Eliminating the Brittleness Constituent to Enhance Toughness of the High-Strength Steel Weld Heat-Affected Zone Using Electropulsing

Abstract

:1. Introduction

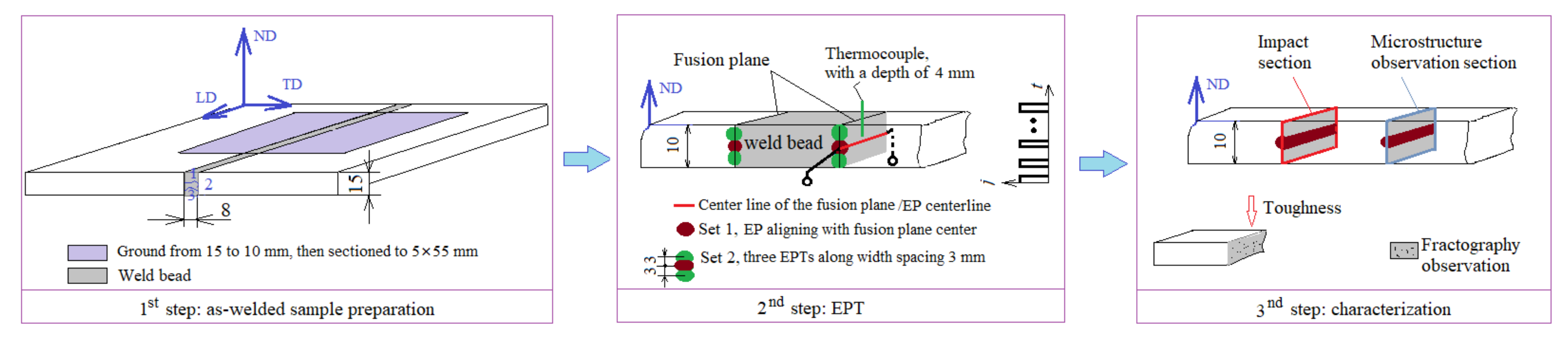

2. Materials and Methods

2.1. Material and Weld Procedure

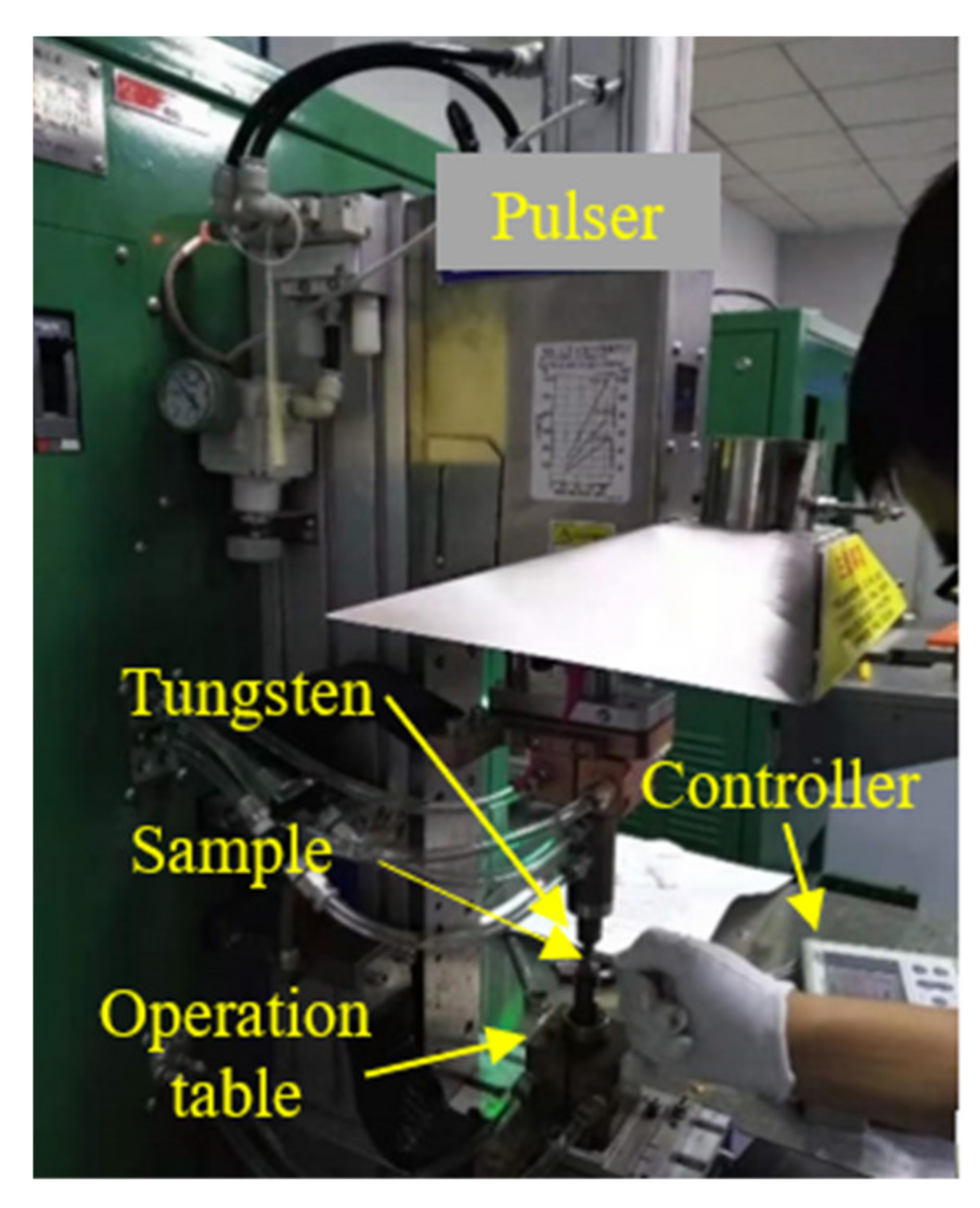

2.2. EP Treatment

2.3. Microstructural Characterization and Mechanical Properties

3. Results

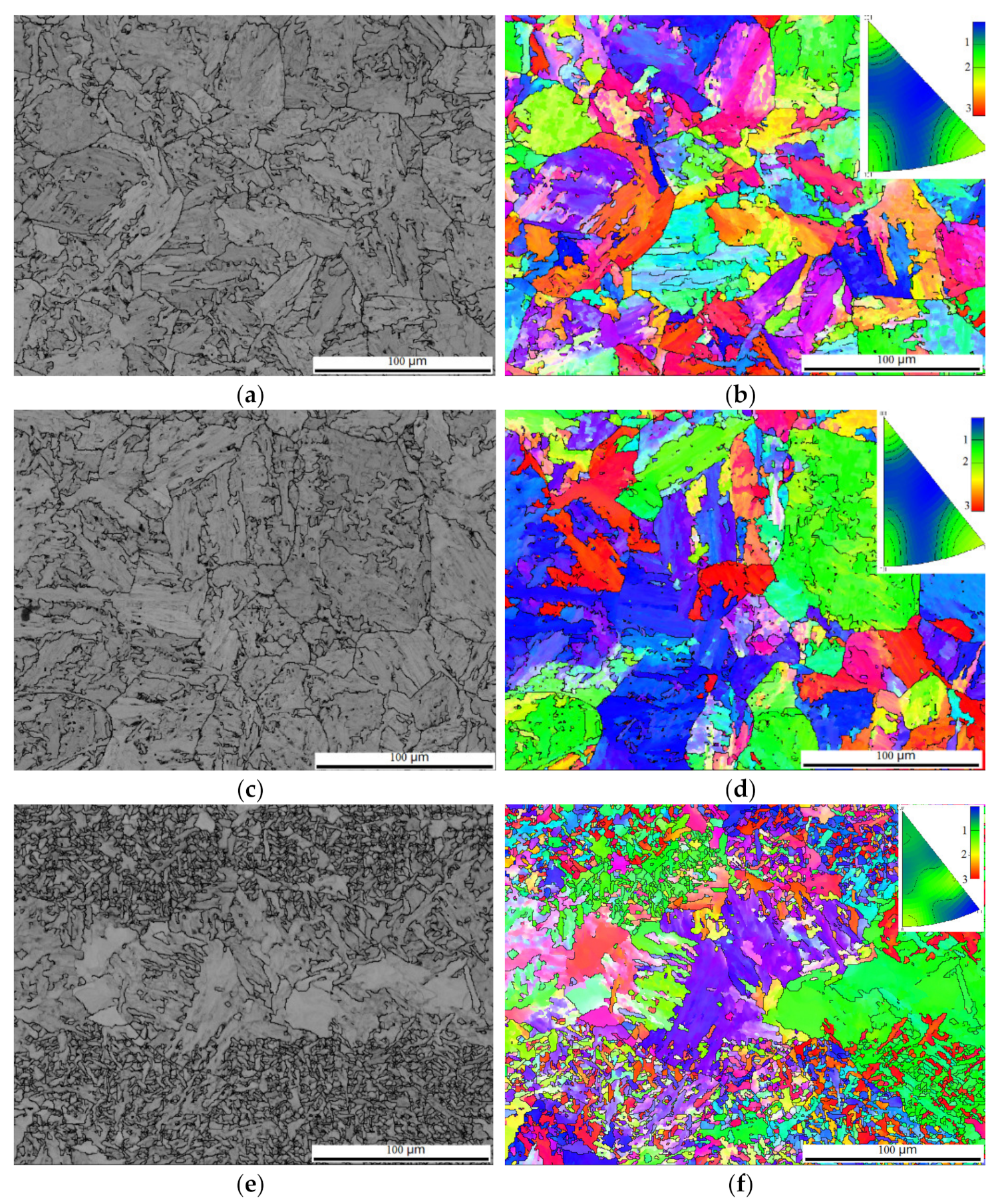

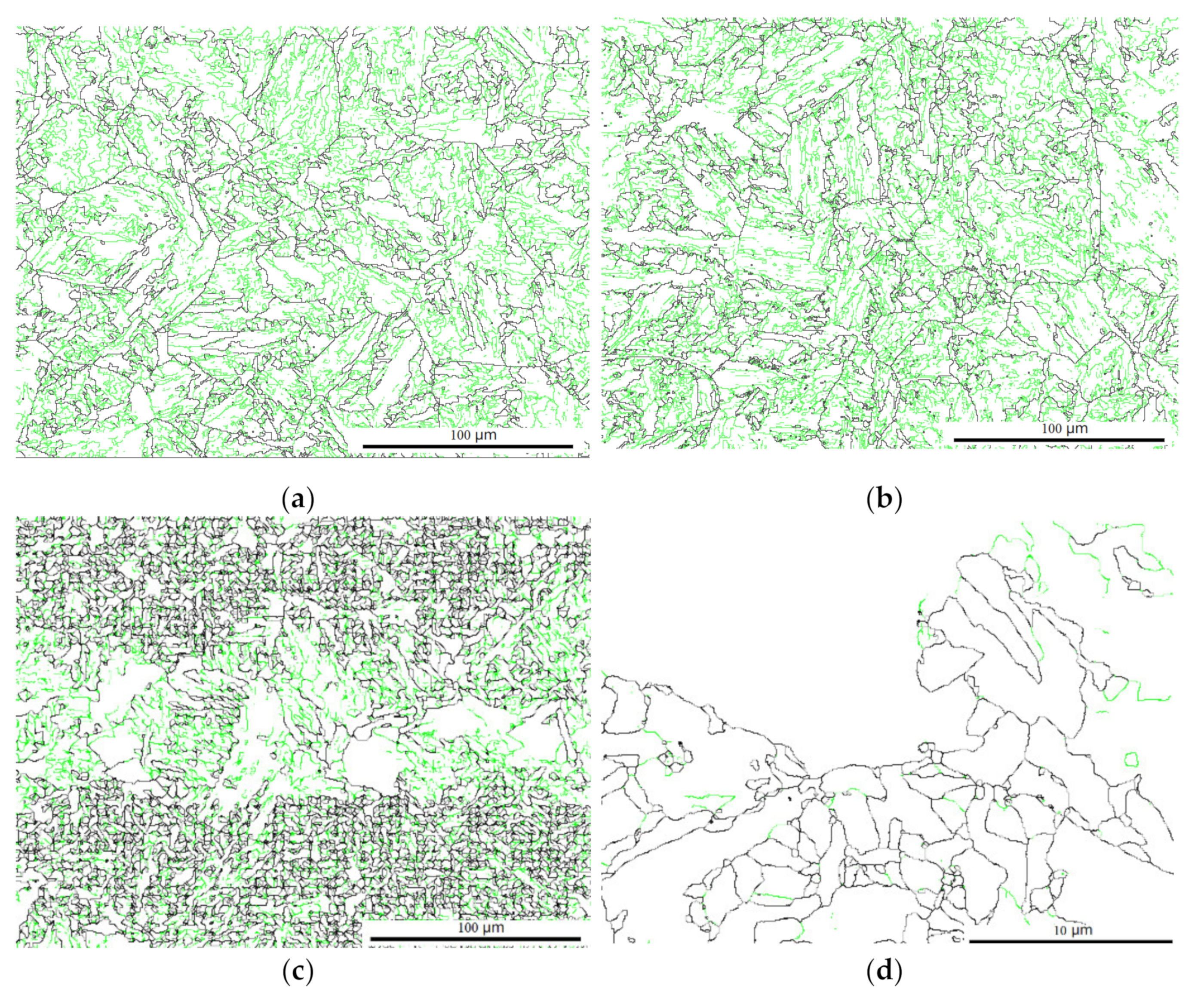

3.1. Microstructural Examination

3.2. Phase Distribution

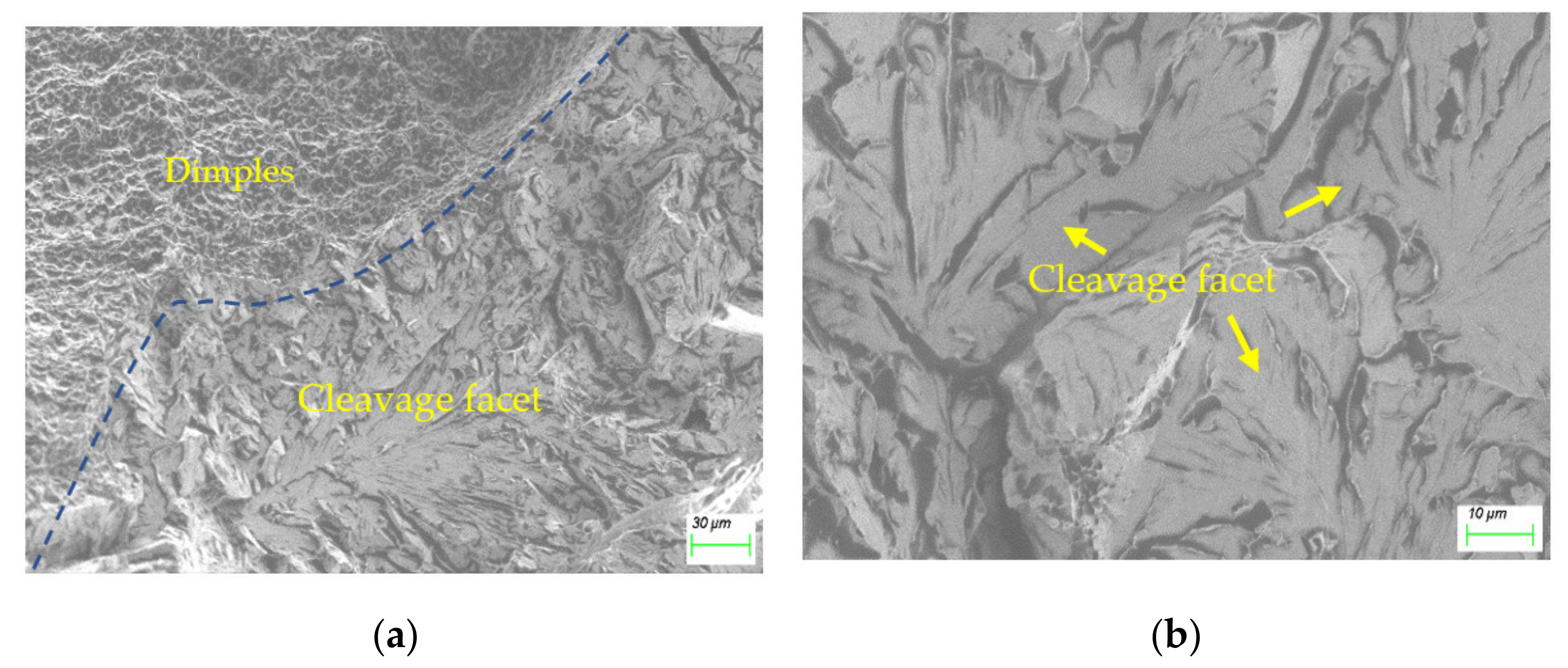

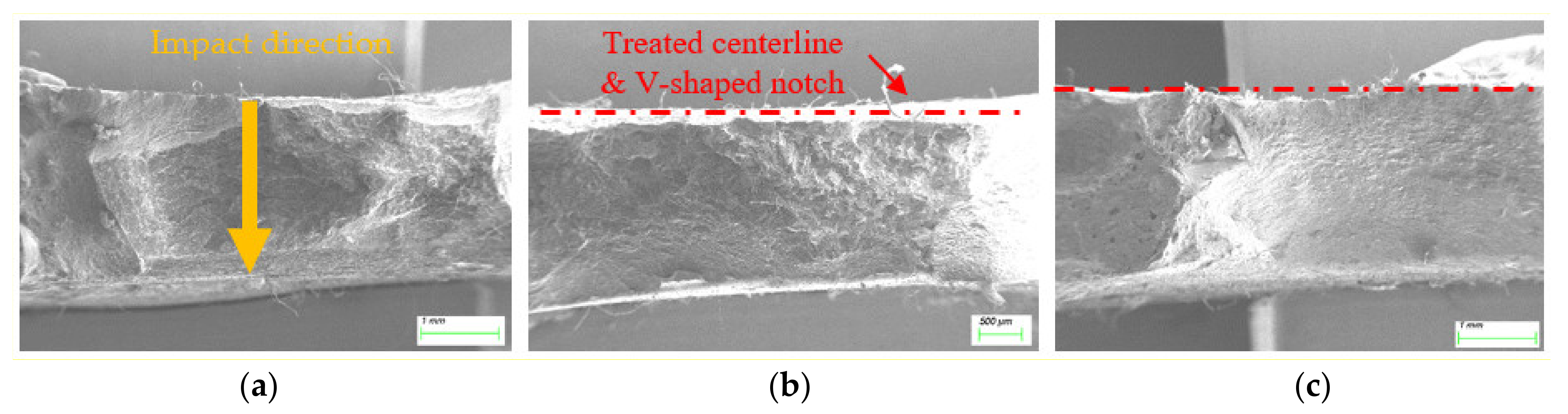

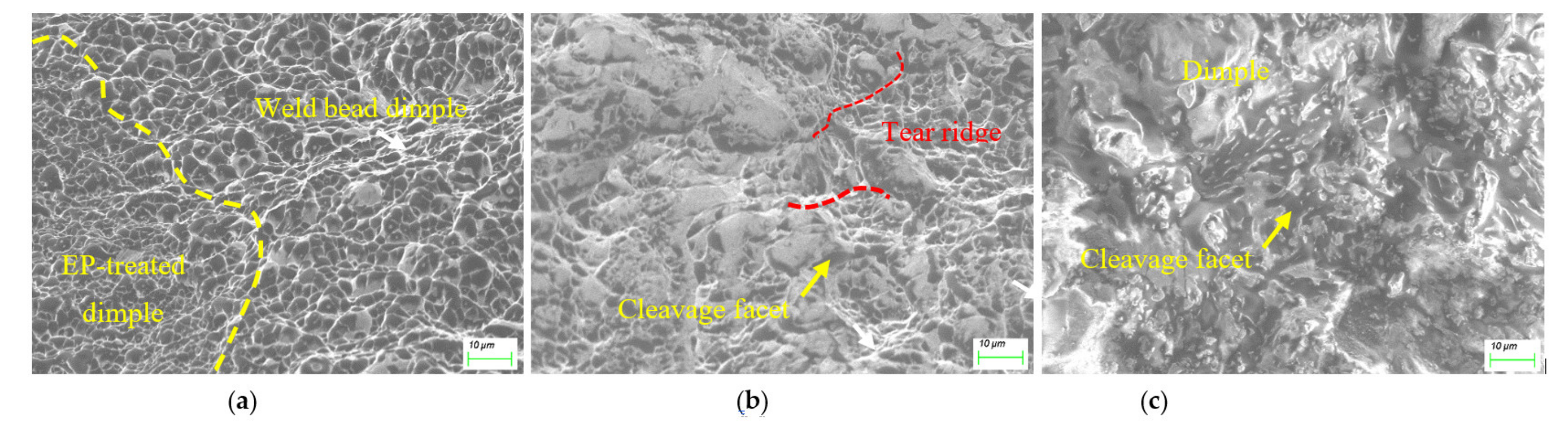

3.3. Fractography

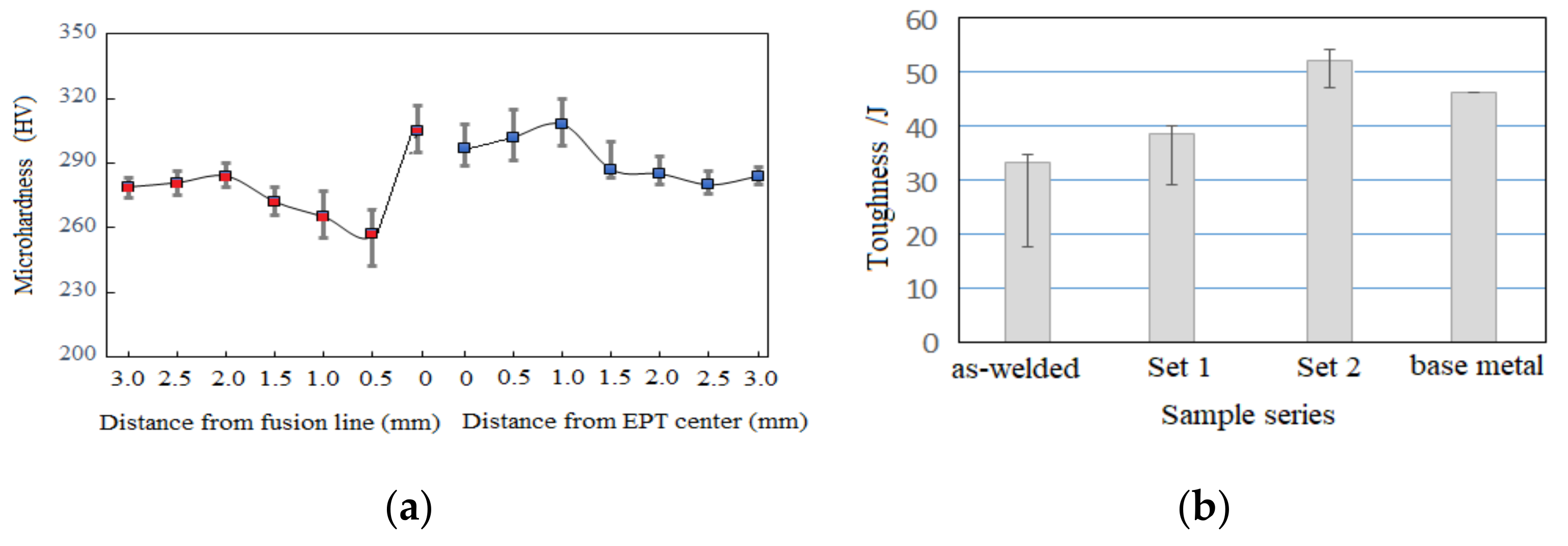

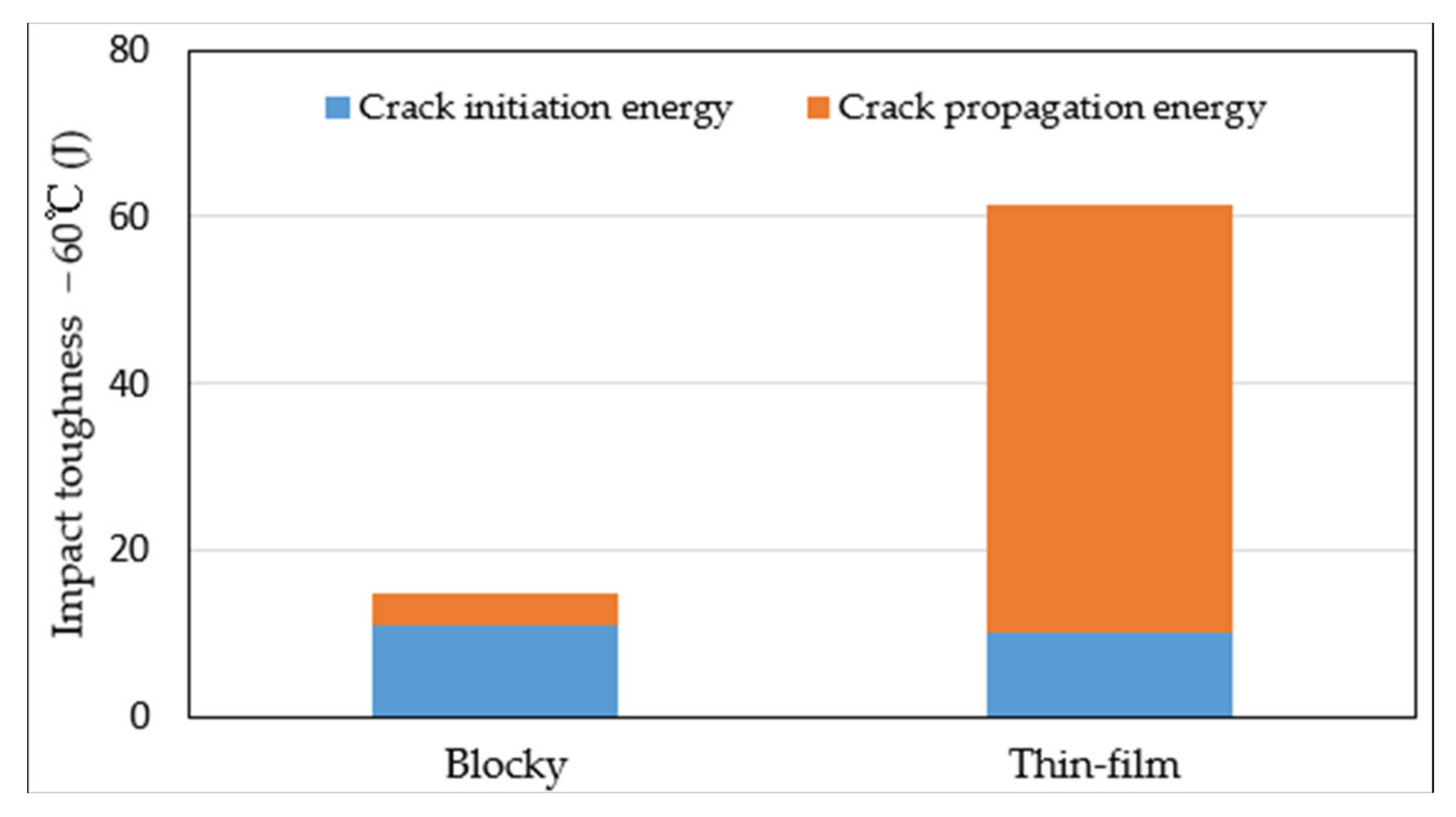

3.4. Mechanical Performance

4. Discussion

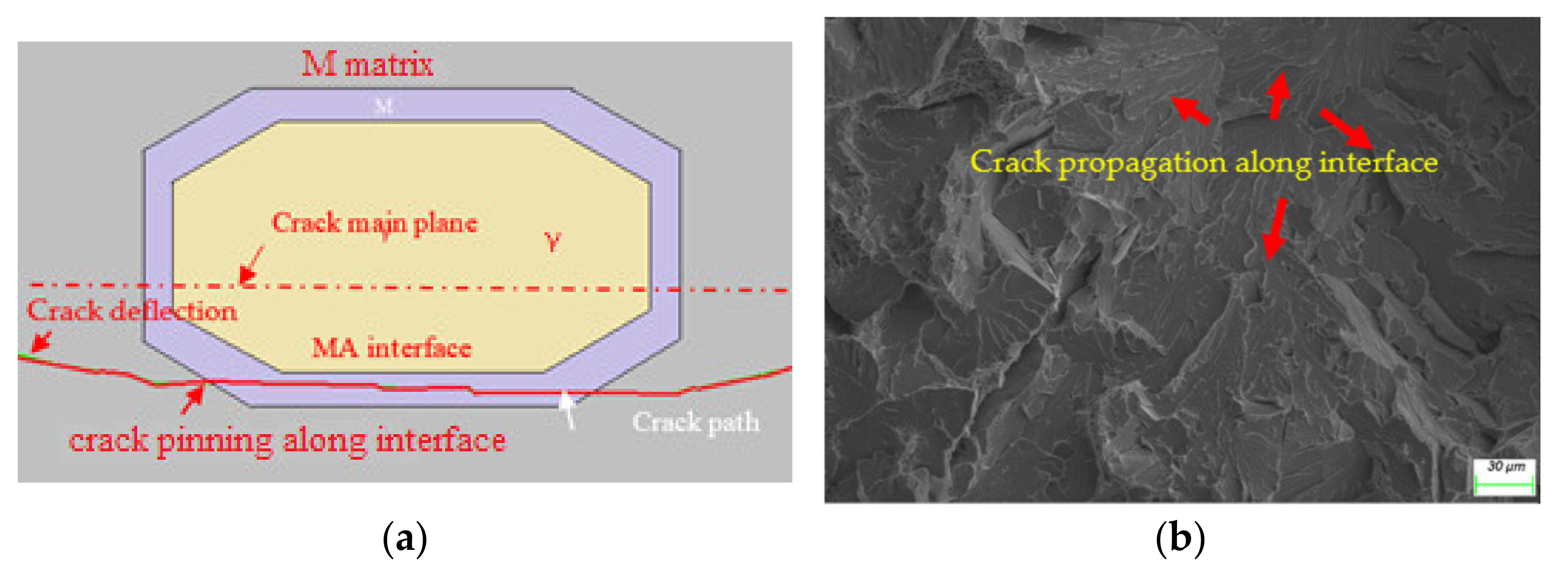

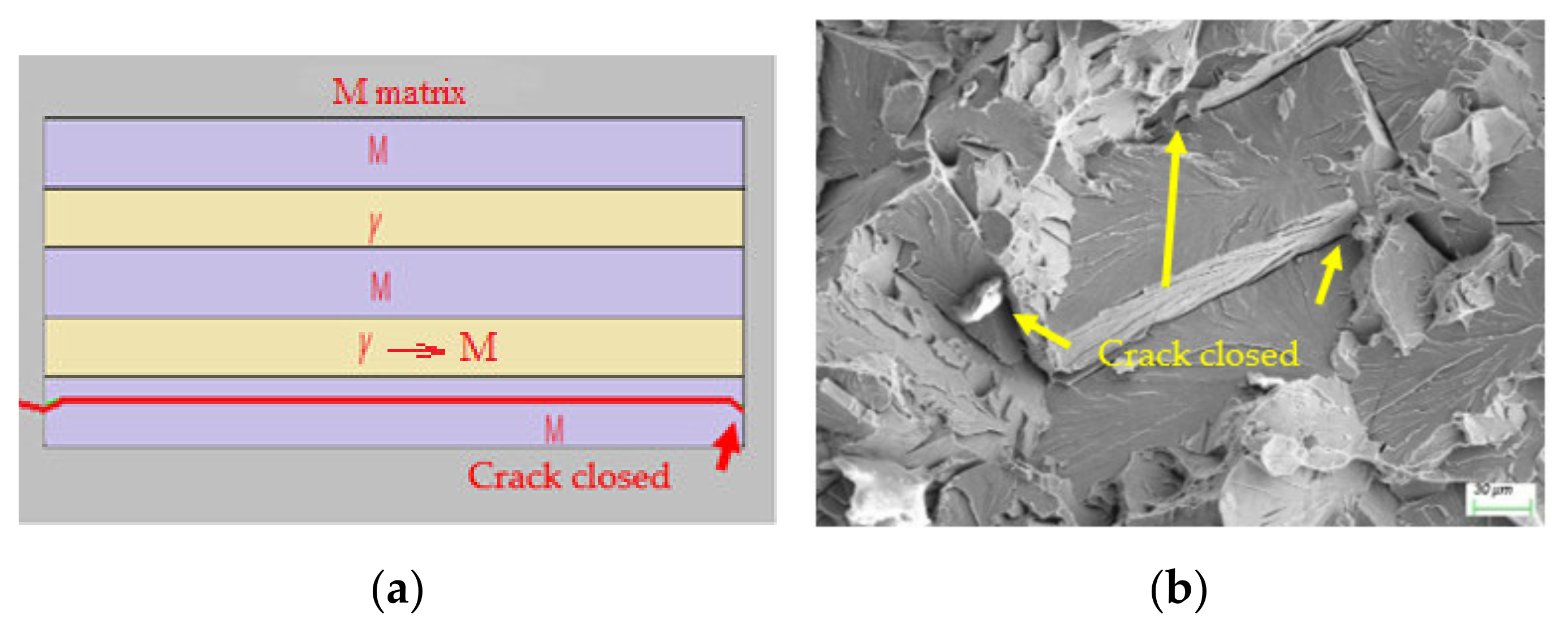

4.1. Mechanism of Toughness Improvement

4.2. Electro-Thermomechanical Mechanism of RA under EP

4.2.1. The Local Austenitization

4.2.2. The Stability and Appearance of RA

5. Conclusions

- The MA in HAZ characterized by a rich chemical composition and high dislocation density, and therefore electrical resistivity, enabled concentrated Joule heating and lowered Ac1, facilitating a preferred austenitization compared to the matrix recrystallization below Ac1 during the EPT, which eliminated the MA constituent.

- When subjected to EP-introduced undercooling, the reverse austenite evolved to a refined microstructure with an average grain size of 7.07 μm to 4.26 μm, accompanied by the elimination of MA, which improved the toughness of HAZ from 34.1 J to 51.8 J.

- The effect of EPT toughening faded away with increasing distance from the EP centerline, indicating an effective method for toughening the microstructure within a limited region with a width less than 2 mm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, J.; Cai, C.; Liang, Y.; Liu, Z.J.; Ma, Y.R. Microstructure and mechanical properties of heat affected zone of laser-MAG hybrid welded low carbon bainitic steel joints. Opt. Laser Technol. 2022, 148, 107729. [Google Scholar] [CrossRef]

- Griffith, A. The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. Lond. Ser. A 1921, 221, 163–198. [Google Scholar]

- Chen, Z.L.; Liu, J.M.; Qiu, H.J. Solidification crack evolution in high-strength steel welding using the extended finite element method. Materials 2020, 13, 483. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, S.; Kang, D.; Kim, T.W.; Lee, J.K.; Lee, C.H. Fatigue crack growth behavior of the simulated HAZ of 800 MPa grade high-performance steel. Mater. Sci. Eng. A 2011, 528, 2331. [Google Scholar] [CrossRef]

- Xie, C.S.; Liu, Z.D.; He, X.K.; Wang, X.T.; Qiao, S.B. Effect of martensite-austenite constituents on impact toughness of pre-tempered MnNiMo bainitic steel. Mater. Charact. 2020, 161, 110139. [Google Scholar] [CrossRef]

- Tian, S.Y.; Xu, F.; Zhang, G.Y.; Saifan, A.; Saleh, B.; Li, X.B. Influence of post-weld heat treatment on microstructure and toughness properties of 13MnNiMoR high strength low alloy steel weld joint. Materials 2021, 14, 5336. [Google Scholar] [CrossRef]

- Khalaj, G.; Pouraliakbar, H.; Jandaghi, M.R.; Gholami, A. Microalloyed steel welds by HF-ERW technique: Novel PWHT cycles, microstructure evolution and mechanical properties enhancement. Int. J. Press. Vessel. Pip. 2017, 152, 15–26. [Google Scholar] [CrossRef]

- Luo, X.; Xu, G.; Chen, X.H.; Wang, Z.D. Effect of undercooled austenite ausforming on the role of the M-A constituents in the CGHAZ toughness of the HSLA steels with bainite strcture. Mater. Sci. Eng. A 2022, 833, 142571. [Google Scholar] [CrossRef]

- Li, X.D.; Shang, C.J.; Ma, X.P.; Subramanian, S.V.; Misra, R.D.K.; Sun, J.B. Structure and crystallography of martensite-austenite constituent in the intercritically reheated coarse-grained heat affected zone of a high strength pipeline steel. Mater. Charact. 2018, 138, 107–112. [Google Scholar] [CrossRef]

- Yin, P.L.; Zang, H.B.; Zhao, Y.G.; Wu, C.; Xu, X.F.; Pan, D.; Jiang, W.Q. Superior mechanical properties of 40Cr steel obtained by quenching and microstress relieving under electropulsing. Mater. Sci. Eng. A 2020, 772, 138782. [Google Scholar] [CrossRef]

- Zhang, J.T.; Liu, Z.H.; Sun, J.X.; Zhao, H.L.; Shi, Q.Y.; Ma, D.W. Microstructure and mechanical property of electropulsing tempered ultrafine grained 42CrMo steel. Mater. Sci. Eng. A 2020, 785, 139213. [Google Scholar] [CrossRef]

- Haque, A.; Sherbondy, J.; Warywoba, D.; Hsu, P.; Roy, S. Room-temperature stress reduction in welded joints through electropulsing. J. Mater. Process. Technol. 2022, 299, 117391. [Google Scholar] [CrossRef]

- Zhou, Y.; Guo, J.; Zhang, W. Influence of electropulsing on nucleation during phase transformation. J. Mater. Res. 2002, 17, 3012–3014. [Google Scholar] [CrossRef]

- Bohnenkamp, U.; Sandström, R.; Grimvall, G. Electrical resistivity of steels and face-centered-cubic iron. J. Appl. Phys. 2002, 92, 4402–4407. [Google Scholar] [CrossRef]

- China Classification Society. Rules for the Classification of Steel Ships Part D: Materials and Welding; China Classification Society: Beijing, China, 2020; pp. 19–21. [Google Scholar]

- You, W.; Xu, W.; Bai, B.; Fang, H. Materialometrical approach of predicting the austenite formation temperatures. Mater. Sci. Eng. A 2006, 419, 276–282. [Google Scholar] [CrossRef]

- Hall, E.O. The deformation and ageing of mild steel: III Discussion of result. Proc. Phys. Soc. 1951, B64, 747. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25. [Google Scholar]

- Bhansali, K.; Keche, A.J.; Gogte, C.L.; Chopra, S. Effect of grain size on Hall-Petch relationship during rolling process of reinforcement bar. Mater. Today Proc. 2020, 26, 3173–3178. [Google Scholar] [CrossRef]

- Huda, N.; Midawi, A.R.H.; Gianetto, J.; Lazor, R. Influence of martensite-austenite (MA) on impact toughness of X80 line pipe steels. Mater. Sci. Eng. A 2016, 662, 481–491. [Google Scholar] [CrossRef]

- Ramachandran, D.C.; Kim, S.D.; Moon, J. Classification of martensite-austenite constituents according to its internal morphology in high-strength low alloy steel. Mater. Lett. 2020, 278, 128422. [Google Scholar] [CrossRef]

- Lee, S.G.; Sohn, S.S.; Kim, B.; Kim, W.G.; Um, K.K.; Lee, S. Effects on martensite-austenite constituent on crack initiation and propagation in inter-critical heat-affected zone of high-strength low-alloy (HSLA) steel. Mater. Sci. Eng. A 2018, 715, 332–339. [Google Scholar] [CrossRef]

- Luo, H.W.; Wang, X.H.; Liu, Z.B.; Yang, Z.Y. Influence of refined hierarchical martensitic microstructures on yield strength and impact toughness of ultra-high strength stainless steel. J. Mat. Sci. Technol. 2020, 51, 130–136. [Google Scholar] [CrossRef]

- Zhao, Y.G.; Ma, B.D.; Guo, H.C.; Ma, J.; Yang, Q.; Song, J.S. Electropulsing strengthened 2GPa boron steel with good ductility. Mater. Des. 2013, 43, 195–199. [Google Scholar] [CrossRef]

- Dolinsky, Y.; Elperin, T. Critical currents in normal conductors. J. Appl. Phys. 1993, 73, 5283–5285. [Google Scholar] [CrossRef]

- Zheng, Y.S.; Tang, G.Y.; Kuang, J.; Zheng, X.P. Effect of electropulse on solid solution treatment of 6061 aluminum alloy. J. Alloys Compd. 2014, 615, 849–853. [Google Scholar] [CrossRef]

- Watts, B.R. Conduction Electron Scattering in Dislocated Metals. In Dislocations in Solids; Nabarro, R.R.N., Ed.; Elsevier Science B.V.: Amsterdam, The Netherlands, 1989; pp. 175–419. [Google Scholar]

- Kundu, A.; Field, D.P. Influence of plastic deformation heterogeneity on development of geometrically necessary dislocation density in dual phase steel. Mater. Sci. Eng. A 2016, 667, 435–443. [Google Scholar] [CrossRef]

- Xu, Z.H.; Tang, G.Y.; Tian, S.Q.; He, J.C. Research on the engineering application of multiple pulses treatment for recrystallization of fine copper wire. Mater. Sci. Eng. A 2006, 424, 300–306. [Google Scholar] [CrossRef]

- Jiang, Y.B.; Tang, G.Y.; She, C.H.; Zhu, Y.H.; Xu, Z.H. On the thermodynamics and kinetics of electropulsing induced dissolution of phase in an aged Mg-9Al-1Zn alloy. Acta Mater. 2019, 57, 4797–4808. [Google Scholar] [CrossRef]

- Grajcar, A.; Skowronek, A.; Radwanski, K. Mechanical behavior and stability of dispersed retained austenite in thermomechanically rolled and isothermally-treated TRIP-aided multiphase steel. Mater. Sci. Eng. A 2022, 830, 142300. [Google Scholar] [CrossRef]

- Li, X.D.; Shang, C.J.; Ma, X.P.; Gault, B.; Subramanian, S.V.; Sun, J.B.; Misra, R.D.K. Elemental distribution in the martensite-austenite constituent in intercritically reheated coarse-grained heat-affected zone of a high-strength pipeline steel. Scr. Mater. 2017, 139, 67–70. [Google Scholar] [CrossRef]

- Conrad, H. Effect of electric current on solid state phase transformations in metals. Mater. Sci. Eng. A 2000, 287, 227–237. [Google Scholar] [CrossRef]

- Trzaska, J. Empirical formulae for the calculation of austenite supercooled transformation temperature. Arch. Metall. Mater. 2015, 60, 181–185. [Google Scholar] [CrossRef]

- Wang, J.; Van Der Zwaag, S. Stabilization mechanisms of retained austenite in transformation-induced plasticity steel. Metall. Mater. Trans. 2001, 32, 1527–1539. [Google Scholar] [CrossRef]

- Blondé, R.; Jimenez-Melero, E.; Zhao, L.; Wright, J.P.; Brück, E.; van der Zwaag, S.; van Dijk, N.H. High-energy X-ray diffraction study on the temperature-dependent mechanical stability of retained austenite in low-alloyed TRIP steels. Acta Mater. 2012, 60, 565–577. [Google Scholar] [CrossRef]

- Nobuo, N.; Yuji, I.; Toshihiro, T.; Setsuo, T. Self-stabilization of untransformed austenite by hydrostatic pressure via martensitic transformation. Acta Mater. 2016, 110, 95–102. [Google Scholar]

| C | Si | Mn | S | P | Ni | Cu + Cr + Mo | Nb + V + Ti |

|---|---|---|---|---|---|---|---|

| 0.08 | 0.15 | 1.58 | 0.002 | 0.003 | 0.8 | 2.3 | 0.135 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Xiong, Y.; Li, X.; Li, Z. Eliminating the Brittleness Constituent to Enhance Toughness of the High-Strength Steel Weld Heat-Affected Zone Using Electropulsing. Materials 2022, 15, 2135. https://doi.org/10.3390/ma15062135

Chen Z, Xiong Y, Li X, Li Z. Eliminating the Brittleness Constituent to Enhance Toughness of the High-Strength Steel Weld Heat-Affected Zone Using Electropulsing. Materials. 2022; 15(6):2135. https://doi.org/10.3390/ma15062135

Chicago/Turabian StyleChen, Zhanglan, Yunfeng Xiong, Xiaowen Li, and Zongmin Li. 2022. "Eliminating the Brittleness Constituent to Enhance Toughness of the High-Strength Steel Weld Heat-Affected Zone Using Electropulsing" Materials 15, no. 6: 2135. https://doi.org/10.3390/ma15062135

APA StyleChen, Z., Xiong, Y., Li, X., & Li, Z. (2022). Eliminating the Brittleness Constituent to Enhance Toughness of the High-Strength Steel Weld Heat-Affected Zone Using Electropulsing. Materials, 15(6), 2135. https://doi.org/10.3390/ma15062135