Characterization of Microstructure, Phase Composition, and Mechanical Behavior of Ballistic Steels

Abstract

:1. Introduction

2. Experimental Work

2.1. Materials

2.2. Methods

2.2.1. Metallography

2.2.2. Etching

2.3. Testing and Characterization

2.3.1. Optical Emission Spectroscopy (OES)

2.3.2. Microscopy

2.3.3. X-ray Diffraction

2.3.4. Tensile Testing

2.3.5. Charpy Impact Testing

2.3.6. Vickers Microhardness Testing

2.3.7. Nanoindentation Testing

2.3.8. Fractography

2.3.9. Corrosion Testing

3. Results and Discussion

3.1. Chemical Composition

3.2. Microstructure

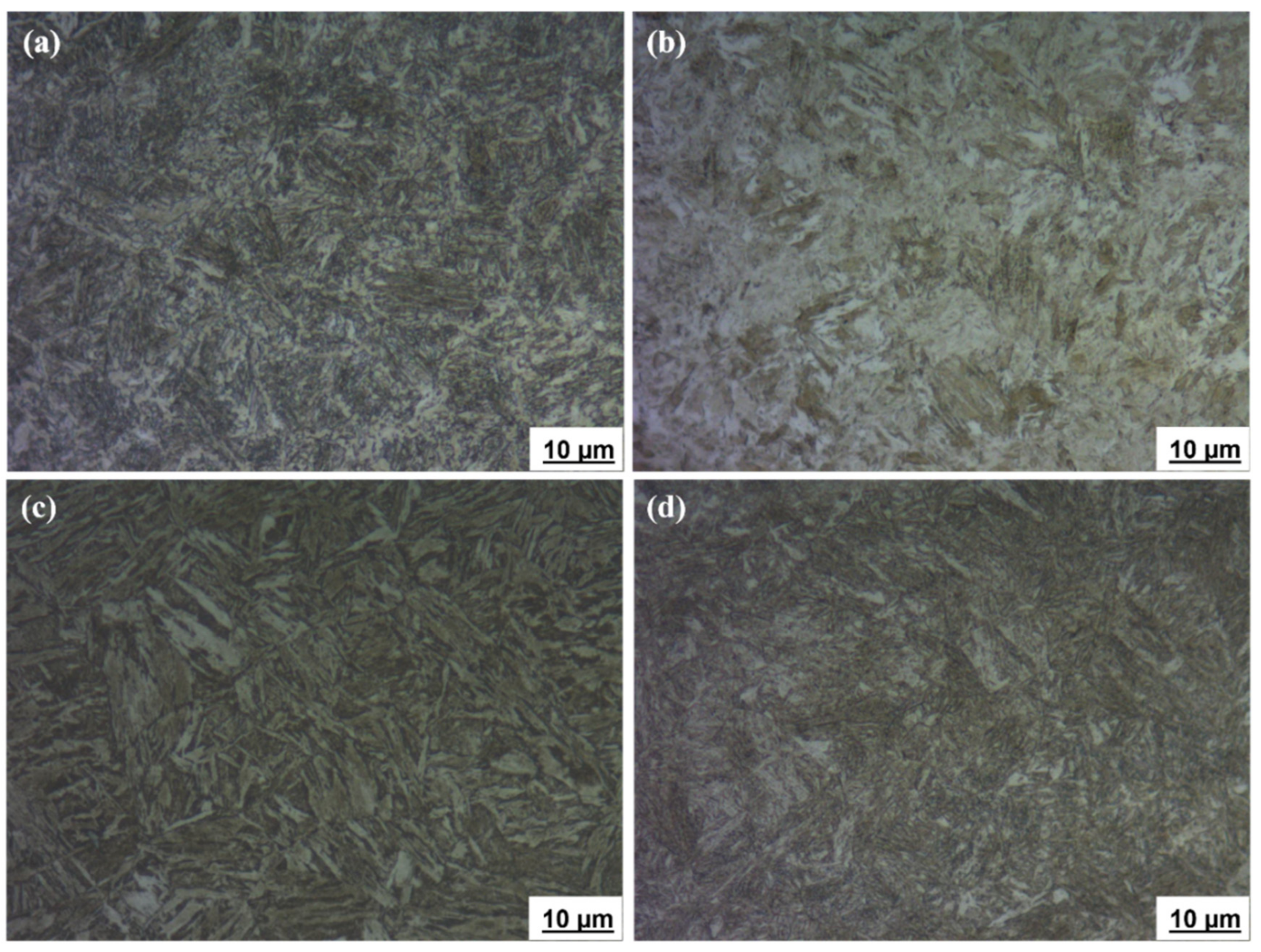

3.2.1. Optical Microscope

3.2.2. Scanning Electron Microscope

3.3. X-ray Diffraction Analysis

3.4. Mechanical Properties

3.4.1. Tensile Properties

3.4.2. Impact Resistance

3.4.3. Vickers Microhardness

3.4.4. Nanoindentation Analysis

3.5. Fractography

3.5.1. Tensile Samples

3.5.2. Impact Samples

3.5.3. Microstructure and Mechanical Behavior Co-Relationships

3.6. Corrosion Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Edwards, M.; Mathewson, A. The ballistic properties of tool steel as a potential improvised armour plate. Int. J. Impact Eng. 1997, 19, 297–309. [Google Scholar] [CrossRef]

- Shokrieh, M.; Javadpour, G. Penetration analysis of a projectile in ceramic composite armor. Compos. Struct. 2008, 82, 269–276. [Google Scholar] [CrossRef]

- Madhu, V.; Bhat, T.B. Armour Protection and Affordable Protection for Futuristic Combat Vehicles. Def. Sci. J. 2011, 61, 394–402. [Google Scholar] [CrossRef] [Green Version]

- Jena, K.; Manickam, M.A.M.; Venketachari, S.; Srivastava, S.C.; Srivastava, A.; Chakrabarty, S.; Kumar, K.S. Microstructure, mechanical, ballistic property evaluation of RHA steel produced by continuous-casting route. J. Appl. Res. Technol. 2020, 18, 1–13. [Google Scholar] [CrossRef]

- Manganello, S.; Wilson, A. Direct Quenching and its Effects on High-Strength Armor Plate. In Proceedings of the International Symposium on Low-Carbon Steels for the 90’s, Pittsburgh, PA, USA, 18–21 October 1993; The Minerals, Metals & Materials Society: Pittsburgh, PA, USA, 1993; pp. 235–241. [Google Scholar]

- Atapek, S.H.; Karagoz, S. Ballistic impact behaviour of a tempered bainitic steel against 7.62 mm armour piercing projectile. Def. Sci. J. 2011, 61, 81. [Google Scholar] [CrossRef] [Green Version]

- Dikshit, S.; Kutumbarao, V.; Sundararajan, G. The influence of plate hardness on the ballistic penetration of thick steel plates. Int. J. Impact Eng. 1995, 16, 293–320. [Google Scholar] [CrossRef]

- Demir, T.; Übeyli, M.; Yıldırım, R.O. Investigation on the ballistic impact behavior of various alloys against 7.62 mm armor piercing projectile. Mater. Des. 2008, 29, 2009–2016. [Google Scholar] [CrossRef]

- Jena, P.K.; Kumar, K.S.; Bhat, T.B. Effect of heat treatment on mechanical and ballistic properties of ultrahigh strength DMR-1700 steel. Met. Mater. Processes 2007, 19, 339. [Google Scholar]

- Bekci, M.L.; Canpolat, C.H.; Usta, E.; Güler, M.S.; Cora, Ö.N. Ballistic performances of Ramor 500 and Ramor 550 armor steels at mono and bilayered plate configurations. Eng. Sci. Technol. Int. J. 2021, 24, 990–995. [Google Scholar] [CrossRef]

- Übeyli, M.; Yıldırım, R.O.; Ögel, B. On the comparison of the ballistic performance of steel and laminated composite armors. Mater. Des. 2007, 28, 1257–1262. [Google Scholar] [CrossRef]

- Jena, P.K.; Senthil, P. Effect of tempering time on the ballistic performance of a high strength armour steel. J. Appl. Res. Technol. 2016, 14, 47–53. [Google Scholar] [CrossRef]

- Jena, P.K.; Mishra, B.; Kumar, K.S.; Bhat, B.T. An experimental study on the ballistic impact behavior of some metallic armour materials against 7.62 mm deformable projectile. Mater. Des. 2010, 31, 3308–3316. [Google Scholar] [CrossRef]

- Mishra, B.; Jena, P.K.; Ramakrishna, B.; Madhu, V.; Bhat, T.B.; Gupta, N.K. Effect of tempering temperature, plate thickness and presence of holes on ballistic impact behavior and ASB formation of a high strength steel. Int. J. Impact Eng. 2012, 44, 17–28. [Google Scholar] [CrossRef]

- Maweja, K.; Stumpf, W.; van der Berg, N. Characteristics of martensite as a function of the Ms temperature in low-carbon armour steel plates. Mater. Sci. Eng. A 2009, 519, 121–127. [Google Scholar] [CrossRef] [Green Version]

- Lee, W.-S.; Su, T.-T. Mechanical properties and microstructural features of AISI 4340 high-strength alloy steel under quenched and tempered conditions. J. Mater. Processing Technol. 1999, 87, 198–206. [Google Scholar] [CrossRef]

- Malakondaiah, G.; Srinivas, M.; Rao, R. Ultrahigh-strength low-alloy steels with enhanced fracture toughness. Prog. Mater. Sci. 1997, 42, 209–242. [Google Scholar] [CrossRef]

- Channa, I.A.; Shah, A.A.; Abro, S.H.; Siddiqui, M.A.; Mujahid, M.; Chandio, A.D. Effect of Tempering Temperature on the Properties of Martensitic Stainless Steel AISI-420. J. Emerg. Technol. 2019, 2, 51–56. [Google Scholar]

- Wolsky, S.; Czanderna, A. Methods and Phenomena 5, Ballistic Materials and Penetration Mechanics; Elsevier Scientific Publishing Company: Berlin/Heidelberg, Germany, 1982. [Google Scholar]

- Srivathsa, B.; Ramakrishnan, N. Ballistic performance maps for thick metallic armour. J. Mater. Processing Technol. 1999, 96, 81–91. [Google Scholar] [CrossRef]

- Maweja, K.; Stumpf, W. The design of advanced performance high strength low-carbon martensitic armour steels: Part 1. Mechanical property considerations. Mater. Sci. Eng. A 2008, 485, 140–153. [Google Scholar] [CrossRef]

- Ahmad, S.; Channa, I.A. Mathematical relationship between ferritic, pearlitic and average grain size of steel. J. Mod. Sci. Technol. 2013, 1, 1–18. [Google Scholar]

- Jena, P.K.; Mishra, B.; RameshBabu, M.; Babu, A.; Singh, A.K.; SivaKumar, K.; Balakrishna Bhat, T. Effect of heat treatment on mechanical and ballistic properties of a high strength armour steel. Int. J. Impact Eng. 2010, 37, 242–249. [Google Scholar] [CrossRef]

- Konca, E. A Comparison of the Ballistic Performances of Various Microstructures in MIL-A-12560 Armor Steel. Metals 2020, 10, 446. [Google Scholar] [CrossRef] [Green Version]

- Zhang, P.; Chen, Y.; Xiao, W.; Ping, D.; Zhao, X. Twin structure of the lath martensite in low carbon steel. Prog. Nat. Sci. Mater. Int. 2016, 26, 169–172. [Google Scholar] [CrossRef] [Green Version]

- Bhat, T.B. Principles of armor design. Trans. Indian Inst. Met. 1984, 37, 313–335. [Google Scholar]

- Atapek, S.H. Development of a new armor steel and its ballistic performance. Def. Sci. J. 2013, 63, 271–277. [Google Scholar] [CrossRef] [Green Version]

- Whittington, W.R.; Oppedal, A.L.; Turnage, S.; Hammi, Y.; Rhee, H.; Allison, P.G.; Crane, C.K.; Horstemeyer, M.F. Capturing the effect of temperature, strain rate, and stress state on the plasticity and fracture of rolled homogeneous armor (RHA) steel. Mater. Sci. Eng. A 2014, 594, 82–88. [Google Scholar] [CrossRef]

- Katiyar, P.K.; Behera, P.K.; Misra, S.; Mondal, K. Comparative corrosion behavior of five different microstructures of rebar steels in simulated concrete pore solution with and without chloride addition. J. Mater. Eng. Perform. 2019, 28, 6275–6286. [Google Scholar] [CrossRef]

- Handoko, W.; Pahlevani, F.; Sahajwalla, V.J.M. Enhancing corrosion resistance and hardness properties of carbon steel through modification of microstructure. Materials 2018, 11, 2404. [Google Scholar] [CrossRef] [Green Version]

- Showalter, D.D.; Gooch, W.A.; Burkins, M.S.; Koch, R.S. Ballistic Testing of SSAB Ultra-High-Hardness Steel for Armor Applications; Weapons and Materials Research; Army Research Lab: Aberdeen Proving Ground, MD, USA, 2008. [Google Scholar]

- Gooch, W.; Burkins, M.S.; Squillacioti, R.; Stockman Koch, R.-M.; Oscarsson, H.; Nash, C. Ballistic testing of Swedish steel armox plate for US armor applications. In Proceedings of the 21st International Ballistic Symposium, Adelaide, Australia, 19–23 April 2004. [Google Scholar]

- Weissmann, S. Search Manual for Selected Powder Diffraction Data for Metals and Alloys; JCPDS International Center for Diffraction Data: Swarthmore, PA, USA, 1978. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Fischer-Cripps, A.C. Introduction to Contact Mechanics; Springer: Berlin/Heidelberg, Germany, 2007; Volume 101. [Google Scholar]

- Deng, X.; Fu, T.L.; Wang, Z.D.; Misra, R.D.K.; Wang, G.D. Epsilon carbide precipitation and wear behaviour of low alloy wear resistant steels. Mater. Sci. Technol. 2016, 32, 320–327. [Google Scholar] [CrossRef]

- Thomson, R.; Miller, M. Carbide precipitation in martensite during the early stages of tempering Cr-andMo-containing low alloy steels. Acta Mater. 1998, 46, 2203–2213. [Google Scholar] [CrossRef]

- Doerner, M.F.; Nix, W.D. A method for interpreting the data from depth-sensing indentation instruments. J. Mater. Res. 1986, 1, 601–609. [Google Scholar] [CrossRef]

- Karagöz, Ş.; Atapek, Ş.H.; Yilmaz, A. Microstructural and fractographical studies on quenched and tempered armor steels. Mater. Test. 2010, 52, 316–322. [Google Scholar] [CrossRef] [Green Version]

- Katiyar, P.K.; Misra, S.; Mondal, K. Comparative corrosion behavior of five microstructures (pearlite, bainite, spheroidized, martensite, and tempered martensite) made from a high carbon steel. Metall. Mater. Trans. A 2019, 50, 1489–1501. [Google Scholar] [CrossRef]

- Inam, A.; Hafeez, M.A.; Atif, M.; Ishtiaq, M.; Hassan, M.H.; Hussain, T.; Mughal, M.S.; Raza, M.A.; Abbas, M.A.Q.; Ullah, I. Microstructural, Mechanical, and Electrochemical Properties of Quenched and Partitioned 3 wt% Mn Steel. Arab. J. Sci. Eng. 2021, 46, 417–423. [Google Scholar] [CrossRef]

- Wan, H.; Cai, Y.; Song, D.; Chen, S. Effect of Cr/Mo carbides on corrosion behaviour of Fe_Mn_C twinning induced plasticity steel. Corros. Sci. 2020, 167, 108518. [Google Scholar] [CrossRef]

| S.No. | Sample ID | Material Details | Thickness | Threat Level | Supplier |

|---|---|---|---|---|---|

| 1 | *LT-1 | Ballistic Steel | 7.0 mm | FB6 | Pak Armoring |

| 2 | *LT-2 | Ballistic Steel | 6.7 mm | FB6 | Streit Pakistan |

| 3 | **HT-1 | Ballistic Steel | 15.0 mm | FB7 | Pak Armoring |

| 4 | **HT-2 | Ballistic Steel | 13.0 mm | FB7 | Streit Pakistan |

| Chemical Composition (wt. %) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Elements | C | Si | Mn | P | S | Cr | Mo | Ni | B | Fe |

| Standard Limit | 0.32 max | 0.50 max | 1.30 max | 0.010 max | 0.005 max | 1.00 max | 0.70 max | 1.80 max | 0.005 max | Balance |

| Material | Mechanical Properties | ||||

|---|---|---|---|---|---|

| Armox 500T | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Vickers Hardness Number (VHN) | Impact Toughness (J) |

| 1250–1450 | 1450–1750 | 7–10 | 530–620 | Min 25 | |

| Sample ID | Chemical Composition (wt. %) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | P | S | Cr | Ni | Mo | B | Fe | |

| LT-1 | 0.26 | 0.90 | 0.30 | 0.006 | 0.001 | 0.90 | 0.96 | 0.26 | 0.003 | Balance |

| LT-2 | 0.29 | 1.35 | 0.55 | 0.009 | 0.003 | 0.70 | 0.44 | 0.27 | 0.002 | Balance |

| HT-1 | 0.30 | 1.00 | 0.38 | 0.005 | 0.004 | 0.60 | 0.38 | 0.42 | 0.004 | Balance |

| HT-2 | 0.30 | 1.30 | 0.52 | 0.007 | 0.002 | 0.60 | 0.40 | 0.34 | 0.003 | Balance |

| Sample ID | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Charpy Impact Energy (J) | Vickers Hardness Number (VHN) |

|---|---|---|---|---|---|

| LT-1 | 1500 | 1718 | 6.7 | 38 | 535 |

| LT-2 | 1470 | 1710 | 7.4 | 44 | 560 |

| HT-1 | 1510 | 1725 | 8.0 | 68 | 590 |

| HT-2 | 1530 | 1750 | 7.0 | 55 | 540 |

| Sample ID | Hardness (H) (GPa) | Elastic Modulus (E) (GPa) | Stiffness (S) (mN/nm) |

|---|---|---|---|

| LT-1 | 6.80 | 265.87 | 0.9880 |

| LT-2 | 7.95 | 244.26 | 0.8199 |

| HT-1 | 8.20 | 240.94 | 0.7908 |

| HT-2 | 7.42 | 252.75 | 0.9572 |

| Sample ID | Icorr (A/cm2) | Ecorr (V) | Corrosion Rate (mm/Year) |

|---|---|---|---|

| LT-1 | 3.60 × 10−6 | −0.340 | 0.0418 |

| LT-2 | 4.10 × 10−6 | −0.368 | 0.0476 |

| HT-1 | 5.30 ×10−6 | −0.394 | 0.0615 |

| HT-2 | 5.10 × 10−6 | −0.384 | 0.0592 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, W.; Tufail, M.; Chandio, A.D. Characterization of Microstructure, Phase Composition, and Mechanical Behavior of Ballistic Steels. Materials 2022, 15, 2204. https://doi.org/10.3390/ma15062204

Khan W, Tufail M, Chandio AD. Characterization of Microstructure, Phase Composition, and Mechanical Behavior of Ballistic Steels. Materials. 2022; 15(6):2204. https://doi.org/10.3390/ma15062204

Chicago/Turabian StyleKhan, Waseem, Muhammad Tufail, and Ali Dad Chandio. 2022. "Characterization of Microstructure, Phase Composition, and Mechanical Behavior of Ballistic Steels" Materials 15, no. 6: 2204. https://doi.org/10.3390/ma15062204

APA StyleKhan, W., Tufail, M., & Chandio, A. D. (2022). Characterization of Microstructure, Phase Composition, and Mechanical Behavior of Ballistic Steels. Materials, 15(6), 2204. https://doi.org/10.3390/ma15062204