Compressive Strength Assessment of Soil–Cement Blocks Incorporated with Waste Tire Steel Fiber

Abstract

:1. Introduction

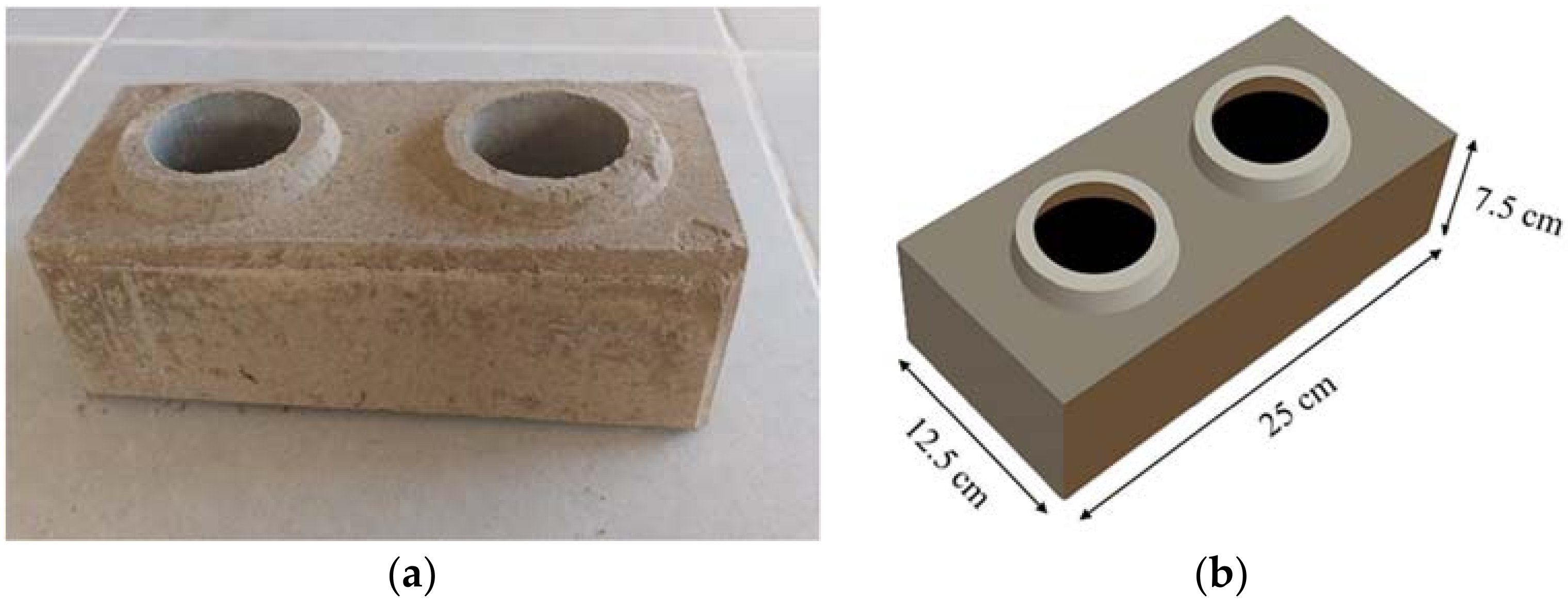

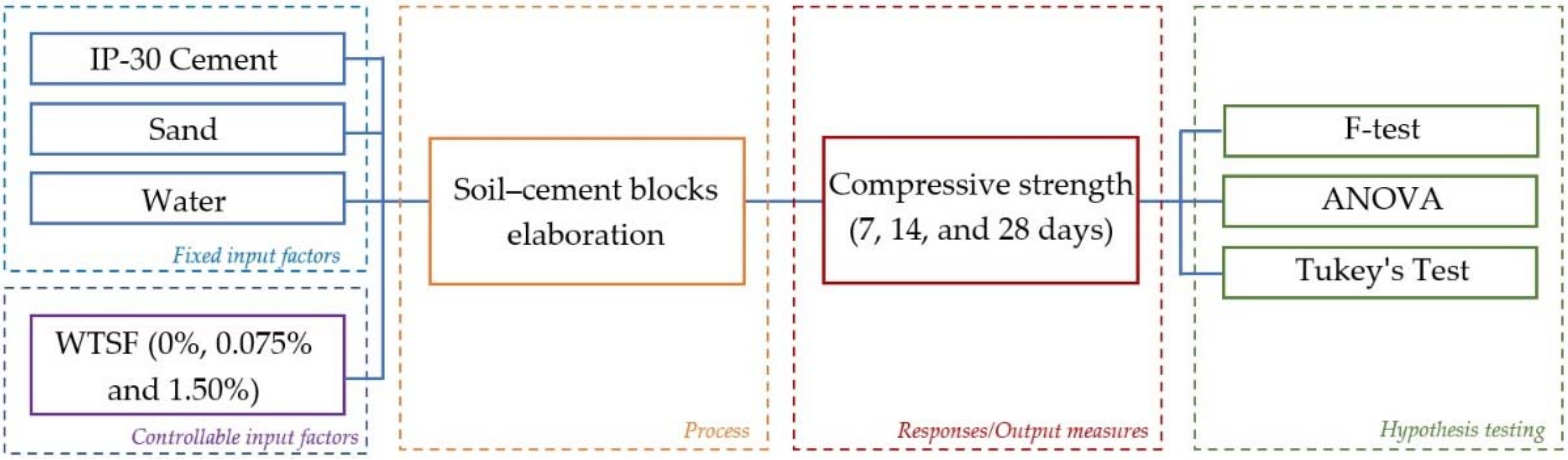

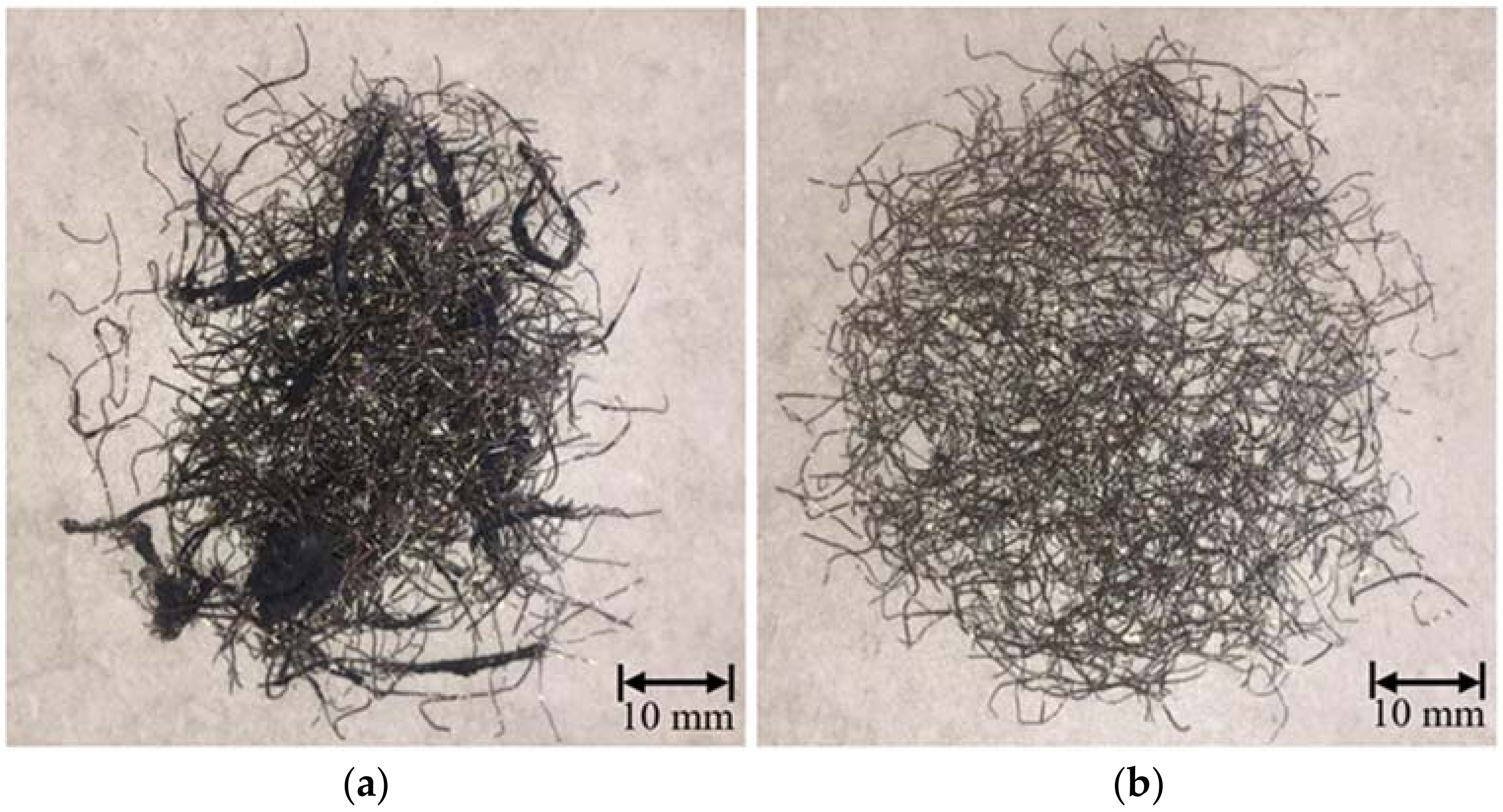

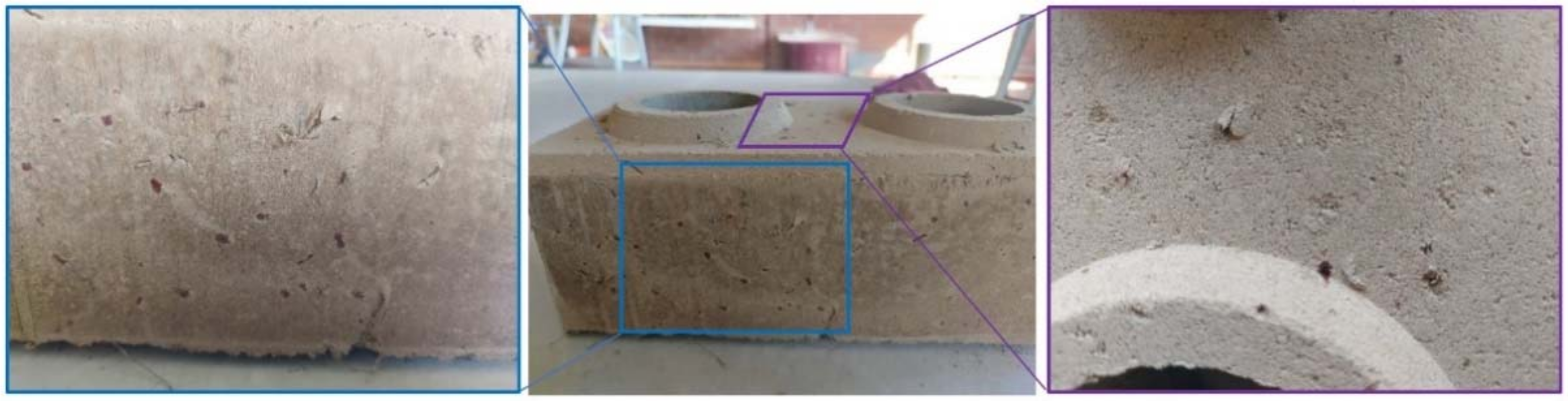

2. Materials and Methods

3. Results and Discussion

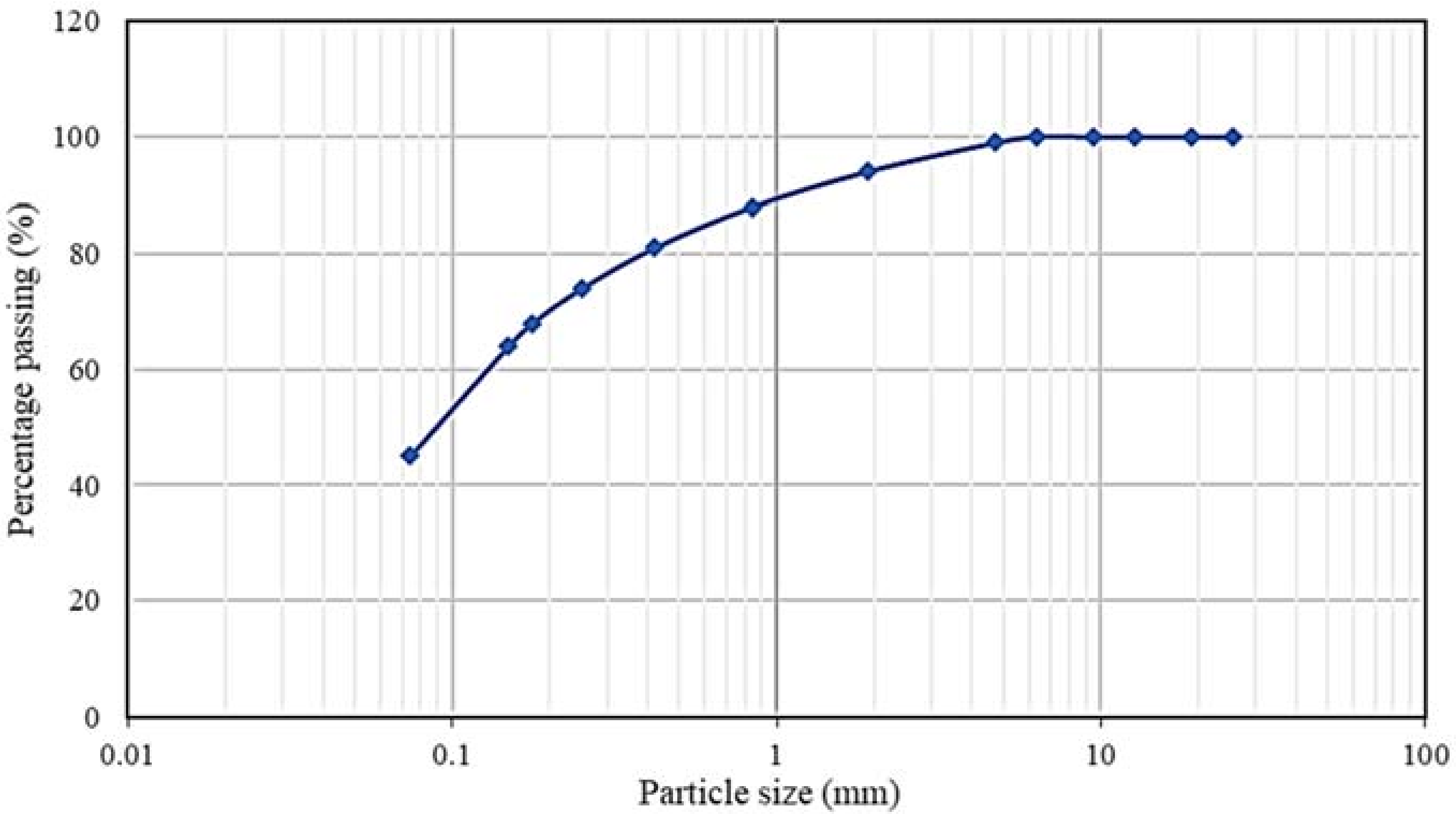

3.1. Soil Properties

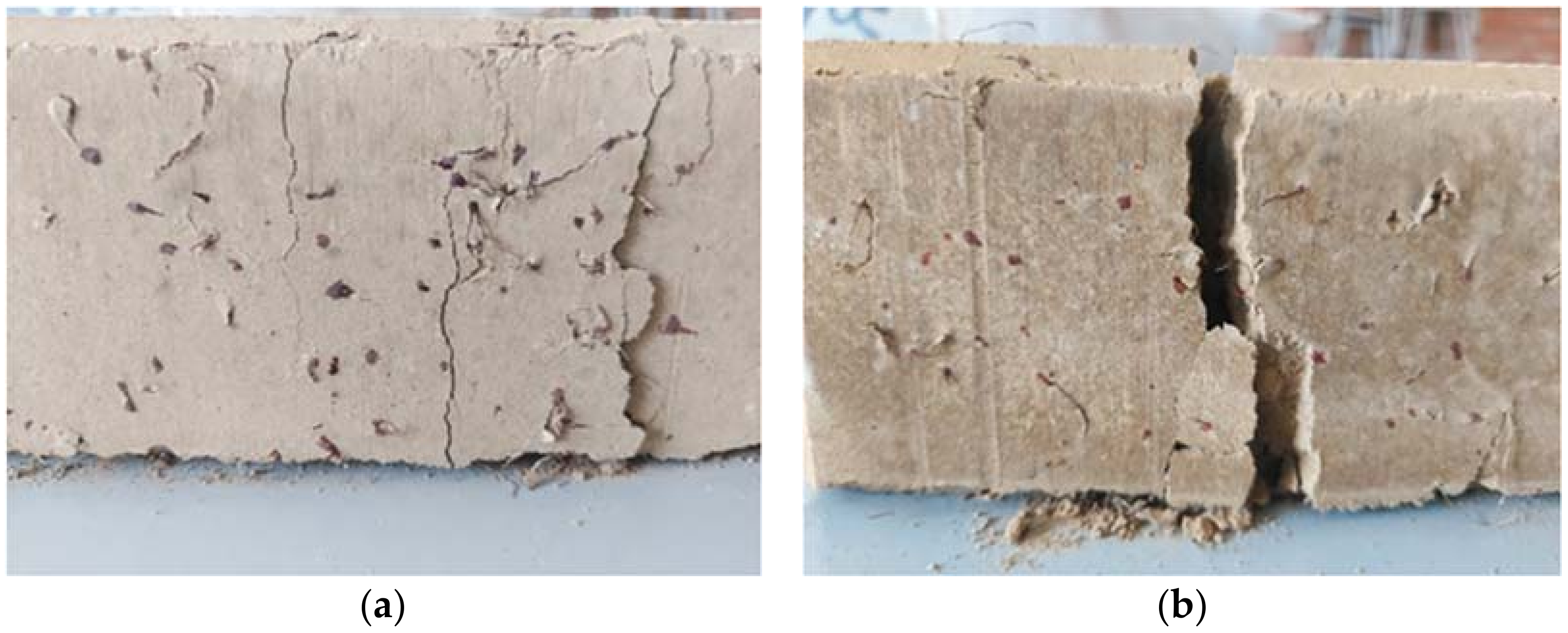

3.2. Compressive Strength

4. Conclusions

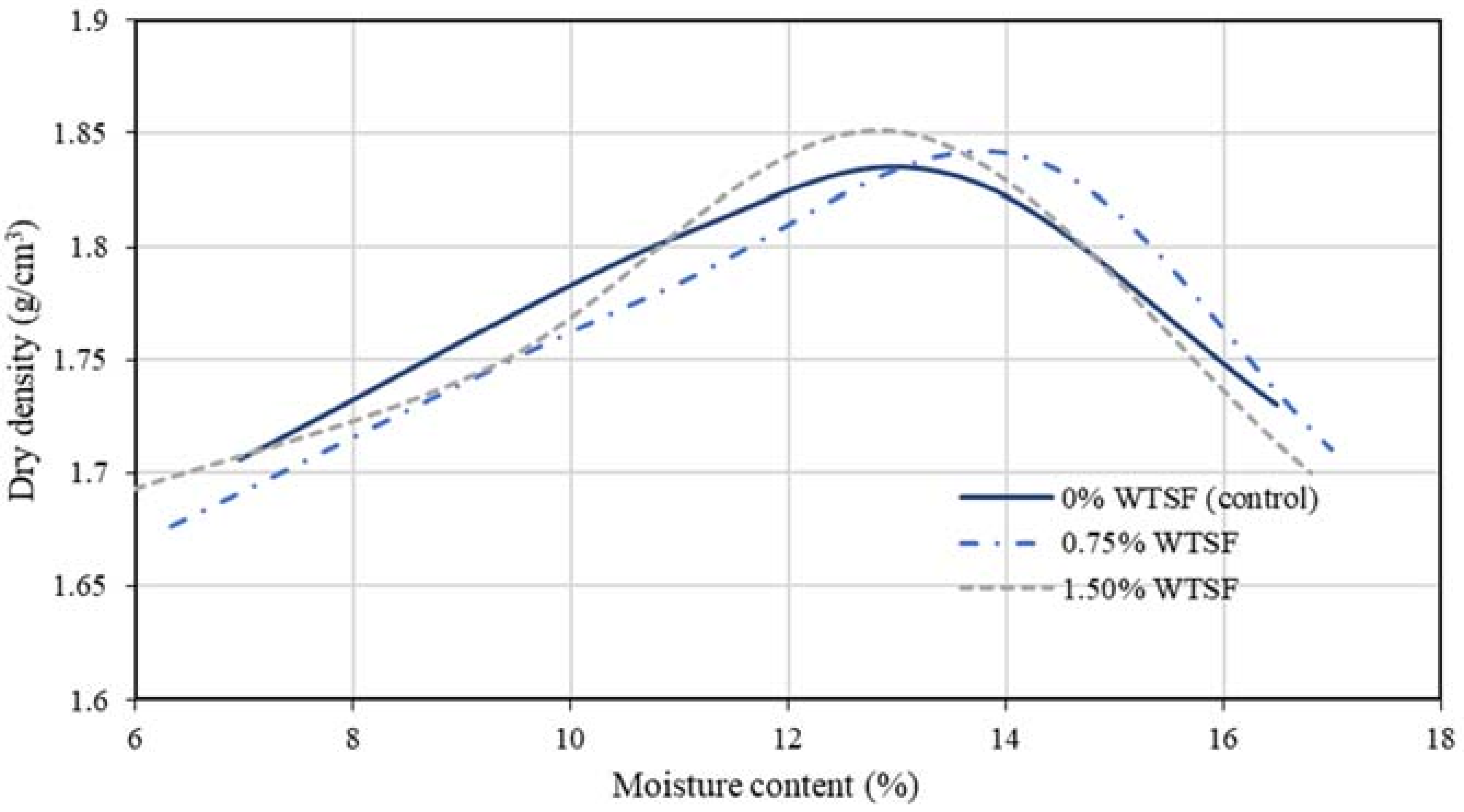

- The Proctor test on the samples revealed that the amount of WTSF does not influence optimal humidity content in the specimens. However, block samples with WTSF showed higher dry density.

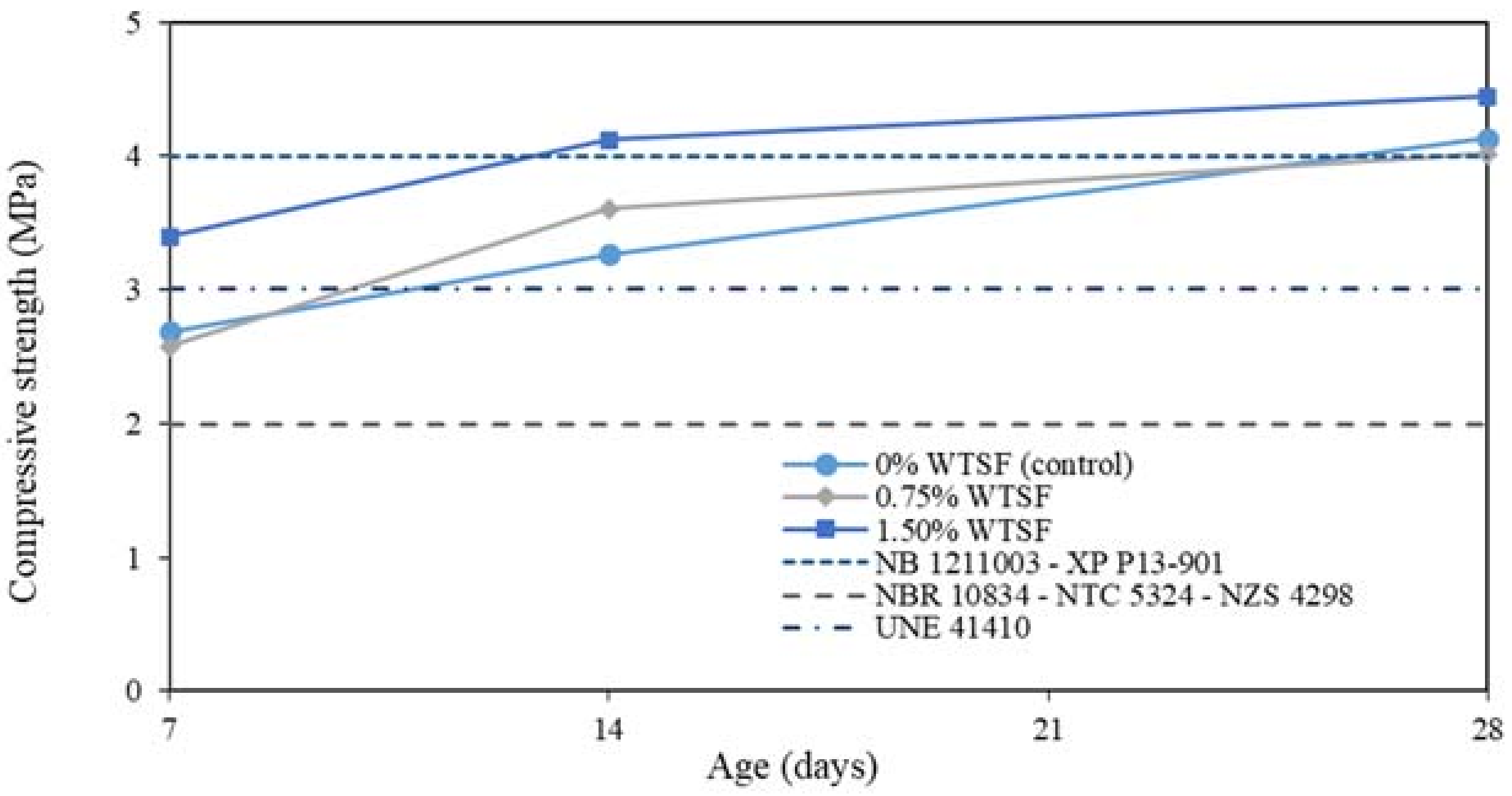

- The highest compressive strength was found for the 1.50% WTSF blocks. This latter can be extended to all the samples regarding the content of WTSF in their matrices.

- After seven days of curing, all block samples topped the minimum compressive strength requirement established in the ABNT standard [32]. Regarding the Bolivian specification for building materials [33], the blocks were classified as Category C, accomplishing the minimum strength of 4 MPa after 14 days of curing for 1.50% WTSF blocks and after 28 days for 0.75% WTSF samples. At the age of 28 days, all the soil–cement blocks beat the minimum compressive strength requirements, considering the standards of Colombia [34], Spain [35], France [36], and New Zealand [37].

- An ANOVA analysis supported by the Tukey’s test on the compressive resistance’s results revealed that the growth in strength for soil–cement blocks tested occurred after seven days of curing and for 1.50 % WTSF blocks only. Thus, adding higher percentages of recycled steel fibers to the blocks may positively impact their compressive strength.

- The current study was exploratory, only considering the compressive strength assessment; the main mechanical property required by the regulations for its use in construction. Therefore, subsequent research is needed to consider other mechanical properties, such as tensile strength, flexural strength, durability, plastic energy absorption, large deformation resist, and others to consolidate the soil–cement WTSF blocks usage in building construction.

- The compressive strength results are favorable for 1.5% of WTSF, reaching the minimum category for construction with ease, especially for walls with nonstructural function. Thus, soil–cement blocks with WTSF are presented as a sustainable option in developing countries due to the reuse of waste and to help reduce the housing deficit.

- The current study was limited to three mixing groups, which does not provide a deep understanding of the influence of WTSF on the compressive strength of soil–cement blocks. Future lines of research may consider higher amounts of WTSF to find an optimal percentage addition to obtain advantageous physical and mechanical properties. Additionally, WTSF with rubber can be considered for further studies since this waste is obtained directly from the recycling companies. Hence, waste tire material selection could be avoided, saving time and providing greater practicality.

- Although this exploratory study accomplished the regulations regarding the minimum number of block samples to be tested by age, it is essential to explore larger samples to have more satisfactory results and have the possibility of a broader statistical analysis.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ACI Committee 544. State-of-the-Art Report on Fiber Reinforced Concrete; ACI Committee 544 Report 544.1R-96; American Concrete Institute: Detroit, MI, USA, 1996. [Google Scholar]

- Shi, X.; Brescia-Norambuena, L.; Tavares, C.; Grasley, Z. Semicircular bending fracture test to evaluate fracture properties and ductility of cement mortar reinforced by scrap tire recycled steel fiber. Eng. Fract. Mech. 2020, 236, 107228. [Google Scholar] [CrossRef]

- Achilleos, C.; Hadjimitsis, D.; Neocleous, K.; Pilakoutas, K.; Neophytou, P.O.; Kallis, S. Proportioning of steel fibre reinforced concrete mixes for pavement construction and their impact on environment and cost. Sustainability 2011, 3, 965–983. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Zhang, Z.; Shi, C.; Zhu, D.; Li, N.; Deng, Y. Development of ultra-high performance geopolymer concrete (UHPGC): Influence of steel fiber on mechanical properties. Cem. Concr. Compos. 2020, 112, 103670. [Google Scholar] [CrossRef]

- Awolusi, T.F.; Oke, O.L.; Akinkurolere, O.O.; Sojobi, A.O. Application of response surface methodology: Predicting and optimizing the properties of concrete containing steel fibre extracted from waste tires with limestone powder as filler. Case Stud. Constr. Mater. 2019, 10, e00212. [Google Scholar] [CrossRef]

- Awolusi, T.F.; Oke, O.L.; Atoyebi, O.D.; Akinkurolere, O.O.; Sojobi, A.O. Waste tires steel fiber in concrete: A review. Innov. Infrastruct. Solut. 2021, 6, 34. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C. A comprehensive review on the applications of waste tire rubber in cement concrete. Renew. Sustain. Energ. Rev. 2016, 54, 1323–1333. [Google Scholar] [CrossRef]

- United Nations. World Economic and Social Survey 2013: Sustainable Development Challenges; United Nations: New York, NY, USA, 2013.

- Pilakoutas, K.; Neocleous, K.; Tlemat, H. Reuse of tyre steel fibres as concrete reinforcement. Proc. Inst. Civ. Eng. Eng. Sustain. 2004, 157, 131–138. [Google Scholar] [CrossRef]

- World Business Council for Sustainable Development. Managing End-of-Life Tires; Atar Roto Presse SA: Satigny, Switzerland, 2008. [Google Scholar]

- US Tire Manufacturers Association. 2019 US Scrap Tire Management Summary. 2020. Available online: https://www.ustires.org/sites/default/files/2019%20USTMA%20Scrap%20Tire%20Management%20Summary%20Report.pdf (accessed on 30 December 2021).

- Cámara Boliviana de Hidrocarburos. En Bolivia 1.5 Millones de Llantas se Usan al Año. 2016. Available online: http://www.cbhe.org.bo/noticias/13225-en-bolivia-1-5-millones-de-llantas-se-usan-al-ano (accessed on 30 December 2021).

- Thomas, B.S.; Gupta, R.C.; Kalla, P.; Cseteneyi, L. Strength, abrasion and permeation characteristics of cement concrete containing discarded rubber fine aggregates. Constr. Build. Mater. 2014, 59, 204–212. [Google Scholar] [CrossRef]

- Gupta, T.; Sharma, R.K.; Chaudhary, S. Impact resistance of concrete containing waste rubber fiber and silica fume. Int. J. Impact Eng. 2015, 83, 76–87. [Google Scholar] [CrossRef]

- Shu, X.; Huang, B. Recycling of waste tire rubber in asphalt and portland cement concrete: An overview. Constr. Build. Mater. 2014, 67, 217–224. [Google Scholar] [CrossRef]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Bjegovic, D.; Baricevic, A.; Lakusic, S.; Damjanovic, D.; Duvnjak, I. Positive interaction of industrial and recycled steel fibres in fibre reinforced concrete. J. Civ. Eng. Manag. 2013, 19 (Suppl. S1), S50–S60. [Google Scholar] [CrossRef] [Green Version]

- Leone, M.; Centonze, G.; Colonna, D.; Micelli, F.; Aiello, M.A. Fiber-reinforced concrete with low content of recycled steel fiber: Shear behaviour. Constr. Build. Mater. 2018, 161, 141–155. [Google Scholar] [CrossRef]

- Al-Tikrite, A.; Hadi, M.N. Mechanical properties of reactive powder concrete containing industrial and waste steel fibres at different ratios under compression. Constr. Build. Mater. 2017, 154, 1024–1034. [Google Scholar] [CrossRef] [Green Version]

- Neocleous, K.; Tlemat, H.; Pilakoutas, K. Design issues for concrete reinforced with steel fibers, including fibers recovered from used tires. J. Mater. Civ. Eng. 2006, 18, 677–685. [Google Scholar] [CrossRef] [Green Version]

- Nascimento, E.S.S.; de Souza, P.C.; de Oliveira, H.A.; Júnior, C.M.M.; de Oliveira Almeida, V.G.; de Melo, F.M.C. Soil-cement brick with granite cutting residue reuse. J. Clean. Prod. 2021, 321, 129002. [Google Scholar] [CrossRef]

- da Silva Segantini, A.; Wada, P. An evaluation of the composition of soil cement bricks with construction and demolition waste. Acta Sci. Technol. 2011, 33, 179–184. [Google Scholar] [CrossRef]

- Sivakumar Babu, G.L.; Vasudevan, A.K. Strength and stiffness response of coir fiber-reinforced tropical soil. J. Mater. Civ. Eng. 2008, 20, 571–577. [Google Scholar] [CrossRef]

- Islam, M.S.; Iwashita, K. Performance of Composite Soil Reinforced with Jute Fiber. In Proceedings of the Getty Seismic Adobe Project 2006 Colloquium, 1st ed.; Hardy, M., Cancino, C., Ostergren, G., Eds.; The Getty Conservation Institute: Los Angeles, CA, USA, 2009; Volume 1, pp. 11–22. [Google Scholar]

- Eko, R.M.; Offa, E.D.; Ngatcha, T.Y.; Minsili, L.S. Potential of salvaged steel fibers for reinforcement of unfired earth blocks. Constr. Build. Mater. 2012, 35, 340–346. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Jamsawang, P. Use of steel and polypropylene fibers to improve flexural performance of deep soil–cement column. Constr. Build. Mater. 2012, 29, 201–205. [Google Scholar] [CrossRef]

- Tajdini, M.; Hajialilue Bonab, M.; Golmohamadi, S. An Experimental Investigation on Effect of Adding Natural and Synthetic Fibres on Mechanical and Behavioural Parameters of Soil–Cement Materials. Int. J. Civ. Eng. 2018, 16, 353–370. [Google Scholar] [CrossRef]

- Bakam, A.; Ndikontar, M.; Njilah, I. Essais de stabilisation de la latérite avec les fibres cellulosiques. Afr. J. Sci. Technol. 2004, 5, 22–28. [Google Scholar] [CrossRef]

- Centonze, G.; Leone, M.; Aiello, M.A. Steel fibers from waste tires as reinforcement in concrete: A mechanical characterization. Constr. Build. Mater. 2012, 36, 46–57. [Google Scholar] [CrossRef]

- Samarakoon, S.; Ruben, P.; Pedersen, J.; Evangelista, L. Mechanical performance of concrete made of steel fibers from tire waste. Case Stud. Constr. Mater. 2019, 11, e00259. [Google Scholar] [CrossRef]

- Moghadam, A.; Omidinasab, F.; Abdalikia, M. The effect of initial strength of concrete wastes on the fresh and hardened properties of recycled concrete reinforced with recycled steel fibers. Constr. Build. Mater. 2021, 300, 124284. [Google Scholar] [CrossRef]

- Associação Brasileira de Normas Técnicas. NBR 10834: Bloco De Solo-Cimento Sem Função Estrutural—Requisitos; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brasil, 2013. [Google Scholar]

- Instituto Boliviano de Normalización y Calidad. NB 1211003: Ladrillos Cerámicos—Ladrillos Macizos—Clasificación Y Requisitos (Tercera Revisión); Instituto Boliviano de Normalización y Calidad: La Paz, Bolivia, 2013. [Google Scholar]

- ICONTEC. NTC 5324: Bloques de Suelo Cemento Para Muros y Divisiones. Definiciones. Especificaciones. Métodos de Ensayo. Condiciones de Entrega; ICONTEC: Bogota, Colombia, 2004. [Google Scholar]

- Asociación Española de Normalización y Certificación. UNE 41410. Compressed Earth Blocks for Walls and Partitations; Definitions, Specifications and Test Methods; Asociación Española de Normalización y Certificación: Madrid, Spain, 2008. [Google Scholar]

- Association française de Normalisation. XP P13-901: Compressed Earth Blocks for Walls and Partitions: Definitions—Specifications—Test Methods—Delivery Acceptance Conditions; Association Française de Normalisation: Paris, France, 2001. [Google Scholar]

- Standards New Zealand. NZS 4298: Materials and Workmanship for Earth Buildings; Standards New Zealand: Wellington, New Zealand, 1998. [Google Scholar]

- Carvalho, M.; Ramos, F.; Zegarra, J.; Pereira, C. Evaluation over time of the mechanical properties of soil-cement blocks used in semi-permeable pavements. Revista Ingeniería de Construcción 2016, 31, 61–70. [Google Scholar] [CrossRef] [Green Version]

- Arooz, F.R.; Halwatura, R.U. Mud-concrete block (MCB): Mix design & durability characteristics. Case Stud. Constr. Mater. 2018, 8, 39–50. [Google Scholar] [CrossRef]

- Rocha, J.H.A.; Rosas, M.H.; Chileno, N.G.C.; Tapia, G.S.C. Physical-mechanical assessment for soil-cement blocks including rice husk ash. Case Stud. Constr. Mater. 2021, 14, e00548. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. ASTM C595/C595M-20, Standard Specification for Blended Hydraulic Cements; American Society for Testing and Materials: West Conshohocken, PA, USA, 2020. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. ASTM D422-463(2007)e2, Standard Test Method for Particle-Size Analysis of Soils (Withdrawn 2016); American Society for Testing and Materials: West Conshohocken, PA, USA, 2007. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. ASTM D4318-17e1, Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils; American Society for Testing and Materials: West Conshohocken, PA, USA, 2017. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials. M145-91 Standard Specification for Classification of Soils and Soil-Aggregate Mixtures for Highway Construction Purposes; American Association of State Highway and Transportation Officials: Washington, DC, USA, 1995. [Google Scholar]

- American Society for Testing and Materials. ASTM D2487-17e1, Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); American Society for Testing and Materials: West Conshohocken, PA, USA, 2017. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. ASTM D698-12e2, Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12 400 ft-lbf/ft3 (600 kN-m/m3)); American Society for Testing and Materials: West Conshohocken, PA, USA, 2012. [Google Scholar] [CrossRef]

- Shulman, V. Tire Recycling. In Waste, 2nd ed.; Letcher, T., Vallero, D., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 489–515. [Google Scholar]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-performance fiber-reinforced concrete. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar] [CrossRef] [Green Version]

- Hu, H.; Papastergiou, P.; Angelakopoulos, H.; Guadagnini, M.; Pilakoutas, K. Mechanical properties of SFRC using blended manufactured and recycled tyre steel fibres. Constr. Build. Mater. 2018, 163, 376–389. [Google Scholar] [CrossRef]

- Gatani, M.P. Ladrillos de suelo-cemento: Mampuesto tradicional en base a un material sostenible. Inf. Constr. 2000, 51, 35–47. [Google Scholar] [CrossRef]

- Associação Brasileira de Normas Técnicas. NBR 8492: Tijolo De Solo Cimento—Análise Dimensional, Determinação Da Resistência à Compressão E Da Absorção De Água–Método De Ensaio; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brasil, 2012. [Google Scholar]

- Nasir, B. Steel Fiber Reinforced Concrete Made with Fibers Extracted from Used Tyres. Ph.D. Thesis, Addis Ababa University, Addis Ababa, Ethiopia, 2009. [Google Scholar]

- Ndayambaje, J.C. Structural Performance and Impact Resistance of Rubberized Concrete. Ph.D. Thesis, Pan-African University for Basic Science, Technology and Inovation, Juja, Kenya, 2018. [Google Scholar]

- Mastali, M.; Dalvand, A. Use of silica fume and recycled steel fibers in self-compacting concrete (SCC). Constr. Build. Mater. 2016, 125, 196–209. [Google Scholar] [CrossRef]

| Parameter | Unit | IP-30 Cement |

|---|---|---|

| Loss on ignition | % | 2.33 |

| SiO2 | % | 32.83 |

| Al2O3 | % | 4.53 |

| Fe2O3 | % | 2.32 |

| CaO | % | 50.77 |

| MgO | % | 4.55 |

| SO3 | % | 2.10 |

| Parameter | Unit | IP-30 Cement |

|---|---|---|

| Blaine | m2/kg | 448 |

| Residue T325 | % | 5.34 |

| True Density | g/cm3 | 2.98 |

| Bulk Density | g/cm3 | 1.05 |

| Initial Setting | h | 2.32 |

| Final Setting | h | 4.65 |

| 3-Day Strength | MPa | 19.19 |

| 7-Day Strength | MPa | 24.90 |

| 28-Day Strength | MPa | 30.63 |

| Mixture | 0% WTSF | 0.75% WTSF | 1.50% WTSF |

|---|---|---|---|

| Dry density (g/cm3) | 1.83 | 1.84 | 1.85 |

| Optimum moisture (%) | 13.56 | 13.99 | 13.02 |

| Age | F | F Crit | p Value | Significance |

|---|---|---|---|---|

| 7 | 53.94017 | 8.02152 | 9.75561E-06 | Yes |

| 14 | 39.49235 | 8.02152 | 3.50154E-05 | Yes |

| 28 | 16.04894 | 8.02152 | 0.00108 | Yes |

| Group (WTSF) | p Value per Age (Days) | |||

|---|---|---|---|---|

| 7 | 14 | 28 | ||

| 0% | 0.75% | 0.49364751 | 0.01659152 | 0.34869971 |

| 0% | 1.50% | 4.1885 × 10−5 | 2.6717 × 10−5 | 0.0078263 |

| 0.75% | 1.50% | 1.424 × 10−5 | 0.00124796 | 0.001025 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rocha, J.H.A.; Galarza, F.P.; Chileno, N.G.C.; Rosas, M.H.; Peñaranda, S.P.; Diaz, L.L.; Abasto, R.P. Compressive Strength Assessment of Soil–Cement Blocks Incorporated with Waste Tire Steel Fiber. Materials 2022, 15, 1777. https://doi.org/10.3390/ma15051777

Rocha JHA, Galarza FP, Chileno NGC, Rosas MH, Peñaranda SP, Diaz LL, Abasto RP. Compressive Strength Assessment of Soil–Cement Blocks Incorporated with Waste Tire Steel Fiber. Materials. 2022; 15(5):1777. https://doi.org/10.3390/ma15051777

Chicago/Turabian StyleRocha, Joaquin Humberto Aquino, Fernando Palacios Galarza, Nahúm Gamalier Cayo Chileno, Marialaura Herrera Rosas, Sheyla Perez Peñaranda, Luis Ledezma Diaz, and Rodrigo Pari Abasto. 2022. "Compressive Strength Assessment of Soil–Cement Blocks Incorporated with Waste Tire Steel Fiber" Materials 15, no. 5: 1777. https://doi.org/10.3390/ma15051777

APA StyleRocha, J. H. A., Galarza, F. P., Chileno, N. G. C., Rosas, M. H., Peñaranda, S. P., Diaz, L. L., & Abasto, R. P. (2022). Compressive Strength Assessment of Soil–Cement Blocks Incorporated with Waste Tire Steel Fiber. Materials, 15(5), 1777. https://doi.org/10.3390/ma15051777