Anaerobic Reactor Filling for Phosphorus Removal by Metal Dissolution Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Scope of Research

- − temperature distribution along the extrusion head, °C;

- − rotational speed of the screw, υ·s−1;

- − type of the cooling medium;

- − temperature (t) of the cooling medium, °C;

- − sample diameter (Dw), mm;

- − extrusion head nozzle diameter (Dd), mm;

- − sample length (L), mm.

- − normal density (ρn) of the sample, kg/m3;

- − porosity (SP) of the sample, %;

- − tensile strength (σr) of the sample, MPa;

- − relative elongation (εr) at break of the sample, %;

- − the Barus β effect, %.

2.2. Materials

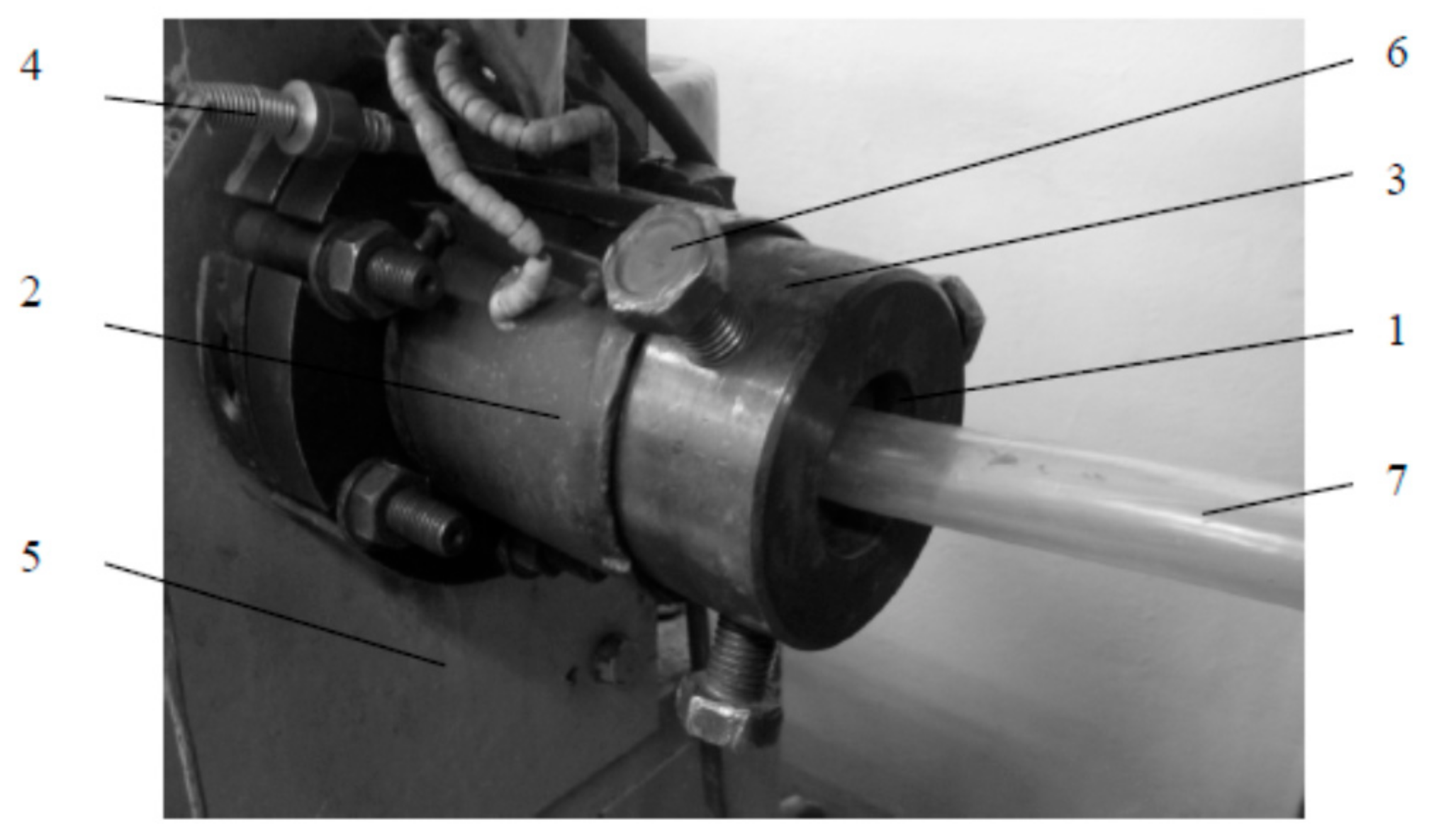

2.3. Experimental Station

2.4. Analysis of Mechanical Properties

2.5. Technological Effectivity of Active Filling

2.6. Statistical Analysis

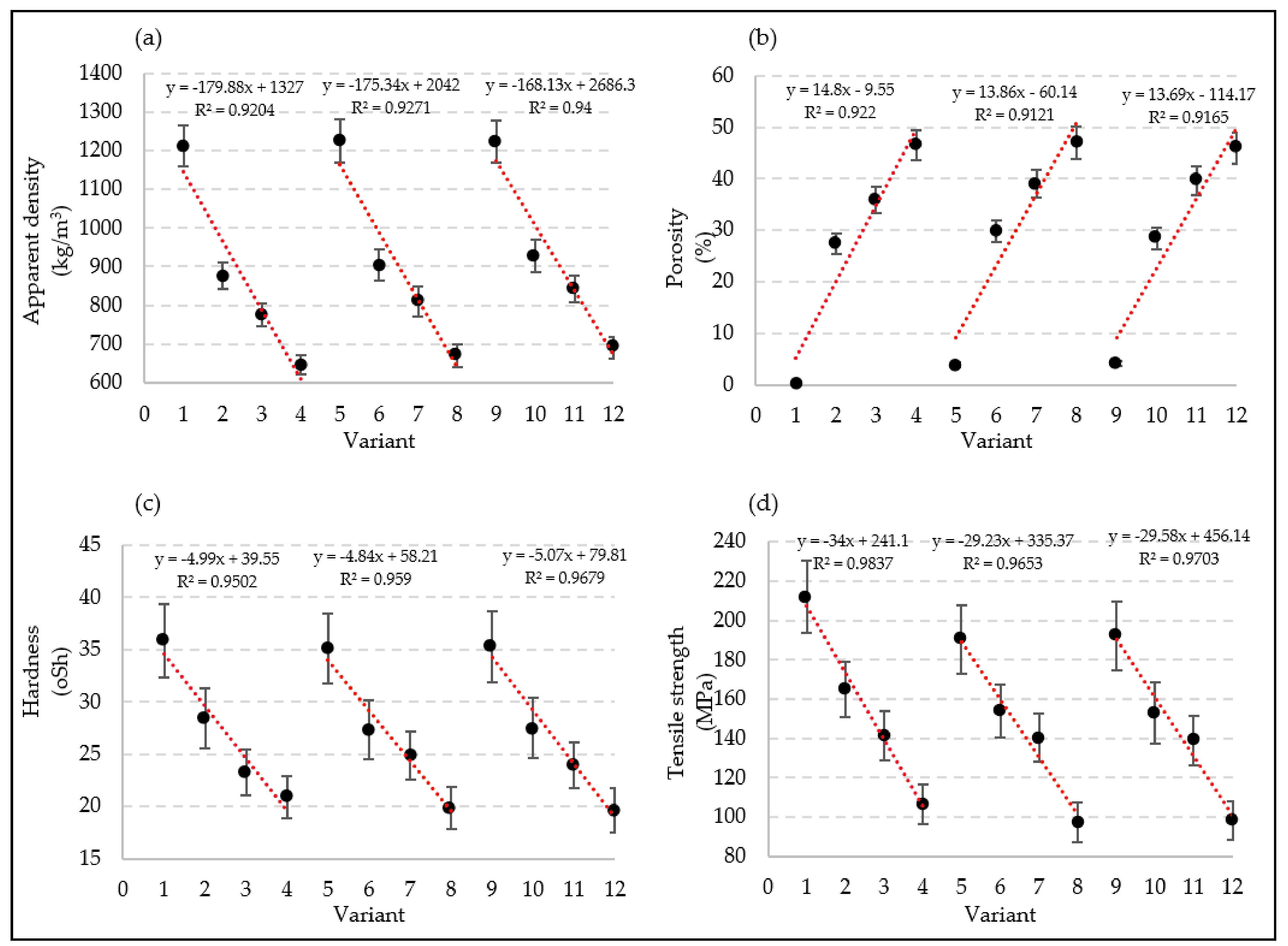

3. Results and Discussion

3.1. Filling Characteristics

3.2. Technological Effectivity of Active Filling

3.3. Technological Effectivity of Other Used Fillings

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, J.; Pemberton, B.; Lewis, J.; Scales, P.J.; Martin, G.J. Wastewater treatment using filamentous algae—A review. Bioresour. Technol. 2019, 298, 122556. [Google Scholar] [CrossRef]

- Preisner, M.; Neverova-Dziopak, E.; Kowalewski, Z. An analytical review of different approaches to wastewater discharge standards with particular emphasis on nutrients. Environ. Manag. 2020, 66, 694–708. [Google Scholar] [CrossRef]

- Żyłka, R.; Karolinczak, B.; Dąbrowski, W. Structure and indicators of electric energy consumption in dairy wastewater treatment plant. Sci. Total Environ. 2021, 782, 146599. [Google Scholar] [CrossRef]

- Sakson, G.; Brzezińska, A.; Kowalski, K. Threats to wastewater treatment plant in combined sewer system—Analysis of problems and possible solutions on the example of Lodz. Annu. Set Environ. Prot. 2020, 22, 1132–1144. [Google Scholar]

- Drewnowski, J.; Remiszewska-Skwarek, A.; Duda, S.; Łagód, G. Aeration Process in Bioreactors as the Main Energy Consumer in a Wastewater Treatment Plant. Review of Solutions and Methods of Process Optimization. Processes 2019, 7, 311. [Google Scholar] [CrossRef] [Green Version]

- Cepan, C.; Segneanu, A.-E.; Grad, O.; Mihailescu, M.; Cepan, M.; Grozescu, I. Assessment of the Different Type of Materials Used for Removing Phosphorus from Wastewater. Materials 2021, 14, 4371. [Google Scholar] [CrossRef]

- Villarín, M.C.; Merel, S. Paradigm shifts and current challenges in wastewater management. J. Hazard. Mater. 2020, 390, 122139. [Google Scholar] [CrossRef]

- Chen, H.; Zeng, L.; Wang, D.; Zhou, Y.; Yang, X. Recent advances in nitrous oxide production and mitigation in wastewater treatment. Water Res. 2020, 184, 116168. [Google Scholar] [CrossRef]

- Karolinczak, B.; Miłaszewski, R.; Dąbrowski, W. Cost Optimization of Wastewater and Septage Treatment Process. Energies 2020, 13, 6406. [Google Scholar] [CrossRef]

- Limousy, L.; Thiebault, T.; Brendle, J. New Materials and Technologies for Wastewater Treatment. Materials 2022, 15, 1927. [Google Scholar] [CrossRef]

- Calise, F.; Cappiello, F.L.; Cimmino, L.; d’Accadia, M.D.; Vicidomini, M. A Review of the State of the Art of Biomethane Production: Recent Advancements and Integration of Renewable Energies. Energies 2021, 14, 4895. [Google Scholar] [CrossRef]

- Kehrein, P.; van Loosdrecht, M.; Osseweijer, P.; Garfí, M.; Dewulf, J.; Posada, J. A critical review of resource recovery from municipal wastewater treatment plants–market supply potentials, technologies and bottlenecks. Environ. Sci. Water Res. Technol. 2020, 6, 877–910. [Google Scholar] [CrossRef] [Green Version]

- Kong, Z.; Li, L.; Wu, J.; Wang, T.; Rong, C.; Luo, Z.; Pan, Y.; Li, D.; Li, Y.; Huang, Y.; et al. Evaluation of bio-energy recovery from the anaerobic treatment of municipal wastewater by a pilot-scale submerged anaerobic membrane bioreactor (AnMBR) at ambient temperature. Bioresour. Technol. 2021, 339, 125551. [Google Scholar] [CrossRef]

- Stazi, V.; Tomei, M.C. Enhancing anaerobic treatment of domestic wastewater: State of the art, innovative technologies and future perspectives. Sci. Total Environ. 2018, 635, 78–91. [Google Scholar] [CrossRef]

- Ashraf, A.; Ramamurthy, R.; Rene, E.R. Wastewater treatment and resource recovery technologies in the brewery industry: Current trends and emerging practices. Sustain. Energy Technol. Assess. 2021, 47, 101432. [Google Scholar] [CrossRef]

- Dębowski, M.; Zieliński, M.; Kisielewska, M.; Kazimierowicz, J. Evaluation of Anaerobic Digestion of Dairy Wastewater in an Innovative Multi-Section Horizontal Flow Reactor. Energies 2020, 13, 2392. [Google Scholar] [CrossRef]

- Zieliński, M.; Dębowski, M.; Kazimierowicz, J. Microwave Radiation Influence on Dairy Waste Anaerobic Digestion in a Multi-Section Hybrid Anaerobic Reactor (M-SHAR). Processes 2021, 9, 1772. [Google Scholar] [CrossRef]

- Kazimierowicz, J.; Zieliński, M.; Dębowski, M. Influence of the Heating Method on the Efficiency of Biomethane Production from Expired Food Products. Fermentation 2021, 7, 12. [Google Scholar] [CrossRef]

- Zieliński, M.; Dębowski, M.; Kazimierowicz, J. The Effect of Static Magnetic Field on Methanogenesis in the Anaerobic Digestion of Municipal Sewage Sludge. Energies 2021, 14, 590. [Google Scholar] [CrossRef]

- Kazimierowicz, J.; Bartkowska, I.; Walery, M. Effect of Low-Temperature Conditioning of Excess Dairy Sewage Sludge with the Use of Solidified Carbon Dioxide on the Efficiency of Methane Fermentation. Energies 2021, 14, 150. [Google Scholar] [CrossRef]

- Dębowski, M.; Zieliński, M.; Kisielewska, M.; Kazimierowicz, J.; Dudek, M.; Świca, I.; Rudnicka, A. The Cultivation of Lipid-Rich Microalgae Biomass as Anaerobic Digestate Valorization Technology—A Pilot-Scale Study. Processes 2020, 8, 517. [Google Scholar] [CrossRef]

- Kisielewska, M.; Zieliński, M.; Dębowski, M.; Kazimierowicz, J.; Romanowska-Duda, Z.; Dudek, M. Effectiveness of Scenedesmus sp. Biomass Grow and Nutrients Removal from Liquid Phase of Digestates. Energies 2020, 13, 1432. [Google Scholar] [CrossRef] [Green Version]

- Capodaglio, A.G.; Olsson, G. Energy Issues in Sustainable Urban Wastewater Management: Use, Demand Reduction and Recovery in the Urban Water Cycle. Sustainability 2020, 12, 266. [Google Scholar] [CrossRef] [Green Version]

- Aziz, A.; Basheer, F.; Sengar, A.; Irfanullah; Khan, S.U.; Farooqi, I.H. Biological wastewater treatment (anaerobic-aerobic) technologies for safe discharge of treated slaughterhouse and meat processing wastewater. Sci. Total Environ. 2019, 686, 681–708. [Google Scholar] [CrossRef]

- Von Sperling, M.; Almeida, P.G.S.; Bressani-Ribeiro, T.; Chernicharo, C.A.L. Post-treatment of anaerobic effluents. In Anaerobic Reactors for Sewage Treatment: Design, Construction and Operation; Chernicharo, C.A.L., Bressani-Ribeiro, T., Eds.; IWA Publishing: London, UK, 2019; pp. 285–348. [Google Scholar] [CrossRef]

- Dębowski, M.; Zieliński, M. Technological Effectiveness of Sugar-Industry Effluent Methane Fermentation in a Fluidized Active Filling Reactor (FAF-R). Energies 2020, 13, 6626. [Google Scholar] [CrossRef]

- Liu, X.; Yang, H.; Fang, X.; Wang, X.; Su, Y. Performance study and population structure analysis of hydrolytic acidification immobilized fillers using municipal wastewater. Process Saf. Environ. Prot. 2021, 146, 126–135. [Google Scholar] [CrossRef]

- Kong, Q.; Guo, W.; Sun, R.; Qin, M.; Zhao, Z.; Du, Y.; Zhang, H.; Zhao, C.; Wang, X.; Zhang, R.; et al. Enhancement of chromium removal and energy production simultaneously using iron scrap as anodic filling material with pyrite-based constructed wetland-microbial fuel cell. J. Environ. Chem. Eng. 2021, 9, 106630. [Google Scholar] [CrossRef]

- Tetteh, E.K.; Rathilal, S. Kinetics and Nanoparticle Catalytic Enhancement of Biogas Production from Wastewater Using a Magnetized Biochemical Methane Potential (MBMP) System. Catalysts 2020, 10, 1200. [Google Scholar] [CrossRef]

- Bering, S.; Mazur, J.; Tarnowski, K.; Janus, M.; Mozia, S.; Morawski, A.W. The use of moving bed bio-reactor to laundry wastewater treatment. In E3S Web of Conferences; EDP Sciences: Ulis, France, 2017; Volume 22, p. 00015. [Google Scholar] [CrossRef] [Green Version]

- Leyva-Díaz, J.C.; Monteoliva-García, A.; Martín-Pascual, J.; Munio, M.M.; García-Mesa, J.J.; Poyatos, J.M. Moving bed biofilm reactor as an alternative wastewater treatment process for nutrient removal and recovery in the circular economy model. Bioresour. Technol. 2020, 299, 122631. [Google Scholar] [CrossRef]

- Feng, Q.; Guo, W.; Wang, T.; Alvarez, C.M.L.; Luo, M.; Ge, R.; Zhou, C.; Zhang, Q.; Luo, J. Iron coupling with carbon fiber to stimulate biofilms formation in aerobic biological film systems for improved decentralized wastewater treatment: Performance, mechanisms and implications. Bioresour. Technol. 2021, 319, 124151. [Google Scholar] [CrossRef]

- Duarte, N.C.; Barbosa, A.C.; Magalhães, T.M.; Montagner, C.C.; de Oliveira Cruz, L.M.; Tonetti, A.L. Conventional Anaerobic Reactors Applied to Denitrification: A Comparison between Packed Bed and UASB Reactors under Low COD Conditions. Water Air Soil Pollut. 2021, 232, 54. [Google Scholar] [CrossRef]

- Zieliński, M.; Dębowski, M.; Krzemieniewski, M.; Brudniak, A.; Kisielewska, M. Possibility of improving technological effectiveness of dairy wastewater treatment through application of active fillings and microwave radiation. J. Water Chem. Technol. 2016, 38, 342–348. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, D.; Huang, W.; Yang, Y.; Ji, M.; Nghiem, L.; Trinh, Q.; Tran, N. Insights into biofilm carriers for biological wastewater treatment processes: Current state-of-the-art, challenges, and opportunities. Bioresour. Technol. 2019, 288, 121619. [Google Scholar] [CrossRef] [PubMed]

- Cai, H.; Wang, Y.; Wu, K.; Guo, W. Enhanced Hydrophilic and Electrophilic Properties of Polyvinyl Chloride (PVC) Biofilm Carrier. Polymers 2020, 12, 1240. [Google Scholar] [CrossRef] [PubMed]

- Ginter-Kramarczyk, D.; Kruszelnicka, I.; Michałkiewicz, M.; Muszyński, M.; Zajchowski, P.; Tomaszewska, J. Biofilm on the polymer composites—Qualitative and quantitative microbiological analysis. J. Environ. Health Sci. Eng. 2021, 19, 641–649. [Google Scholar] [CrossRef] [PubMed]

- Ishak, S.A.; Murshed, M.F.; Akil, H.; Ismail, N.; Rasib, S.Z.; Al-Gheethi, A.A.S. The Application of Modified Natural Polymers in Toxicant Dye Compounds Wastewater: A Review. Water 2020, 12, 2032. [Google Scholar] [CrossRef]

- Kotowska, U.; Wawrzkiewicz, M.; Polska-Adach, E. Mechanism of interactions in C.I. Acid Red 18–Floating plants and polymeric resins systems: Kinetic, equilibrium, auxiliaries impact and column studies. J. Mol. Liq. 2021, 333, 115903. [Google Scholar] [CrossRef]

- Jin, F.-L.; Zhao, M.; Park, M.; Park, S.-J. Recent Trends of Foaming in Polymer Processing: A Review. Polymers 2019, 11, 953. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.-C.; Yu, C.-N.; Liang, Y.; Lin, G.-X.; Meng, C. Foaming Behavior and Microcellular Morphologies of Incompatible SAN/CPE Blends with Supercritical Carbon Dioxide as a Physical Blowing Agent. Polymers 2019, 11, 89. [Google Scholar] [CrossRef] [Green Version]

- Jahan, E. Development of Multifunctional Nanofibrous Membrane Material for Biological Wastewater Treatment. Master’s Thesis, York University, Toronto, ON, Canada, 2021. [Google Scholar]

- Zhu, X.; Blanco, E.; Bhatti, M.; Borrion, A. Impact of metallic nanoparticles on anaerobic digestion: A systematic review. Sci. Total Environ. 2021, 757, 143747. [Google Scholar] [CrossRef]

- Kokilaramani, S.; Al-Ansari, M.M.; Rajasekar, A.; Al-Khattaf, F.S.; Hussain, A.; Govarthanan, M. Microbial influenced corrosion of processing industry by re-circulating waste water and its control measures-A review. Chemosphere 2020, 265, 129075. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Li, B.; Liu, J.; Luan, M.; Yue, L.; Jiang, X.-T.; Yu, K.; Guan, Y. The bacterial community significantly promotes cast iron corrosion in reclaimed wastewater distribution systems. Microbiome 2018, 6, 222. [Google Scholar] [CrossRef] [PubMed]

- Dębowski, M.; Zieliński, M.; Kisielewska, M.; Krzemieniewski, M.; Makowska, M.; Grądkowski, M.; Tor-Świątek, A. Simulated dairy wastewater treatment in a pilot plant scale magneto-active hybrid anaerobic biofilm reactor (MA-HABR). Braz. J. Chem. Eng. 2018, 35, 553–562. [Google Scholar] [CrossRef] [Green Version]

- Kisielewska, M.; Dębowski, M.; Zieliński, M.; Krzemieniewski, M. Enhancement of Dairy Wastewater Treatment in a Combined Anaerobic Baffled and Biofilm Reactor with Magneto-Active Packing Media. J. Ecol. Eng. 2018, 19, 165–171. [Google Scholar] [CrossRef]

- Zieliński, M.; Dębowski, M.; Krzemieniewski, M.; Brudniak, A. Effectiveness of dairy wastewater treatment in anaerobic reactors with magnetoactive filling. Environ. Prog. Sustain. Energy 2014, 34, 427–431. [Google Scholar] [CrossRef]

- Zielińska, M.; Zieliński, M.; Dębowski, M. Organic compounds and phosphorus removal from dairy wastewater by biofilm on iron-containing supports. J. Environ. Eng. 2018, 144, 04017087. [Google Scholar] [CrossRef]

- Huang, J.; Zhou, Z.; Zheng, Y.; Sun, X.; Yu, S.; Zhao, X.; Yang, A.; Wu, C.; Wang, Z. Biological nutrient removal in the anaerobic side-stream reactor coupled membrane bioreactors for sludge reduction. Bioresour. Technol. 2020, 295, 122241. [Google Scholar] [CrossRef] [PubMed]

- Gannoun, H.; Khelifi, E.; Bouallagui, H.; Touhami, Y.; Hamdi, M. Ecological clarification of cheese whey prior to anaerobic digestion in upflow anaerobic filter. Bioresour. Technol. 2008, 99, 6105–6111. [Google Scholar] [CrossRef]

- Ratusznei, S.M.; Rodrigues, J.A.D.; Zaiat, M. Operating feasibility of anaerobic whey treatment in a stirred sequencing batch reactor containing immobilized biomass. Water Sci. Technol. 2003, 48, 179–186. [Google Scholar] [CrossRef]

- Puñal, A.; Méndez-Pampín, R.J.; Lema, J.M. Characterization and comparison of biomasses from single- and multi-fed upflow anaerobic filters. Bioresour. Technol. 1999, 68, 293–300. [Google Scholar] [CrossRef]

- Patel, P.; Desai, M.; Madamwar, D. Biomethanation of cheese whey using anaerobic upflow fixed film reactor. J. Ferment. Bioeng. 1995, 79, 398–399. [Google Scholar] [CrossRef]

| Variant (V) | Blowing Agent Content, wt.% | Iron Content, wt.% | Copper Content, wt.% |

|---|---|---|---|

| 1 | 0 | 0 | 0 |

| 2 | 0.5 | 0 | 0 |

| 3 | 0.8 | 0 | 0 |

| 4 | 1.0 | 0 | 0 |

| 5 | 0 | 4.5 | 0.5 |

| 6 | 0.5 | 4.5 | 0.5 |

| 7 | 0.8 | 4.5 | 0.5 |

| 8 | 1.0 | 4.5 | 0.5 |

| 9 | 0 | 4.0 | 1.0 |

| 10 | 0.5 | 4.0 | 1.0 |

| 11 | 0.8 | 4.0 | 1.0 |

| 12 | 1.0 | 4.0 | 1.0 |

| Variant | Barus Effect β % | Apparent Density ρc, kg/m3 | Porosity p, % | Hardness, °Sh | Tensile Strength σr, MPa | Elongation at Break εr, % |

|---|---|---|---|---|---|---|

| 1 | 110 ± 12 | 1211.6 ± 52.6 | 0.0 ± 0.0 | 35.8 ± 3.5 | 211.8 ± 18.3 | 160 ± 15 |

| 2 | 120 ± 11 | 876.9 ± 35.5 | 27.4 ± 2.0 | 28.4 ± 2.9 | 164.9 ± 14.2 | 140 ± 14 |

| 3 | 129 ± 10 | 774.3 ± 29.4 | 35.9 ± 2.6 | 23.2 ± 2.2 | 141.4 ± 12.5 | 120 ± 12 |

| 4 | 111 ± 12 | 646.2 ± 25.1 | 46.5 ± 2.9 | 20.9 ± 2.0 | 106.3 ± 10.1 | 110 ± 10 |

| 5 | 123 ± 13 | 1224.6 ± 55.8 | 3.9 ± 0.4 | 35.1 ± 3.3 | 190.1 ± 17.4 | 140 ± 15 |

| 6 | 131 ± 14 | 903.2 ± 40.5 | 29.8 ± 2.1 | 27.3 ± 2.8 | 153.8 ± 13.5 | 120 ± 13 |

| 7 | 130 ± 14 | 810.0 ± 38.6 | 39.1 ± 2.7 | 24.8 ± 2.3 | 140.5 ± 12.2 | 110 ± 12 |

| 8 | 110 ± 11 | 671.2 ± 29.5 | 47.0 ± 3.2 | 19.8 ± 2.0 | 97.1 ± 10.0 | 110 ± 11 |

| 9 | 121 ± 12 | 1223.0 ± 54.2 | 4.1 ± 0.5 | 35.3 ± 3.4 | 192.1 ± 17.5 | 150 ± 16 |

| 10 | 130 ± 14 | 927.4 ± 42.2 | 28.5 ± 2.1 | 27.5 ± 2.9 | 153.0 ± 15.5 | 120 ± 12 |

| 11 | 131 ± 13 | 842.7 ± 33.5 | 39.7 ± 2.8 | 23.9 ± 2.2 | 138.9 ± 12.8 | 120 ± 13 |

| 12 | 134 ± 14 | 690.8 ± 27.6 | 46.0 ± 3.0 | 19.6 ± 2.1 | 98.2 ± 10.0 | 110 ± 10 |

| Reactor Type | Wastewater Type | COD Removal Effectiveness, % | Phosphorus Removal Effectiveness, % | Biogas Yield, dm3/kg CODrem. | Content of Methane in Biogas, % | Ref. |

|---|---|---|---|---|---|---|

| Fluidized active filling reactor (FAF-R) | Sugar-industry effluent | >74 | 64.4 ± 2.4–81.2 ± 8.2 | 356 ± 25–427 ± 14 | 70 | [26] |

| Anaerobic reactor with active filling (AF), heated with microwave (EMR) | Dairy wastewater | 88 | >90 | 380 ± 17 | 64 | [34] |

| Magneto-active hybrid anaerobic biofilm reactor (MA-HABR) | Dairy wastewater | 80 | 82.9–90.7 | 256.7–310.9 | 61–68 | [46] |

| Vertical reactor with labyrinth flow | Dairy wastewater | 86 | 85–87 | 415 | 66–67 | [47] |

| Vertical reactor with labyrinth flow | Dairy wastewater | 72–76 | 84–88 | - | - | [48] |

| Anaerobic moving biofilm reactors (AMBRs) | Dairy wastewater | 86.6 ± 7.8 | 72.1 ± 8.4 | 130.0 ± 56.1 | 25.8–83.8 | [49] |

| Reactor Type | Wastewater Type | COD Removal Effectiveness, % | Phosphorus Removal Effectiveness, % | Biogas Yield | Content of Methane in Biogas | Ref. | |

|---|---|---|---|---|---|---|---|

| Anaerobic side-stream reactor (ASSR) filled with polyethylene carriers coupled with membrane bioreactor (MBR) filling fraction of 15% | Wastewater from the grit chamber | 95.4 | 40.2 | - | - | [50] | |

| Upflow anaerobic filter (UAF) reactor filled with Flocor (φ3L3, porosity 95%, active surface 230 m2·m−3) | Cheese whey wastewater | 72 ± 5–90.2 ± 0.5 | - | 0.47 ± 0.05–1.15 ± 0.28 dm3·day | 89 ± 0.3–89 ± 0.3 dm3CH4/kg COD removed | [51] | |

| Anaerobic batch reactor filled with polyurethane foam cubes with 0.5 cm sides and an apparent density of 23 kg/m3 | Dairy whey wastewater | 96 | - | - | - | [52] | |

| UAF reactors filled withraschig rings of corrugated polyvinyl chloride (PVC) | Multi-fed anaerobic filter (MFR) | Wastewaters from a tuna-processing factory | 87 | - | - | - | [53] |

| Single-fed reactor (SFR) | 65 | ||||||

| Anaerobic upflow fixed film reactors filled with: | Charcoal | Cheese whey wastewater | 76.6 | - | 6.0 ± 0.011 dm3/day/dm3 digester | 70% ± 0.66% | [54] |

| Brick pieces | 71.9 | 5.1 ± 0.020 dm3/day/dm3 digester | 68% ± 0.83% | ||||

| Gravel | 73.7 | 5.4 ± 0.008 dm3/day/dm3 digester | 68% ± 1.33% | ||||

| PVC pieces | 69.7 | 4.3 ± 0.013 dm3/day/dm3 digester | 67% ± 0.16% | ||||

| Pumice stone | 67.5 | 3.8 ± 0.013 dm3/day/dm3 digester | 64% ± 0.83% | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dębowski, M.; Zieliński, M.; Kazimierowicz, J. Anaerobic Reactor Filling for Phosphorus Removal by Metal Dissolution Method. Materials 2022, 15, 2263. https://doi.org/10.3390/ma15062263

Dębowski M, Zieliński M, Kazimierowicz J. Anaerobic Reactor Filling for Phosphorus Removal by Metal Dissolution Method. Materials. 2022; 15(6):2263. https://doi.org/10.3390/ma15062263

Chicago/Turabian StyleDębowski, Marcin, Marcin Zieliński, and Joanna Kazimierowicz. 2022. "Anaerobic Reactor Filling for Phosphorus Removal by Metal Dissolution Method" Materials 15, no. 6: 2263. https://doi.org/10.3390/ma15062263

APA StyleDębowski, M., Zieliński, M., & Kazimierowicz, J. (2022). Anaerobic Reactor Filling for Phosphorus Removal by Metal Dissolution Method. Materials, 15(6), 2263. https://doi.org/10.3390/ma15062263