Impact of Location and Insulation Material on Energy Performance of Residential Buildings as per Saudi Building Code (SBC) 601/602 in Saudi Arabia

Abstract

1. Introduction

2. Materials and Methods

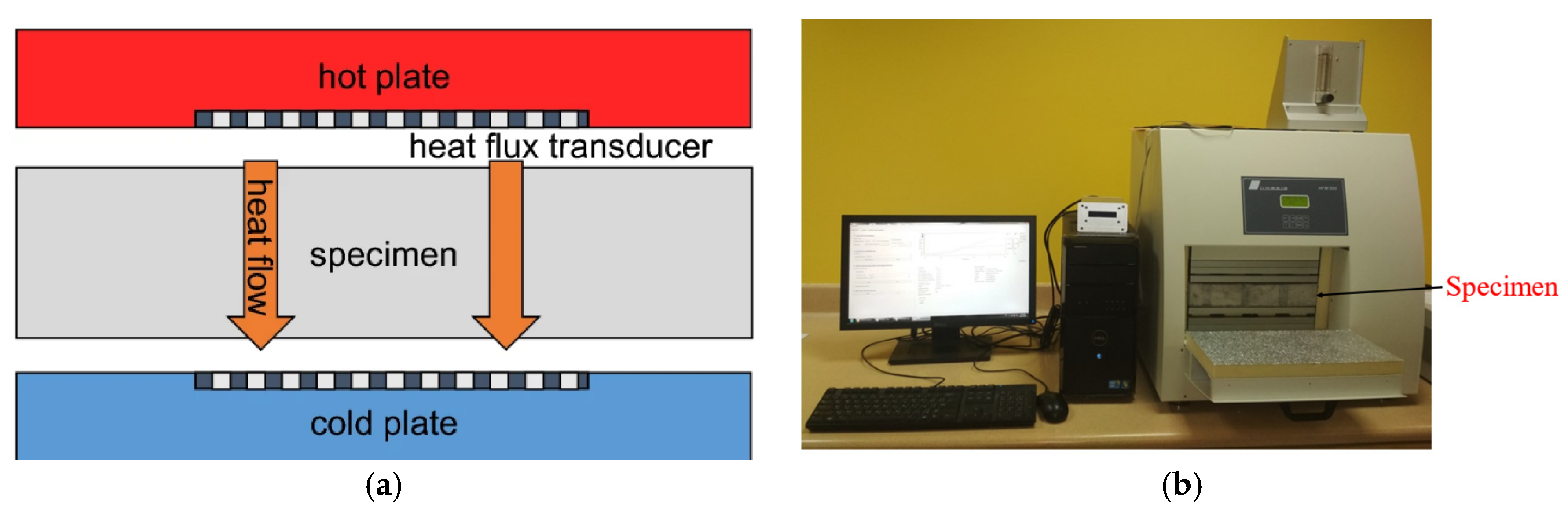

2.1. Thermal Conductivity Test

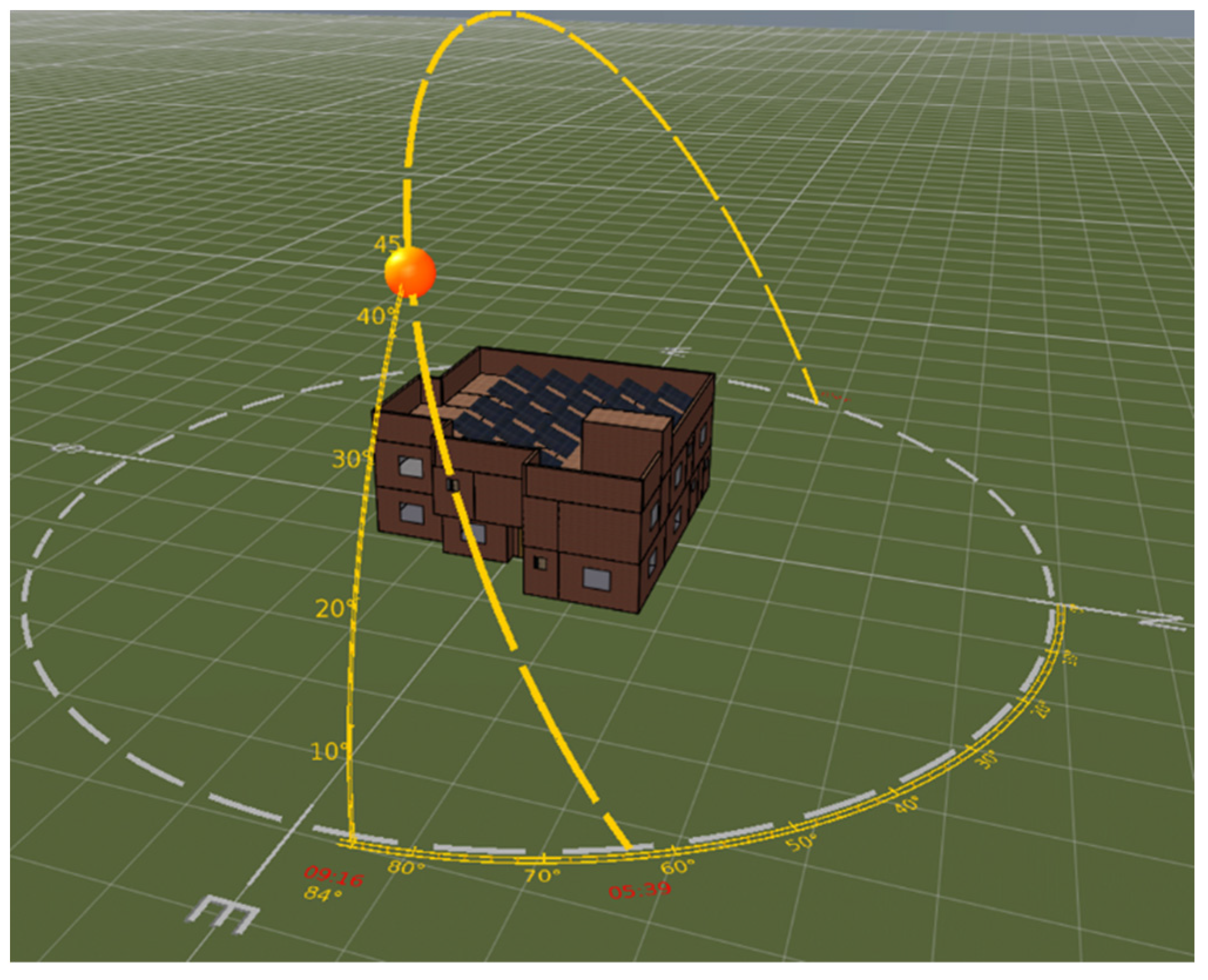

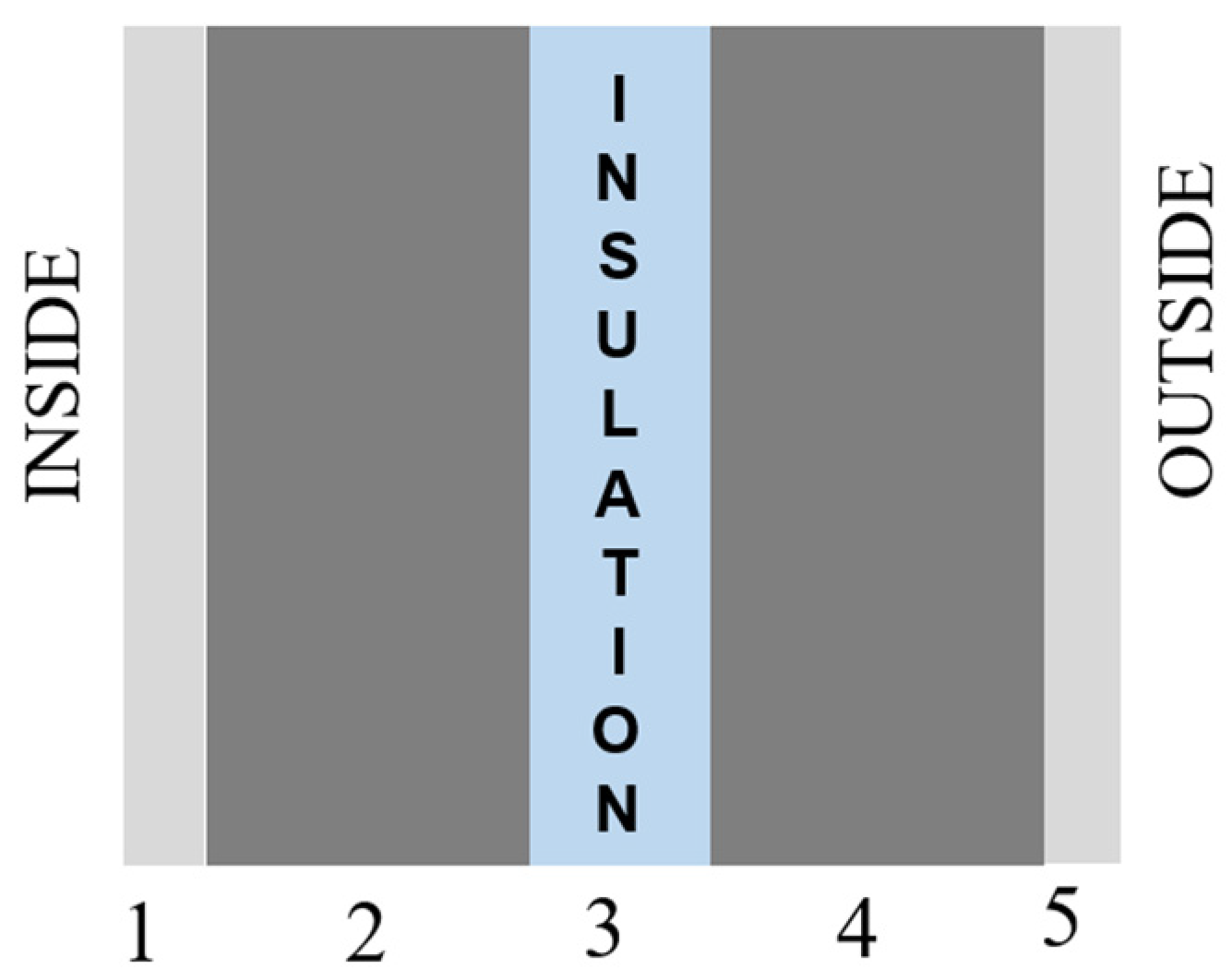

2.2. Simulation Software and Building Specification

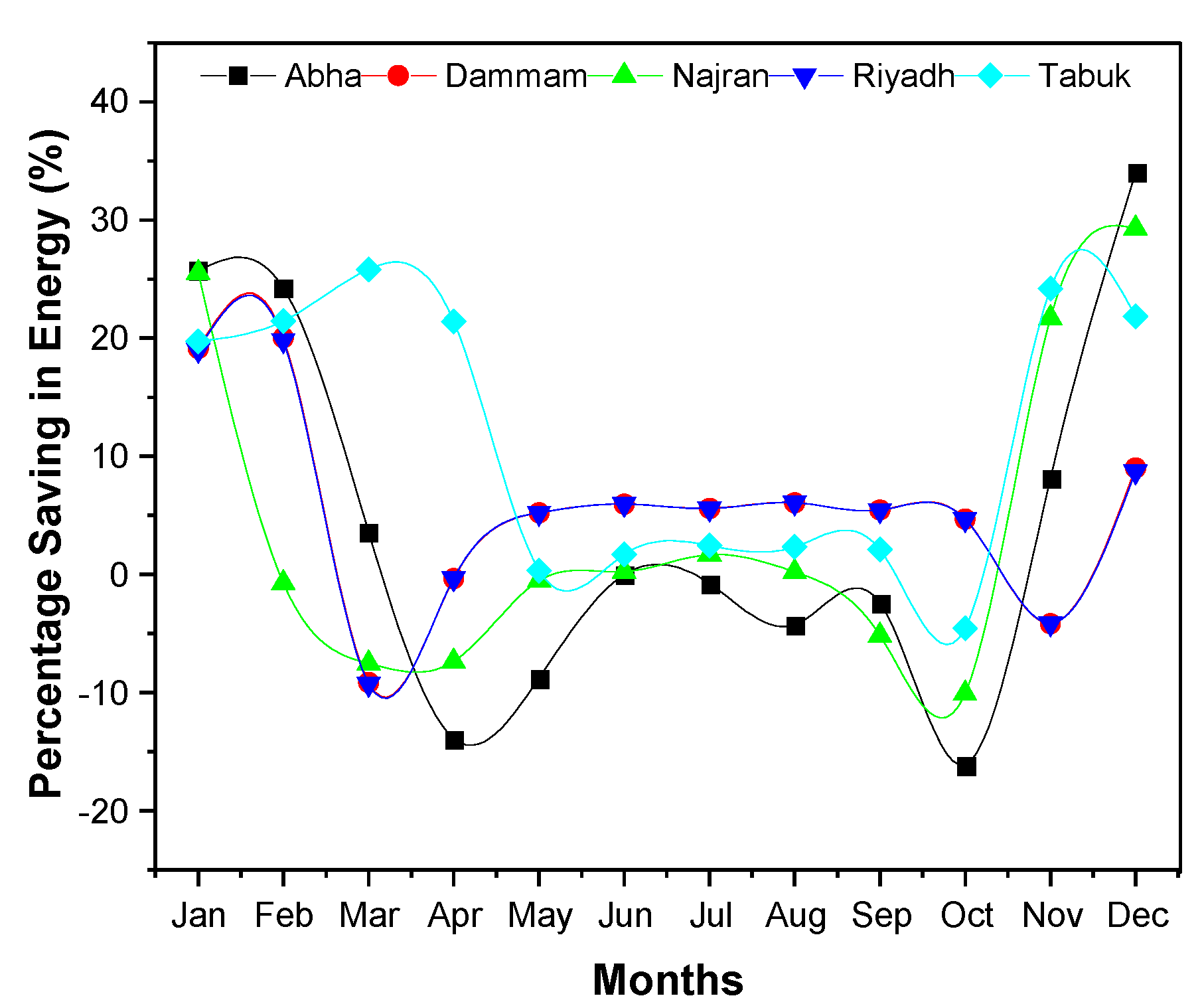

2.3. Weather Data and Climatic Classification

2.4. Mathematical Modeling

- Sensible heat transmission through walls and opaque exterior surfaces (walls, roofs, floors, doors, and ceilings) as well as transparent façade surfaces (glazed windows and skylights). Sensible and latent heat flows from ventilation/infiltration.

- Heat gains from people, illumination, and machinery that are sensible and latent.

- Direct power consumption for devices and lighting.

3. Results and Discussion

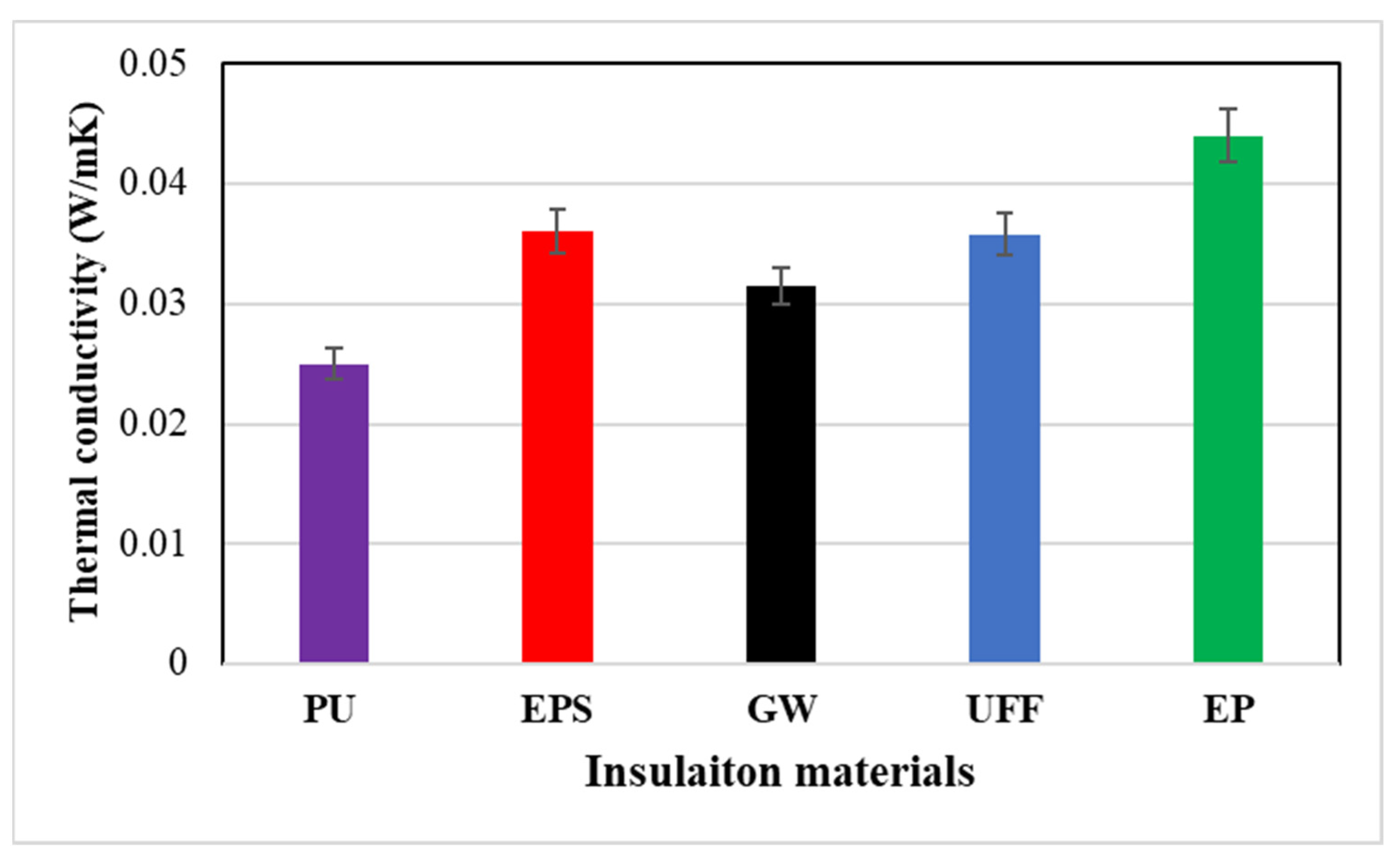

3.1. Thermal Conductivity

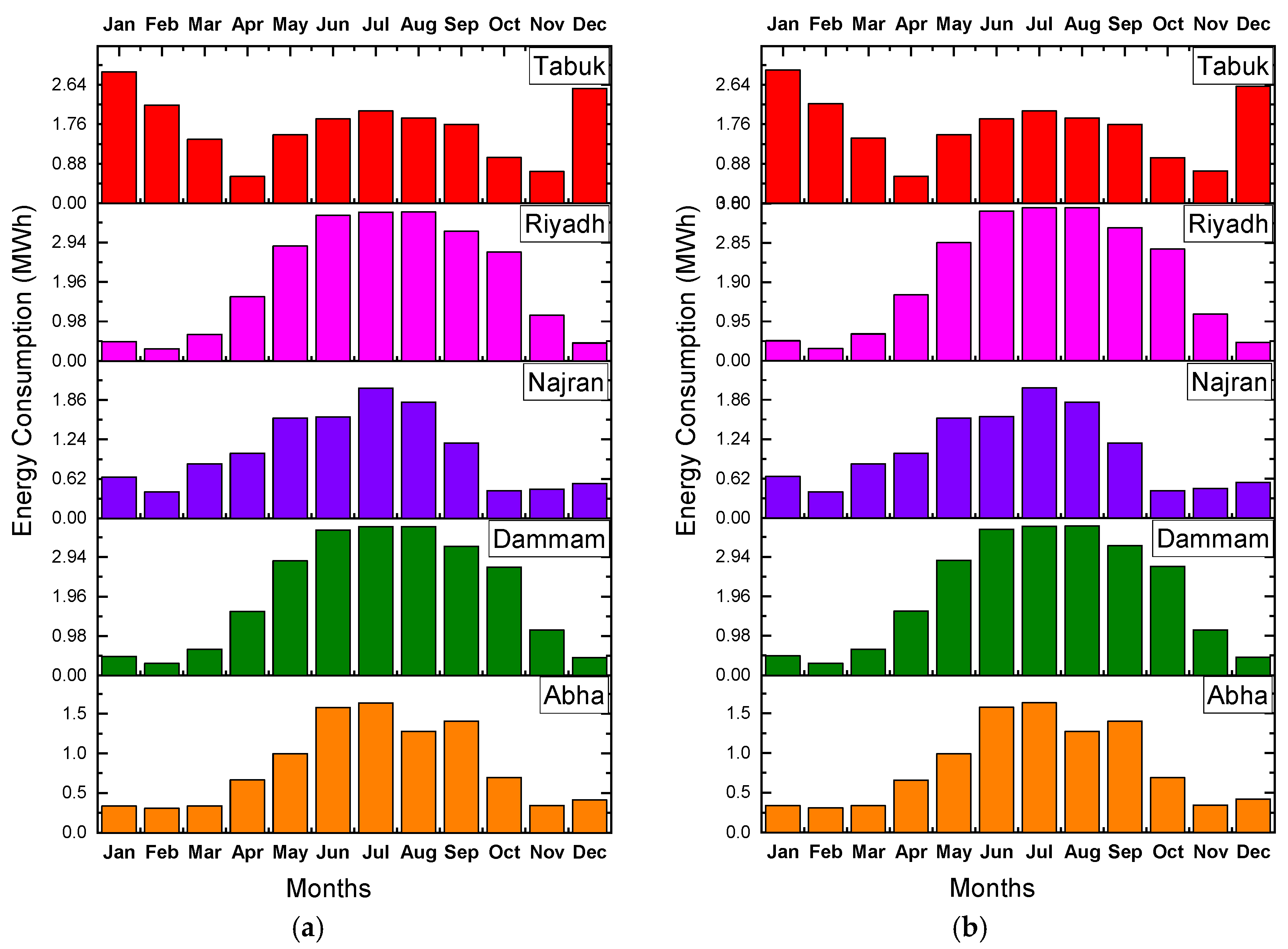

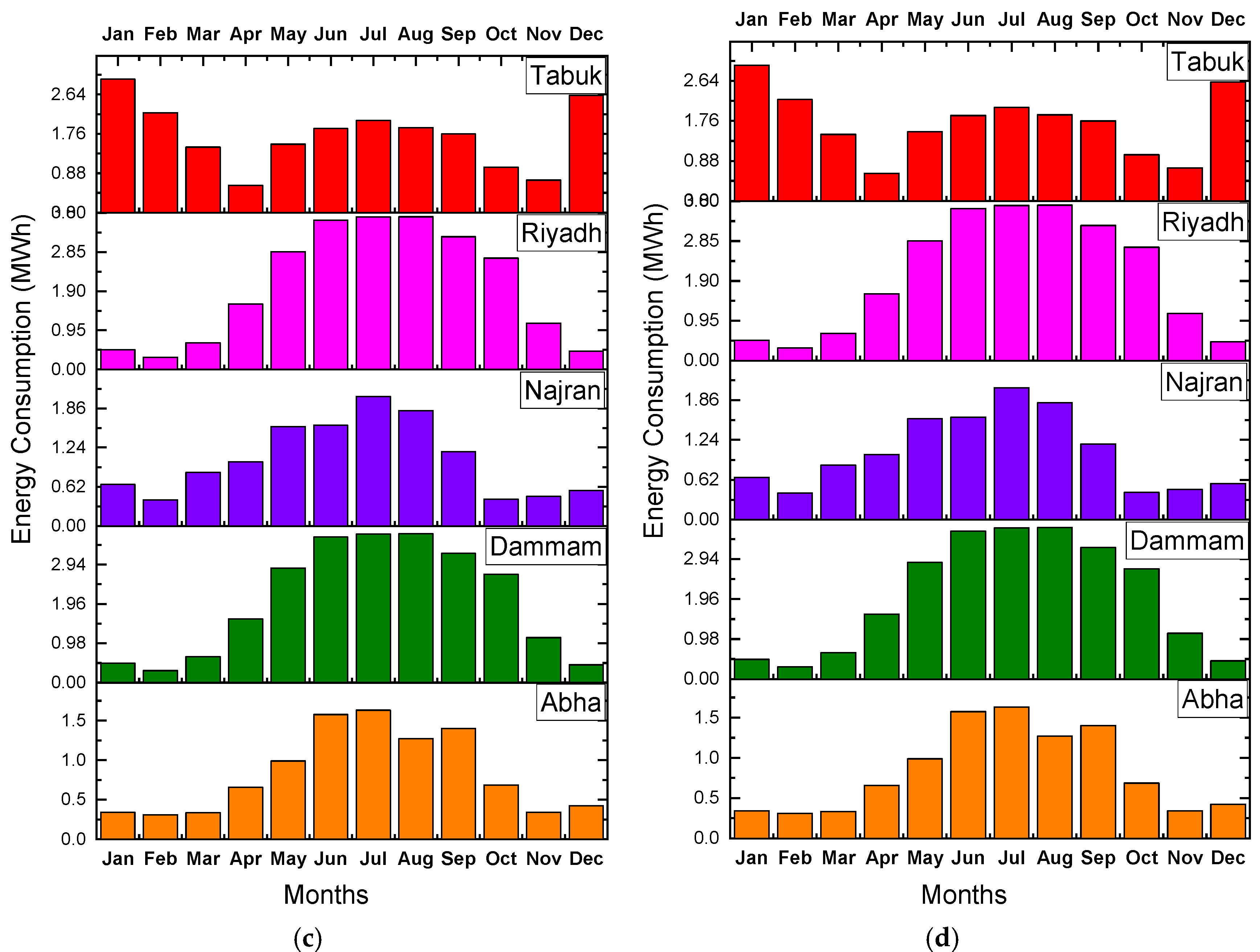

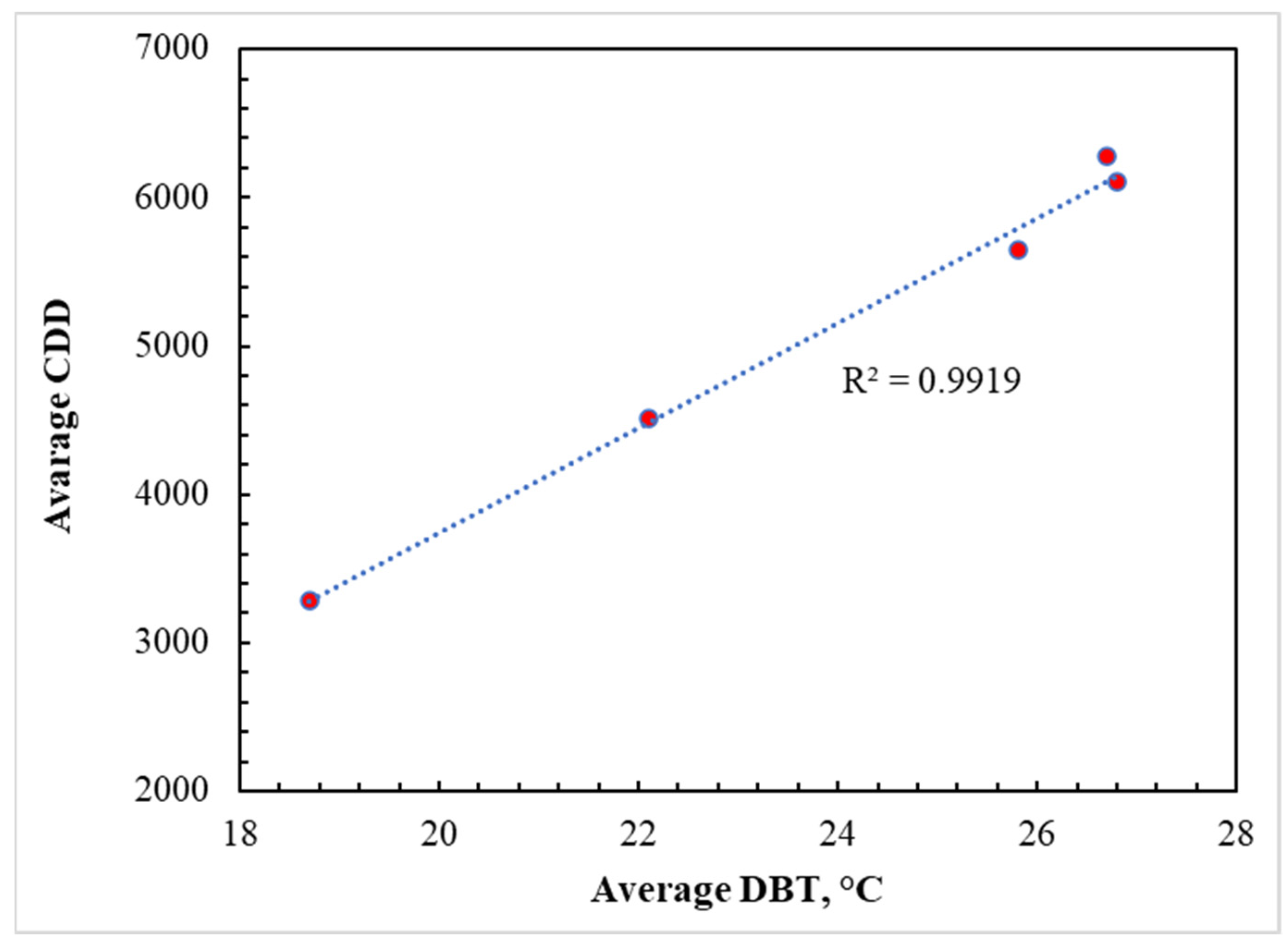

3.2. Effect of Climate and Location on Monthly Energy Consumptions with Various Insulations

3.3. Effect of Climate and Location on Annual Energy Consumptions by Insulation Type

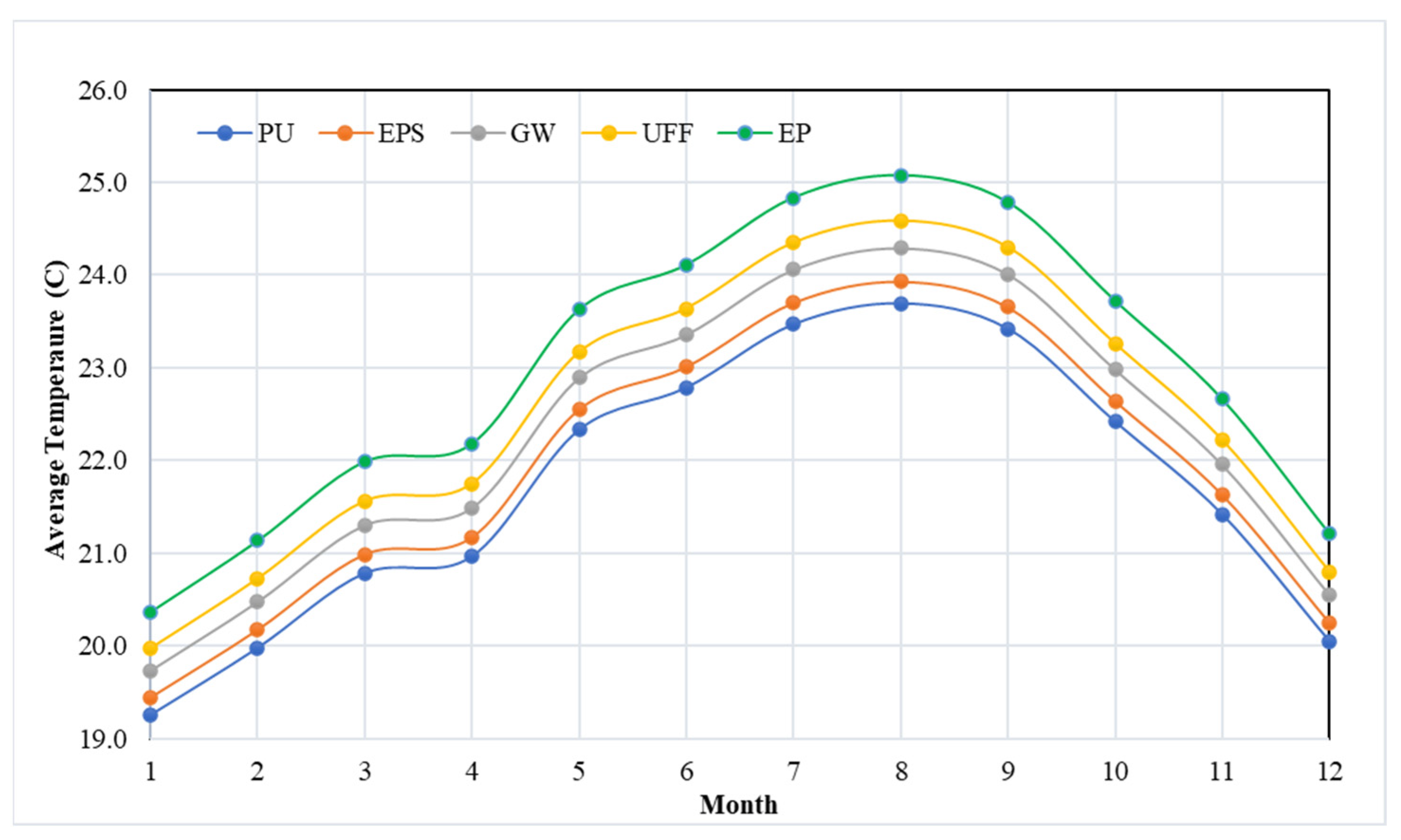

3.4. Indoor Air Temperature

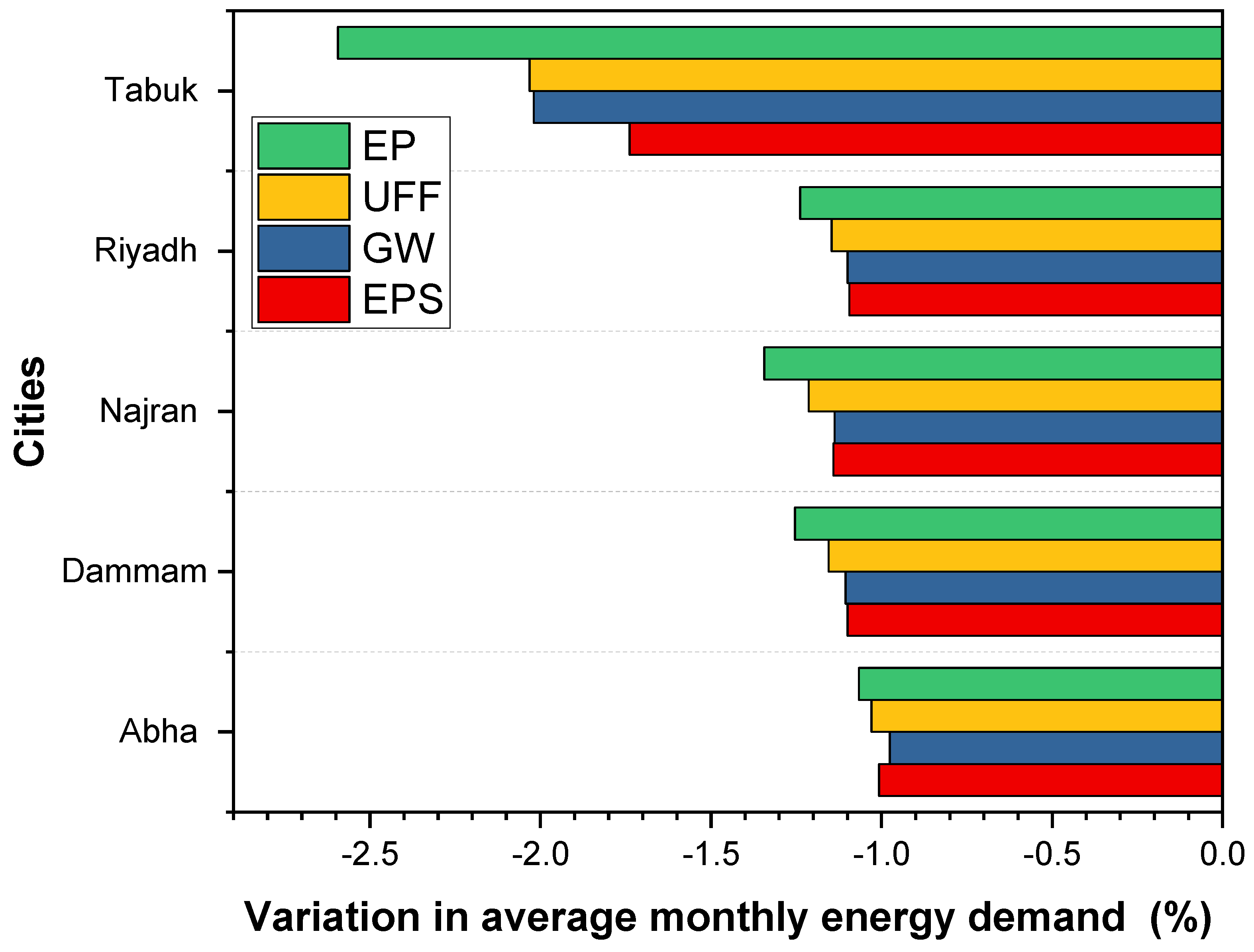

3.5. Comparative Analysis between the Insulation Materials

3.6. Sensitivity Analysis

4. Conclusions

- The thermal conductivities of the PU, EPS, GW, UFF, and EP insulations were 0.025 W/mK, 0.036 W/mK, 0.0315 W/mK, 0.0358 W/mK, and 0.044 W/mK, respectively.

- The insulated wall, irrespective of the type of insulation, reduced the annual energy demand by around 2 to 14% compared to the uninsulated wall of the building structure. The energy saving potential of the insulation materials significantly differed with the climatic conditions.

- The application of insulation could yield energy saving of 1.2%, 5.2%, 5.15%, 3.16%, and 13.6% in Abha, Dammam, Riyadh, Najran, and Tabuk, respectively.

- A sensitivity study on operational factors including RH and ST was used to validate the estimated energy saving potential and showed that it was relatively independent of RH and valid for the commonly used range of ST.

- The annual average indoor air temperature of the building was found to be 21.7 °C, 21.9 °C, 22.3 °C, 22.5 °C, and 23.2 °C for walls with PU, EPS, GW, UFF, and EP insulation, respectively.

- The results showed that while meeting the code requirement for an energy efficient envelope could result in a significant reduction in cooling energy demand, it actually increases the cooling demand in Abha, which represented hot regions.

- The difference in primary energy was not significant between glass wool (GW) and urea-formaldehyde foam (UFF) insulation.

- The polyurethane board (PU) insulation was found to be the most effective for the cities of extremely hot regions (Dammam and Riyadh), whereas expanded perlite (EP) insulation was efficient in hot climatic zones (Abha).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviation

| SHcond | Sensible heat flow by conduction (W); sensible heat flow by conduction |

| SHRadia | Sensible heat flow by radiation (W) |

| SH(vi,s) | Sensible ventilation/infiltration load (W); |

| SH(vi,l) | Latent ventilation/infiltration load (W) |

| SH(vi,t) | Total ventilation/infiltration load (W); |

| U | Overall heat transfer coefficient of the structure considered (W/m2K) |

| A | Surface area (m2) |

| CLTD | Cooling load temperature variation between the building’s interior and exterior (K) |

| SHGC | Solar heat gain coefficient |

| SC | Shading coefficient |

| CLF | Solar cooling load factor |

| Cs | Air sensible heat factor |

| Cl | Air latent heat factor |

| Ct | Air total heat factor |

| Q | Ventilation/infiltration air flow rate (L/s) |

| ∆T | Temperature difference across process (K) |

| ∆w | Difference in humidity ratio over the process (kgw/kgda) |

| ∆h | Air enthalpy difference over the process (kJ/kg). |

| ACH | Air exchange rate (changes/h) |

| V | Volume (m3). |

| H_(ig,s) | Sensible cooling load from internal heat gains (W) |

| H_(ig,l) | Latent cooling load from internal heat gains (W) |

| N_oc | Number of inhabitants |

| H_(ig,s) | Sensible cooling load from internal heat gains (W) |

| A_cf | Conditioned floor area (m2) |

| N_oc | Number of inhabitants. |

| W_L | Lighting load |

| LPD | Light power density (W/m2) |

| W_eqp | Equipment load |

| EPD | Equipment power density (W/m2) |

| t | Operating hours (h) |

| A | Building area (m2) |

References

- IEA. World Energy Balances: Overview; IEA: Paris, France, 2020. [Google Scholar]

- Energy Information Administration. International Energy Outlook 2016 With Projection to 2040, DOE/EIA-0484; Energy Information Administration (EIA): Washington, DC, USA, 2016.

- Ozel, M. Cost analysis for optimum thicknesses and environmental impacts of different insulation materials. Energy Build. 2012, 49, 552–559. [Google Scholar] [CrossRef]

- Chen, Y.; Li, M.; Cao, J.; Cheng, S.; Zhang, R. Effect of climate zone change on energy consumption of office and residential buildings in China. Theor. Appl. Climatol. 2021, 144, 353–361. [Google Scholar] [CrossRef]

- Taleb, H.M.; Sharples, S. Developing sustainable residential buildings in Saudi Arabia: A case study. Appl. Energy 2011, 88, 383–391. [Google Scholar] [CrossRef]

- Alshamrani, O.S.; Mujeebu, M.A.; Ashraf, N.; Al-Ghonamy, A.; Aichouni, M. Selection of External Wall Material by LCC Technique for Ofice-cum-Commercial Building in the Eastern Province of Saudi Arabia. J. Archit. Plan. 2017, 29, 243–256. [Google Scholar]

- Cabeza, L.F.; Castell, A.; Medrano, M.; Martorell, I.; Pérez, G.; Fernández, I. Experimental study on the performance of insulation materials in Mediterranean construction. Energy Build. 2010, 42, 630–636. [Google Scholar] [CrossRef]

- Qengel, Y.A.; Qerci, Y.; Turner, R.H. Some Simple and Economical Ways of Saving Energy in Industrial Facilities. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Anaheim, CA, USA, 15–20 November 1998; American Society of Mechanical Engineers: New York, NY, USA, 1998; pp. 143–149. [Google Scholar]

- Deng, S.; Wang, R.Z.; Dai, Y.J. How to evaluate performance of net zero energy building—A literature research. Energy 2014, 71, 1–16. [Google Scholar] [CrossRef]

- Cohen, B.; Muñoz, P. Toward a Theory of Purpose-Driven Urban Entrepreneurship. Organ. Environ. 2015, 28, 264–285. [Google Scholar] [CrossRef]

- Kheiri, F. A review on optimization methods applied in energy-efficient building geometry and envelope design. Renew. Sustain. Energy Rev. 2018, 92, 897–920. [Google Scholar] [CrossRef]

- Alardhi, A.; S Alaboodi, A.; Almasri, R. Impact of the new Saudi energy conservation code on Saudi Arabia residential buildings. Aust. J. Mech. Eng. 2020, 20, 1802919. [Google Scholar] [CrossRef]

- Sadineni, S.B.; Madala, S.; Boehm, R.F. Passive building energy savings: A review of building envelope components. Renew. Sustain. Energy Rev. 2011, 15, 3617–3631. [Google Scholar] [CrossRef]

- Baba, A.; Mahdjoubi, L.; Olomolaiye, P.; Booth, C. State-of-the-art on buildings performance energy simulations tools for architects to deliver low impact building (LIB) in the UK. Int. J. Dev. Sustain. 2013, 2, 1867–1884. [Google Scholar]

- Attia, S.; Beltrán, L.; De Herde, A.; Hensen, J. ‘Architect friendly’: A comparison of ten different building performance simulation tools. In Proceedings of the IBPSA 2009—International Building Performance Simulation Association 2009, International Building Performance Simulation Association (IBPSA), Glasgow, UK, 27–30 July 2009; pp. 204–211. [Google Scholar]

- Crawley, D.B.; Hand, J.W.; Kummert, M.; Griffith, B.T. Contrasting the capabilities of building energy performance simulation programs. Build. Environ. 2008, 661–673. [Google Scholar] [CrossRef]

- Korjenic, A.; Petránek, V.; Zach, J.; Hroudová, J. Development and performance evaluation of natural thermal-insulation materials composed of renewable resources. Energy Build. 2011, 43, 2518–2523. [Google Scholar] [CrossRef]

- Abdel-rahman, W.S.M. Thermal performance optimization of parametric building envelope based on bio-mimetic inspiration. Ain Shams Eng. J. 2020. [Google Scholar] [CrossRef]

- Axaopoulos, I.; Axaopoulos, P.; Panayiotou, G.; Kalogirou, S.; Gelegenis, J. Optimal economic thickness of various insulation materials for different orientations of external walls considering the wind characteristics. Energy 2015, 90, 939–952. [Google Scholar] [CrossRef]

- Al-Sanea, S.A.; Zedan, M.F.; Al-Mujahid, A.M.; Al-Suhaibani, Z.A. Optimum R-values of building walls under different climatic conditions in the Kingdom of Saudi Arabia. Appl. Therm. Eng. 2016, 96, 92–106. [Google Scholar] [CrossRef]

- Al-Sanea, S.A.; Zedan, M.F.; Al-Hussain, S.N. Effect of thermal mass on performance of insulated building walls and the concept of energy savings potential. Appl. Energy 2012, 89, 430–442. [Google Scholar] [CrossRef]

- Al-Sanea, S.A.; Zedan, M.F. Optimum insulation thickness for building walls in a hot-dry climate. Int. J. Ambient Energy 2002, 23, 115–126. [Google Scholar] [CrossRef]

- Krarti, M. Optimal energy performance of dynamic sliding and insulated shades for residential buildings. Energy 2023, 263, 125699. [Google Scholar] [CrossRef]

- Serrano-Jiménez, A.; Díaz-López, C.; Verichev, K.; Barrios-Padura, Á. Providing a feasible energy retrofitting technique based on polyurethane foam injection to improve windows performance in the building stock. Energy Build. 2023, 278, 112595. [Google Scholar] [CrossRef]

- Zhao, K.; Jiang, Z.; Huang, Y.; Sun, Z.; Wang, L.; Gao, W.; Ge, J. The method of reducing heat loss from thermal bridges in residential buildings with internal insulation in the hot summer and cold winter zone of China. J. Build. Eng. 2022, 62, 105421. [Google Scholar] [CrossRef]

- Alwetaishi, M. Energy performance in residential buildings: Evaluation of the potential of building design and environmental parameter. Ain Shams Eng. J. 2022, 13, 101708. [Google Scholar] [CrossRef]

- Densley Tingley, D.; Hathway, A.; Davison, B. An environmental impact comparison of external wall insulation types. Build. Environ. 2015, 85, 182–189. [Google Scholar] [CrossRef]

- Dickson, T.; Pavía, S. Energy performance, environmental impact and cost of a range of insulation materials. Renew. Sustain. Energy Rev. 2021, 140, 110752. [Google Scholar] [CrossRef]

- Long, L.; Ye, H. The roles of thermal insulation and heat storage in the energy performance of the wall materials: A simulation study. Sci. Rep. 2016, 6, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Rosti, B.; Omidvar, A.; Monghasemi, N. Optimum position and distribution of insulation layers for exterior walls of a building conditioned by earth-air heat exchanger. Appl. Therm. Eng. 2019, 163, 114362. [Google Scholar] [CrossRef]

- Alghamdi, A.A. Numerical investigation of thermal insulation options for non-insulated buildings in Saudi Arabia. Int. J. Ambient Energy 2019, 42, 1428–1434. [Google Scholar] [CrossRef]

- Alrashed, F.; Asif, M. Climatic Classifications of Saudi Arabia for Building Energy Modelling. Energy Procedia 2015, 75, 1425–1430. [Google Scholar] [CrossRef]

- Abdou, A.A.; Budaiwi, I.M. Comparison of Thermal Conductivity Measurements of Building Insulation Materials under Various Operating Temperatures. J. Therm. Envel. Build. Sci. 2005, 29, 171–184. [Google Scholar] [CrossRef]

- Linseis. Heat Flow Meter, Germany; Linseis: Selb, Germany, 2013. [Google Scholar]

- Weingrill, H.; Hohenauer, W.; Resch-Fauster, K.; Zauner, C. Analyzing Thermal Conductivity of Polyethylene-Based Compounds Filled with Copper. Macromol. Mater. Eng. 2019, 304, 4. [Google Scholar] [CrossRef]

- Yang, I.; Kim, D.; Lee, S.; Jang, H. Construction and calibration of a large-area heat flow meter apparatus. Energy Build. 2019, 203, 109445. [Google Scholar] [CrossRef]

- Luo, X.J.; Oyedele, L.O. Assessment and optimisation of life cycle environment, economy and energy for building retrofitting. Energy Sustain. Dev. 2021, 65, 77–100. [Google Scholar] [CrossRef]

- Ashraf, N.; Nasir, M.; Al-Kutti, W.; Al-Maziad, F.A. Assessment of thermal and energy performance of masonry blocks prepared with date palm ash. Mater. Renew. Sustain. Energy 2020, 9, 1–13. [Google Scholar] [CrossRef]

- Alyami, S.H.; Almutlaqa, A.A.; Alqahtany, A.M.; Ashraf, N. Likelihood of Reaching Zero Energy Building Design in Hot Dry Climate: Saudi Arabia. IEEE Access 2021, 9, 167054–167066. [Google Scholar] [CrossRef]

- Al-hadhrami, L.M. Comprehensive review of cooling and heating degree days characteristics over Kingdom of Saudi Arabia. Renew. Sustain. Energy Rev. 2013, 27, 305–314. [Google Scholar] [CrossRef]

- Pinterić, M. Building Physics; Springer Nature: Berlin/Heidelberg, Germany, 2017; ISBN 3857480254. [Google Scholar]

- ASHRAE Handbook—Fundamentals. 2021. Available online: https://www.ashrae.org/technical-resources/ashrae-handbook/description-2021-ashrae-handbook-fundamentals (accessed on 5 December 2022).

- Zhang, H.; Fang, W.Z.; Li, Y.M.; Tao, W.Q. Experimental study of the thermal conductivity of polyurethane foams. Appl. Therm. Eng. 2017, 115, 528–538. [Google Scholar] [CrossRef]

- Lakatos, Á.; Kalmár, F. Investigation of thickness and density dependence of thermal conductivity of expanded polystyrene insulation materials. Mater. Struct. 2012, 46, 1101–1105. [Google Scholar] [CrossRef]

- Knickle, H.N.; Kalthod, V. The Effective Thermal Conductivity of Various Forms of Urea-Formaldehyde Foam. SAGE J. 2016, 5, 185–197. [Google Scholar] [CrossRef]

- Bailey, W.O.S.; McDonald, P.; Bostock, T. The thermal conductivity of perlite insulation under varying conditions of temperature, humidity and packing density. In Proceedings of the ICES 24—ICMC 2012 24th International Cryogenics Engineering Conference, Fukuoka-Ken, Japan, 13–17 May 2012. [Google Scholar]

- Budaiwi, I.M. Envelope thermal design for energy savings in mosques in hot-humid climate. J. Build. Perform. Simul. 2011, 4, 49–61. [Google Scholar] [CrossRef]

- Budaiwi, I.; Abdou, A.; Al-Homoud, M. Variations of Thermal Conductivity of Insulation Materials Under Different Operating Temperatures: Impact on Envelope-Induced Cooling Load. J. Archit. Eng. 2002, 8, 125–132. [Google Scholar] [CrossRef]

- Abdul Mujeebu, M.; Ashraf, N. Impact of location and deadband on energy performance of nano aerogel glazing for office building in Saudi Arabia. Build. Res. Inf. 2020, 48, 645–658. [Google Scholar] [CrossRef]

- Abdul Mujeebu, M.; Ashraf, N.; Alsuwayigh, A. Energy performance and economic viability of nano aerogel glazing and nano vacuum insulation panel in multi-story office building. Energy 2016, 113, 949–956. [Google Scholar] [CrossRef]

- Abdul Mujeebu, M.; Ashraf, N.; Alsuwayigh, A.H. Effect of nano vacuum insulation panel and nanogel glazing on the energy performance of office building. Appl. Energy 2016, 173, 141–151. [Google Scholar] [CrossRef]

- Saudi Energy Conservation Code 602; National Committee of Saudi Building Code: Riyadh, Saudi Arabia, 2018.

- Chen, T.-J.G.; Liu, Y.-T.; Lee, C.-Y.; Chang, Y.-C.W.; Cheng, C.-P.; Lee, M.-H.; Chan, Y.-C.; Huang, J.-C.; Chao, K.-Y.C. Effects of weather forecasting on indoor comfort and energy savings in office buildings. Build. Environ. 2022, 221, 109280. [Google Scholar] [CrossRef]

- Alaidroos, A.; Krarti, M. Optimal design of residential building envelope systems in the Kingdom of Saudi Arabia. Energy Build. 2015, 86, 104–117. [Google Scholar] [CrossRef]

- Krarti, M.; Dubey, K.; Howarth, N. Evaluation of building energy efficiency investment options for the Kingdom of Saudi Arabia. Energy 2017, 134, 595–610. [Google Scholar] [CrossRef]

| Type of building | Residential building |

| No. of floors | 2 floors |

| Orientation | North–south |

| External wall | 200 mm CMU, outside 10 mm cement plaster, inside 20 mm gypsum plaster (U-value = 2.17 W/m2K) |

| Roof | 12 mm cement roof tiles, 4 mm thick bitumen layer, 50 mm expanded polystyrene, 4 mm thick bitumen layer, 300 mm concrete slab, 20 mm inside gypsum plaster (U-value = 0.45 W/m2K) |

| Glazing | Double-glazed clear low-e 6/12/6 mm (U-value = 1.78 W/m2K) |

| Floor height | 4.2 m |

| Longitude | 50.17° E |

| HVAC system | Package air-conditioning system |

| Set-point temperature | 19 to 27 °C |

| Occupancy | 0.02 person/m2 |

| Lighting power density | 6 W/m2 |

| WWR | 1:6.5 |

| Sr. No | Insulation Name | Abbreviation |

|---|---|---|

| 1 | Polyurethane board | PU |

| 2 | Expanded polystyrene | EPS |

| 3 | Glass wool | GW |

| 4 | Urea-formaldehyde foam | UFF |

| 5 | Expanded perlite | EP |

| Sr. No. | Cities | Latitude | Longitude | Climate Classification According to SBC 601/602 | Zone According to IECC | Elevation | CDD10 | DBT (Max) °C |

|---|---|---|---|---|---|---|---|---|

| 1 | Abha | 18.23 N | 42.65 E | 3 | 3A and 3B | 2093 | 3289 | 34 |

| 2 | Dammam | 26.45 N | 49.82 E | 1 | 1 | 12 | 6274 | 49.2 |

| 3 | Najran | 17.62 N | 44.42 E | 1 | 1 | 1212 | 5643 | 42.7 |

| 4 | Riyadh | 24.70 N | 46.73 E | 1 | 1 | 620 | 6107 | 47.6 |

| 5 | Tabuk | 28.38 N | 36.60 E | 2 | 2 | 768 | 4508 | 44.2 |

| Climate Classification as per SBC 601/602 | Zone as per SBC | CDD 10 °C Range | Climatic Zones |

|---|---|---|---|

| Extremely hot | 1 | Greater than 5000 | Riyadh, Dammam, Najran |

| Very hot | 2 | From 3500 to 5000 | Tabuk |

| Hot | 3 | Less than 3500 | Abha |

| Operating Parameter | Saving in Annual Energy Consumption (%) Option | ||||

|---|---|---|---|---|---|

| PU | EPS | GW | UFF | EP | |

| Relative humidity (%) | |||||

| 35 | 14.47 | 13.83 | 13.58 | 13.58 | 13.09 |

| 40 | 14.47 | 13.83 | 13.58 | 13.58 | 13.09 |

| 45 | 14.47 | 13.83 | 13.58 | 13.58 | 13.09 |

| 50 | 14.47 | 13.83 | 13.58 | 13.58 | 13.09 |

| 55 | 14.47 | 13.83 | 13.58 | 13.58 | 13.09 |

| 60 | 14.47 | 13.83 | 13.58 | 13.58 | 13.09 |

| Set-point temperature (°C) | |||||

| 19–27 | 14.47 | 13.83 | 13.58 | 13.58 | 13.09 |

| 20–24 | 16.21 | 15.49 | 15.21 | 15.20 | 14.66 |

| 20–25 | 15.92 | 15.21 | 14.94 | 14.93 | 14.40 |

| 22–23 | 15.63 | 14.94 | 14.67 | 14.66 | 14.14 |

| 24–24 | 16.65 | 15.91 | 15.62 | 15.61 | 15.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alyami, S.H.; Alqahtany, A.; Ashraf, N.; Osman, A.; Aldossary, N.A.; Almutlaqa, A.; Al-Maziad, F.; Alshammari, M.S.; Al-Gehlani, W.A.G. Impact of Location and Insulation Material on Energy Performance of Residential Buildings as per Saudi Building Code (SBC) 601/602 in Saudi Arabia. Materials 2022, 15, 9079. https://doi.org/10.3390/ma15249079

Alyami SH, Alqahtany A, Ashraf N, Osman A, Aldossary NA, Almutlaqa A, Al-Maziad F, Alshammari MS, Al-Gehlani WAG. Impact of Location and Insulation Material on Energy Performance of Residential Buildings as per Saudi Building Code (SBC) 601/602 in Saudi Arabia. Materials. 2022; 15(24):9079. https://doi.org/10.3390/ma15249079

Chicago/Turabian StyleAlyami, Saleh H., Ali Alqahtany, Noman Ashraf, Abdelbagi Osman, Naief Ali Aldossary, Ayman Almutlaqa, Faris Al-Maziad, Maher S. Alshammari, and Wadee Ahmed Ghanem Al-Gehlani. 2022. "Impact of Location and Insulation Material on Energy Performance of Residential Buildings as per Saudi Building Code (SBC) 601/602 in Saudi Arabia" Materials 15, no. 24: 9079. https://doi.org/10.3390/ma15249079

APA StyleAlyami, S. H., Alqahtany, A., Ashraf, N., Osman, A., Aldossary, N. A., Almutlaqa, A., Al-Maziad, F., Alshammari, M. S., & Al-Gehlani, W. A. G. (2022). Impact of Location and Insulation Material on Energy Performance of Residential Buildings as per Saudi Building Code (SBC) 601/602 in Saudi Arabia. Materials, 15(24), 9079. https://doi.org/10.3390/ma15249079