Triboelectric Energy-Harvesting Floor Tile

Abstract

:1. Introduction

2. Performance Evaluation of TEHTB

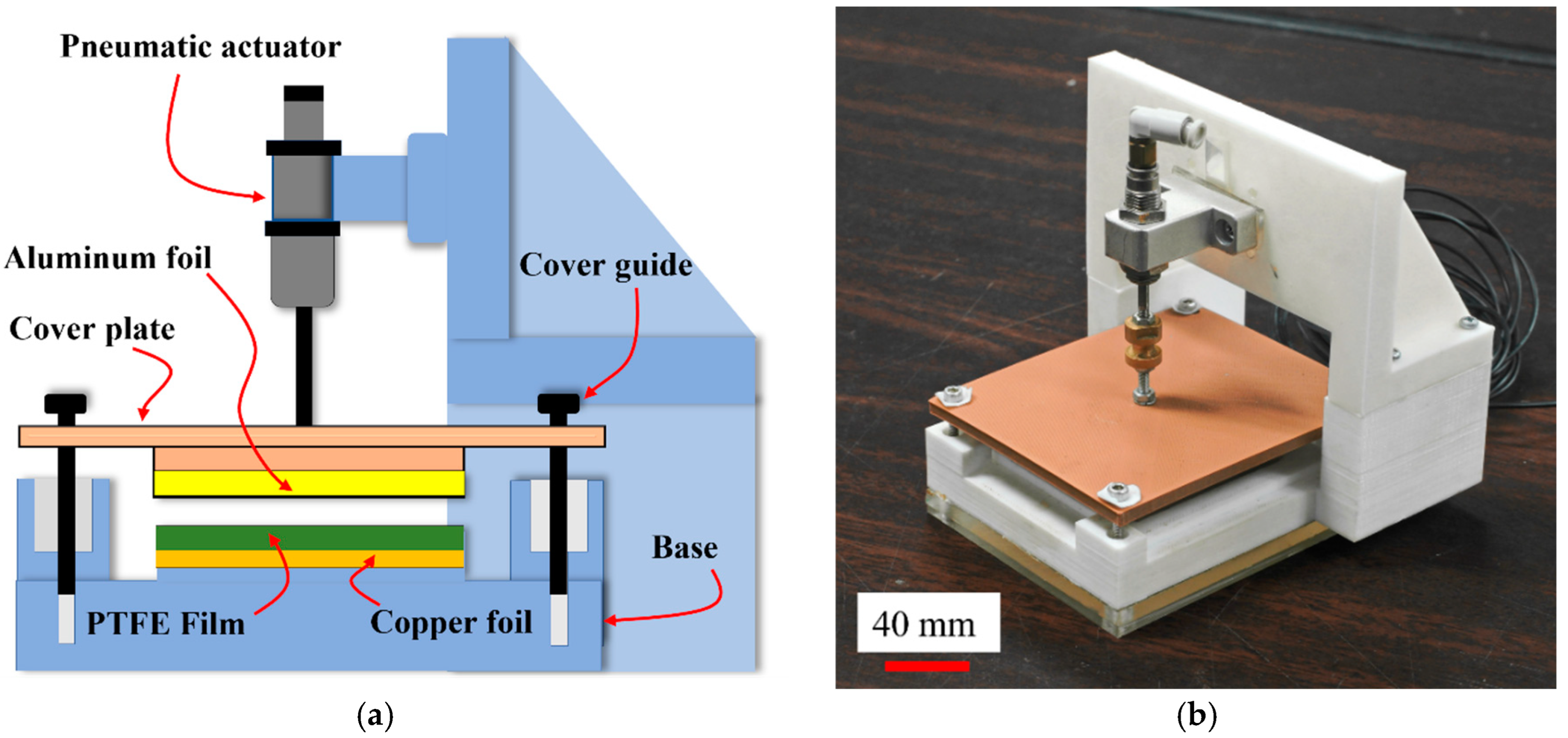

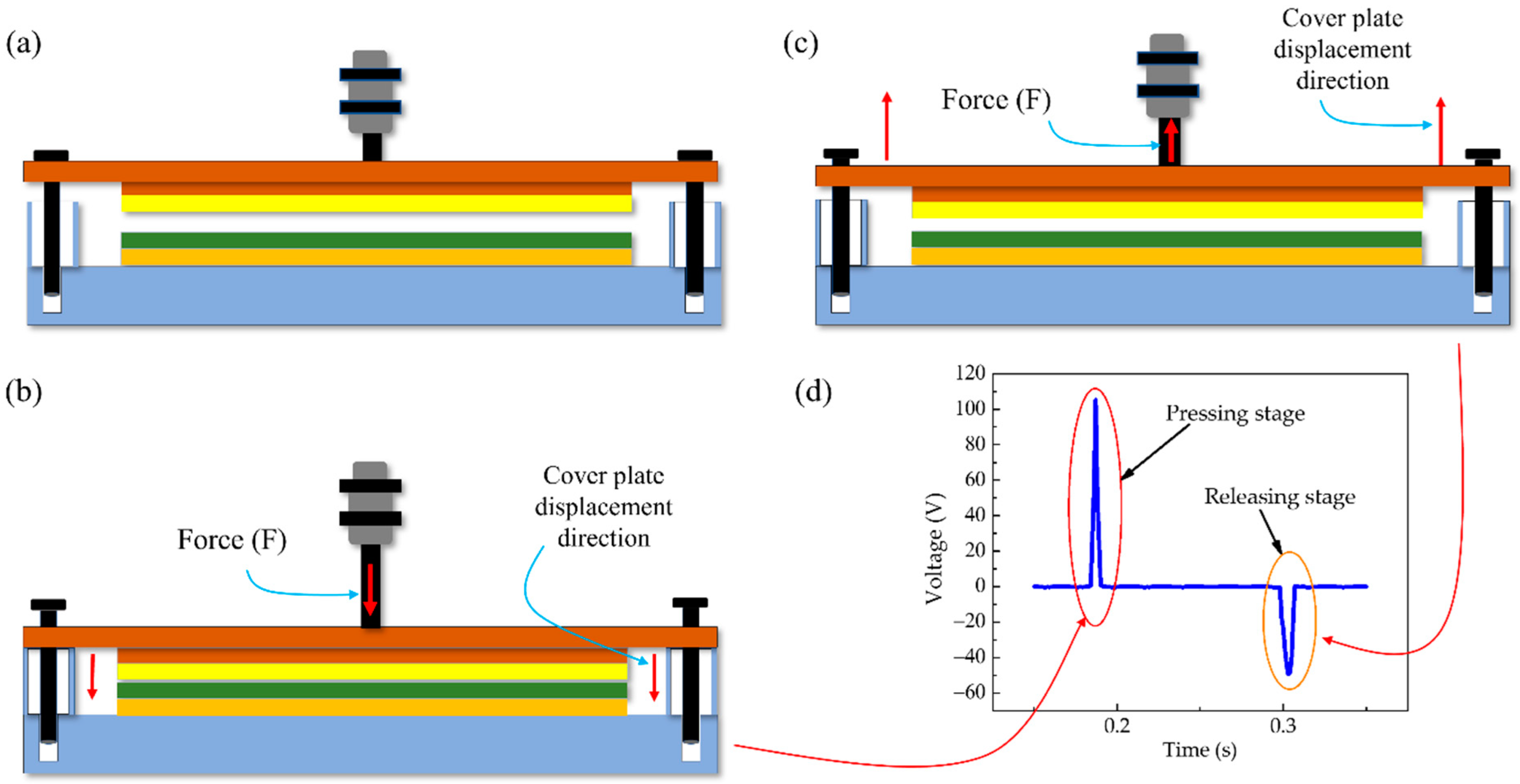

2.1. TEHTB Structure and Working Principle

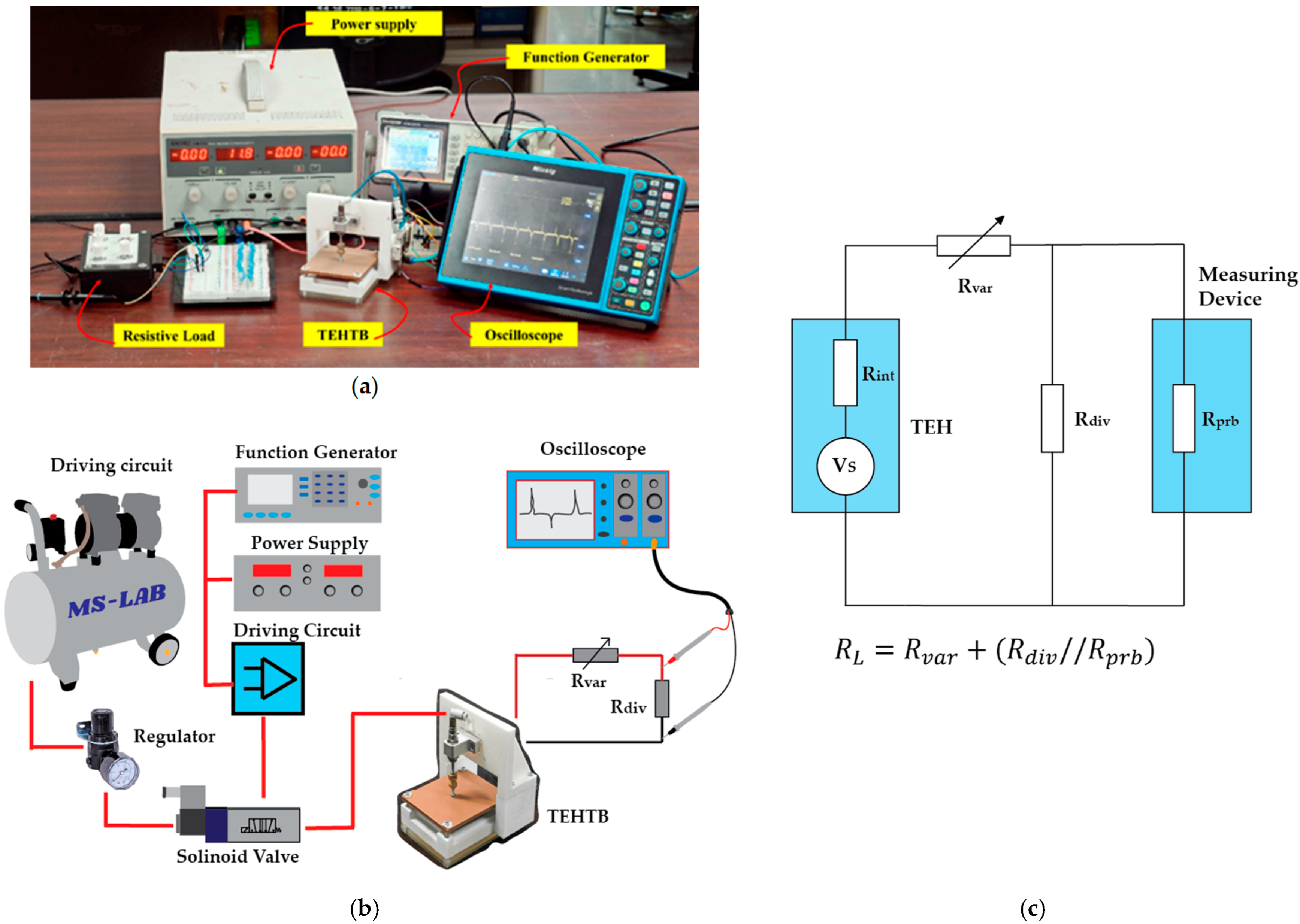

2.2. Experimental Method

- (1)

- Twenty repeatedly measured voltages were obtained for the evaluation; current and power were derived from the obtained voltage.

- (2)

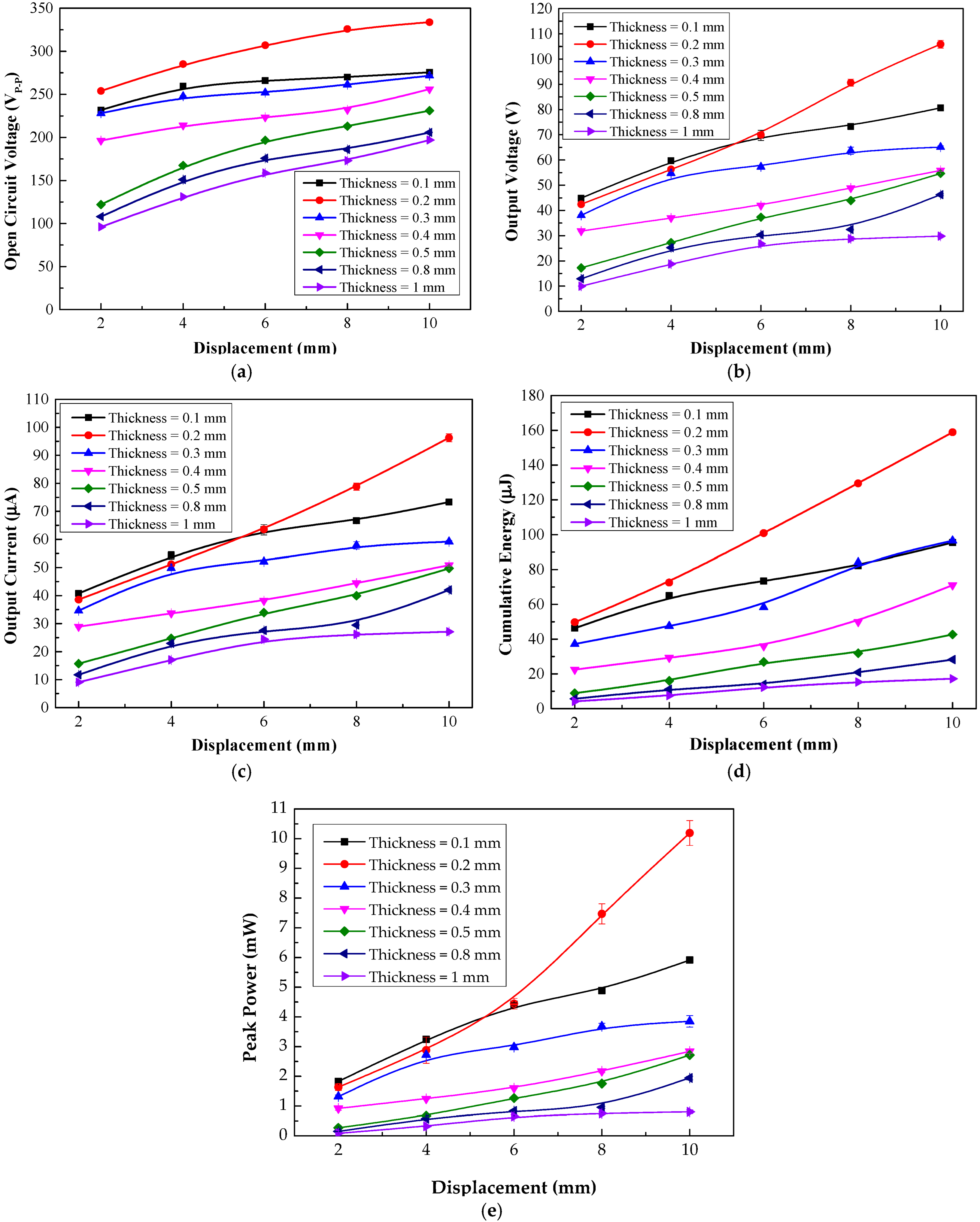

- Various thicknesses of the PTFE sheet inside the test bench were electrically tested; the displacement (gap width) between the cover plate and the base was varied to be 2, 4, 6, 8, and 10 mm.

- (3)

- The effect of pressing frequency on the electrical output of the TEHTB was examined by varying the pressing frequency on the cover plate from 0.5 to 3 Hz.

- (4)

- The electrical outputs of the TEHTB with different PTFE thicknesses were compared, then two optimal thicknesses were selected for fabricating the TEHFT prototype.

2.3. TEHTB Experimental Results and Discussion

3. Performance Evaluation of the Triboelectric Energy Harvesting Floor Tile Prototype

3.1. Triboelectric Energy Harvesting Floor Tile (TEHFT)

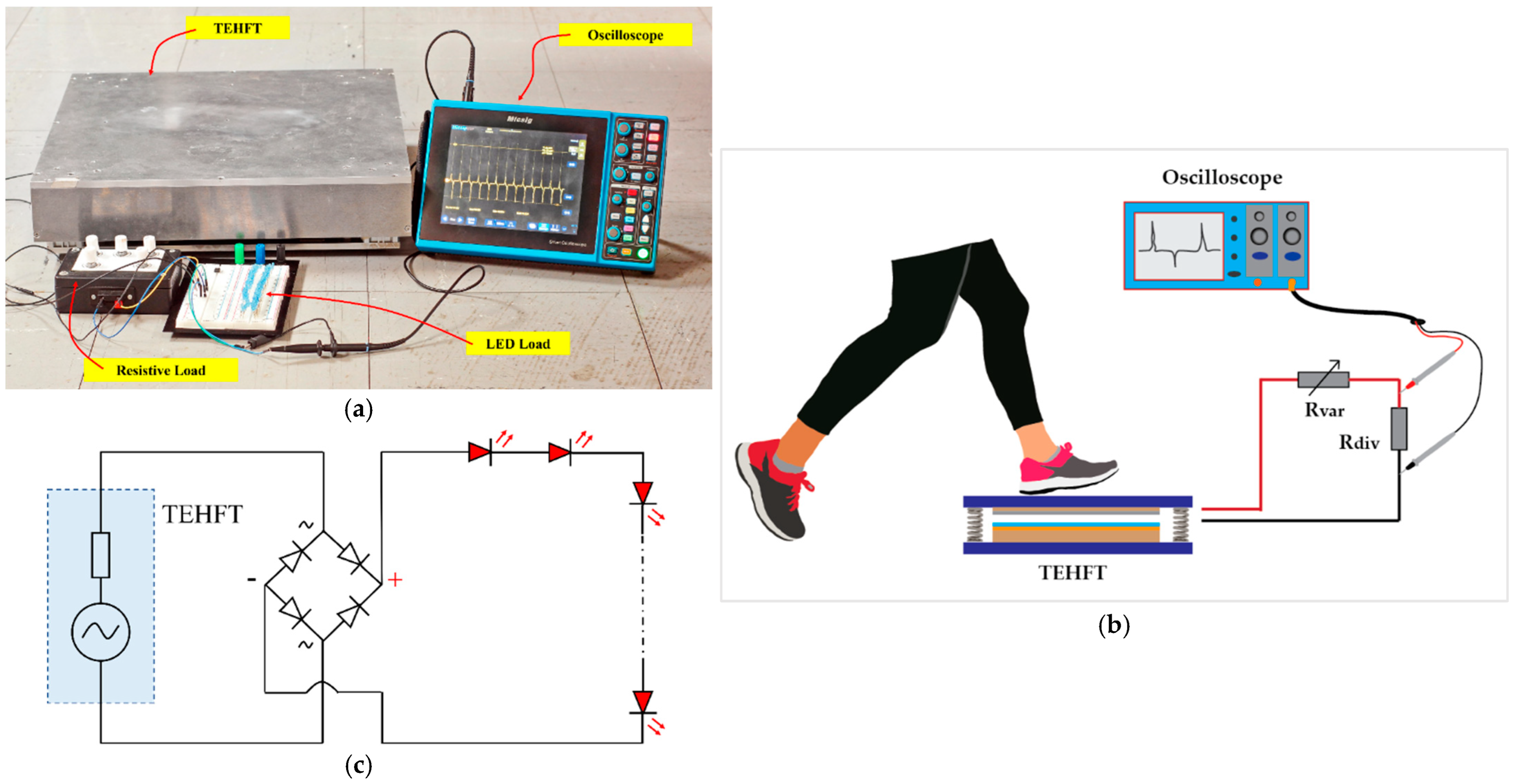

3.2. Performance Evaluation Method and Experimental Setup

- (1)

- Measuring the output voltage of the TEHFT equipped with 0.1 mm and 0.2 mm thick PTFE layer.

- (2)

- Connecting an optimal resistive load to the TEHFT and measuring the output voltage, then deriving the accumulative energy at different stepping or pressing frequencies of 0.5, 1, 1.5, and 2 Hz.

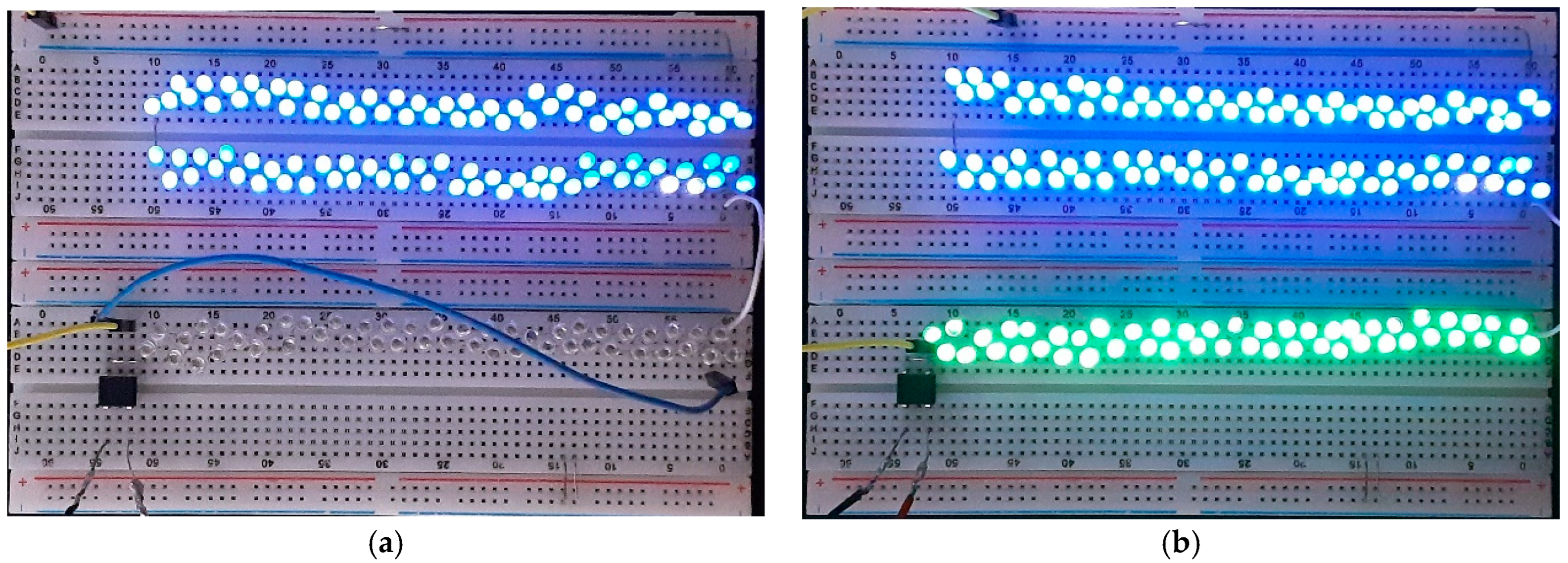

- (3)

- Evaluating the real-world performance of the TEHFT with light-emitting diodes (LEDs). The schematic of the experimental setup is shown in Figure 8c.

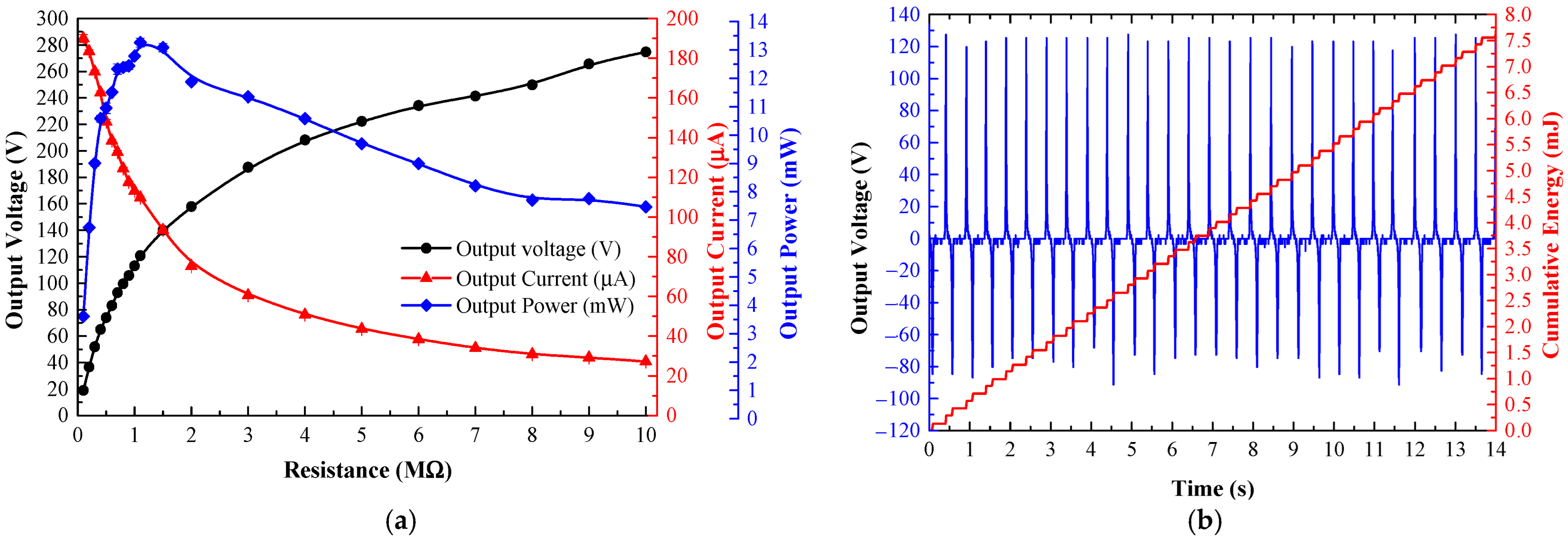

3.3. Experimental Results and Discussion

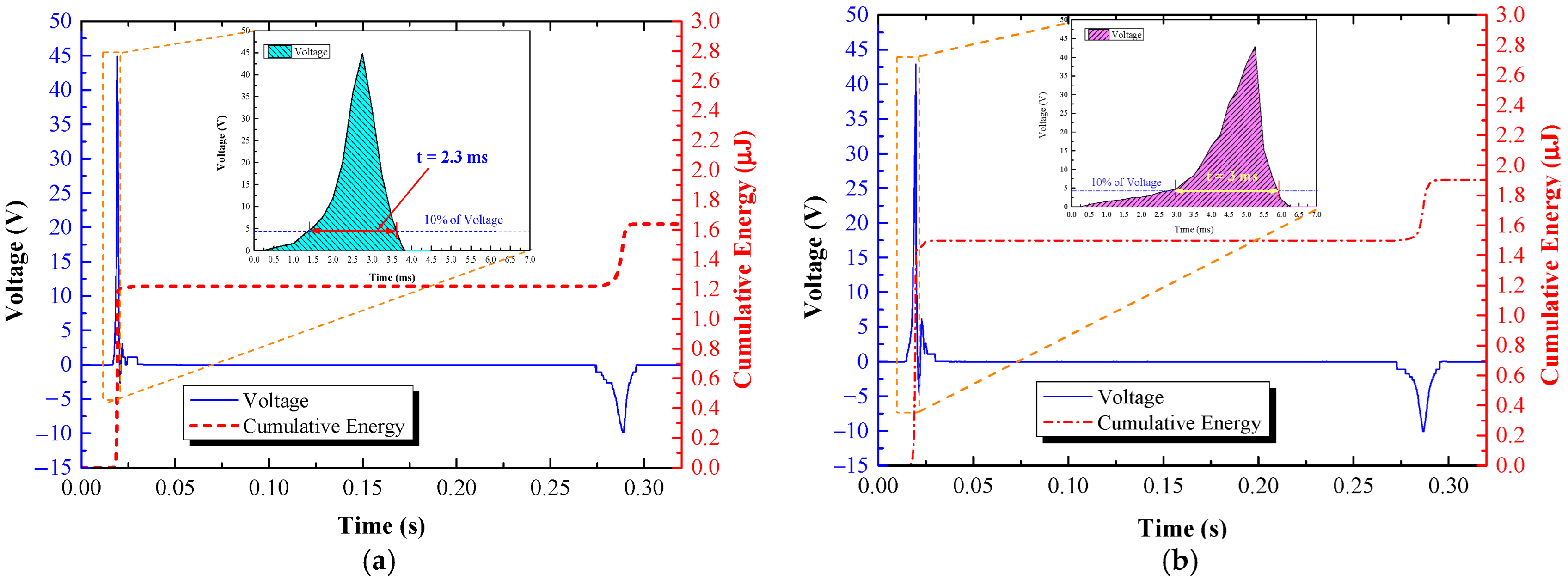

3.3.1. Electrical Characteristics of TEHFT with 0.1 mm Thick PTFE Layer

3.3.2. Electrical Characteristics of TEHFT with 0.2 mm Thick PTFE Layer

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xie, L.; Cai, M. Increased Piezoelectric Energy Harvesting from Human Footstep Motion by Using an Amplification Mechanism. Appl. Phys. Lett. 2014, 105, 143901. [Google Scholar] [CrossRef]

- Veena, R.M.; Reddy, B.H.; Shyni, S.M. Maximum Energy Harvesting from Electromagnetic Micro Generators by Footsteps Using Photo Sensor. In Proceedings of the 2016 International Conference on Computation of Power, Energy Information and Commuincation (ICCPEIC), Bandung, Indonesia, 20–21 April 2016; IEEE: Chennai, India, 2016; pp. 757–761. [Google Scholar]

- Yao, M.; Xie, G.; Gong, Q.; Su, Y. Walking Energy Harvesting and Self-Powered Tracking System Based on Triboelectric Nanogenerators. Beilstein J. Nanotechnol. 2020, 11, 1590–1595. [Google Scholar] [CrossRef] [PubMed]

- He, C.; Zhu, W.; Chen, B.; Xu, L.; Jiang, T.; Han, C.B.; Gu, G.Q.; Li, D.; Wang, Z.L. Smart Floor with Integrated Triboelectric Nanogenerator As Energy Harvester and Motion Sensor. ACS Appl. Mater. Interfaces 2017, 9, 26126–26133. [Google Scholar] [CrossRef]

- Islam, E.; Abdullah, A.M.; Chowdhury, A.R.; Tasnim, F.; Martinez, M.; Olivares, C.; Lozano, K.; Uddin, M.J. Electromagnetic-Triboelectric-Hybrid Energy Tile for Biomechanical Green Energy Harvesting. Nano Energy 2020, 77, 105250. [Google Scholar] [CrossRef]

- Sharma, S.; Kiran, R.; Azad, P.; Vaish, R. A Review of Piezoelectric Energy Harvesting Tiles: Available Designs and Future Perspective. Energy Convers. Manag. 2022, 254, 115272. [Google Scholar] [CrossRef]

- Sharpes, N.; Vučković, D.; Priya, S. Floor Tile Energy Harvester for Self-Powered Wireless Occupancy Sensing. Energy Harvest. Syst. 2016, 3, 43–60. [Google Scholar] [CrossRef]

- Panthongsy, P.; Isarakorn, D.; Janphuang, P.; Hamamoto, K. Fabrication and Evaluation of Energy Harvesting Floor Using Piezoelectric Frequency Up-Converting Mechanism. Sens. Actuators A Phys. 2018, 279, 321–330. [Google Scholar] [CrossRef]

- Yingyong, P.; Thainiramit, P.; Jayasvasti, S.; Thanach-Issarasak, N.; Isarakorn, D. Evaluation of Harvesting Energy from Pedestrians Using Piezoelectric Floor Tile Energy Harvester. Sens. Actuators A Phys. 2021, 331, 113035. [Google Scholar] [CrossRef]

- Niu, S.; Wang, S.; Lin, L.; Liu, Y.; Zhou, Y.S.; Hu, Y.; Wang, Z.L. Theoretical Study of Contact-Mode Triboelectric Nanogenerators as an Effective Power Source. Energy Environ. Sci. 2013, 6, 3576. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric Nanogenerators as New Energy Technology for Self-Powered Systems and as Active Mechanical and Chemical Sensors. ACS Nano 2013, 7, 9533–9557. [Google Scholar] [CrossRef]

- Zhang, H.; Yao, L.; Quan, L.; Zheng, X. Theories for Triboelectric Nanogenerators: A Comprehensive Review. Nanotechnol. Rev. 2020, 9, 610–625. [Google Scholar] [CrossRef]

- Thainiramit, P.; Yingyong, P.; Isarakorn, D. Impact-Driven Energy Harvesting: Piezoelectric Versus Triboelectric Energy Harvesters. Sensors 2020, 20, 5828. [Google Scholar] [CrossRef] [PubMed]

- Charanya, S.; Chandrasekhar, A. Biomechanical Energy Harvesting Triboelectric Nanogenerator as a Self Powered Sensor. AIP Conf. Proc. 2020, 2265, 030652. [Google Scholar]

- Bukhari, M.U.; Riaz, K.; Tauqeer, T.; Sajid, M. Simple and Low Cost Triboelectric Nanogenerator (TENG) for Resource Limited Environment. In Proceedings of the 2019 International Conference on Robotics and Automation in Industry (ICRAI), Rawalpindi, Pakistan, 21–22 October 2019; IEEE: Rawalpindi, Pakistan, 2019; pp. 1–4. [Google Scholar]

- Pallares, R.M.; Su, X.; Lim, S.H.; Thanh, N.T.K. Fine-Tuning of Gold Nanorod Dimensions and Plasmonic Properties Using the Hofmeister Effects. J. Mater. Chem. C 2016, 4, 53–61. [Google Scholar] [CrossRef] [Green Version]

- Sukumaran, C.; Viswanathan, P.; Munirathinam, P.; Chandrasekhar, A. A Flexible and Wearable Joint Motion Sensor Using Triboelectric Nanogenerators for Hand Gesture Monitoring. IJNT 2021, 18, 697. [Google Scholar] [CrossRef]

- Niu, S.; Wang, Z.L. Theoretical Systems of Triboelectric Nanogenerators. Nano Energy 2015, 14, 161–192. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Sun, X.; Chen, Y.; Debeli, D.K.; Guo, J. Comprehensive Dependence of Triboelectric Nanogenerator on Dielectric Thickness and External Impact for High Electric Outputs. J. Appl. Phys. 2018, 124, 045106. [Google Scholar] [CrossRef]

- Gomes, A.; Rodrigues, C.; Pereira, A.M.; Ventura, J. Influence of Thickness and Contact Area on the Performance of PDMS-Based Triboelectric Nanogenerators. arXiv 2018, arXiv:1803.10070. [Google Scholar]

- Oh, H.J.; Bae, J.H.; Park, Y.K.; Song, J.; Kim, D.K.; Lee, W.; Kim, M.; Heo, K.J.; Kim, Y.; Kim, S.H.; et al. A Highly Porous Nonwoven Thermoplastic Polyurethane/Polypropylene-Based Triboelectric Nanogenerator for Energy Harvesting by Human Walking. Polymers 2020, 12, 1044. [Google Scholar] [CrossRef]

- Xia, K.; Wu, D.; Fu, J.; Hoque, N.A.; Ye, Y.; Xu, Z. A High-Output Triboelectric Nanogenerator Base on Nickel-Copper Bimetallic Hydroxide Nanowrinkles for Self-Powered Wearable Electronics. J. Mater. Chem. A 2020, 8, 25995–26003. [Google Scholar] [CrossRef]

- Saadatnia, Z.; Mosanenzadeh, S.G.; Esmailzadeh, E.; Naguib, H.E. A High Performance Triboelectric Nanogenerator Using Porous Polyimide Aerogel Film. Sci. Rep. 2019, 9, 1370. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Palaniappan, V.; Bazuin, B.J.; Atashbar, M.Z.; Masihi, S.; Zhang, X.; Emamian, S.; Bose, A.K.; Maddipatla, D.; Hajian, S.; Panahi, M.; et al. A Flexible Triboelectric Nanogenerator Fabricated Using Laser-Assisted Patterning Process. In Proceedings of the 2019 IEEE SENSORS, Montreal, QC, Canada, 27–30 October 2019; IEEE: Montreal, QC, Canada, 2019; pp. 1–4. [Google Scholar]

- Heinemann, P.; Kasperski, M. Damping Induced by Walking and Running. Procedia Eng. 2017, 199, 2826–2831. [Google Scholar] [CrossRef]

- Song, S.; Geyer, H. Regulating Speed and Generating Large Speed Transitions in a Neuromuscular Human Walking Model. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, St Paul, MN, USA, 14–18 May 2012; IEEE: St Paul, MN, USA, 2012; pp. 511–516. [Google Scholar]

- Zhang, R.; Olin, H. Material Choices for Triboelectric Nanogenerators: A Critical Review. EcoMat 2020, 2, e12062. [Google Scholar] [CrossRef]

- Jayasvasti, S.; Thainiramit, P.; Yingyong, P.; Isarakorn, D. Technique for Measuring Power across High Resistive Load of Triboelectric Energy Harvester. Micromachines 2021, 12, 766. [Google Scholar] [CrossRef] [PubMed]

- Janphuang, P.; Lockhart, R.A.; Isarakorn, D.; Henein, S.; Briand, D.; de Rooij, N.F. Harvesting Energy From a Rotating Gear Using an AFM-Like MEMS Piezoelectric Frequency Up-Converting Energy Harvester. J. Microelectromech. Syst. 2015, 24, 742–754. [Google Scholar] [CrossRef]

- Satkunskienė, D.; Grigas, V.; Eidukynas, V.; Domeika, A. Acceleration Based Evaluation of the Human Walking and Running Parameters. J. Vibroeng. 2009, 11, 506–510. [Google Scholar]

- Morrow, M.M.B.; Hurd, W.J.; Fortune, E.; Lugade, V.; Kaufman, K.R. Accelerations of the Waist and Lower Extremities Over a Range of Gait Velocities to Aid in Activity Monitor Selection for Field-Based Studies. J. Appl. Biomech. 2014, 30, 581–585. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.L.; Lin, L.; Chen, J.; Niu, S.; Zi, Y. Triboelectric Nanogenerators; Green Energy and Technology; Springer International Publishing: Cham, Switzerland, 2016; ISBN 978-3-319-40038-9. [Google Scholar]

- Yang, B.; Zeng, W.; Peng, Z.; Lui, S.-R.; Chen, K.; Tao, X. A Fully Verified Theoretical Analysis of Contact-Mode Triboelectric Nanogenerators as a Wearable Power Source. Adv. Energy Mater. 2016, 6, 1600505. [Google Scholar] [CrossRef]

- Tronco Jurado, U.; Pu, S.H.; White, N.M. Dielectric-Metal Triboelectric Nanogenerators for Ocean Wave Impact Self-Powered Applications. IEEE Sens. J. 2019, 19, 6778–6785. [Google Scholar] [CrossRef] [Green Version]

- Grosse-Puppendahl, T.; Hodges, S.; Chen, N.; Helmes, J.; Taylor, S.; Scott, J.; Fromm, J.; Sweeney, D. Exploring the Design Space for Energy-Harvesting Situated Displays. In Proceedings of the 29th Annual Symposium on User Interface Software and Technology, Tokyo, Japan, 16–19 October 2016; ACM: Tokyo Japan, 2016; pp. 41–48. [Google Scholar]

- Mathúna, C.Ó.; O’Donnell, T.; Martinez-Catala, R.V.; Rohan, J.; O’Flynn, B. Energy Scavenging for Long-Term Deployable Wireless Sensor Networks. Talanta 2008, 75, 613–623. [Google Scholar] [CrossRef]

| Stepping Frequency (Hz) | 0.1 mm Thickness | 0.2 mm Thickness | ||||

|---|---|---|---|---|---|---|

| Voltage (VP-P) | Peak Power (mW) | Energy (J) | Voltage (VP-P) | Peak Power (mW) | Energy (J) | |

| 0.5 | 115.20 ± 2.65 | 7.36 ± 0.37 | 1.01 × 10−3 | 199.73 ± 4.10 | 14.42 ± 0.84 | 1.87 × 10−3 |

| 1 | 113.03 ± 1.07 | 6.96 ± 0.10 | 1.91 × 10−3 | 200.59 ± 2.76 | 14.08 ± 0.13 | 3.64 × 10−3 |

| 1.5 | 113.76 ± 1.24 | 7.19 ± 0.14 | 2.89 × 10−3 | 198.83 ± 2.03 | 13.90 ± 0.18 | 5.41 × 10−3 |

| 2 | 116.76 ± 1.31 | 7.03 ± 0.19 | 3.81 × 10−3 | 200.64 ± 2.66 | 13.96 ± 0.23 | 7.69 × 10−3 |

| Device | Rated Voltage (V) | Rated Power (W) | Consumption Energy (J) |

|---|---|---|---|

| MCU + BLE [35] | n/a | 68 × 10−5 | 6.8 × 10−3 |

| Humidity sensor [36] | 3.3 | 99 × 10−5 | 79 × 10−5 |

| Temperature sensor [36] | 3.3 | 26 × 10−6 | 5.28 × 10−9 |

| Light sensor [36] | 3.3 | 99 × 10−6 | 19.8 × 10−9 |

| Vibration sensor [36] | 3.3 | 1.98 × 10−3 | 39.6 × 10−6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thainiramit, P.; Jayasvasti, S.; Yingyong, P.; Nandrakwang, S.; Isarakorn, D. Triboelectric Energy-Harvesting Floor Tile. Materials 2022, 15, 8853. https://doi.org/10.3390/ma15248853

Thainiramit P, Jayasvasti S, Yingyong P, Nandrakwang S, Isarakorn D. Triboelectric Energy-Harvesting Floor Tile. Materials. 2022; 15(24):8853. https://doi.org/10.3390/ma15248853

Chicago/Turabian StyleThainiramit, Panu, Subhawat Jayasvasti, Phonexai Yingyong, Songmoung Nandrakwang, and Don Isarakorn. 2022. "Triboelectric Energy-Harvesting Floor Tile" Materials 15, no. 24: 8853. https://doi.org/10.3390/ma15248853

APA StyleThainiramit, P., Jayasvasti, S., Yingyong, P., Nandrakwang, S., & Isarakorn, D. (2022). Triboelectric Energy-Harvesting Floor Tile. Materials, 15(24), 8853. https://doi.org/10.3390/ma15248853