Influence of Pentaerythritol Tetraacrylate Crosslinker on Polycarboxylate Superplasticizer Performance in Cementitious System

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

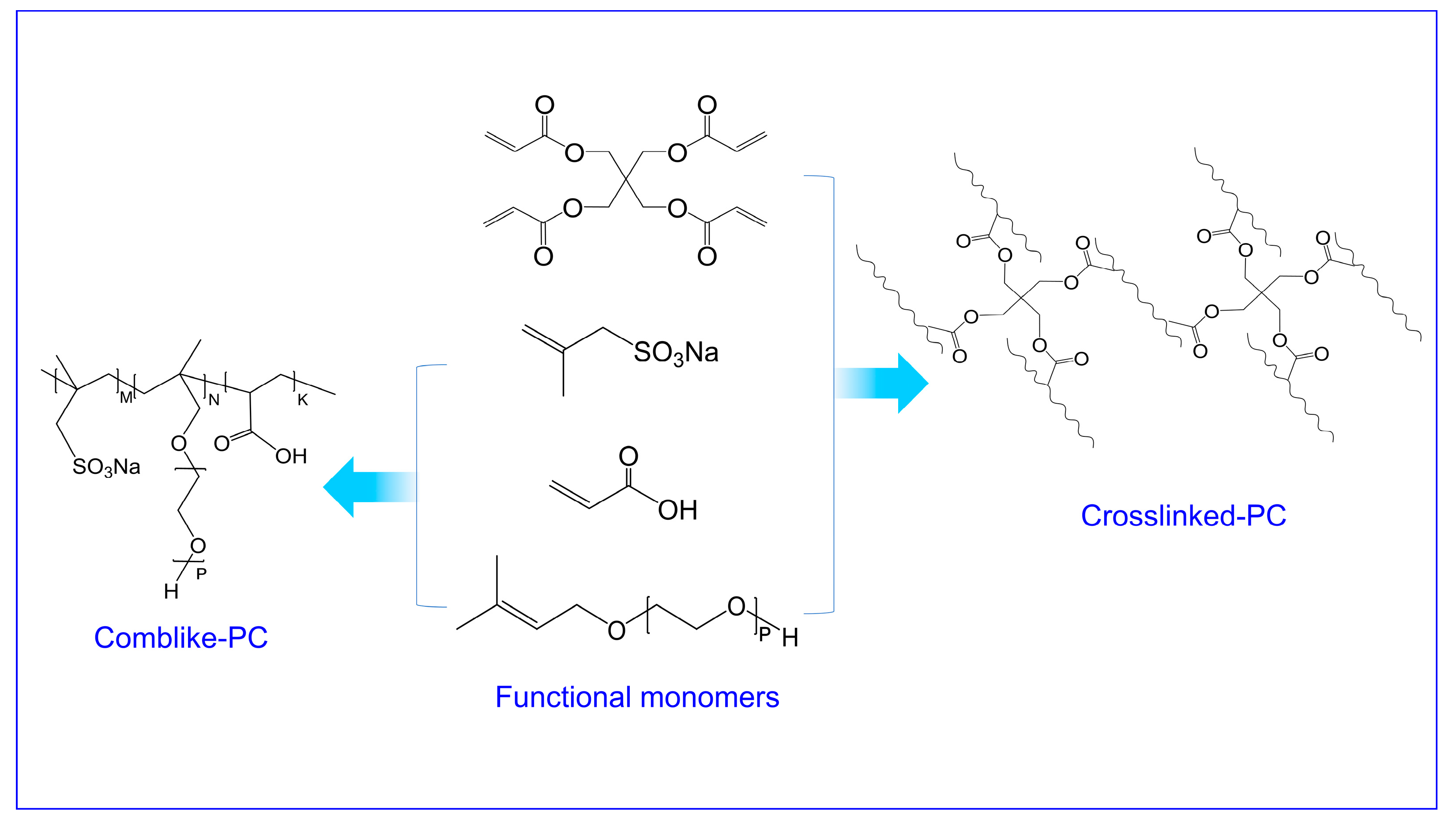

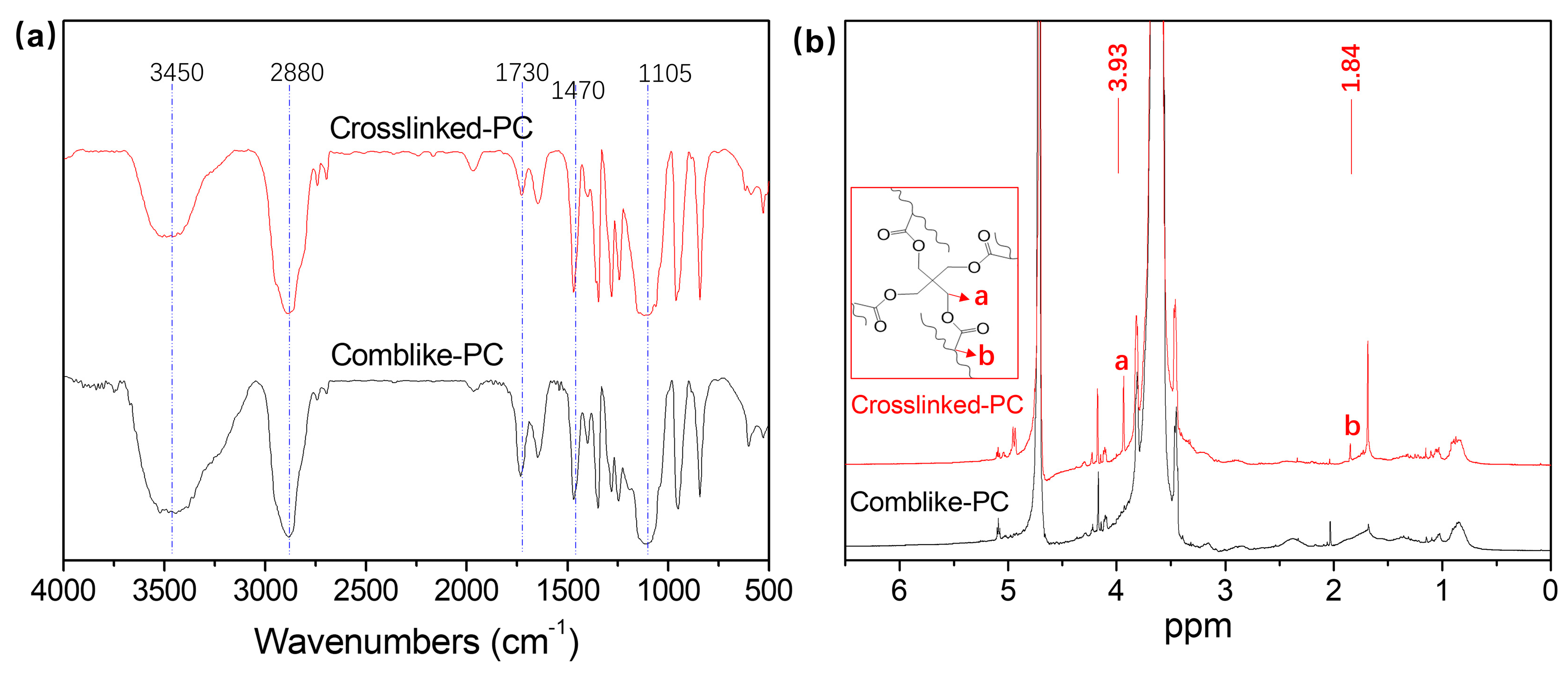

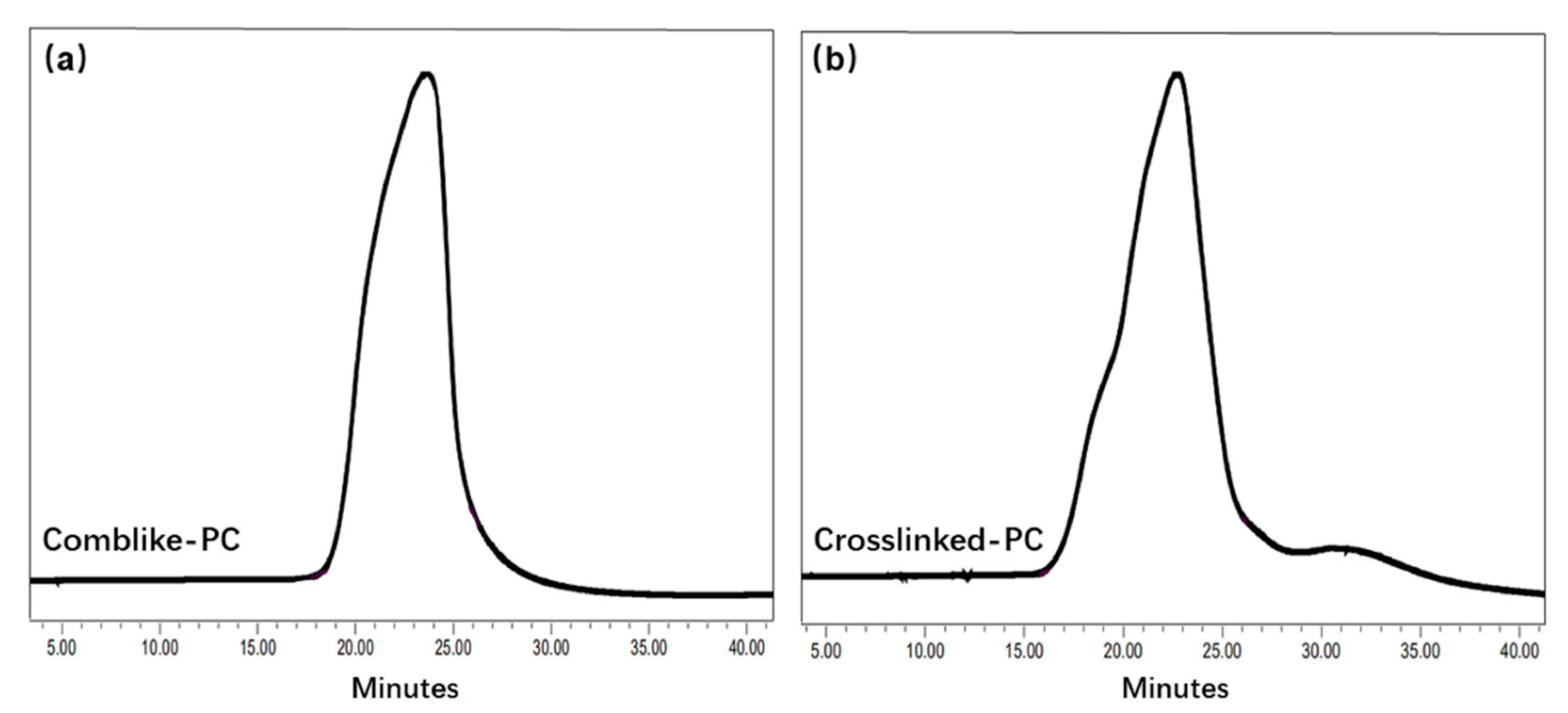

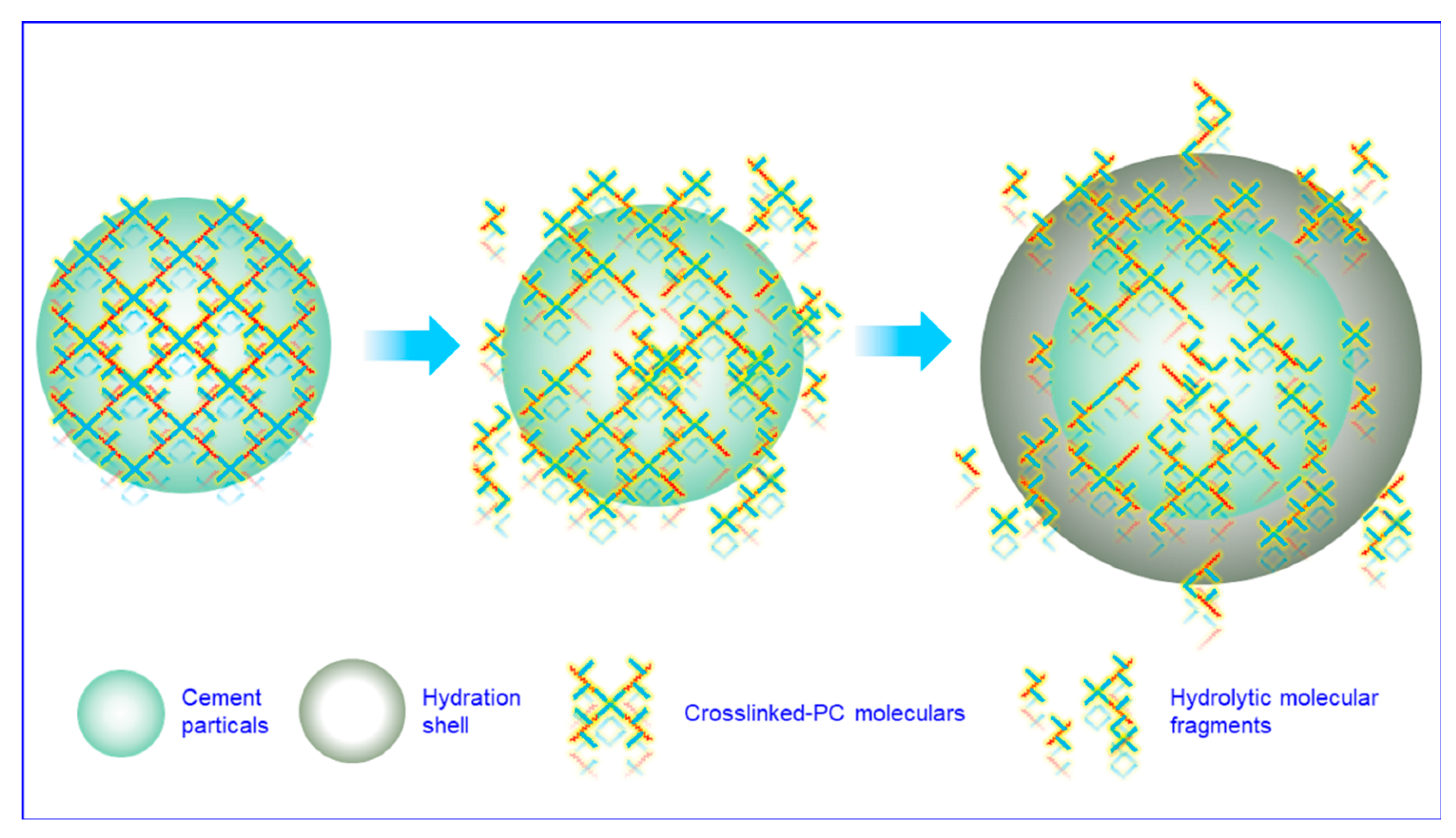

3.1. Structure of the Comb-like-PC and Crosslinked-PC

3.2. Fluidity and Time-Dependent Fluidity Loss

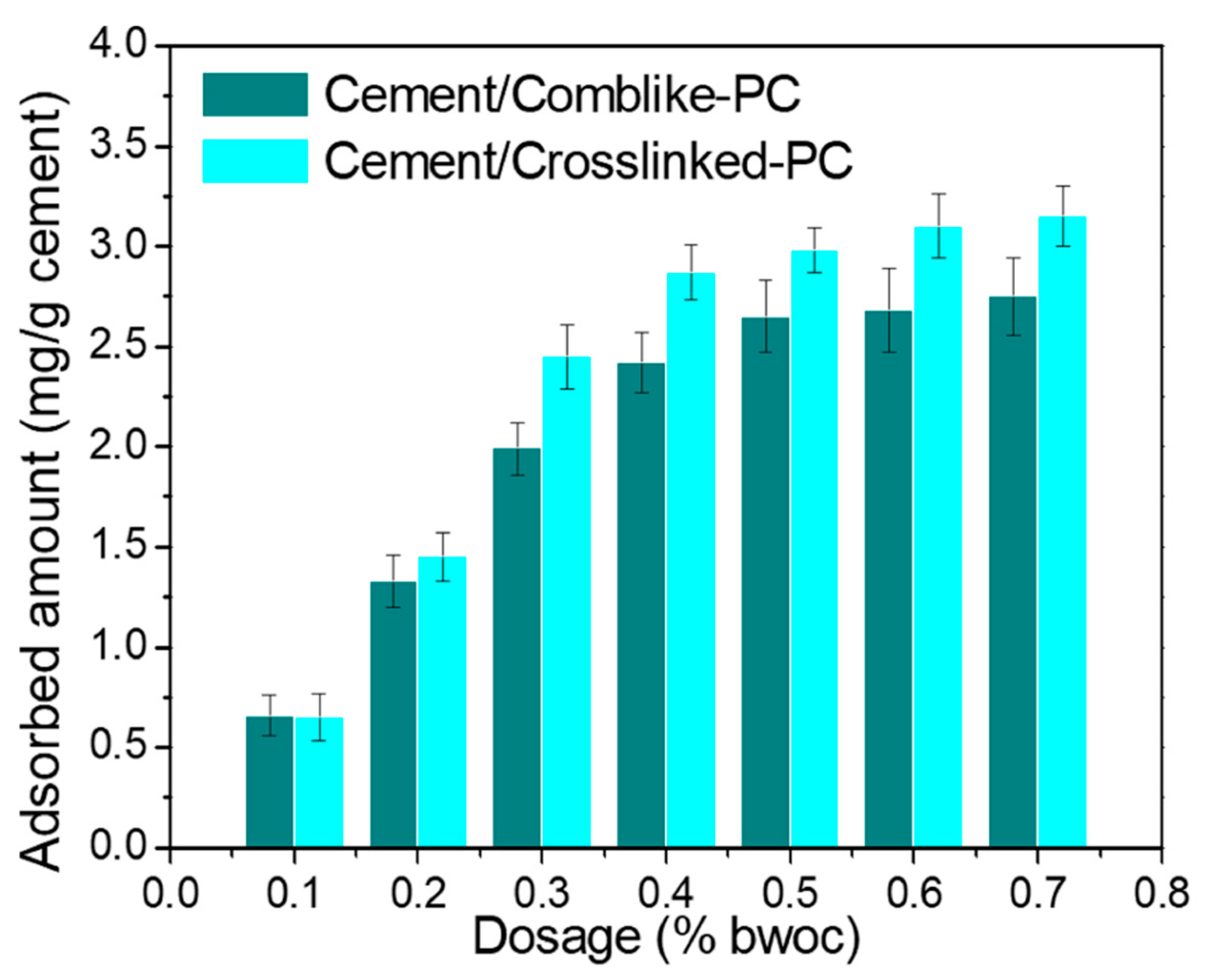

3.3. Adsorption on Cement Particles

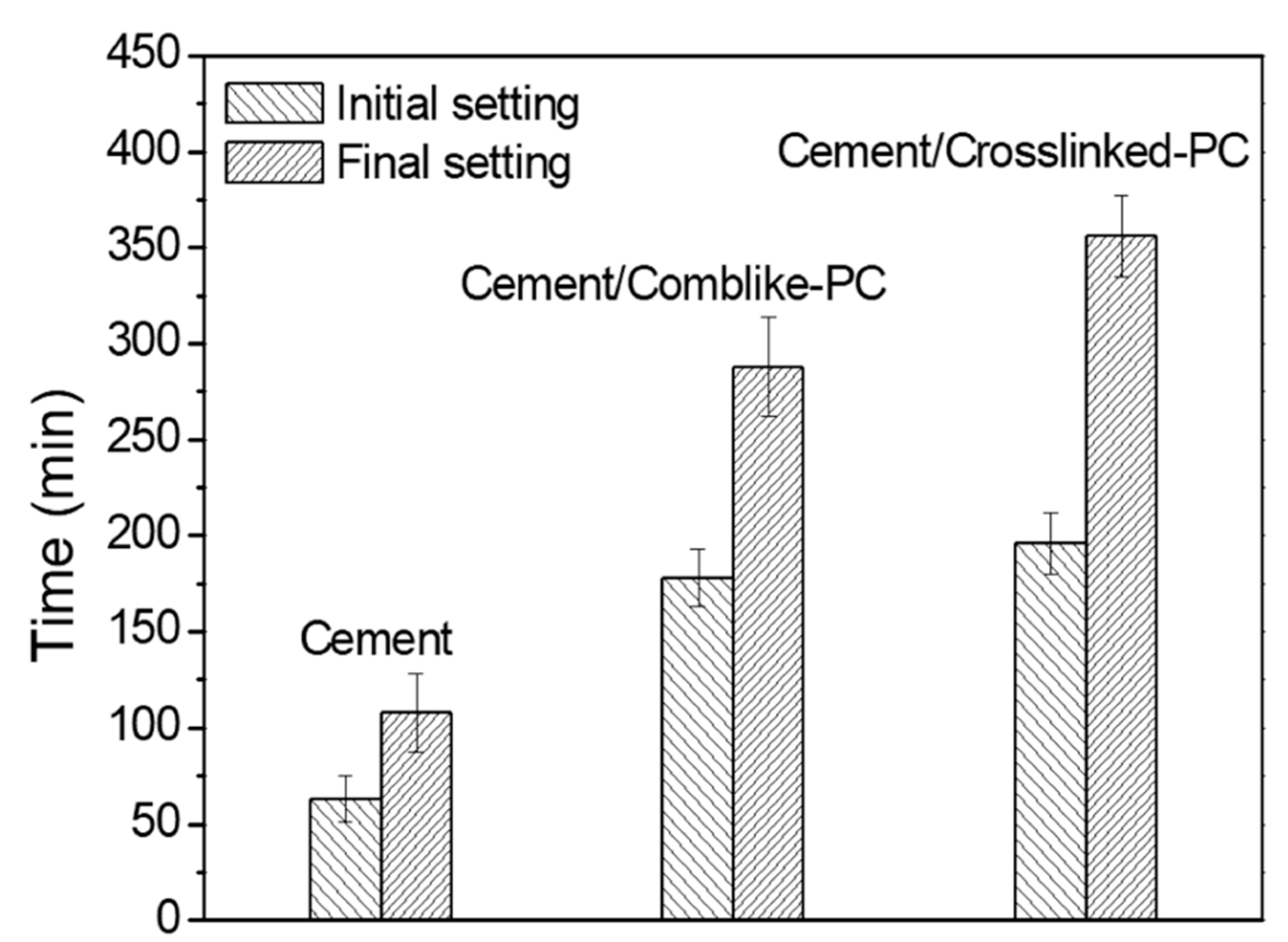

3.4. Setting Duration of the Cement Pastes

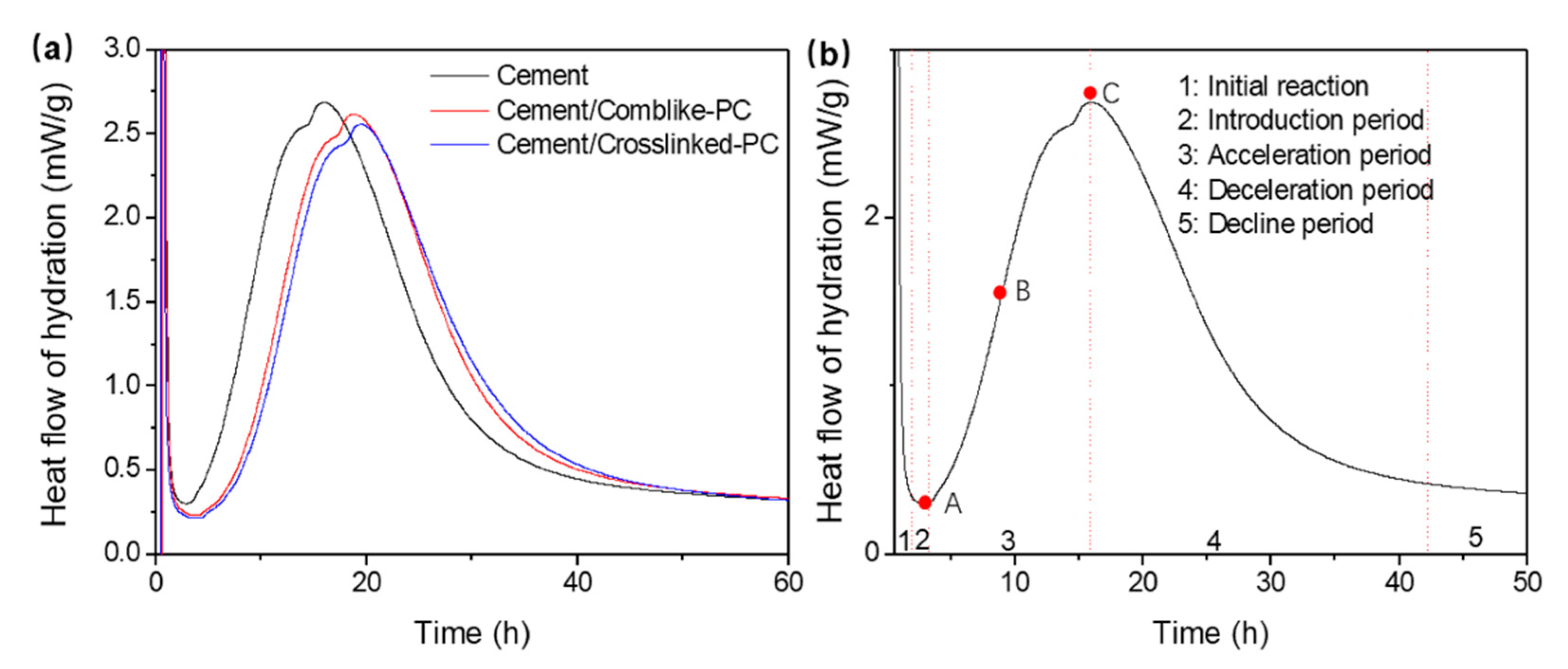

3.5. Hydration Heat Flow of Cement

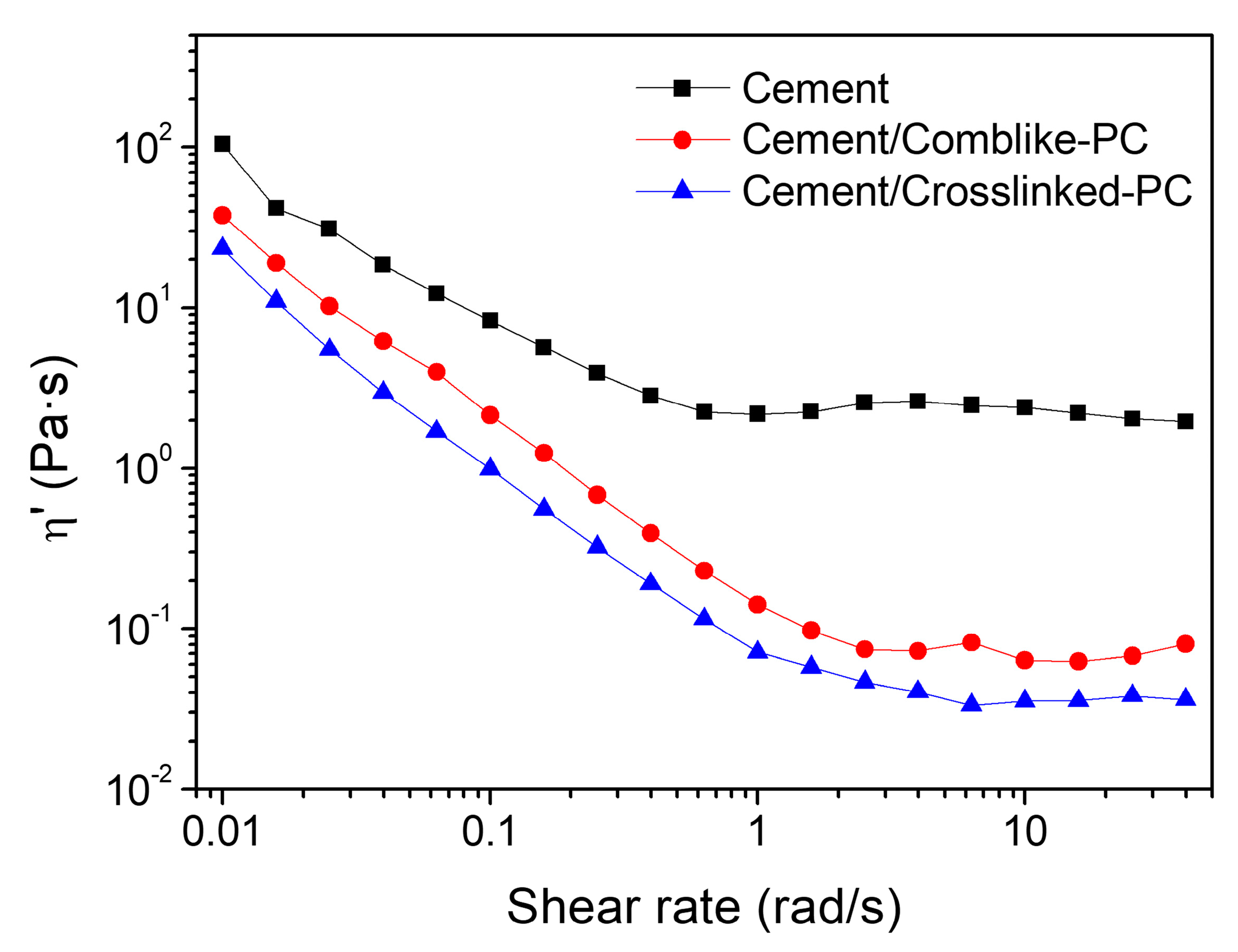

3.6. Rheology Behavior of Cement Pastes

3.7. XRD and Compressive Strength Analysis of Hydration Products

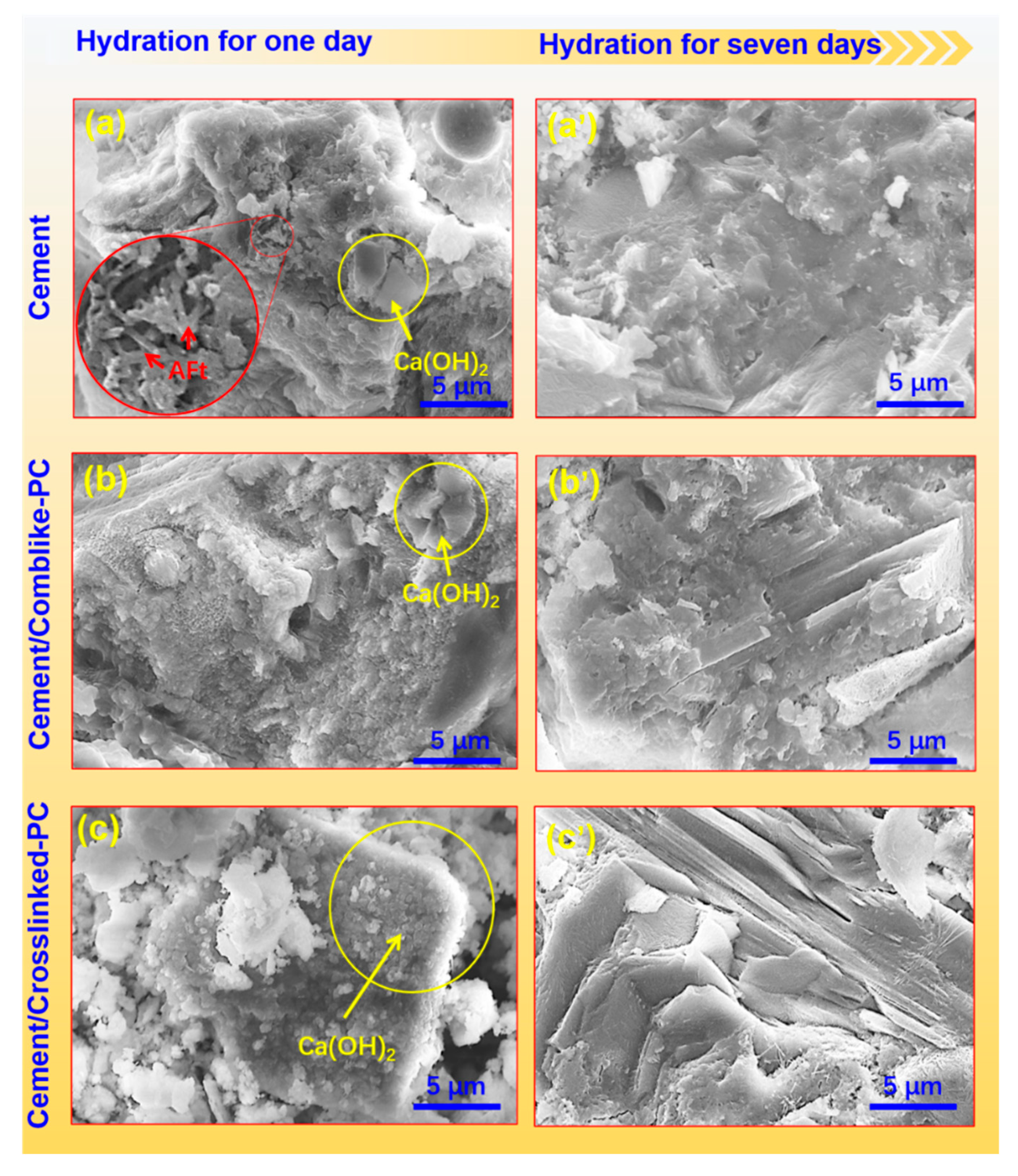

3.8. SEM Analysis of the Hydrated Products

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Lee, T.; Lee, J.; Jeong, J.; Jeong, J. Improving Marine Concrete Performance Based on Multiple Criteria Using Early Portland Cement and Chemical Superplasticizer Admixture. Materials 2021, 14, 4903. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Liao, B.; Nian, F.; Zhao, Y.; Wang, K.; Pang, H. Synthesis and characterization of a PAMAM dendrimer-based superplasticizer and its effect on the properties in cementitious system. J. Appl. Polym. Sci. 2018, 135, 46550. [Google Scholar] [CrossRef]

- Jimma, B.E.; Rangaraju, P.R. Chemical admixtures dose optimization in pervious concrete paste selection–A statistical approach. Constr. Build. Mater. 2015, 101, 1047–1058. [Google Scholar] [CrossRef]

- Haruna, S.; Fall, M. Time- and temperature-dependent rheological properties of cemented paste backfill that contains superplasticizer. Powder Technol. 2019, 360, 731–740. [Google Scholar] [CrossRef]

- Ma, B.; Peng, Y.; Tan, H.; Lv, Z.; Deng, X. Effect of Polyacrylic Acid on Rheology of Cement Paste Plasticized by Polycarboxylate Superplasticizer. Materials 2018, 11, 1081. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Kong, M.; Lu, B.; Lu, Z.; Hou, S. Effects of the charge characteristics of polycarboxylate superplasticizers on the adsorption and the retardation in cement pastes. Cem. Concr. Res. 2015, 67, 184–196. [Google Scholar] [CrossRef]

- Li, H.; Yao, Y.; Wang, Z.; Cui, S.; Wang, Y. Influence of Monomer Ratios on Molecular Weight Properties and Dispersing Effectiveness in Polycarboxylate Superplasticizers. Materials 2020, 13, 1022. [Google Scholar] [CrossRef] [PubMed]

- Carabba, L.; Manzi, S.; Bignozzi, M.C. Superplasticizer Addition to Carbon Fly Ash Geopolymers Activated at Room Temperature. Materials 2016, 9, 586. [Google Scholar] [CrossRef]

- Ilg, M.; Plank, J. Synthesis and Properties of a Polycarboxylate Superplasticizer with a Jellyfish-Like Structure Comprising Hyperbranched Polyglycerols. Ind. Eng. Chem. Res. 2019, 58, 12913–12926. [Google Scholar] [CrossRef]

- Yu, P.; Pang, H.; Huang, J.; Meng, Y.; Huang, H.; Li, S.; Liao, B.; Liang, L. Synthesis and rapid cement hardening evaluation of polycarboxylate superplasticizers incorporating ester groups in their backbone chain. J. Appl. Polym. Sci. 2020, 137, 48989. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Jin, B.; Zhang, X.; Li, Z.; Guan, X. Effect of superplasticizers on hydration kinetics of ultrafine sulfoaluminate cement-based grouting material. Thermochim. Acta 2021, 703, 178988. [Google Scholar] [CrossRef]

- Qian, Y.; De Schutter, G. Different Effects of NSF and PCE Superplasticizer on Adsorption, Dynamic Yield Stress and Thixotropy of Cement Pastes. Materials 2018, 11, 695. [Google Scholar] [CrossRef]

- Gelardi, G.; Sanson, N.; Nagy, G.; Flatt, R. Characterization of comb-shaped copolymers by Multidetection SEC, DLS and SANS. Polymers 2017, 9, 61. [Google Scholar] [CrossRef] [PubMed]

- Weckwerth, S.A.; Radke, W.; Flatt, R.J. A Method for Characterizing the Chemical Heterogeneity of Comb-Copolymers and Its Dependence on Synthesis Routes. Polymers 2021, 13, 1921. [Google Scholar] [CrossRef] [PubMed]

- Etsuo, S.; Kazuo, Y.; Akira, O. Molecular Structure and Dispersion-Adsorption Mechanisms of Comb-Type Superplasticizers Used in Japan, J. Adv. Concr. Technol. 2003, 1, 16–25. [Google Scholar] [CrossRef]

- Cai, Y.; Yang, T.; Ren, Q.; Liang, M.; Zhou, S. Enhanced slump retention using polycarboxylate superplasticizers obtained by micro-crosslinking reaction. Mater. Express 2019, 9, 587–595. [Google Scholar] [CrossRef]

- Liu, H.; Pang, H.; Ou, J.; Zhang, L.; Dai, Y.; Liao, B. Effect of cross-linked polycarboxylate-type superplasticizers on the properties in cementitious system. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Liu, X.; Guan, J.; Lai, G.; Wang, Z.; Zhu, J.; Cui, S.; Lan, M.; Li, H. Performances and working mechanism of a novel polycarboxylate superplasticizer synthesized through changing molecular topological structure. J. Colloid Interface Sci. 2017, 504, 12–24. [Google Scholar] [CrossRef]

- Lin, X.; Pang, H.; Wei, D.; Lu, M.; Liao, B. Effect of the cross-linker structure of cross-linked polycarboxylate superplasticizers on the behavior of cementitious mixtures. Colloids Surf. A Physicochem. Eng. Asp. 2021, 608, 125437. [Google Scholar] [CrossRef]

- GB/T 8077-2012; Method for Testing Uniformity of Concrete Admixture. China Academy of Building Research: Beijing, China, 2012.

- GB/T 50080-2002; Standard for Test Method of Performance on Ordinary Fresh Concrete. China Academy of Building Research: Beijing, China, 2002.

- GB/T 1346-2011; Test Methods for Water Requirement of Normal Consistency, Setting Time and Soundness of the Portland Cement. China Academy of Building Research: Beijing, China, 2011.

- Shameli, K.; Bin Ahmad, M.; Jazayeri, S.D.; Sedaghat, S.; Shabanzadeh, P.; Jahangirian, H.; Mahdavi, M.; Abdollahi, Y. Synthesis and Characterization of Polyethylene Glycol Mediated Silver Nanoparticles by the Green Method. Int. J. Mol. Sci. 2012, 13, 6639–6650. [Google Scholar] [CrossRef]

- Zhao, H.; Liao, B.; Nian, F.; Wang, K.; Guo, Y.; Pang, H. Investigation of the clay sensitivity and cement hydration process of modified HPEG-type polycarboxylate superplasticizers. J. Appl. Polym. Sci. 2018, 135, 46572. [Google Scholar] [CrossRef]

- Schennach, R.; Cocke, D.; Mollah, M.; Adams, W. A Review of Cement-Superplasticizer Interactions and Their Models. Adv. Cem. Res. 2000, 12, 153–161. [Google Scholar] [CrossRef]

- Plank, J.; Hirsch, C. Impact of zeta potential of early cement hydration phases on superplasticizer adsorption. Cem. Concr. Res. 2007, 37, 537–542. [Google Scholar] [CrossRef]

- Pourchet, S.; Liautaud, S.; Rinaldi, D.; Pochard, I. Effect of the repartition of the PEG side chains on the adsorption and dispersion behaviors of PCP in presence of sulfate. Cem. Concr. Res. 2012, 42, 431–439. [Google Scholar] [CrossRef]

- Aggarwal, S.L. Structure and properties of block polymers and multiphase polymer systems: An overview of present status and future potential. Polymer 1976, 17, 938–956. [Google Scholar] [CrossRef]

- Verdonck, B.; Gohy, J.F.; Khousakoun, E.; Jérôme, R.; Du Prez, F. Association behavior of thermo-responsive block copolymers based on poly(vinyl ethers). Polymer 2005, 46, 9899–9907. [Google Scholar] [CrossRef][Green Version]

- Plank, J.; Yu, B. Preparation of hydrocalumite-based nanocomposites using polycarboxylate comb polymers possessing high grafting density as interlayer spacers. Appl. Clay Sci. 2010, 47, 378–383. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Z.; Zhu, J.; Zheng, Y.; Cui, S.; Lan, M.; Li, H. Synthesis, characterization and performance of a polycarboxylate superplasticizer with amide structure. Colloids Surf. A Physicochem. Eng. Asp. 2014, 448, 119–129. [Google Scholar] [CrossRef]

- Pourchet, S.; Comparet, C.; Nicoleau, L.; Nonat, A. Influence of PC Superplasticizers on Tricalcium Silicate Hydration. In Proceedings of the 12th International Congress on the Chemistry of Cement, Montréal, QC, Canada, 8–13 July 2007; pp. 132–145. [Google Scholar]

- Cartuxo, F.; Brito, J.; Evangelista, L.; Jimenez, J.R.; Ledesma, E.F. Rheological behaviour of concrete made with fine recycled concrete aggregates—Influence of the superplasticizer. Constr. Build. Mater. 2015, 89, 36–47. [Google Scholar] [CrossRef]

- Bullard, J.W.; Jennings, H.M.; Livingston, R.A.; Nonat, A.; Scherer, G.W.; Schweitzer, J.S.; Scrivener, K.L.; Thomas, J.J. Mechanisms of cement hydration. Cem. Concr. Res. 2011, 41, 1208–1223. [Google Scholar] [CrossRef]

- Zhang, Y.; Kong, X. Influences of superplasticizer, polymer latexes and asphalt emulsions on the pore structure and impermeability of hardened cementitious materials. Constr. Build. Mater. 2014, 53, 392–402. [Google Scholar] [CrossRef]

- Pratt, P.L.; Ghosh, A.; Skalny, J.; Hewlett, P.C.; Hirsch, P.B.; Birchall, J.D.; Double, D.D.; Kelly, A.; Moir, G.K.; Pomeroy, C.D. Electron microscope studies of Portland cement microstructures during setting and hardening. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1983, 310, 93–103. [Google Scholar] [CrossRef]

| Sample | HPEG (mmol) | KPS (mmol) | AA (mmol) | SAMS (mmol) | PETA (mmol) | TGA (mL) | H2O (mL) |

|---|---|---|---|---|---|---|---|

| Comb-like-PC | 20 | 15 | 30 | 10 | 0 | 0.5 | 60 |

| Crosslinked-PC | 20 | 15 | 30 | 10 | 3.2 | 0.5 | 60 |

| Sample | Mn | Mw | PD |

|---|---|---|---|

| Comb-like-PC | 27,348 | 69,706 | 2.55 |

| Crosslinked-PC | 38,882 | 109,588 | 2.82 |

| Sample | tA (h) | kA–B | (dQ/dt)A (mW/g) | (dQ/dt)C (mW/g) |

|---|---|---|---|---|

| Cement | 2.79 | 0.25 | 0.11 | 0.32 |

| Cement/Comb-like-PC | 3.85 | 0.15 | 0.07 | 0.30 |

| Cement/Crosslinked-PC | 4.05 | 0.14 | 0.05 | 0.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Zhao, H.; Chen, G.; Peng, Q.; Liu, Y.; Song, F.; Liu, Q. Influence of Pentaerythritol Tetraacrylate Crosslinker on Polycarboxylate Superplasticizer Performance in Cementitious System. Materials 2022, 15, 1524. https://doi.org/10.3390/ma15041524

Gao Y, Zhao H, Chen G, Peng Q, Liu Y, Song F, Liu Q. Influence of Pentaerythritol Tetraacrylate Crosslinker on Polycarboxylate Superplasticizer Performance in Cementitious System. Materials. 2022; 15(4):1524. https://doi.org/10.3390/ma15041524

Chicago/Turabian StyleGao, Yu, Hongwei Zhao, Guang Chen, Qi Peng, Yingying Liu, Fei Song, and Qingquan Liu. 2022. "Influence of Pentaerythritol Tetraacrylate Crosslinker on Polycarboxylate Superplasticizer Performance in Cementitious System" Materials 15, no. 4: 1524. https://doi.org/10.3390/ma15041524

APA StyleGao, Y., Zhao, H., Chen, G., Peng, Q., Liu, Y., Song, F., & Liu, Q. (2022). Influence of Pentaerythritol Tetraacrylate Crosslinker on Polycarboxylate Superplasticizer Performance in Cementitious System. Materials, 15(4), 1524. https://doi.org/10.3390/ma15041524