Microstructure Evolution and Performance Improvement of Silicon Carbide Ceramics via Impregnation Method

Abstract

:1. Introduction

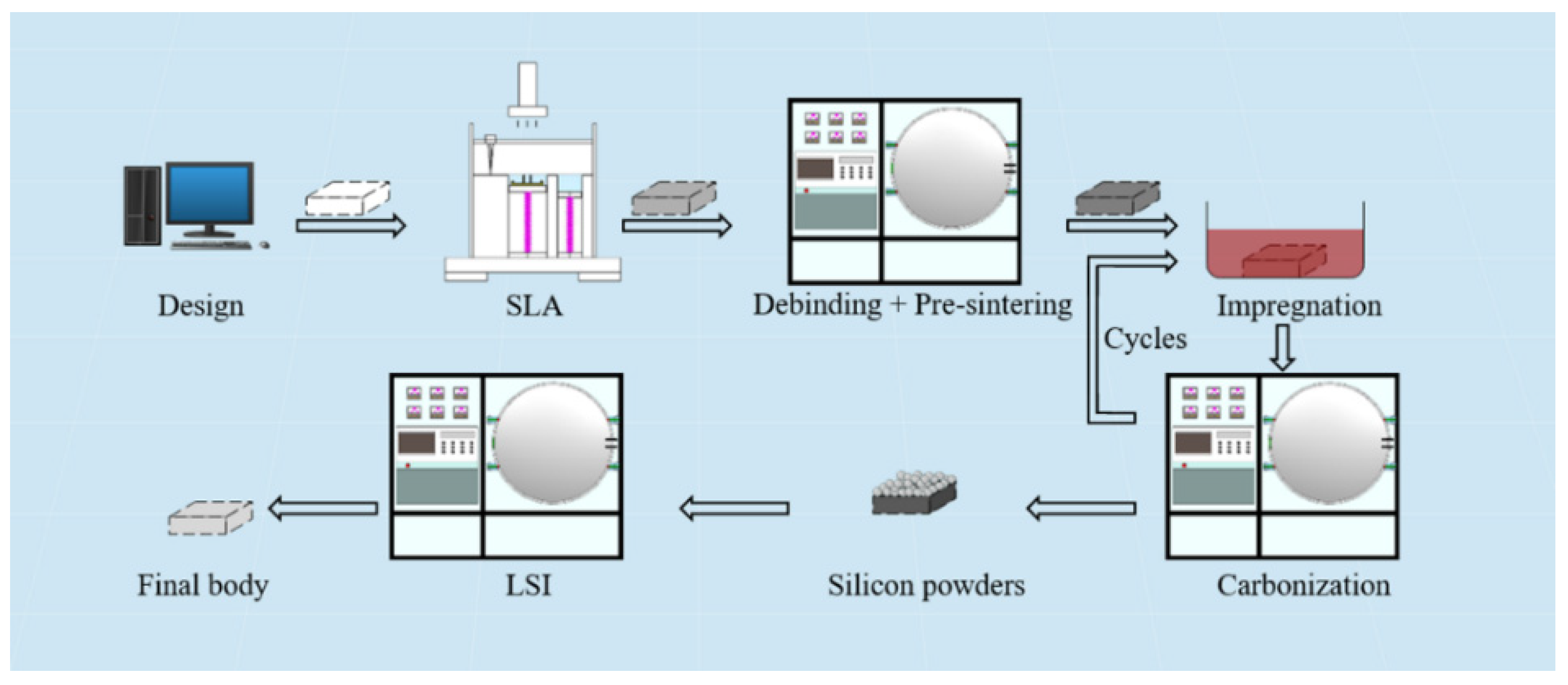

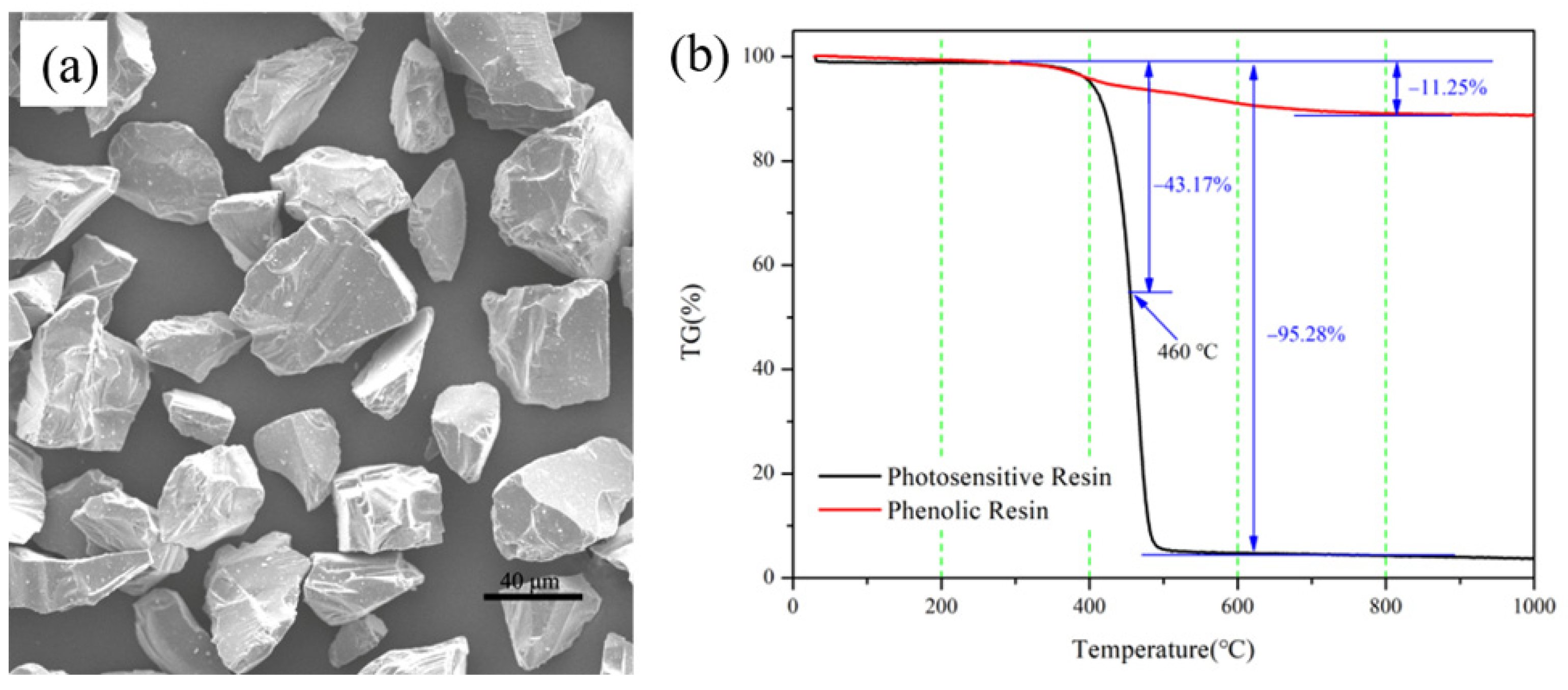

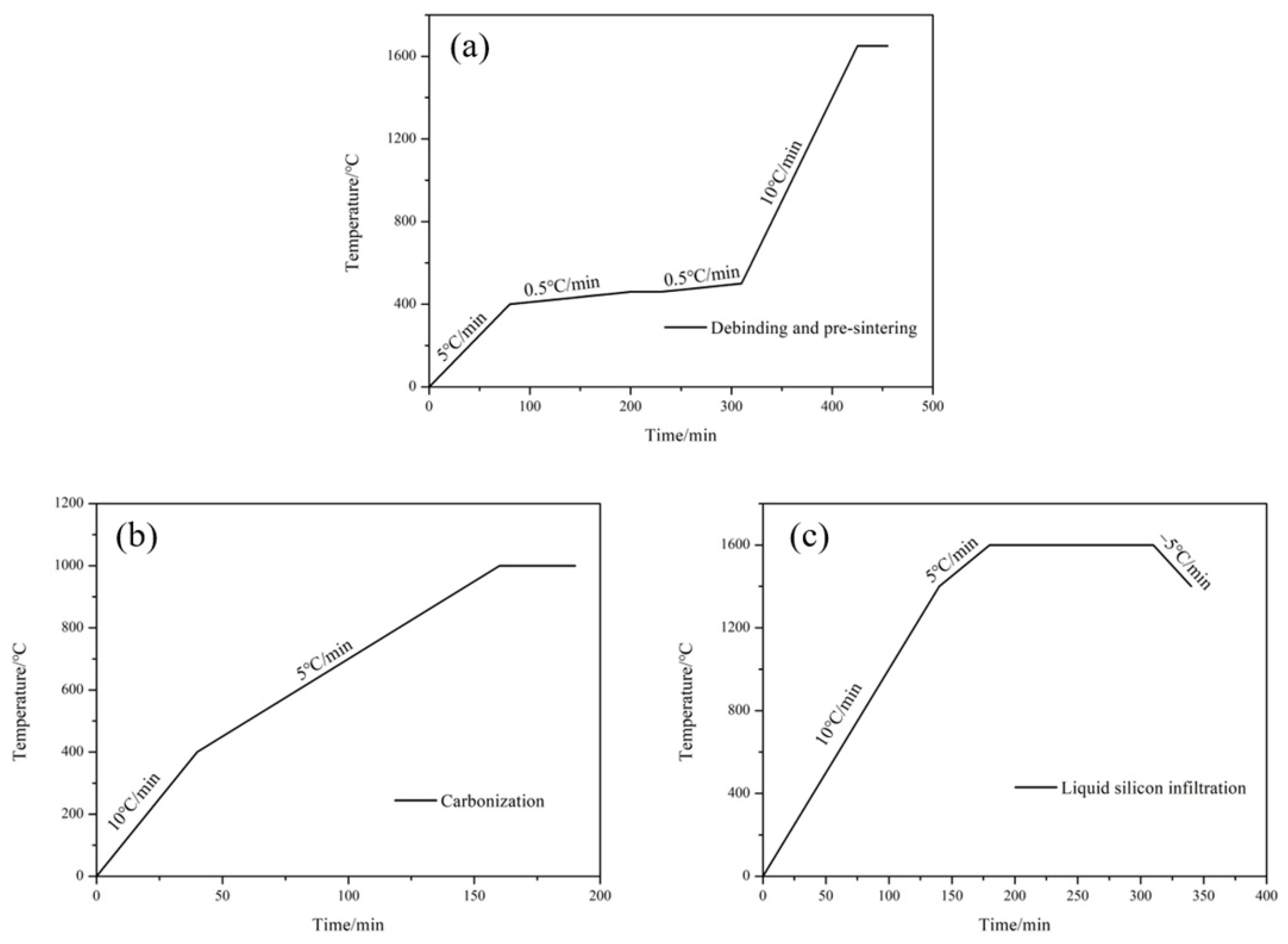

2. Materials and Methods

3. Results and Discussion

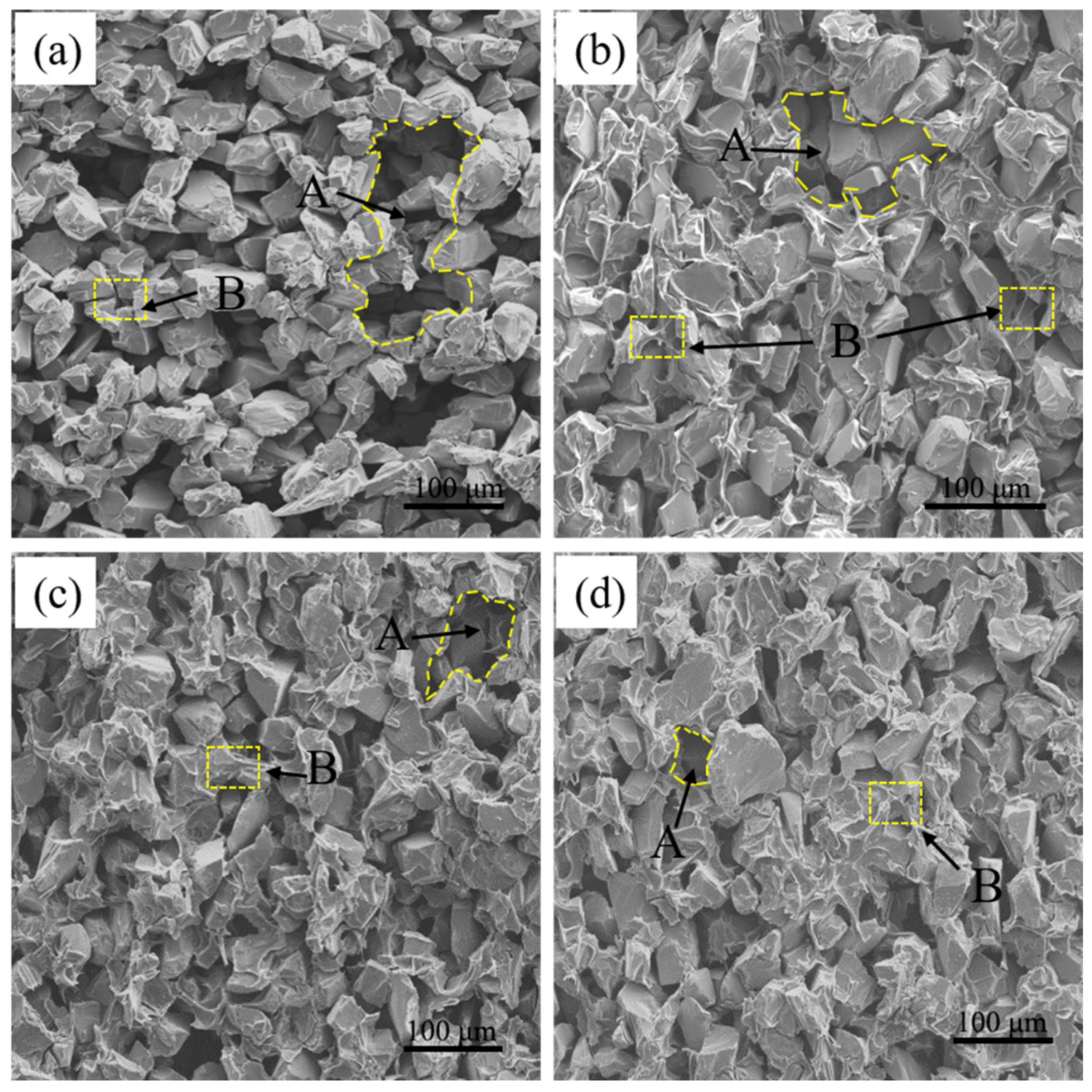

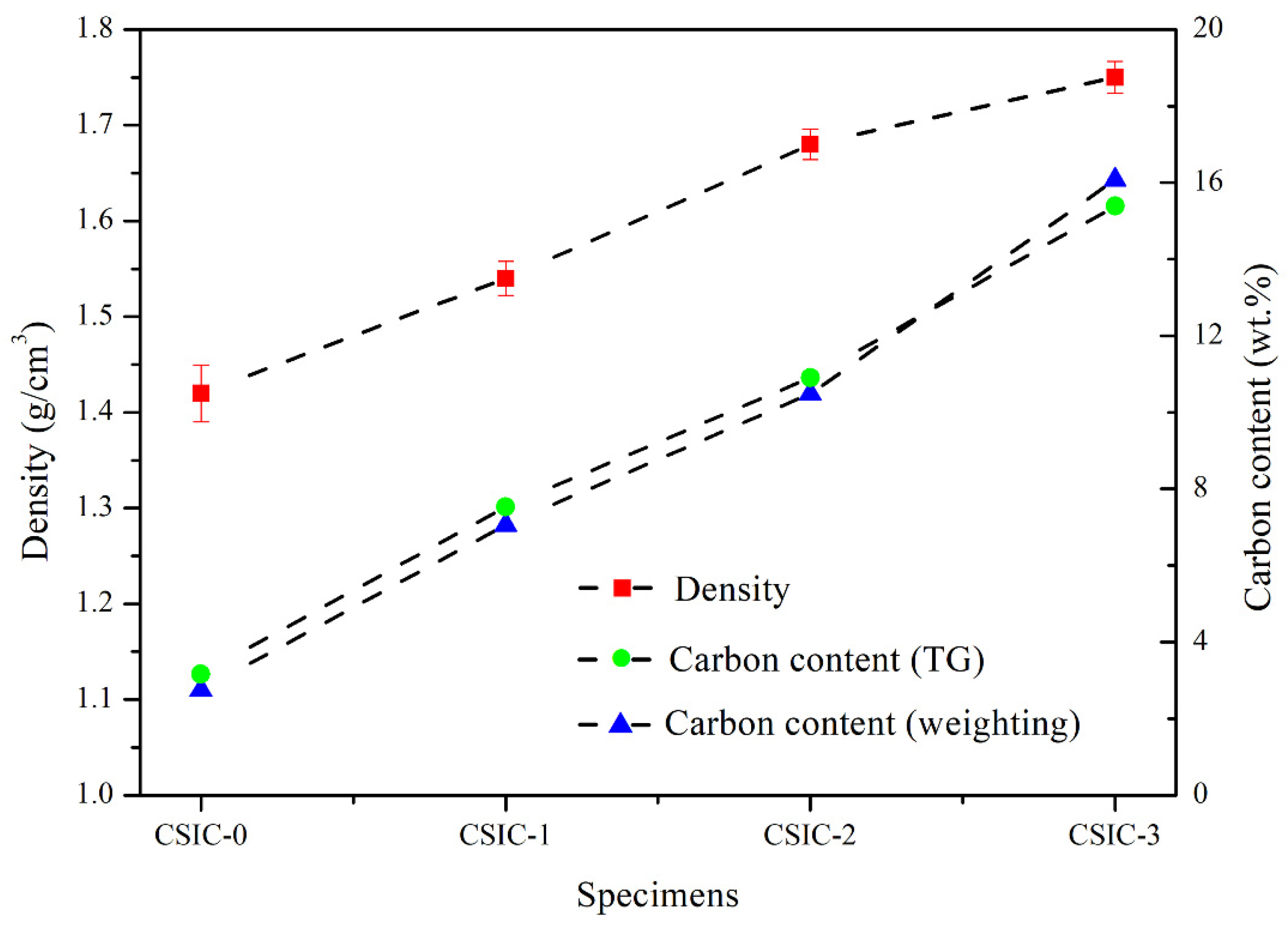

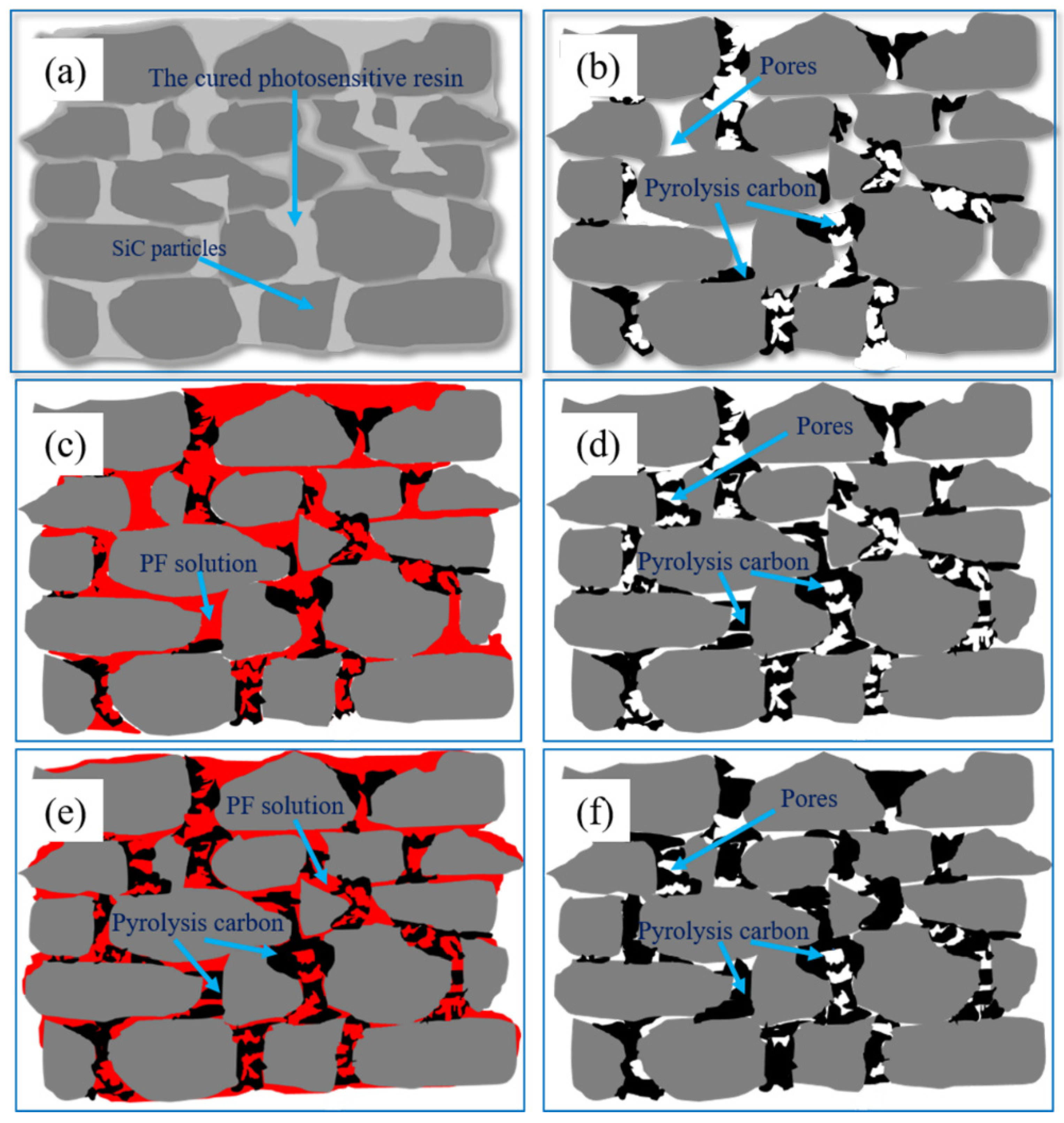

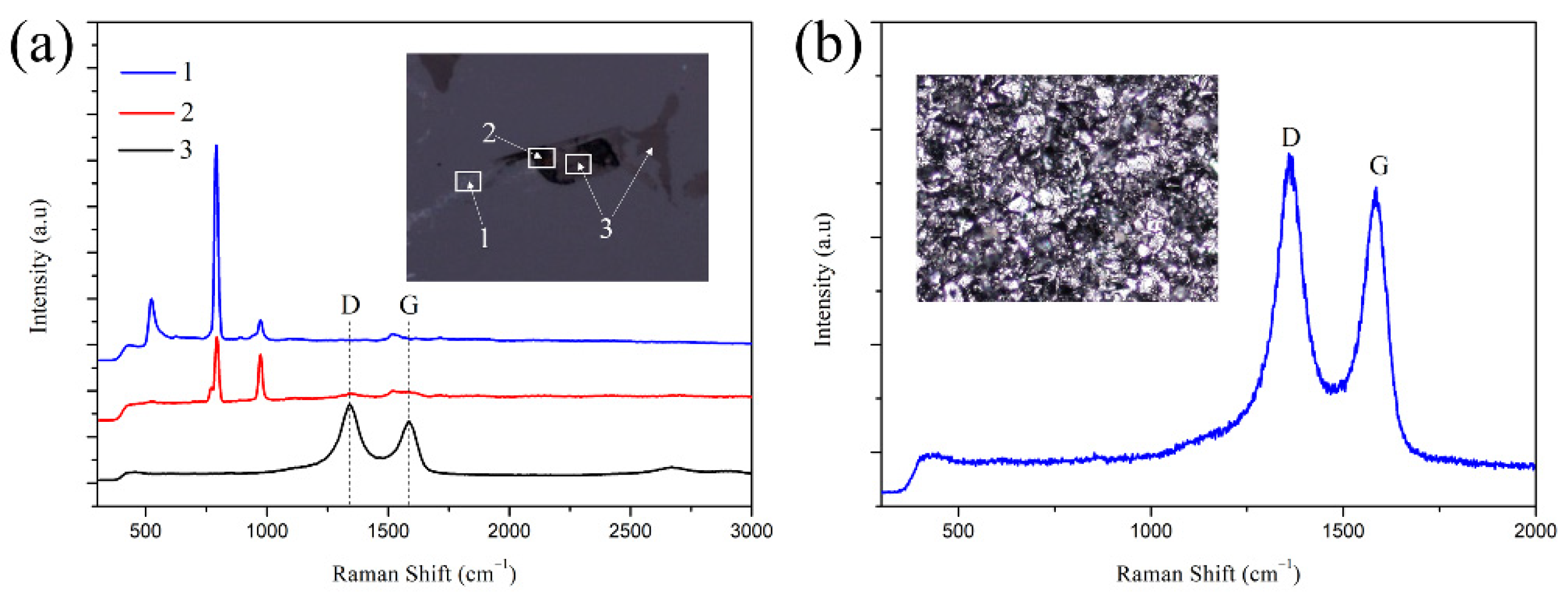

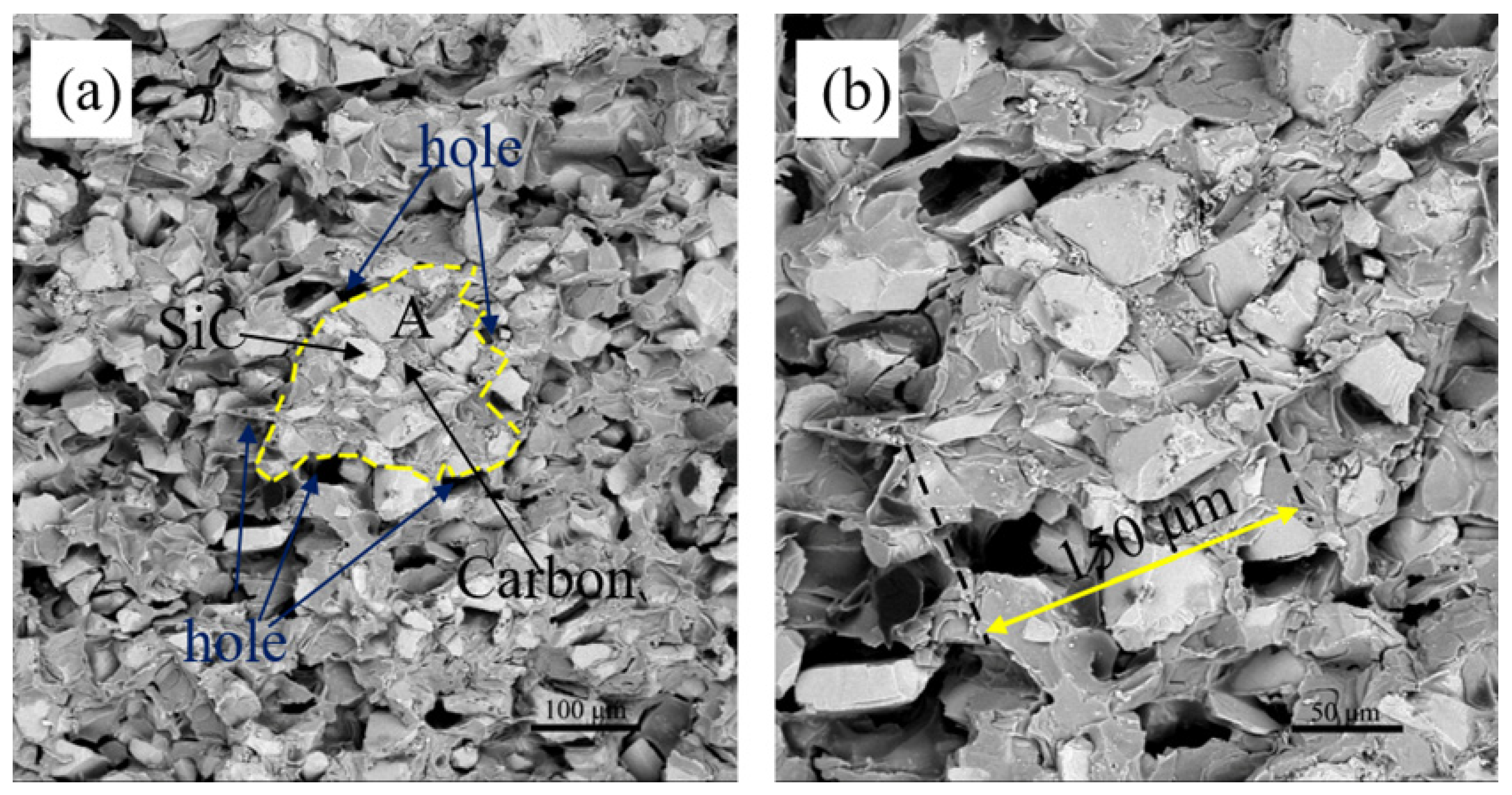

3.1. Characterization of C/SiC Preform

3.2. Characterization of RB-SiC

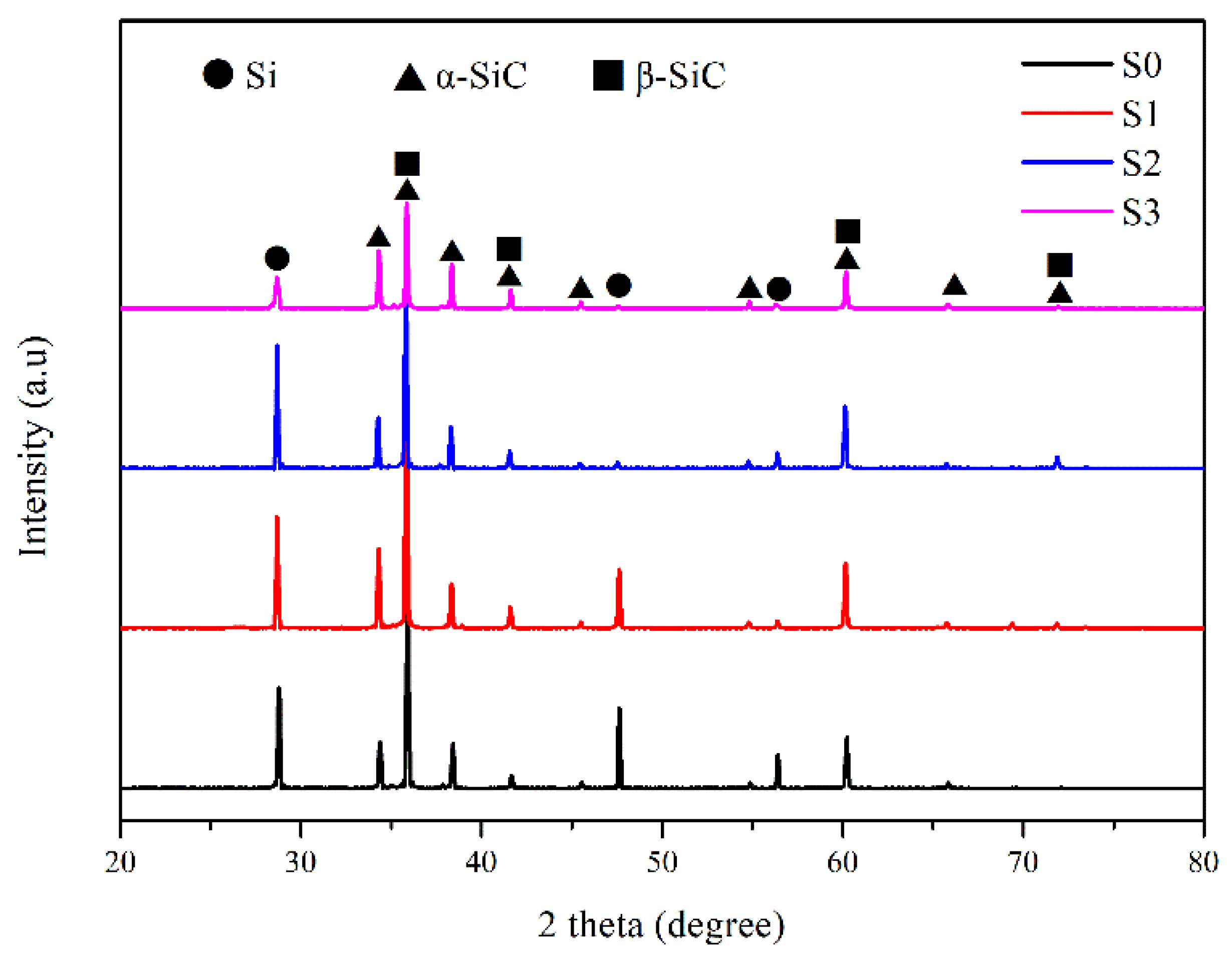

3.2.1. Compositional Characteristics of RB-SiC Ceramics

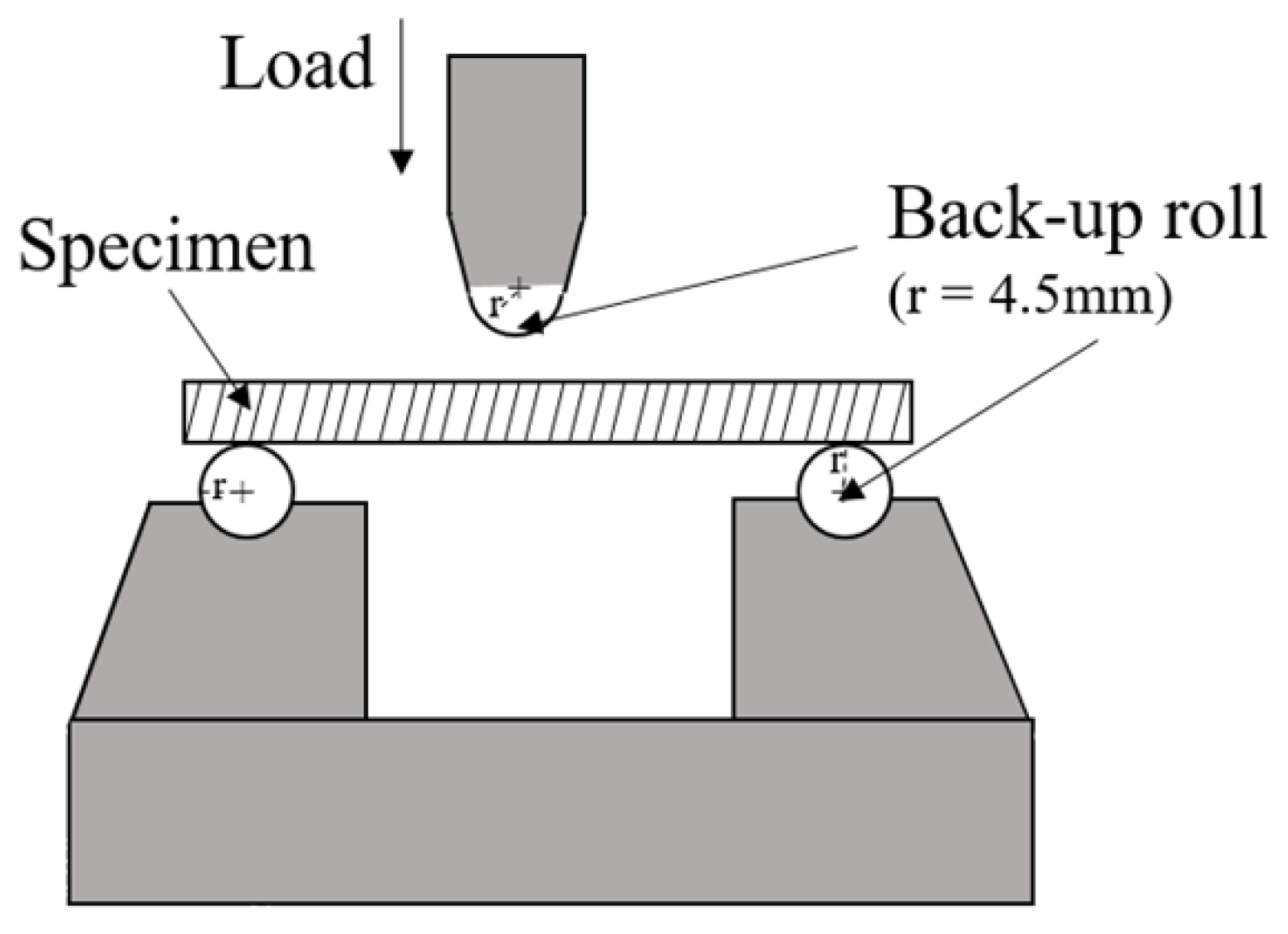

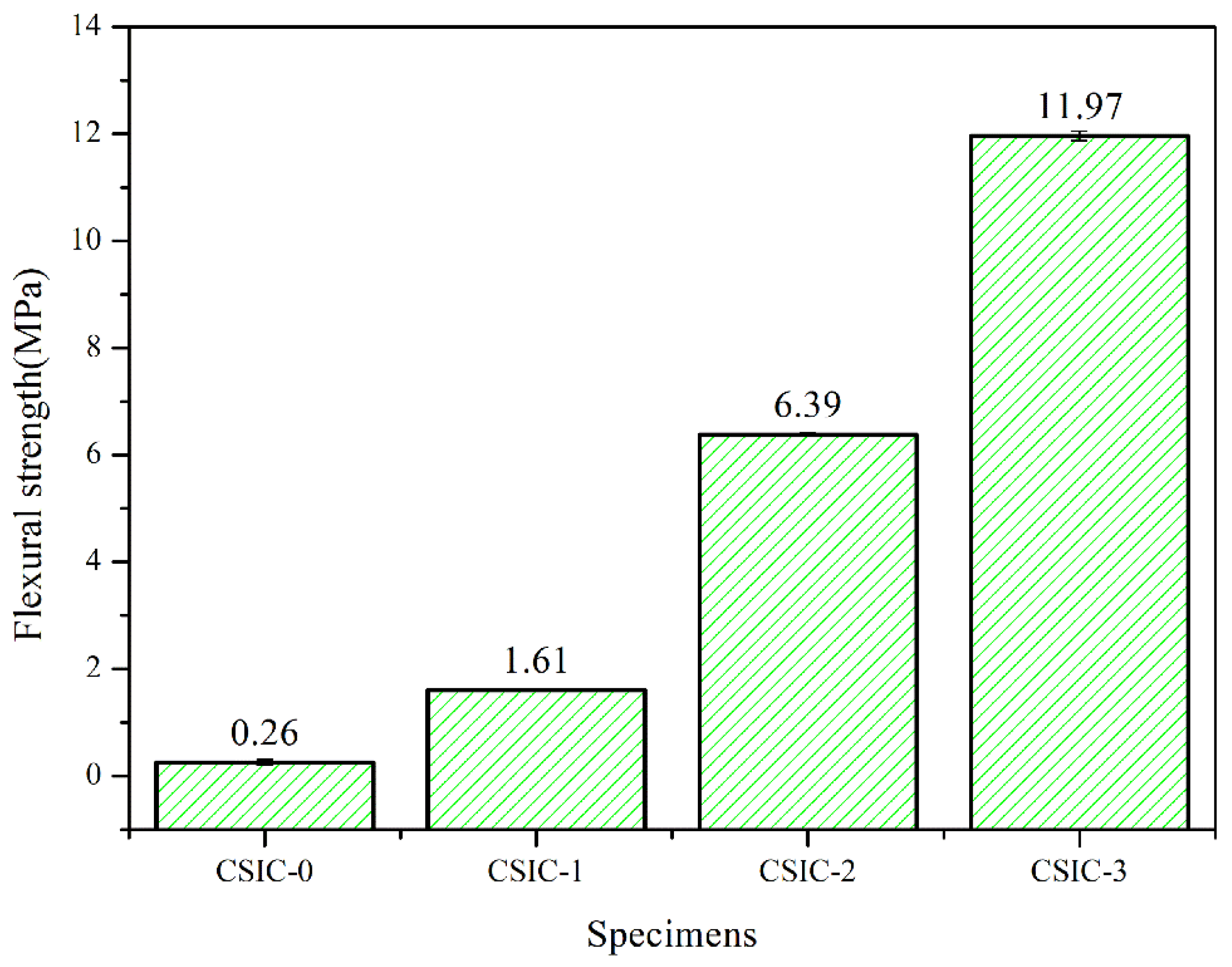

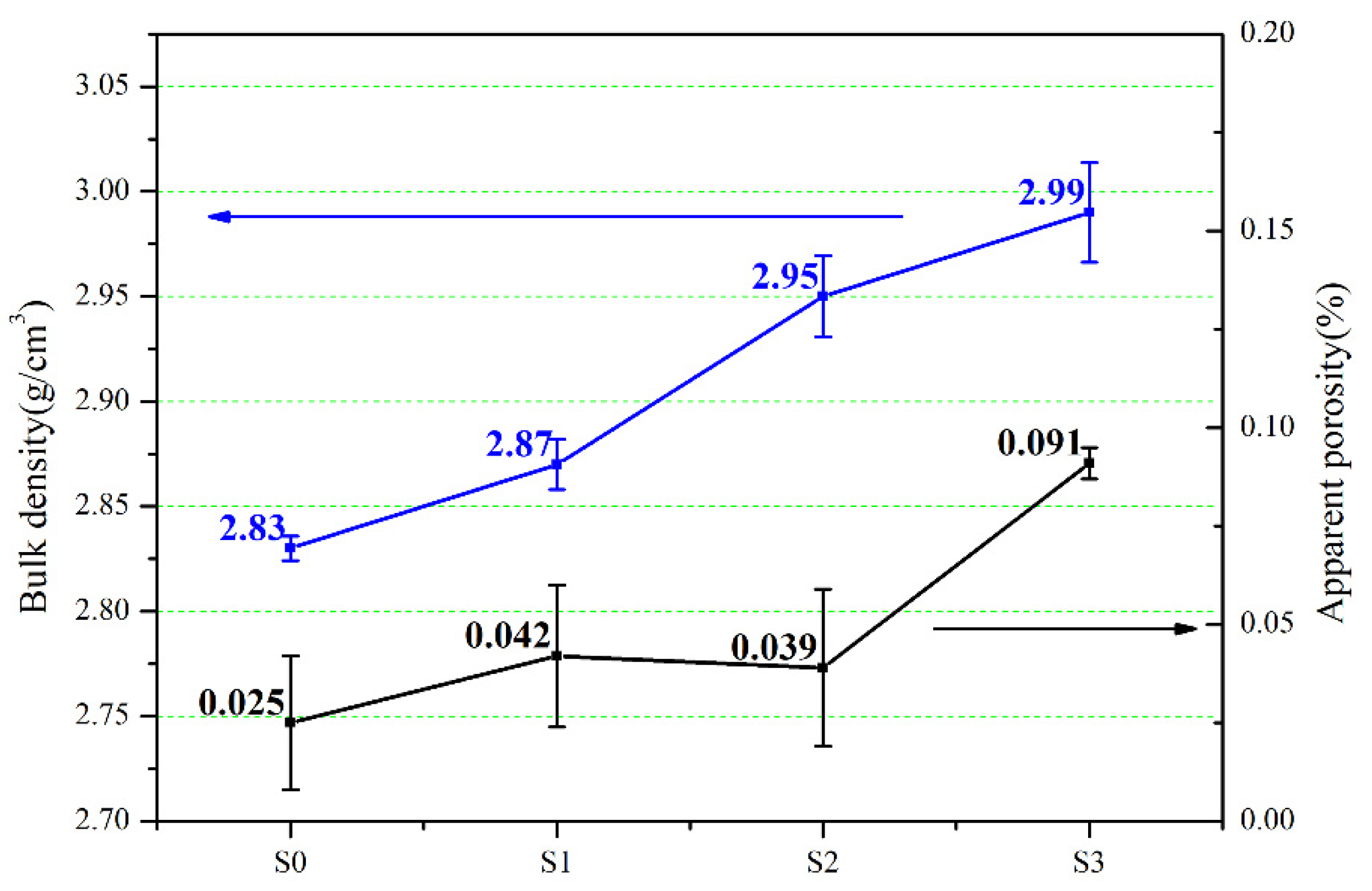

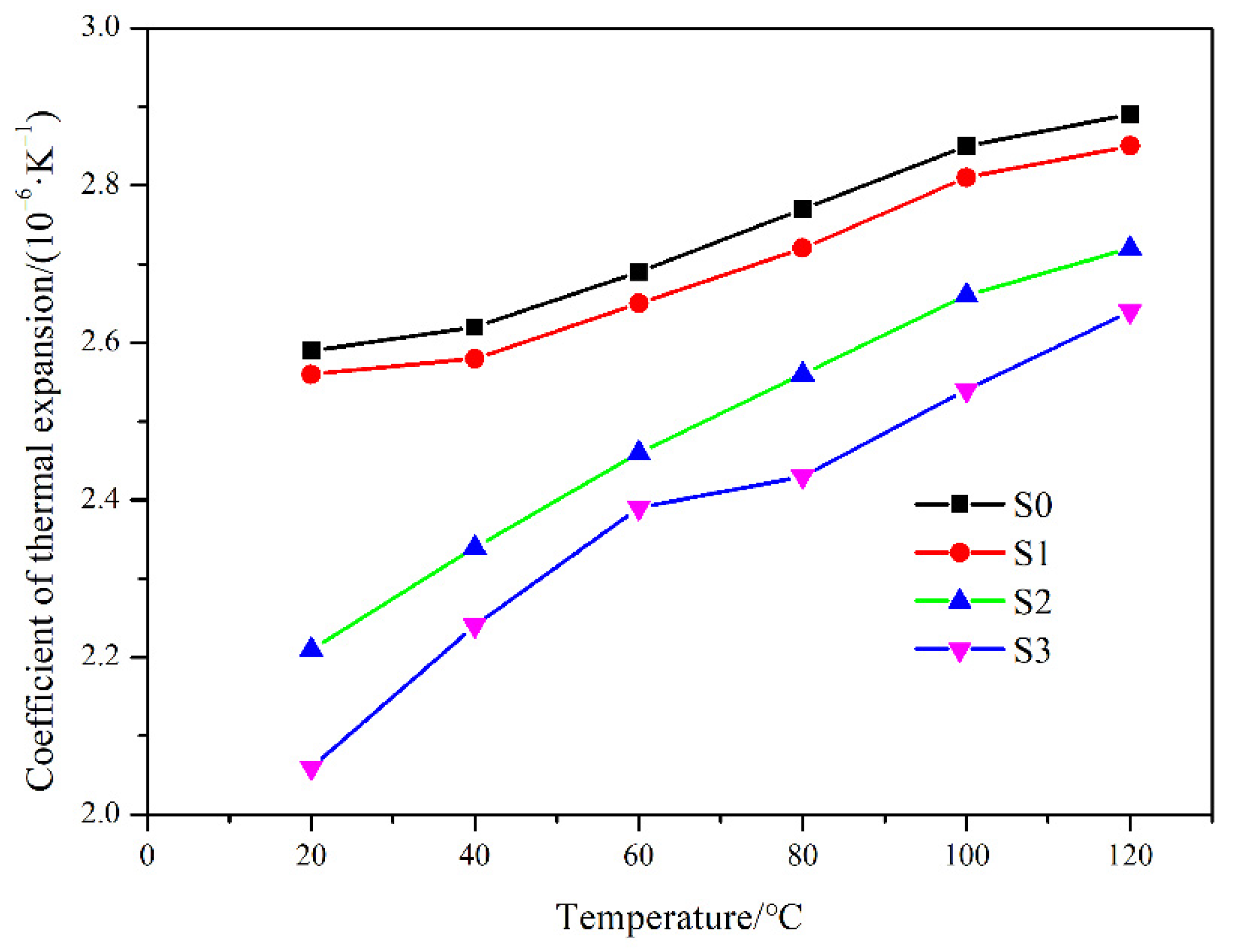

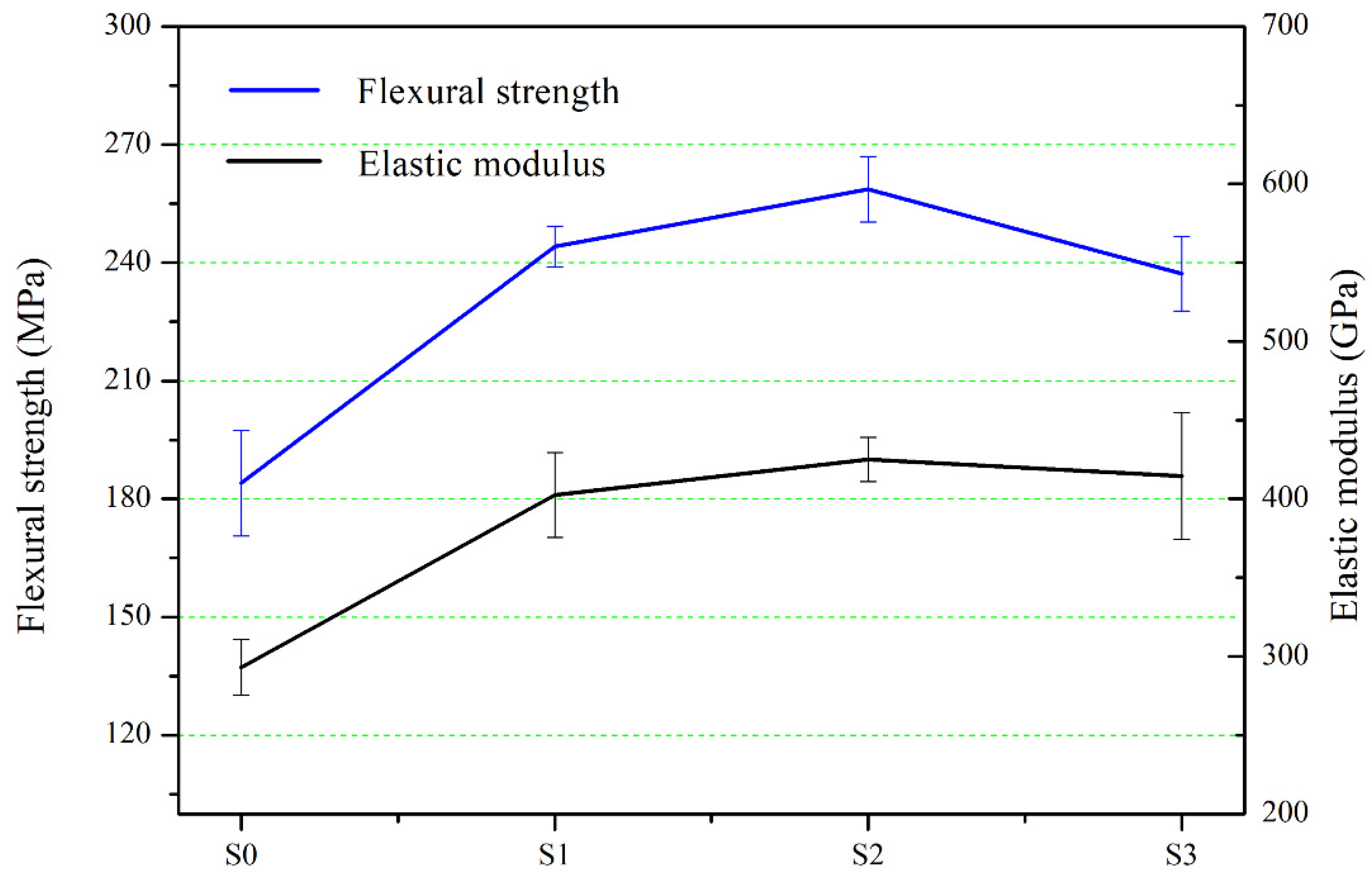

3.2.2. Comprehensive Performance of RB-SiC Ceramics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ding, G.J.; He, R.J.; Zhang, K.Q.; Zhou, N.P.; Xu, H. Stereolithography 3D printing of SiC ceramic with potential for lightweight optical mirror. Ceram. Int. 2020, 46, 18785–18790. [Google Scholar] [CrossRef]

- Das, J.; Patel, P.; Reddy, J.J.; Prasad, V.V. Microstructure and mechanical properties of a SiC containing advanced structural ceramics. Int. J. Refract. Met. Hard Mater. 2019, 84, 105030. [Google Scholar] [CrossRef]

- Fu, Z.; Schlier, L.; Travitzky, N.; Greil, P. Three-dimensional printing of SiSiC lattice truss structures. Mater. Sci. Eng. A 2013, 560, 851–856. [Google Scholar] [CrossRef]

- Li, Y.; Lin, J.; Gao, J.Q.; Qiao, G.J.; Wang, H.J. Fabrication of reaction-bonded SiC ceramics by slip casting of SiC/C suspension. Mater. Sci. Eng. A 2008, 483–484, 676–678. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Yuan, Z.Y.; Zhou, Y.F. Gelcasting of silicon carbide ceramics using phenolic resin and furfuryl alcohol as the gel former. Ceram. Int. 2014, 40, 7873–7878. [Google Scholar] [CrossRef]

- Rasaki, S.A.; Xiong, D.Y.; Xiong, S.F.; Su, F.; Idrees, M.; Chen, Z.W. Photopolymerization-based additive manufacturing of ceramics: A systematic review. J. Adv. Ceram. 2021, 10, 442–471. [Google Scholar] [CrossRef]

- Oh, J.W.; Park, J.; Nahm, S.; Choi, H. SiC-Si composite part fabrication via SiC powder binder jetting additive manufacturing and molten-Si infiltration. Int. J. Refract. Met. Hard Mater. 2021, 101, 105686. [Google Scholar] [CrossRef]

- Larson, C.M.; Choi, J.J.; Gallardo, P.A.; Henderson, S.W.; Niemack, M.D.; Rajagopalan, G.; Shepherd, R.F. Direct Ink Writing of Silicon Carbide for Microwave Optics. Adv. Eng. Mater. 2015, 18, 39–45. [Google Scholar] [CrossRef]

- Xing, H.Y.; Zou, B.; Wang, X.F.; Hu, Y.F.; Huang, C.Z.; Xue, K. Fabrication and characterization of SiC whiskers toughened Al2O3 paste for stereolithography 3D printing applications. J. Alloy. Compd. 2020, 828, 154347. [Google Scholar] [CrossRef]

- Tian, X.Y.; Zhang, W.G.; Li, D.C.; Heinrich, J.G. Reaction-bonded SiC derived from resin precursors by Stereolithography. Ceram. Int. 2012, 38, 589–597. [Google Scholar] [CrossRef]

- Zhang, K.Q.; Meng, Q.Y.; Zhang, X.Q.; Qu, Z.L.; Jing, S.K.; He, R.J. Roles of solid loading in stereolithography additive manufacturing of ZrO2 ceramic. Int. J. Refract. Met. Hard Mater. 2021, 99, 105604. [Google Scholar] [CrossRef]

- Bai, X.J.; Ding, G.J.; Zhang, K.Q.; Wang, W.Q.; Zhou, N.P.; Fang, D.N.; He, R.J. Stereolithography additive manufacturing and sintering approaches of SiC ceramics. Open Ceram. 2021, 5, 100046. [Google Scholar] [CrossRef]

- Fitriani, P.; Yoon, D.H.; Sharma, A.S. Effects of post-sintering annealing on the microstructure and toughness of hot-pressed SiCf/SiC composites with Al2O3-Y2O3 additions. Ceram. Int. 2017, 43, 13330–13338. [Google Scholar] [CrossRef]

- Rui, M.Q.; Zhang, Y.X.; Ye, J. Environment-Friendly Preparation of Reaction-Bonded Silicon Carbide by Addition of Boron in the Silicon Melt. Materials 2021, 14, 1090. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Yang, Y.; Hu, K.H.; Liu, B.; Liu, M.; Huang, Z.R. Stereolithography-based additive manufacturing of lightweight and high-strength Cf/SiC ceramics. Addit. Manuf. 2020, 34, 101199. [Google Scholar] [CrossRef]

- Grinchuk, P.S.; Kiyashko, M.V.; Abuhimd, H.M.; Alshahrani, M.S.; Solovei, D.V.; Stepkin, M.O.; Akulich, A.V.; Shashkov, M.D.; Kuznetsova, T.A.; Danilovatretiak, S.M.; et al. Advanced technology for fabrication of reaction-bonded SiC with controlled composition and properties. J. Eur. Ceram. Soc. 2021, 41, 5813–5824. [Google Scholar] [CrossRef]

- Xu, S.J.; Qiao, G.J.; Li, D.C.; Yang, H.; Liu, Y.N.; Lu, T.J. Reaction forming of silicon carbide ceramic using phenolic resin derived porous carbon preform. J. Eur. Ceram. Soc. 2009, 29, 2395–2402. [Google Scholar] [CrossRef]

- Kheyrinia, L.; Baharvandi, H.R.; Ehsani, N.; Yaghobizadeh, O. Fabrication of SiC bodies by optimized gel-casting method. Int. J. Refract. Met. Hard Mater. 2019, 81, 225–232. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.S.; Liu, Y.S.; Zeng, Q.F.; Hu, K.H.; Lu, Z.G.; Liang, J.J. Effect of debinding temperature under an argon atmosphere on the microstructure and properties of 3D-printed alumina ceramics. Mater. Charact. 2020, 168, 110548. [Google Scholar] [CrossRef]

- Cao, S.; Xie, F.X.; He, X.M.; Zhang, C.F.; Wu, M.P. Postprocessing Study for the Controllable Structures of Ceramic Green Parts Realized by a Flexible Binder Jetting Printing (BJP) Solution. Adv. Mater. Sci. Eng. 2020, 2020, 3865752. [Google Scholar] [CrossRef] [Green Version]

- Calderon, N.R.; Martínez-Escandell, M.; Narciso, J.; Rodríguez-Reinoso, F. The combined effect of porosity and reactivity of the carbon preforms on the properties of SiC produced by reactive infiltration with liquid Si. Carbon 2009, 47, 2200–2210. [Google Scholar] [CrossRef]

- Yao, W.; Zhang, Y.M.; Han, J.C.; Zuo, H.B. Fabrication and test of reaction bond silicon carbide for optical applications. Trans. Nonferrous Met. Soc. China 2006, 16, 409–413. [Google Scholar] [CrossRef]

- Song, S.C.; Lu, B.H.; Gao, Z.Q.; Bao, C.G.; Ma, Y. Microstructural development and factors affecting the performance of a reaction-bonded silicon carbide composite. Ceram. Int. 2019, 45, 17987–17995. [Google Scholar] [CrossRef]

- Izhevskyi, V.A.; Genova, L.A.; Bressiani, A.H.A.; Bressiani, J.C. Microstructure and properties tailoring of liquid-phase sintered SiC. Int. J. Refract. Met. Hard Mater. 2001, 19, 409–417. [Google Scholar] [CrossRef]

- Lodhe, M.; Chawake, N.; Yadav, D.; Balasubramanian, M. On correlation between β→α transformation and densification mechanisms in SiC during spark plasma sintering. Scr. Mater. 2016, 115, 137–140. [Google Scholar] [CrossRef]

- Aguiar, H.; Chiussi, S.; López-Álvarez, M.; González, P.; Serra, J. Structural characterization of bioceramics and mineralized tissues based on Raman and XRD techniques. Ceram. Int. 2018, 44, 495–504. [Google Scholar] [CrossRef]

- Padovano, E.; Giorcelli, M.; Bianchi, G.; Biamino, S.; Rovere, M.; Tagliaferro, A.; Ortona, A. Graphite-Si-SiC ceramics produced by microwave assisted reactive melt infiltration. J. Eur. Ceram. Soc. 2019, 39, 2232–2243. [Google Scholar] [CrossRef]

- Wang, Q.; Allred, D.D.; Herna´ndez, J.G. Low-frequency feature in the first-order Raman spectrum of amorphous carbon. Phys. Rev. B 1993, 47, 6119–6121. [Google Scholar] [CrossRef] [Green Version]

- Inam, A.; Brydson, R.; Edmonds, D.V. Raman spectroscopy study of the crystallinity of graphite formed in an experimental free-machining steel. Mater. Charact. 2020, 163, 110264. [Google Scholar] [CrossRef]

- Fu, H.; Zhu, W.; Xu, Z.F.; Chen, P.; Yan, C.Z.; Zhou, K.; Shi, Y.S. Effect of silicon addition on the microstructure, mechanical and thermal properties of Cf/SiC composite prepared via selective laser sintering. J. Alloy. Compd. 2019, 792, 1045–1053. [Google Scholar] [CrossRef]

- Margiotta, J.C.; Zhang, D.J.; Nagle, D.C. Microstructural evolution during silicon carbide (SiC) formation by liquid silicon infiltration using optical microscopy. Int. J. Refract. Met. Hard Mater. 2010, 28, 191–197. [Google Scholar] [CrossRef]

- Hon, M.H.; Davis, R.F.; Newbury, D.E. Self-diffusion of 30Si in polycrystalline β-SiC. J. Mater. Sci. 1980, 15, 2073–2080. [Google Scholar] [CrossRef]

- Greil, P.; Lifka, T.; Kaindl, A. Biomorphic Cellular Silicon Carbide Ceramics from Wood: I. Processing and Microstructure. J. Eur. Ceram. Soc. 1998, 18, 1961–1973. [Google Scholar] [CrossRef]

- Michaux, A.; Sauder, C.; Camus, G.; Pailler, R. Young’s modulus, thermal expansion coefficient and fracture behavior of selected Si–B–C based carbides in the 20–1200 °C temperature range as derived from the behavior of carbon fiber reinforced microcomposites. J. Eur. Ceram. Soc. 2007, 27, 3551–3560. [Google Scholar] [CrossRef]

- Watanabe, H.; Yamada, N.; Okaji, M. Linear Thermal Expansion Coefficient of Silicon from 293 to 1000 K. Int. J. Thermophys. 2004, 25, 221–236. [Google Scholar] [CrossRef]

- Marshall, A.L.; Chhillar, P.; Karandikar, P.; Cormick, A.M.; Aghajanian, M.K. The Effects of Si Content and SiC Polytype on the Microstructure and Properties of RBSC. In Mechanical Properties and Processing of Ceramic Binary, Ternary, and Composite Systems: Ceramic Engineering and Science Proceedings; Salem, J., Hilmas, G., Fahrenholtz, W., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2009; Volume 29, pp. 115–126. [Google Scholar] [CrossRef]

- White, J.F.; Ma, L.Y.; Forwald, K.; Du, S.C. Reactions Between Silicon and Graphite Substrates at High Temperature: In Situ Observations. Metall. Mater. Trans. B 2014, 45, 150–160. [Google Scholar] [CrossRef]

- Li, Y.S.; Yin, J.; Wu, H.B.; Lu, P.; Yan, Y.J.; Liu, X.J.; Huang, Z.R.; Jiang, D.L. High thermal conductivity in pressureless densified SiC ceramics with ultra-low contents of additives derived from novel boron–carbon sources. J. Eur. Ceram. Soc. 2014, 34, 2591–2595. [Google Scholar] [CrossRef]

- Du, P.H.; Zhou, J. Thermal property and lattice thermal conductivity of three-dimensional pentagonal silicon. Phys. B Condens. Matter 2021, 618, 413178. [Google Scholar] [CrossRef]

- Feng, D.; Ren, Q.X.; Ru, H.Q.; Wang, W.; Ren, S.Y.; Zhang, C.P. Mechanical properties and microstructure evolution of SiC ceramics prepared from the purified powders. Mater. Sci. Eng. A 2021, 802, 140443. [Google Scholar] [CrossRef]

- Chakrabarti, O.P.; Ghosh, S.; Mukerji, J. Influence of grain size, free silicon content and temperature on the strength and toughness of reaction-bonded silicon carbide. Ceram. Int. 1994, 20, 283–286. [Google Scholar] [CrossRef]

- Grinchuk, P.S.; Kiyashko, M.V.; Abuhimd, H.M.; Alshahrani, M.S.; Stepkin, M.O.; Toropov, V.V.; Khort, A.A.; Solovei, D.V.; Akulich, A.V.; Shashakov, M.D.; et al. Effect of technological parameters on densification of reaction bonded Si/SiC ceramics. J. Eur. Ceram. Soc. 2018, 38, 4815–4823. [Google Scholar] [CrossRef]

- Huang, L.M.; Liu, R.J.; Wang, Y.F.; Zhang, C.R.; Long, X.H. Fabrication and properties of dense silicon carbide ceramic via gel-casting and gas silicon infiltration. Ceram. Int. 2016, 42, 18547–18553. [Google Scholar] [CrossRef] [Green Version]

| Specimens | Band | Max Intensity (a.u) | Wave Number (cm−1) |

|---|---|---|---|

| S3 | D | 17,779 | 1341.98 |

| G | 13,823 | 1582.80 | |

| Pyrolytic carbon | D | 3778 | 1358.52 |

| G | 3465 | 1585.35 |

| Reference | [10] | [12] | [15] | [17] | This work |

| 3D printing | SLA | SLA | SLA | SLA | SLA |

| Main raw materials of 3D printing | PF + PR + SiC | PR + SiC | Cf + PR + SiC * | PF + PR | PR + SiC |

| After debinding | C/SiC | C/SiC | C/Cf/SiC | Porous carbon preforms | C/SiC |

| Other process | No | No | No | No | Cyclic impregnation/carbonization of PF solution in C/SiC preform |

| Sintering process | LSI | LSI | LSI | LSI | LSI |

| Final body | Si/SiC | Si/SiC | Si/SiC | Si/SiC | Si/SiC |

| Flexural strength | 127.80 | 210.40 | 262.60 | 239.00 | 258.63 |

| Fabrication Process | Flexural Strength/MPa | Elastic Modulus (E)/GPa | Density(ρ)/(g/cm3) | Specific Stability/(E/ρ) | Reference |

|---|---|---|---|---|---|

| Preferred Value | Large | Large | Small | Large | |

| Gelcasting + LSI | 300 ± 20 | —— | 3.04 | —— | [5] |

| Powder injection molding + LSI | 225 | 427 | 3.14 ± 0.02 | 135.99 | [16] |

| Powder injection molding + LSI | —— | 318.7 | 3.04 ± 0.01 | 104.84 | [42] |

| Slip casting + LSI | 274 ± 15 | —— | 3.01 | —— | [4] |

| Gelcasting + gas silicon infiltration | 245 | 220 | —— | —— | [43] |

| SLA + LSI | 258.63 ± 8.33 | 425.16 ± 14.15 | 2.95 ± 0.02 | 144.12 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Guo, C.; Cui, C.; Bao, J.; Zhang, G.; Zhang, Y.; Li, S.; Wang, G. Microstructure Evolution and Performance Improvement of Silicon Carbide Ceramics via Impregnation Method. Materials 2022, 15, 1717. https://doi.org/10.3390/ma15051717

Li W, Guo C, Cui C, Bao J, Zhang G, Zhang Y, Li S, Wang G. Microstructure Evolution and Performance Improvement of Silicon Carbide Ceramics via Impregnation Method. Materials. 2022; 15(5):1717. https://doi.org/10.3390/ma15051717

Chicago/Turabian StyleLi, Wei, Conghui Guo, Congcong Cui, Jianxun Bao, Ge Zhang, Yubei Zhang, Shan Li, and Gong Wang. 2022. "Microstructure Evolution and Performance Improvement of Silicon Carbide Ceramics via Impregnation Method" Materials 15, no. 5: 1717. https://doi.org/10.3390/ma15051717

APA StyleLi, W., Guo, C., Cui, C., Bao, J., Zhang, G., Zhang, Y., Li, S., & Wang, G. (2022). Microstructure Evolution and Performance Improvement of Silicon Carbide Ceramics via Impregnation Method. Materials, 15(5), 1717. https://doi.org/10.3390/ma15051717