Experimental Research on Sheared Edge Formation in the Shear-Slitting of Grain-Oriented Electrical Steel Workpieces

Abstract

:1. Introduction

- -

- Determination of appropriate conditions for the shear-slitting process to obtain minimum burr heights and minimum shape deviations, enabling the correct packaging of sheets. Currently, there is no information on how to select process parameters and conditions to minimize these features at the same time. Knowledge on this subject will allow for the manufacture of products ready for direct packaging without the need for additional machining operations.

- -

- Comprehensive tests for coated and uncoated sheets. Electrical engineering materials in industry are shaped by cutting techniques in different phases, often before or after coating. Currently, the literature lacks information on how to cut such materials depending on their condition. Here, we have proposed universal solutions that can be used for the cutting process of both coated and uncoated materials.

- -

- Optimization techniques that allow for determining the areas of acceptable solutions and the optimal solution. Based on our results, these techniques can be used on production lines, enabling technologists to select appropriate conditions for the cutting process, depending on the assumptions made.

- -

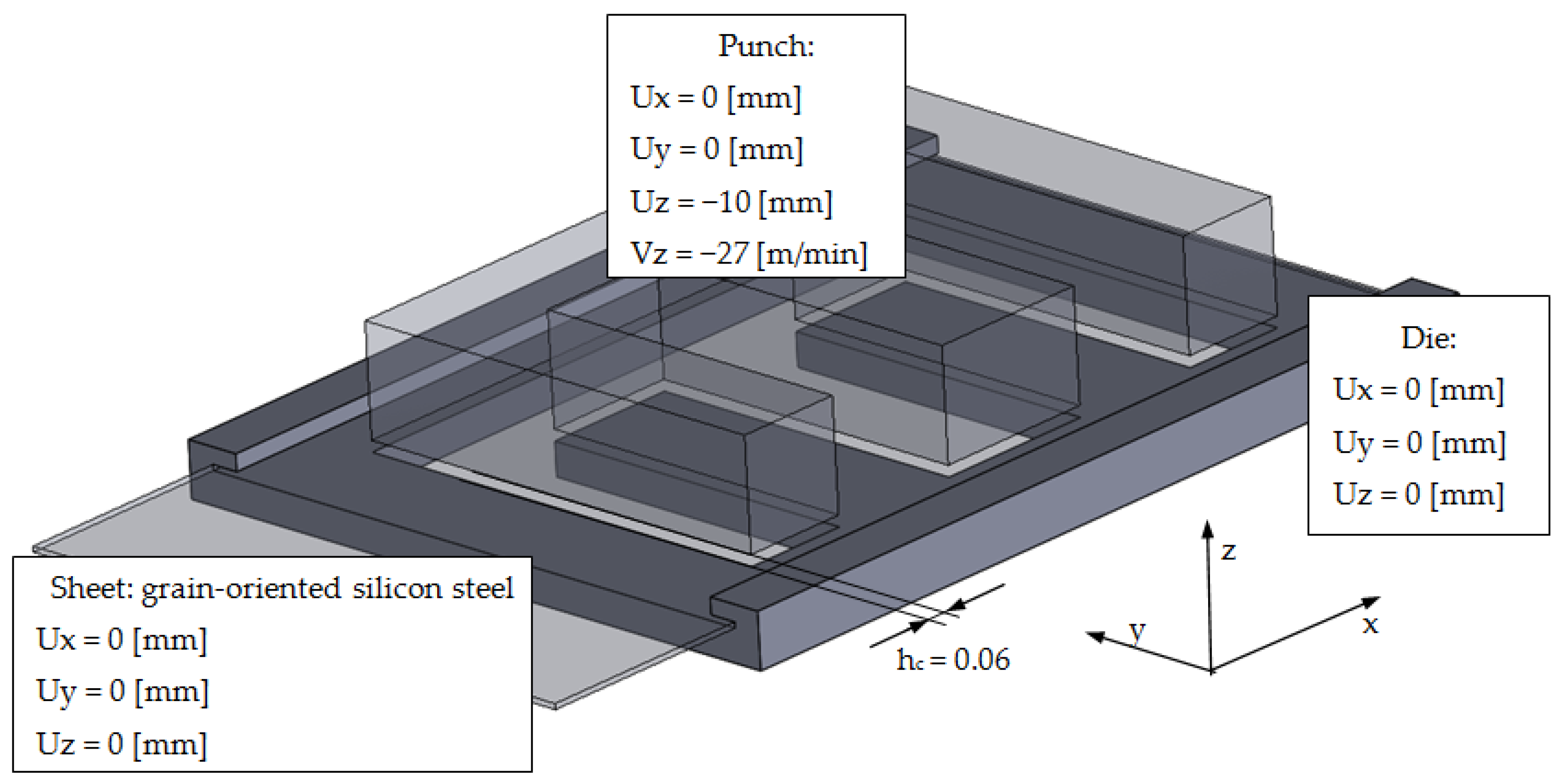

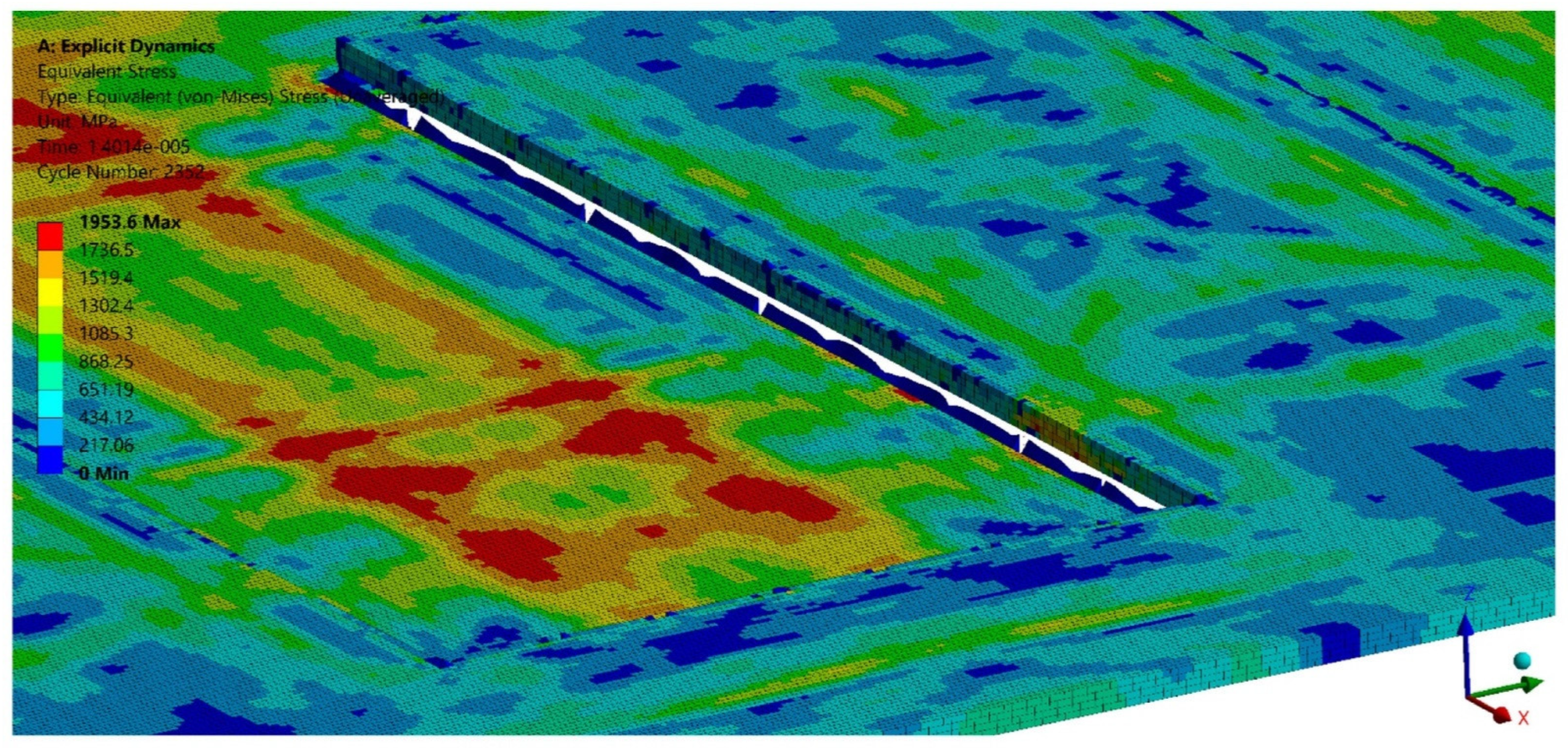

- Partial experimental research, result analysis, and multi-criteria optimization of the cutting process, which enables the development of an effective numerical model of the process for blanking parts for electric machines. On the basis of the obtained research results, a computer model was developed using the finite element method for the process of blanking parts from grain-oriented electrical sheets for the construction of an electric transformer. The developed model is aimed at verifying the results of fragmentary tests and implementing research conclusions in production.

2. Materials and Methods

2.1. Material Characteristics

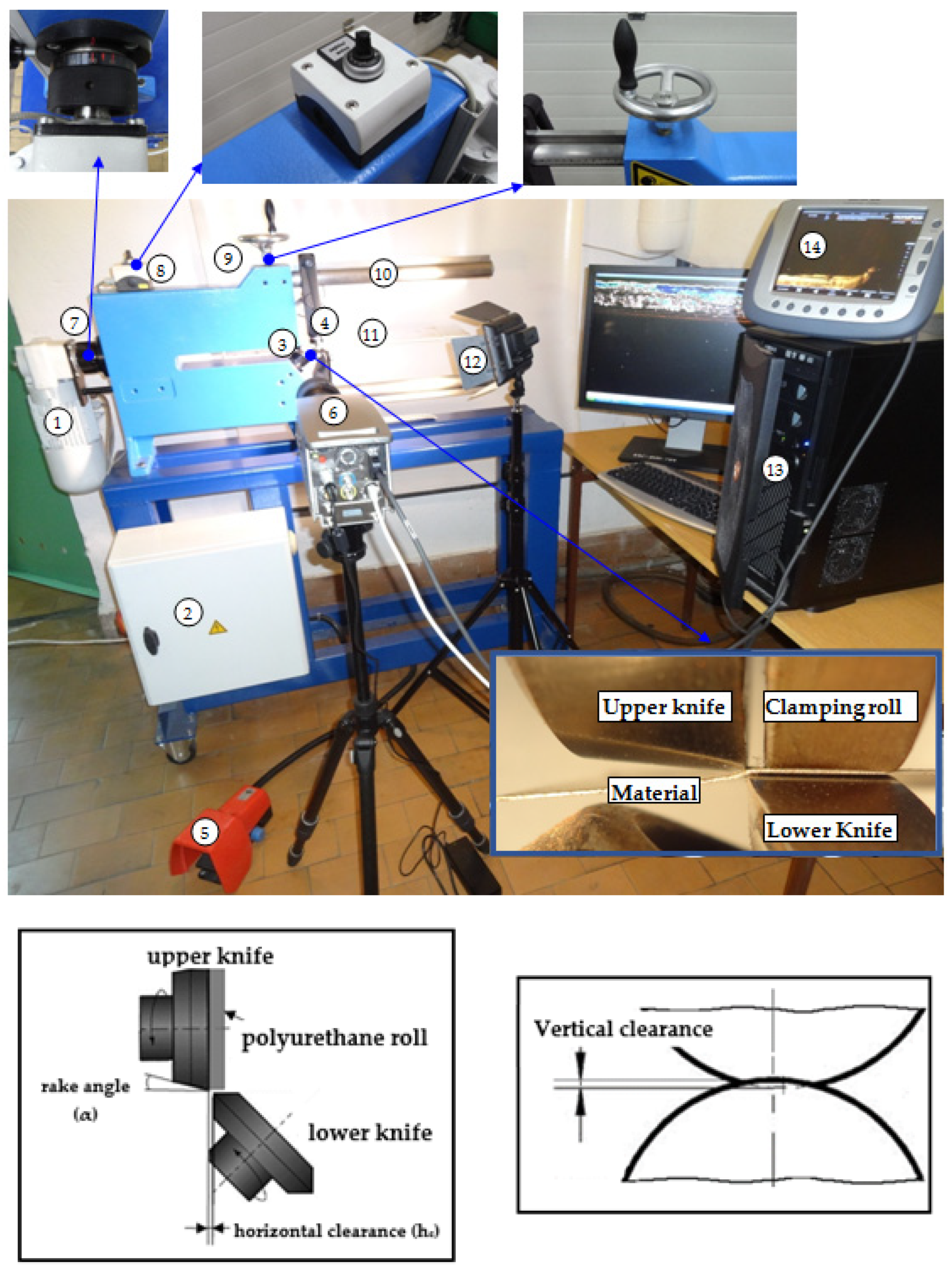

2.2. Experimental Setup

3. Experimental Results and Discussion

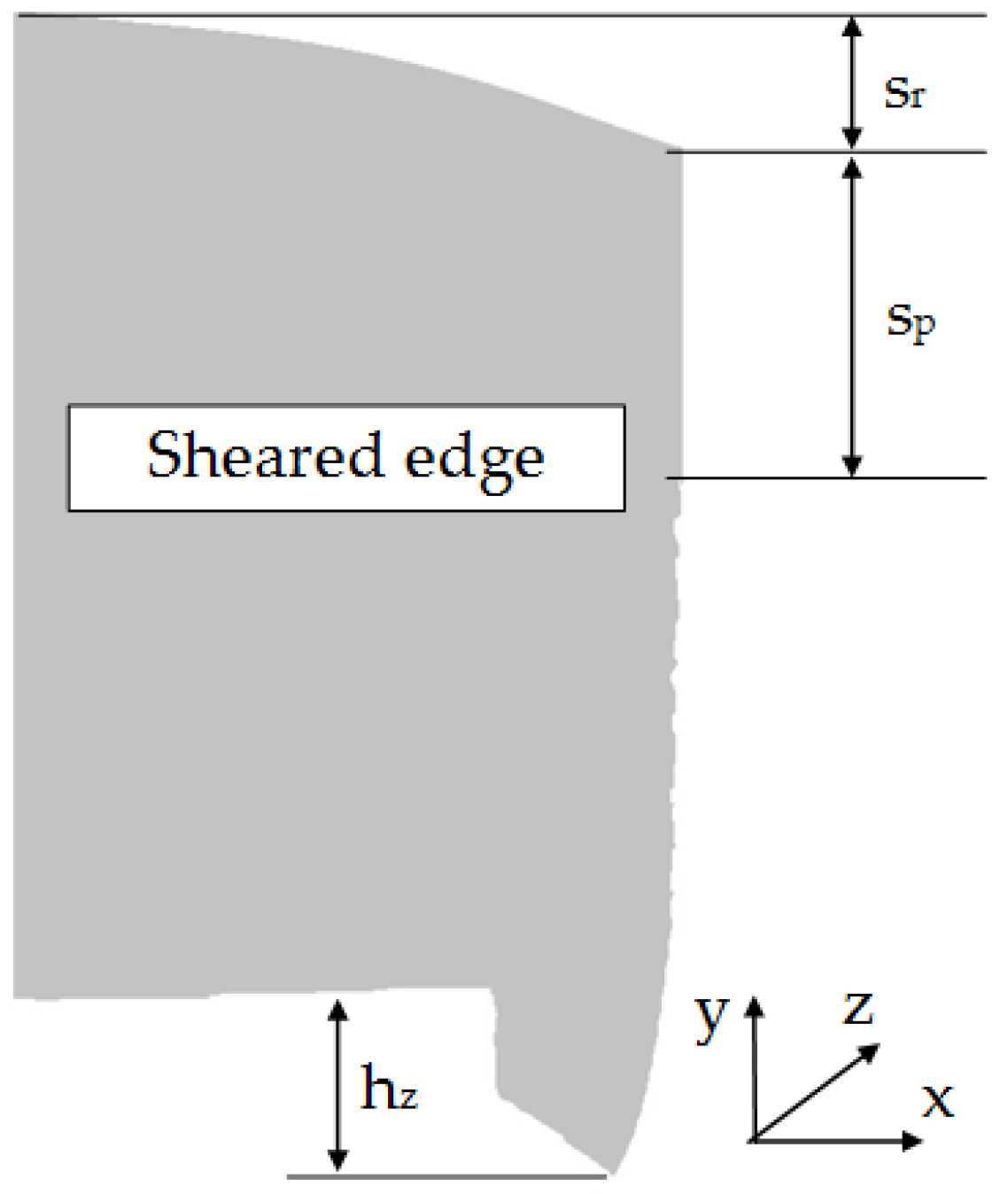

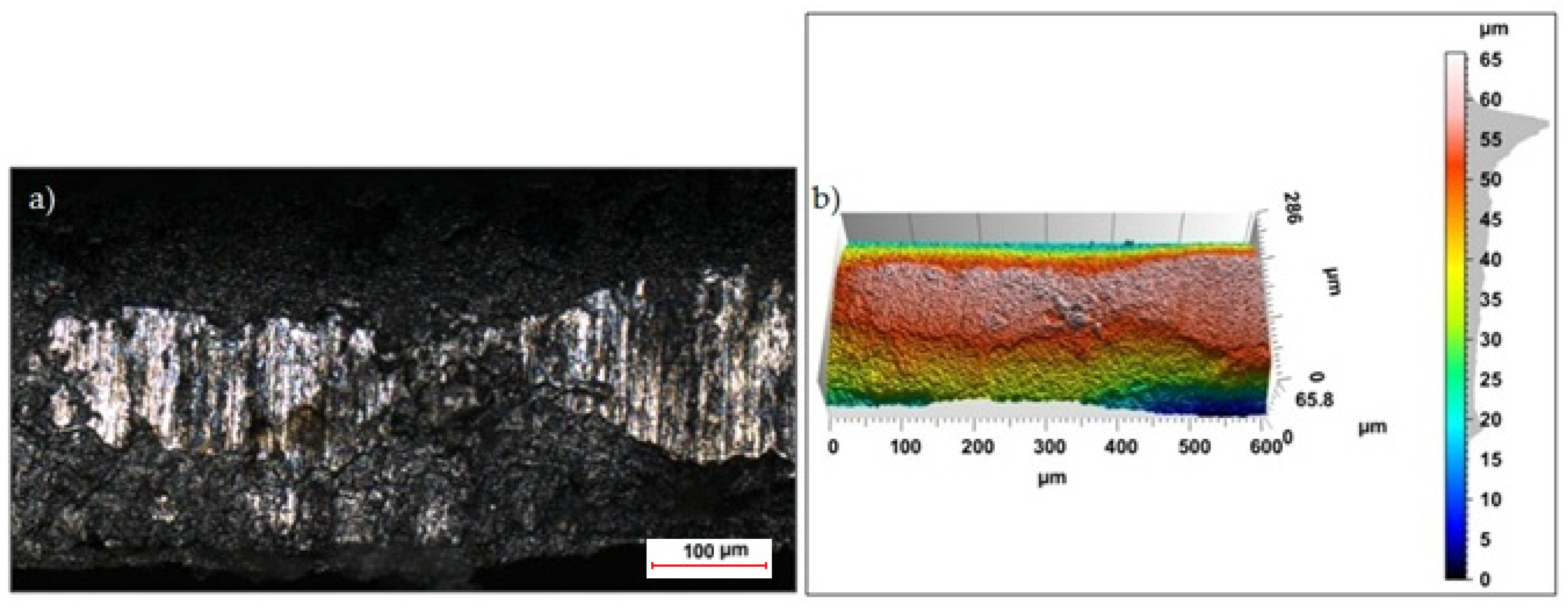

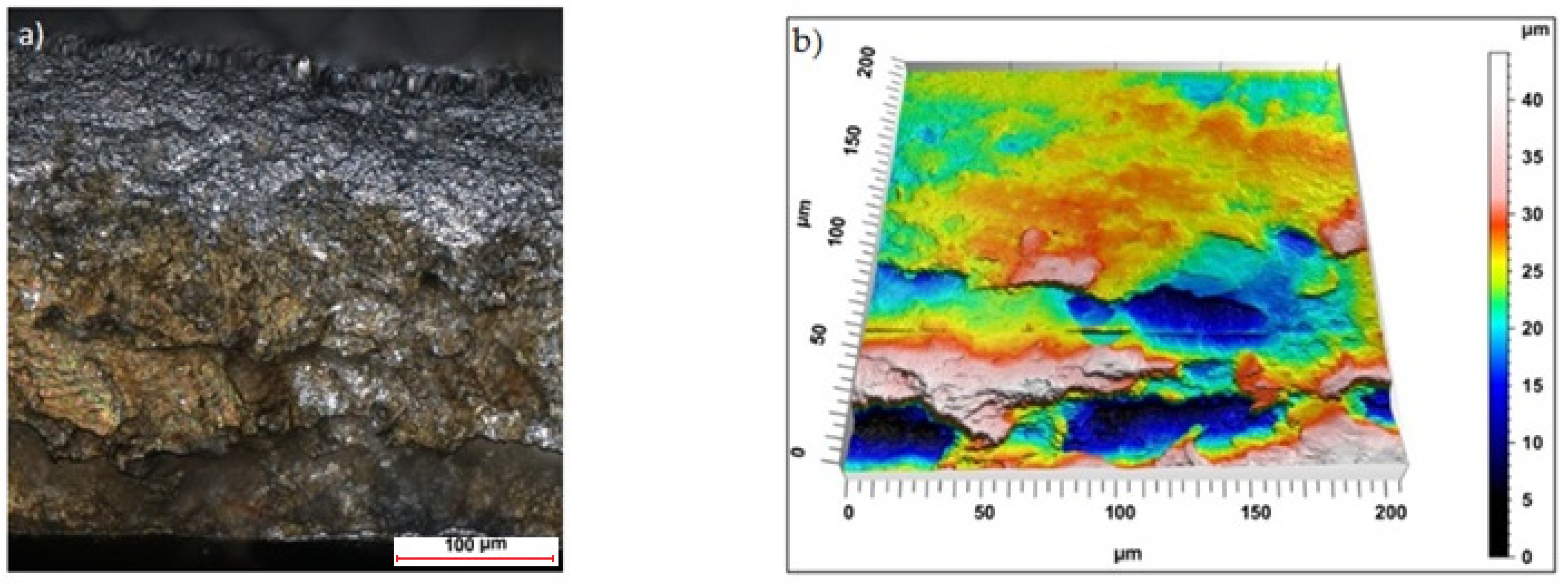

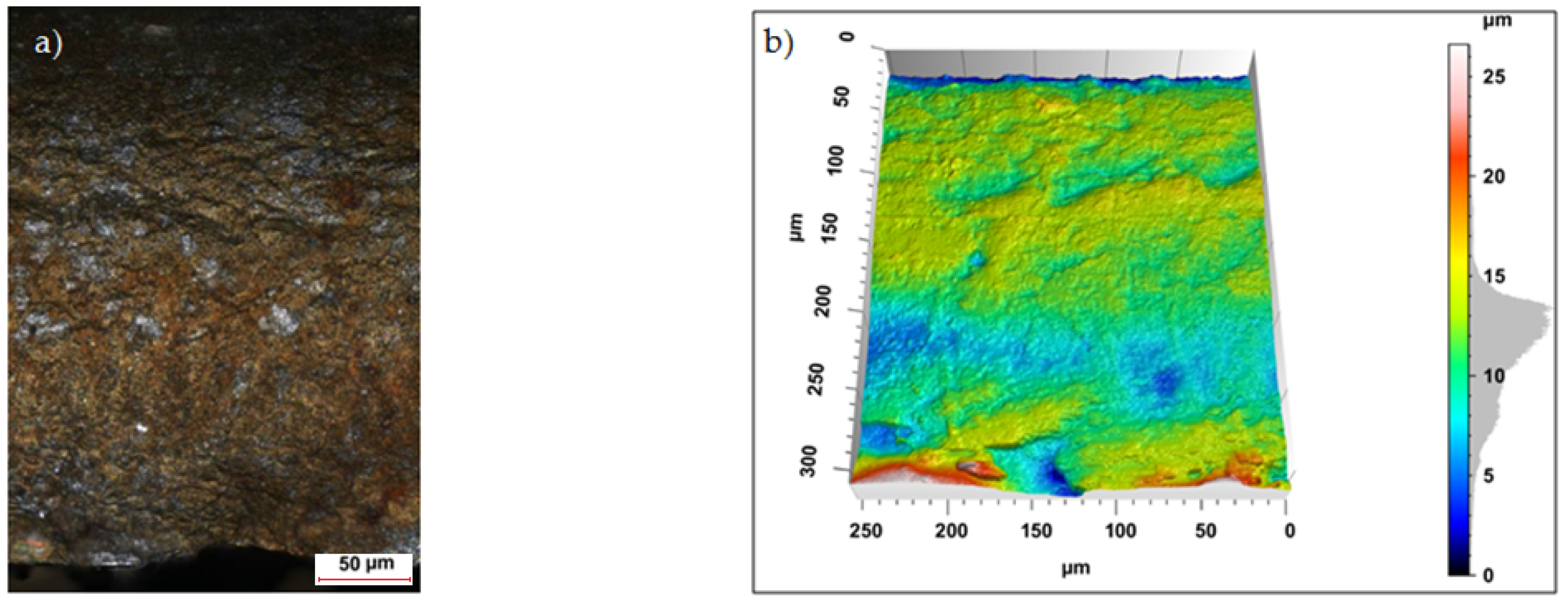

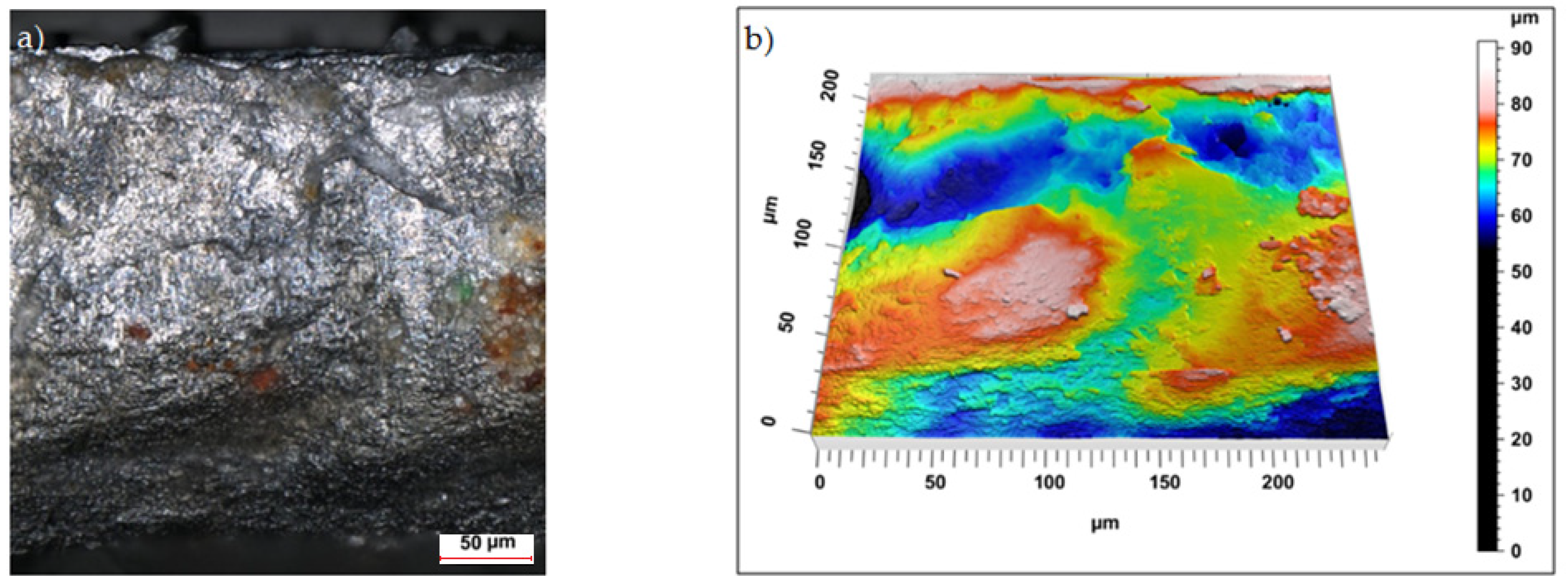

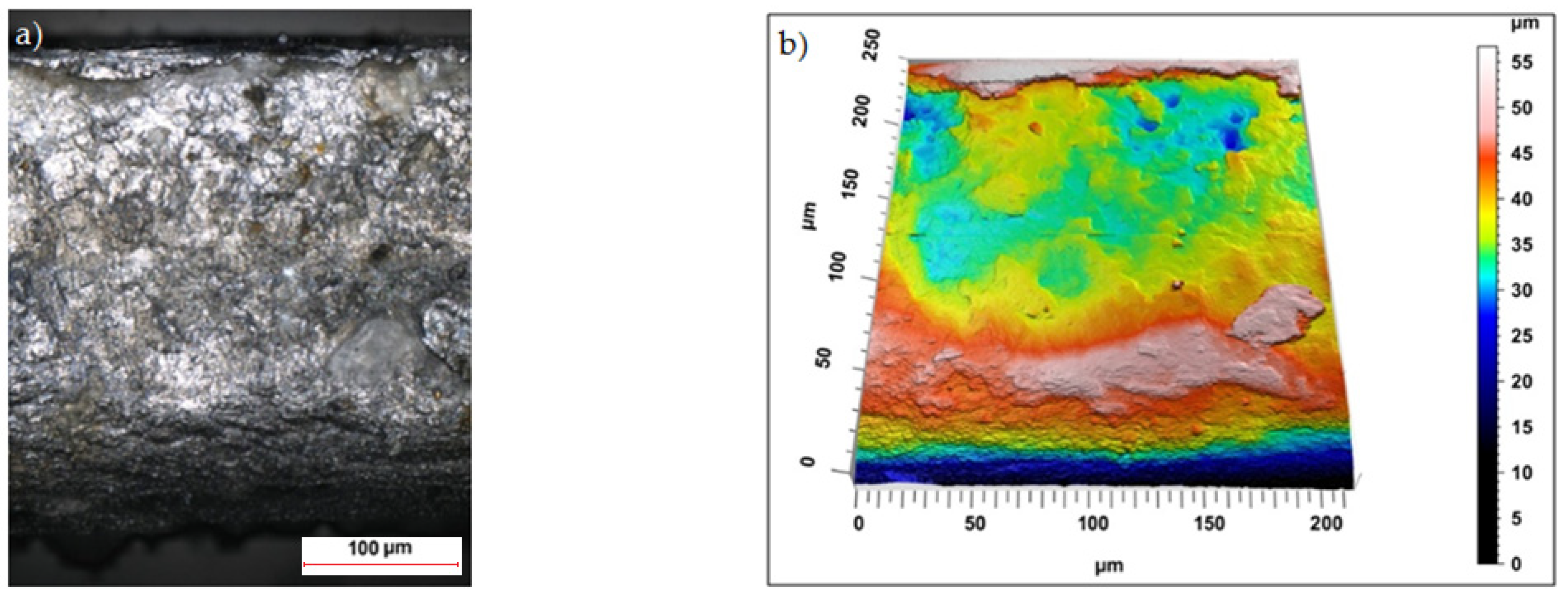

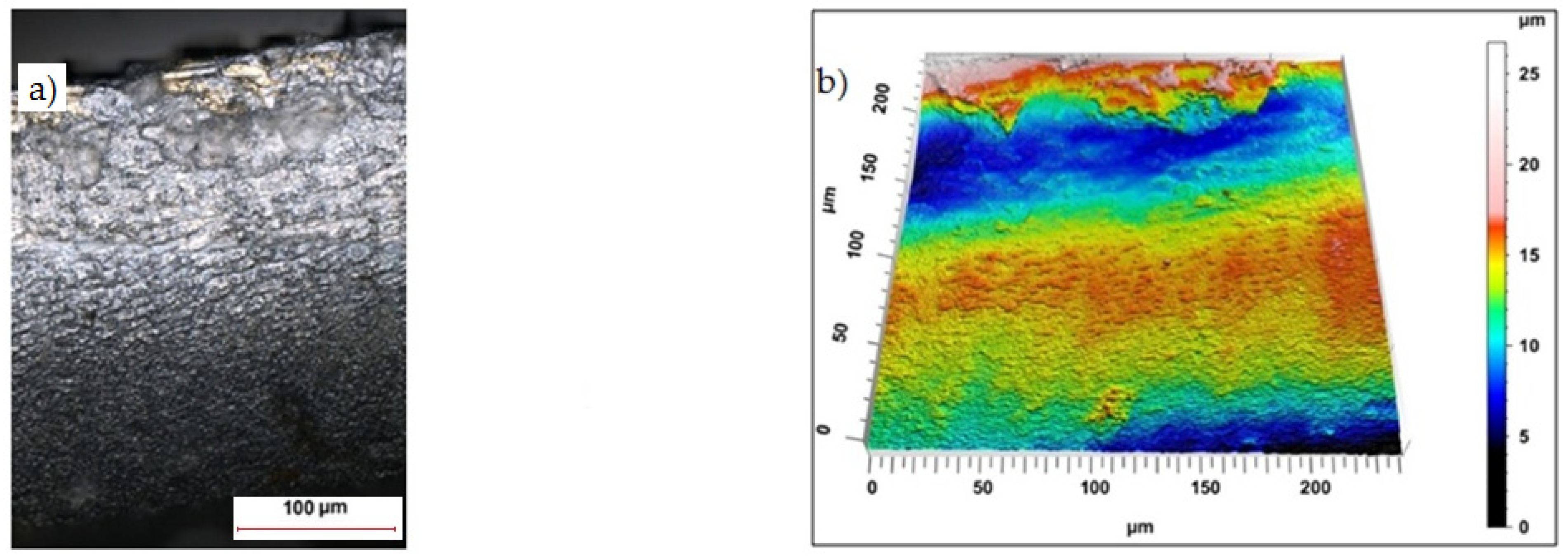

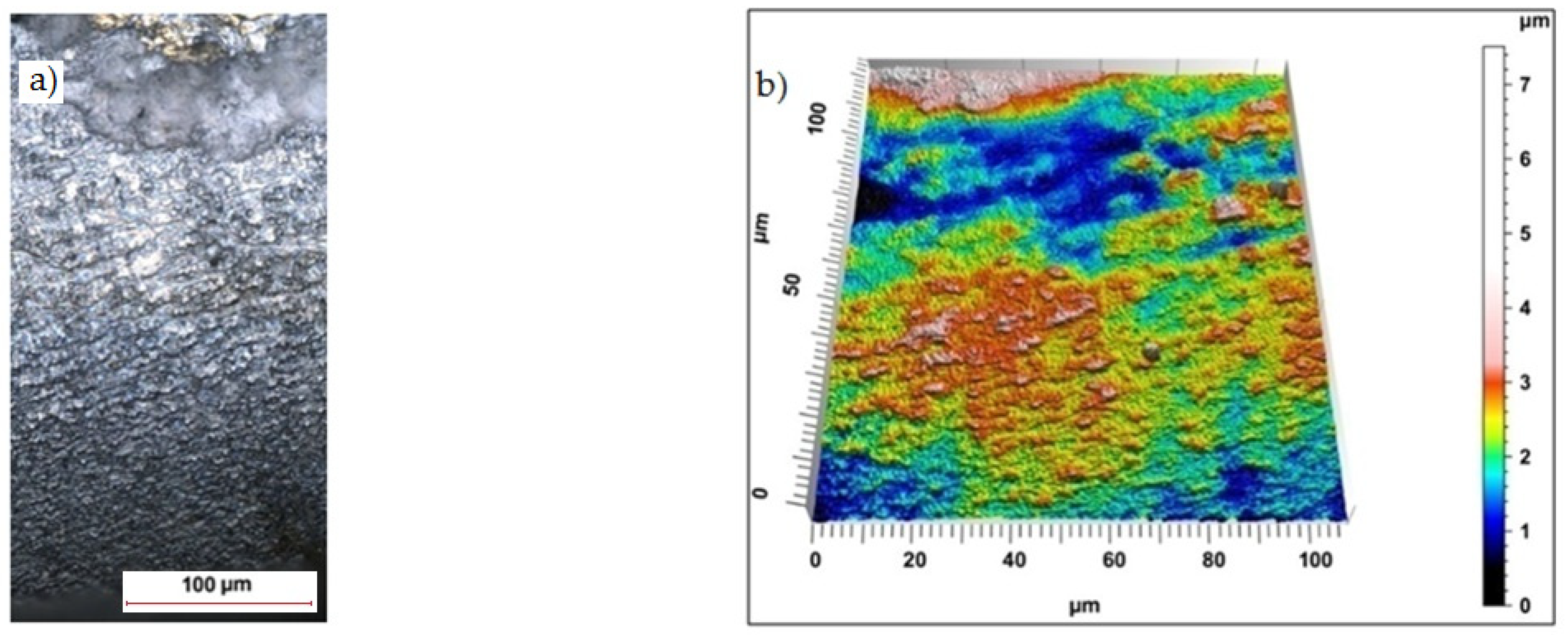

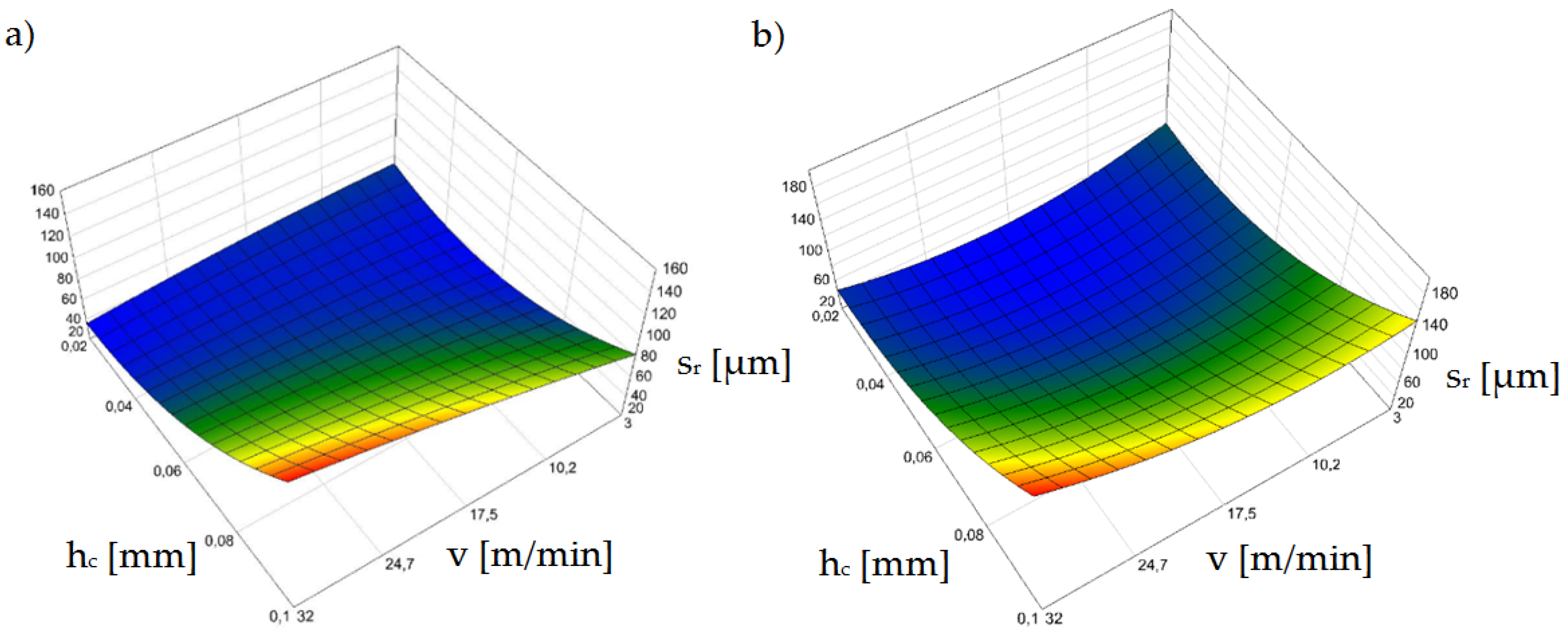

3.1. Sheared-Edge Topography

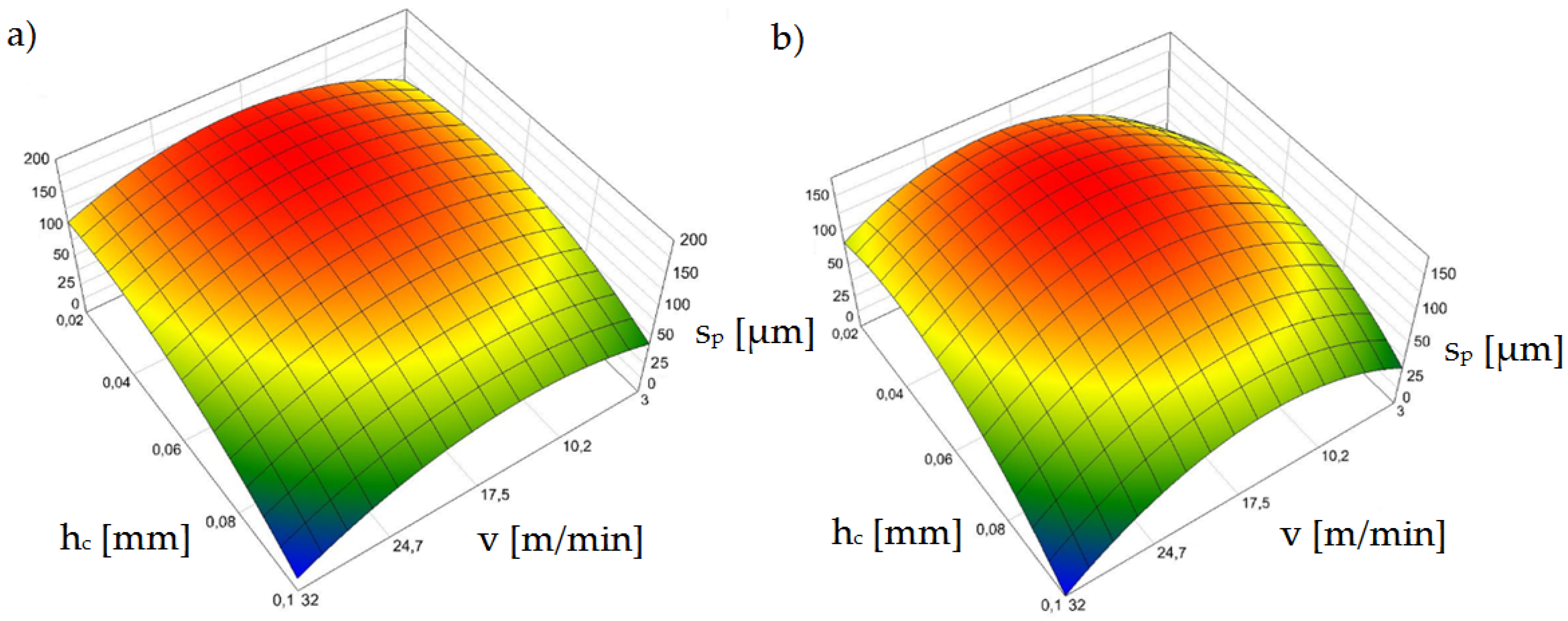

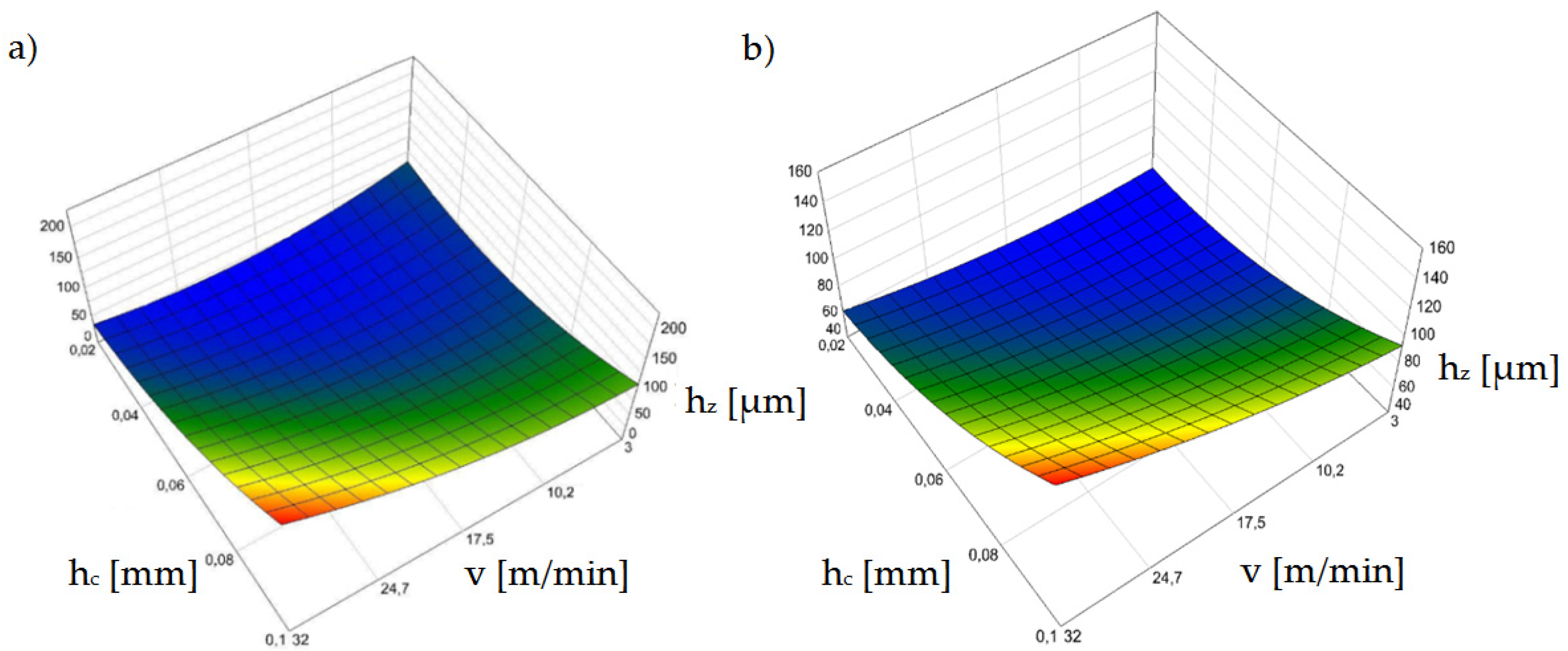

3.2. Sheared-Edge Quality

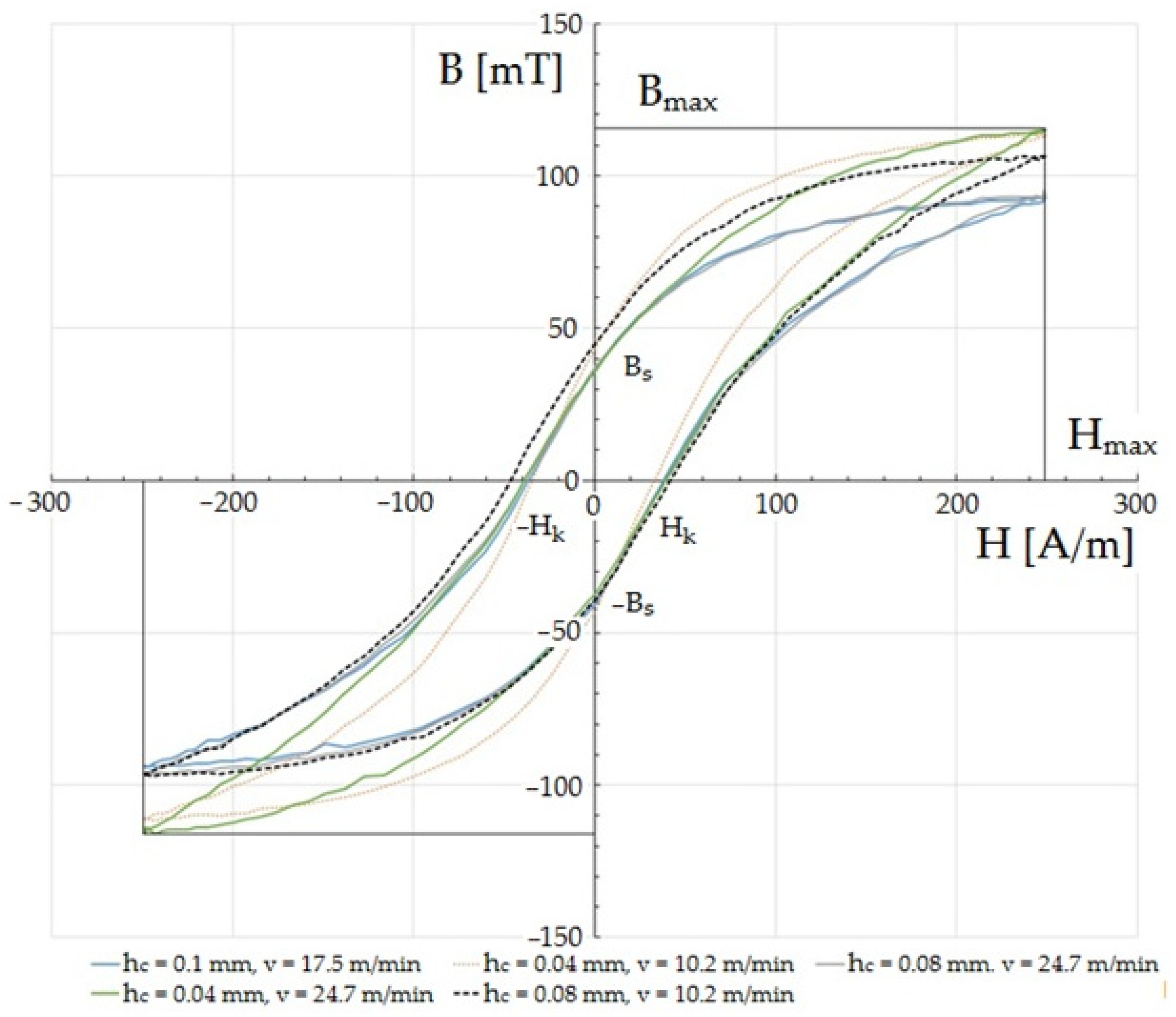

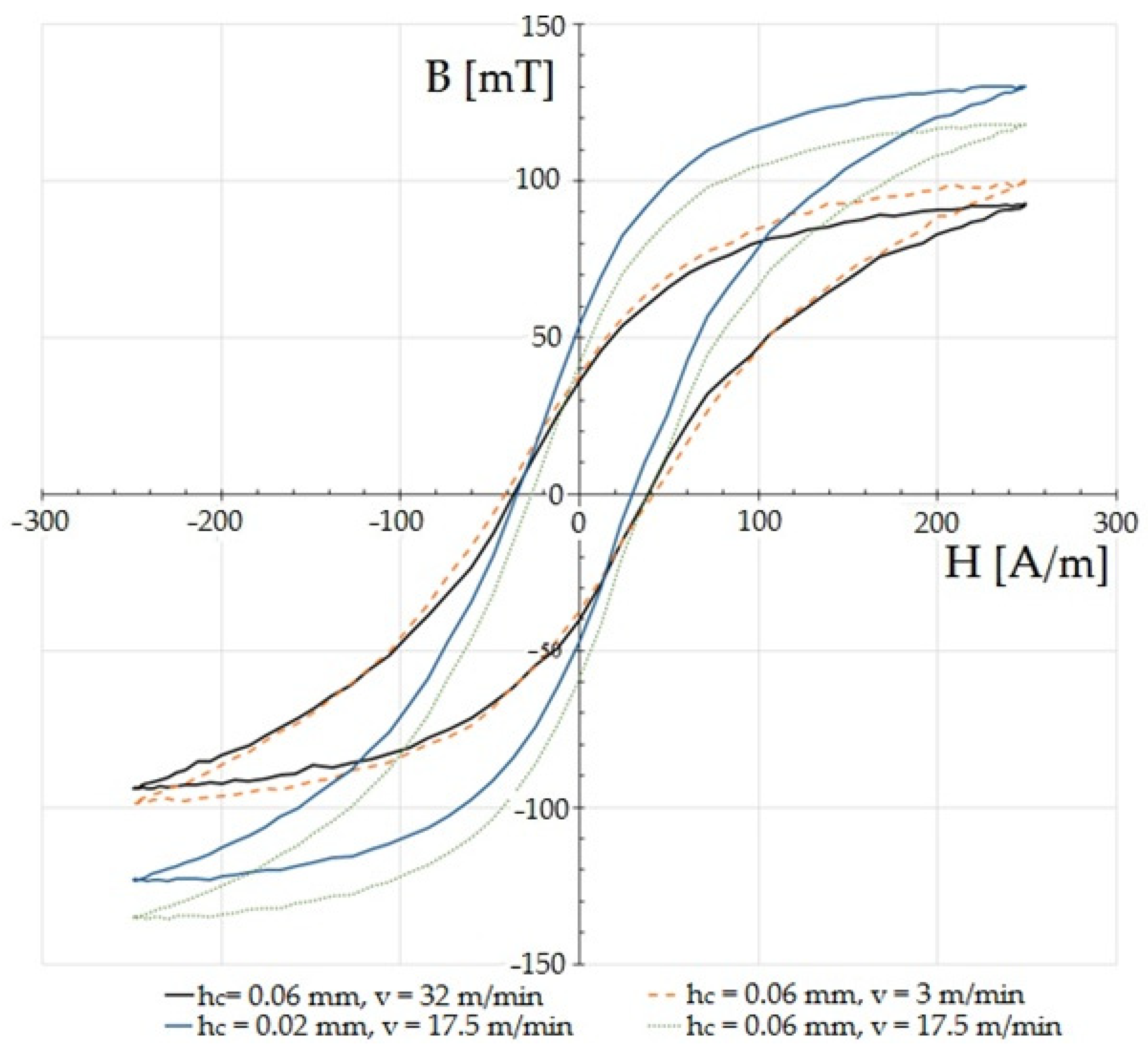

3.3. Magnetic Characteristics

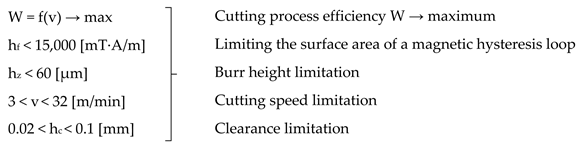

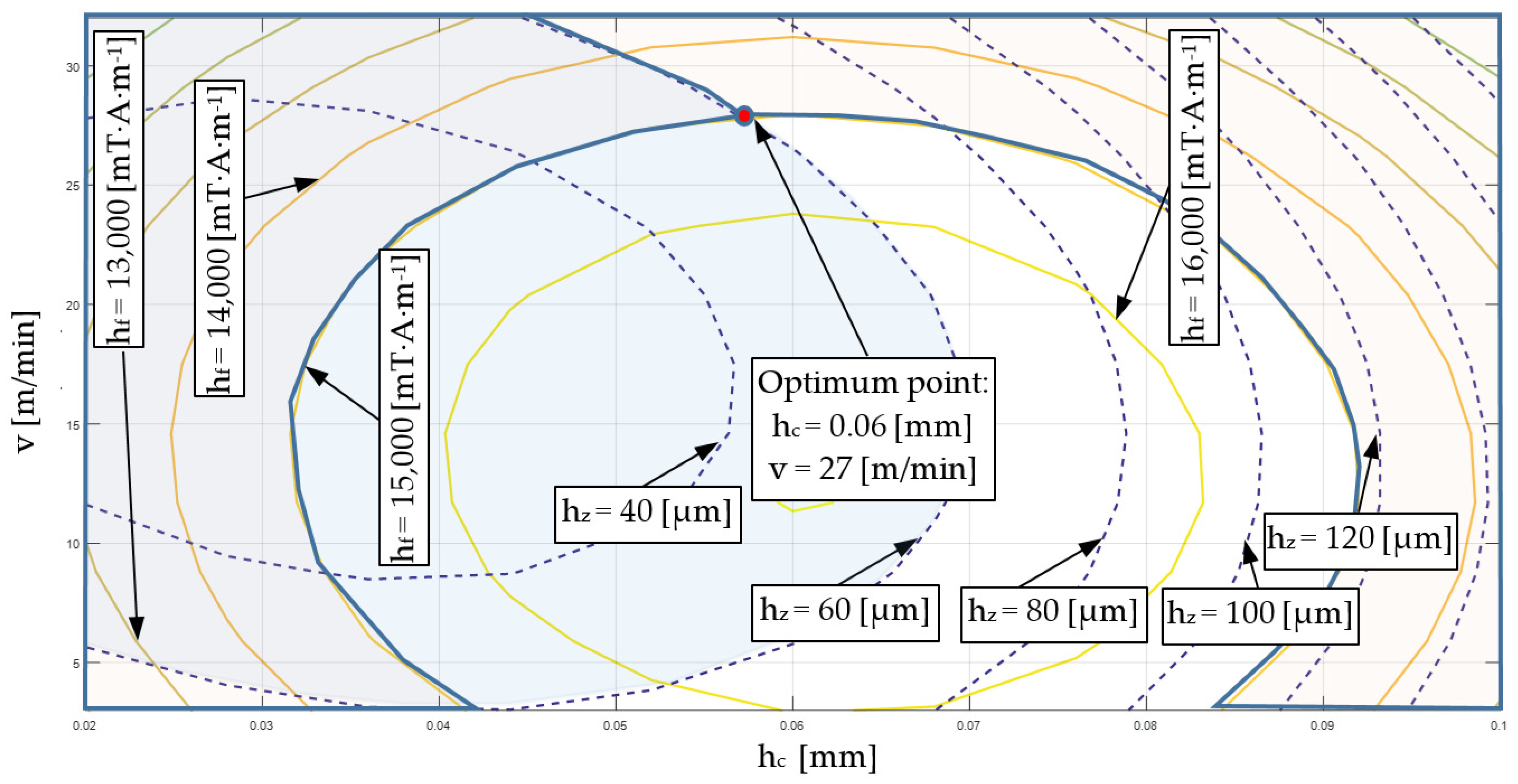

4. Optimization of the Process

5. Practical Application of Analysis Results

6. Conclusions

- Conducting tests for a material with an insulating coating, which has a composite structure, and for the same material without the coating, allowed for determining the local changes in the quality of the cut edge and identifying the appropriate cutting conditions for each of the cases. This creates new possibilities for production planning and the possibility of proper selection of machining parameters depending on whether the material will be cut with or without a coating.

- The analysis of the test results showed a strong influence of cutting speed and horizontal clearance on the formation of the width of individual zones on the cut surface, both in the case of sheets with and without an insulating coating. The test results indicate that the lowest process stability can be obtained at high cutting speeds above 24 m/min. This especially applies to variants of clearances above hc = 0.08 mm.

- The use of an insulating coating reduces the effect of cutting speed on the width of the sheared burnished zone (by approx. 15%). On the other hand, the effect of horizontal clearance increases (by approx. 20%). The coating increases the stability of the plastic flow process as well as the propagation and the course of cracking for clearances in the range of hc = 0.02–0.06 mm.

- In some cases, at the edge of the burr along the cut line, fragments of the insulating coating, which is a form of built-up edge on the cut surface, were observed. This can have a very negative effect on the magnetic properties and accelerate the wear of the cutting tools.

- As horizontal clearance increased, there was an excessive increase in the bending moment and local edge damage. The use of an insulating coating resulted in a narrowing of the ranges of favorable input parameters settings and an increase in roundness in the case of using minimal clearances and increased cutting speeds.

- The cutting process changes the shapes of the hysteresis loop in the areas of the upper curve of the characteristic and saturation. For reduced cutting clearances beyond the range of hc = 0.02–0.04 mm, the cutting speed mainly affected the characteristics of the saturation area and the maximum induction. In the case of increased cutting clearances, the value of the saturation induction decreased. This was especially visible in clearance values above hc = 0.08 mm. The increase in clearance also caused an increase in the intensity of coercivity and induction of remanence.

- Based on the research results and the use of graphical optimization, a set of acceptable solutions and an optimal solution were determined to ensure the highest quality of the cut edge and minimum disturbances in magnetic properties (v = 27 m/min, hc = 0.06 mm). The proposed approach enables the implementation of the process for other data.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar, R.; Chatopadhyaya, S.; Hloch, S.; Krolczyk, G.; Legutko, S. Wear characteristics and defects analysis of friction stir welded joint of aluminum alloy 6061-T6. Eksploat. I Niezawodn.-Maint. Reliab. 2016, 18, 128–135. [Google Scholar] [CrossRef]

- Maruda, R.W.; Feldshtein, E.; Legutko, S.; Krolczyk, G.M. Research on emulsion mist generation in the conditions of Minimum Quantity Cooling Lubrication (MQCL). Teh. Vjesn.-Tech. Gaz. 2015, 22, 1213–1218. [Google Scholar]

- Krinninger, M.; Steinlehner, F.; Opritescu, D.; Golle, R.; Volk, W. On the influence of different parameters on the characteristic cutting surface when shear cutting aluminum. Procedia CIRP 2017, 63, 230–235. [Google Scholar] [CrossRef]

- Gasiorek, D.; Baranowski, P.; Malachowski, J.; Mazurkiewicz, L.; Wiercigroch, M. Modelling of guillotine cutting of multi-layered aluminum sheets. J. Manuf. Process. 2018, 34, 374–388. [Google Scholar] [CrossRef]

- Li, M. Micromechanisms of deformation and fracture in shearing aluminum alloy sheet. Int. J. Mech. Sci. 2000, 42, 889–906. [Google Scholar] [CrossRef]

- Aggarwal, S.; Bhushan, B.; Katsube, N. Three-dimensional finite element analysis of the magnetic tape slitting process. J. Mater. Process. Technol. 2005, 170, 71–88. [Google Scholar] [CrossRef]

- Pater, Z.; Tofil, A.; Tomczak, J.; Bulzak, T. Numerical analysis of the cross wedge rolling proces (CWR) for a stepped shaft. Metalurgija 2015, 54, 177–180. [Google Scholar]

- Slota, J.; Kaščák, L. FEM Modeling of shear cutting of electrical steel sheets under various technological conditions. Acta Mech. Slovaca 2018, 22, 24–30. [Google Scholar] [CrossRef]

- Ghadbeigi, H. Blanking induced damage in thin 3.2% silicon steel sheets. Prod. Eng. 2020, 14, 53–64. [Google Scholar] [CrossRef] [Green Version]

- Kuo, S.K.; Lee, W.C.; Lin, S.Y.; Lu, C.Y. The influence of cutting edge deformations on magnetic performance degradation of electrical steel. In Proceedings of the 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 22 October 2014; pp. 3041–3046. [Google Scholar]

- Boehm, L.; Hartmann, C.; Gilch, I.; Stoecker, A.; Kawalla, R.; Wei, X.; Hirt, G.; Heller, M.; Korte-Kerzel, S.; Leuning, N.; et al. Grain size influence on the magnetic property deterioration of blanked non-oriented electrical steels. Materials 2021, 14, 7055. [Google Scholar] [CrossRef]

- Bohdal, L. Application of a SPH coupled FEM method for simulation of trimming of aluminum autobody sheet. Acta Mech. Autom. 2016, 10, 56–61. [Google Scholar] [CrossRef] [Green Version]

- Moses, A.J. Energy efficient electrical steels: Magnetic performance prediction and optimization. Scr. Mater. 2012, 67, 560–565. [Google Scholar] [CrossRef]

- Samborski, S.; Józwik, J.; Skoczylas, J.; Kłonica, M. Adaptation of fracture mechanics methods for quality assessment of tungsten carbide cutting inserts. Materials 2021, 14, 3441. [Google Scholar] [CrossRef] [PubMed]

- Arshad, W.; Ryckebusch, T.; Magnussen, F.; Lendenmann, H.; Eriksson, B.; Soulard, J.; Malmros, B. Incorporating lamination processing and component manufacturing in electrical machine design tools. In Proceedings of the 42nd IAS Annual Meeting, Industry Applications Conference, New Orleans, LA, USA, 23–27 September 2007; Volume 1, pp. 94–102. [Google Scholar]

- Harstick, H.M.S.; Ritter, M.; Plath, A.; Riehemann, W. EBSD investigations on cutting edges of non-oriented electrical steel. Metallogr. Microstruct. Anal. 2014, 3, 244–251. [Google Scholar] [CrossRef]

- Tongsrinak, P.; Panichnok, V.; Dechjarern, S. Study of blanking process with V-Ring using experiment and Finite Element Method. Key Eng. Mater. 2017, 728, 96–102. [Google Scholar] [CrossRef]

- He, J.; Wang, Z.; Li, S.; Dong, L.; Cao, X.; Zhang, W. Optimum clearance determination in blanking coarse-grained non-oriented electrical steel sheets: Experiment and simulation. Int. J. Mater. Form. 2019, 12, 575–586. [Google Scholar] [CrossRef]

- Zhang, H.; Xiang, Q.; Xiong, L.; Chen, C.; Jin, X.; Kang, B. Effect of processing methods on mechanical properties of non oriented high grade electrical steel. J. Electr. Steel 2020, 2, 34–38. [Google Scholar]

- Hofmann, M.; Naumoski, H.; Herr, U.; Herzog, H.-G. Magnetic properties of electrical steel sheets in respect of cutting: Micromagnetic analysis and macromagnetic modeling. IEEE Trans. Magn. 2016, 52, 2000114. [Google Scholar] [CrossRef]

- Baudouin, P.; De Wulf, M.; Kestens, L.; Houbaert, Y. The effect of the guillotine clearance on the magnetic properties of electrical steels. J. Magn. Magn. Mater. 2003, 256, 32–40. [Google Scholar] [CrossRef]

- Weiss, H.A.; Leuning, N.; Steentjes, S.; Hameyer, K.; Andorfer, T.; Jenner, S.; Volk, W. Influence of shear cutting parameters on the electromagnetic properties of non-oriented electrical steel sheets. J. Magn. Magn. Mater. 2017, 421, 250–259. [Google Scholar] [CrossRef]

- Vandenbossche, L.; Jacobs, S.; Henrotte, F.; Hameyer, K. Impact of cut edges in magnetization curves and iron losses in e-machines for automotive traction. In Proceedings of the 25th World Battery, Hybrid and Fuel Cell Electric Vehicle Symposium & Exhibition, EVS, Shenzhen, China, 7–9 November 2010. [Google Scholar]

- Kurosaki, Y.; Mogi, H.; Fujii, H.; Kubota, T.; Shiozaki, M. Importance of punching and workability in non-oriented electrical steel sheets. J. Magn. Magn. Mater. 2008, 320, 2474–2480. [Google Scholar] [CrossRef]

- Ma, J.; Lu, H.; Li, M.; Wang, B. Burr height in shear slitting of aluminum webs. ASME J. Manuf. Sci. Eng. 2006, 128, 46–55. [Google Scholar] [CrossRef]

- Lu, H.; Ma, J.; Li, M. Edge trimming of aluminum sheets using shear slitting at a rake angle. ASME J. Manuf. Sci. Eng. 2006, 128, 866–873. [Google Scholar] [CrossRef]

- Zu, G.; Zhang, X.; Zhao, J.; Cui, Y.; Wang, Y.; Jiang, Z. Analysis of the microstructure, texture and magnetic properties of strip casting 4.5 wt.% Si non-oriented electrical steel. Mater. Des. 2015, 85, 455–460. [Google Scholar] [CrossRef]

- Godec, Z. Influence of slitting on core losses and magnetization curve of grain oriented electrical steels. IEEE Trans. Magn. 1977, 13, 1053–1057. [Google Scholar] [CrossRef]

- Hubert, C.; Dubar, L.; Dubar, M.; Dubois, A. Finite Element simulation of the edge-trimming/cold rolling sequence: Analysis of edge cracking. J. Mater. Process. Technol. 2012, 212, 1049–1060. [Google Scholar] [CrossRef]

- Weiss, H.A.; Trober, P.; Golle, R.; Steentjes, S.; Leuning, N.; Elfgen, S.; Hameyer, K.; Volk, W. Impact of punching parameter variations on magnetic properties of non-grain oriented electrical steel. IEEE Trans. Ind. Appl. 2018, 54, 5869–5878. [Google Scholar] [CrossRef]

- Winter, K.; Liao, Z.; Ramanathan, R.; Axinte, D.; Vakil, G.; Gerada, C. How non-conventional machining affects the surface integrity and magnetic properties of non-oriented electrical steel. Mater. Des. 2021, 210, 110051. [Google Scholar] [CrossRef]

- Hamzehbahmani, H.; Anderson, P.; Jenkins, K.; Lindenmo, M. Experimental study on inter-laminar short- circuit faults atrandom positions inlaminated magnetic cores. IET Electr. Power Appl. 2016, 10, 604–613. [Google Scholar] [CrossRef] [Green Version]

- Mazurek, R.; Marketos, P.; Moses, A.; Vincent, J.-N. Effect of artificial burrs on the total power loss of a three-phase transformer core. IEEE Trans. Magn. 2010, 46, 638–641. [Google Scholar] [CrossRef]

- Schulz, C.A.; Duchesne, S.; Roger, D.; Vincent, J.-N. Capacitive short circuit detection in transformer core laminations. J. Magn. Magn. Mater. 2008, 320, 911–914. [Google Scholar] [CrossRef]

- ASTM A976; Standard Classification of Insulating Coatings for Electrical Steels by Composition. Relative Insulating Ability and Application. ASTM International (ASTM): West Conshohocken, PA, USA, 2018.

- PN-EN 10002-1:2002; Metale—Próba rozciągania—Część 1: Metoda Badania w Temperaturze Otoczenia. Polski Komitet Normalizacyjny: Warsaw, Poland, 2002. (In Polish)

- Rodriguez, A.; de Lacalle, L.N.; Pereira, O.; Fernandez, A.; Ayesta, I. Isotropic finishing of austempered iron casting cylindrical parts by roller burnishing. Int. J. Adv. Manuf. Technol. 2020, 110, 753–761. [Google Scholar] [CrossRef] [PubMed]

- Subramonian, S.; Altan, T.; Campbell, C.; Ciocirlan, B. Determination of forces in high speed blanking using FEM and experiments. J. Mater. Process. Technol. 2013, 213, 2184–2190. [Google Scholar] [CrossRef]

- Gaudilleire, C.; Ranc, N.; Larue, A.; Maillard, A.; Lorong, P. High speed blanking: An experimental method to measure induced cutting forces. Soc. Exp. Mech. 2013, 53, 1117–1126. [Google Scholar] [CrossRef] [Green Version]

- Bohdal, Ł.; Kukiełka, L.; Legutko, S.; Patyk, R.; Radchenko, A.M. Modeling and experimental analysis of Shear-Slitting of AA6111-T4 Aluminum alloy sheet. Materials 2020, 13, 3175. [Google Scholar] [CrossRef] [PubMed]

- Fernández-Abia, A.I.; Barreiro, J.; López de Lacalle, L.N.; Martínez-Pellitero, S. Behavior of austenitic stainless steels at high speed turning using specific force coefficients. Int. J. Adv. Manuf. Technol. 2012, 62, 505–515. [Google Scholar] [CrossRef]

- Rodríguez, A.; López de Lacalle, L.N.; Celaya, A.; Lamikiz, A.; Albizuri, J. Surface improvement of shafts by the deep ball-burnishing technique. Surf. Coat. Technol. 2012, 206, 2817–2824. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, C.; Han, H.; Shan, D.; Guo, B. Investigation on effect of ultrasonic vibration on micro-blanking process of copper foil. Int. J. Adv. Manuf. Technol. 2017, 93, 2243–2249. [Google Scholar] [CrossRef]

- Mucha, J.; Tutak, J. Analysis of the influence of blanking clearance on the wear of the punch, the change of the burr size and the geometry of the hook blanked in the hardened steel sheet. Materials 2019, 12, 1261. [Google Scholar] [CrossRef] [Green Version]

- Molitor, D.A.; Kubik, C.; Hetfleisch, R.H.; Groche, P. Workpiece image-based tool wear classification in blanking processes using deep convolutional neural networks. Prod. Eng. 2022, 16, 481–492. [Google Scholar] [CrossRef]

- Wilczyński, W. Wpływ technologii na właściwości magnetyczne rdzeni maszyn elektrycznych. IEI Warszawa 2003, 215, 6–187. (In Polish) [Google Scholar]

- Lewis, N.; Anderson, P.; Hall, J.; Gao, Y. Power loss models in punched non-oriented electrical steel rings. IEEE Trans. Magn. 2016, 52, 7300704. [Google Scholar] [CrossRef]

- Leuning, N.; Jaeger, M.; Schauerte, B.; Stöcker, A.; Kawalla, R.; Wei, X.; Hirt, G.; Heller, M.; Korte-Kerzel, S.; Böhm, L.; et al. Material design for low loss non-oriented electrical steel for energy efficient drives. Materials 2021, 14, 6588. [Google Scholar] [CrossRef] [PubMed]

- Hergli, K.; Marouani, H.; Zidi, M.; Fouad, Y. Magneto-Mechanical Behavior Analysis using an Extended Jiles-Atherton Hysteresis Model for a Sheet Metal Blanking Application. ACES J. 2020, 35, 727–734. [Google Scholar]

- Xiong, X.; Hu, S.; Hu, K.; Zeng, S. Texture and magnetic property evolution of non-oriented Fe-Si steel due to mechanical cutting. J. Magn. Magn. Mater. 2016, 401, 982–990. [Google Scholar] [CrossRef]

- Kaldunski, P.; Kukielka, L.; Patyk, R.; Kulakowska, A.; Bohdal, L.; Chodor, J.; Kukielka, K. Study of the Influence of Selected Anisotropic Parameter in the Barlat’s Model on the Drawpiece Shape. In Proceedings of the 21st International ESAFORM Conference on Material Forming: ESAFORM 2018, Palermo, Italy, 23–25 April 2018; p. 160014. [Google Scholar]

- Kukiełka, L. New damping models of metallic materials and its application in non-linear dynamical cold processes of metal forming. In Steel Research International, Proceedings of the 13th International Conference Metal Forming 2010, Toyohashi, Japan, 19–22 September 2010; Special Edition 2010; Stahleisen GmbH: Düsseldorf, Germany, 2010; Volume 81, pp. 1482–1485. ISBN 978-3-514-00774-1. [Google Scholar]

- Kukiełka, L.; Geleta, K.; Kukiełka, K. Modelling and analysis of nonlinear physical phenomena in the burnishing rolling operation with electrical current. In Steel Research International, Metal Forming 2012; Wiley-VCH GmbH & Co. KGaA: Weinheim, Germany, 2012; pp. 1379–1382. [Google Scholar]

| Density [kg/dm3] | Rp0.2 [MPa] | Rm [MPa] | Fm [kN] | Ag [%] | Hardness [HB] | Hardness [HV] | |

|---|---|---|---|---|---|---|---|

| 7.8 | 318 | 332 | 1 | 11.4 | 148 | 157 | |

| 1.1 | 10.88 | 9 | 0.03 | 2.79 | 2.98 | 2.06 | |

| Density [kg/dm3] | Rp0.2 [MPa] | Rm [MPa] | Fm [kN] | Ag [%] | Hardness [HB] | Hardness [HV] | |

|---|---|---|---|---|---|---|---|

| 7.8 | 314 | 337 | 0.96 | 10.93 | 157 | 165 | |

| 1.3 | 12.3 | 9.4 | 0.02 | 0.02 | 0.81 | 2.38 | |

| Horizontal clearance, hc | 0.02−0.1 mm |

| Vertical clearance, cv | 0.1 mm |

| Slitting velocity, v | 3−32 m/min |

| Rake angle, α | 7° |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bohdal, Ł.; Kułakowska, A.; Patyk, R.; Kułakowski, M.; Szada-Borzyszkowska, M.; Banaszek, K. Experimental Research on Sheared Edge Formation in the Shear-Slitting of Grain-Oriented Electrical Steel Workpieces. Materials 2022, 15, 8824. https://doi.org/10.3390/ma15248824

Bohdal Ł, Kułakowska A, Patyk R, Kułakowski M, Szada-Borzyszkowska M, Banaszek K. Experimental Research on Sheared Edge Formation in the Shear-Slitting of Grain-Oriented Electrical Steel Workpieces. Materials. 2022; 15(24):8824. https://doi.org/10.3390/ma15248824

Chicago/Turabian StyleBohdal, Łukasz, Agnieszka Kułakowska, Radosław Patyk, Marcin Kułakowski, Monika Szada-Borzyszkowska, and Kamil Banaszek. 2022. "Experimental Research on Sheared Edge Formation in the Shear-Slitting of Grain-Oriented Electrical Steel Workpieces" Materials 15, no. 24: 8824. https://doi.org/10.3390/ma15248824

APA StyleBohdal, Ł., Kułakowska, A., Patyk, R., Kułakowski, M., Szada-Borzyszkowska, M., & Banaszek, K. (2022). Experimental Research on Sheared Edge Formation in the Shear-Slitting of Grain-Oriented Electrical Steel Workpieces. Materials, 15(24), 8824. https://doi.org/10.3390/ma15248824