Investigation of the Effect of Graphene Oxide on the Properties and Microstructure of Clay-Cement Composite Grouting Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of CCGO Grouting Materials

2.3. Testing Method

3. Results

3.1. Rheology

3.2. Bleeding Rate and Bulk Shrinkage Rate

3.3. Setting Time

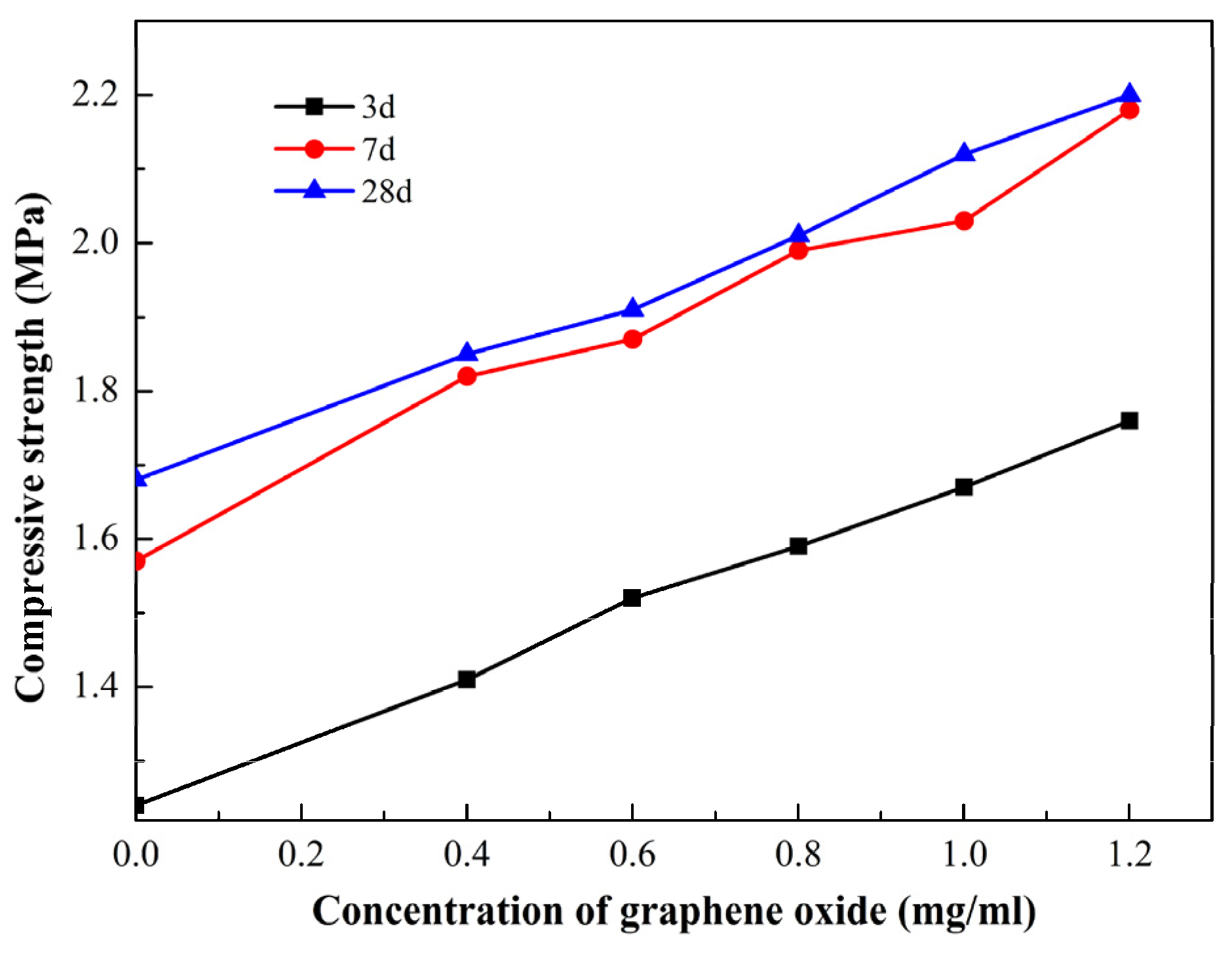

3.4. Unconfined Compressive Strength

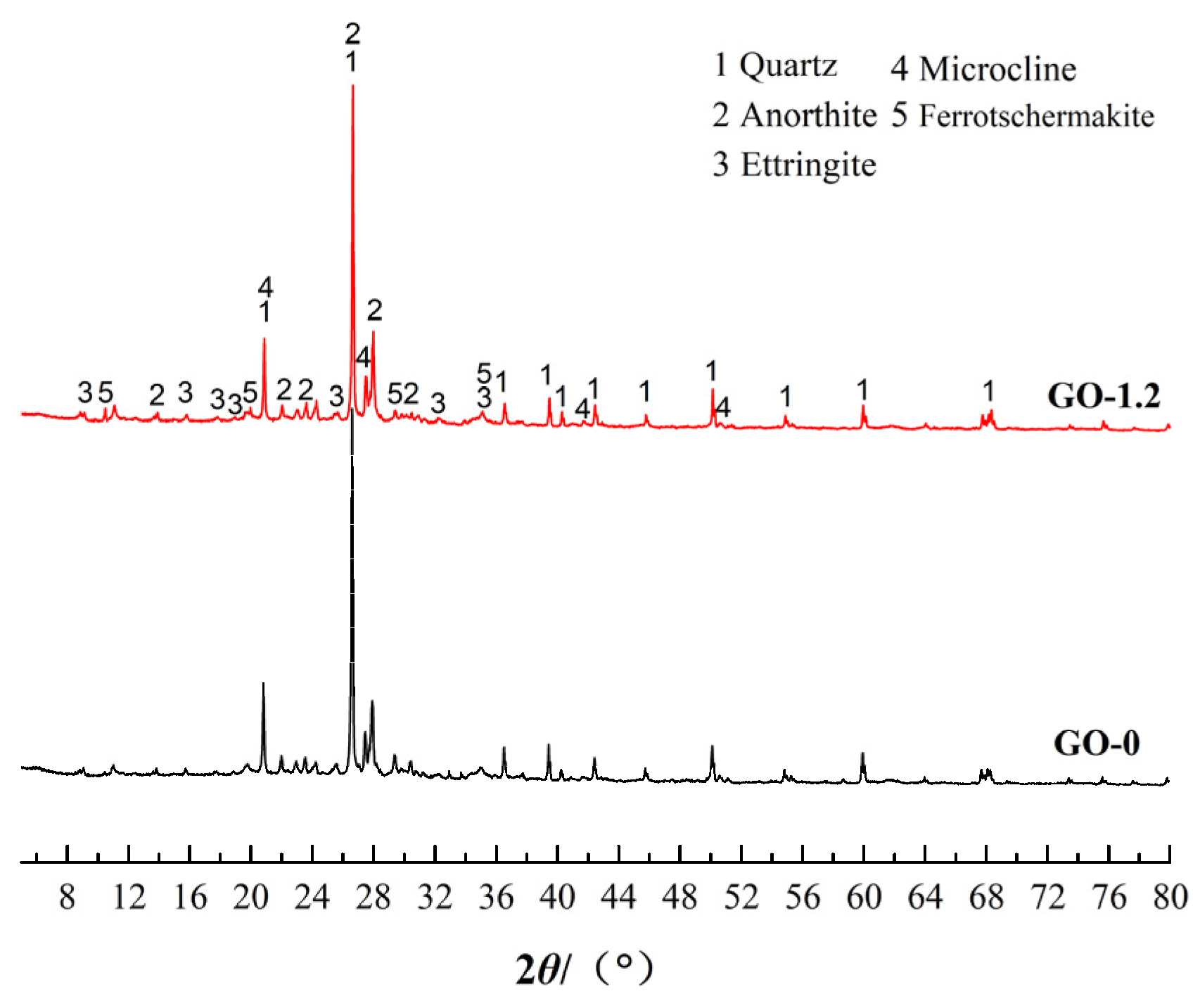

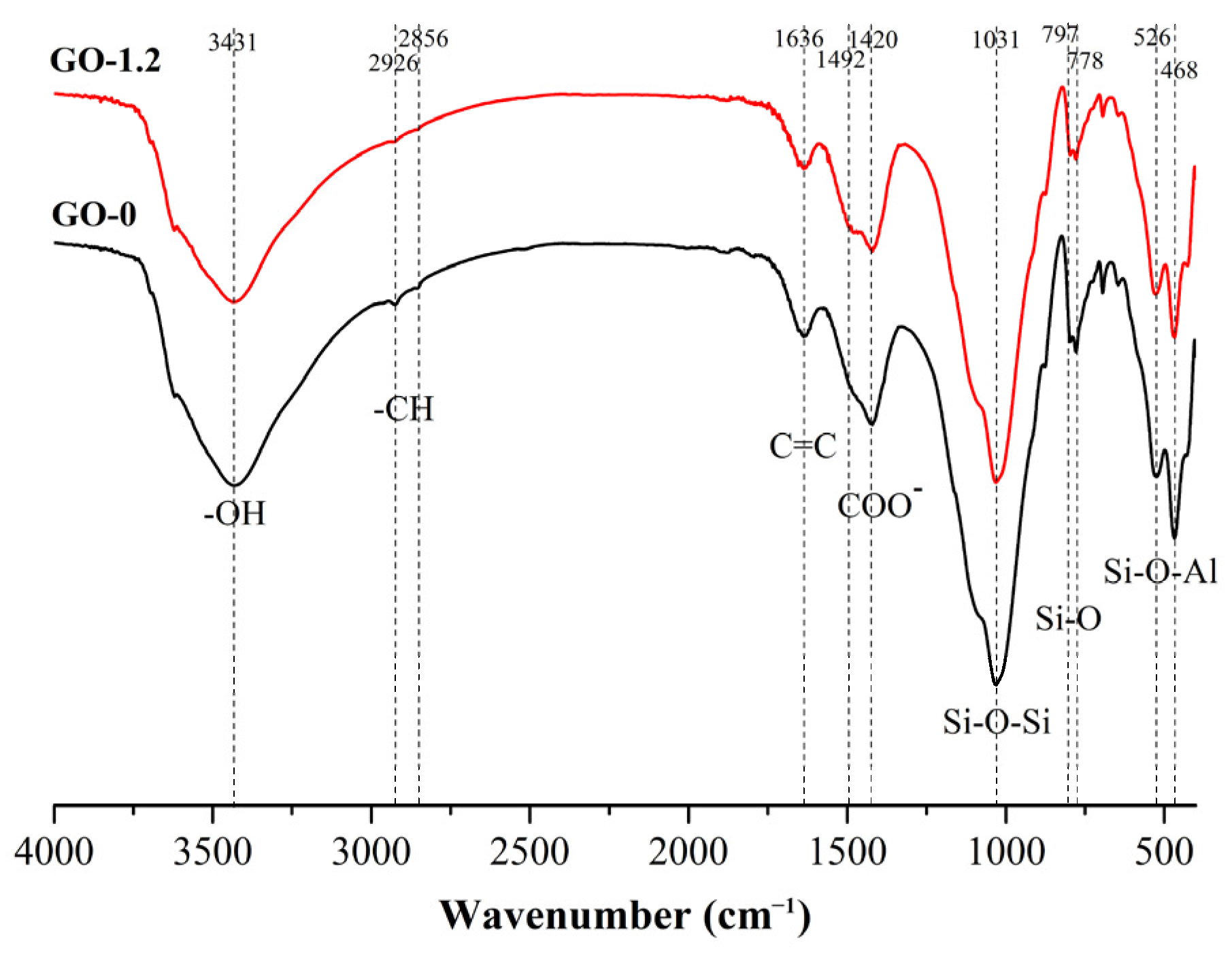

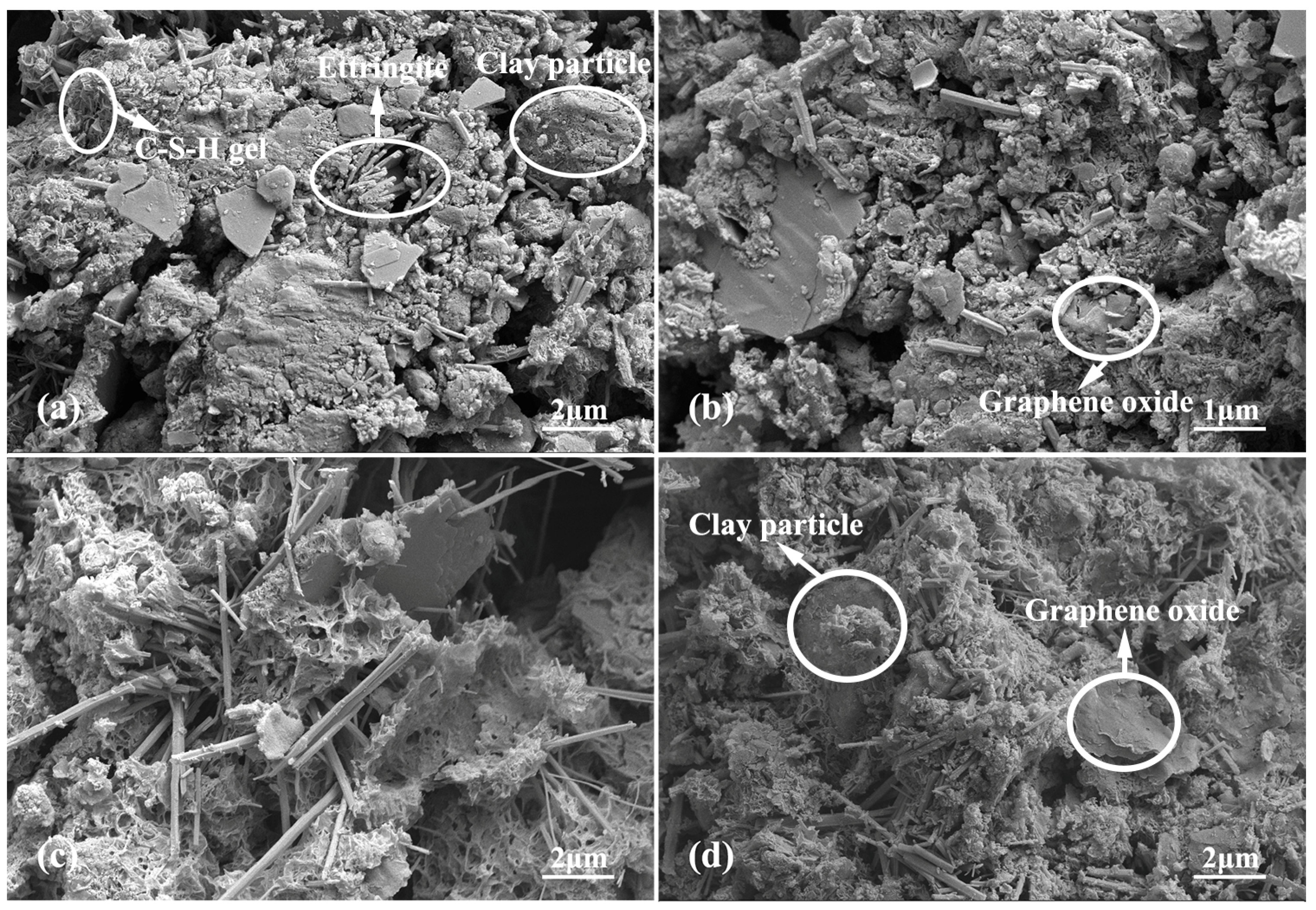

3.5. Microstructure of CCGO Grouting Materials

4. Discussion

5. Conclusions

- (1)

- The rheology of cement CCGO grouting materials is very sensitive to GO concentration. The shear stress of slurry increased rapidly with the increase in GO concentration. The shear stress of GO-1.2 was 3.28 times higher than that of GO-0 when the shear rate is 200 s−1. The apparent viscosity decreased sharply with the increase in shear rate, showing obvious thixotropy. The apparent viscosity decreased sharply with the increase in shear rate and showed obvious thixotropy;

- (2)

- The bleeding rate, bulk shrinkage rate, initial setting time and UCS of CCGO grouting materials have a significant positive correlation with the concentration of GO, which were improved with the increase in GO concentration. The optimal GO concentration was found to be 1.2 mg/mL, where the initial setting time is 372 min, there is no bleeding rate and bulk shrinkage, and the 28 d UCS reaches 2.2 MPa.

- (3)

- The results of XRD, FTIR and SEM show that the hydration products of CCGO grouting materials are mainly ettringite and C-S(A)-H cementitious hydration products. Moreover, SEM photos show that GO flakes can fill the pores of clay particles, which can provide a flat platform near which many hydration products grow, so that the porosity of composite materials is reduced and the structure is more compact.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, F.; Song, Z.Q.; Liu, Y.H.; Luo, B.H.; Zhang, W.B. Construction of the spatially varying ground motion field of a bedrock-overburden layer site and its influence on the seismic response of earth-rock dams. Arab. J. Geosci. 2021, 14, 1914. [Google Scholar] [CrossRef]

- Bayat, M.; Eslamian, S.; Shams, G.; Hajiannia, A. The 3D analysis and estimation of transient seepage in earth dams through PLAXIS 3D software: Neural network. Environ. Earth. Sci. 2019, 78, 571. [Google Scholar] [CrossRef]

- Park, D.S.; Oh, J. Permeation grouting for remediation of dam cores. Eng. Geol. 2017, 233, 63–75. [Google Scholar] [CrossRef]

- Güllü, H.; Cevik, A.; Al-Ezzi, K.; Gülsan, M. On the rheology of using geopolymer for grouting: A comparative study with cement-based grout included fly ash and cold bonded fly ash. Constr. Build. Mater. 2019, 196, 594–610. [Google Scholar] [CrossRef]

- Chahar, B.R. Determination of length of a horizontal drain in homogeneous earth dams. J. Irrig. Drain. Eng. 2004, 130, 530–536. [Google Scholar] [CrossRef]

- Azadi, M.R.; Taghichian, A.; Taheri, A. Optimization of cement-based grouts using chemical additives. J. Rock. Mech. Geotech. Eng. 2017, 9, 623–637. [Google Scholar] [CrossRef]

- Zhu, M.; Sui, H.; Yang, H. The differences between soil grouting with cement slurry and cement-water glass slurry. IOP Conf. Ser. Earth Environ. Sci. 2018, 108, 022013. [Google Scholar] [CrossRef]

- Zhang, G.J.; Liu, J.; Li, Y.; Liang, J.W. A pasty clay–cement grouting material for soft and loose ground under groundwater conditions. Adv. Cem. Res. 2017, 29, 54–62. [Google Scholar] [CrossRef]

- Wang, C.J.; Liu, Q.; Guo, C.C.; Xia, Y.Y. An Experimental Study on the Reinforcement of Silt with Permeable Polyurethane by Penetration Grouting. Adv. Civ. Eng. 2020, 2020, 8834331. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, J.S.; Fu, J.Y.; Ou, X.F.; Xie, Y.P.; Dai, Y.; Lei, J.S. A new clay-cement composite grouting material for tunnelling in underwater karst area. J. Cent. South. Univ. 2019, 26, 1863–1873. [Google Scholar] [CrossRef]

- Fei, J.; Wang, F.; Al-Tabbaa, A. Three-year performance of in-situ solidified/stabilised soil using novel MgO-bearing binders. Chemosphere 2016, 144, 681–688. [Google Scholar]

- Yi, Y.L.; Liska, M.; Al-Tabbaa, A. Properties of two model soils stabilized with different blends and contents of GGBS, MgO, lime, and PC. J. Mater. Civil. Eng. 2014, 26, 267–274. [Google Scholar] [CrossRef]

- Cai, G.H.; Liu, S.Y.; Tu, Y.J.; Zhang, D.W.; Zheng, X. Strength and deformation characteristics of carbonated reactive magnesia treated silt soil. J. Cent. South. Univ. 2015, 22, 1859–1868. [Google Scholar] [CrossRef]

- Noor-ul-Amin; Muhammad, K.; Alam, S.; Gul, S. Chemical activation of clay in cement mortar, using calcium chloride. Adv. Cem. Res. 2013, 25, 164–170. [Google Scholar] [CrossRef]

- Jongpradist, P.; Jumlongrach, N.; Youwai, S.; Chucheepsakul, S. Influence of Fly Ash on Unconfined Compressive Strength of Cement-Admixed Clay at High Water Content. J. Mater. Civil. Eng. 2010, 22, 49–58. [Google Scholar] [CrossRef]

- Diniz, D.H.; Carvalho, J.M.F.; Mendes, J.C.; Peixoto, R.A.F. Blast Oxygen Furnace Slag as Chemical Soil Stabilizer for Use in Roads. J. Mater. Civil. Eng. 2017, 29, 04017118. [Google Scholar] [CrossRef]

- Goodarzi, A.R.; Akbari, H.R.; Salimia, M. Enhanced stabilization of highly expansive clays by mixing cement and silica fume. Appl. Clay Sci. 2016, 132, 675–684. [Google Scholar] [CrossRef]

- Reches, Y. Nanoparticles as concrete additives: Review and perspectives. Constr. Build. Mater. 2018, 175, 483–495. [Google Scholar] [CrossRef]

- Valizadeh, M.; Choobbasti, A.J. Evaluation of nano-graphene effect on mechanical behavior of clayey sand with microstructural and self-healing approach. J. Adhes. Sci. Technol. 2020, 34, 299–318. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, L. Experimental studies on nanomaterials for soil improvement: A review. Environ. Earth. Sci. 2016, 75, 497. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, C.; Zhao, M.Z.; Guo, W.B.; Luo, Q. Comparison of Nanomaterials with Other Unconventional Materials Used as Additives for Soil Improvement in the Context of Sustainable Development: A Review. Nanomaterials 2020, 11, 15. [Google Scholar] [CrossRef] [PubMed]

- Figueiredo, D.; Correia, A.; Hunkeler, D.; Rasteiroa, M. Surfactants for dispersion of carbon nanotubes applied in soil stabilization. Colloids Surf. A. Physicochem. Eng. Asp. 2015, 480, 405–412. [Google Scholar] [CrossRef] [Green Version]

- Yao, K.; An, D.L.; Wang, W.; Li, N.; Zhou, A.Z. Effect of nano-MgO on mechanical performance of cement stabilized silty clay. Mar. Georesource Geotechnol. 2019, 38, 250–255. [Google Scholar] [CrossRef]

- Newell, M.; Garcia-Taengua, E. Fresh and hardened state properties of hybrid graphene oxide/nanosilica cement composites. Constr. Build. Mater. 2019, 221, 433–442. [Google Scholar] [CrossRef]

- Peng, L.; Xu, Z.; Liu, Z.; Wei, Y.Y.; Sun, H.Y.; Li, Z.; Zhao, X.L.; Gao, C. An iron-based green approach to 1-h production of single-layer graphene oxide. Nat. Commun. 2015, 6, 5716. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tong, T.; Fan, Z.; Liu, Q.; Wang, S.; Tan, S.S.; Yu, Q. Investigation of the effects of graphene and graphene oxide nanoplatelets on the micro-and macro-properties of cementitious materials. Constr. Build. Mater. 2016, 106, 102–114. [Google Scholar] [CrossRef]

- Wang, M.; Wang, R.M.; Yao, H.; Farhan, S.; Zheng, S.R.; Du, C.C. Study on the three dimensional mechanism of graphene oxide nanosheets modified cement. Constr. Build. Mater. 2016, 126, 730–739. [Google Scholar] [CrossRef]

- Lv, S.H.; Ma, Y.J.; Qiu, C.C.; Liu, J.J.; Zhou, Q.F. Effect of graphene oxide nanosheets of microstructure and mechanical properties of cement composites. Constr. Build. Mater. 2013, 49, 121–127. [Google Scholar] [CrossRef]

- Naseri, F.; Irani, M.; Dehkhodarajabi, M. Effect of graphene oxide nanosheets on the geotechnical properties of cemented silty soil. Arch. Civ. Mech. Eng. 2016, 16, 695–701. [Google Scholar] [CrossRef]

- Zhao, L.; Guo, X.L.; Liu, Y.Y.; Ge, C.; Chen, Z.T.; Guo, L.P.; Shu, X.; Liu, J.P. Investigation of dispersion behavior of GO modified by different water reducing agents in cement pore solution. Carbon 2018, 127, 255–269. [Google Scholar] [CrossRef]

- Li, D.B.; Lei, P.B.; Zhang, H.C.; Liu, J.P.; Lu, W. Co-Effects of Graphene Oxide and Cement on Geotechnical Properties of Loess. Adv. Mater. Sci. Eng. 2021, 2021, 7429310. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, W.; Zhu, Z.D.; Li, N.; Pu, S.Y.; Wan, Y.; Huo, W.W. Triaxial mechanical characteristics and microscopic mechanism of graphene-modified cement stabilized expansive soil. KSCE J. Civ. Eng. 2021, 26, 96–106. [Google Scholar] [CrossRef]

- Zhou, G.X.; Zhong, J.; Zhang, H.; Hu, X.Y.; Wu, J.L.; Koratkar, N.; Shi, X.M. Influence of releasing graphene oxide into a clayey sand: Physical and mechanical properties. RSC Adv. 2017, 7, 18060–18067. [Google Scholar] [CrossRef] [Green Version]

- Chougan, M.; Marotta, E.; Lamastra, F.R.; Vivio, F.; Montesperelli, G.; Ianniruberto, U.; Bianco, A. A systematic study on EN-998-2 premixed mortars modified with graphene-based materials. Constr. Build. Mater. 2019, 227, 116701. [Google Scholar] [CrossRef]

- Farooq, F.; Akbar, A.; Khushnood, R.A.; Muhammad, W.L.B.; Rehman, S.K.U.; Javed, M.F. Experimental investigation of hybrid carbon nanotubes and graphite nanoplatelets on rheology, shrinkage, mechanical, and microstructure of SCCM. Materials 2020, 13, 230. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Azevedo, A.; Matos, P.D.; Marvila, M.; Sakata, R.; Silvestro, L.; Gleize, P.; Brito, J.D. Rheology, Hydration, and Microstructure of Portland Cement Pastes Produced with Ground Açaí Fibers. Appl. Sci. 2021, 11, 3036. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.; Lv, C.X.; Cui, S.Y.; Li, S.Y.; Wang, X. Rheological behavior of fresh cement pastes with a graphene oxide additive—ScienceDirect. New Carbon. Mater. 2016, 31, 574–584. [Google Scholar] [CrossRef]

- Bizzozero, J.; Scrivener, K.L. Limestone reaction in calcium aluminate cement–calcium sulfate systems. Cement. Concr. Res. 2015, 76, 159–169. [Google Scholar] [CrossRef] [Green Version]

- Balaji, S.; Swathika, A. Review on mechanical and microstructural properties of cementitious composites with graphene oxide. Mater. Today Proc. 2021, 50, 2280–2287. [Google Scholar] [CrossRef]

- Yang, H.B.; Monasterio, M.; Cui, H.Z.; Han, N.X. Experimental study of the effects of graphene oxide on microstructure and properties of cement paste composite. Compos. Part. A Appl. Sci. Manuf. 2017, 102, 263–272. [Google Scholar] [CrossRef]

- Faria, P.; Duarte, P.; Barbosa, D.; Ferreira, I. New composite of natural hydraulic lime mortar with graphene oxide. Constr. Build. Mater. 2017, 156, 1150–1157. [Google Scholar] [CrossRef] [Green Version]

- Li, Q.C.; He, C.; Zhou, H.; Xie, Z.Y.; Li, D.X. Effects of polycarboxylate superplasticizer-modified graphene oxide on hydration characteristics and mechanical behavior of cement. Constr. Build. Mater. 2021, 272, 121904. [Google Scholar] [CrossRef]

- Hong, Z.J.; Zuo, J.P.; Zhang, Z.S.; Liu, C.; Liu, L.; Liu, H.Y. Effects of nano-clay on the mechanical and microstructural properties of cement-based grouting material in sodium chloride solution. Constr. Build. Mater. 2020, 245, 118420. [Google Scholar] [CrossRef]

- Zhao, S.Q.; Liu, G.; Ou, Q.H.; Xu, J.; Ren, J.; Hao, J.M. FTIR and ICP-MS analysis of different types of soils. Spectrosc. Spectr. Anal. 2014, 34, 3401–3405. (In Chinese) [Google Scholar]

- Lecomte, I.; Liegeois, M.; Rulmont, A.; Cloots, R.; Maseri, F. Synthesis and characterization of new inorganic polymeric composites based on kaolin or white clay and on ground-granulated blast furnace slag. J. Mater. Res. 2003, 18, 2571–2579. [Google Scholar] [CrossRef]

- Bullard, J.W.; Jennings, H.M.; Livingston, R.A.; Nonat, A.; Scherer, G.W.; Schweitzer, J.S.; Scrivener, K.L.; Thomas, J.J. Mechanisms of cement hydration. Cement. Concr. Res. 2011, 41, 1208–1223. [Google Scholar] [CrossRef]

| Material | CaO | Al2O3 | SiO2 | MgO | SO3 | Fe2O3 | TiO2 | K2O |

|---|---|---|---|---|---|---|---|---|

| Cement | 64.39 | 5.61 | 19.69 | 1.25 | 2.80 | 4.14 | 0.31 | — |

| Clay | 2.85 | 17.45 | 64.89 | 1.99 | — | 6.53 | 1.12 | 3.46 |

| Mineral admixture | 22.64 | 23.14 | 37.23 | 0.65 | 14.65 | 0.43 | 0.04 | — |

| Number | Clay/% | Cement/% | Mineral Admixture/% | PCs (Additional)/% | GO (Additional)/g/kg | Water Solid Ratio |

|---|---|---|---|---|---|---|

| GO-0 | 81 | 15 | 4 | 0.3 | 0 | 0.9 |

| GO-0.4 | 81 | 15 | 4 | 0.3 | 0.36 | 0.9 |

| GO-0.6 | 81 | 15 | 4 | 0.3 | 0.54 | 0.9 |

| GO-0.8 | 81 | 15 | 4 | 0.3 | 0.72 | 0.9 |

| GO-1 | 81 | 15 | 4 | 0.3 | 0.9 | 0.9 |

| GO-1.2 | 81 | 15 | 4 | 0.3 | 1.08 | 0.9 |

| Number | Fitting Equation | τ0 (Pa) | ηp (Pa·s) | Correlation Coefficient (R2) |

|---|---|---|---|---|

| GO-0 | y = 0.00065x2 + 0.3578x + 17.78 | 17.78 | 0.3578 | 0.9968 |

| GO-0.4 | y = 0.0013x2 + 0.4637x + 115.11 | 115.11 | 0.4637 | 0.9968 |

| GO-0.8 | y = 0.0012x2 + 0.4778x + 147.86 | 147.86 | 0.4778 | 0.9923 |

| GO-1.2 | y = 0.00076x2 + 1.2240x + 213.52 | 213.52 | 1.2240 | 0.9960 |

| Sample Name | Bleeding Rate (%) | Bulk Shrinkage Rate (%) |

|---|---|---|

| GO-0 | 1.27 | 1.12 |

| GO-0.4 | 0.51 | 0.45 |

| GO-0.6 | 0.43 | 0.30 |

| GO-0.8 | 0.31 | 0.15 |

| GO-1 | 0.16 | 0 |

| GO-1.2 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ling, X.; Guo, X.; Zhong, J.; Ma, J.; Tang, L.; Xing, D.; Su, J.; Cong, S. Investigation of the Effect of Graphene Oxide on the Properties and Microstructure of Clay-Cement Composite Grouting Materials. Materials 2022, 15, 1623. https://doi.org/10.3390/ma15051623

Ling X, Guo X, Zhong J, Ma J, Tang L, Xing D, Su J, Cong S. Investigation of the Effect of Graphene Oxide on the Properties and Microstructure of Clay-Cement Composite Grouting Materials. Materials. 2022; 15(5):1623. https://doi.org/10.3390/ma15051623

Chicago/Turabian StyleLing, Xianzhang, Xiaoyu Guo, Jing Zhong, Jinji Ma, Liang Tang, Dongliang Xing, Jianguang Su, and Shengyi Cong. 2022. "Investigation of the Effect of Graphene Oxide on the Properties and Microstructure of Clay-Cement Composite Grouting Materials" Materials 15, no. 5: 1623. https://doi.org/10.3390/ma15051623

APA StyleLing, X., Guo, X., Zhong, J., Ma, J., Tang, L., Xing, D., Su, J., & Cong, S. (2022). Investigation of the Effect of Graphene Oxide on the Properties and Microstructure of Clay-Cement Composite Grouting Materials. Materials, 15(5), 1623. https://doi.org/10.3390/ma15051623