Numerical Tensile Damage Procedure Analysis of Angle-Ply Laminate Using Multi-Scale RVEs with Smear Crack Models

Abstract

:1. Introduction

2. Experimental System

3. Numerical Analysis

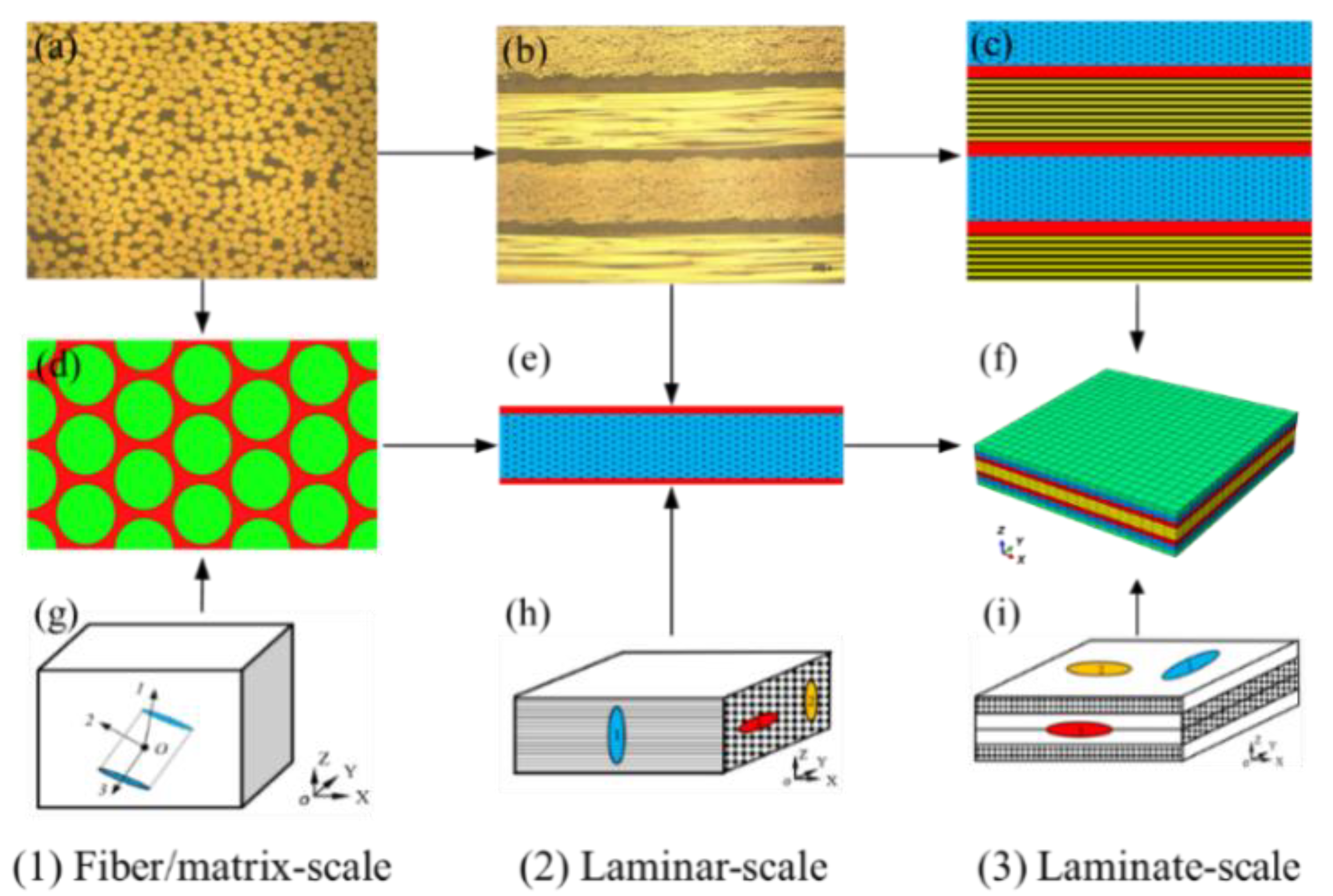

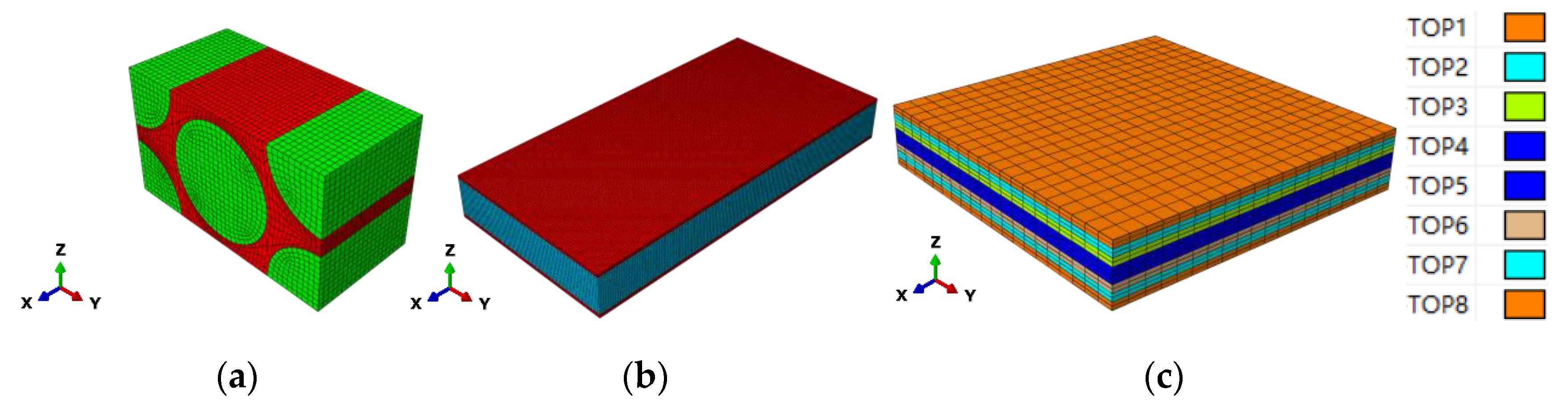

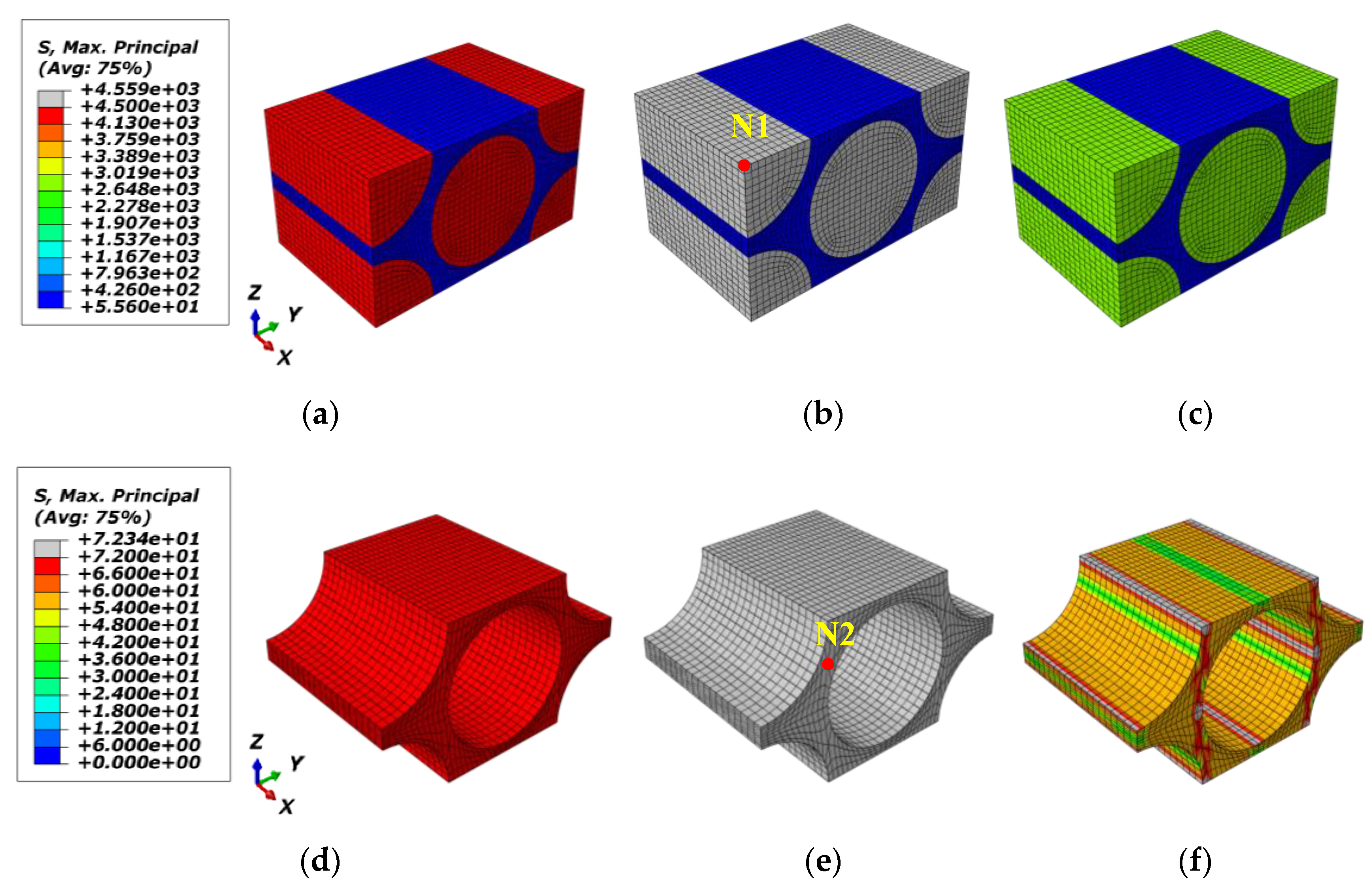

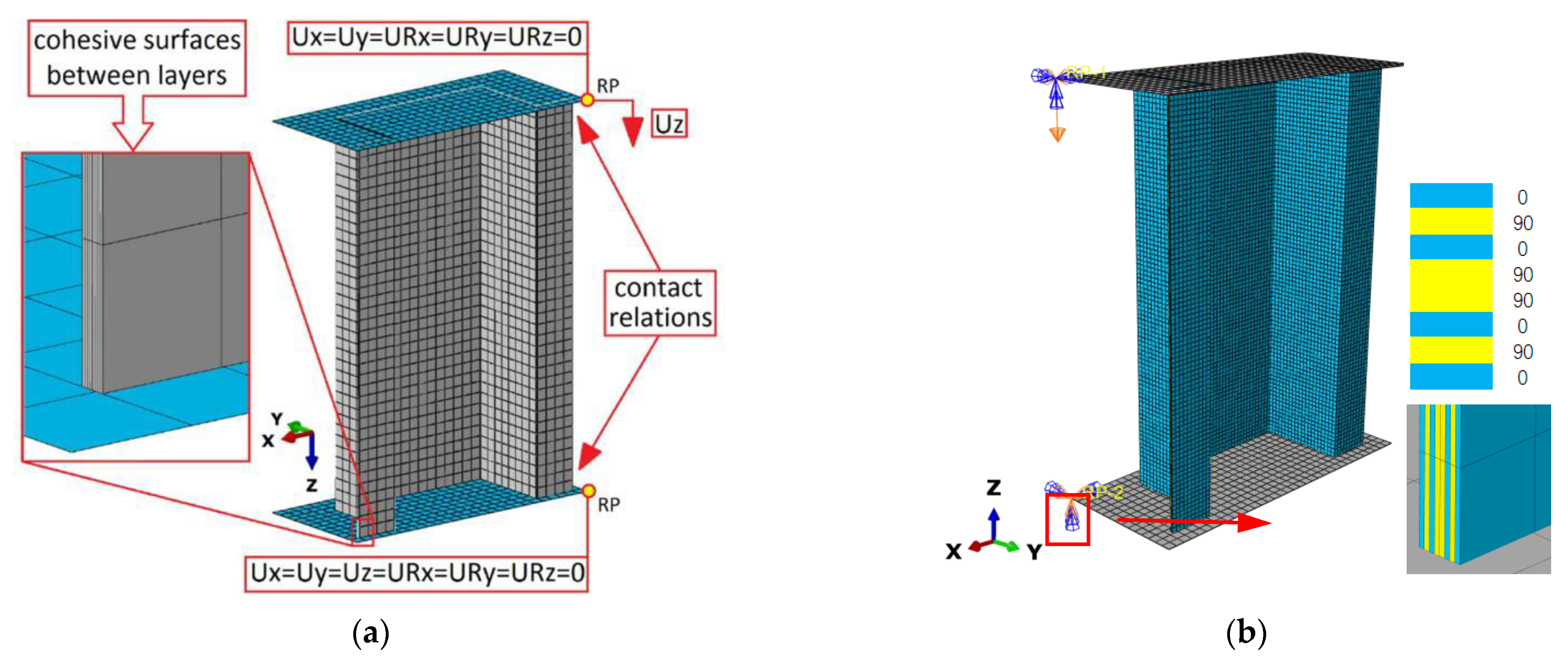

3.1. Multi-Scale RVEs

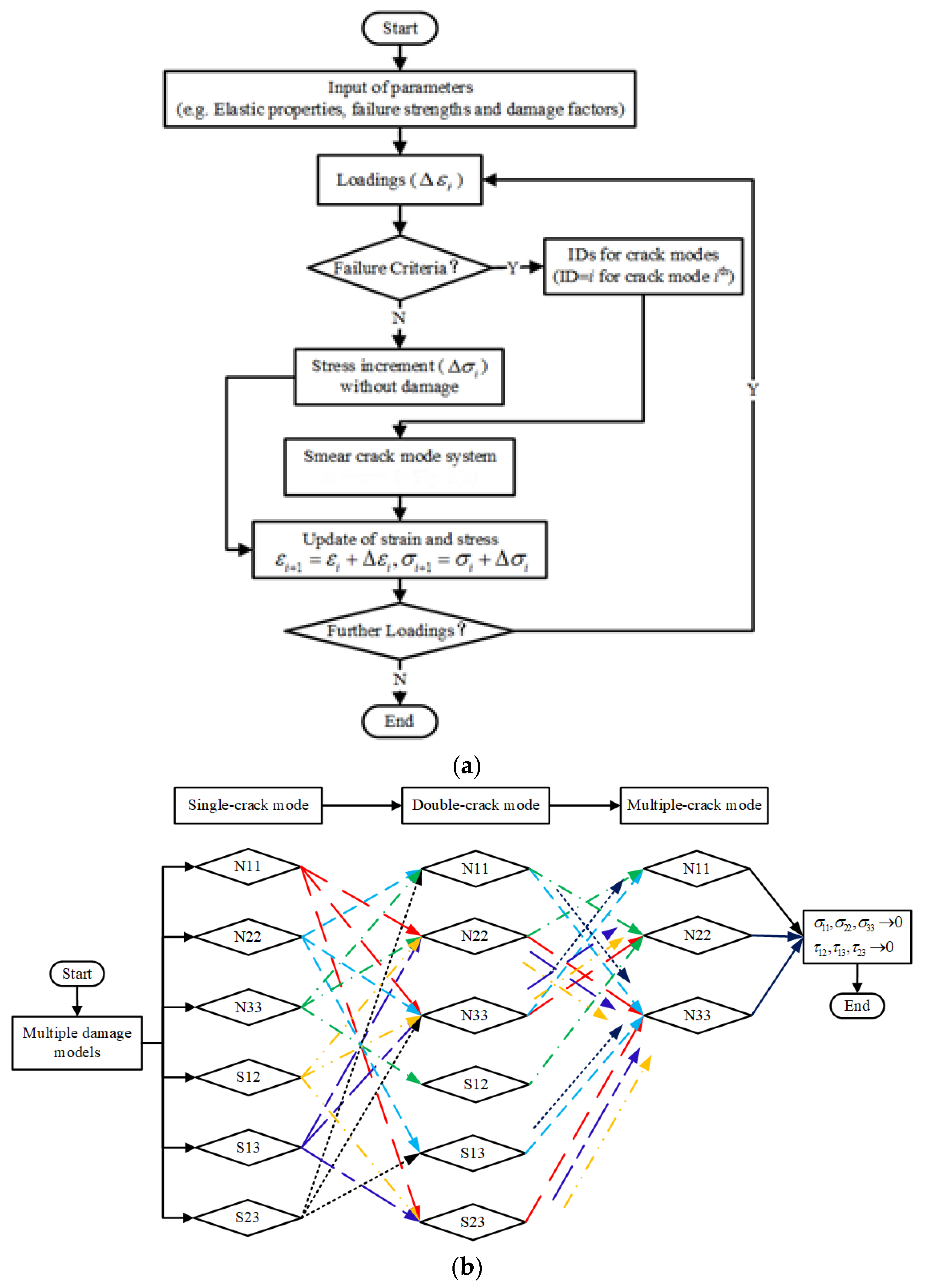

3.2. Multi-Scale Damage Models

4. Results and Discussions

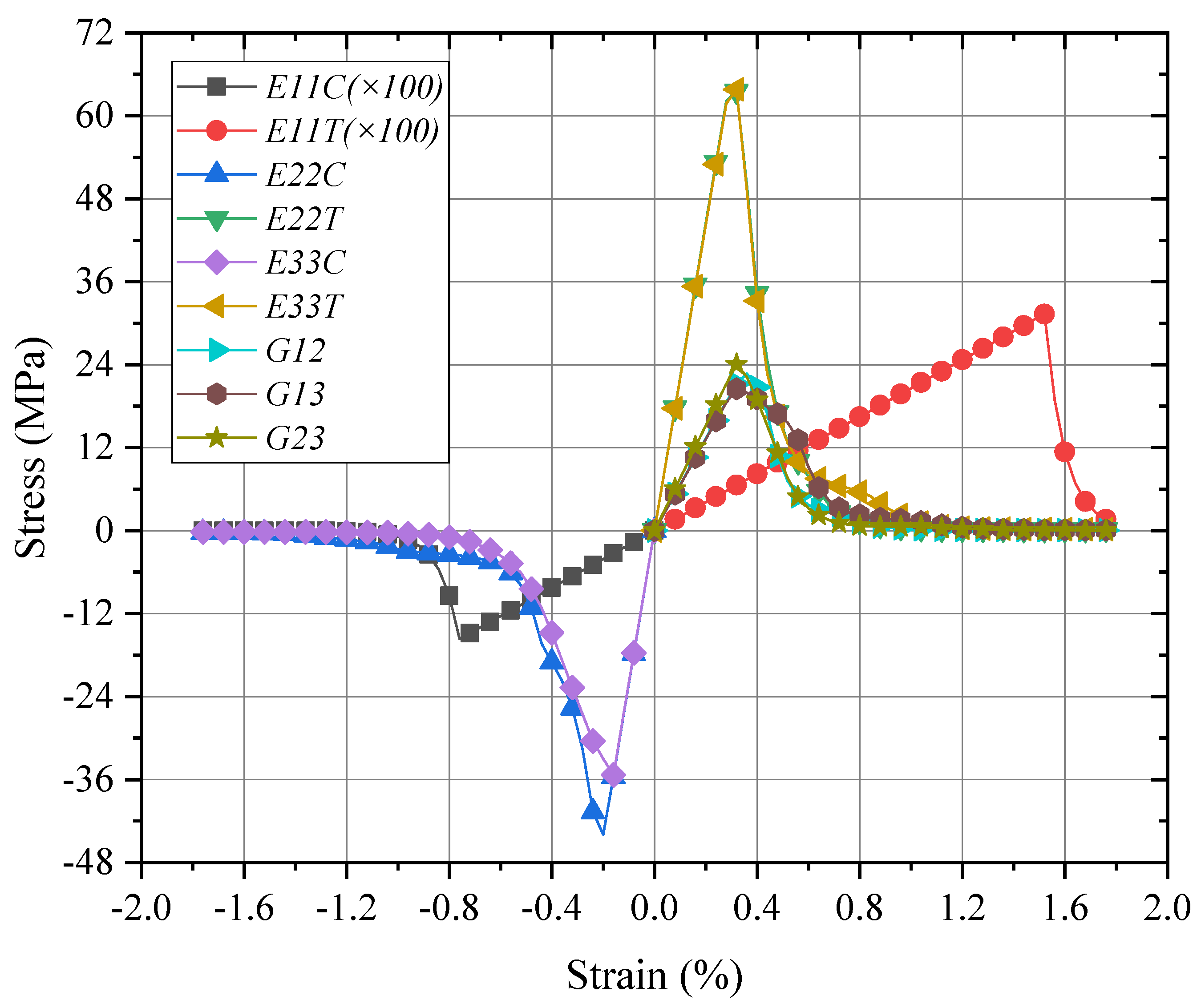

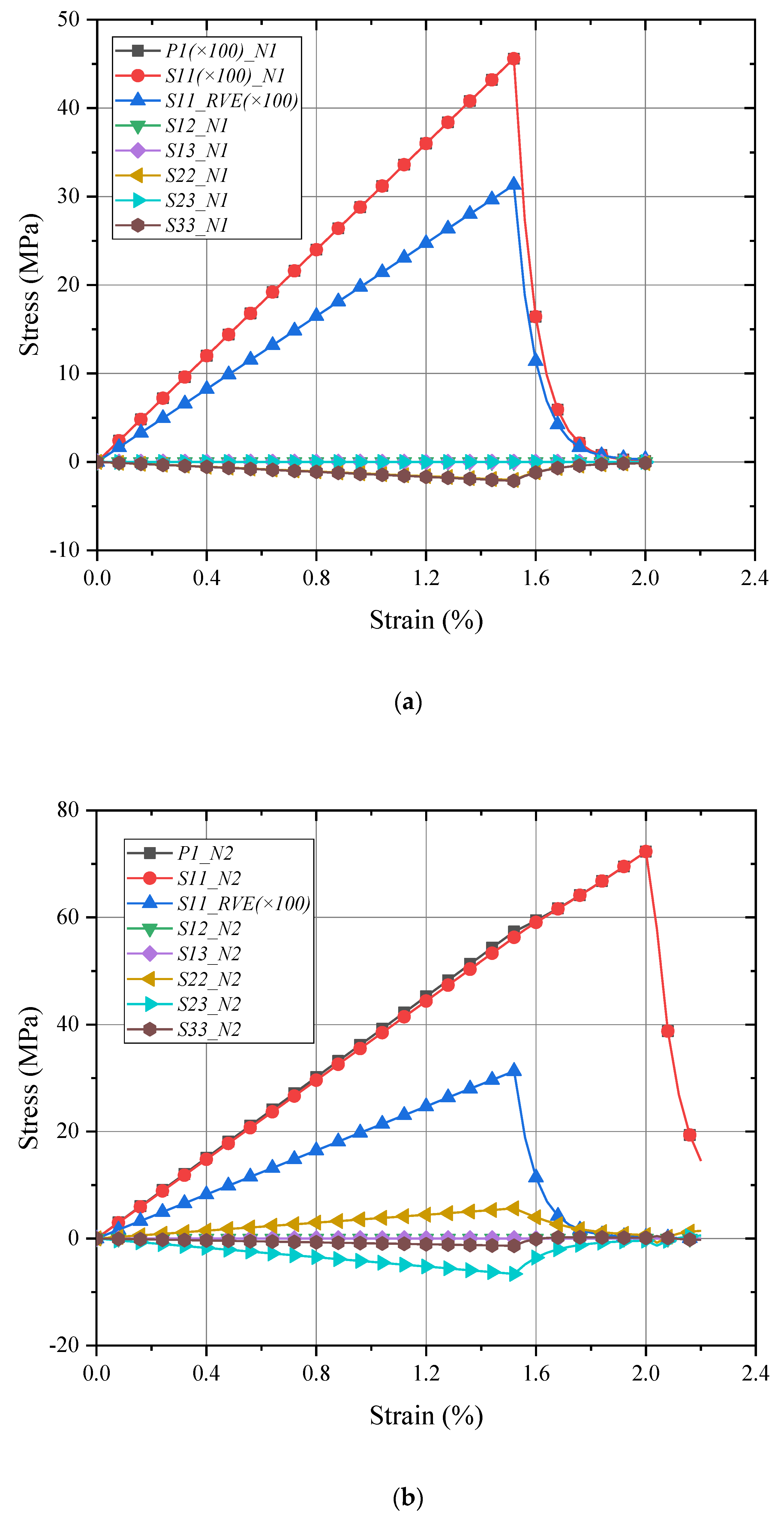

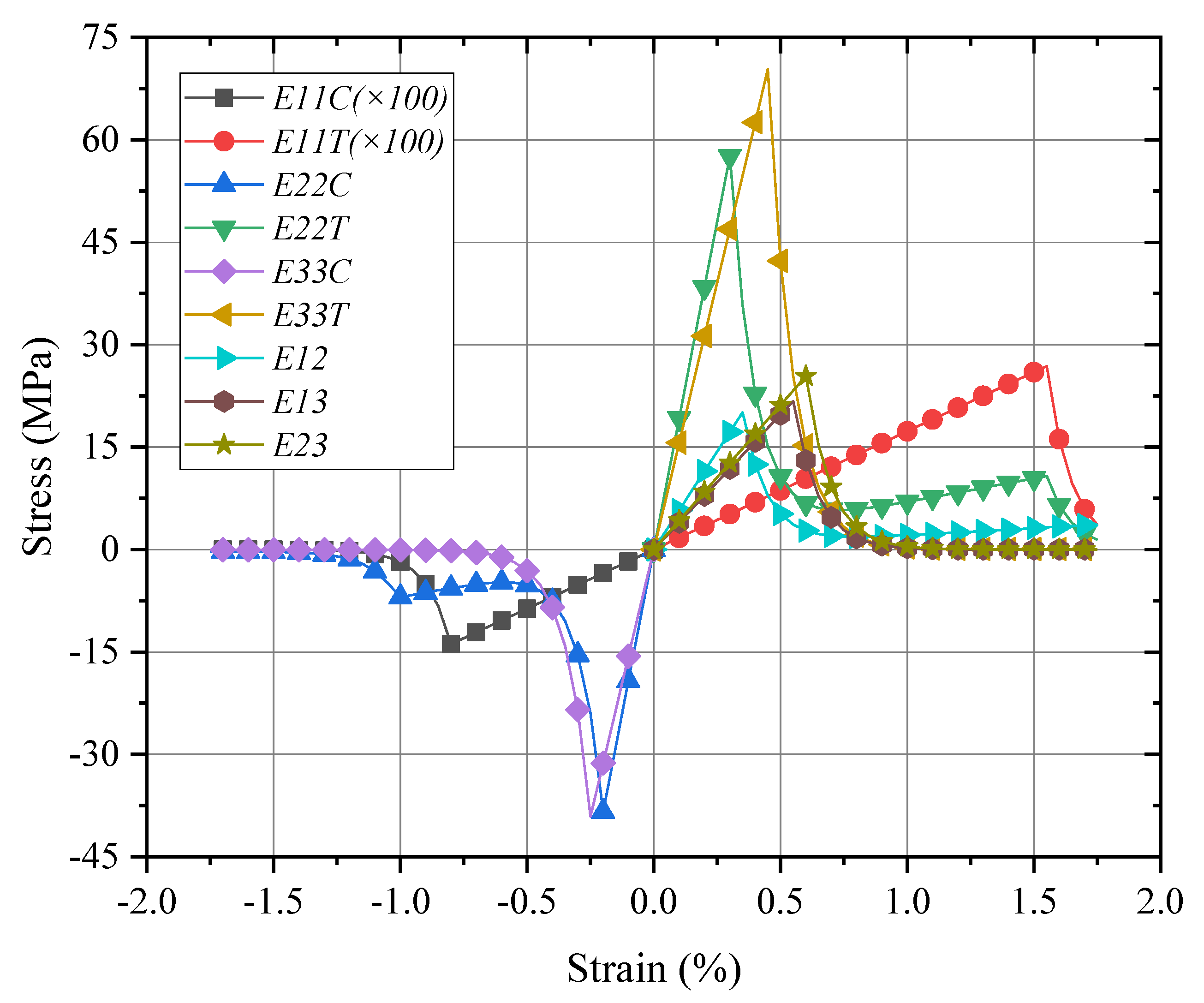

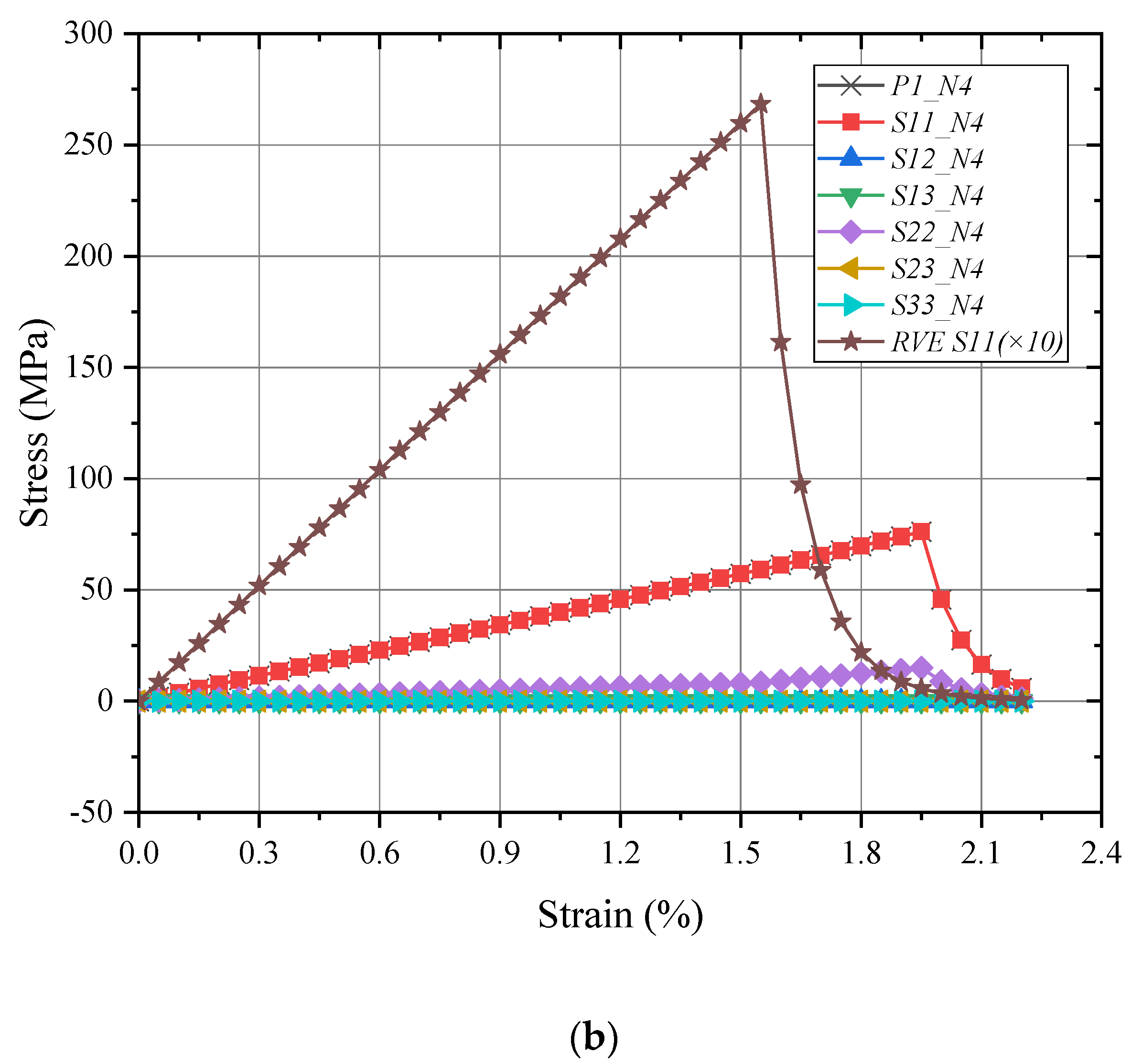

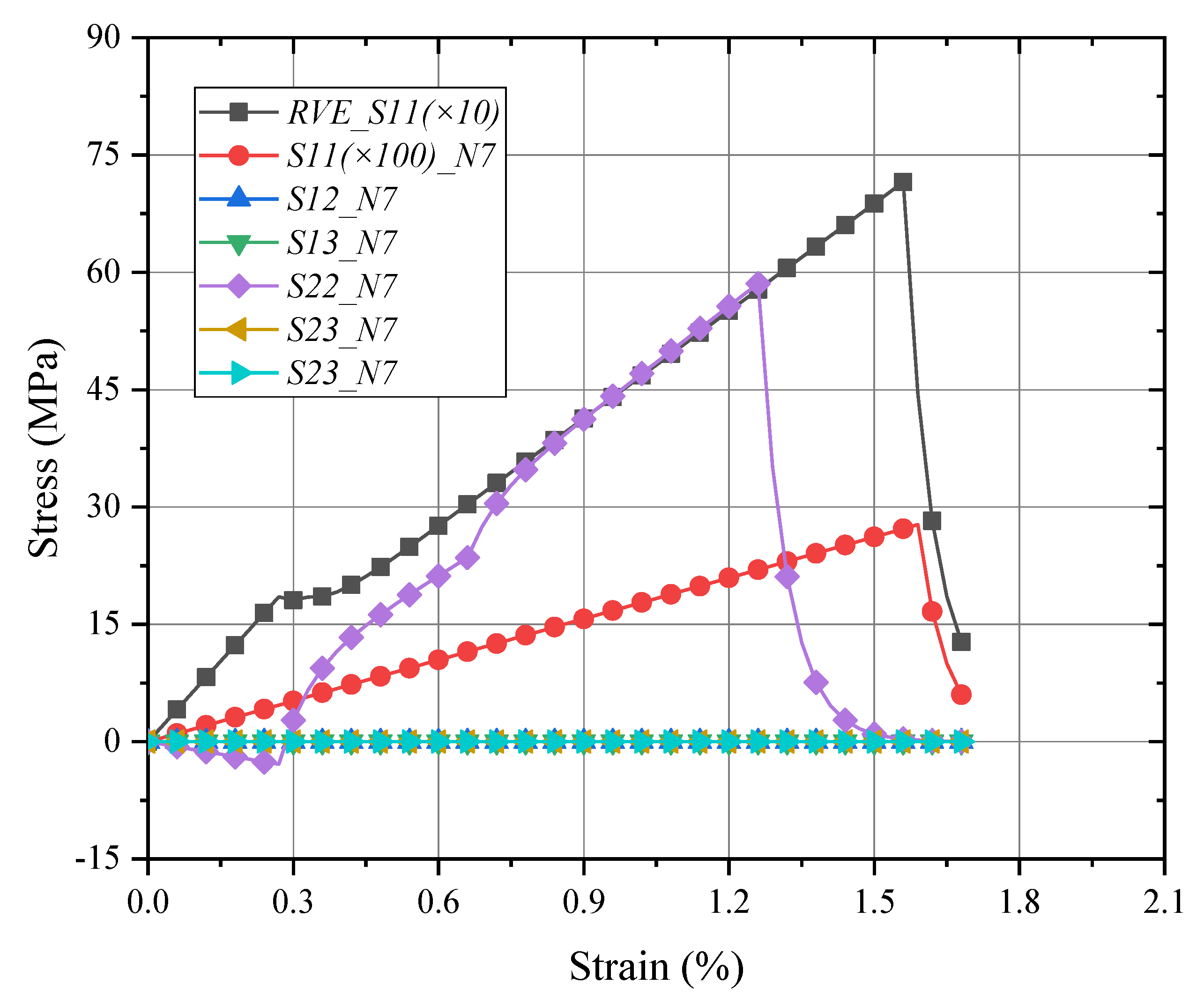

4.1. Global/Local Responses of Micro-RVE

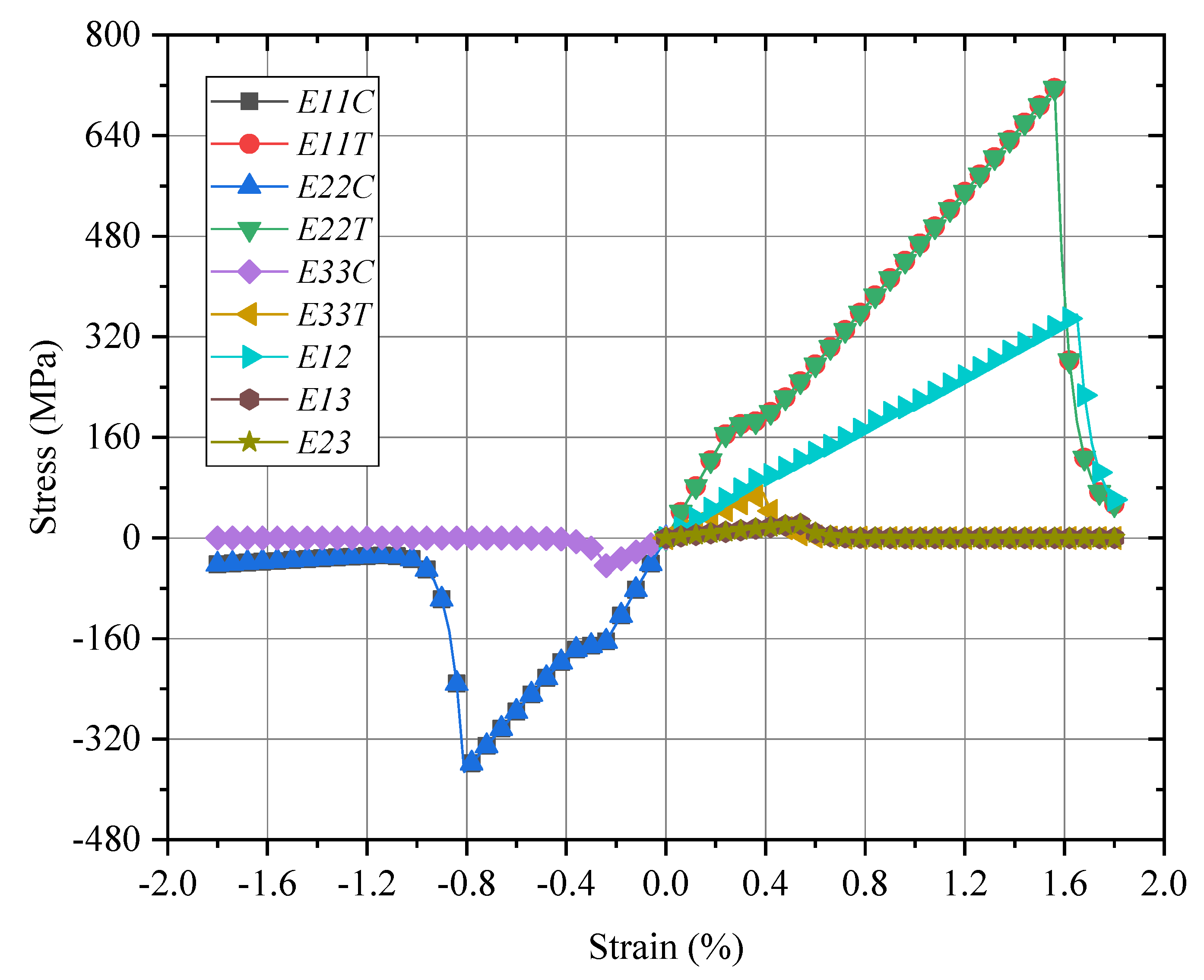

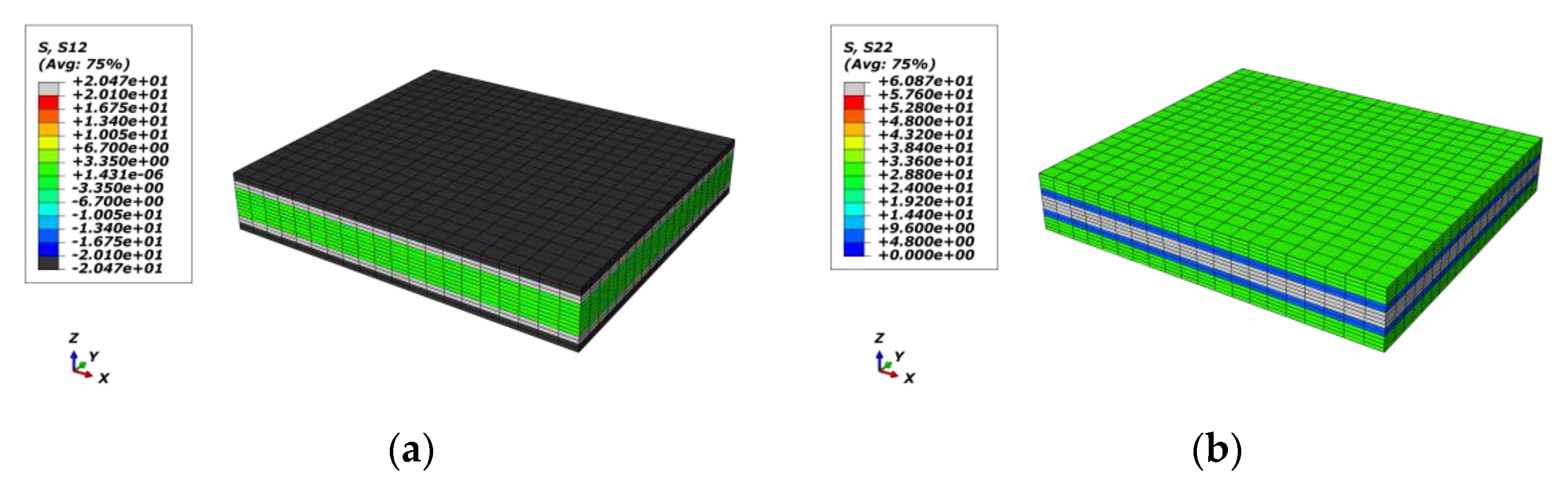

4.2. Global/Local Responses of Meso-RVE

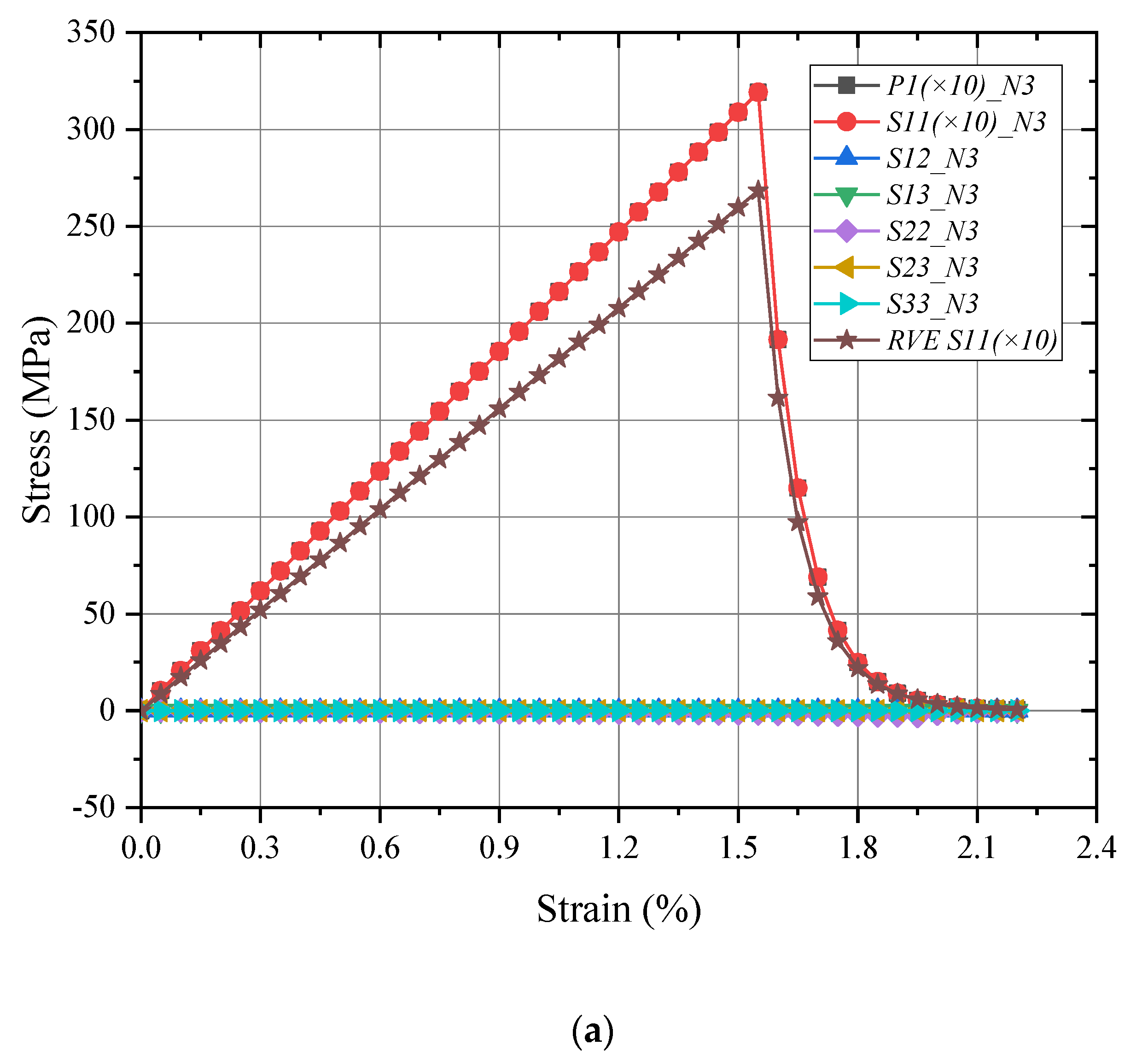

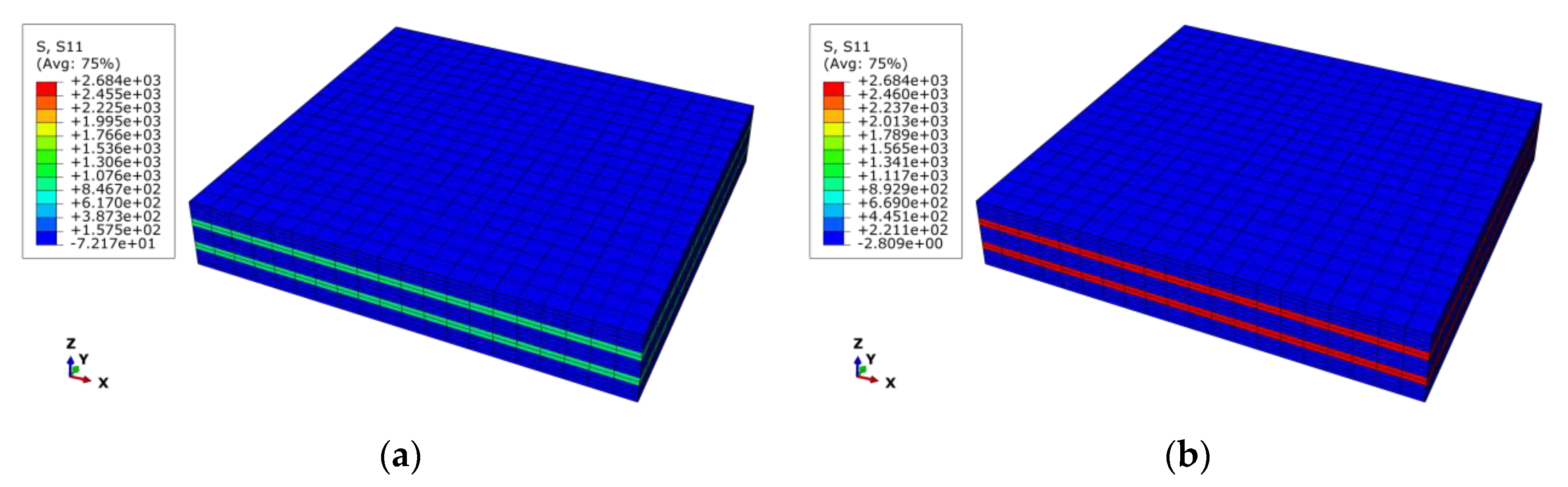

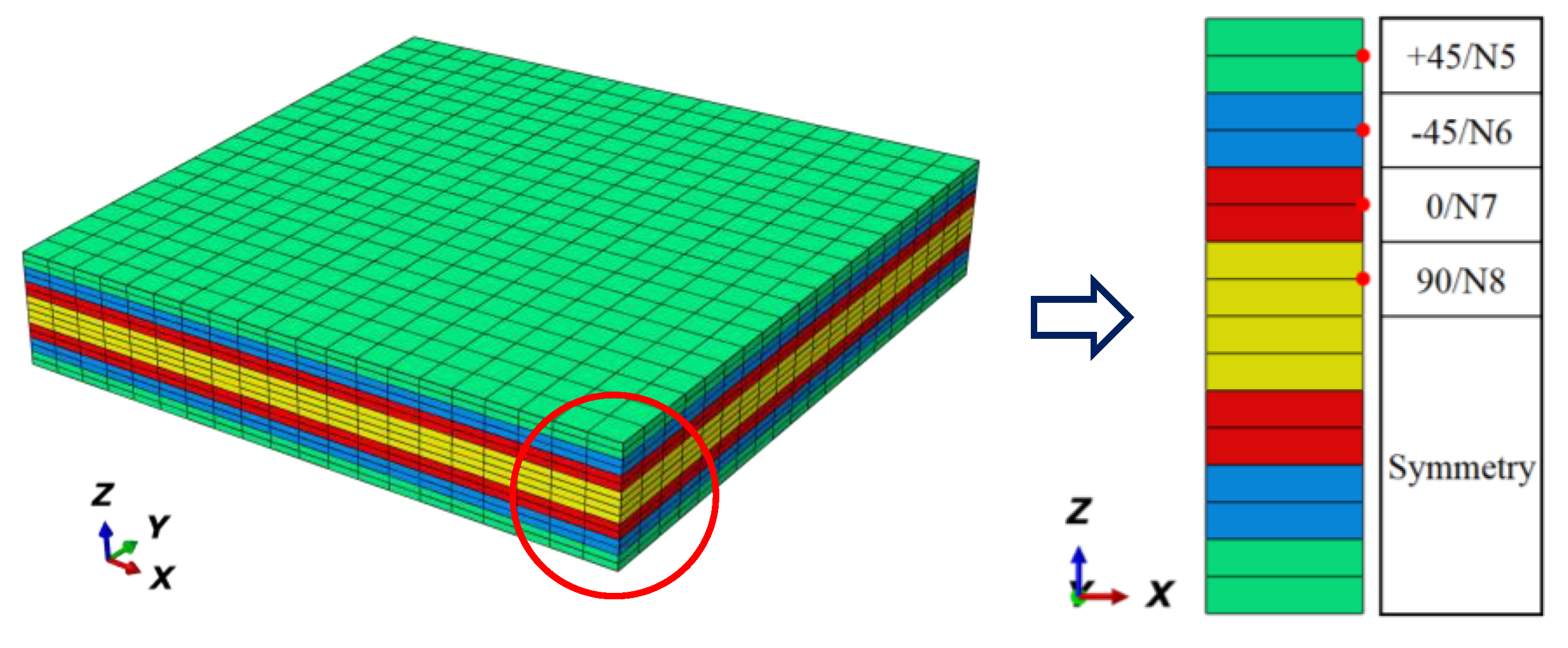

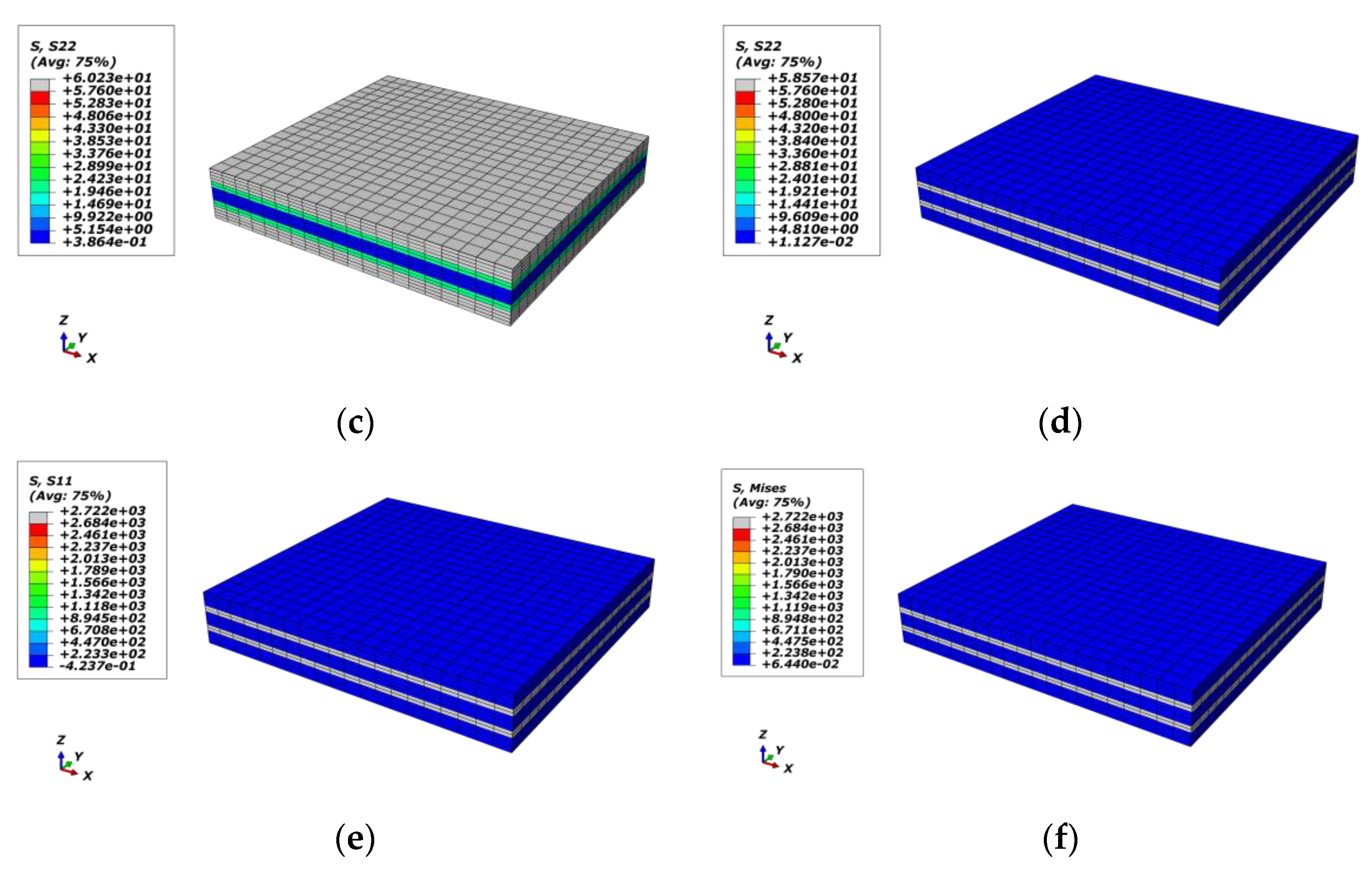

4.3. Global/Local Responses of Macro-RVE

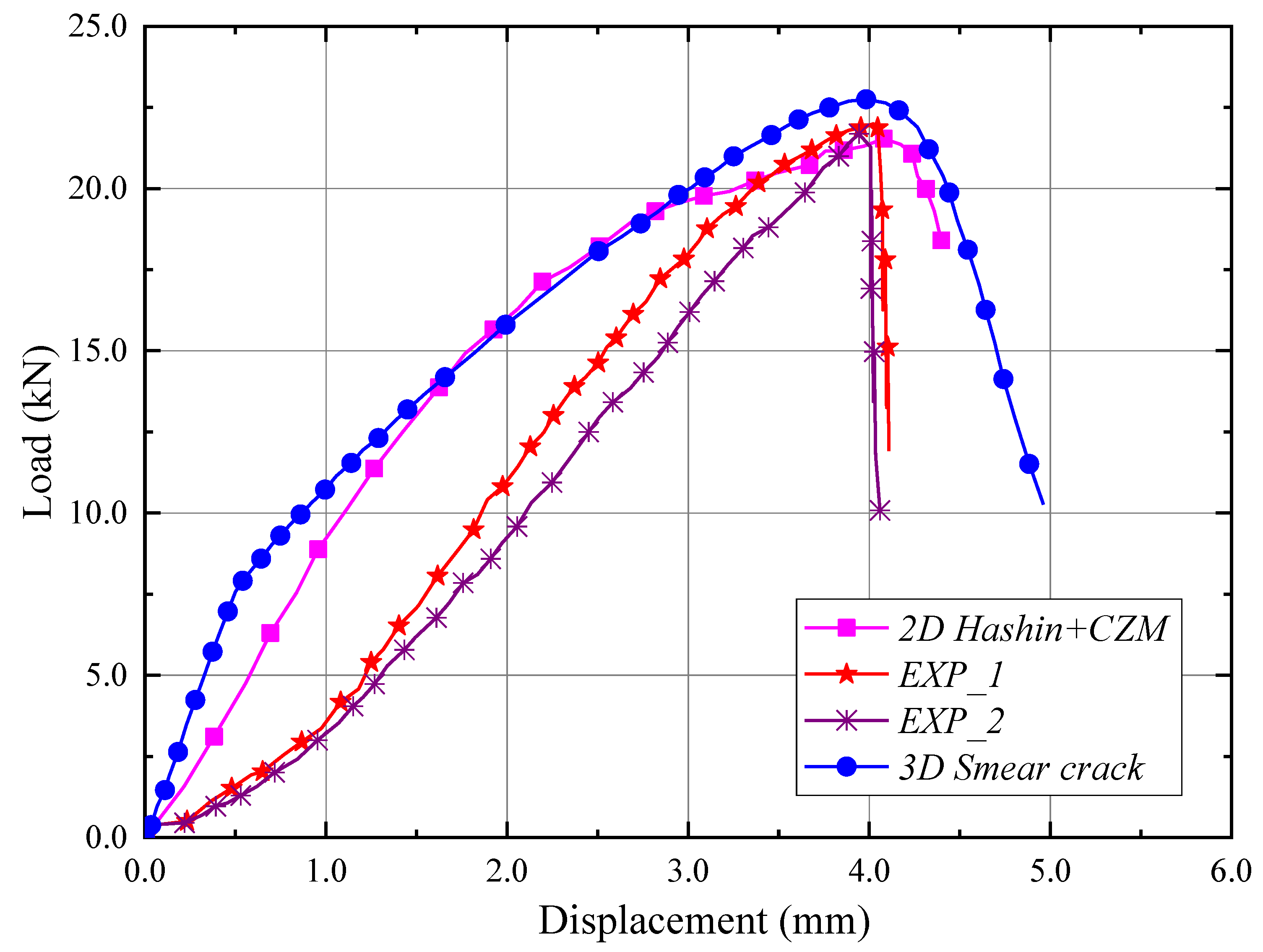

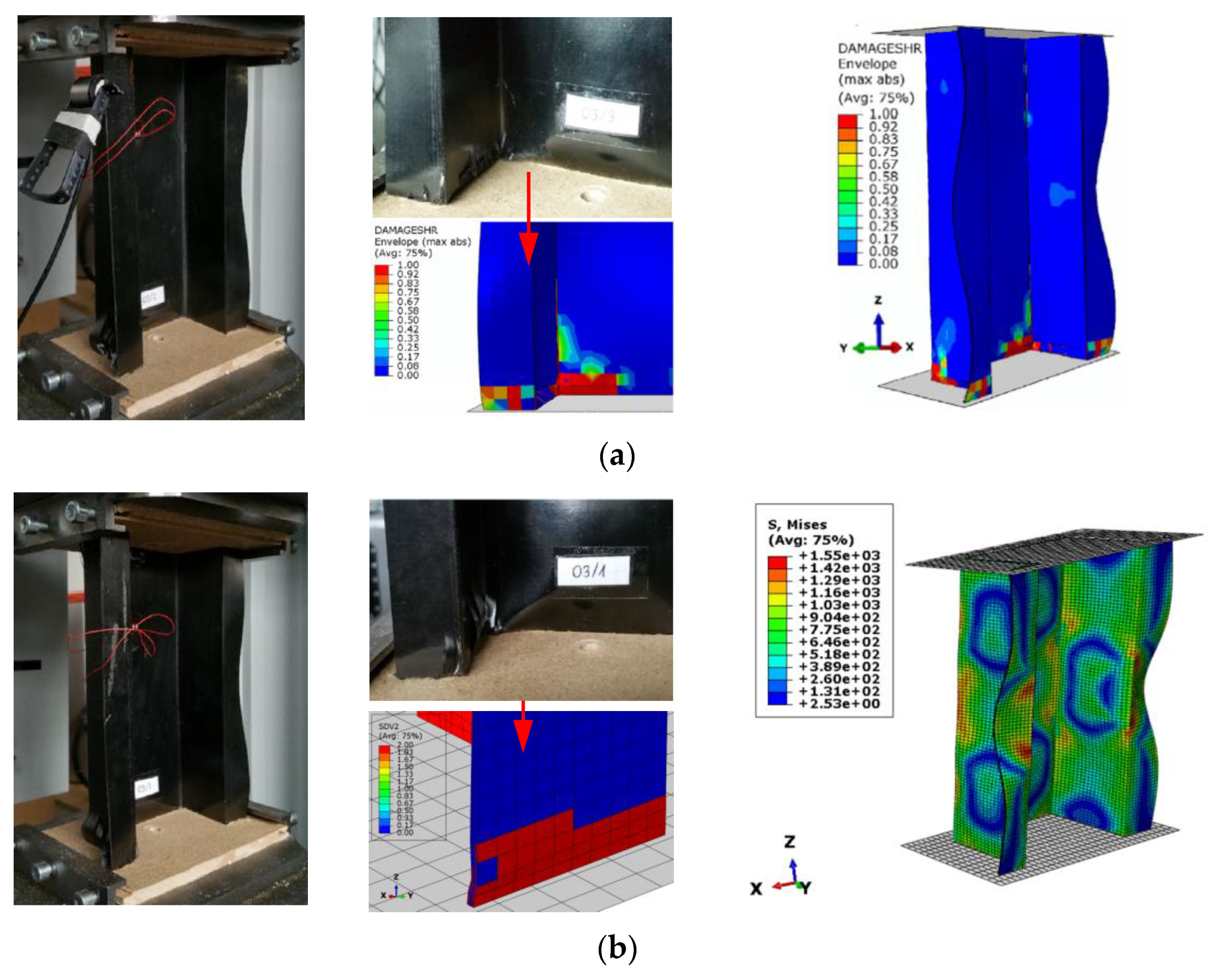

4.4. Damage Procedure Validations

5. The Extended Validation of UMAT

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pinho, S.; Robinson, P.; Iannucci, L. Fracture toughness of the tensile and compressive fibre failure modes in laminated composites. Compos. Sci. Technol. 2006, 66, 2069–2079. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Guan, Z.; Du, S.; Han, G.; Li, Z. An accurate and easy to implement method for predicting matrix crack and plasticity of composites with an efficient search algorithm for LaRC05 criterion. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105808. [Google Scholar] [CrossRef]

- Talreja, R. Assessment of the fundamentals of failure theories for composite materials. Compos. Sci. Technol. 2014, 105, 190–201. [Google Scholar] [CrossRef]

- Fakoor, M.; Shahsavar, S. Fracture assessment of cracked composite materials: Progress in models and criteria. Theor. Appl. Fract. Mech. 2020, 105, 102430. [Google Scholar] [CrossRef]

- Parambil, N.K.; Gururaja, S. Bridging micro-to-macro scale damage in UD-FRP laminates under tensile loading. Int. J. Mech. Sci. 2019, 157–158, 184–197. [Google Scholar] [CrossRef]

- Zhuang, L.; Talreja, R.; Varna, J. Transverse crack formation in unidirectional composites by linking of fibre/matrix debond cracks. Compos. Part A Appl. Sci. Manuf. 2018, 107, 294–303. [Google Scholar] [CrossRef]

- Maragoni, L.; Talreja, R. Transverse crack formation in unidirectional plies predicted by means of a percolation concept. Compos. Part A Appl. Sci. Manuf. 2019, 117, 317–323. [Google Scholar] [CrossRef]

- Huang, Y.; Varna, J.; Talreja, R. Statistical methodology for assessing manufacturing quality related to transverse cracking in cross ply laminates. Compos. Sci. Technol. 2014, 95, 100–106. [Google Scholar] [CrossRef]

- Melro, A.; Camanho, P.; Pires, F.; Pinho, S. Micromechanical analysis of polymer composites reinforced by unidirectional fibres: Part I–Constitutive modelling. Int. J. Solids Struct. 2013, 50, 1897–1905. [Google Scholar] [CrossRef] [Green Version]

- Melro, A.; Camanho, P.; Pires, F.; Pinho, S. Micromechanical analysis of polymer composites reinforced by unidirectional fibres: Part II–Micromechanical analyses. Int. J. Solids Struct. 2013, 50, 1906–1915. [Google Scholar] [CrossRef] [Green Version]

- Naderi, M.; Iyyer, N. Micromechanical analysis of damage mechanisms under tension of 0°–90° thin-ply composite laminates. Compos. Struct. 2020, 234, 111659. [Google Scholar] [CrossRef]

- Elnekhaily, S.A.; Talreja, R. Effect of axial shear and transverse tension on early failure events in unidirectional polymer matrix composites. Compos. Part A Appl. Sci. Manuf. 2019, 119, 275–282. [Google Scholar] [CrossRef]

- Bullegas, G.; Lamela, J.M.; Pimenta, S.; Pinho, S.T. On the role of dynamic stress concentrations and fracture mechanics in the longitudinal tensile failure of fibre-reinforced composites. Eng. Fract. Mech. 2020, 228, 106920. [Google Scholar] [CrossRef]

- Chen, B.; Tay, T.; Pinho, S.; Tan, V. Modelling delamination migration in angle-ply laminates. Compos. Sci. Technol. 2017, 142, 145–155. [Google Scholar] [CrossRef]

- Pimenta, S.; Gutkin, R.; Pinho, S.; Robinson, P. A micromechanical model for kink-band formation: Part I—Experimental study and numerical modelling. Compos. Sci. Technol. 2009, 69, 948–955. [Google Scholar] [CrossRef] [Green Version]

- Pimenta, S.; Gutkin, R.; Pinho, S.; Robinson, P. A micromechanical model for kink-band formation: Part II—Analytical modelling. Compos. Sci. Technol. 2009, 69, 956–964. [Google Scholar] [CrossRef] [Green Version]

- Andraju, L.B.; Raju, G. Continuum and cohesive zone damage models to study intra/inter-laminar failure of curved composite laminates under four-point bending. Compos. Struct. 2020, 253, 112768. [Google Scholar] [CrossRef]

- Forghani, A.; Poursartip, A.; Vaziri, R. An orthotropic non-local approach to modeling intra-laminar damage progression in laminated composites. Int. J. Solids Struct. 2019, 180–181, 160–175. [Google Scholar] [CrossRef]

- Boon, Y.D.; Joshi, S.C. A review of methods for improving interlaminar interfaces and fracture toughness of laminated composites. Mater. Today Commun. 2020, 22, 100830. [Google Scholar] [CrossRef]

- Farrokhabadi, A.; Babaei, R. Development of an integrated micro macro model for anticipating matrix cracking evolution and fiber breakage in the laminated composite containing an open hole. Eng. Fract. Mech. 2019, 211, 161–179. [Google Scholar] [CrossRef]

- Ren, M.-F.; Zhang, X.-W.; Huang, C.; Wang, B.; Li, T. An integrated macro/micro-scale approach for in situ evaluation of matrix cracking in the polymer matrix of cryogenic composite tanks. Compos. Struct. 2019, 216, 201–212. [Google Scholar] [CrossRef]

- Patel, D.K.; Waas, A.M. Multiscale analysis of notched fiber reinforced laminates. Compos. Part B Eng. 2019, 173, 106986. [Google Scholar] [CrossRef]

- Massarwa, E.; Aboudi, J.; Haj-Ali, R. A multiscale modeling for failure predictions of fiber reinforced composite laminates. Compos. Part B Eng. 2019, 175, 107166. [Google Scholar] [CrossRef]

- Yuan, M.; Yang, Y.; Zhao, H.; Wang, Y.; Li, R.; Zhang, B.; Chen, J. A novel trans-scale method for predicting mode I matrix crack density of composite laminates. Compos. Struct. 2020, 235, 111726. [Google Scholar] [CrossRef]

- Laux, T.; Gan, K.W.; Dulieu-Barton, J.; Thomsen, O.T. Ply thickness and fibre orientation effects in multidirectional composite laminates subjected to combined tension/compression and shear. Compos. Part A Appl. Sci. Manuf. 2020, 133, 105864. [Google Scholar] [CrossRef]

- Kumagai, Y.; Onodera, S.; Salviato, M.; Okabe, T. Multiscale analysis and experimental validation of crack initiation in quasi-isotropic laminates. Int. J. Solids Struct. 2020, 193–194, 172–191. [Google Scholar] [CrossRef]

- Jia, X.; Xia, Z.; Gu, B. Numerical analyses of 3D orthogonal woven composite under three-point bending from multi-scale microstructure approach. Comput. Mater. Sci. 2013, 79, 468–477. [Google Scholar] [CrossRef]

- Jia, X.; Xia, Z.; Gu, B. Nonlinear viscoelastic multi-scale repetitive unit cell model of 3D woven composites with damage evolution. Int. J. Solids Struct. 2013, 50, 3539–3554. [Google Scholar] [CrossRef] [Green Version]

- Tan, P. Numerical simulation of the ballistic protection performance of a laminated armor system with pre-existing debonding/delamination. Compos. Part B Eng. 2014, 59, 50–59. [Google Scholar] [CrossRef]

- Kolanu, N.R.; Raju, G.; Ramji, M. A unified numerical approach for the simulation of intra and inter laminar damage evolution in stiffened CFRP panels under compression. Compos. Part B Eng. 2020, 190, 107931. [Google Scholar] [CrossRef]

- Rozylo, P. Failure analysis of thin-walled composite structures using independent advanced damage models. Compos. Struct. 2021, 262, 113598. [Google Scholar] [CrossRef]

- Almeida, J.H.S., Jr.; Ribeiro, M.L.; Tita, V.; Amico, S.C. Damage and failure in carbon/epoxy filament wound composite tubes under external pressure: Experimental and numerical approaches. Mater. Des. 2016, 96, 431–438. [Google Scholar] [CrossRef]

- Almeida, J.H.S.; Ribeiro, M.; Tita, V.; Amico, S. Damage modeling for carbon fiber/epoxy filament wound composite tubes under radial compression. Compos. Struct. 2017, 160, 204–210. [Google Scholar] [CrossRef]

- Almeida, J.H.S.; Tonatto, M.; Ribeiro, M.L.; Tita, V.; Amico, S. Buckling and post-buckling of filament wound composite tubes under axial compression: Linear, nonlinear, damage and experimental analyses. Compos. Part B Eng. 2018, 149, 227–239. [Google Scholar] [CrossRef]

- Almeida, J.H.S.; St-Pierre, L.; Wang, Z.; Ribeiro, M.L.; Tita, V.; Amico, S.C.; Castro, S.G. Design, modeling, optimization, manufacturing and testing of variable-angle filament-wound cylinders. Compos. Part B Eng. 2021, 225, 109224. [Google Scholar] [CrossRef]

- Oz, F.E.; Ersoy, N.; Mehdikhani, M.; Lomov, S.V. Multi-instrument in-situ damage monitoring in quasi-isotropic CFRP laminates under tension. Compos. Struct. 2018, 196, 163–180. [Google Scholar] [CrossRef]

- Li, D.; Guo, Q.; Xu, D.; Yang, X. Three-dimensional micromechanical analysis models of fiber reinforced composite plates with damage. Comput. Struct. 2017, 191, 100–114. [Google Scholar] [CrossRef]

- Jia, X.; Xia, Z.; Gu, B. Micro/meso-scale damage analysis of three-dimensional orthogonal woven composites based on sub-repeating unit cells. J. Strain Anal. Eng. Des. 2012, 47, 313–328. [Google Scholar] [CrossRef]

- Malvar, L.; Fourney, M. A three dimensional application of the smeared crack approach. Eng. Fract. Mech. 1990, 35, 251–260. [Google Scholar] [CrossRef]

- De Borst, R. Smeared cracking, plasticity, creep, and thermal loading—A unified approach. Comput. Methods Appl. Mech. Eng. 1987, 1, 89–110. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Xia, Z.; Ellyin, F. Nonlinear viscoelastic micromechanical analysis of fibre-reinforced polymer laminates with damage evolution. Int. J. Solids Struct. 2005, 42, 591–604. [Google Scholar] [CrossRef]

- Ellyin, F.; Zhang, Y.; Xia, Z. Meso-scale analysis of angle-ply laminates. Procedia Eng. 2011, 10, 63–68. [Google Scholar] [CrossRef]

- Han, W.; Hu, K.; Shi, Q.; Zhu, F. Damage evolution analysis of open-hole tensile laminated composites using a progress damage model verified by AE and DIC. Compos. Struct. 2020, 247, 112452. [Google Scholar] [CrossRef]

- Oz, F.E.; Mehdikhani, M.; Ersoy, N.; Lomov, S.V. In-situ imaging of inter- and intra-laminar damage in open-hole tension tests of carbon fibre-reinforced composites. Compos. Struct. 2020, 244, 112302. [Google Scholar] [CrossRef]

- Sharifpour, F.; Montesano, J.; Talreja, R. Assessing the effects of ply constraints on local stress states in cross-ply laminates containing manufacturing induced defects. Compos. Part B Eng. 2020, 199, 108227. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| (GPa) | 300 |

| 0.22 | |

| (GPa) | 4.5 |

| (GPa) | −2.25 |

| (GPa) | 1.23 |

| (GPa) | 3.6 |

| 0.4 | |

| (GPa) | 72 |

| (MPa) | −36 |

| (MPa) | 25.7 |

| Property | Value |

|---|---|

| (GPa) | 206.00 |

| (GPa) | 22.20 |

| (GPa) | 22.10 |

| (GPa) | 6.60 |

| (GPa) | 6.60 |

| (GPa) | 7.60 |

| 0.27 | |

| 0.27 | |

| 0.47 | |

| (MPa) | 3131.50 |

| (MPa) | −1568.80 |

| (MPa) | 63.60 |

| (MPa) | −40.70 |

| (MPa) | 63.80 |

| (MPa) | −33.30 |

| (MPa) | 22.70 |

| (MPa) | 20.50 |

| (MPa) | 24.10 |

| Property | Value |

|---|---|

| (GPa) | 173.20 |

| (GPa) | 19.20 |

| (GPa) | 15.60 |

| (GPa) | 5.70 |

| (GPa) | 4.00 |

| (GPa) | 4.20 |

| 0.2747 | |

| 0.3027 | |

| 0.4981 | |

| (MPa) | 2684.4 |

| (MPa) | −1385.5 |

| (MPa) | 57.60 |

| (MPa) | −38.40 |

| (MPa) | 70.40 |

| (MPa) | −39.10 |

| (MPa) | 20.10 |

| (MPa) | 21.80 |

| (MPa) | 25.40 |

| Property | Value |

|---|---|

| (GPa) | 68.60 |

| (GPa) | 68.60 |

| (GPa) | 18.30 |

| (GPa) | 25.8 |

| (GPa) | 4.10 |

| (GPa) | 4.10 |

| 0.3303 | |

| 0.3199 | |

| 0.3199 | |

| (MPa) | 715.44 |

| (MPa) | −317.97 |

| (MPa) | 715.44 |

| (MPa) | −317.97 |

| (MPa) | 71.5 |

| (MPa) | −44.00 |

| (MPa) | 355.47 |

| (MPa) | 22.10 |

| (MPa) | 22.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Zhang, F.; Lu, Z.; Cao, D.; Jia, X. Numerical Tensile Damage Procedure Analysis of Angle-Ply Laminate Using Multi-Scale RVEs with Smear Crack Models. Materials 2022, 15, 2002. https://doi.org/10.3390/ma15062002

Wang Q, Zhang F, Lu Z, Cao D, Jia X. Numerical Tensile Damage Procedure Analysis of Angle-Ply Laminate Using Multi-Scale RVEs with Smear Crack Models. Materials. 2022; 15(6):2002. https://doi.org/10.3390/ma15062002

Chicago/Turabian StyleWang, Qianwen, Fa Zhang, Zhenqian Lu, Dongfeng Cao, and Xiwen Jia. 2022. "Numerical Tensile Damage Procedure Analysis of Angle-Ply Laminate Using Multi-Scale RVEs with Smear Crack Models" Materials 15, no. 6: 2002. https://doi.org/10.3390/ma15062002

APA StyleWang, Q., Zhang, F., Lu, Z., Cao, D., & Jia, X. (2022). Numerical Tensile Damage Procedure Analysis of Angle-Ply Laminate Using Multi-Scale RVEs with Smear Crack Models. Materials, 15(6), 2002. https://doi.org/10.3390/ma15062002