Investigating the Mechanical Properties and Durability of Metakaolin-Incorporated Mortar by Different Curing Methods

Abstract

:1. Introduction

2. Materials and Methods

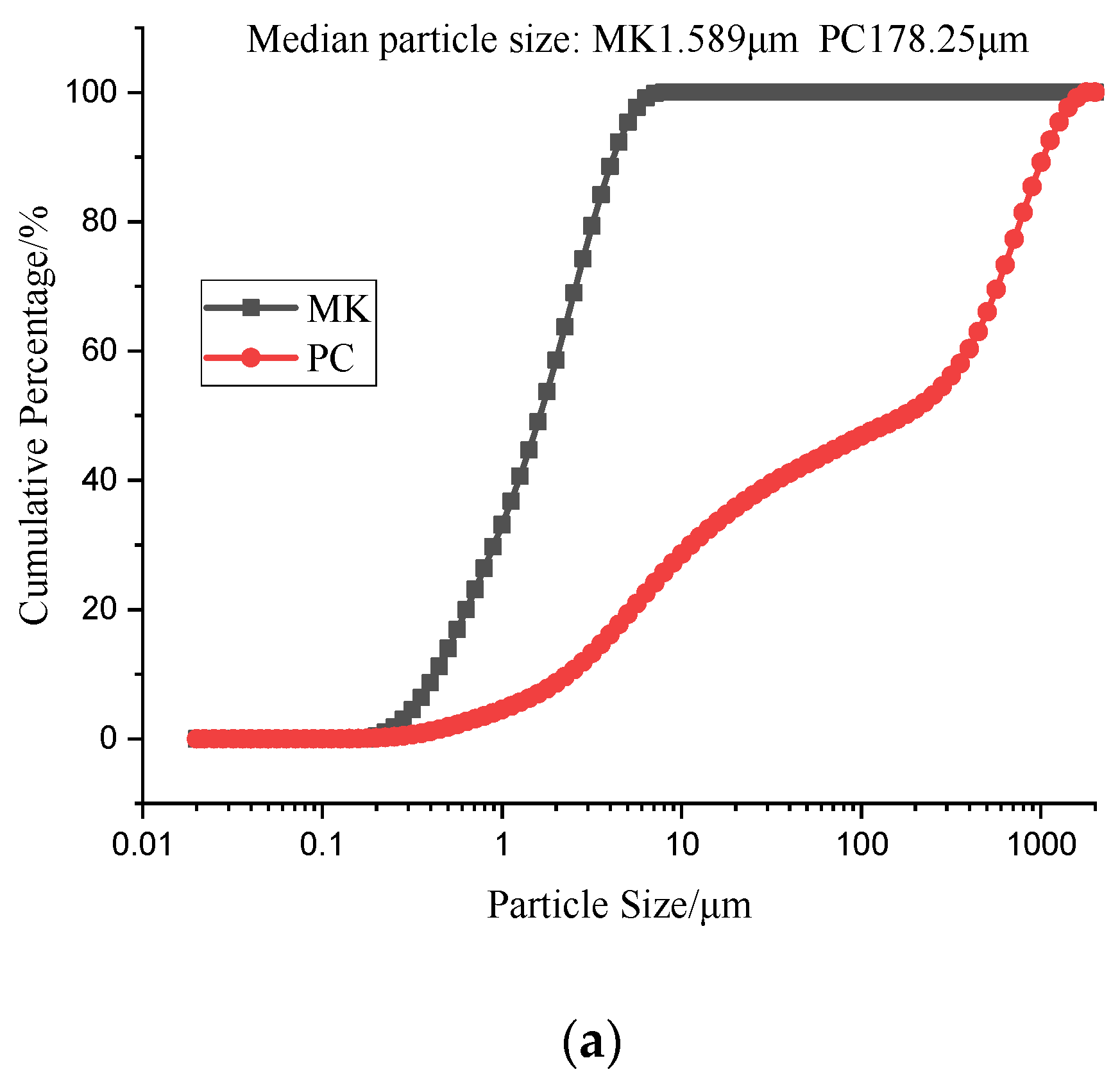

2.1. Raw Materials

2.2. Specimen Preparation

2.3. Test Methods

3. Results and Discussion

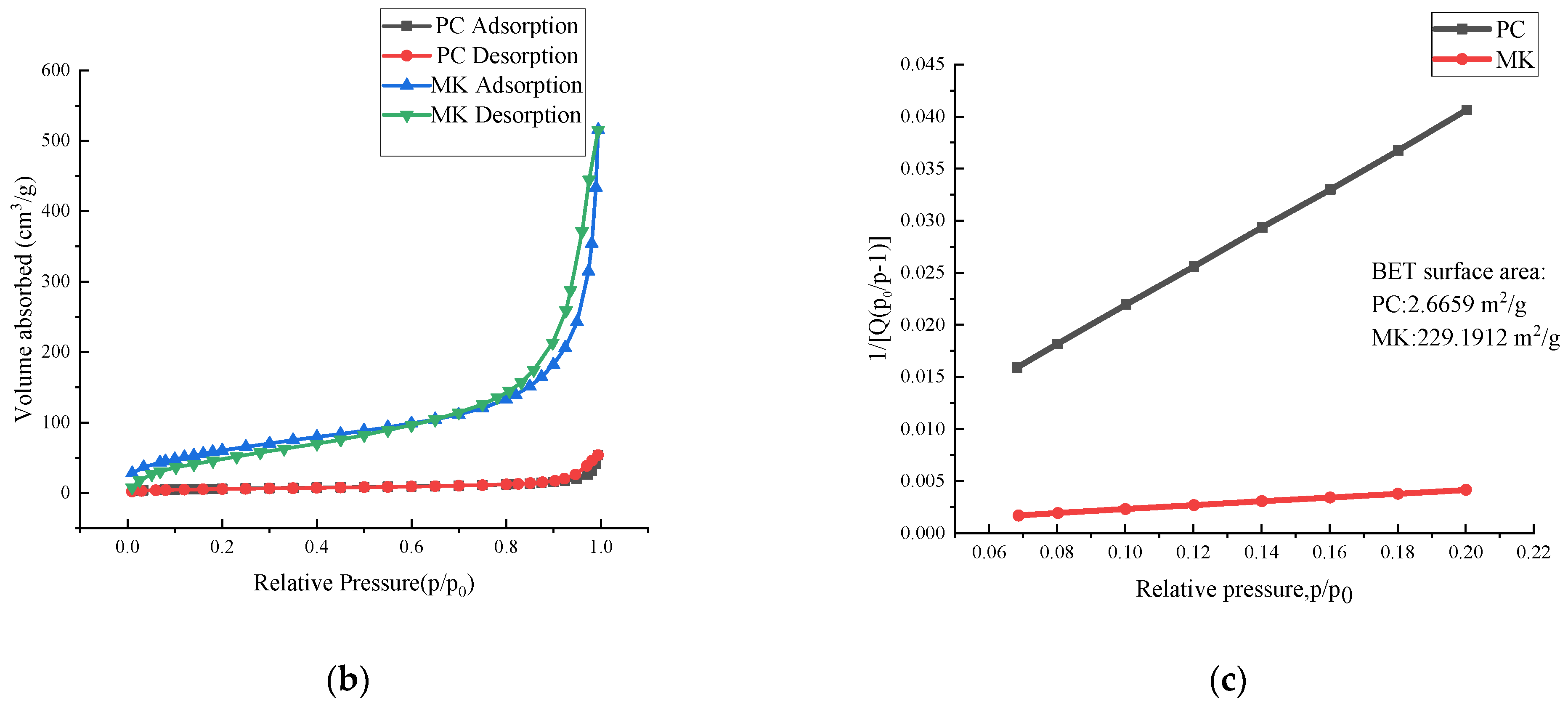

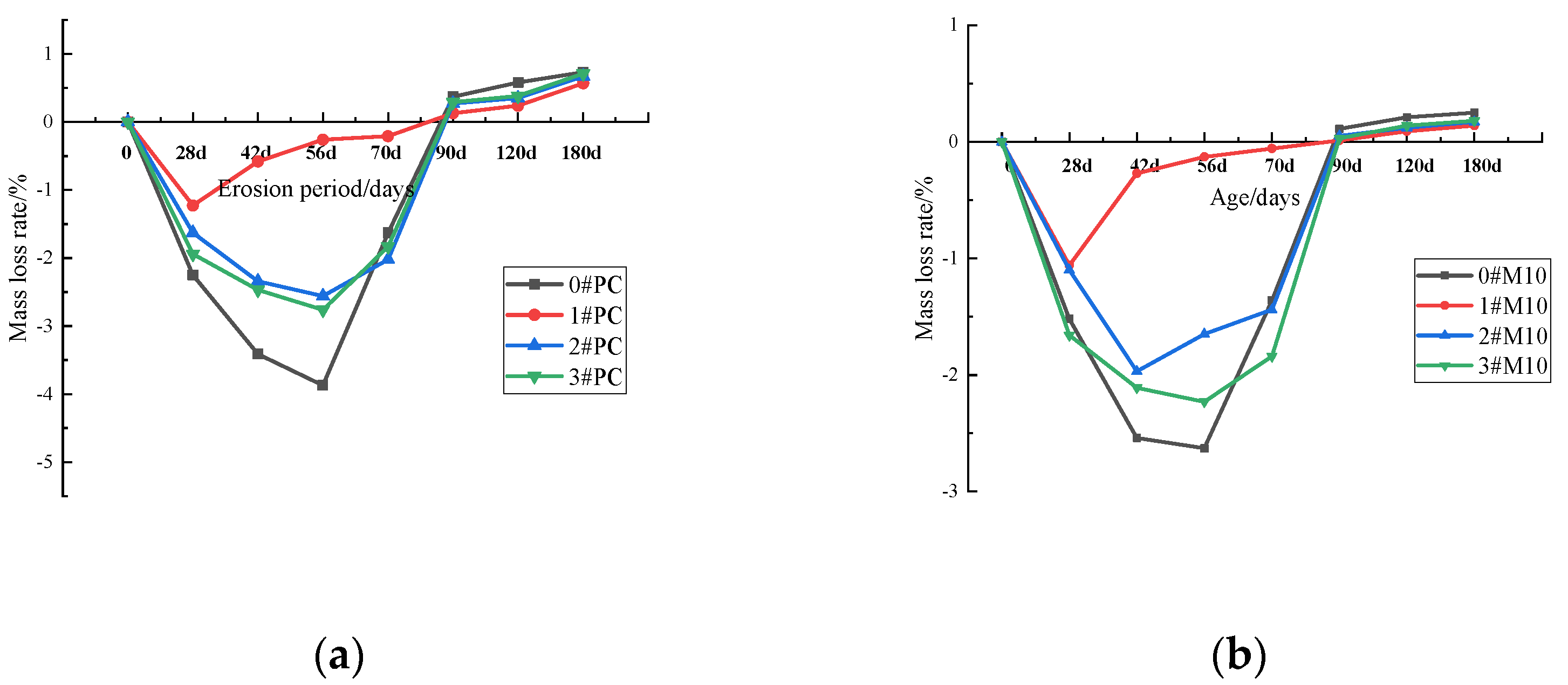

3.1. Effects of Four Curing Methods on the Mechanical Properties of Mortar

3.2. Effect of Four Curing Methods on the Durability of Mortar

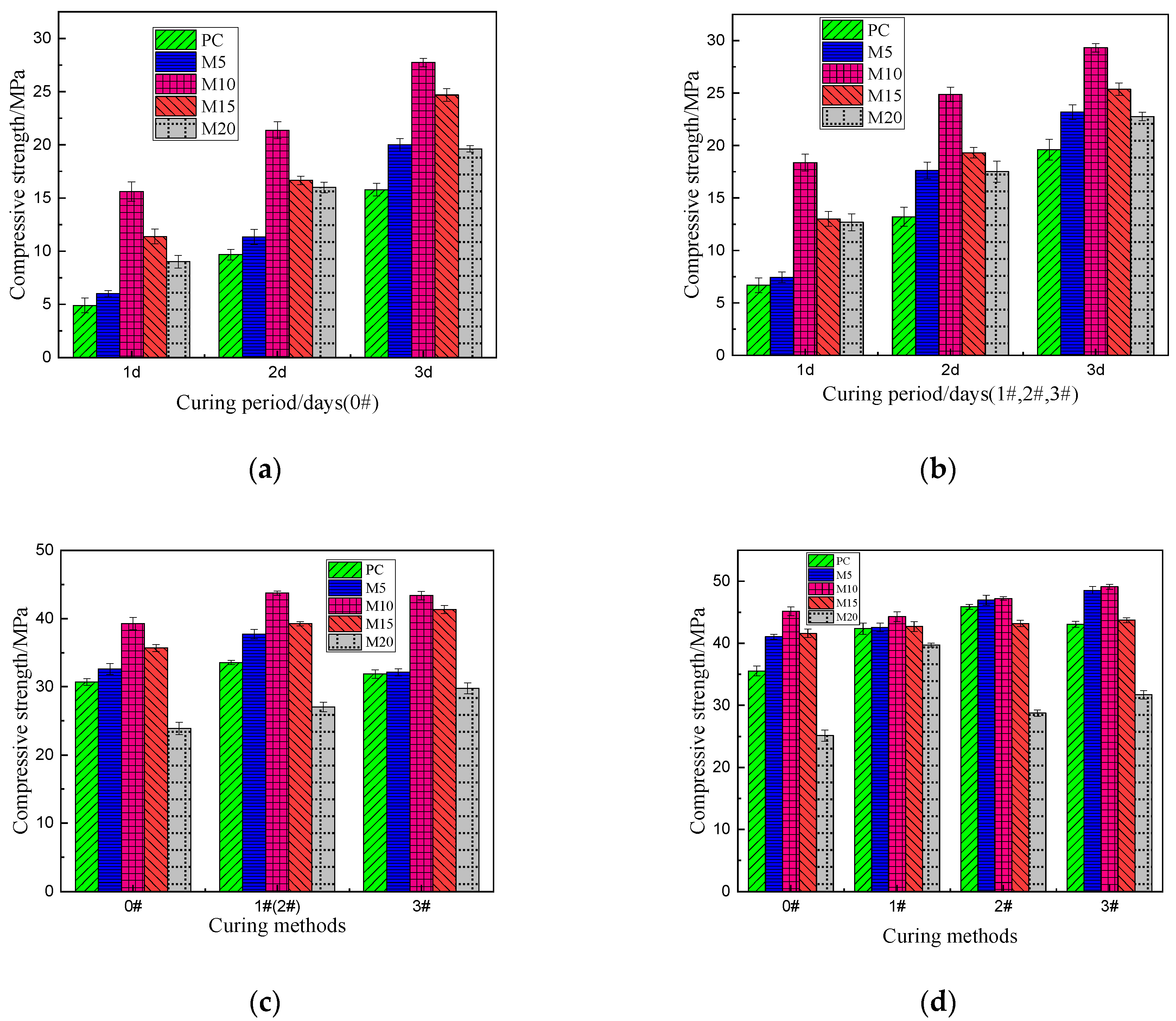

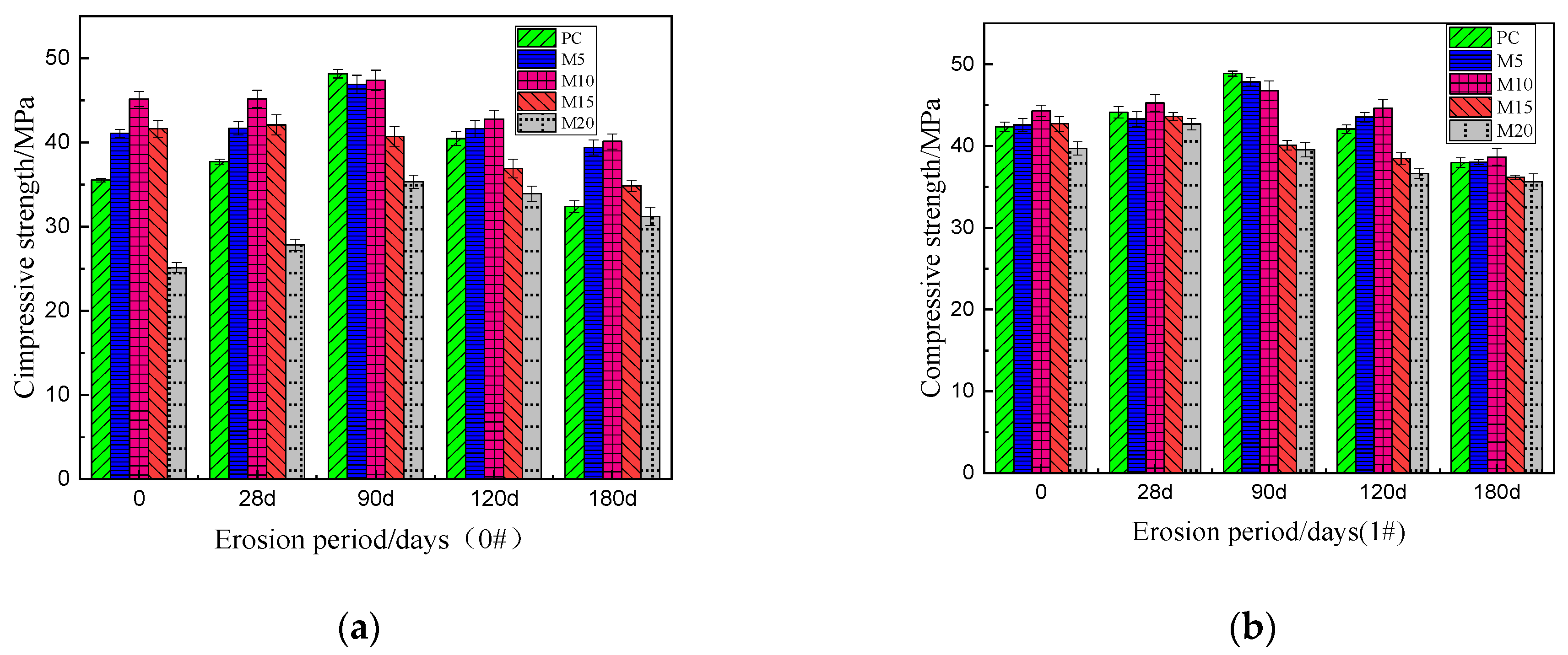

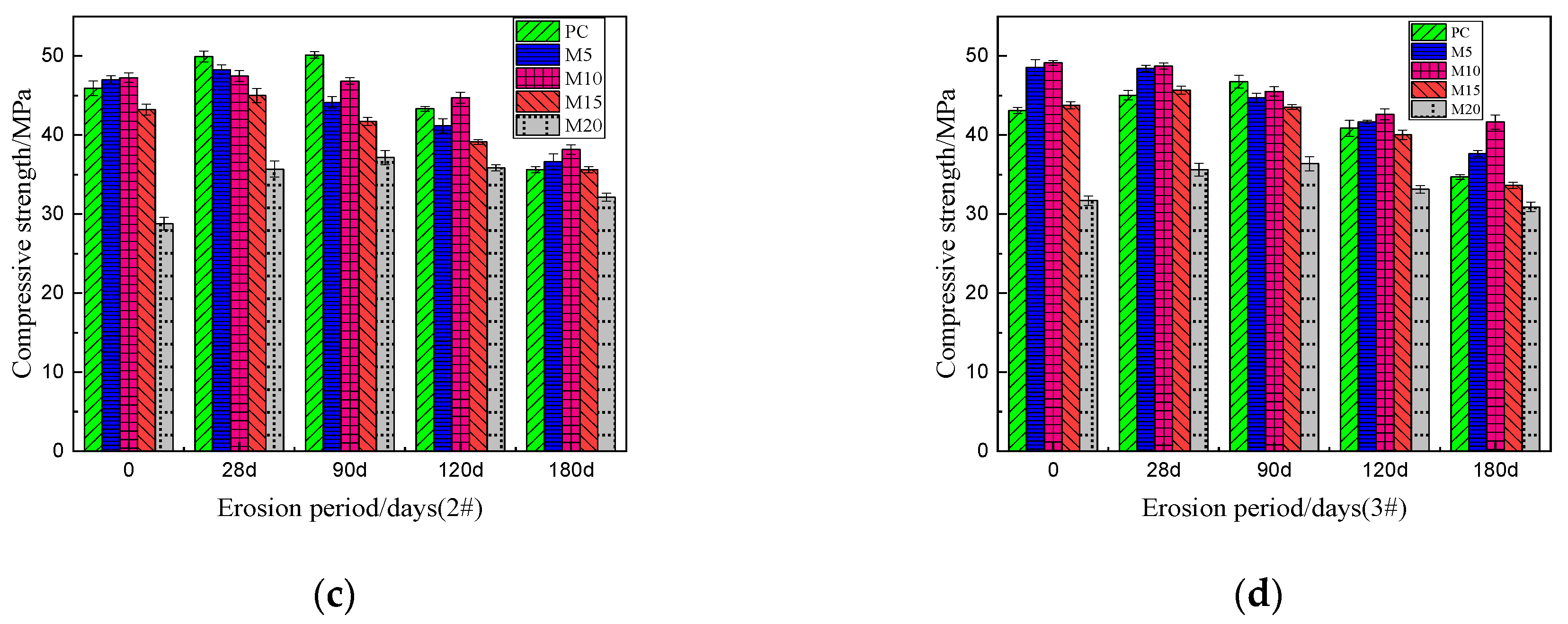

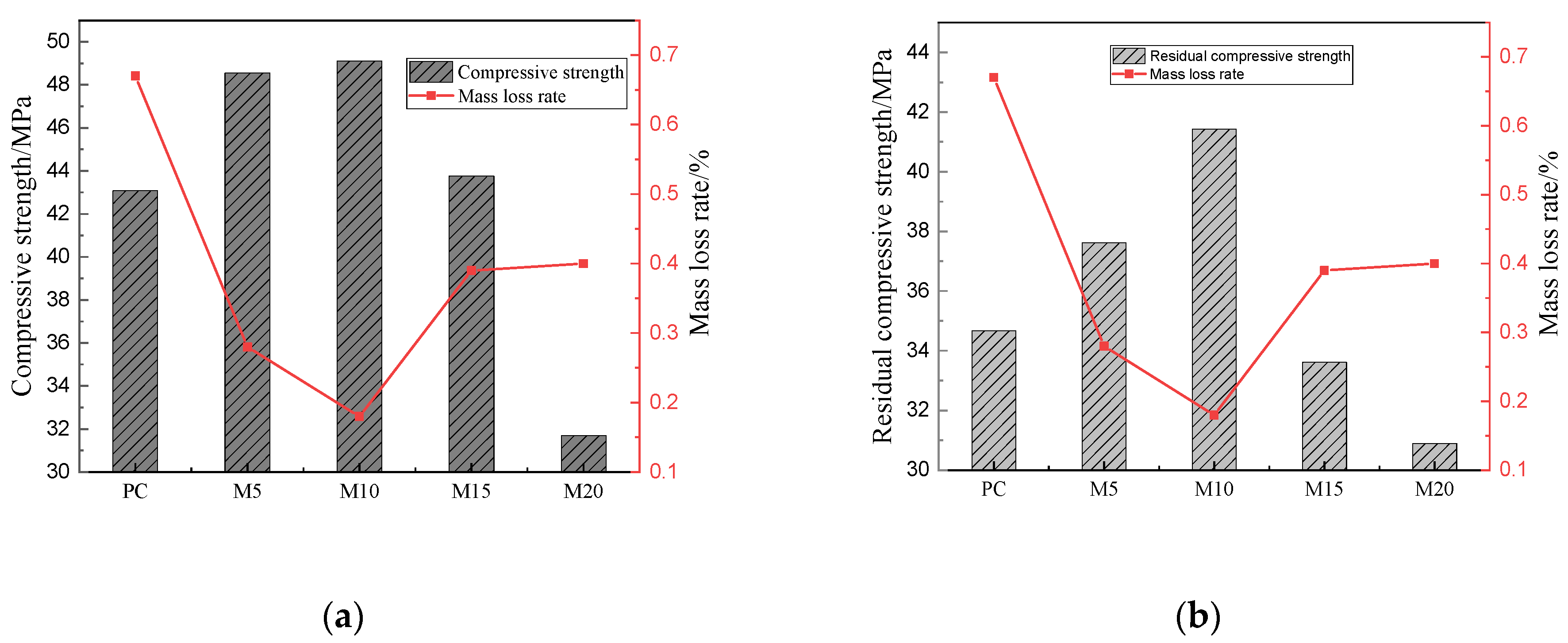

3.2.1. Compressive Strength after Sulfate Attack under Four Curing Methods

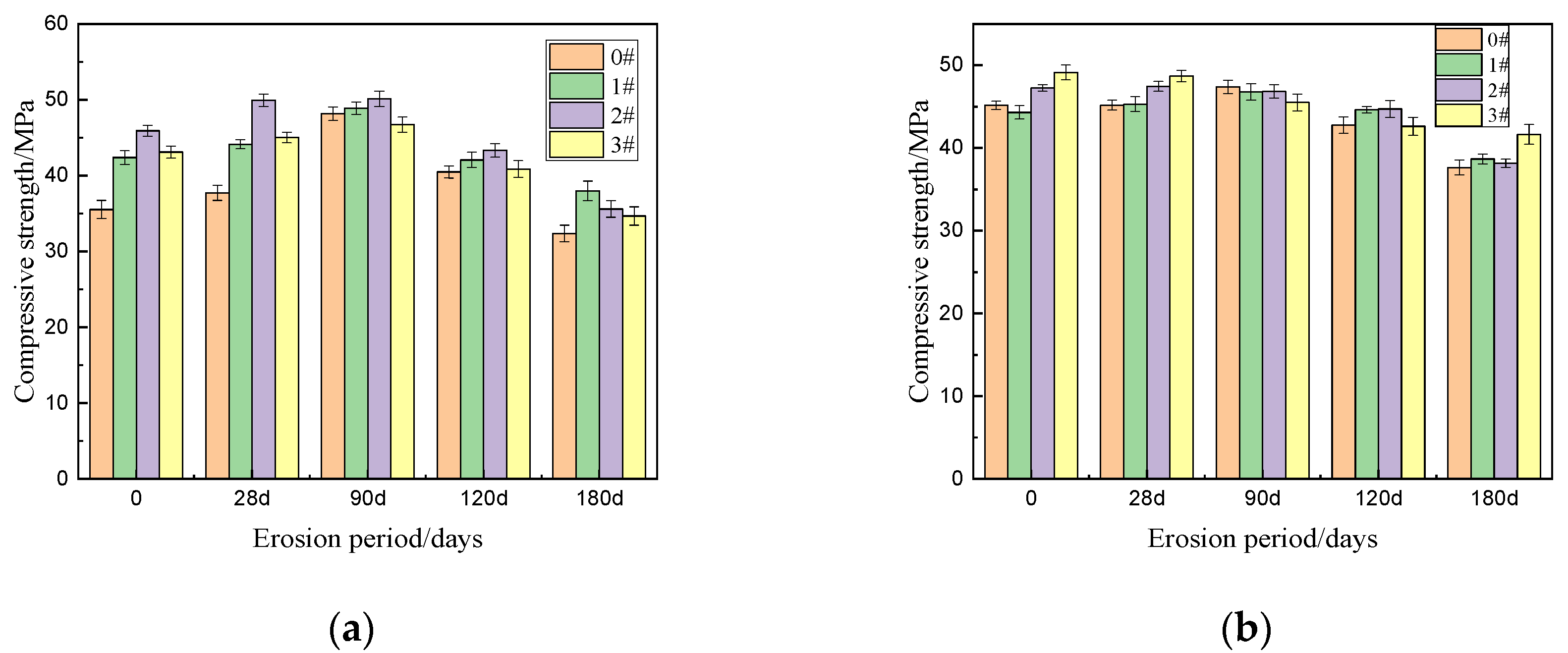

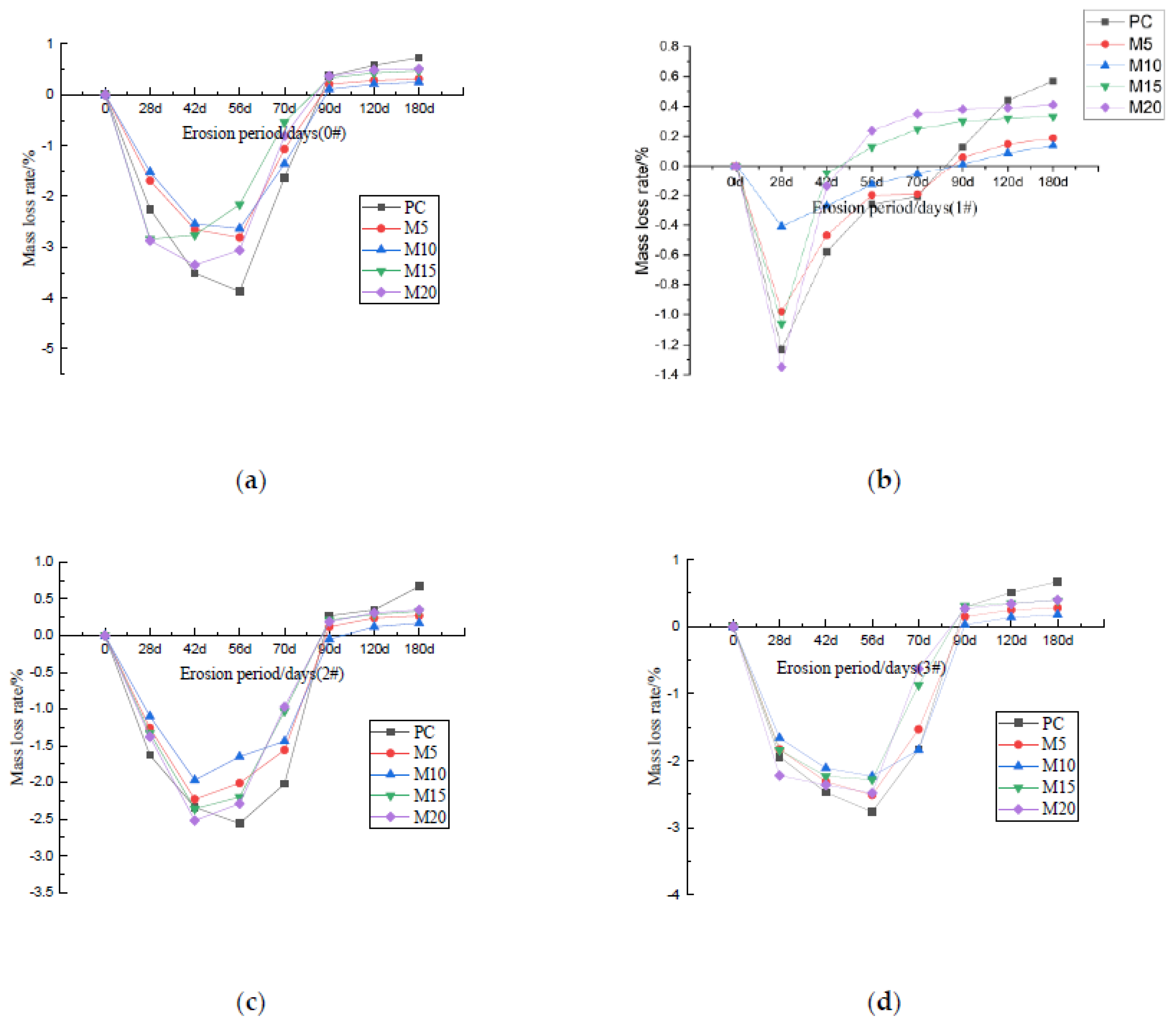

3.2.2. Mass Loss Rate after Sulfate Attack under Four Curing Methods

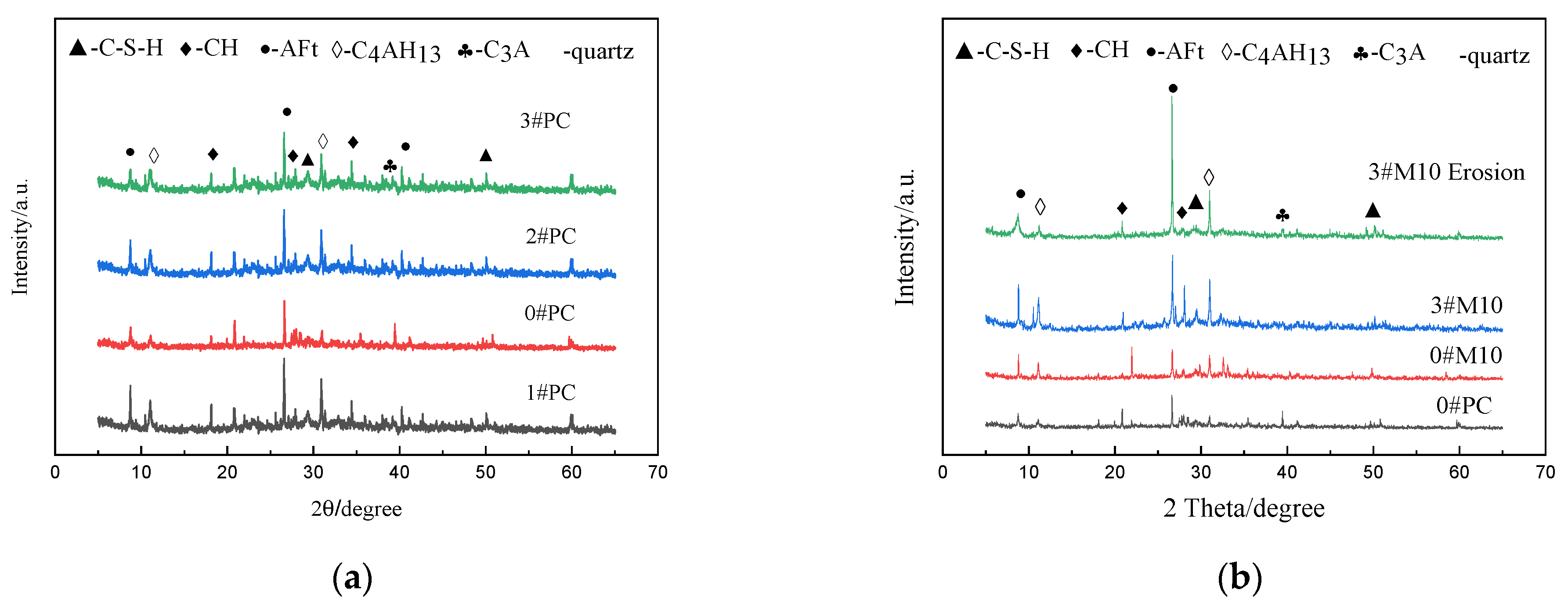

3.3. X-ray Diffraction (XRD) Analysis

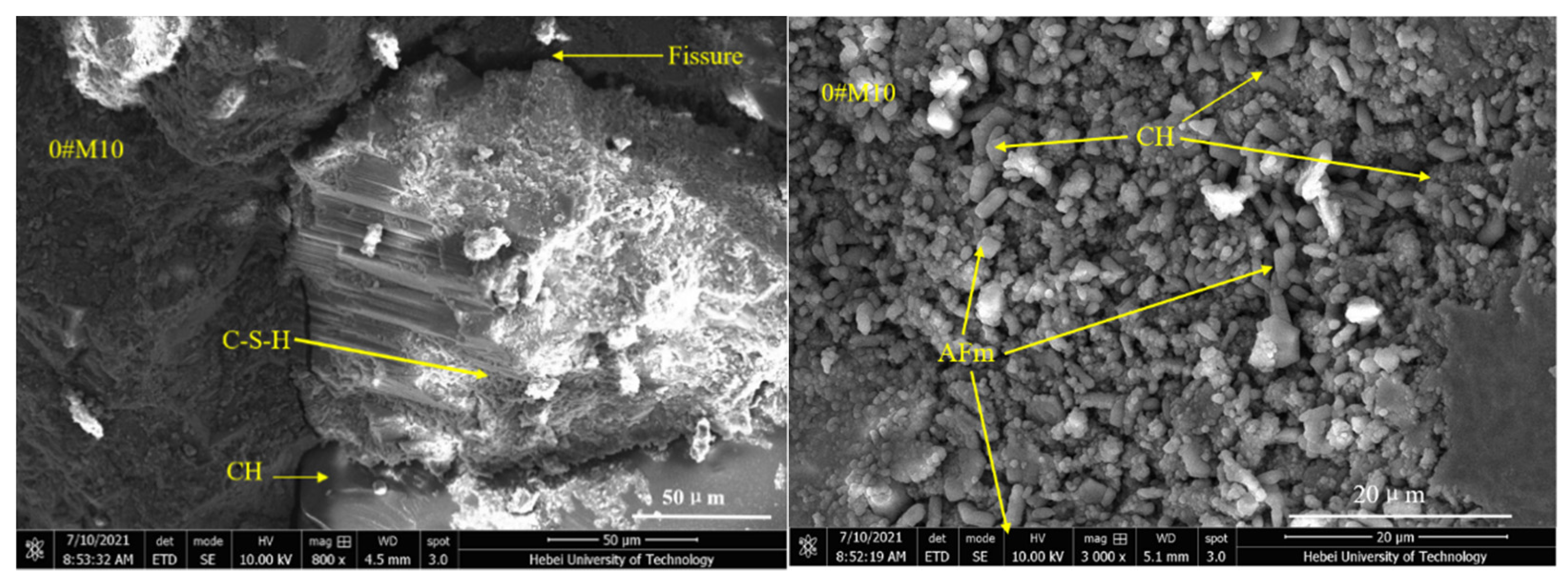

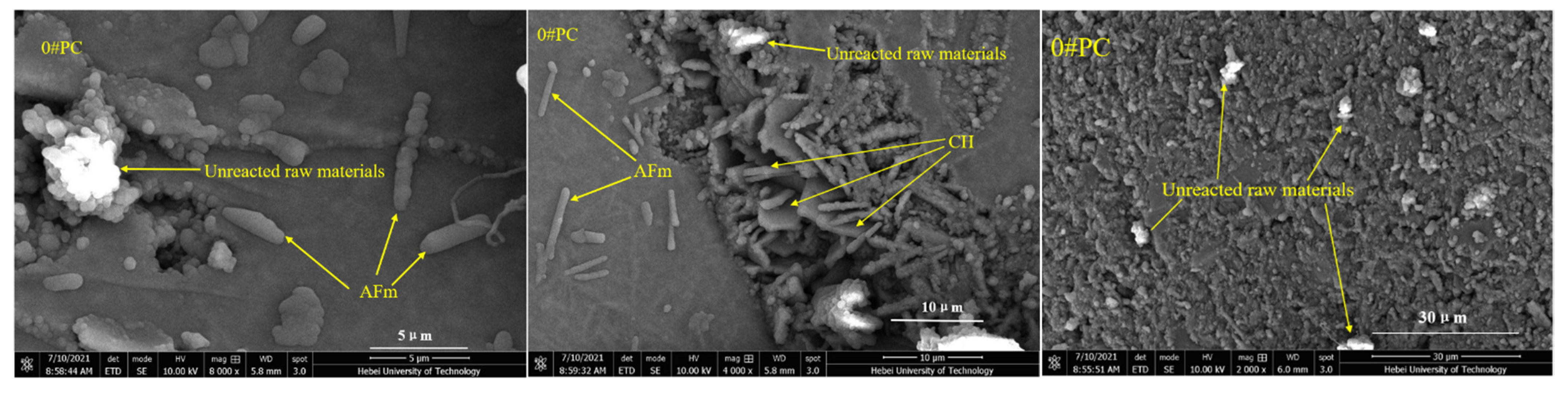

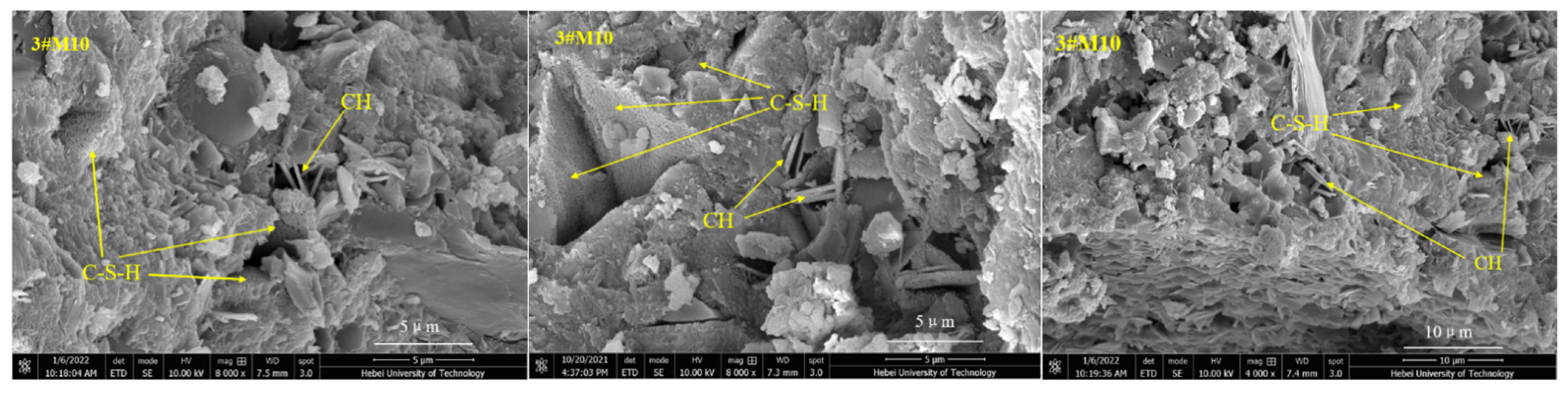

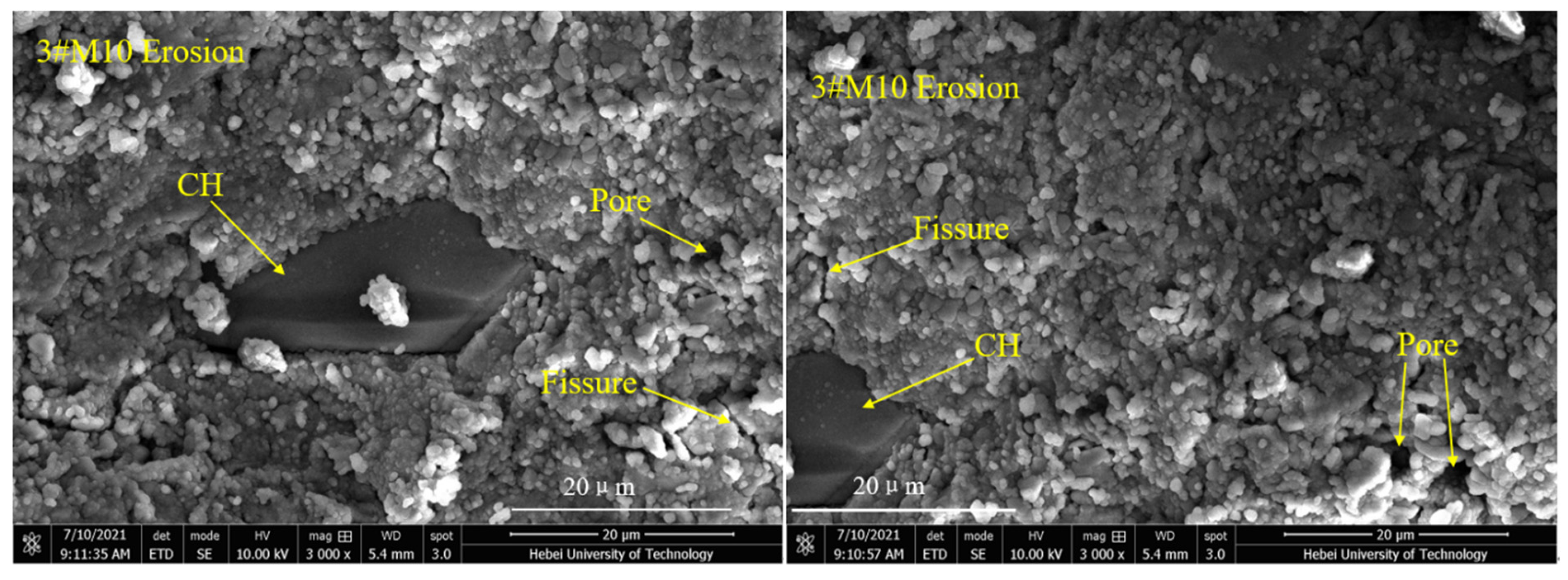

3.4. SEM Analysis

4. Conclusions

- In this paper, the influence of the addition of metakaolin on mechanical properties and durability of Portland cement mortar was studied. The results show that: The filling effect of metakaolin (MK) can effectively increase the density of Portland cement (PC). Moreover, the large surface area and strong water absorption of MK will thicken the water film on the surface of the cement, which lubricates the particles, accelerating the reaction speed and extent, and the optimal dosage of metakaolin (MK) is 10%. The sample can significantly improve the compressive strength and durability of Portland cement mortar, especially the early strength. The compressive strength (at 28 day) and durability of MK10 are superior to that of the other samples.

- In this paper, four different curing methods were designed by changing the early wet curing time, and the influences of the four curing methods on each sample were explored. The results showed that: The traditional silicate-based PC is highly dependent on the wet curing time in the initial curing stages, and typically requires a wet curing time of at least seven days. However, the incorporation of MK can greatly reduce the dependency of PC to water. Moreover, the compressive strength of MK-incorporated cement (3#M10) that has been wet cured for as short as three days can reach 49.12 MPa after 28 days, which can greatly shorten the curing time that require humid conditions. Therefore, the addition of metakaolin can alleviate the problem of high maintenance cost caused by the long wet curing time of Portland cement products in the actual production. Especially in areas with low humidity and when the early wet curing time cannot be guaranteed, the addition of metakaolin has more practical production significance.

- The optimized amount of MK in cement was found to be at 10% (M10), which demonstrated an excellent, comprehensive performance. Under four different curing methods, the best condition for optimizing compressive strength involved the first three days: humidity 95%, followed by humidity 60% for remaining days (3#). From the microstructure of 3#M10, the surface was densely compacted and the hydration was more thorough. Regardless of the 28 day compressive strength, the sulfate resistance and mass retention rate were outstanding.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Divvala, S.; Rani, M.S. Strength Properties and Durability Studies on Modified Geopolymer Concrete Composites Incorporating GGBS and Metakaolin. Appl. Nanosci. 2021, 11, 1–16. [Google Scholar] [CrossRef]

- Mohanraj, A.; Senthilkumar, V. Effect of Metakaolin on the Durability Property of Superabsorbent Polymer Blended Self-Compacting Concrete. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 1–12. [Google Scholar] [CrossRef]

- Kumar, R.; Shafiq, N.; Kumar, A.; Jhatial, A.A. Investigating Embodied Carbon, Mechanical Properties, and Durability of High-Performance Concrete Using Ternary and Quaternary Blends of Metakaolin, Nano-Silica, and Fly Ash. Environ. Sci. Pollut. Res. 2021, 28, 49074–49088. [Google Scholar] [CrossRef] [PubMed]

- Nehdi, M.; Suleiman, A.; Soliman, A. Investigation of Concrete Exposed to Dual Sulfate Attack. Cem. Concr. Res. 2014, 64, 42–53. [Google Scholar] [CrossRef]

- Wianglor, K.; Sinthupinyo, S.; Piyaworapaiboon, M.; Chaipanich, A. Effects of Alkali-Activated Metakaolin Cement on Compressive Strength of Mortars. Appl. Clay Sci. 2017, 141, 272–279. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Wang, Y.C.; Xu, D.L.; Li, S. Mechanical Performance and Hydration Mechanism of Geopolymer Composite Reinforced by Resin. Mater. Sci. Eng. A 2010, 527, 6574–6580. [Google Scholar] [CrossRef]

- Atiş, C.D.; Özcan, F.; Kılıç, A.; Karahan, O.; Bilim, C.M.; Severcan, H. Influence of Dry and Wet Curing Conditions on Compressive Strength of Silica Fume Concrete. Build. Environ. 2004, 40, 1678–1683. [Google Scholar] [CrossRef]

- Qiao, C.; Ni, W.; Wang, C. Hydration and Mechanical Properties of Cement-Based Materials with High Use Level of Metakaolin. J. Build. Mater. 2015, 18, 757–762. [Google Scholar]

- Qin, Z.; Ma, C.; Zheng, Z.; Long, G. Effects of Metakaolin on Properties and Microstructure of Magnesium Phosphate Cement. Constr. Build. Mater. 2020, 234, 117353. [Google Scholar] [CrossRef]

- Tang, J.; Wei, S.; Li, W.; Ma, S.; Ji, P.; Shen, X. Synergistic Effect of Metakaolin and Limestone on the Hydration Properties of Portland Cement. Constr. Build. Mater. 2019, 223, 177–184. [Google Scholar] [CrossRef]

- Qian, X.; Wang, J.; Wang, L.; Fang, Y. Enhancing the Performance of Metakaolin Blended Cement Mortar through in-Situ Production of Nano to Sub-Micro Calcium Carbonate Particles. Constr. Build. Mater. 2019, 196, 681–691. [Google Scholar] [CrossRef]

- Marchetti, G.; Rahhal, V.F.; Irassar, E.F. Influence of Packing Density and Water Film Thickness on Early-Age Properties of Cement Pastes with Limestone Filler and Metakaolin. Mater. Struct. 2017, 50, 111. [Google Scholar] [CrossRef]

- Cabrera, J.; Rojas, M.F. Mechanism of Hydration of the Metakaolin-Lime-Water System. Cem. Concr. Res. 2001, 31, 177–182. [Google Scholar] [CrossRef]

- Wang, L.; Li, X.; Cheng, Y.; Zhang, Y.; Bai, X. Effects of Coal-Bearing Metakaolin on the Compressive Strength and Permeability of Cemented Silty Soil and Mechanisms. Constr. Build. Mater. 2018, 186, 174–181. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Karaoğlu, S.; Mermerdaş, K. Strength, Permeability and Shrinkage Cracking of Silica Fume and Metakaolin Concretes. Constr. Build. Mater. 2012, 34, 120–130. [Google Scholar] [CrossRef]

- Al-Akhras, N.M. Durability of Metakaolin Concrete to Sulfate Attack. Cem. Concr. Res. 2006, 36, 1727–1734. [Google Scholar] [CrossRef]

- Hu, L.; He, Z. A Fresh Perspective on Effect of Metakaolin and Limestone Powder on Sulfate Resistance of Cement-Based Materials. Constr. Build. Mater. 2020, 262, 119847. [Google Scholar] [CrossRef]

- Lee, S.T.; Moon, H.Y.; Hooton, R.D.; Kim, J.P. Effect of Solution Concentrations and Replacement Levels of Metakaolin on the Resistance of Mortars Exposed to Magnesium Sulfate Solutions. Constr. Build. Mater. 2005, 35, 1314–1323. [Google Scholar] [CrossRef]

- Helmy, A.I.I. Intermittent Curing of Fly Ash Geopolymer Mortar. Constr. Build. Mater. 2006, 110, 54–64. [Google Scholar] [CrossRef]

- El-Hassan, H. Effect of Curing Regime on the Performance and Microstructure Characteristics of Alkali-Activated Slag-Fly Ash Blended Concrete. J. Sustain. Cen.-Based Mater. 2021, 10, 289–317. [Google Scholar] [CrossRef]

- Athira, V.S.; Bahurudeen, A.; Saljas, M.; Jayachandran, K. Influence of Different Curing Methods on Mechanical and Durability Properties of Alkali Activated Binders. Constr. Build. Mater. 2021, 299, 123963. [Google Scholar] [CrossRef]

- GB/T 1346-2001; Test Methods for Water Requirement of Normal Consistency, Setting Time and Soundness of the Portland Cements. China Standard Press: Beijing, China, 2011.

- GB/17671-1999; Method of Testing Cements-Determination of Strength. China Standard Press: Beijing, China, 1999.

- Ma, C.; Peng, J.; Zhou, H.; Zhou, R.; Ren, W.; Du, Y. An Effective Method for Preparing High Early-Strength Cement-Based Materials: The Effects of Direct Electric Curing on Portland Cement. J. Build. Eng. 2021, 43, 102485. [Google Scholar] [CrossRef]

- Boháč, M.; Palou, M.; Novotný, R.; Masilko, J. Influence of Temperature on Early Hydration of Portland Cement—Metakaolin—Slag System. J. Therm. Anal. Calorim. 2017, 127, 309–318. [Google Scholar] [CrossRef]

- JGJ/T 70-2009; Standard for Test Method of Performance on Building Mortar. China Architecture and Building Press: Beijing, China, 2009.

- Chu, S.H.; Chen, J.J.; Li, L.G.; Ng, P.L.; Kwan, A.K.H. Roles of Packing Density and Slurry Film Thickness in Synergistic Effects of Metakaolin and Silica Fume. Powder Technol. 2021, 387, 575–583. [Google Scholar] [CrossRef]

- Hasan, Z.A.; Nasr, M.S.; Abed, M.K. Properties of Reactive Powder Concrete Containing Different Combinations of Fly Ash and Metakaolin. Mater. Today Proc. 2021, 42, 2436–2440. [Google Scholar] [CrossRef]

- Cai, R.; Tian, Z.; Ye, H.; He, Z.; Tang, S. The Role of Metakaolin in Pore Structure Evolution of Portland Cement Pastes Revealed by an Impedance Approach. Cem. Concr. Compos. 2021, 119, 103999. [Google Scholar] [CrossRef]

- Yu, T.; Doh, S.I.; Chin, S.C. The Effect of Different Curing Methods on the Compressive Strength of Eggshell Concrete. Indian J. Sci. Technol. 2017, 10, 1–4. [Google Scholar] [CrossRef]

- Khaliq, W.; Javaid, W. Efficiency Comparison of Conventional and Unconventional Curing Methods in Concrete. ACI Mater. J. 2018, 115, 161–163. [Google Scholar] [CrossRef]

- Solikin, M.; Setiawan, B. The Effects of Design Strength, Fly Ash Content and Curing Method on Compressive Strength of High-Volume Fly Ash Concrete: A Design of Experimental. MATEC Web Conf. 2017, 103, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Aprianti, E.; Shafigh, P.; Zawawi, R.; Hassan, Z.F.A. Introducing an Effective Curing Method for Mortar Containing High Volume Cementitious Materials. Constr. Build. Mater. 2016, 107, 365–377. [Google Scholar] [CrossRef]

- Francis, K.N.G.W.; Kennedy, A.B.; Firmin, A. Impact of Curing Methods on the Porosity and Compressive Strength of Concrete. J. Eng. Res. Rep. 2021, 20, 18–30. [Google Scholar]

- Manomi, N.; Sathyan, D.; Anand, K.B. Coupled Effect of Superplasticizer Dosage and Fly Ash Content on Strength and Durability of Concrete. Mater. Today Proc. 2018, 5, 24033–24042. [Google Scholar] [CrossRef]

- Zapala-Slaweta, J. Alkali Silica Reaction in the Presence of Metakaolin-the Significant Role of Calcium Hydroxide. IOP Conf. Ser.-Mater. Sci. Eng. 2017, 245, 022020. [Google Scholar] [CrossRef]

- Wang, L.; Guo, F.; Lin, Y.; Yang, H.; Tang, S. Comparison between the Effects of Phosphorous Slag and Fly Ash on the C-S-H Structure, Long-Term Hydration Heat and Volume Deformation of Cement-Based Materials. Constr. Build. Mater. 2020, 250, 118807. [Google Scholar] [CrossRef]

- Diamond, S.; Kjellsen, K.O. Resolution of Fine Fibrous C-S-H in Backscatter SEM Examination. Cem. Concr. Compos. 2006, 28, 130–132. [Google Scholar] [CrossRef]

- Berti, D.; Biscontin, G.; Lau, J. Effect of Biochar Filler on the Hydration Products and Microstructure in Portland Cement—Stabilized Peat. J. Mater. Civ. Eng. 2021, 33, 04021263. [Google Scholar] [CrossRef]

- Han, S.; Zhong, J.; Ding, W.; Ou, J. Strength, Hydration, and Microstructure of Seawater Sea-Sand Concrete Using High-Ferrite Portland Cement. Constr. Build. Mater. 2021, 295, 123703. [Google Scholar] [CrossRef]

| Material | CaO | SiO2 | Fe2O3 | Al2O3 | MgO | SO3 | TiO2 | K2O | Others | LOI |

|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 49.06 | 26.56 | 2.58 | 10.37 | 6.33 | 1.80 | 1.53 | 0.828 | 0.942 | 1.62 |

| MK | 0.283 | 58.05 | 0.845 | 38.15 | - | - | 2.17 | 0.224 | 0.278 | 0.40 |

| Raw Material | Water Absorption/% | Specific Gravity | Fineness Modulus | Unit wt% (kg/m3) |

|---|---|---|---|---|

| River Sand | 0.95 | 2.58 | 2.70 | 1588 |

| Mix | Samples | W/b | Cement (kg/m3) | MK (kg/m3) | Sand (kg/m3) | Water (kg/m3) | Superplasticizer (kg/m3) |

|---|---|---|---|---|---|---|---|

| 1 | PC | 0.45 | 595.18 | 0 | 892.76 | 267.84 | 5.95 |

| 2 | M5 | 0.45 | 565.42 | 29.76 | 889.83 | 267.84 | 7.14 |

| 3 | M10 | 0.45 | 535.66 | 59.52 | 886.90 | 267.84 | 8.33 |

| 4 | M15 | 0.45 | 505.9 | 89.28 | 883.96 | 267.84 | 9.52 |

| 5 | M20 | 0.45 | 476.14 | 119.04 | 881.03 | 267.84 | 10.71 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, Y.; Pei, L.; Fu, J.; Yang, Y.; Liu, T.; Liang, H.; Yang, H. Investigating the Mechanical Properties and Durability of Metakaolin-Incorporated Mortar by Different Curing Methods. Materials 2022, 15, 2035. https://doi.org/10.3390/ma15062035

Dong Y, Pei L, Fu J, Yang Y, Liu T, Liang H, Yang H. Investigating the Mechanical Properties and Durability of Metakaolin-Incorporated Mortar by Different Curing Methods. Materials. 2022; 15(6):2035. https://doi.org/10.3390/ma15062035

Chicago/Turabian StyleDong, Yudong, Lianjun Pei, Jindong Fu, Yalong Yang, Tong Liu, Huihui Liang, and Hongjian Yang. 2022. "Investigating the Mechanical Properties and Durability of Metakaolin-Incorporated Mortar by Different Curing Methods" Materials 15, no. 6: 2035. https://doi.org/10.3390/ma15062035

APA StyleDong, Y., Pei, L., Fu, J., Yang, Y., Liu, T., Liang, H., & Yang, H. (2022). Investigating the Mechanical Properties and Durability of Metakaolin-Incorporated Mortar by Different Curing Methods. Materials, 15(6), 2035. https://doi.org/10.3390/ma15062035