Self-Powered and Flexible Triboelectric Sensors with Oblique Morphology towards Smart Swallowing Rehabilitation Monitoring System

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of Triboelectric Nanogenerator for Swallowing Rehabilitation (TSR) and Smart Swallowing Rehabilitation Monitoring System (SSRMS)

2.2. Characterization

2.3. Electrical Measurement

2.4. Implementation of the Smart Swallowing Rehabilitation Monitoring System

3. Results and Discussions

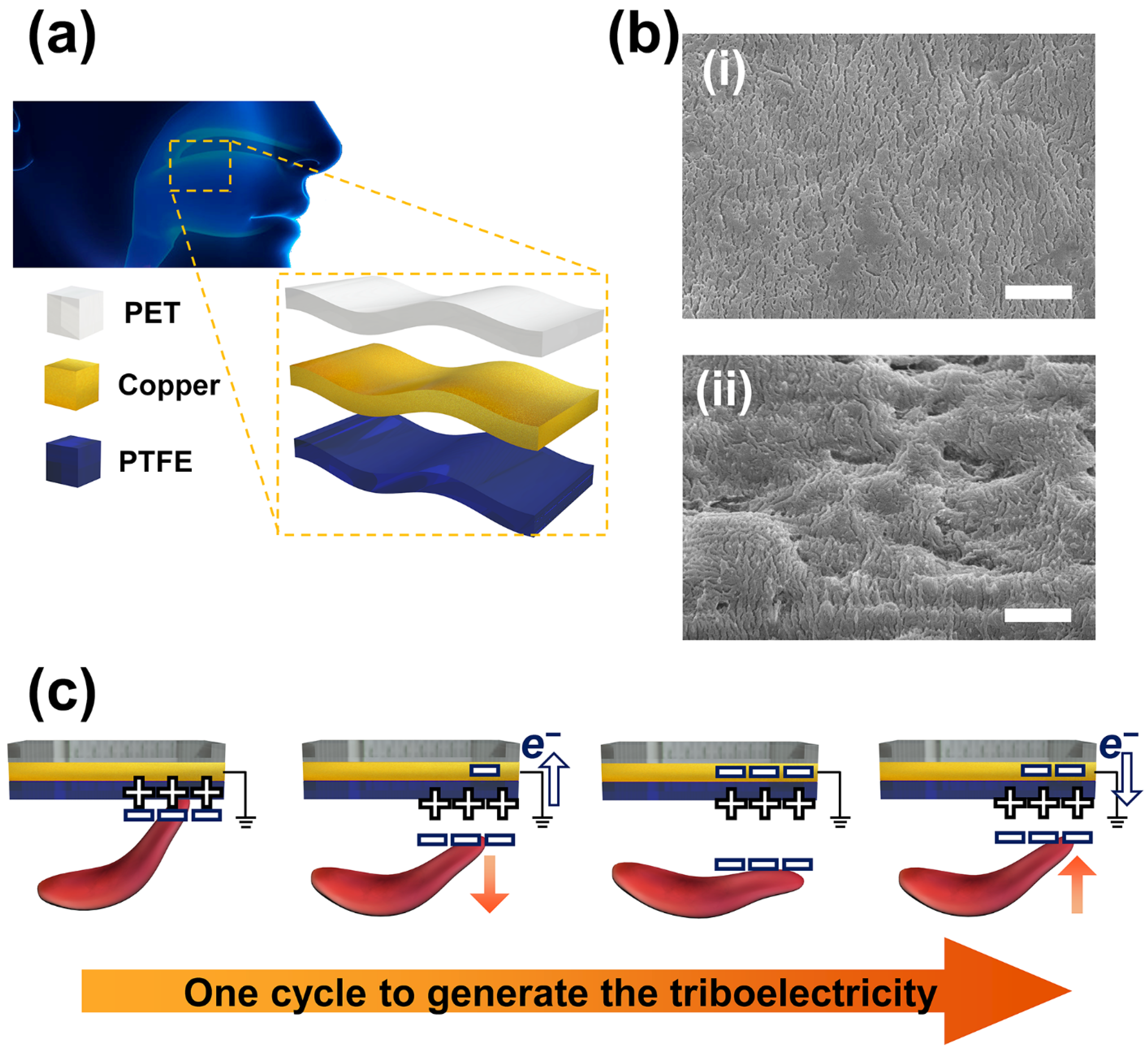

3.1. Fabricate the Triboelectric Nanogenerator for Swallowing Rehabilitation

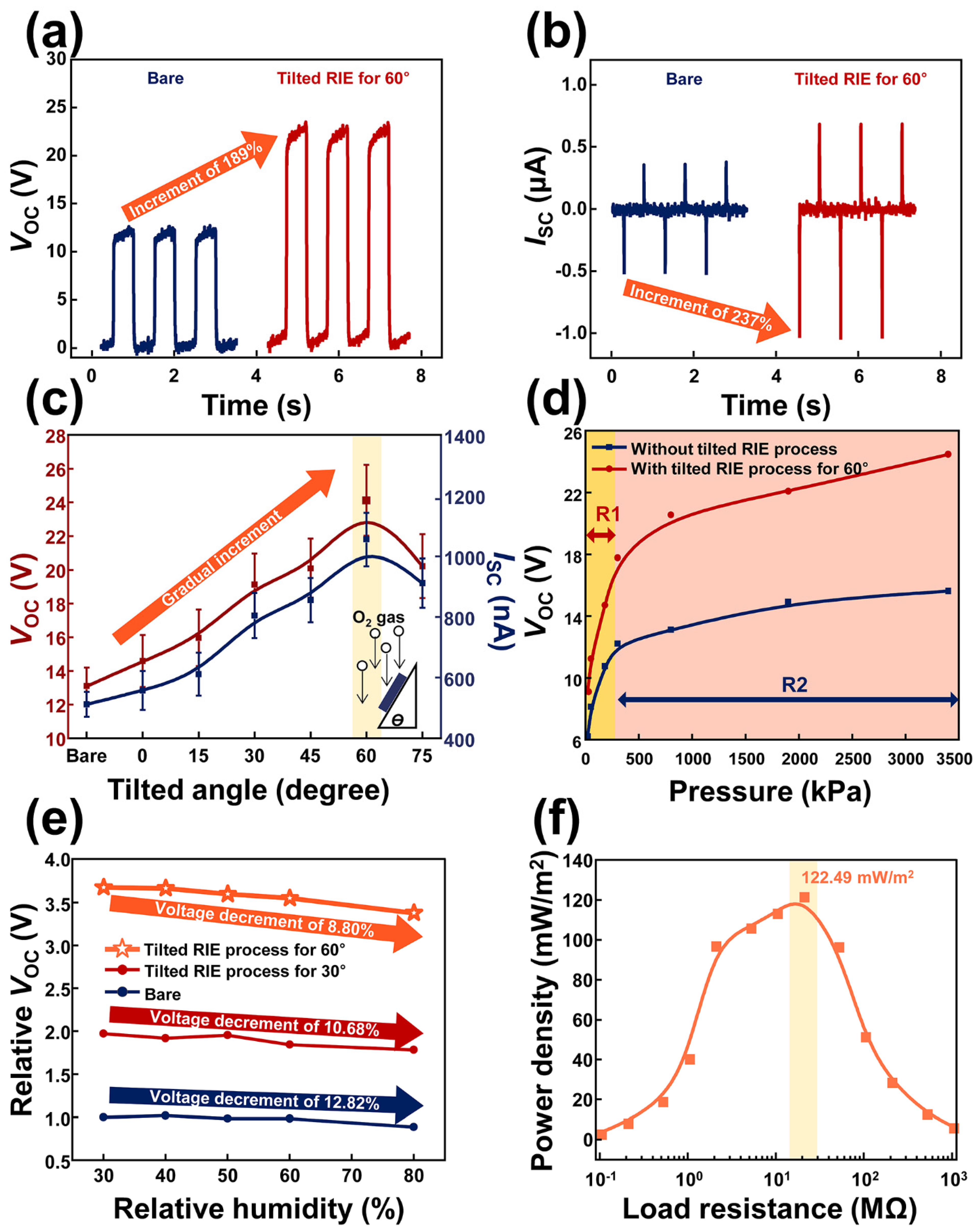

3.2. Electrical Output Generated from the TSR

3.3. Surface of the PTFE Film after Conducting the Tilted Reactive Ion Etching Observed by the Scanning Electron Microscope

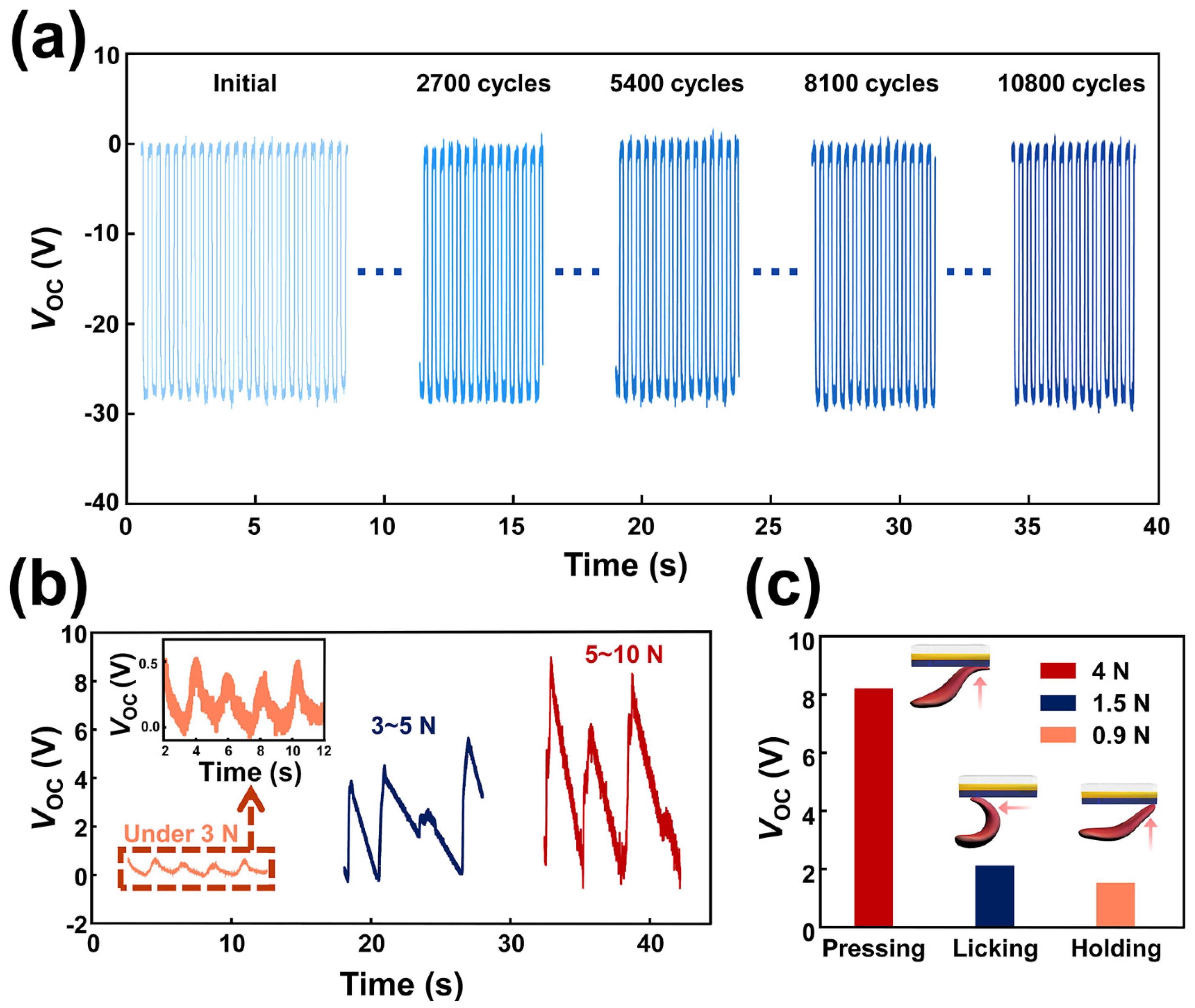

3.4. Durability of the TSR and Ability to Detect the Motion of the Tongue with the TSR

3.5. Implementation of the Smart Swallowing Rehabilitation Monitoring System

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Roser, M.; Ortiz-Ospina, E.; Ritchie, H. Life-Expectancy. Available online: https://ourworldindata.org/life-expectancy (accessed on 1 January 2022).

- Xing, X.; Chitrakar, B.; Hati, S.; Xie, S.; Li, H.; Li, C.; Liu, Z.; Mo, H. Development of black fungus-based 3D printed foods as dysphagia diet: Effect of gums incorporation. Food Hydrocoll. 2022, 123, 107173. [Google Scholar] [CrossRef]

- O’Gara, J.A. Dietary adjustments and nutritional therapy during treatment for Oral-Pharyngeal Dysphagia. Dysphagia 1990, 212, 209–212. [Google Scholar] [CrossRef]

- Yokoyama, S.; Hori, K.; Tamine, K.I.; Fujiwara, S.; Inoue, M.; Maeda, Y.; Funami, T.; Ishihara, S.; Ono, T. Tongue pressure modulation for initial gel consistency in a different oral strategy. PLoS ONE 2014, 9, e91920. [Google Scholar] [CrossRef] [Green Version]

- Konaka, K.; Kondo, J.; Hirota, N.; Tamine, K.; Hori, K.; Ono, T.; Maeda, Y.; Sakoda, S.; Naritomi, H. Relationship between tongue pressure and dysphagia in stroke patients. Eur. Neurol. 2010, 64, 101–107. [Google Scholar] [CrossRef]

- Lazarus, C.L.; Husaini, H.; Falciglia, D.; Delacure, M.; Branski, R.C.; Kraus, D.; Lee, N.; Ho, M.; Ganz, C.; Smith, B.; et al. Effects of exercise on swallowing and tongue strength in patients with oral and oropharyngeal cancer treated with primary radiotherapy with or without chemotherapy. Int. J. Oral Maxillofac. Surg. 2014, 43, 523–530. [Google Scholar] [CrossRef]

- Leoncini, E.; Ricciardi, W.; Cadoni, G.; Arzani, D.; Petrelli, L.; Paludetti, G.; Brennan, P.; Luce, D.; Stucker, I.; Matsuo, K.; et al. Adult height and head and neck cancer: A pooled analysis within the INHANCE Consortium. Head Neck 2007, 29, 632–637. [Google Scholar] [CrossRef] [Green Version]

- Van den Steen, L.; Baudelet, M.; Tomassen, P.; Bonte, K.; De Bodt, M.; Van Nuffelen, G. Effect of tongue-strengthening exercises on tongue strength and swallowing-related parameters in chronic radiation-associated dysphagia. Head Neck 2020, 42, 2298–2307. [Google Scholar] [CrossRef]

- Zheng, Q.; Shi, B.; Li, Z.; Wang, Z.L. Recent Progress on Piezoelectric and Triboelectric Energy Harvesters in Biomedical Systems. Adv. Sci. 2017, 4, 1700029. [Google Scholar] [CrossRef]

- Indira, S.S.; Vaithilingam, C.A.; Oruganti, K.S.P.; Mohd, F.; Rahman, S. Nanogenerators as a Sustainable Power Source: State of art, Applications, and Challenges. Nanomaterials 2019, 9, 773. [Google Scholar] [CrossRef] [Green Version]

- Shi, Q.; He, T.; Lee, C. More than energy harvesting—Combining triboelectric nanogenerator and flexible electronics technology for enabling novel micro-/nano-systems. Nano Energy 2019, 57, 851–871. [Google Scholar] [CrossRef]

- Disalvo, F.J. Thermoelectric cooling and power generation. Science 1999, 285, 703–706. [Google Scholar] [CrossRef]

- Kim, J.Y.; Lee, J.W.; Jung, H.S.; Shin, H.; Park, N.G. High-Efficiency Perovskite Solar Cells. Chem. Rev. 2020, 120, 7867–7918. [Google Scholar] [CrossRef] [PubMed]

- Yang, R.; Qin, Y.; Dai, L.; Wang, Z.L. Power generation with laterally packaged piezoelectric fine wires. Nat. Nanotechnol. 2009, 4, 34–39. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.R.; Tang, W.; Wang, Z.L. Flexible Nanogenerators for Energy Harvesting and Self-Powered Electronics. Adv. Mater. 2016, 28, 4283–4305. [Google Scholar] [CrossRef]

- Lu, M.P.; Song, J.; Lu, M.Y.; Chen, M.T.; Gao, Y.; Chen, L.J.; Wang, Z.L. Piezoelectric nanogenerator using p-type ZnO nanowire arrays. Nano Lett. 2009, 9, 1223–1227. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; Shi, Q.; He, T.; Yi, Z.; Ma, Y.; Yang, B.; Chen, T.; Lee, C. Self-Powered and Self-Functional Cotton Sock Using Piezoelectric and Triboelectric Hybrid Mechanism for Healthcare and Sports Monitoring. ACS Nano 2019, 13, 1940–1952. [Google Scholar] [CrossRef] [PubMed]

- Seol, M.L.; Im, H.; Moon, D.I.; Woo, J.H.; Kim, D.; Choi, S.J.; Choi, Y.K. Design strategy for a piezoelectric nanogenerator with a well-ordered nanoshell array. ACS Nano 2013, 7, 10773–10779. [Google Scholar] [CrossRef] [PubMed]

- Wen, Z.; Guo, H.; Zi, Y.; Yeh, M.H.; Wang, X.; Deng, J.; Wang, J.; Li, S.; Hu, C.; Zhu, L.; et al. Harvesting Broad Frequency Band Blue Energy by a Triboelectric-Electromagnetic Hybrid Nanogenerator. ACS Nano 2016, 10, 6526–6534. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Liu, W.; Xi, Y.; Lai, M.; Guo, H.; Liu, G.; Wang, M.; Li, T.; Ji, X.; Li, X. Rolling friction contact-separation mode hybrid triboelectric nanogenerator for mechanical energy harvesting and self-powered multifunctional sensors. Nano Energy 2018, 47, 539–546. [Google Scholar] [CrossRef]

- Saha, C.R.; O’Donnell, T.; Loder, H.; Beeby, S.; Tudor, J. Optimization of an electromagnetic energy harvesting device. IEEE Trans. Magn. 2006, 42, 3509–3511. [Google Scholar] [CrossRef]

- Chen, X.; Ren, Z.; Guo, H.; Cheng, X.; Zhang, H. Self-powered flexible and transparent smart patch for temperature sensing. Appl. Phys. Lett. 2020, 116, 043902. [Google Scholar] [CrossRef]

- Sala de Medeiros, M.; Chanci, D.; Martinez, R.V. Moisture-insensitive, self-powered paper-based flexible electronics. Nano Energy 2020, 78, 105301. [Google Scholar] [CrossRef]

- Ma, M.; Zhang, Z.; Liao, Q.; Yi, F.; Han, L.; Zhang, G.; Liu, S.; Liao, X.; Zhang, Y. Self-powered artificial electronic skin for high-resolution pressure sensing. Nano Energy 2017, 32, 389–396. [Google Scholar] [CrossRef]

- Chen, J.; Guo, H.; He, X.; Liu, G.; Xi, Y.; Shi, H.; Hu, C. Enhancing Performance of Triboelectric Nanogenerator by Filling High Dielectric Nanoparticles into Sponge PDMS Film. ACS Appl. Mater. Interfaces 2016, 8, 736–744. [Google Scholar] [CrossRef]

- Fan, F.R.; Tian, Z.Q.; Lin Wang, Z. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Zou, H.; Zhang, Y.; Guo, L.; Wang, P.; He, X.; Dai, G.; Zheng, H.; Chen, C.; Wang, A.C.; Xu, C.; et al. Quantifying the triboelectric series. Nat. Commun. 2019, 10, 1427. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.W.; Lee, J.H.; Kim, J.K.; Jeong, U. Material aspects of triboelectric energy generation and sensors. NPG Asia Mater. 2020, 12, 6. [Google Scholar] [CrossRef]

- Kim, Y.J.; Lee, J.; Park, S.; Park, C.; Park, C.; Choi, H.J. Effect of the relative permittivity of oxides on the performance of triboelectric nanogenerators. RSC Adv. 2017, 7, 49368–49373. [Google Scholar] [CrossRef] [Green Version]

- Yu, J.; Hou, X.; He, J.; Cui, M.; Wang, C.; Geng, W.; Mu, J.; Han, B.; Chou, X. Ultra-flexible and high-sensitive triboelectric nanogenerator as electronic skin for self-powered human physiological signal monitoring. Nano Energy 2020, 69, 104437. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, W.; Yan, Y.; Wu, X.; Wang, X.; Zhou, Y.; Hu, Y.; Chen, H.; Guo, T. Self-powered high-sensitivity sensory memory actuated by triboelectric sensory receptor for real-time neuromorphic computing. Nano Energy 2020, 75, 104930. [Google Scholar] [CrossRef]

- Cao, X.; Jie, Y.; Wang, N.; Wang, Z.L. Triboelectric Nanogenerators Driven Self-Powered Electrochemical Processes for Energy and Environmental Science. Adv. Energy Mater. 2016, 6, 1600665. [Google Scholar] [CrossRef]

- Vera Anaya, D.; He, T.; Lee, C.; Yuce, M.R. Self-powered eye motion sensor based on triboelectric interaction and near-field electrostatic induction for wearable assistive technologies. Nano Energy 2020, 72, 104675. [Google Scholar] [CrossRef]

- Hao, S.; Jiao, J.; Chen, Y.; Wang, Z.L.; Cao, X. Natural wood-based triboelectric nanogenerator as self-powered sensing for smart homes and floors. Nano Energy 2020, 75, 104957. [Google Scholar] [CrossRef]

- Wang, S.; Lin, L.; Wang, Z.L. Nanoscale triboelectric-effect-enabled energy conversion for sustainably powering portable electronics. Nano Lett. 2012, 12, 6339–6346. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Zhang, H.; Yu, R.; Dong, L.; Peng, D.; Zhang, A.; Zhang, Y.; Liu, H.; Pan, C.; Wang, Z.L. Dynamic pressure mapping of personalized handwriting by a flexible sensor matrix based on the mechanoluminescence process. Adv. Mater. 2015, 27, 2324–2331. [Google Scholar] [CrossRef]

- Ubaidullah, M.; Al-Enizi, A.M.; Shaikh, S.; Ghanem, M.A.; Mane, R.S. Waste PET plastic derived ZnO@NMC nanocomposite via MOF-5 construction for hydrogen and oxygen evolution reactions. J. King Saud Univ. Sci. 2020, 32, 2397–2405. [Google Scholar] [CrossRef]

- Ubaidullah, M.; Al-Enizi, A.M.; Ahamad, T.; Shaikh, S.F.; Al-Abdrabalnabi, M.A.; Samdani, M.S.; Kumar, D.; Alam, M.A.; Khan, M. Fabrication of highly porous N-doped mesoporous carbon using waste polyethylene terephthalate bottle-based MOF-5 for high performance supercapacitor. J. Energy Storage 2021, 33, 102125. [Google Scholar] [CrossRef]

- Kuji, T.; Masaki, T.; Goteti, K.; Li, L.; Zhuplatov, S.; Terry, C.M.; Zhu, W.; Leypoldt, J.K.; Rathi, R.; Blumenthal, D.K.; et al. Efficacy of local dipyridamole therapy in a porcine model of arteriovenous graft stenosis. Kidney Int. 2006, 69, 2179–2185. [Google Scholar] [CrossRef] [Green Version]

- Manabe, K.; Nara, H. Construction of stable biological albumin/heparin multilayers for elastic coatings on hydrophobic antithrombogenic artificial blood vessels. Tribol. Int. 2021, 156, 106843. [Google Scholar] [CrossRef]

- Meinhart, J.G.; Deutsch, M.; Fischlein, T.; Howanietz, N.; Fröschl, A.; Zilla, P. Clinical autologous in vitro endothelialization of 153 infrainguinal ePTFE grafts. Ann. Thorac. Surg. 2001, 71, S327–S331. [Google Scholar] [CrossRef]

- Ramachandran, B.; Chakraborty, S.; Kannan, R.; Dixit, M.; Muthuvijayan, V. Immobilization of hyaluronic acid from Lactococcus lactis on polyethylene terephthalate for improved biocompatibility and drug release. Carbohydr. Polym. 2019, 206, 132–140. [Google Scholar] [CrossRef]

- Çaykara, T.; Sande, M.G.; Azoia, N.; Rodrigues, L.R.; Silva, C.J. Exploring the potential of polyethylene terephthalate in the design of antibacterial surfaces. Med. Microbiol. Immunol. 2020, 209, 363–372. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, J.; Zhu, G.; Yang, W.; Jing, Q.; Bai, P.; Yang, Y.; Hou, T.C.; Wang, Z.L. Harmonic-resonator-based triboelectric nanogenerator as a sustainable power source and a self-powered active vibration sensor. Adv. Mater. 2013, 25, 6094–6099. [Google Scholar] [CrossRef]

- Qin, H.; Cheng, G.; Zi, Y.; Gu, G.; Zhang, B.; Shang, W.; Yang, F.; Yang, J.; Du, Z.; Wang, Z.L. High Energy Storage Efficiency Triboelectric Nanogenerators with Unidirectional Switches and Passive Power Management Circuits. Adv. Funct. Mater. 2018, 28, 1805216. [Google Scholar] [CrossRef]

- Yang, J.; Yang, F.; Zhao, L.; Shang, W.; Qin, H.; Wang, S.; Jiang, X.; Cheng, G.; Du, Z. Managing and optimizing the output performances of a triboelectric nanogenerator by a self-powered electrostatic vibrator switch. Nano Energy 2018, 46, 220–228. [Google Scholar] [CrossRef]

- Zhao, K.; Gu, G.; Zhang, Y.; Zhang, B.; Yang, F.; Zhao, L.; Zheng, M.; Cheng, G.; Du, Z. The self-powered CO2 gas sensor based on gas discharge induced by triboelectric nanogenerator. Nano Energy 2018, 53, 898–905. [Google Scholar] [CrossRef]

- Ouyang, H.; Tian, J.; Sun, G.; Zou, Y.; Liu, Z.; Li, H.; Zhao, L.; Shi, B.; Fan, Y.; Fan, Y.; et al. Self-Powered Pulse Sensor for Antidiastole of Cardiovascular Disease. Adv. Mater. 2017, 29, 1703456. [Google Scholar] [CrossRef] [PubMed]

- Jeon, S.B.; Kim, W.G.; Park, S.J.; Tcho, I.W.; Jin, I.K.; Han, J.K.; Kim, D.; Choi, Y.K. Self-powered wearable touchpad composed of all commercial fabrics utilizing a crossline array of triboelectric generators. Nano Energy 2019, 65, 103994. [Google Scholar] [CrossRef]

- Yun, J.; Jayababu, N.; Kim, D. Self-powered transparent and flexible touchpad based on triboelectricity towards artificial intelligence. Nano Energy 2020, 78, 105325. [Google Scholar] [CrossRef]

| Nomenclature | |||

|---|---|---|---|

| Abbreviations | Abbreviations | ||

| VOC | Open-circuit voltage | TSR | TENG for the swallowing rehabilitation |

| ISC | Short-circuit current | TSR-B | TSR with bare PTFE film |

| TENG | Triboelectric nanogenerator | TSR-T60 | TSR with PTFE film conducting the tilted RIE for 60° |

| PTFE | Polytetrafluoroethylene | SSRMS | Smart swallowing rehabilitation monitoring system |

| PET | Polyethylene terephthalate | SEM | Scanning electron microscopy |

| Tilted Angle | Bare | 0° | 15° | 30° | 45° | 60° | 75° |

|---|---|---|---|---|---|---|---|

| Mean value of VOC (V) | 13.10 | 14.64 | 16.08 | 19.21 | 20.10 | 24.12 | 20.22 |

| Standard deviation | 1.1 | 1.54 | 16.8 | 1.82 | 1.75 | 2.1 | 1.89 |

| Mean value of ISC (nA) | 512 | 558 | 612 | 805 | 856 | 1056 | 912 |

| Standard deviation | 41 | 64 | 71 | 75 | 73 | 88 | 81 |

| Pressure (kPa) | 20 | 50 | 180 | 300 | 800 | 1900 | 3400 | |

|---|---|---|---|---|---|---|---|---|

| Without tilted RIE process | VOC (V) | 6.21 | 8.14 | 11.77 | 12.22 | 13.13 | 14.94 | 15.64 |

| With tilted RIE process for 60° | VOC (V) | 9.11 | 11.25 | 14.72 | 17.79 | 20.56 | 22.09 | 24.49 |

| Without tilted RIE process | ISC (nA) | 112 | 131 | 202 | 276 | 332 | 529 | 676 |

| With tilted RIE process for 60° | ISC (nA) | 152 | 205 | 407 | 503 | 749 | 866 | 1011 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yun, J.; Cho, H.; Park, J.; Kim, D. Self-Powered and Flexible Triboelectric Sensors with Oblique Morphology towards Smart Swallowing Rehabilitation Monitoring System. Materials 2022, 15, 2240. https://doi.org/10.3390/ma15062240

Yun J, Cho H, Park J, Kim D. Self-Powered and Flexible Triboelectric Sensors with Oblique Morphology towards Smart Swallowing Rehabilitation Monitoring System. Materials. 2022; 15(6):2240. https://doi.org/10.3390/ma15062240

Chicago/Turabian StyleYun, Jonghyeon, Hyunwoo Cho, Jihyeon Park, and Daewon Kim. 2022. "Self-Powered and Flexible Triboelectric Sensors with Oblique Morphology towards Smart Swallowing Rehabilitation Monitoring System" Materials 15, no. 6: 2240. https://doi.org/10.3390/ma15062240

APA StyleYun, J., Cho, H., Park, J., & Kim, D. (2022). Self-Powered and Flexible Triboelectric Sensors with Oblique Morphology towards Smart Swallowing Rehabilitation Monitoring System. Materials, 15(6), 2240. https://doi.org/10.3390/ma15062240