Numerical Simulation of Conical and Linear-Shaped Charges Using an Eulerian Elasto-Plastic Multi-Material Multi-Phase Flow Model with Detonation

Abstract

:1. Introduction

2. Governing Equations

3. Numerical Method

Ghost Fluid Method

| Algorithm 1 The numerical procedure for the present hydrocode. |

|

4. Results and Discussion

4.1. One-Dimensional Shockwave Propagation in Elasto-Plastic Solid

4.2. Taylor Bar Impact Problem

4.3. Generation and Penetration of a High-Speed Metal Jet

4.4. Conical-Shaped Charge

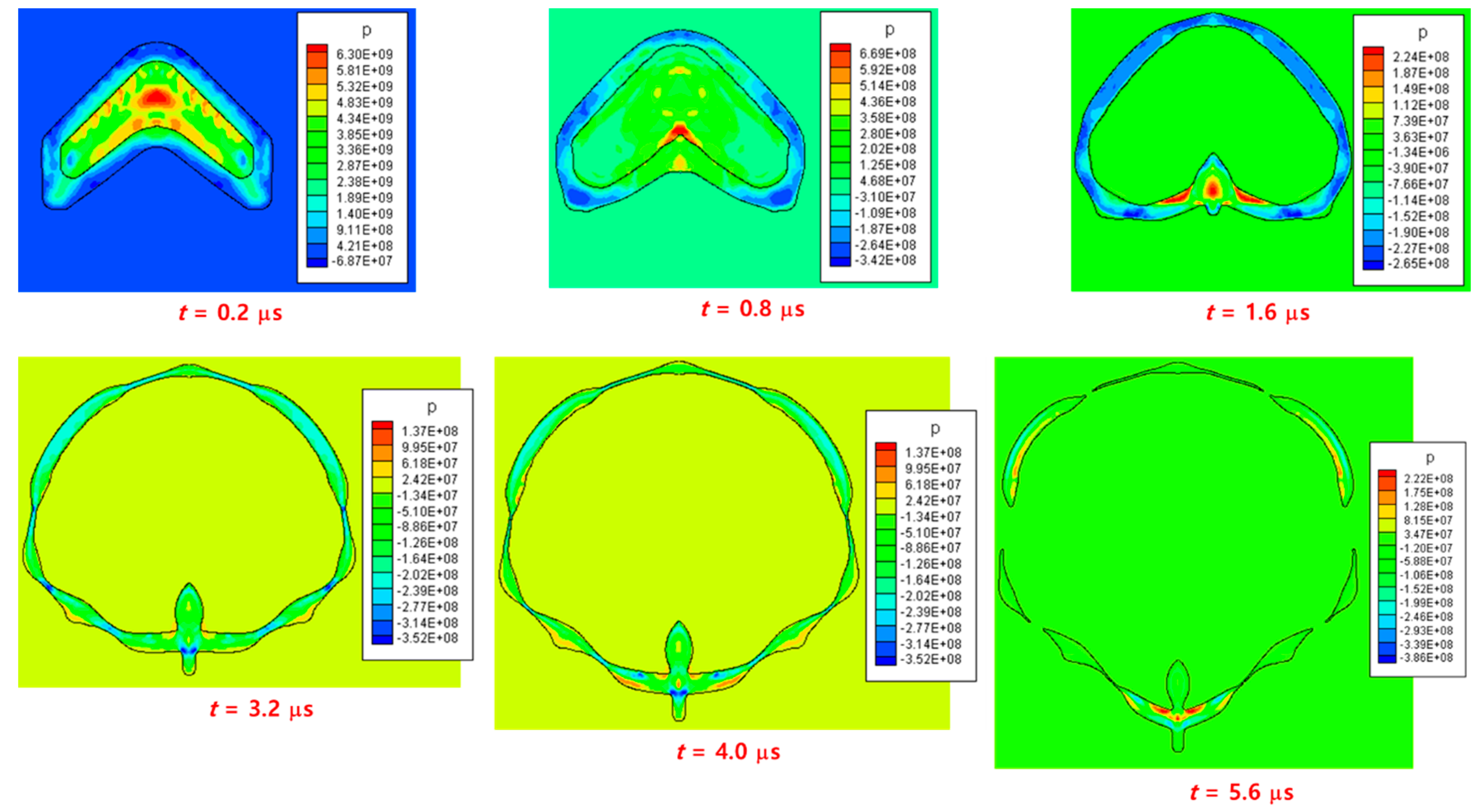

4.5. Linear-Shaped Charge

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Governing Equations

Appendix A.1. Eulerian Elasto-Plastic Solid Model

Appendix A.2. Material Model

Appendix A.3. Radial Return Mapping Algorithm

Appendix A.4. Mie–Grüneisen EOS for Solids

Appendix A.5. Programmed Burn Model

Appendix B. Numerical Methods

Appendix B.1. Third-Order Runge–Kutta Scheme

Appendix B.2. Third-Order CENO Scheme

Appendix B.3. Fifth-Order WENO Scheme

Appendix B.4. Level-Set Method for Interface Tracking

References

- Walters, W.P.; Zukas, J.A. Fundamentals of Shaped Charges; Wiley-Interscience: Hoboken, NJ, USA, 1989. [Google Scholar]

- Żochowski, P.; Warchoł, R.; Miszczak, M.; Nita, M.; Pankowski, Z.; Bajkowski, M. Experimental and Numerical Study on the PG-7VM Warhead Performance against High-Hardness Armor Steel. Materials 2021, 14, 3020. [Google Scholar] [CrossRef]

- Duprey, K.; Saucier, E. Separation Systems Comparison for ARES I Launch Vehicle. In Proceedings of the 44th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Hartford, CT, USA, 21–23 July 2008; p. 4514. [Google Scholar]

- Molinari, J.F. Finite element simulation of shaped charges. Finite Elem. Anal. Des. 2002, 38, 921–936. [Google Scholar] [CrossRef]

- Liu, M.B.; Liu, G.R.; Lam, K.Y.; Zong, Z. Meshfree particle simulation of the detonation process for high explosives in shaped charge unlined cavity configurations. Shock Waves 2003, 12, 509–520. [Google Scholar] [CrossRef]

- Liu, M.B.; Liu, G.R.; Zong, Z.; Lam, K.Y. Computer simulation of high explosive explosion using smoothed particle hydrodynamics methodology. Comput. Fluids 2003, 32, 305–322. [Google Scholar] [CrossRef]

- Ma, T.; Wang, C.; Ning, J. Numerical study on the shaped charges. In Engineering Plasticity and Its Applications from Nanoscale to Macroscale: (with CD-ROM), Proceedings of the 9th AEPA2008, Daejeon, Korea, 20–24 October 2008; World Scientific: Singapore, 2009; pp. 377–382. [Google Scholar]

- Kim, K.H.; Yoh, J.J. Shock compression of condensed matter using multimaterial reactive ghost fluid method. J. Math. Phys. 2008, 49, 043511. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, C.; Huang, F. Penetration of shaped charge jets with tungsten–copper and copper liners at the same explosive-to-liner mass ratio into water. Shock Waves 2010, 20, 263–267. [Google Scholar] [CrossRef]

- Chen, Q.; Liu, K. A high-resolution Eulerian method for numerical simulation of shaped charge jet including solid–fluid coexistence and interaction. Comput. Fluids 2012, 56, 92–101. [Google Scholar] [CrossRef]

- Sambasivan, S.K.; Udaykumar, H.S. A sharp interface method for high-speed multi-material flows: Strong shocks and arbitrary materialpairs. Int. J. Comput. Fluid Dyn. 2011, 25, 139–162. [Google Scholar] [CrossRef]

- Sambasivan, S.; Kapahi, A.; Udaykumar, H.S. Simulation of high speed impact, penetration and fragmentation problems on locally refined Cartesian grids. J. Comput. Phys. 2013, 235, 334–370. [Google Scholar] [CrossRef]

- Feng, D.L.; Liu, M.B.; Li, H.Q.; Liu, G.R. Smoothed particle hydrodynamics modeling of linear shaped charge with jet formation and penetration effects. Comput. Fluids 2013, 86, 77–85. [Google Scholar] [CrossRef] [Green Version]

- Yi, J.; Wang, Z.; Yin, J.; Zhang, Z. Simulation study on expansive jet formation characteristics of polymer liner. Materials 2019, 12, 744. [Google Scholar] [CrossRef] [Green Version]

- Pyka, D.; Kurzawa, A.; Bocian, M.; Bajkowski, M.; Magier, M.; Sliwinski, J.; Jamroziak, K. Numerical and experimental studies of the ŁK type shaped charge. Appl. Sci. 2020, 10, 6742. [Google Scholar] [CrossRef]

- Du, Y.; He, G.; Liu, Y.; Guo, Z.; Qiao, Z. Study on Penetration Performance of Rear Shaped Charge Warhead. Materials 2021, 14, 6526. [Google Scholar] [CrossRef]

- Peng, J.; Jiang, J.; Men, J.; Li, J.; Zhou, D.; Hu, Y. The Penetration–Explosion Effects of Differently Distributed Inactive/Active Composite Shaped Charge Jets. Materials 2022, 15, 344. [Google Scholar] [CrossRef]

- Liu, X.D.; Osher, S. Convex ENO high order multi-dimensional schemes without field by field decomposition or staggered grids. J. Comput. Phys. 1998, 142, 304–330. [Google Scholar] [CrossRef]

- Fedkiw, R.P.; Aslam, T.; Merriman, B.; Osher, S. A non-oscillatory Eulerian approach to interfaces in multimaterial flows (the ghost fluid method). J. Comput. Phys. 1999, 152, 457–492. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Ponthot, J.P. An extension of the radial return algorithm to account for rate-dependent effects in frictional contact and visco-plasticity. J. Mater. Process. Technol. 1998, 80, 628–634. [Google Scholar] [CrossRef]

- Ponthot, J.P. Unified stress update algorithms for the numerical simulation of large deformation elasto-plastic and elasto-viscoplastic processes. Int. J. Plast. 2002, 18, 91–126. [Google Scholar] [CrossRef]

- Shu, C.W. High-order finite difference and finite volume WENO schemes and discontinuous Galerkin methods for CFD. Int. J. Comput. Fluid Dyn. 2003, 17, 107–118. [Google Scholar] [CrossRef]

- Sethian, J.A. Level Set Methods and Fast Marching Methods: Evolving Interfaces in Computational Geometry, Fluid Mechanics, Computer Vision, and Materials Science; Cambridge University Press: Cambridge, UK, 1999; Volume 3. [Google Scholar]

- Udaykumar, H.S.; Tran, L.; Belk, D.M.; Vanden, K.J. An Eulerian method for computation of multimaterial impact with ENO shock-capturing and sharp interfaces. J. Comput. Phys. 2003, 186, 136–177. [Google Scholar] [CrossRef]

- Mehmandoust, B.; Pishevar, A.R. An Eulerian particle level set method for compressible deforming solids with arbitrary EOS. Int. J. Numer. Methods Eng. 2009, 79, 1175–1202. [Google Scholar] [CrossRef]

- Tran, L.; Udaykumar, H.S. A particle-level set-based sharp interface cartesian grid method for impact, penetration, and void collapse. J. Comput. Phys. 2004, 193, 469–510. [Google Scholar] [CrossRef]

- Camacho, G.T.; Ortiz, M. Adaptive Lagrangian modelling of ballistic penetration of metallic targets. Comput. Methods Appl. Mech. Eng. 1997, 142, 269–301. [Google Scholar] [CrossRef]

- Cooper, S.R.; Benson, D.J.; Nesterenko, V.F. A numerical exploration of the role of void geometry on void collapse and hot spot formation in ductile materials. Int. J. Plast. 2000, 16, 525–540. [Google Scholar] [CrossRef]

- Shimamura, K.; Ootsuka, T. Study of water entry of high-špeed projectile. Procedia Eng. 2013, 58, 232–239. [Google Scholar] [CrossRef] [Green Version]

- Saran, S.; Ayısıt, O.; Yavuz, M.S. Experimental investigations on aluminum shaped charge liners. Procedia Eng. 2013, 58, 479–486. [Google Scholar] [CrossRef] [Green Version]

- Sun, S.; Jiang, J.; Wang, S.; Men, J.; Li, M.; Wang, Y. Comparison of Shaped Charge Jet Performance Generated by Machined and Additively Manufactured CuSn10 Liners. Materials 2021, 14, 7149. [Google Scholar] [CrossRef]

- Rolc, S.; Buchar, J.; Akstein, Z. Computer simulation of explosively formed projectiles (EFP). In Proceedings of the 23rd International Symposium on Ballistics, Tarragona, Spain, 16–20 April 2007; pp. 185–192. [Google Scholar]

- Cheng, X.; Huang, G.; Liu, C.; Feng, S. Design of a novel linear shaped charge and factors influencing its penetration performance. Appl. Sci. 2018, 8, 1863. [Google Scholar] [CrossRef] [Green Version]

- Soares, G.C.; Hokka, M. The Taylor–Quinney coefficients and strain hardening of commercially pure titanium, iron, copper, and tin in high rate compression. Int. J. Impact Eng. 2021, 156, 103940. [Google Scholar] [CrossRef]

- Khan, A.S.; Huang, S. Continuum Theory of Plasticity; John Wiley & Sons: Hoboken, NJ, USA, 1995. [Google Scholar]

- Lemons, D.S.; Lund, C.M. Thermodynamics of high temperature, Mie–Gruneisen solids. Am. J. Phys. 1999, 67, 1105–1108. [Google Scholar] [CrossRef]

- Heuzé, O. General form of the Mie–Grüneisen equation of state. Comptes Rendus Mec. 2012, 340, 679–687. [Google Scholar] [CrossRef]

- Peng, D.; Merriman, B.; Osher, S.; Zhao, H.; Kang, M. A PDE-based fast local level set method. J. Comput. Phys. 1999, 155, 410–438. [Google Scholar] [CrossRef] [Green Version]

| TNT | 1630 | 21 | 6930 | 371.2 | 3.210 | 4.15 | 0.95 | 0.30 | |

| Composition B | 1717 | 29 | 7980 | 524.2 | 7.678 | 4.20 | 1.10 | 0.34 |

| 2.0 | 1.49 | 3940 | 8930 | 110,920 | 45 | 90 |

| Elastic Precursor | Plastic Shock | |||

|---|---|---|---|---|

| Udaykumar et al. [25] | Present | Udaykumar et al. [25] | Present | |

| Density () | 8938.9 | 8939.8 | 8973.5 | 8973.3 |

| Final Height (mm) | Final Base Radius (mm) | ||

|---|---|---|---|

| Present | 21.44 | 6.65 | 2.672 |

| Sambasivan et al. [12] | 21.53 | 7.05 | 3.169 |

| Mehmandoust and Pishevar [26] | 21.80 | 6.53 | 2.178 |

| Tran and Udaykumar [27] | 21.15 | 7.15 | 2.86 |

| Udaykumar et al. [25] | 21.4 | 6.97–7.24 | - |

| Camacho and Ortiz [28] | 21.42–21.44 | 7.21–7.24 | 2.97–3.25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yeom, G.-S. Numerical Simulation of Conical and Linear-Shaped Charges Using an Eulerian Elasto-Plastic Multi-Material Multi-Phase Flow Model with Detonation. Materials 2022, 15, 1700. https://doi.org/10.3390/ma15051700

Yeom G-S. Numerical Simulation of Conical and Linear-Shaped Charges Using an Eulerian Elasto-Plastic Multi-Material Multi-Phase Flow Model with Detonation. Materials. 2022; 15(5):1700. https://doi.org/10.3390/ma15051700

Chicago/Turabian StyleYeom, Geum-Su. 2022. "Numerical Simulation of Conical and Linear-Shaped Charges Using an Eulerian Elasto-Plastic Multi-Material Multi-Phase Flow Model with Detonation" Materials 15, no. 5: 1700. https://doi.org/10.3390/ma15051700