Mechanism Analysis of Rock Failure Process under High-Voltage Electropulse: Analytical Solution and Simulation

Abstract

:1. Introduction

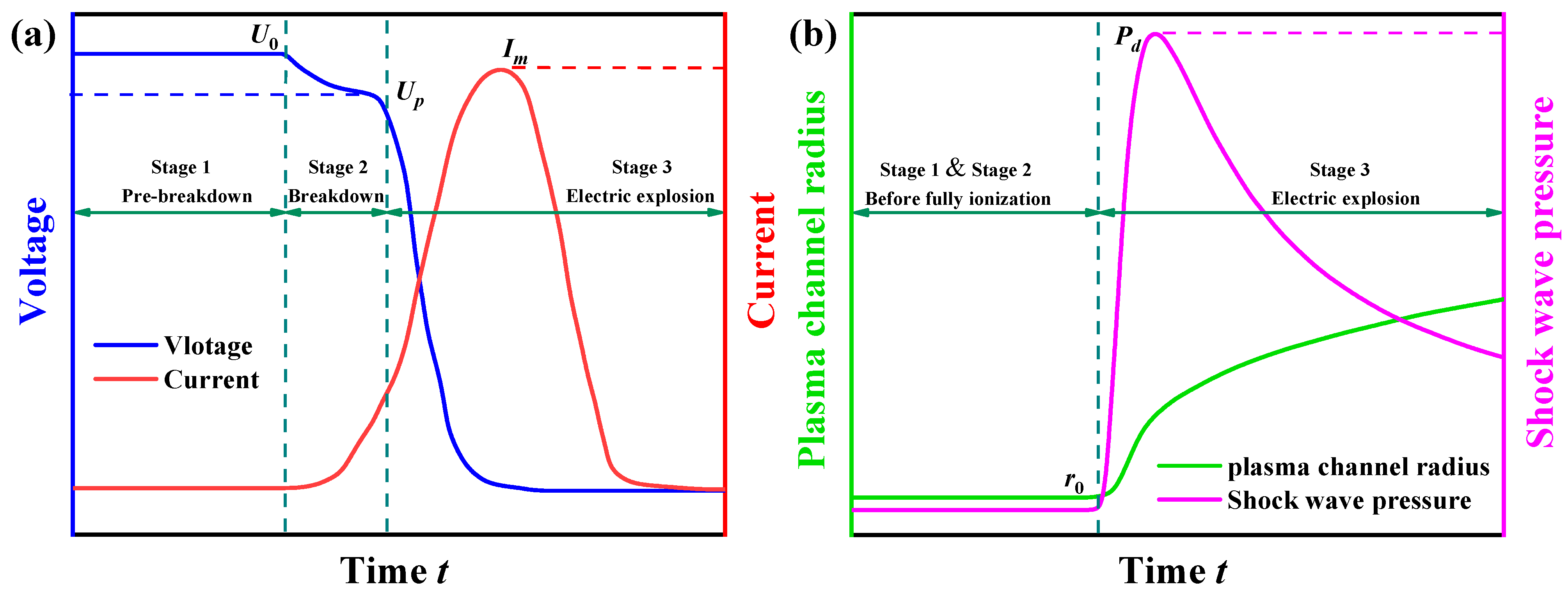

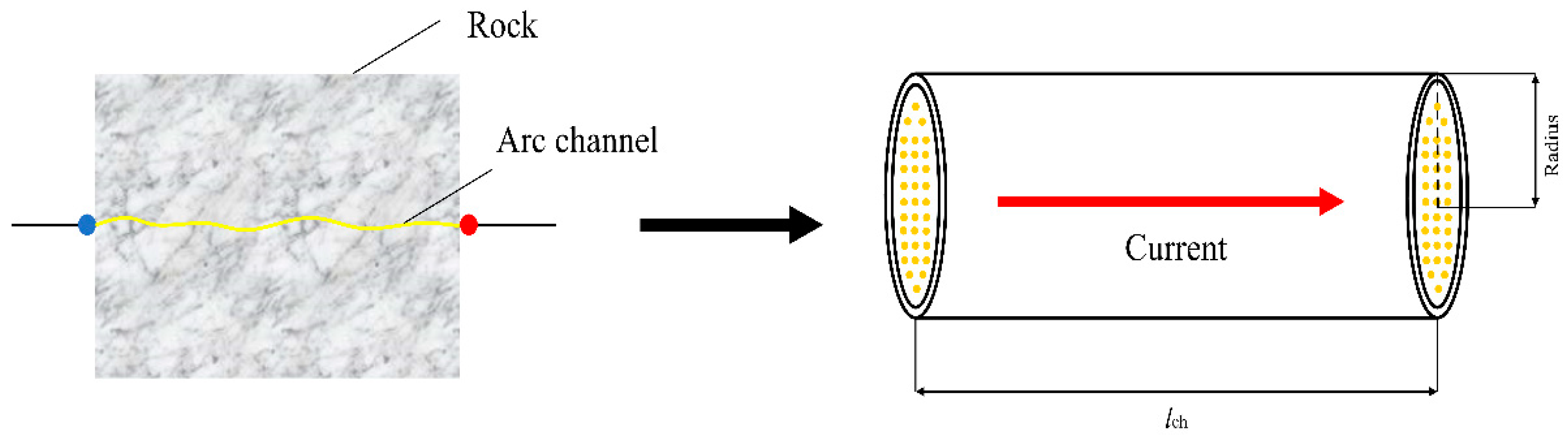

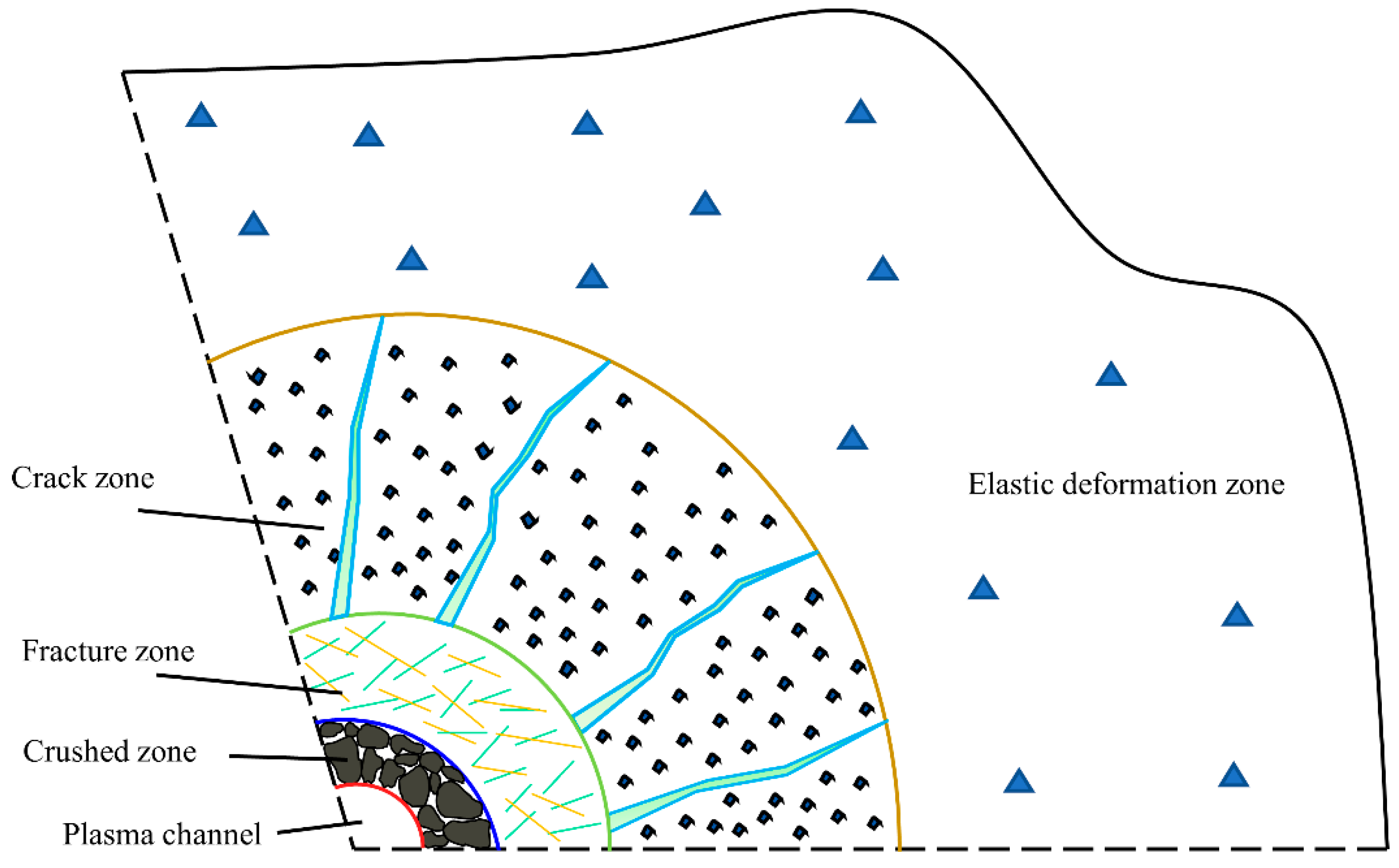

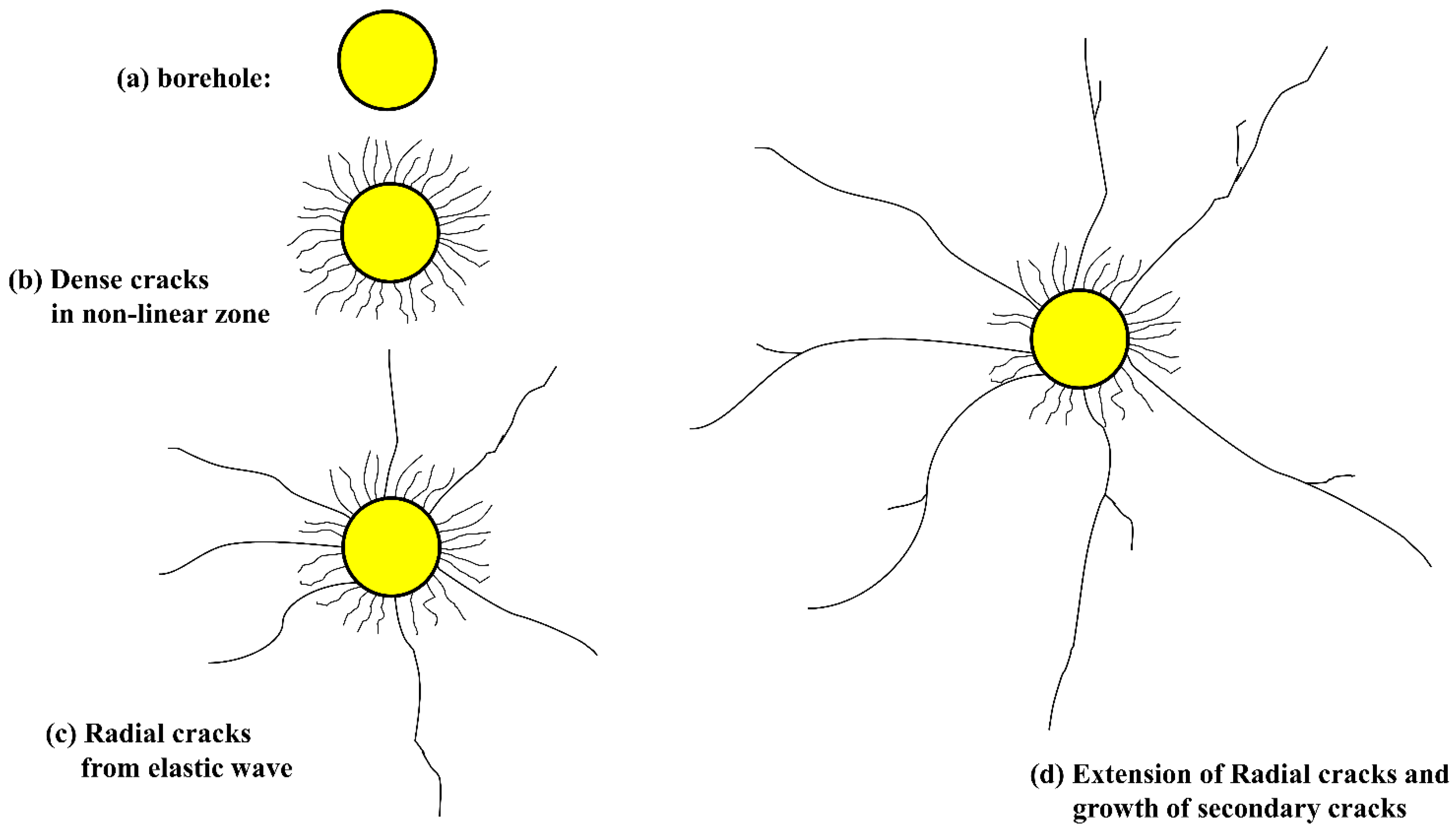

2. Rock Electropulse Broken Process

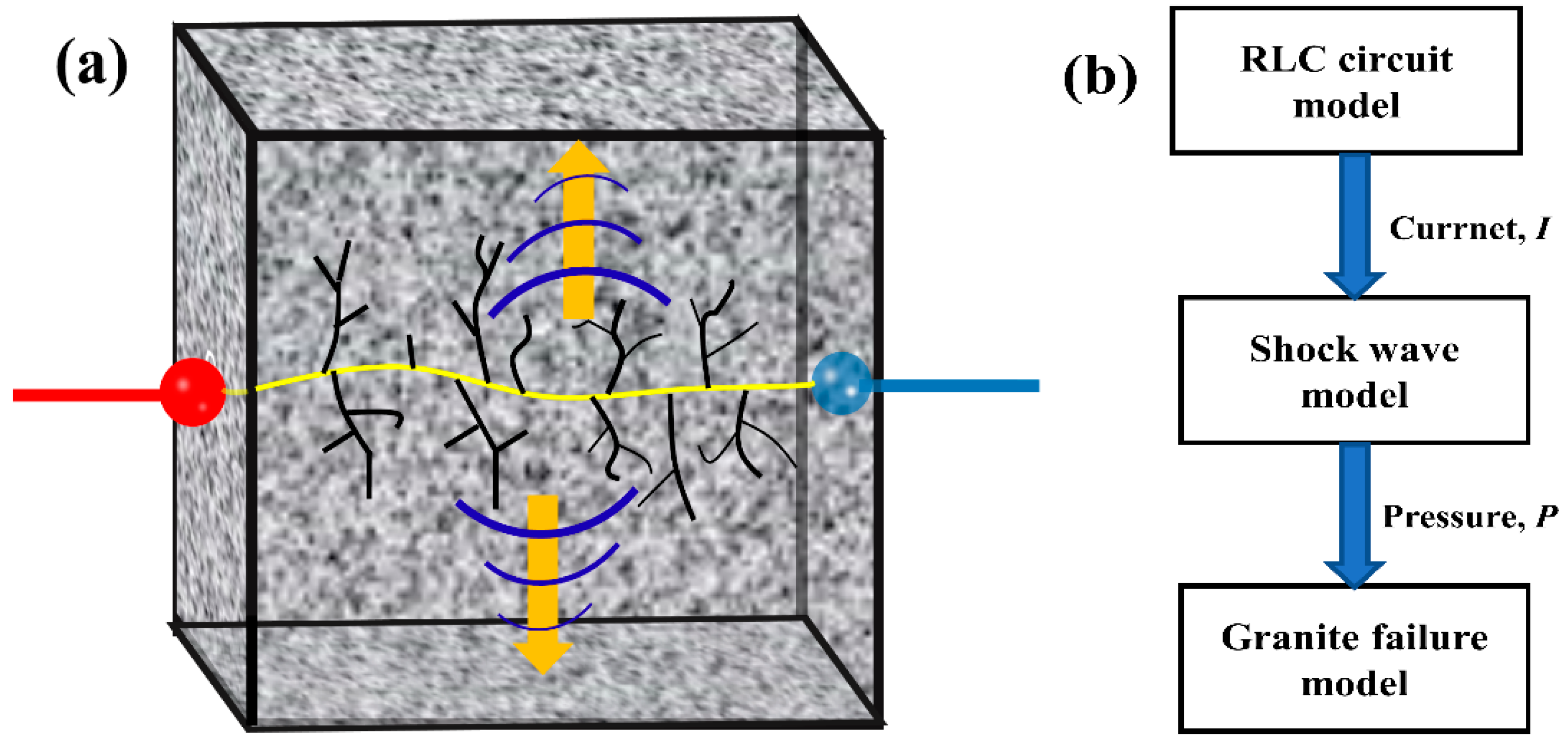

3. Analytical Approach

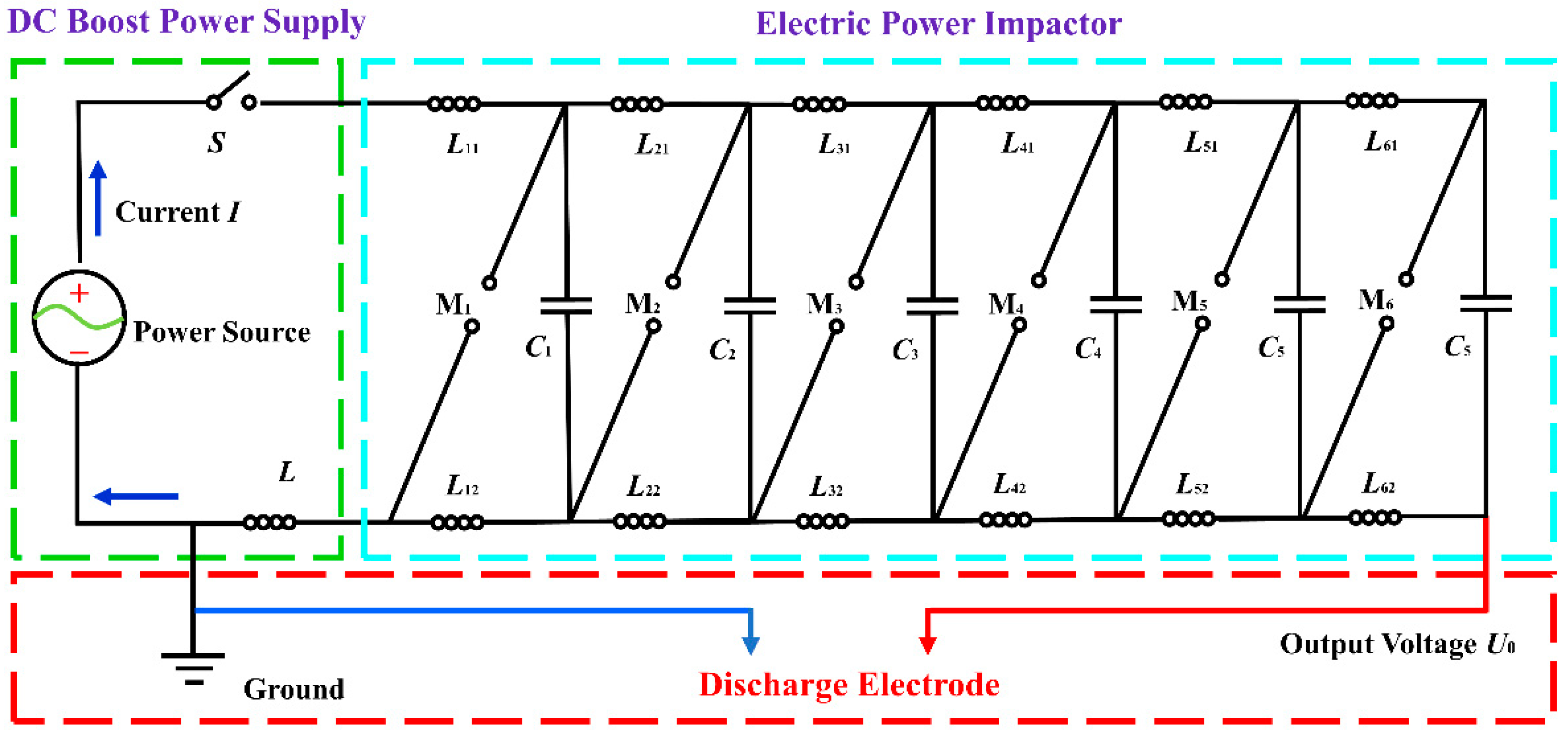

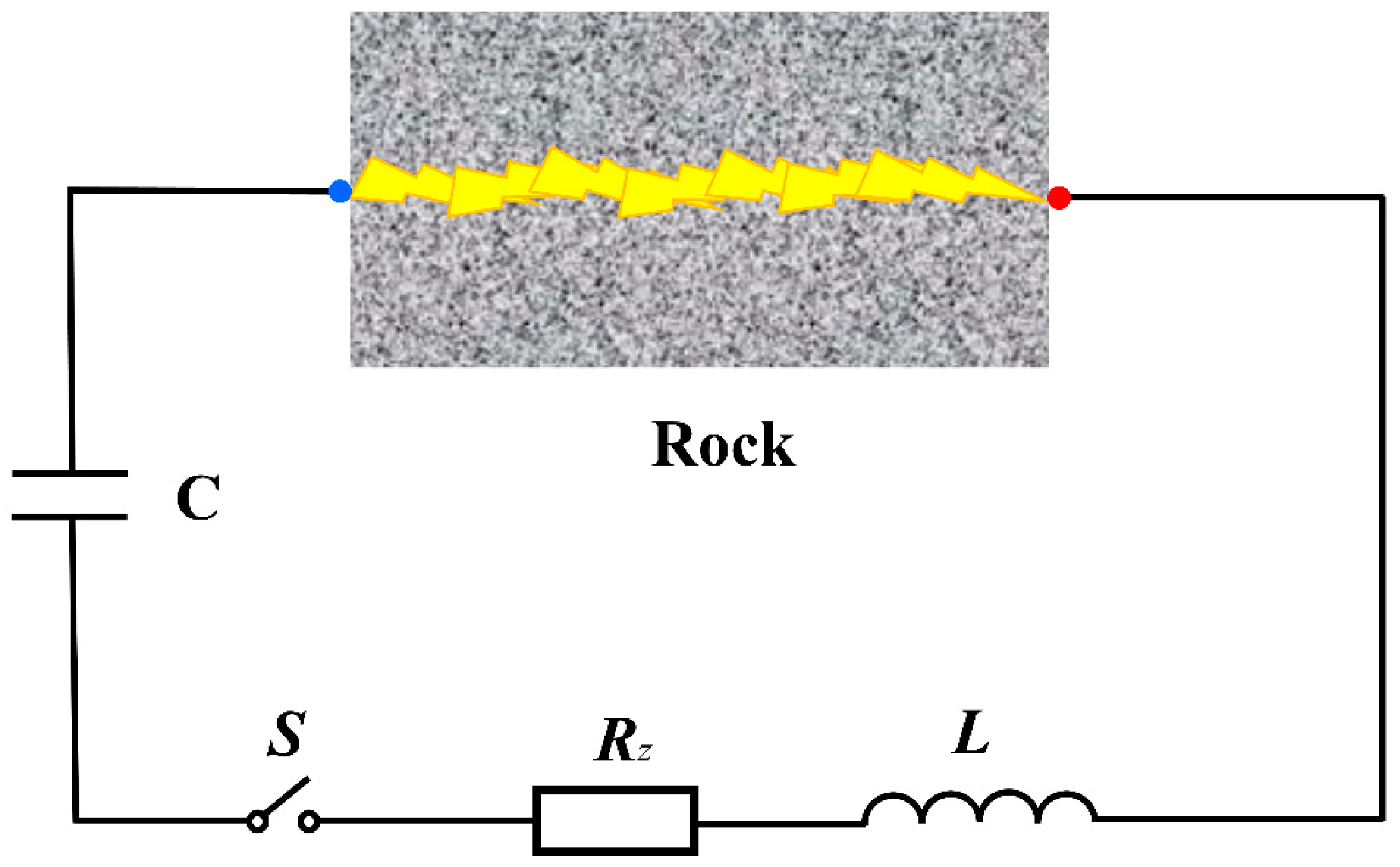

3.1. Equivalent Circuit of High-Voltage Pulse Rock Breaking

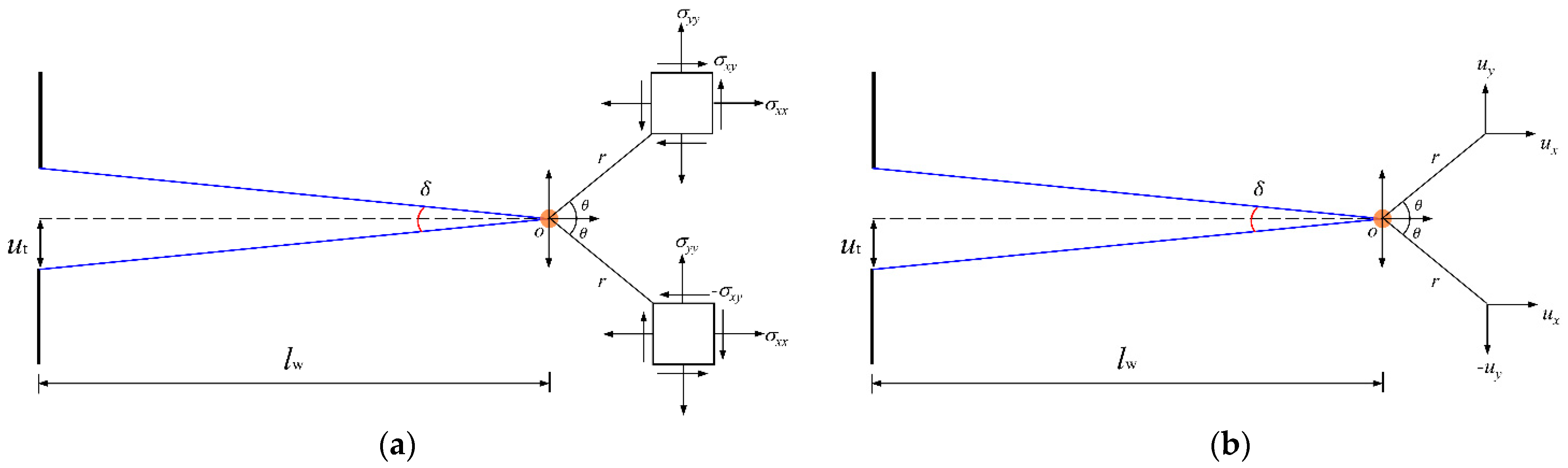

3.2. Mechanical Analysis Model of Electric Pulse

3.3. Mechanical Damage Process Analysis of Rock by Electric Pulse

4. Rock Electropulse Broken Process

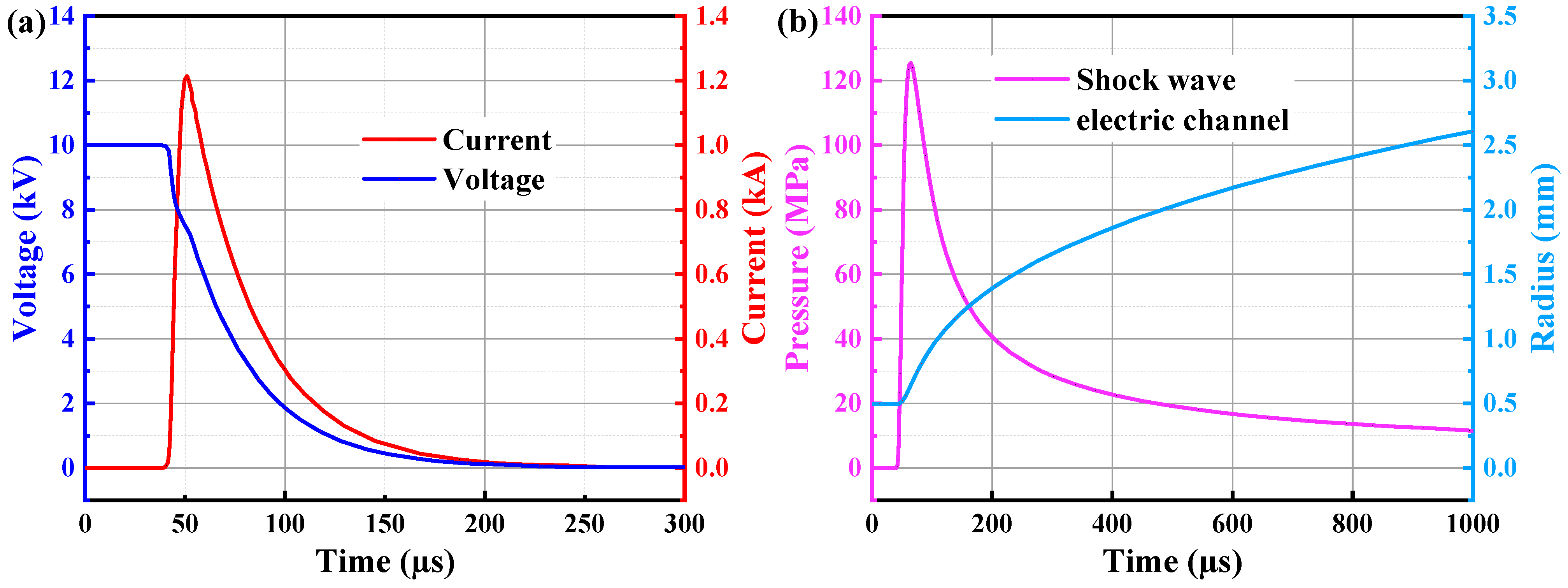

4.1. RLC Circuit and Shock Wave Pressure in the Plasma

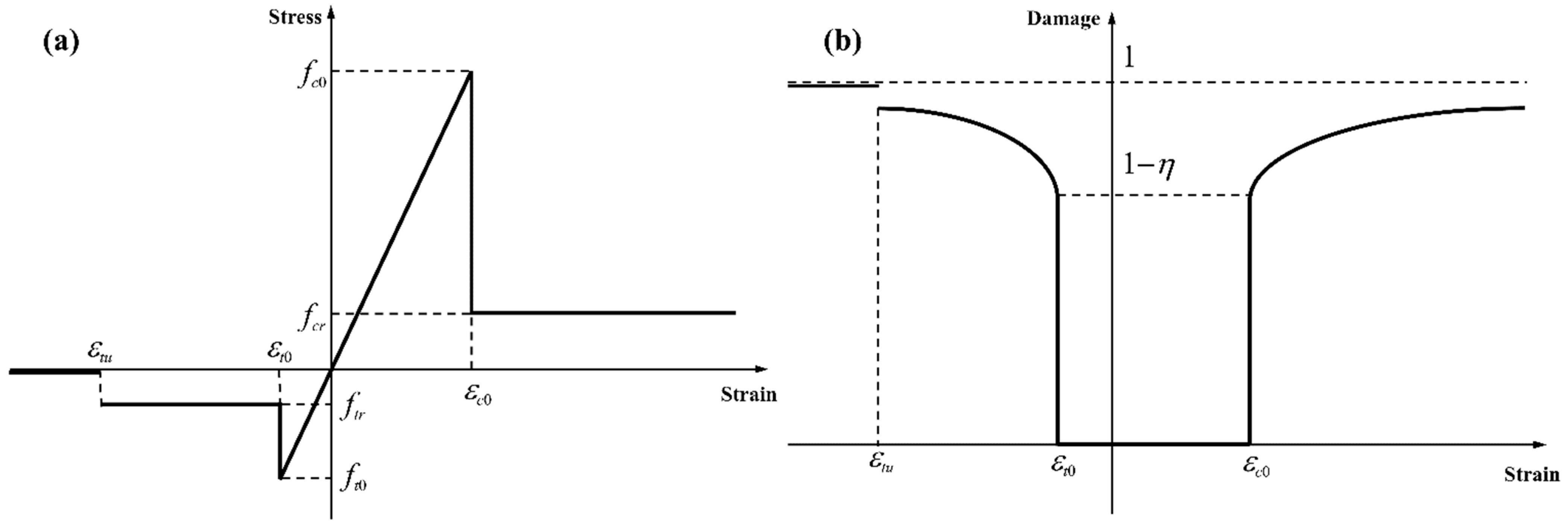

4.2. Deformation and Damage Evolution of Granite

4.3. Model Setup

5. Results and Discussion

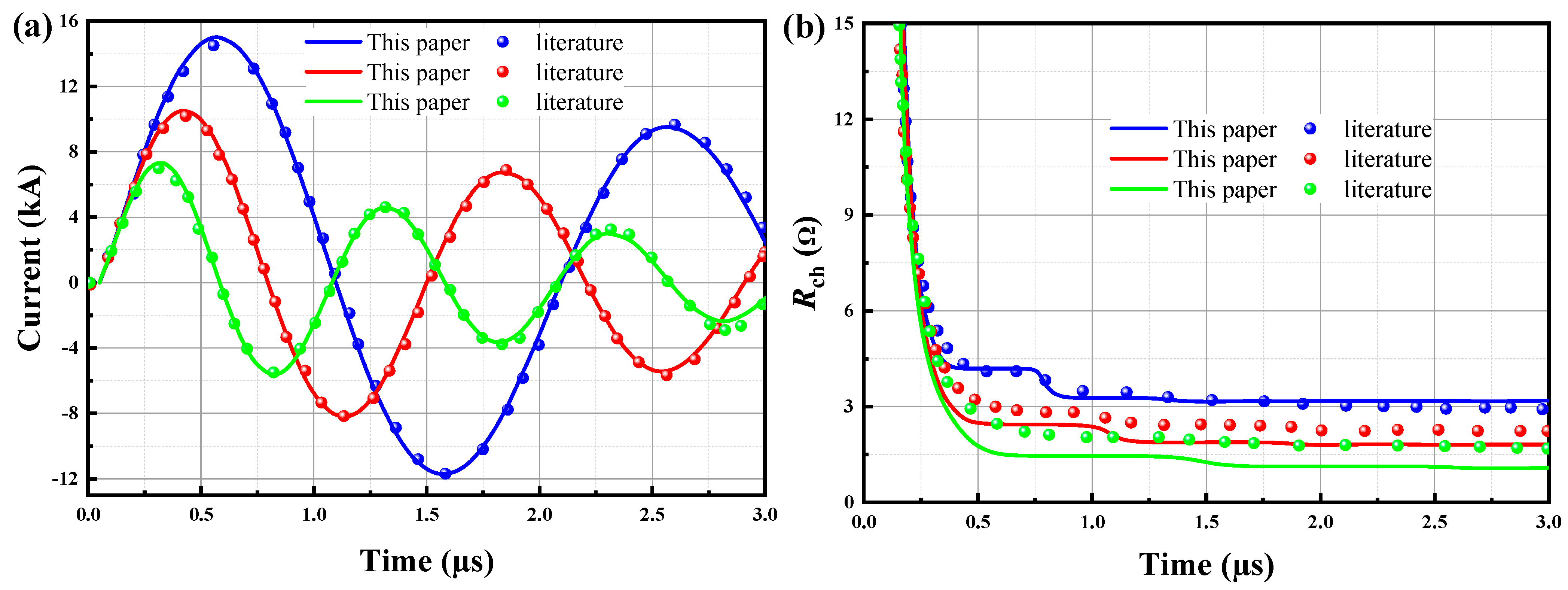

5.1. Verification

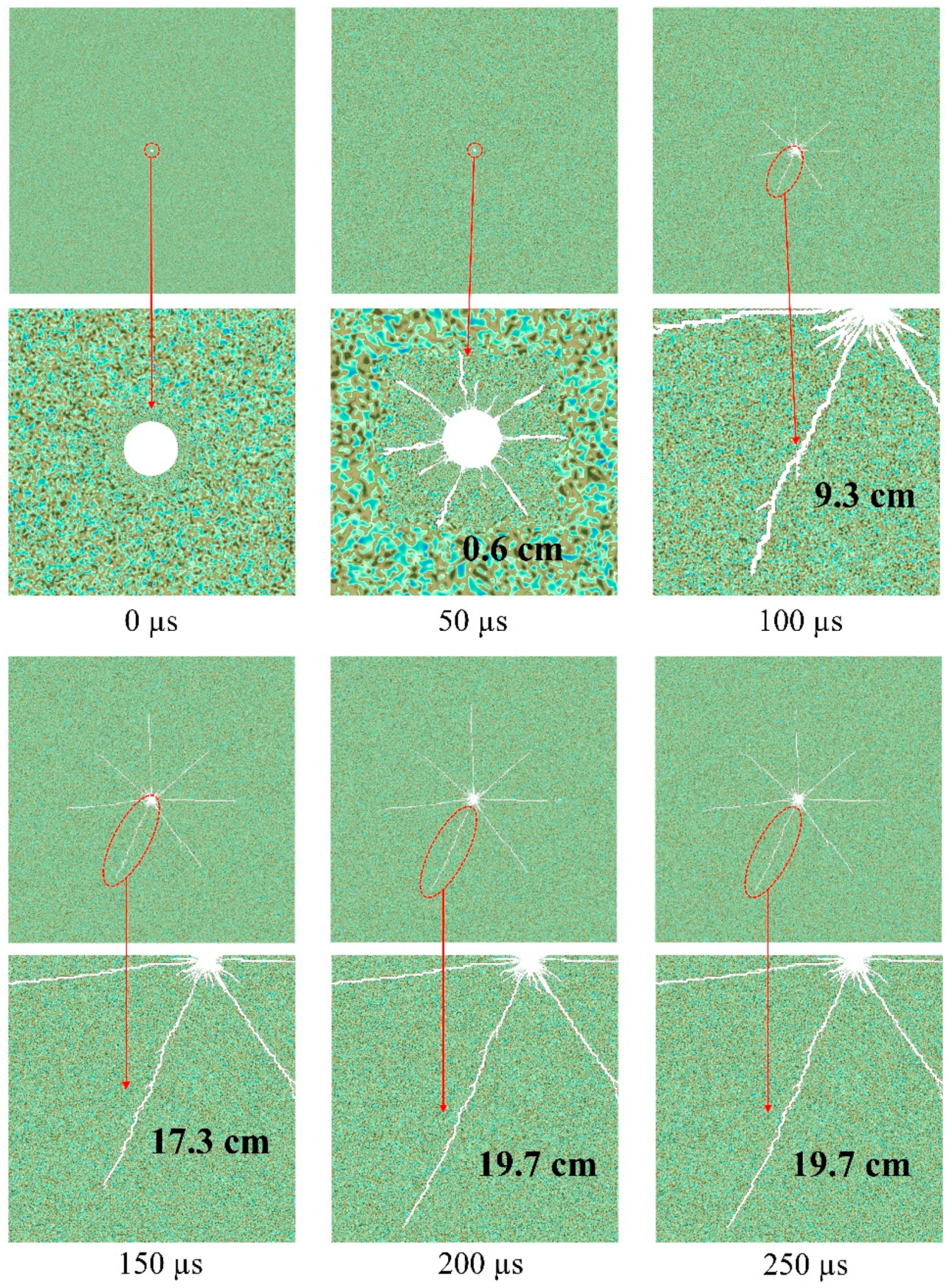

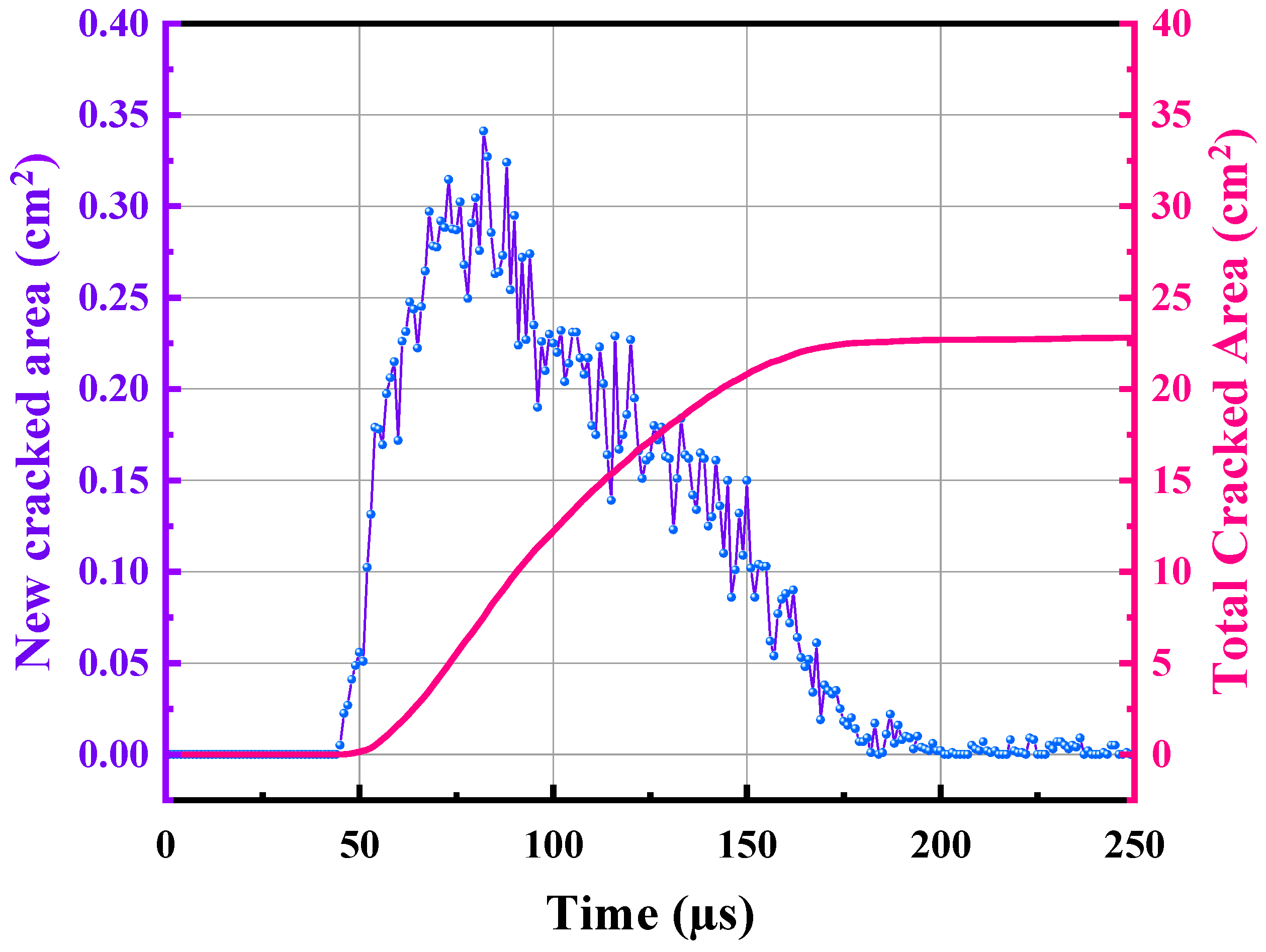

5.2. Granite Failure Process Analysis

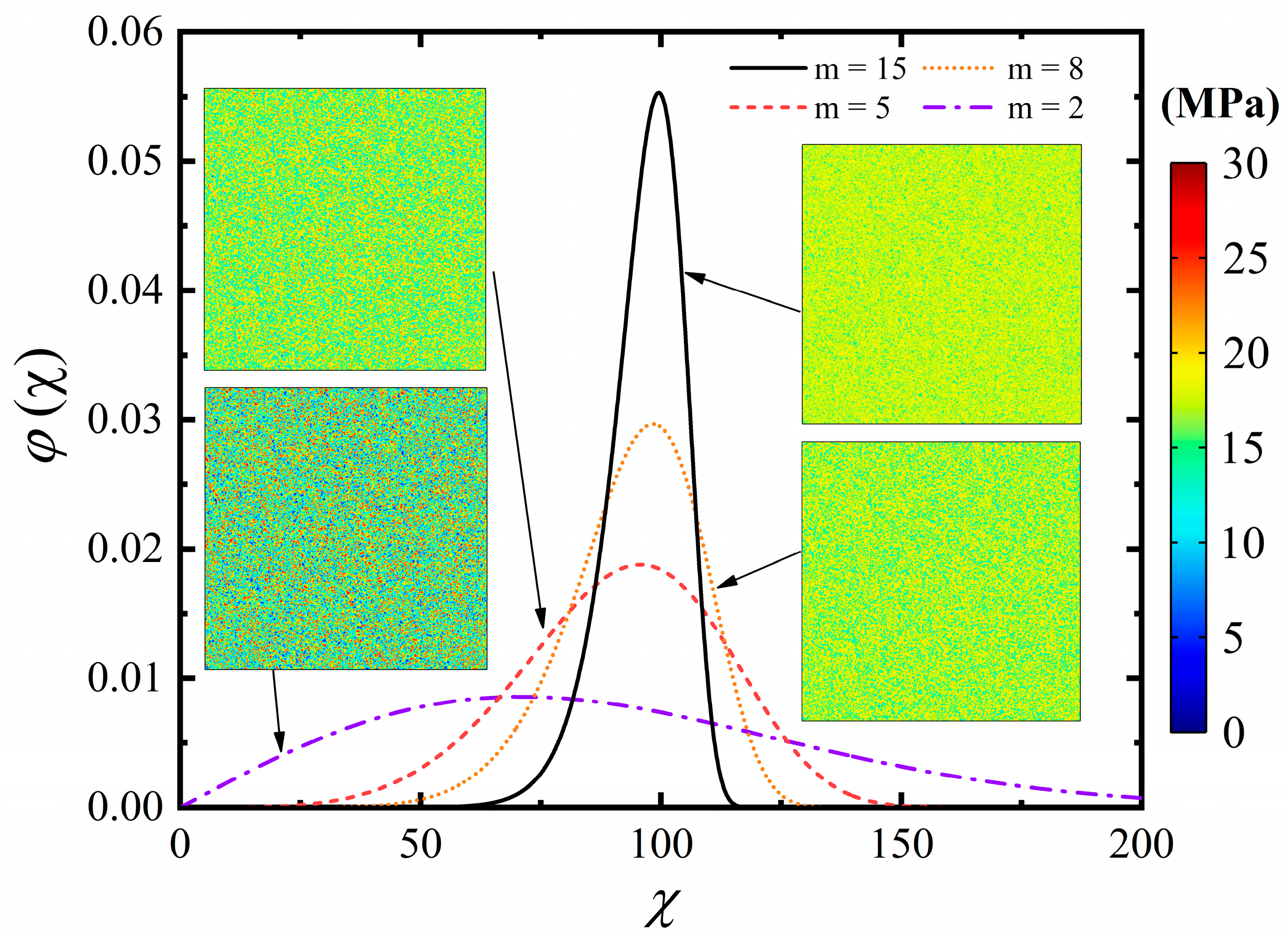

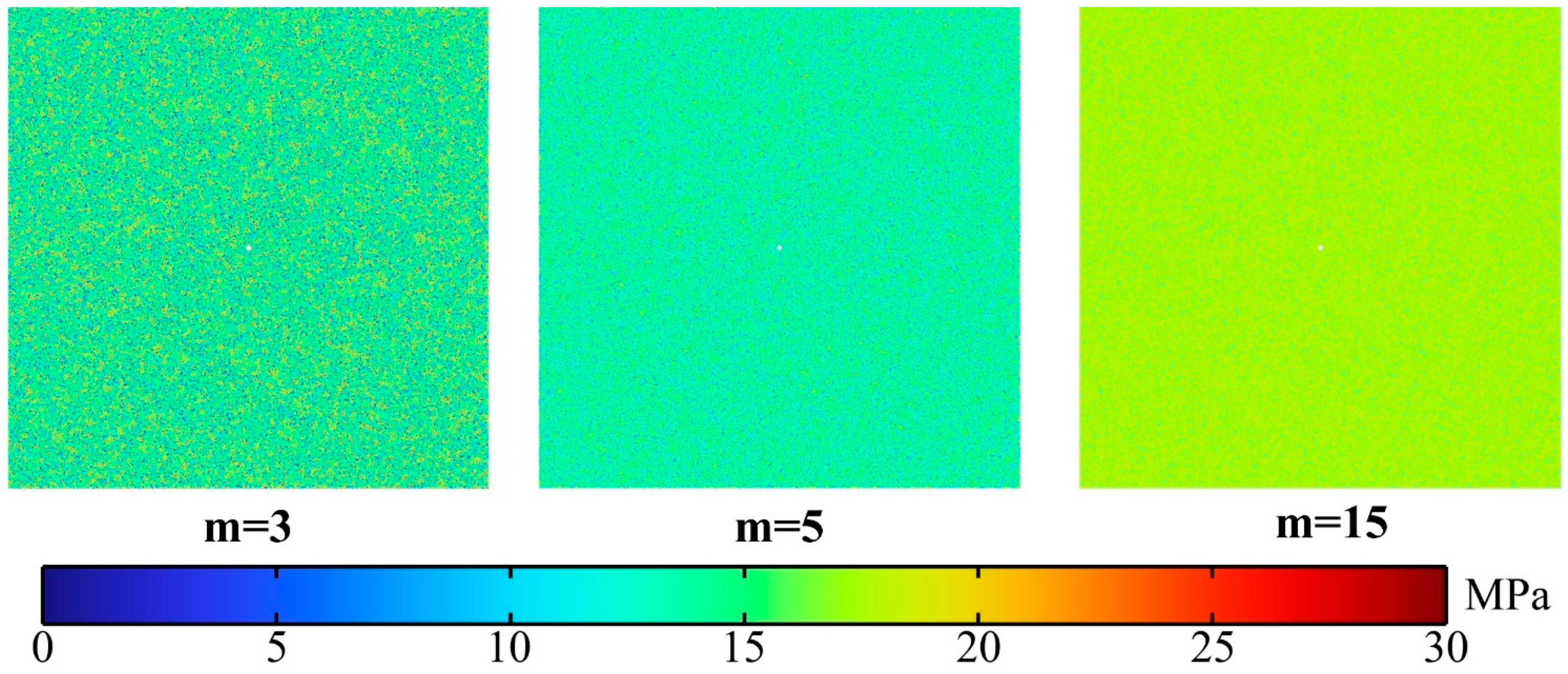

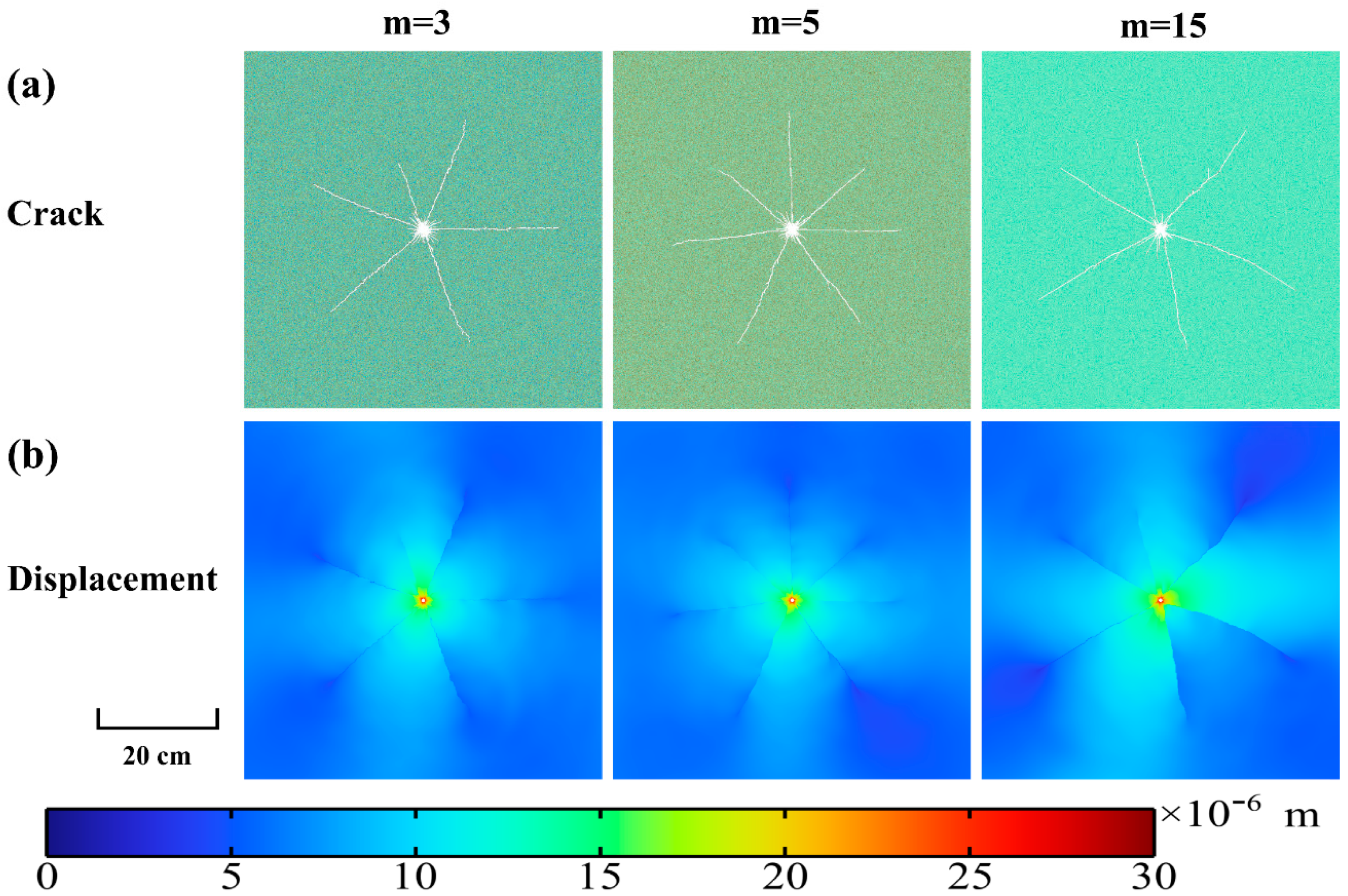

5.3. Effect of Heterogeneity of Tensile Strength

5.4. Discussion

6. Conclusions

- (1)

- The analytical approach and simulations described here are highly consistent with the prior research. The proposed methodologies are capable of accurately calculating the progressive failure process of granite and revealing the mechanism of rock failure under electropulse, thereby guiding electropulse breaking technology and estimating the degree of rock damage.

- (2)

- Under the conditions described in this study, and using granite as an example, the granite is impacted by a discharge device (Marx generator) with an initial voltage U0 that is 10 kV and a capacitance F that is 5 µF before it begins to degrade at about 40 µs after discharge, with the current reaching its peak at approximately 50 µs. The shock wave pressure then attains a peak at about 70 µs. Dense short cracks form around the granite and the dominant cracks grow to an average length of about 20 cm at around 200 µs. The crack width dcr is predicted to be approximately 1.6 mm.

- (3)

- Increasing the initial voltage U0 of the discharge device has a more significant effect on the breaking granite than increasing the capacitance C. The extent to which granite is damaged by an electric pulse is determined mostly by the distribution of tensile stress and the tensile strength.

- (4)

- The lack of coherence in the rock’s tensile strength can result in variations in the length of the dominant cracks. However, heterogeneity has a negligible effect on the rate of crack propagation, the total cracked area, or the number of major cracks. There are around six to seven dominant cracks.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, T.; Du, J.Y.; Li, W.; Bi, X.L.; Yao, S.L. Synthesizing Comment on Efficient Rock Fragmentation Method in Frontier Drilling Technology. Oil Field Equip. 2012, 41, 50–55. [Google Scholar]

- Wang, S.; Guo, Y.C.; Cheng, G.; Li, D.Y. Performance Study of Hybrid Magnetic Coupler Based on Magneto Thermal Coupled Analysis. Energies 2017, 10, 1148. [Google Scholar] [CrossRef] [Green Version]

- Zhu, X.H.; Luo, X.H.; Liu, W.J. On the rock-breaking mechanism of plasma channel drilling technology. J. Pet. Sci. Eng. 2021, 194, 107356. [Google Scholar] [CrossRef]

- Burkin, V.V.; Kuznetsova, N.S.; Lopatin, V.V. Dynamics of electro burst in solids: I. Power characteristics of electro burst. J. Phys. D-Appl. Phys. 2009, 42, 185204. [Google Scholar] [CrossRef]

- Yan, F.Z.; Lin, B.Q.; Zhu, C.J.; Guo, C.; Zhou, Y.; Zou, Q.L.; Liu, T. Using high-voltage electrical pulses to crush coal in an air environment: An experimental study. Rock Mech. Rock Eng. 2016, 298, 50–56. [Google Scholar] [CrossRef]

- Wang, Z.; Shi, F.; Manlapig, E. Pre-concentration of copper ores by high voltage pulses. Part 1: Principle and major findings. Miner. Eng. 2015, 79, 306–314. [Google Scholar]

- Duan, C.L.; Diao, Z.J.; Zhao, Y.M.; Huang, W. Liberation of valuable materials in waste printed circuit boards by high-voltage electrical pulses. Miner. Eng. 2015, 70, 170–177. [Google Scholar] [CrossRef]

- Touzé, S.; Bru, K.; Ménard, Y.; Weh, A.; Weid, F.V.D. Electrical fragmentation applied to the recycling of concrete waste—Effect on aggregate liberation. Int. J. Miner. Process. 2017, 158, 68–75. [Google Scholar] [CrossRef]

- Yudin, A.S.; Zhurkov, M.Y.; Martemyanov, S.M.; Datskevich, S.Y.; Vazhov, V.F. Electrical discharge drilling of granite with positive and negative polarity of voltage pulses. Int. J. Rock Mech. Min. Sci. 2019, 123, 104058. [Google Scholar] [CrossRef]

- Dzhantimirov, K.A.; Krastelev, E.G.; Kryuchkov, S.A.; Nistratov, V.M.; Smirnov, P.V. Geotechnical Technology Based on Electrochemical Explosion and Equipment for Its Implementation. Soil Mech. Found. Eng. 2005, 42, 172–177. [Google Scholar] [CrossRef]

- Park, H.; Lee, S.R.; Kim, N.K.; Kim, T.H. A numerical study of the pullout behavior of grout anchors underreamed by pulse discharge technology. Comput. Geotech. 2013, 47, 78–90. [Google Scholar] [CrossRef]

- Biela, J.; Marxgut, C.; Bortis, D.; Kolar, J.W. Solid state modulator for plasma channel drilling. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 1093–1099. [Google Scholar] [CrossRef]

- Andres, U. Parameters of disintegration of rock by electrical pulses—ScienceDirect. Powder Technol. 1989, 58, 265–269. [Google Scholar] [CrossRef]

- Lisitsyn, I.; Inoue, H.; Nishizawa, I.; Katsuki, N.; Akiyama, H. Breakdown and destruction of heterogeneous solid dielectrics by high voltage pulses. J. Appl. Phys. 1998, 84, 6262. [Google Scholar] [CrossRef]

- Andres, U.; Timoshkin, I.; Soloviev, M. Energy consumption and liberation of minerals in explosive electrical breakdown of ores. Miner. Process Extr. Metall. Rev. 2001, 110, 149–157. [Google Scholar] [CrossRef]

- Timoshkin, I.V.; Mackersie, J.W.; Macgregor, S.J. Plasma channel miniature hole drilling technology. IEEE Trans. Plasma Sci. 2004, 32, 2055–2061. [Google Scholar] [CrossRef]

- Zhang, Z.C.; Pei, Y.L.; Liu, Z.; Wang, K.Y.; Liu, B.H.; Yan, K.P. Experimental research on rock breakdown under short high-voltage pulse. High Volt Eng. 2012, 38, 1719–1725. [Google Scholar]

- Burkin, V.V.; Kuznetsova, N.S.; Lopatin, V.V. Dynamics of electro burst in solids: II. Characteristics of wave process. J. Phys. D-Appl. Phys. 2009, 42, 235209. [Google Scholar] [CrossRef]

- Cho, S.H.; Cheong, S.S.; Yokota, M.; Kaneko, K. The Dynamic Fracture Process in Rocks under High-Voltage Pulse Fragmentation. Rock Mech. Rock Eng. 2016, 49, 3841–3853. [Google Scholar] [CrossRef]

- Zhu, X.H.; Luo, Y.X.; Liu, W.J.; He, L.; Guo, R.; Jia, Y.D. On the Mechanism of High-Voltage Pulsed Fragmentation from Electrical Breakdown Process. Rock Mech. Rock Eng. 2021, 54, 4593–4616. [Google Scholar] [CrossRef]

- Li, G.; Tang, C.A. A statistical meso-damage mechanical method for modeling trans-scale progressive failure process of rock. Int. J. Rock Mech. Min. Sci. 2015, 74, 133–150. [Google Scholar] [CrossRef]

- Yang, S.Q.; Tian, W.L.; Huang, Y.H.; Huang, Y.H.; Ranjith, P.G.; Ju, Y. An Experimental and Numerical Study on Cracking Behavior of Brittle Sandstone Containing Two Non-Coplanar Fissures Under Uniaxial Compression. Rock Mech. Rock Eng. 2016, 49, 1497–1515. [Google Scholar] [CrossRef]

- Li, T.; Chen, M.; Ye, Z.W.; Lu, W.B.; Wei, D. Study on the energy transfer efficiency of explosive blasting with different coupling medium. Explos. Shock. Waves 2021, 41, 062201. [Google Scholar]

- Zhu, Z.M.; Xie, H.P.; Mohanty, B.H. Numerical investigation of blasting-induced damage in cylindrical rocks. Int. J. Rock Mech. Min. Sci. 2008, 45, 11–121. [Google Scholar] [CrossRef]

- Wei, D.; Chen, M.; Ye, Z.W.; Lu, W.B.; Li, T. Study on Blasting Failure Zone Based on Rate-dependent Dynamic Characteristics of Rock Mass. Adv. Eng. Sci. 2021, 53, 67–74. [Google Scholar]

- Dai, J. Calculation of radii of the broken and cracked areas in rock by a long charge explosion. J. Liaoning Tech. Univ. (Nat. Sci.) 2001, 20, 144–147. [Google Scholar]

- Li, L.C.; Tang, C.A.; Li, G.; Wang, S.Y.; Liang, Z.Z.; Zhang, Y.B. Numerical Simulation of 3D Hydraulic Fracturing Based on an Improved Flow-Stress-Damage Model and a Parallel FEM Technique. Rock Mech. Rock Eng. 2012, 45, 801–818. [Google Scholar] [CrossRef]

- Ma, G.W.; An, X.M. Numerical simulation of blasting-induced rock fractures. Int. J. Rock Mech. Min. Sci. 2008, 45, 966–975. [Google Scholar] [CrossRef]

- Vogler, D.; Walsh, S.T.D.; Rohr, P.R.V.; Saar, M.O. Simulation of rock failure modes in thermal spallation drilling. Acta Geotech. 2020, 15, 2327–2340. [Google Scholar] [CrossRef]

- Zuo, W.R.; Li, X.F.; Shi, F.N.; Deng, R.D.; Yin, W.Z.; Guo, B.; Ku, J.G. Effect of high voltage pulse treatment on the surface chemistry and floatability of chalcopyrite and pyrite. Miner. Eng. 2020, 147, 106170. [Google Scholar] [CrossRef]

- Kutter, H.K.; Fairhurst, C. On the fracture process in blasting. Int. J. Rock Mech. Min. Sci. 1971, 8, 181–188. [Google Scholar] [CrossRef]

- Xiong, J.M.; Li, L.; Dai, H.Y.; Wu, H.B.; Peng, M.Y.; Lin, F.C. The development of shock wave overpressure driven by channel expansion of high current impulse discharge arc. Phys. Plasmas 2018, 25, 032115. [Google Scholar] [CrossRef]

- Kratel, A.W.H. Pulsed-Power Discharges in Water; California Institute of Technology: Pasadena, CA, USA, 1996; pp. 130–132. [Google Scholar]

- Li, Y.S.; Liu, J.; Feng, B.Y.; Zhang, X.R.; Zhang, M.Y.; Xiao, H.L.; He, M.B.; Shi, F.N. Numerical modeling and simulation of the electric breakdown of rocks immersed in water using high voltage pulses. Geomech. Geophys. Geo-Energy Geo-Resour. 2021, 7, 1–21. [Google Scholar] [CrossRef]

- Tang, W.H.; Zhang, R.Q. Introduction to Theory and Computation of Equations of State; Higher Education Press: Beijing, China, 2008. (In Chinese) [Google Scholar]

- Zhang, Q. Smash districts and expanding of cavities in rock blasting. Explos. Shock Waves 1990, 10, 68–75. (In Chinese) [Google Scholar]

- Li, X.F.; Liu, H.B.; Liu, K.; Zhang, Q.B.; Chu, F.; Huang, L.X.; Zhao, J. Dynamic properties and fracture characteristics of rocks subject to impact loading. Chin. J. Rock. Mech. Eng. 2017, 36, 2393–2405. (In Chinese) [Google Scholar]

- Chen, J.Z.; Elim, C.; Goldsby, D.; Gieré, R. Generation of shock lamellae and melting in rocks by lightning-induced shock waves and electrical heating. Geophys. Res. Lett. 2017, 44, 8757–8768. [Google Scholar] [CrossRef] [Green Version]

- Elim, C.; Chen, J.Z.; Goldsby, D.; Gieré, R. Mineralogical and compositional features of rock fulgurites: A record of lightning effects on granite. Am. Miner. 2017, 102, 1470–1481. [Google Scholar] [CrossRef]

- Grieve, R.A.F.; Langenhorst, F.; Stöffler, D. Hock metamorphism of quartz in nature and experiment: II. Significance in geoscience. Meteorit. Planet. Sci. 1996, 31, 6–35. [Google Scholar] [CrossRef]

- Rinne, M.; Stephansson, O.; Shen, B.T.; Konietzky, H. Introduction to the Theories of RockFracturing; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Yang, J.X. Study on Confined Blasting Control Mechanism of Hard Coal Rock with High Safety and Efficiency and Test Analysis; China University of Mining & Technology: Xuzhou, China, 2015. (In Chinese) [Google Scholar]

- Jirásek, M.; Bauer, M. Numerical aspects of the crack band approach. Comput. Struct. 2012, 110, 60–78. [Google Scholar] [CrossRef]

- Tang, C.A.; Liang, Z.Z.; Zhang, Y.B.; Chang, X.; Tao, X.; Wang, D.G.; Zhang, J.X.; Liu, J.S.; Zhu, W.C.; Elsworth, D. Fracture spacing in layered materials: A new explanation based on two-dimensional failure process modeling. Am. J. Sci. 2008, 308, 49–72. [Google Scholar] [CrossRef]

- Weibull, W. A statistical distribution function of wide applicability. Int. J. Appl. Mech. 1951, 18, 293–297. [Google Scholar] [CrossRef]

- Li, C.P.; Duan, L.C.; Tan, S.C.; Chikhotkin, V.; Fu, W.P. Damage Model and Numerical Experiment of High-Voltage Electro Pulse Boring in Granite. Energies 2019, 12, 727. [Google Scholar] [CrossRef] [Green Version]

- Xu, T.; Zhou, G.L.; Heap, M.J.; Yang, S.Q.; Konietzky, H.; Baud, P. The Modeling of Time-Dependent Deformation and Fracturing of Brittle Rocks Under Varying Confining and Pore Pressures. Rock Mech. Rock Eng. 2018, 51, 3241–3263. [Google Scholar] [CrossRef]

- Bakholdin, B.V.; Dzhantimirov, K.A. New electric-discharge technologies in geotechnical construction. Soil Mech. Found. Eng. 1998, 35, 154–159. [Google Scholar] [CrossRef]

- Park, H.; Lee, S.R.; Kim, T.H.; Kim, T.H.; Kim, N.K. Numerical modeling of ground borehole expansion induced by application of pulse discharge technology. Comput. Geotech. 2011, 38, 532–545. [Google Scholar] [CrossRef]

- Lee, J.; Lacy, T.E.; Pittman, C.U.; Reddy, J.N. Numerical estimations of lightning-induced mechanical damage in carbon/epoxy composites using shock wave overpressure and equivalent air blast overpressure. Compos. Struct. 2019, 224, 111039. [Google Scholar] [CrossRef]

| Parameter | Values | Source | |

|---|---|---|---|

| Electric circuit | Initial voltage, U0 (kV) | 10 | Burkin et al., 2009a [4]; Li et al., 2019 [46] |

| Capacitance, C (µF) | 5 | ||

| Inductance, L (uH) | 5 | ||

| Circuit resistance, Rz (Ω) | 1 | ||

| Spark constant Kch (V·s1/2·m−1) | 611 | ||

| Arc channel | Initial channel radius, r0 (mm) | 0.5 | Burkin et al., 2009a [4]; Li et al., 2019 [46] |

| Ratio of specific heat, γ | 1.1 | ||

| Material bulk constants, ψ (GPa) | 8.5 | ||

| Material coefficient, n | 4 | ||

| Granite | Young’s modulus, E (GPa) | 35 | Li et al., 2015 [21]; Xu et al., 2018 [47] |

| Density, ρ (kg/m3) | 2700 | ||

| Tensile strength, ft (MPa) | 18 | ||

| Compressive strength fc (MPa) | 240 | ||

| Residual strength ratio η | 0.1 | ||

| Poisson’s ratio, μ | 0.2 | ||

| Homogeneity index, m | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rao, P.; Ouyang, P.; Nimbalkar, S.; Chen, Q.; Cui, J.; Wu, Z. Mechanism Analysis of Rock Failure Process under High-Voltage Electropulse: Analytical Solution and Simulation. Materials 2022, 15, 2188. https://doi.org/10.3390/ma15062188

Rao P, Ouyang P, Nimbalkar S, Chen Q, Cui J, Wu Z. Mechanism Analysis of Rock Failure Process under High-Voltage Electropulse: Analytical Solution and Simulation. Materials. 2022; 15(6):2188. https://doi.org/10.3390/ma15062188

Chicago/Turabian StyleRao, Pingping, Peihao Ouyang, Sanjay Nimbalkar, Qingsheng Chen, Jifei Cui, and Zhilin Wu. 2022. "Mechanism Analysis of Rock Failure Process under High-Voltage Electropulse: Analytical Solution and Simulation" Materials 15, no. 6: 2188. https://doi.org/10.3390/ma15062188

APA StyleRao, P., Ouyang, P., Nimbalkar, S., Chen, Q., Cui, J., & Wu, Z. (2022). Mechanism Analysis of Rock Failure Process under High-Voltage Electropulse: Analytical Solution and Simulation. Materials, 15(6), 2188. https://doi.org/10.3390/ma15062188