60 |

| 11 | 80 | 0.15 | 0.4 | 17 | 373 | 215 | 2067 | 80 |

| 12 | 80 | 0.1 | 0.3 | 17 | 354 | 227 | 2633 | 40 |

| 13 | 80 | 0.2 | 0.3 | 17 | 359 | 242 | 1850 | 80 |

| 14 | 80 | 0.15 | 0.3 | 9 | 248 | 235 | 2067 | 60 |

| 15 | 80 | 0.15 | 0.3 | 25 | 233 | 233 | 1866 | 60 |

| 16 | 80 | 0.2 | 0.4 | 17 | 419 | 228 | 1825 | 107 |

| 17 | 100 | 0.1 | 0.3 | 9 | 294 | 247 | 3300 | 50 |

| 18 | 100 | 0.1 | 0.3 | 25 | 256 | 244 | 3033 | 50 |

| 19 | 100 | 0.2 | 0.3 | 9 | 337 | 263 | 1750 | 100 |

| 20 | 100 | 0.2 | 0.3 | 25 | 339 | 265 | 1533 | 100 |

| 21 | 100 | 0.1 | 0.4 | 9 | 336 | 254 | 3575 | 67 |

| 22 | 100 | 0.1 | 0.4 | 25 | 232 | 256 | 2600 | 67 |

| 23 | 100 | 0.2 | 0.4 | 9 | 331 | 278 | 3500 | 133 |

| 24 | 100 | 0.2 | 0.4 | 25 | 302 | 281 | 2700 | 133 |

| 25 | 100 | 0.15 | 0.3 | 17 | 316 | 256 | 2067 | 75 |

| S. No. | V (m/min) | f (mm/rev) | d (mm) | i (°) | S (MPa) | T (°C) | U (J/mm3) | MRR (N/mm3) |

|---|---|---|---|---|---|---|---|---|

| 1 | 80 | 0.15 | 0.3 | 25 | 233 | 233 | 1866 | 60 |

| 2 | 80 | 0.12 | 0.4 | 25 | 260 | 226 | 2389 | 67 |

| 3 | 70 | 0.15 | 0.4 | 25 | 284 | 221 | 2408 | 70 |

| 4 | 80 | 0.15 | 0.4 | 25 | 289 | 220 | 2082 | 80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Umer, U.; Mian, S.H.; Mohammed, M.K.; Abidi, M.H.; Moiduddin, K.; Kishawy, H. Self-Propelled Rotary Tools in Hard Turning: Analysis and Optimization via Finite Element Models. Materials 2022, 15, 8781. https://doi.org/10.3390/ma15248781

Umer U, Mian SH, Mohammed MK, Abidi MH, Moiduddin K, Kishawy H. Self-Propelled Rotary Tools in Hard Turning: Analysis and Optimization via Finite Element Models. Materials. 2022; 15(24):8781. https://doi.org/10.3390/ma15248781

Chicago/Turabian StyleUmer, Usama, Syed Hammad Mian, Muneer Khan Mohammed, Mustufa Haider Abidi, Khaja Moiduddin, and Hossam Kishawy. 2022. "Self-Propelled Rotary Tools in Hard Turning: Analysis and Optimization via Finite Element Models" Materials 15, no. 24: 8781. https://doi.org/10.3390/ma15248781

APA StyleUmer, U., Mian, S. H., Mohammed, M. K., Abidi, M. H., Moiduddin, K., & Kishawy, H. (2022). Self-Propelled Rotary Tools in Hard Turning: Analysis and Optimization via Finite Element Models. Materials, 15(24), 8781. https://doi.org/10.3390/ma15248781