Combination of Pre- and Post-Mercerization Processes for Cotton Fabric

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mercerization

2.2.1. Caustic Mercerization

2.2.2. Liquid Ammonia Mercerization

2.3. Dyeing Performance

2.3.1. Dyeing Process of Cotton Fabrics

2.3.2. Measurement of Dyeing Performance

2.3.3. Color Strength and Color Uniformity

2.3.4. Colorfastness to Washing and Rubbing

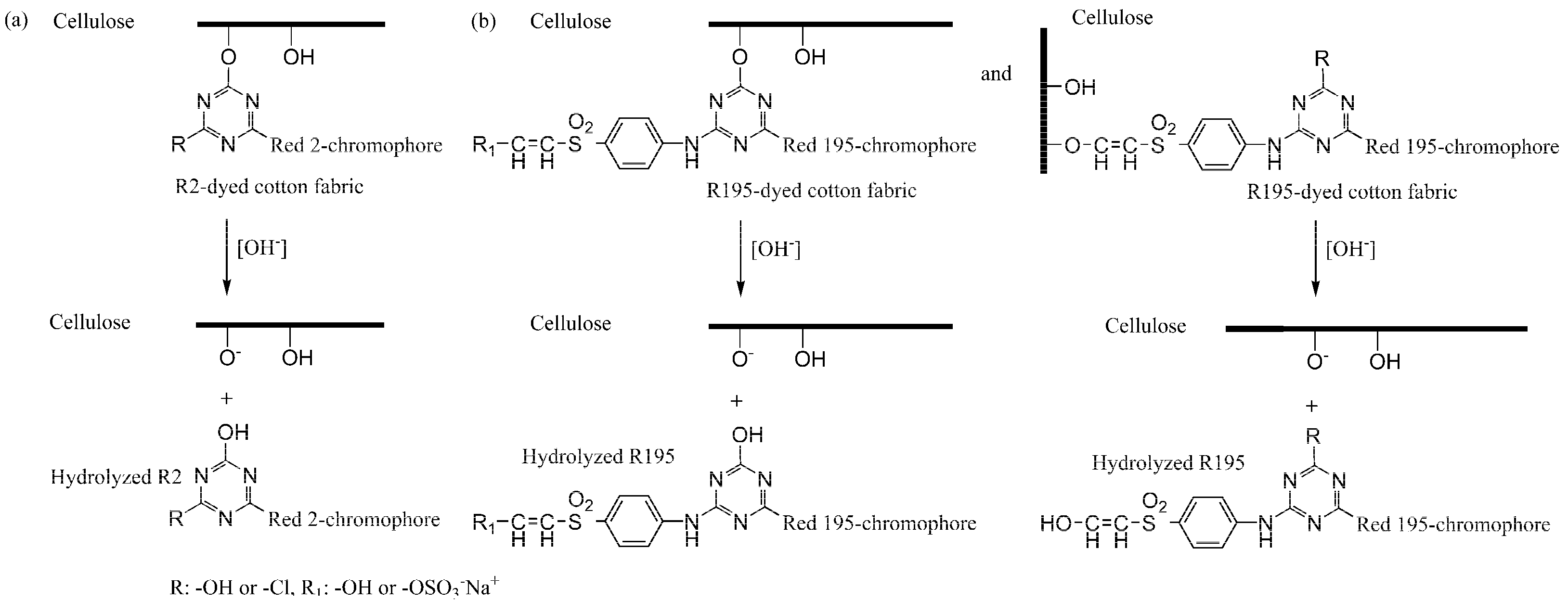

2.3.5. Dye Removal Percentage by CS and LA Post-Mercerization Processes

2.4. Measurements and Characterization

2.4.1. X-ray Diffraction

2.4.2. Thermogravimetric Analysis

2.4.3. Stiffness

2.4.4. Breaking Force and Elongation of Fabrics

3. Results and Discussion

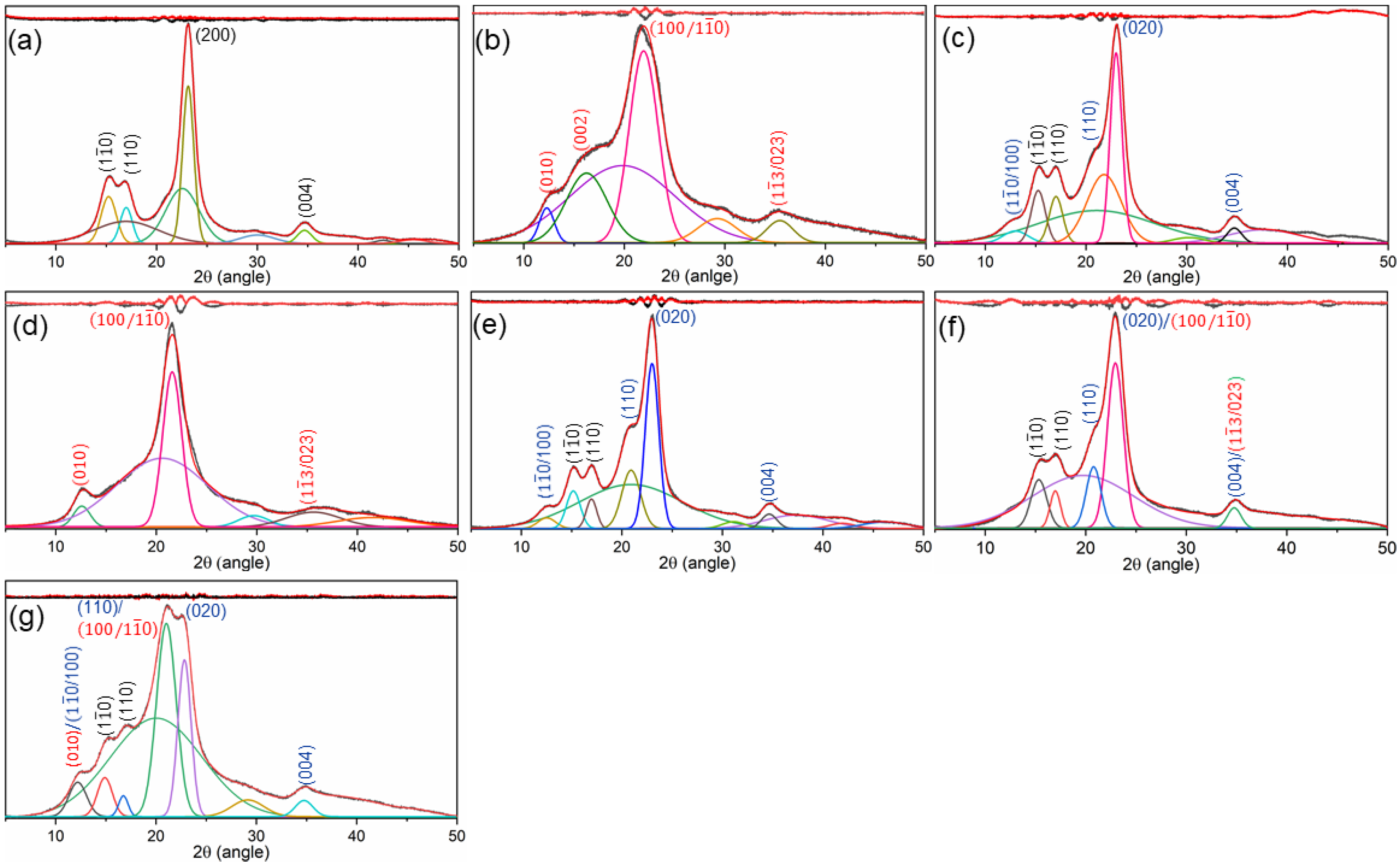

3.1. XRD Analysis

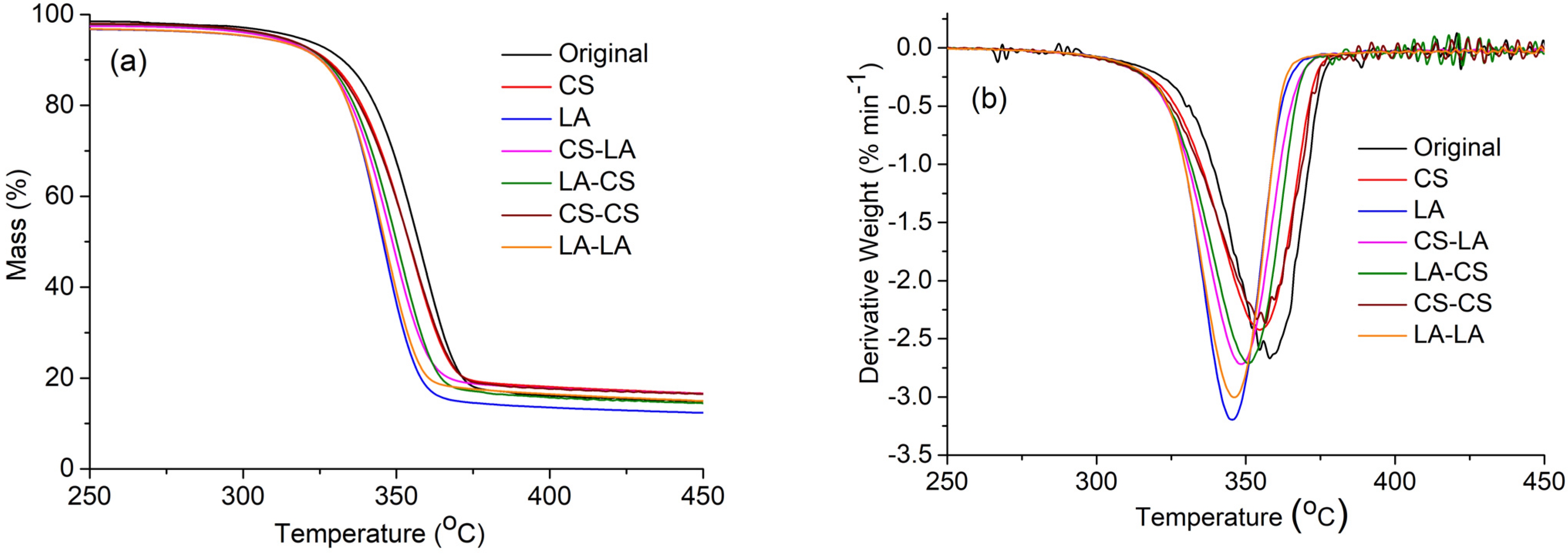

3.2. Thermal Performance

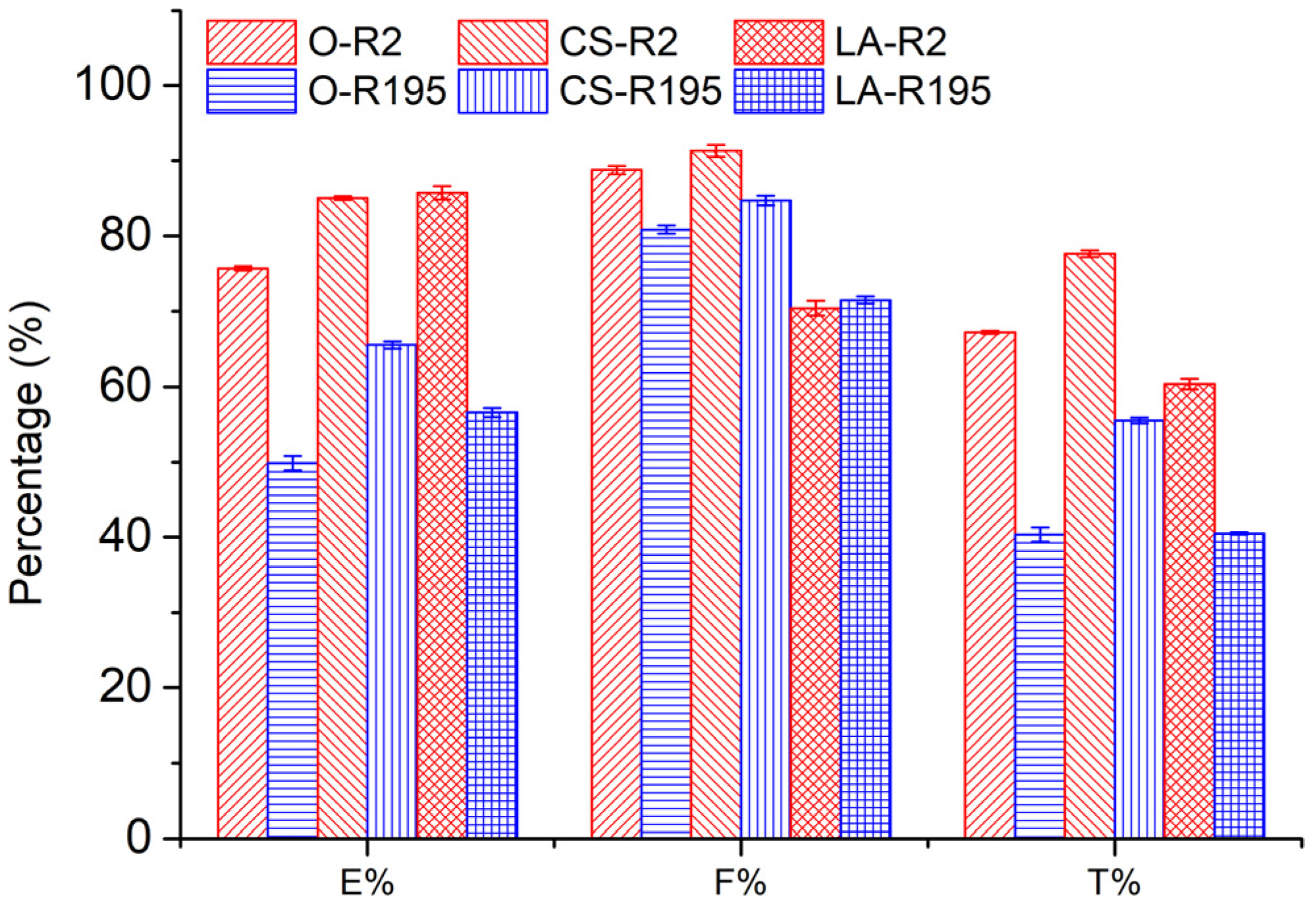

3.3. Influence of Pre-Mercerization on Dyeing Performance of Cotton Fabric

3.4. Influence of Post-Mercerization on Dye Removal

3.5. Color Strength and Color Uniformity

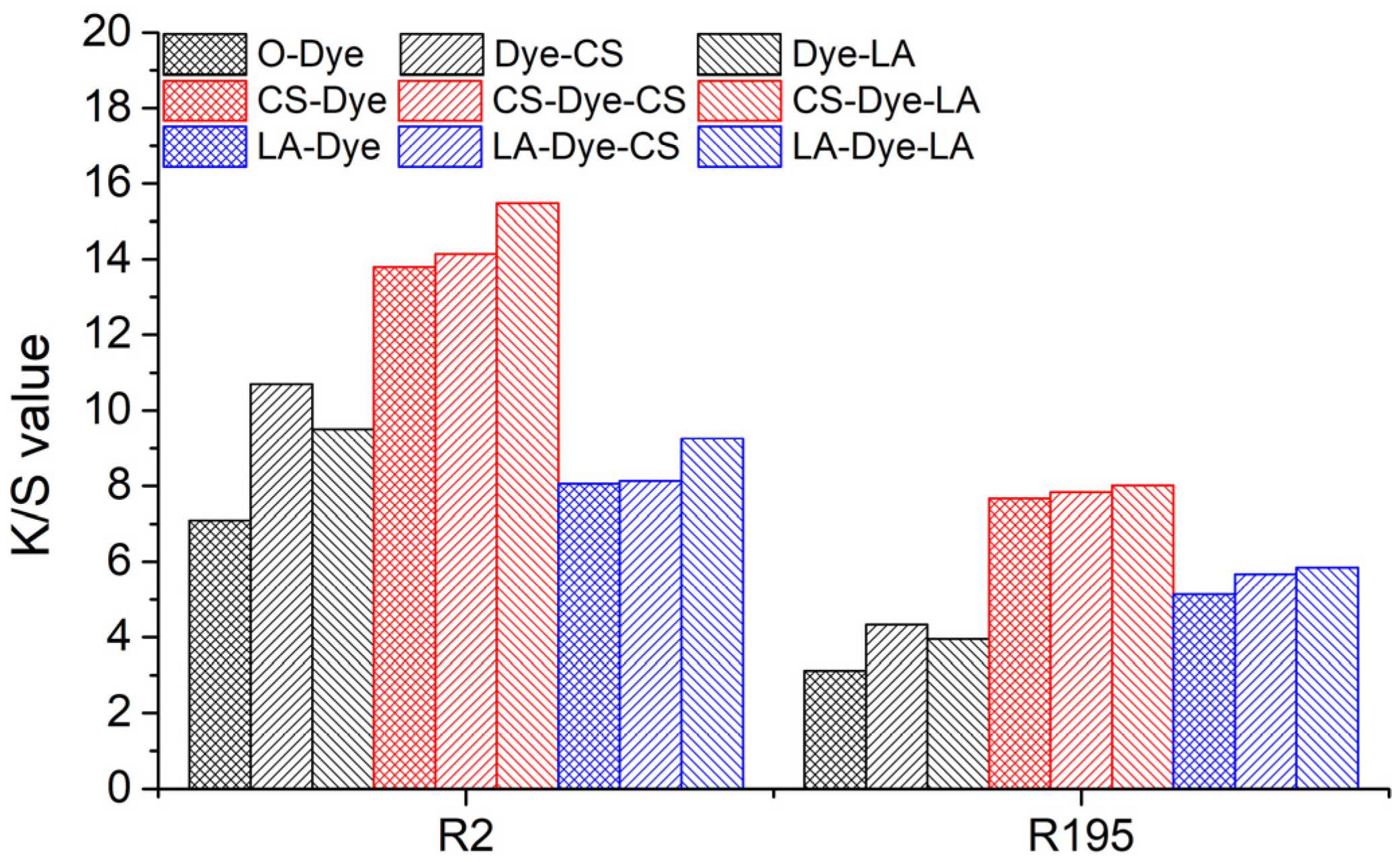

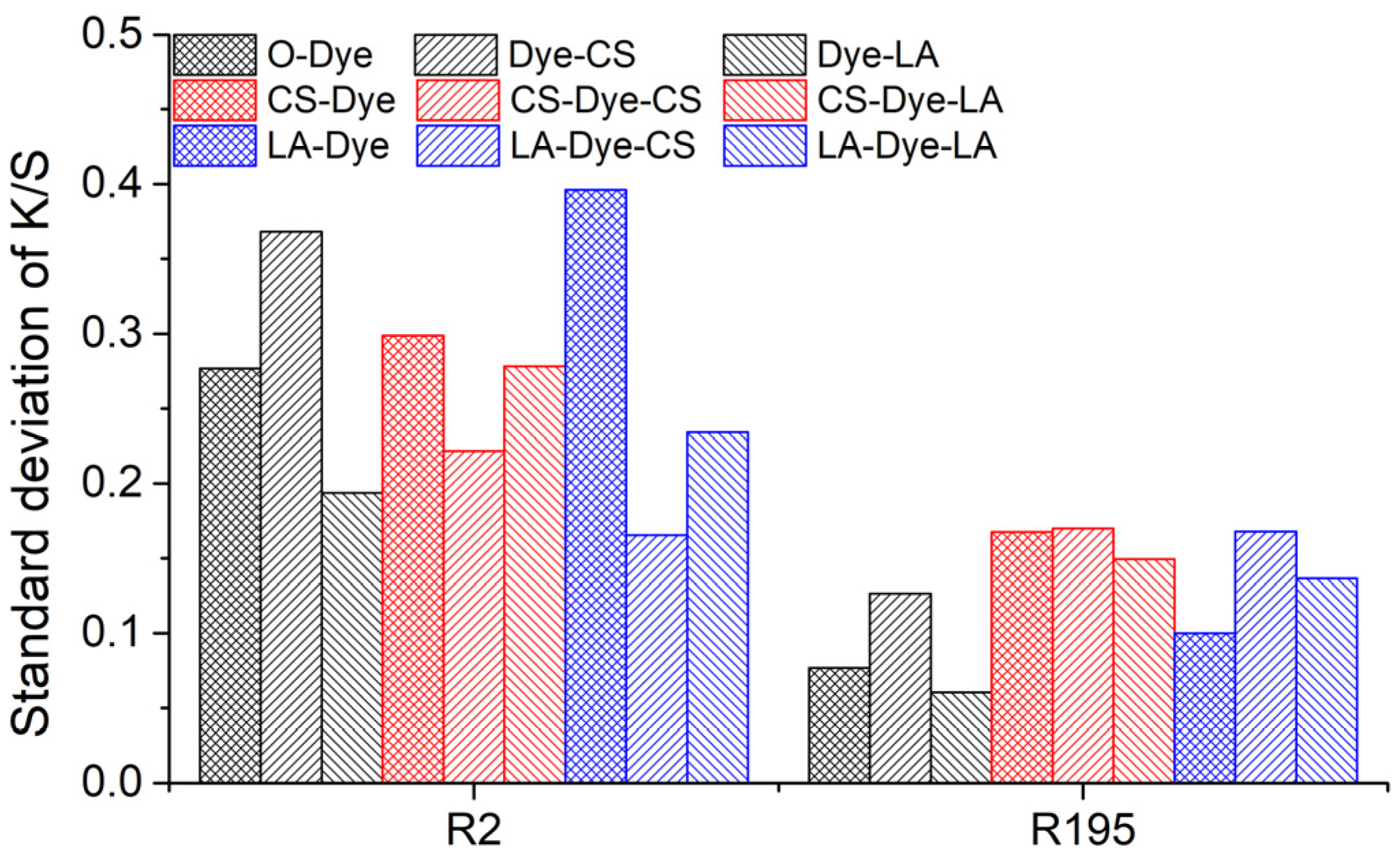

3.6. Colorfastness to Washing and Rubbing

3.7. Fabric Stiffness

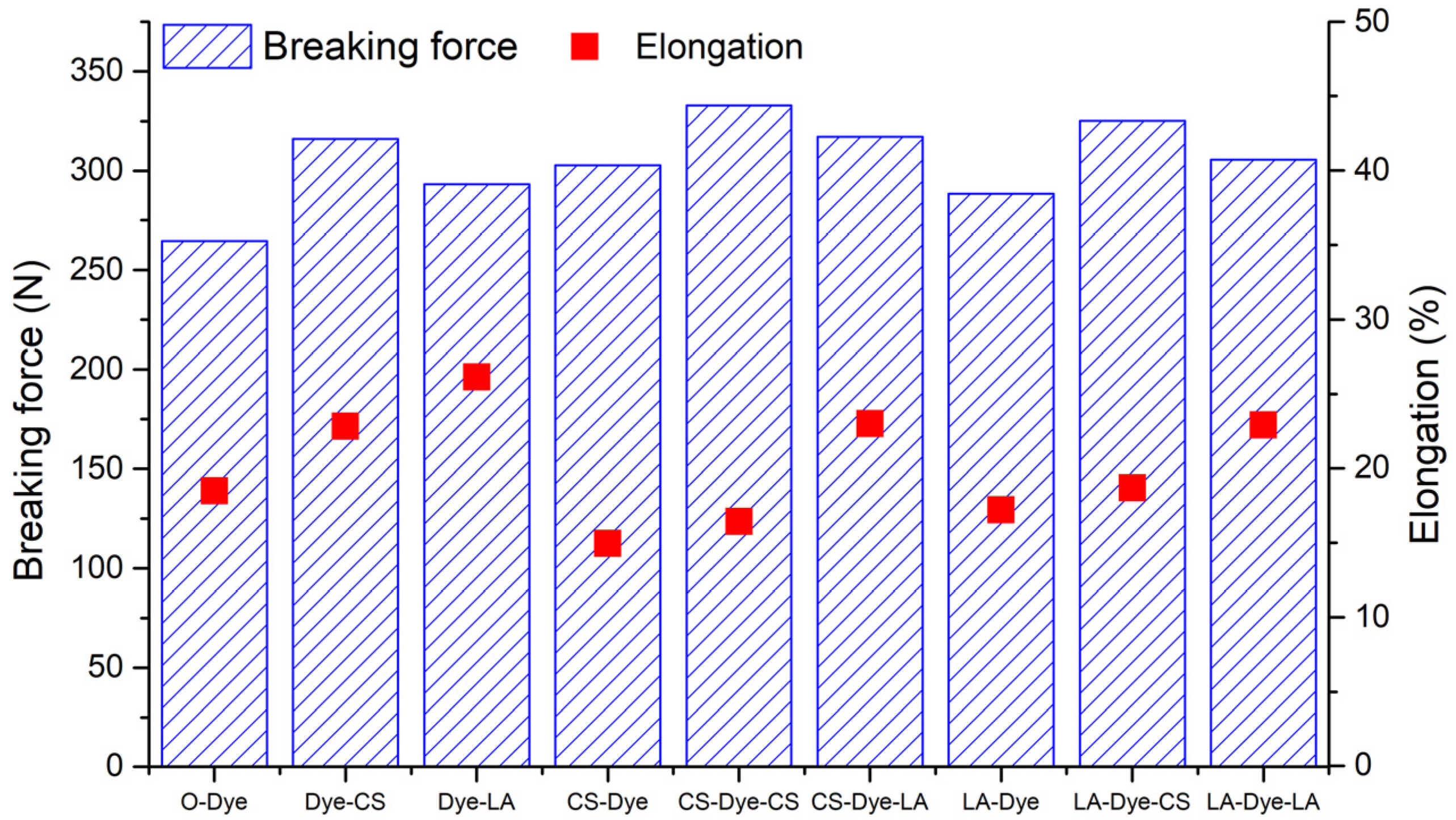

3.8. Breaking Force and Elongation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cai, Y.; Su, S.; Navik, R.; Wen, S.; Peng, X.; Pervez, M.N.; Lin, L. Cationic modification of ramie fibers in liquid ammonia. Cellulose 2018, 25, 4463–4475. [Google Scholar] [CrossRef]

- Hossain, M.Y.; Zhu, W.; Pervez, M.N.; Yang, X.; Sarker, S.; Hassan, M.M.; Hoque, M.I.U.; Naddeo, V.; Cai, Y. Adsorption, kinetics, and thermodynamic studies of cacao husk extracts in waterless sustainable dyeing of cotton fabric. Cellulose 2021, 28, 2521–2536. [Google Scholar] [CrossRef]

- Mahmud, S.; Pervez, M.N.; Taher, M.A.; Mohiuddin, K.; Liu, H.-H. Multifunctional organic cotton fabric based on silver nanoparticles green synthesized from sodium alginate. Text. Res. J. 2019, 90, 1224–1236. [Google Scholar] [CrossRef]

- Shafiq, F.; Pervez, M.N.; Jilani, M.M.; Sarwar, Z.; Hasani, H.; Cai, Y. Structural relationships and optimization of resin-finishing parameters using the Taguchi approach. Cellulose 2018, 25, 6175–6190. [Google Scholar] [CrossRef]

- Bhatti, I.A.; Adeel, S.; Siddique, S.; Abbas, M. Effect of UV radiation on the dyeing of cotton fabric with reactive blue 13. J. Saudi Chem. Soc. 2014, 18, 606–609. [Google Scholar] [CrossRef] [Green Version]

- Adeel, S.; Kiran, S.; Gulzar, T.; Rehman, F.; Azeem, M.; Ahmad, Z.; Zuber, M.; Kamran, M.; Iqbal, Z. Influence of ultrasonic radiation on the dyeing of cotton fabric using reactive yellow 145 dye. J. Nat. Fibers 2017, 14, 658–665. [Google Scholar] [CrossRef]

- Ghaffar, A.; Adeel, S.; Habib, N.; Jalal, F.; Haq, A.; Munir, B.; Ahmad, A.; Jahangeer, M.; Jamil, Q. Effects of microwave radiation on cotton dyeing with reactive blue 21 dye. Pol. J. Environ. Stud. 2019, 28, 1687–1691. [Google Scholar] [CrossRef]

- Zahid, M.; Bhatti, I.A.; Adeel, S.; Saba, S. Modification of cotton fabric for textile dyeing: Industrial mercerization versus gamma irradiation. J. Text. Inst. 2017, 108, 287–292. [Google Scholar] [CrossRef]

- Bhat, N.; Netravali, A.; Gore, A.; Sathianarayanan, M.; Arolkar, G.; Deshmukh, R. Surface modification of cotton fabrics using plasma technology. Text. Res. J. 2011, 81, 1014–1026. [Google Scholar] [CrossRef]

- Fu, S.; Hinks, D.; Hauser, P.; Ankeny, M. High efficiency ultra-deep dyeing of cotton via mercerization and cationization. Cellulose 2013, 20, 3101–3110. [Google Scholar] [CrossRef]

- Karmakar, S.R. Chemical Technology in the Pre-Treatment Processes of Textiles, 1st ed.; Elsevier: Amsterdam, The Netherlands, 1999; Volume 12. [Google Scholar]

- Inglesby, M.K.; Zeronian, S.H. The accessibility of cellulose as determined by dye adsorption. Cellulose 1996, 3, 165–181. [Google Scholar] [CrossRef]

- Brahma, S.; Islam, M.R.; Dina, R.B. Role of mercerizing condition on physical and dyeing properties of cotton knit fabric dyed with reactive dyes. Int. J. Curr. Eng. Technol. 2018, 8, 1052–1057. [Google Scholar] [CrossRef]

- Naikwade, M.; Liu, F.; Wen, S.; Cai, Y.; Navik, R. Combined use of cationization and mercerization as pretreatment for the deep dyeing of ramie fibre. Fibers Polym. 2017, 18, 1734–1740. [Google Scholar] [CrossRef]

- Liang, Y.; Zhu, W.; Zhang, C.; Navik, R.; Ding, X.; Mia, M.S.; Pervez, M.N.; Mondal, M.I.H.; Lin, L.; Cai, Y. Post-treatment of reactive dyed cotton fabrics by caustic mercerization and liquid ammonia treatment. Cellulose 2021, 28, 7435–7453. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, C.; Jiang, T.; Hossain, M.Y.; Zhu, W.; Pervez, M.N.; Hoque, M.I.U.; Khan, I.; Long, X.; Cai, Y. Dyeing of raw ramie yarn with Reactive Orange 5 dye. Ind. Crops Prod. 2022, 176, 114315. [Google Scholar] [CrossRef]

- Su, S.; Liang, Y.; Yin, G.; Wang, Q.; Cai, Y.; Peng, X.; Pervez, M.N.; Lin, L. Anhydrous dyeing processes of ramie fiber in liquid ammonia. Cellulose 2019, 26, 8109–8120. [Google Scholar] [CrossRef]

- Lin, L.; Zhu, W.; Zhang, C.; Hossain, M.Y.; Oli, Z.B.S.; Pervez, M.N.; Sarker, S.; Hoque, M.I.U.; Cai, Y.; Naddeo, V. Combination of wet fixation and drying treatments to improve dye fixation onto spray-dyed cotton fabric. Sci. Rep. UK 2021, 11, 15403. [Google Scholar] [CrossRef]

- Hossain, M.Y.; Liang, Y.; Pervez, M.N.; Ye, X.; Dong, X.; Hassan, M.M.; Cai, Y. Effluent-free deep dyeing of cotton fabric with cacao husk extracts using the Taguchi optimization method. Cellulose 2021, 28, 517–532. [Google Scholar] [CrossRef]

- Pervez, M.N.; Stylios, G.K.; Liang, Y.; Ouyang, F.; Cai, Y. Low-temperature synthesis of novel polyvinylalcohol (PVA) nanofibrous membranes for catalytic dye degradation. J. Clean Prod. 2020, 262, 121301. [Google Scholar] [CrossRef]

- French, A.D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 2014, 21, 885–896. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J.; Cheng, X.; Ren, X.; Huang, T.S. Self-assembled antibacterial coating by N-halamine polyelectrolytes on a cellulose substrate. J. Mater. Chem. B 2015, 3, 1446–1454. [Google Scholar] [CrossRef] [PubMed]

- Saapan, A.; Kandil, S.; Habib, A. Liquid ammonia and caustic mercerization of cotton fibers using X-ray, infrared, and sorption measurements. Text. Res. J. 1984, 54, 863–867. [Google Scholar] [CrossRef]

- Yue, Y.; Han, G.; Wu, Q. Transitional properties of cotton fibers from cellulose I to cellulose II structure. BioResources 2013, 8, 6460–6471. [Google Scholar] [CrossRef] [Green Version]

- Saafan, A.A.; Habib, A.M. Pore structure of modified cotton and its effects on fiber reactive dyeing properties. Colloid. Surf. 1989, 34, 75–80. [Google Scholar] [CrossRef]

- Mittal, A.; Katahira, R.; Himmel, M.E.; Johnson, D.K. Effects of alkaline or liquid-ammonia treatment on crystalline cellulose: Changes in crystalline structure and effects on enzymatic digestibility. Biotechnol. Biofuels 2011, 4, 41. [Google Scholar] [CrossRef] [Green Version]

- Rousselle, M.-A.; Nelson, M.L. Reactivity and fine structure of cotton mercerized in sodium hydroxide or liquid ammonia. Text. Res. J. 1976, 46, 648–653. [Google Scholar] [CrossRef]

- French, A.D.; Pérez, S.; Bulone, V.; Rosenau, T.; Gray, D. Cellulose. In Encyclopedia of Polymer Science and Technology; John Wiley & Sons, Inc.: New York, NY, USA, 2018; pp. 1–69. [Google Scholar]

- Cai, Y.; Su, S.; Navik, R.; Lou, K.; Peng, X.; Wang, Q.; Zhang, P.; Lin, L. Reactive dyeing of ramie yarn washed by liquid ammonia. Cellulose 2018, 25, 1463–1481. [Google Scholar] [CrossRef]

- Mai, Z.; Xiong, Z.; Shu, X.; Liu, X.; Zhang, H.; Yin, X.; Zhou, Y.; Liu, M.; Zhang, M.; Xu, W.; et al. Multifunctionalization of cotton fabrics with polyvinylsilsesquioxane/ZnO composite coatings. Carbohydr. Polym. 2018, 199, 516–525. [Google Scholar] [CrossRef]

- Shafizadeh, F. Pyrolysis and Combustion of Cellulosic Materials. In Advances in Carbohydrate Chemistry; Wolfrom, M.L., Tipson, R.S., Eds.; Academic Press: New York, NY, USA, 1968; Volume 23, pp. 419–474. [Google Scholar]

- Sun, Z.; Zhou, X.; Xing, Z. Effect of liquid ammonia treatment on the pore structure of mercerized cotton and its uptake of reactive dyes. Text. Res. J. 2016, 86, 1625–1636. [Google Scholar] [CrossRef]

- Rowland, S.P.; Wade, C.P.; Bertoniere, N.R. Pore structure analysis of purified, sodium hydroxide-treated and liquid ammonia-treated cotton celluloses. J. Appl. Polym. Sci. 1984, 29, 3349–3357. [Google Scholar] [CrossRef]

- Shore, J. Dyeing with Reactive Dye. In Cellulosics Dyeing; Shore, J., Ed.; Society of Dyers and Colourists: Bradford, UK, 1995; pp. 189–245. [Google Scholar]

- Li, W.; Li, L.; Gao, Y.; Hu, D.; Li, C.-F.; Zhang, H.; Jiu, J.; Nagao, S.; Suganuma, K. Highly conductive copper films based on submicron copper particles/copper complex inks for printed electronics: Microstructure, resistivity, oxidation resistance, and long-term stability. J. Alloys Compd. 2018, 732, 240–247. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Y.S.; Sun, W.G.; Zhou, X.Y. Effect of concentrated alkali treatment on the properties of naturally colored brown cotton. Adv. Mat. Res. 2011, 332, 173–178. [Google Scholar] [CrossRef]

- Nelson, M.L.; Hassenboehler, C.B.; Andrews, F.R.; Markezich, A.R. Mechanical properties of cotton yarns mercerized in liquid ammonia and sodium hydroxide. Text. Res. J. 1976, 46, 872–879. [Google Scholar] [CrossRef]

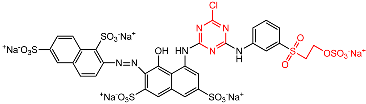

| Dye | Molecular Structure | Molecular Weight (g mol−1) |

|---|---|---|

| R2 |  | 615.32 |

| R195 |  | 1136.28 |

| Sample | Original | LA | CS | LA–LA | CS–CS | LA–CS | CS–LA |

|---|---|---|---|---|---|---|---|

| CI (%) | 73.12 | 52.61 | 63.19 | 51.25 | 58.73 | 38.42 | 40.90 |

| Sample | Temperature at Initial Cleavage (Tonset, °C) | Temperature at Maximum Degradation (Tmax, °C) | Char Residue at 700 °C (wt%) |

|---|---|---|---|

| Original | 321 | 372 | 10.80 |

| CS | 319 | 370 | 10.73 |

| LA | 317 | 361 | 8.18 |

| CS–LA | 312 | 363 | 11.40 |

| LA–CS | 316 | 365 | 10.41 |

| CS–CS | 302 | 370 | 12.31 |

| LA–LA | 300 | 360 | 10.01 |

| Dye | Index | O-Dye | O-Dye Predicted Value-1 | CS-Dye | O-Dye Predicted Value-2 | LA-Dye |

|---|---|---|---|---|---|---|

| R2 | T% | 67.2 | 77.7 | 77.7 | 60.4 | 60.4 |

| K/S | 7.1 | 8.2 | 13.8 | 6.4 | 8.1 | |

| R195 | T% | 40.3 | 55.5 | 55.5 | 40.5 | 40.5 |

| K/S | 3.1 | 4.3 | 7.7 | 3.1 | 5.2 |

| Sample | Wash Fastness (Grade) | Rubbing Fastness (Grade) | ||||

|---|---|---|---|---|---|---|

| R2 | R195 | R2 | R195 | |||

| Dry | Wet | Dry | Wet | |||

| O-Dye | 5 | 5 | 4–5 | 4 | 5 | 4–5 |

| Dye-CS | 5 | 5 | 4–5 | 4 | 5 | 4–5 |

| Dye-LA | 5 | 5 | 4–5 | 4 | 5 | 4–5 |

| CS-Dye | 5 | 5 | 4–5 | 4 | 5 | 4–5 |

| CS-Dye-CS | 5 | 5 | 4–5 | 4 | 5 | 4–5 |

| CS-Dye-LA | 5 | 5 | 4–5 | 4 | 5 | 4–5 |

| LA-Dye | 5 | 5 | 4–5 | 4 | 5 | 4–5 |

| LA-Dye-CS | 5 | 5 | 4–5 | 4 | 5 | 4–5 |

| LA-Dye-LA | 5 | 5 | 4–5 | 4 | 5 | 4–5 |

| O-Dye | Dye-CS | Dye-LA | CS-Dye | CS-Dye-CS | CS-Dye-LA | LA-Dye | LA-Dye-CS | LA-Dye-LA | |

|---|---|---|---|---|---|---|---|---|---|

| Warp-wise bending length (cm) | 1.72 | 2.30 | 1.88 | 2.02 | 2.10 | 2.12 | 1.89 | 2.42 | 2.07 |

| Weft-wise bending length (cm) | 1.57 | 2.21 | 1.69 | 1.58 | 1.96 | 1.77 | 1.51 | 2.02 | 1.71 |

| Total bending length (cm) | 1.64 | 2.25 | 1.78 | 1.79 | 2.03 | 1.94 | 1.69 | 2.21 | 1.88 |

| Warp-wise flexural rigidity (mg·cm) | 0.87 | 2.07 | 1.12 | 1.40 | 1.57 | 1.62 | 1.15 | 2.41 | 1.51 |

| Weft-wise flexural rigidity (mg cm) | 0.66 | 1.83 | 0.82 | 0.67 | 1.28 | 0.94 | 0.59 | 1.40 | 0.85 |

| Total flexural rigidity (mg cm) | 0.75 | 1.94 | 0.96 | 0.97 | 1.42 | 1.24 | 0.82 | 1.84 | 1.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, L.; Jiang, T.; Liang, Y.; Zhu, W.; Inamdar, U.Y.; Pervez, M.N.; Navik, R.; Yang, X.; Cai, Y.; Naddeo, V. Combination of Pre- and Post-Mercerization Processes for Cotton Fabric. Materials 2022, 15, 2092. https://doi.org/10.3390/ma15062092

Lin L, Jiang T, Liang Y, Zhu W, Inamdar UY, Pervez MN, Navik R, Yang X, Cai Y, Naddeo V. Combination of Pre- and Post-Mercerization Processes for Cotton Fabric. Materials. 2022; 15(6):2092. https://doi.org/10.3390/ma15062092

Chicago/Turabian StyleLin, Lina, Tiancheng Jiang, Yonghong Liang, Wenju Zhu, Umarsharif Y. Inamdar, Md. Nahid Pervez, Rahul Navik, Xiaojun Yang, Yingjie Cai, and Vincenzo Naddeo. 2022. "Combination of Pre- and Post-Mercerization Processes for Cotton Fabric" Materials 15, no. 6: 2092. https://doi.org/10.3390/ma15062092

APA StyleLin, L., Jiang, T., Liang, Y., Zhu, W., Inamdar, U. Y., Pervez, M. N., Navik, R., Yang, X., Cai, Y., & Naddeo, V. (2022). Combination of Pre- and Post-Mercerization Processes for Cotton Fabric. Materials, 15(6), 2092. https://doi.org/10.3390/ma15062092