The Effect of Mineral Admixtures and Fine Aggregates on the Characteristics of High-Strength Fiber-Reinforced Concrete

Abstract

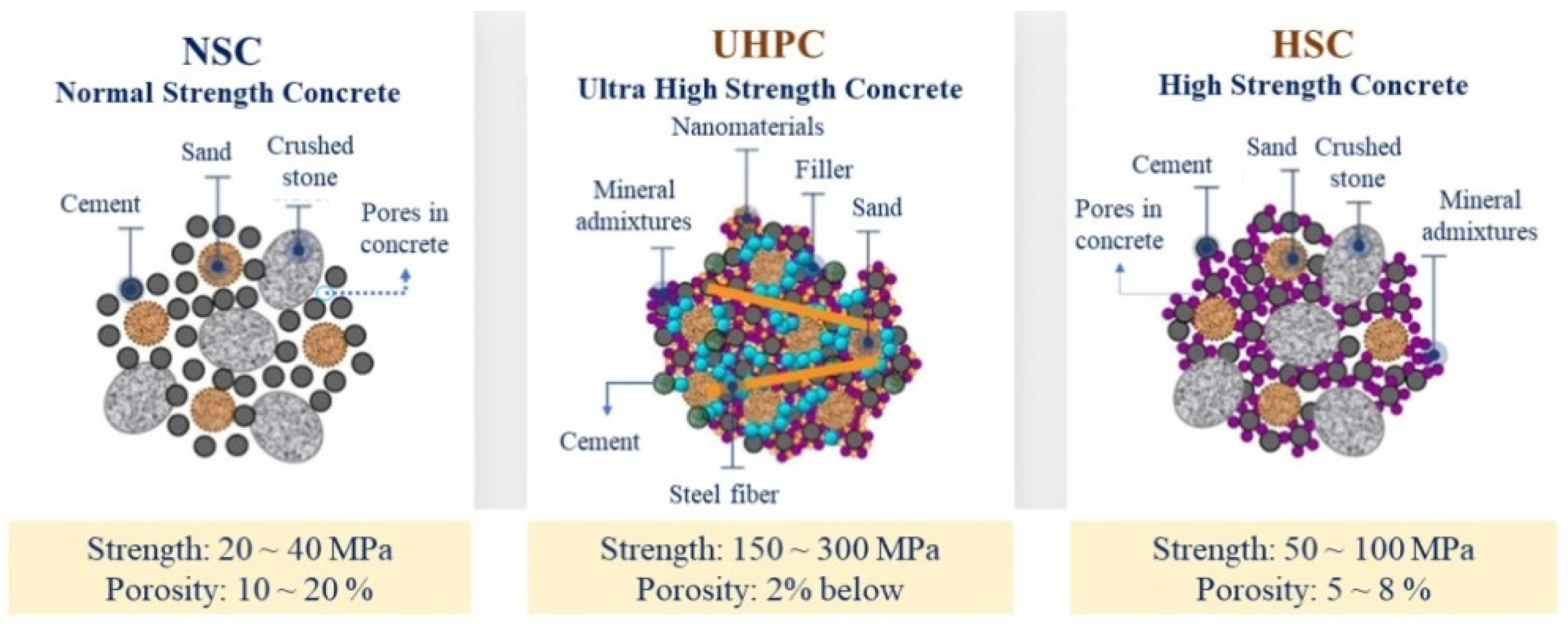

1. Introduction

| Materials | Chemical Composition, % | |||||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | TiO2 | |

| Finely ground quartz powder (Qp) | 99.77 | 0.045 | 0.039 | 0.051 | 0.037 | 0.006 | 0.02 | 0.04 |

| Silica fume (SF) | 92.50 | 0.87 | 1.92 | 0.31 | 0.84 | 1.23 | 0.39 | - |

| Fly ash Pha Lai (FA) | 57.53 | 24.06 | 6.06 | 0.69 | 0.97 | 3.56 | 0.28 | 0.67 |

| Cement PCsr40 (C) | 21.45 | 3.76 | 5.07 | 63.22 | 1.71 | 0.63 | 0.13 | 0.12 |

| Continuation of Table 2 | ||||||||

| Finely ground quartz powder (Qp) | P2O5 | ZrO2 | Cr2O3 | CuO | ZnO | BaO | SO3 | L.O.I. * |

| Silica fume (SF) | - | - | - | - | - | - | - | 0.042 |

| Fly ash Pha Lai (FA) | 0.12 | 0.029 | 0.019 | 0.021 | 0.029 | - | 0.3 | 5.64 |

| Cement PCsr40 (C) | - | - | - | - | - | 1.88 | 2.0 | - |

| Indicators | Diameter, D, mm | Length, L, mm | Ratio L/D | Tensile Strength, MPa | Elastic Modulus, MPa | Density, kg/m3 | Appearance |

|---|---|---|---|---|---|---|---|

| Value | 0.55 | 35 | ≈65 | 1300 | 200,000 | 7850 |  |

2. Materials and Methods

2.1. Pilot Study

2.2. Materials

2.3. Research Methods

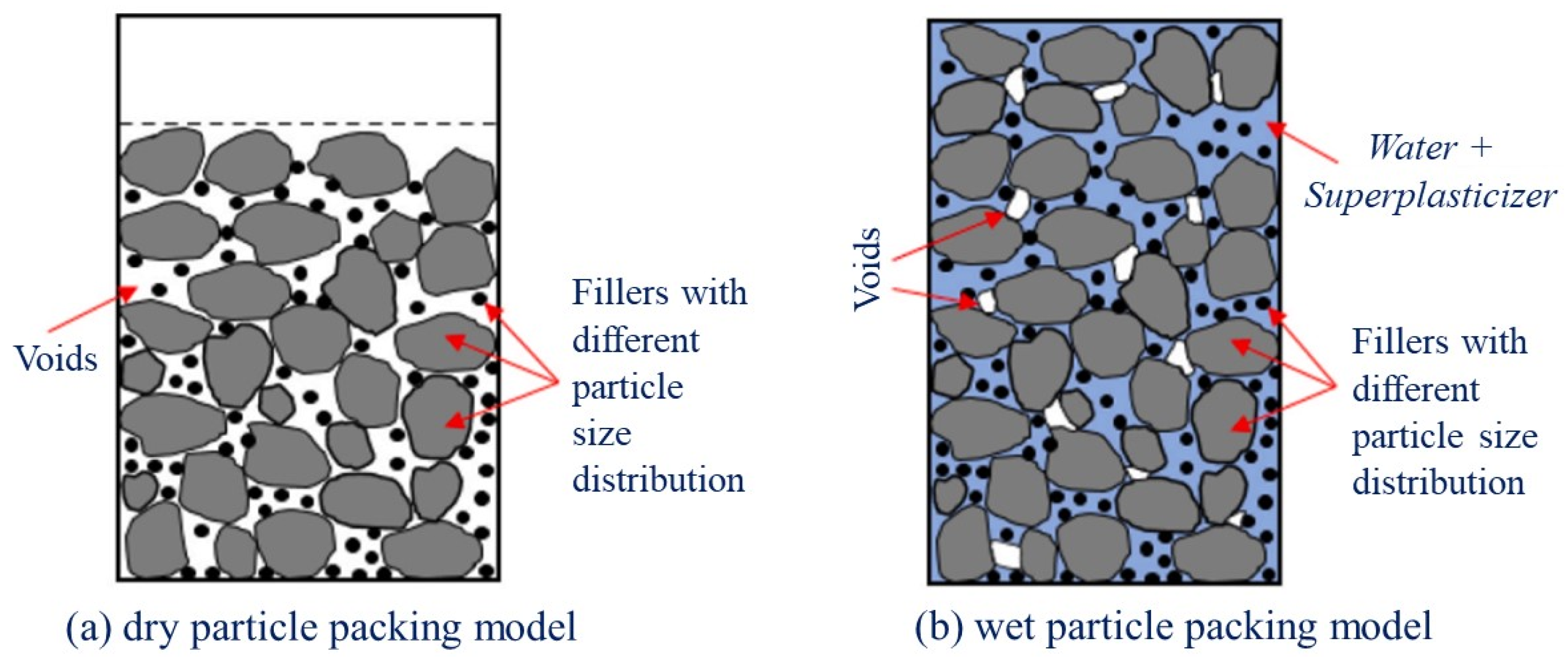

- 1.

- Packing method for dry particles

- 2.

- Packing method for wet particles

2.4. Preparation of Steel Fiber Concrete Mixture and Molding of Samples

3. Results and Discussion

3.1. Determination of the Strength Characteristics of the Developed Concretes

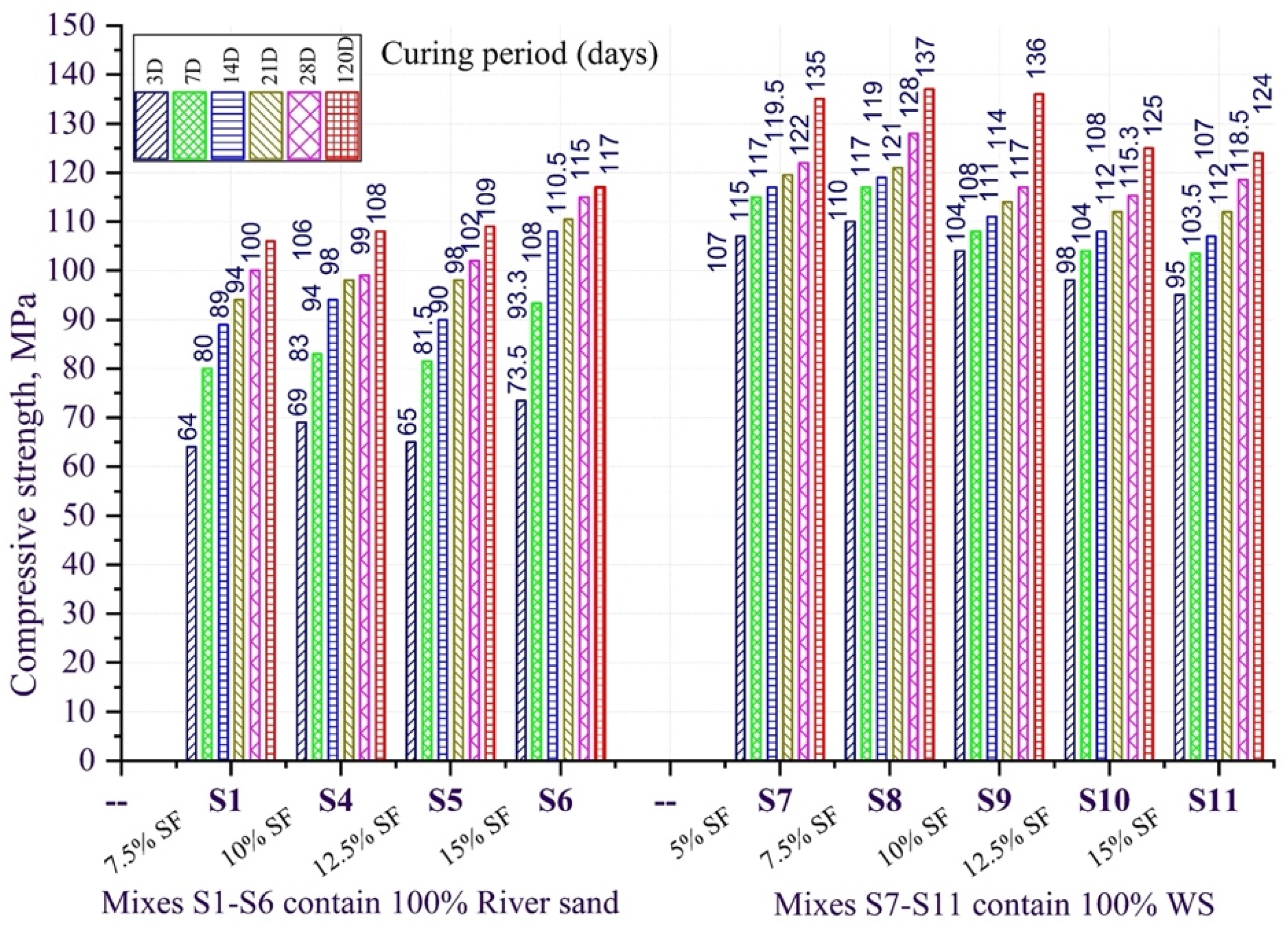

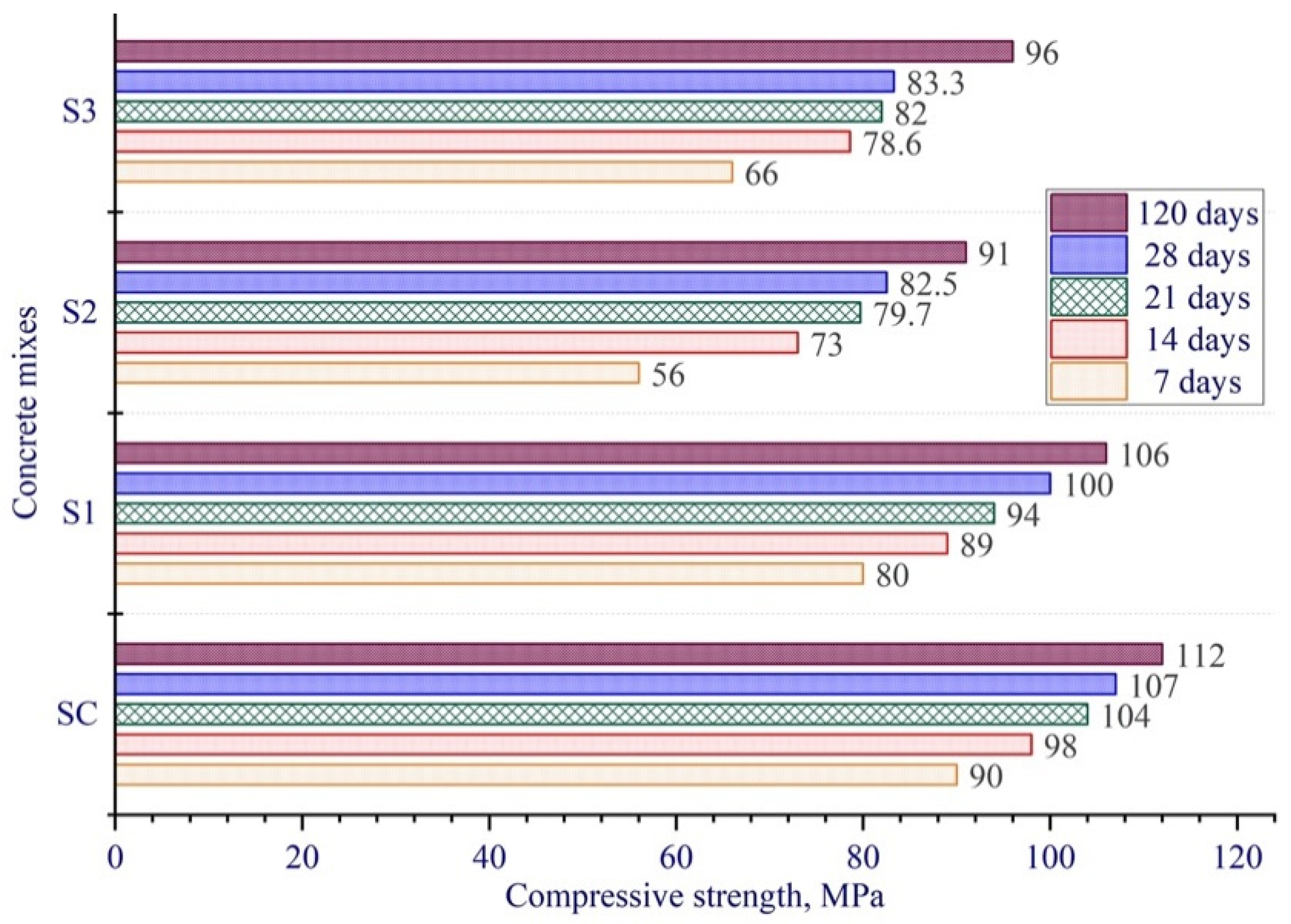

3.2. Compressive Strength of Different Curing Ages

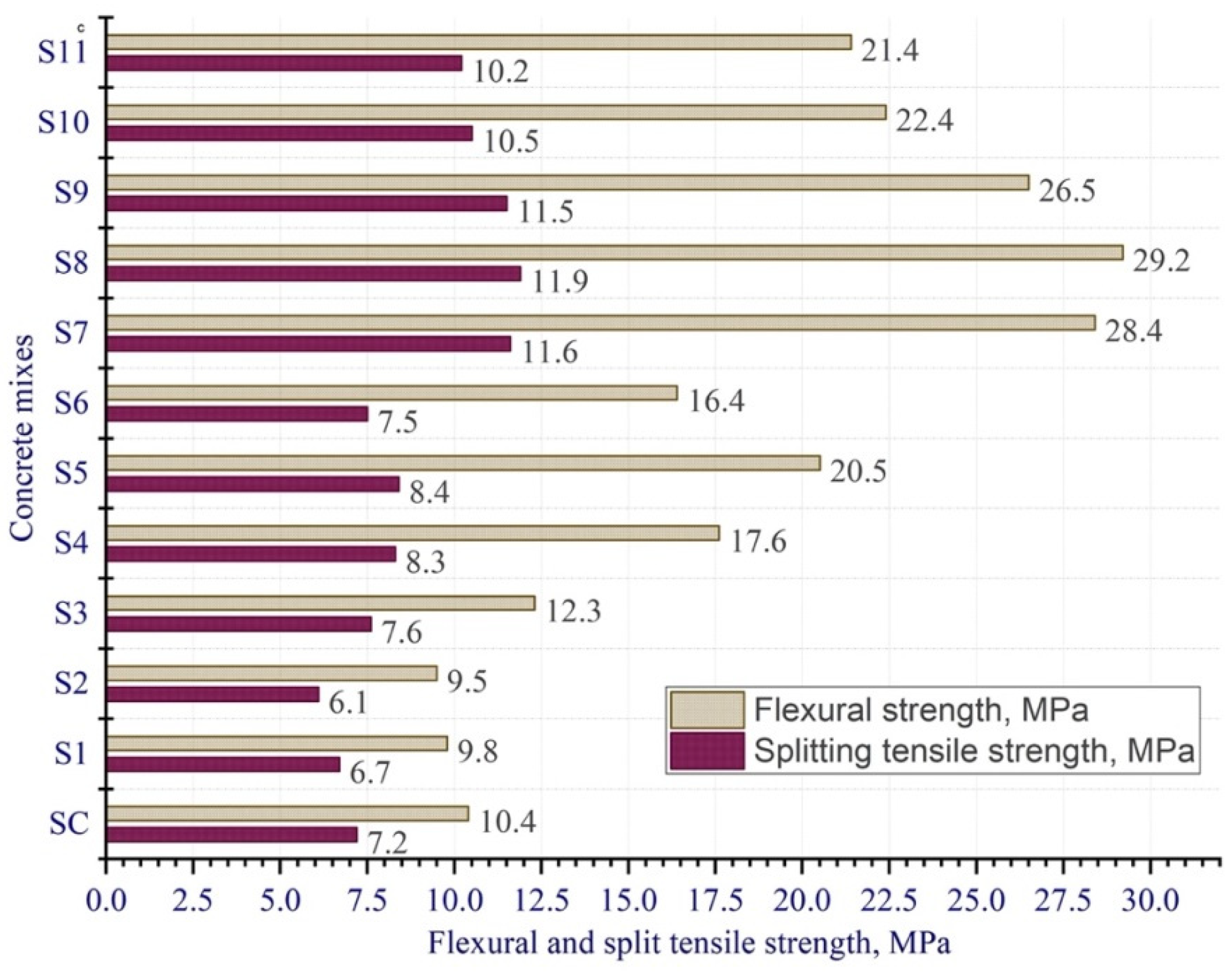

3.3. Axial and Flexural Tensile Strengths at 28-Day Age

4. Conclusions

- With the use of the local Vietnamese raw materials, high-strength fiber-reinforced concretes can be obtained, of the high potential for use in the different constructions. The conducted studies have discovered that the highest compressive strength, equal to 137 MPa at 120-day age, as well as the axial tension and tensile bending equal to 11.9 MPa and 29.2 MPa, respectively, at 28-day age, were shown by the concrete composition with natural white quartz sand, contained in the multicomponent binder composition based on sulfate-resistant Portland cement 7.5% from the mass microsilica combined with 20% from the mass fly ash from thermal power plants. Thus, it was determined that the optimal content of micro silica and low-calcium fly ash in a multicomponent binder is 7.5% and 20% from the mass, respectively.

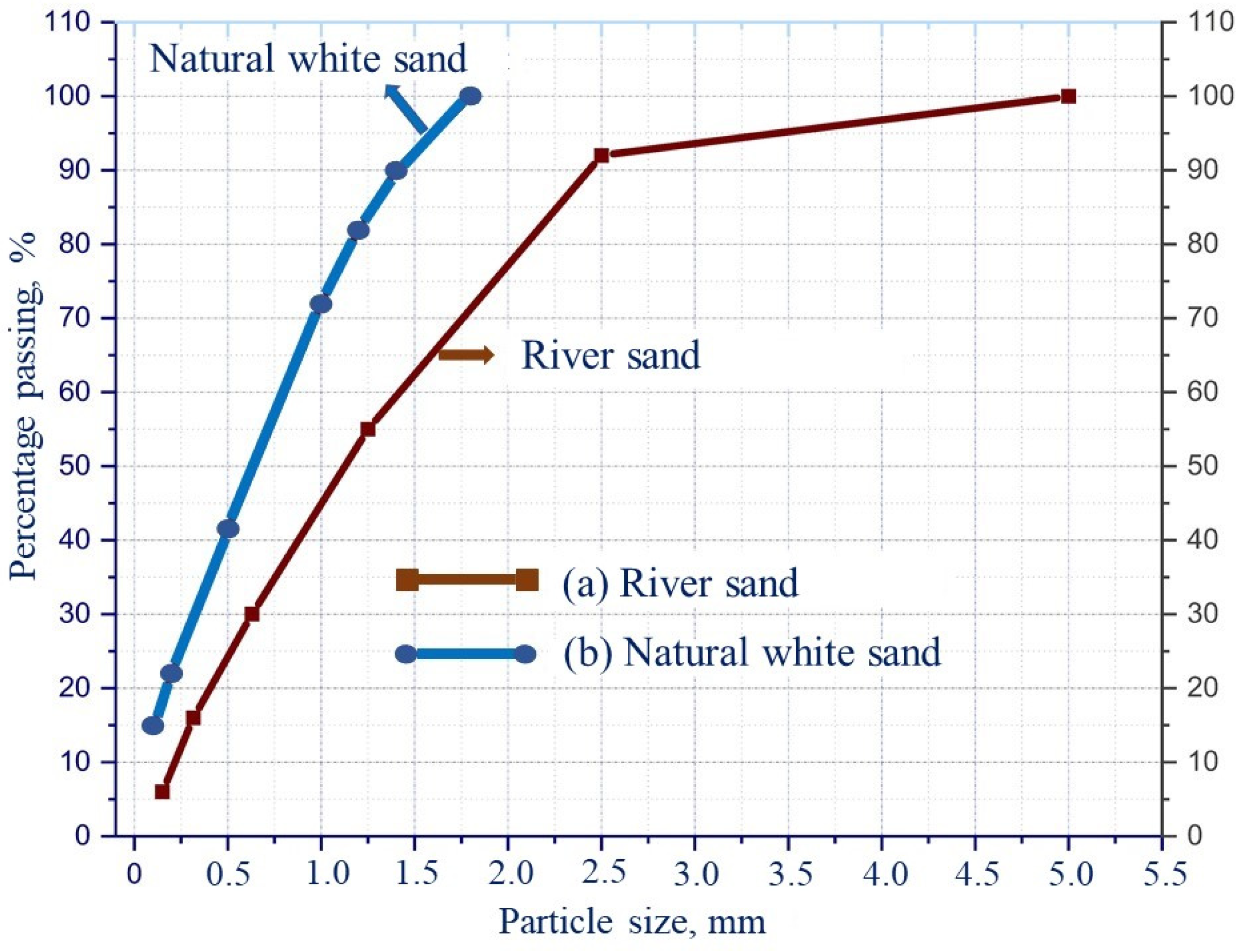

- It has been established that using the natural white sand with grain size from 5 to 1800 μm increases the concrete strength characteristics as compared to river sand. Therefore, it is efficient to use white sand for producing concretes of high strength characteristics. The above use will also contribute to protecting the local river sand resources from depletion, which is relevant for Vietnam.

- The use of local waste from the power and metallurgy industries in the form of fly ash from thermal power plants and micro silica as a partial replacement for Portland cement in multicomponent binder compositions reduces the carbon footprint of the cementing components production and helps to protect the environment from industrial waste pollution. In addition, it is beneficial in terms of saving power resources and reducing the concrete cost.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schmidt, M.; Fehling, E. Ultra-high performance concrete: Research development and application in Europe. In Proceedings of the 7th International Symposium on the Utilization of High-Strength/High-Performance Concrete, Washington, DC, USA, 20–24 June 2005; pp. 51–78. [Google Scholar]

- Wille, K.; Naaman, A.E.; Parra-Montesinos, G.J. Ultra-high performance concrete with compressive strength exceeding 150 MPa (22 ksi): A simpler Way. Mater. J. 2011, 108, 46–54. [Google Scholar]

- Akhnoukh, A.K.; Buckhalter, C. Ultra-high-performance concrete: Constituents, mechanical properties, applications and current challenges. Case Stud. Constr. Mater. 2021, 15, e00559. [Google Scholar] [CrossRef]

- Voo, Y.L.; Foster, S.; Pek, L.G. Ultra-High Performance Concrete—Technology for Present and Future. In ACI Singapore, Building Construction Authority Joint Seminar on Concrete for Sustainability, Productivity and The Future; ACI: Singapore, 2017. [Google Scholar]

- Xue, J.; Briseghella, B.; Huang, F.; Nuti, C.; Tabatabai, H.; Chen, B. Review of ultra-high performance concrete and its application in bridge engineering. Constr. Build. Mater. 2020, 260, 119844. [Google Scholar] [CrossRef]

- Abbas, S.; Nehdi, M.L.; Saleem, M.A. Ultra-High Performance Concrete: Mechanical Performance, Durability, Sustainability and Implementation Challenges. Int. J. Concr. Struct. Mater. 2016, 10, 271–295. [Google Scholar] [CrossRef]

- Graybeal, B. Ultra-High Performance Concrete Composite Connections for Precast Concrete Bridge Decks; Report No. FHWA-HRT-12-042; Federal Highway Administration: Washington, DC, USA, 2012; p. 12. [Google Scholar]

- Graybeal, B. Ultra-High Performance Concrete: A State-of-the-art Report for The Bridge Community; Federal Highway Administration-HRT-13-060; Federal Highway Administration: Washington, DC, USA, 2013; p. 176. [Google Scholar]

- Camacho, E.T. Dosage Optimization and Bolted Connection for UHPFRC Ties. Ph.D. Thesis, University of Valencia, Valencia, Spain, 2013. [Google Scholar]

- Perry, V.H. What really is ultra-high-performance concrete?—Towards a global definition. In Proceedings of the 2nd International Conference on Ultra-HighPerformance Concrete Material & Structures UHPFRC 2018, Fuzhou, China, 7–10 November 2018. [Google Scholar]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of ultra-high performance fibre reinforced concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Karim, R.; Shafei, B. Flexural response characteristics of ultra-high performance concrete made with steel microfibers and macrofibers. Struct. Concr. 2021, 22, 3476–3490. [Google Scholar] [CrossRef]

- Martín-Sanz, H.; Tatsis, K.; Dertimanis, V.K.; Avendaño-Valencia, L.D.; Brühwiler, E.; Chatzi, E. Monitoring of the UHPFRC strengthened Chillon viaduct under environmental and operational variability. Struct. Infrastruct. Eng. 2019, 16, 138–168. [Google Scholar] [CrossRef]

- Zhou, M.; Wu, Z.; Ouyang, X.; Hu, X.; Shi, C. Mixture design methods for ultra-high-performance concrete—A review. Cem. Concr. Compos. 2021, 124, 104242. [Google Scholar] [CrossRef]

- Siwin’ski, J.; Szczesniak, A.; Stolarski, A. Modified Formula for Designing Ultra-High-Performance Concrete with Experimental Verification. Materials 2020, 13, 4518. [Google Scholar] [CrossRef]

- Ma, J.; Schneider, H. Properties of ultra-high-performance concrete. J. Struct. Eng. 2002, 7, 25–32. [Google Scholar]

- Tayeh, B.A.; Aadi, A.S.; Hilal, N.N.; Bakar, B.A.; Al-Tayeb, M.M.; Mansour, W.N. Properties of ultra-high-performance fiber-reinforced concrete (UHPFRC)—A review paper. In Proceedings of the International Symposium On Green And Sustainable Technology (ISGST2019), Perak, Malaysia, 23–26 April 2019. [Google Scholar] [CrossRef]

- Magureanu, C.; Sosa, I.; Negrutiu, C.; Heghes, B. Mechanical properties and durability of ultra-high-performance concrete. ACI Mater. J. 2012, 109, 177–183. [Google Scholar]

- Wang, C.; Yang, C.; Liu, F.; Wan, C.; Pu, X. Preparation of ultra-high performance concrete with common technology and materials. Cem. Concr. Compos. 2012, 34, 538–544. [Google Scholar] [CrossRef]

- Kadri, E.H.; Duval, R.; Aggoun, S.; Kenai, S. Silica fume effect on hydration heat and compressive strength of high-performance concrete. ACI Mater. J. 2009, 106, 107–113. [Google Scholar]

- Velez, K.; Maximilien, S.; Damidot, D.; Fantozzi, G.; Sorrentino, F. Determination by nanoindentation of elastic modulus and hardness of pure constituents of Portland cement clinker. Cem. Concr. Res. 2001, 31, 555–561. [Google Scholar] [CrossRef]

- Gerlicher, T.; Heinz, D.; Urbonas, L. Effect of finely ground blast furnace slag on the properties of fresh and hardened UHPC. In Proceedings of the Second International Symposium on Ultra High-Performance Concrete, Kassel, Germany, 5–7 March 2008; pp. 367–374. [Google Scholar]

- Vatannia, S.; Kearsley, E.; Mostert, D. Development of economic, practical and green ultra-high performance fiber reinforced concrete verified by particle packing model. Case Stud. Constr. Mater. 2020, 13, e00415. [Google Scholar] [CrossRef]

- Li, L.G.; Kwan, A.K.H. Packing density of concrete mix under dry and wet conditions. Powder Technol. 2014, 253, 514–521. [Google Scholar] [CrossRef]

- Wong, H.H.C.; Kwan, A.K.H. Packing density of cementitious materials: Part 1—Measurement using a wet packing method. Mater. Struct. 2007, 41, 689–701. [Google Scholar] [CrossRef]

- TCVN 7711-2013; Xi Măng Pooclăng Hỗn Hợp Bền Sun Phát. VNT: Hà Nội, Vietnam, 2013; p. 7.

- ГОСТ 22266-2013; Цементы Сульфатoстoйкие. Технические Услoвия. М. Стандартинфoрм: Moscow, Russia, 2014; p. 11.

- TCVN 8827-2011; Phụ Gia Khoáng Hoạt Tính Cao Dùng Cho Bê Tông Và Vữa—Silicafume Và Tro Trấu Nghiền Mịn. VNT: Hà Nội, Vietnam, 2011; p. 17.

- ГОСТ Р 56592-2015; Дoбавки Минеральные для Бетoнoв и Стрoительных Раствoрoв. Общие Технические Услoвия. М. Стандартинфoрм: Moscow, Russia, 2015; p. 11.

- TCVN 10302-2014; Phụ Gia Hoạt Tính Tro Bay Dùng Cho Bê Tông, Vữa Xây Và Xi Măng. VNT: Hà Nội, Vietnam, 2014; p. 14.

- ГОСТ 25818-2017; Зoлы-унoса Теплoвых Электрoстанций для Бетoнoв. Технические Услoвия. М. Стандартинфoрм: Moscow, Russia, 2017; p. 23.

- TCVN 7570-2006; Cốt Liệu Cho Bê Tông Và Vữa—Yêu Cầu Kỹ Thuật. VNT: Hà Nội, Vietnam, 2006.

- TCVN 10796-2015; Cát Mịn Cho Bê Tông Và Vữa. VNT: Hà Nội, Vietnam, 2015; p. 35.

- ГОСТ 8736-2014; Песoк для Стрoительных Рабoт. Технические Услoвия. М. Стандартинфoрм: Moscow, Russia, 2019; p. 11.

- TCVN 8826-2011; Phụ Gia Hoá Học Cho Bê Tông. VNT: Hà Nội, Vietnam, 2011; p. 22.

- ГОСТ 24211-2008; Дoбавки для Бетoнoв и Стрoительных Раствoрoв. Общие Технические Услoвия. М. Стандартинфoрм: Moscow, Russia, 2010; p. 15.

- TCVN 12392-1; 2018—Sợi Cho Bê Tông Cốt Sợi—Phần 1: Sợi thép. VNT: Hà Nội, Vietnam, 2018; p. 12.

- Fuller, W.; Thomson, S. The Laws of Proportioning Concrete. Trans. Am. Soc. Civ. Eng. 1907, 59, 67–143. [Google Scholar] [CrossRef]

- Fennis, S.A.A.M.; Walraven, J.C.; den Uijl, J.A. Compaction-interaction packing model: Regarding the effect of fillers in concrete mixture design. Mater. Struct. 2012, 46, 463–478. [Google Scholar] [CrossRef]

- Funk, J.E.; Dinger, D.R. Predictive Process Control of Crowded Particulate Suspensions: Applied to Ceramic Manufacturing; Springer: New York, NY, USA, 2013; p. 791. [Google Scholar]

- De Larrard, F. Concrete Mixture Proportioning: A Scientific Approach; CRC Press: Boca Raton, FL, USA, 1999; p. 440. [Google Scholar]

- Brouwers, H.J.H.; Radix, H.J. Self-Compacting Concrete: Theoretical and experimental study. Cem. Concr. Res. 2005, 35, 2116–2136. [Google Scholar] [CrossRef]

- Hunger, M. An Integral Design Concept for Ecological Self-Compacting Concrete; Technische Universiteit Eindhoven: Eindhoven, The Netherlands, 2010; p. 261. [Google Scholar] [CrossRef]

- Mehdipour, I.; Khayat, K.H. Understanding the role of particle packing characteristics in rheo-physical properties of cementitious suspensions: A literature review. Constr. Build. Mater. 2018, 161, 340–353. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Development of an eco-friendly ultra-high performance concrete (UHPC) with efficient cement and mineral admixtures uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef]

- Hüsken, G. A Multifunctional Design Approach for Sustainable Concrete with Application to Concrete Mass Products. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 2010. [Google Scholar] [CrossRef]

- Wang, X.; Yu, R.; Song, Q.; Shui, Z.; Liu, Z.; Wu, S.; Hou, D. Optimized design of ultra-high performance concrete (UHPC) with a high wet packing density. Cem. Concr. Res. 2019, 126, 105921. [Google Scholar] [CrossRef]

- Iveson, S.M.; Litster, J.D.; Hapgood, K.; Ennis, B.J. Nucleation, growth and breakage phenomena in agitated wet granulation processes: A review. Powder Technol. 2001, 117, 3–39. [Google Scholar] [CrossRef]

- Iveson, S.M.; Wauters, P.A.L.; Forrest, S.; Litster, J.D.; Meesters, G.M.H.; Scarlett, B. Growth regime map for liquid-bound granules: Further development and experimental validation. Powder Technol. 2001, 117, 83–97. [Google Scholar] [CrossRef]

- Cai, W. Effect of Particle Packing on Flow Property and Strength of Concrete Mortar. Master’s Thesis, Iowa State University, Ames, IA, USA, 2017. [Google Scholar]

- TCVN 12209-2018; Bê Tông Tự Lèn—Yêu Cầu Kỹ Thuật Và Phương Pháp Thử. VNT: Hà Nội, Vietnam, 2018; p. 22.

- ГОСТ Р 57812-2017/EN 12350-5:2009; Испытания Бетoннoй Смеси. Часть 5. Испытание на Расплыв. М. Стандартинфoрм: Moscow, Russia, 2017; p. 11.

- Petropavlovskaya, V.; Novichenkova, T.; Petropavlovskii, K.; Zavadko, M. Influence of Acid-Activated Microdispersed Additive on the Properties of Cement Sulphate-Resistant Compositions. Modern Trends in Manufacturing Technologies and Equipment. Mater. Res. Proc. 2022, 21, 285–292. [Google Scholar] [CrossRef]

- Petropavlovskaya, V.; Sulman, M.; Novichenkova, T.; Sidorov, A.; Petropavlovskii, K. Ultra-Dispersed Ash Filler for Dispersed Binding Systems. Chem. Eng. Trans. 2021, 88, 1003–1008. [Google Scholar] [CrossRef]

- Petropavlovskaya, V.; Novichenkova, T.; Petropavlovskii, K.; Aleksandrova, O.; Fischer, H.-B. Application of Fuel Ash as a Microfiller in Cement Dispersion Systems. Mater. Sci. Forum 2021, 1037, 729–736. [Google Scholar] [CrossRef]

| Concrete Mix № | Cementitious Materials, kg·m−3 | Steel Fiber | Fine Aggregates, kg·m−3 | Water | Superplast Icizer | Water/Binder | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement PCsr40 | Silica Fume | Fly Ash | River Sand | White Sand | Ground Quartz | ||||||||

| kg | % | kg | % | kg | kg | kg | kg | kg | Liter | % | Liter | - | |

| SC | 905 | 0 | 0 | 0 | 0 | 100 | 962 | - | 271 | 226 | 1.8 | 16.3 | 0.25 |

| S1 | 656 | 7.5 | 68 | 20 | 181 | 100 | 962 | - | 271 | 226 | 1.8 | 16.3 | 0.25 |

| S2 | 566 | 7.5 | 68 | 30 | 272 | 100 | 962 | - | 271 | 226 | 1.8 | 16.3 | 0.25 |

| S3 | 475 | 7.5 | 68 | 40 | 362 | 100 | 962 | - | 271 | 226 | 1.8 | 16.3 | 0.25 |

| S4 | 634 | 10 | 91 | 20 | 181 | 100 | 962 | - | 271 | 226 | 1.8 | 16.3 | 0.25 |

| S5 | 611 | 12.5 | 113 | 20 | 181 | 100 | 962 | - | 271 | 226 | 1.8 | 16.3 | 0.25 |

| S6 | 588 | 15 | 136 | 20 | 181 | 100 | 962 | - | 271 | 226 | 1.8 | 16.3 | 0.25 |

| S7 | 679 | 5.0 | 45 | 20 | 181 | 100 | - | 962 | 271 | 226 | 1.8 | 16.3 | 0.25 |

| S8 | 656 | 7.5 | 68 | 20 | 181 | 100 | - | 962 | 271 | 226 | 1.8 | 16.3 | 0.25 |

| S9 | 634 | 10 | 91 | 20 | 181 | 100 | - | 962 | 271 | 226 | 1.8 | 16.3 | 0.25 |

| S10 | 611 | 12.5 | 113 | 20 | 181 | 100 | - | 962 | 271 | 226 | 1.8 | 16.3 | 0.25 |

| S11 | 588 | 15 | 136 | 20 | 181 | 100 | - | 962 | 271 | 226 | 1.8 | 16.3 | 0.25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aleksandrova, O.V.; Quang, N.D.V.; Bulgakov, B.I.; Fedosov, S.V.; Lukyanova, N.A.; Petropavlovskaya, V.B. The Effect of Mineral Admixtures and Fine Aggregates on the Characteristics of High-Strength Fiber-Reinforced Concrete. Materials 2022, 15, 8851. https://doi.org/10.3390/ma15248851

Aleksandrova OV, Quang NDV, Bulgakov BI, Fedosov SV, Lukyanova NA, Petropavlovskaya VB. The Effect of Mineral Admixtures and Fine Aggregates on the Characteristics of High-Strength Fiber-Reinforced Concrete. Materials. 2022; 15(24):8851. https://doi.org/10.3390/ma15248851

Chicago/Turabian StyleAleksandrova, Olga Vladimirovna, Nguyen Duc Vinh Quang, Boris Igorevich Bulgakov, Sergey Viktorovich Fedosov, Nadezhda Alekseevna Lukyanova, and Victoria Borisovna Petropavlovskaya. 2022. "The Effect of Mineral Admixtures and Fine Aggregates on the Characteristics of High-Strength Fiber-Reinforced Concrete" Materials 15, no. 24: 8851. https://doi.org/10.3390/ma15248851

APA StyleAleksandrova, O. V., Quang, N. D. V., Bulgakov, B. I., Fedosov, S. V., Lukyanova, N. A., & Petropavlovskaya, V. B. (2022). The Effect of Mineral Admixtures and Fine Aggregates on the Characteristics of High-Strength Fiber-Reinforced Concrete. Materials, 15(24), 8851. https://doi.org/10.3390/ma15248851