Machinability Investigation of Nitronic 60 Steel Turning Using SiAlON Ceramic Tools under Different Cooling/Lubrication Conditions

Abstract

:1. Introduction

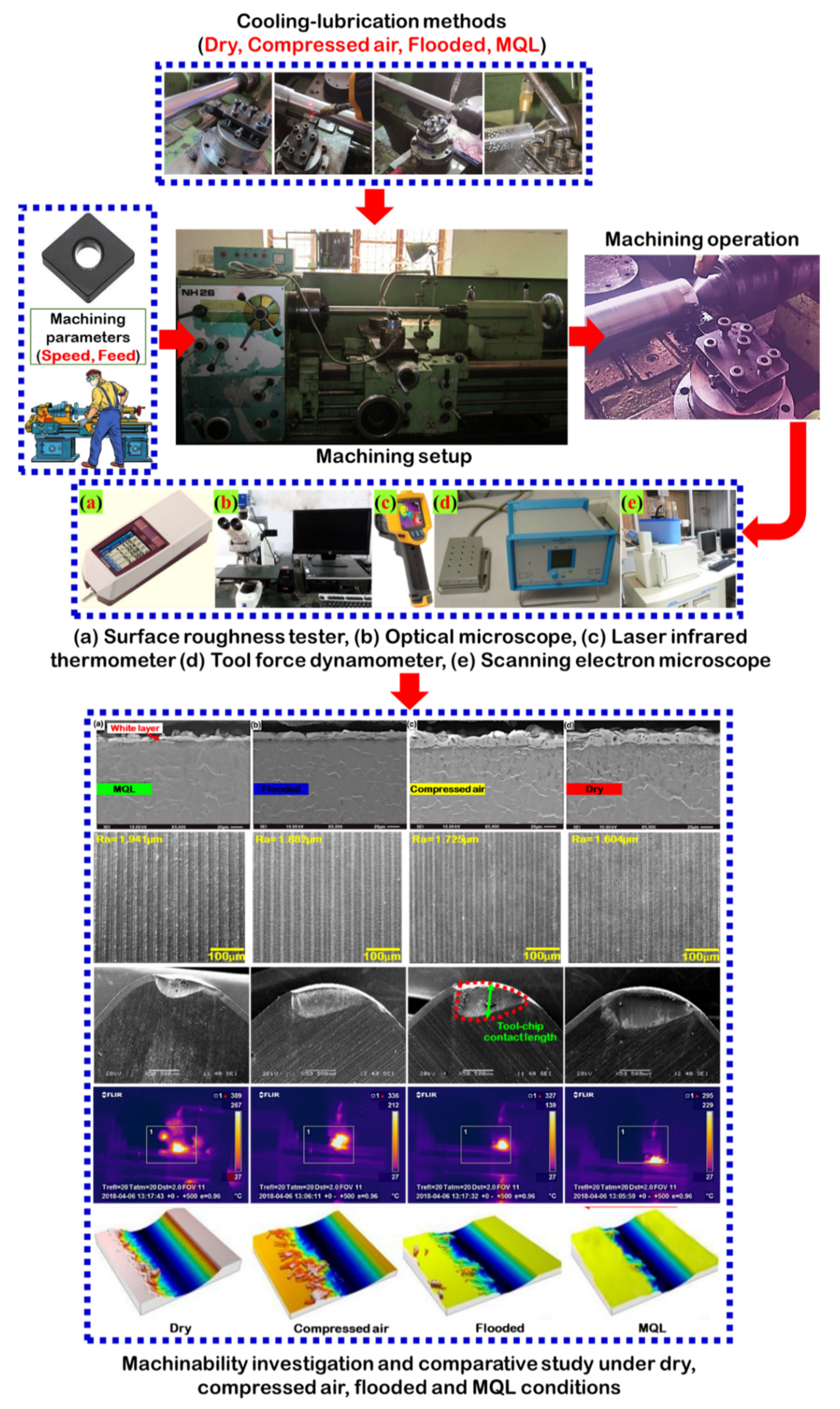

2. Experimental Setup and Procedure

3. Results and Discussion

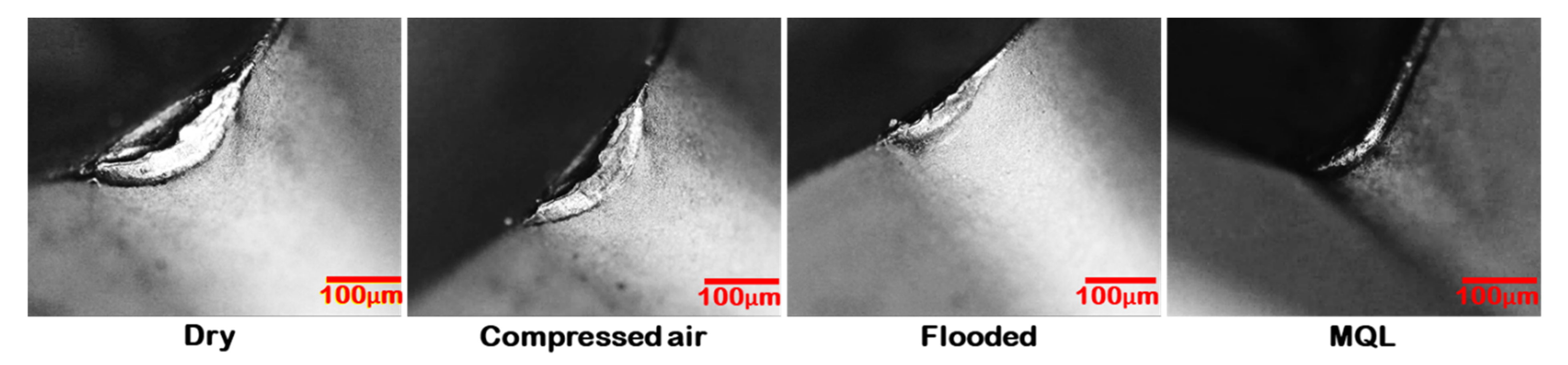

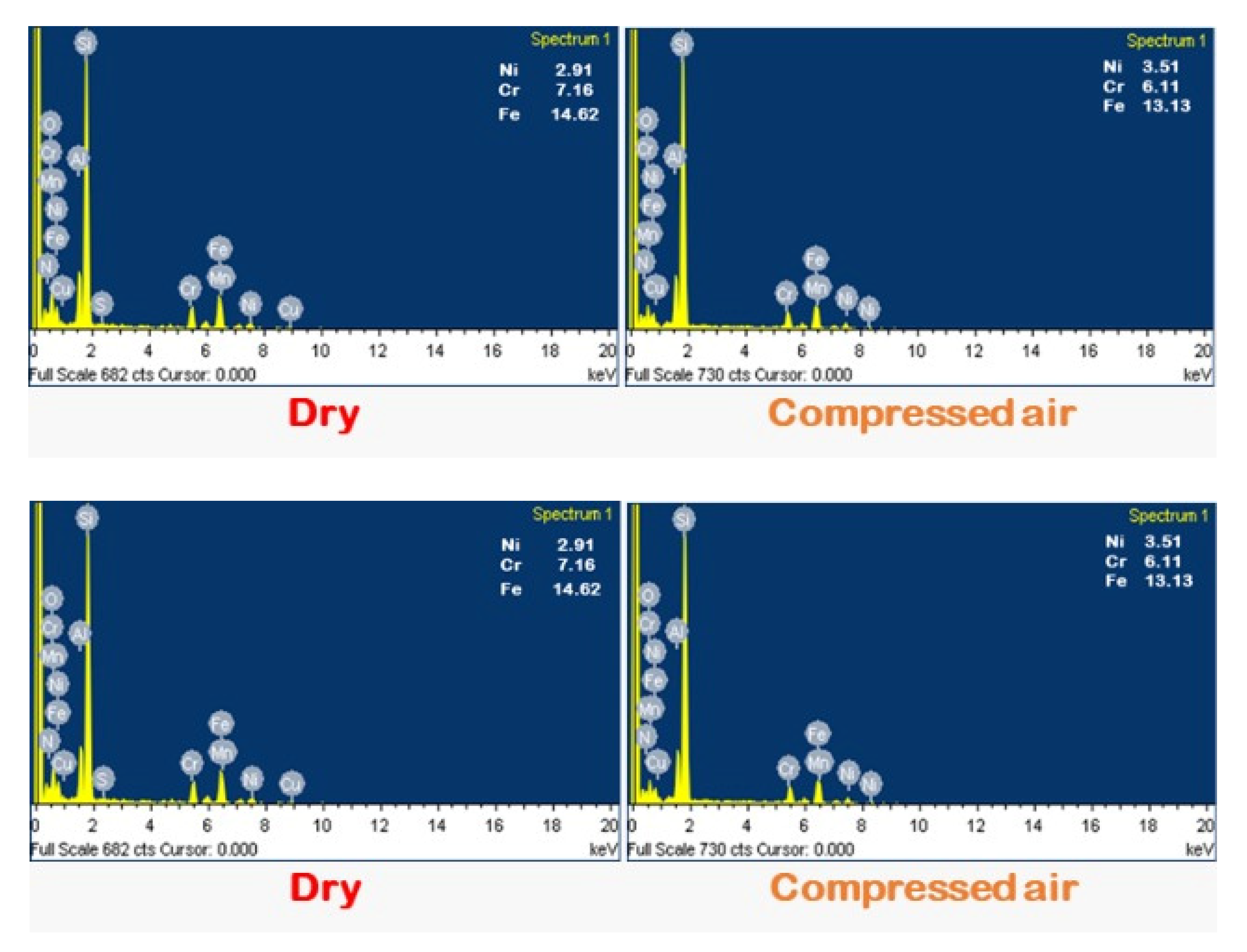

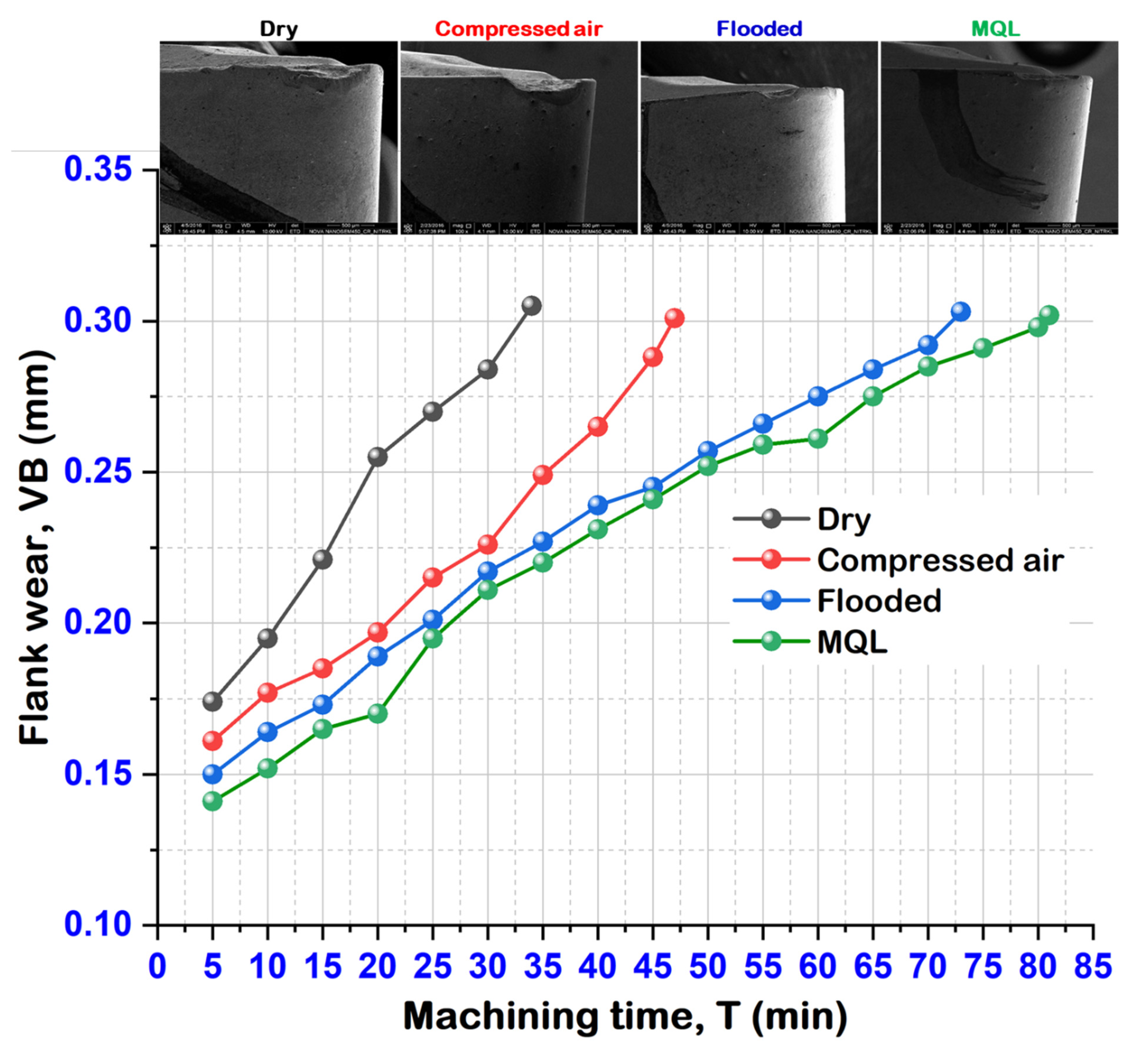

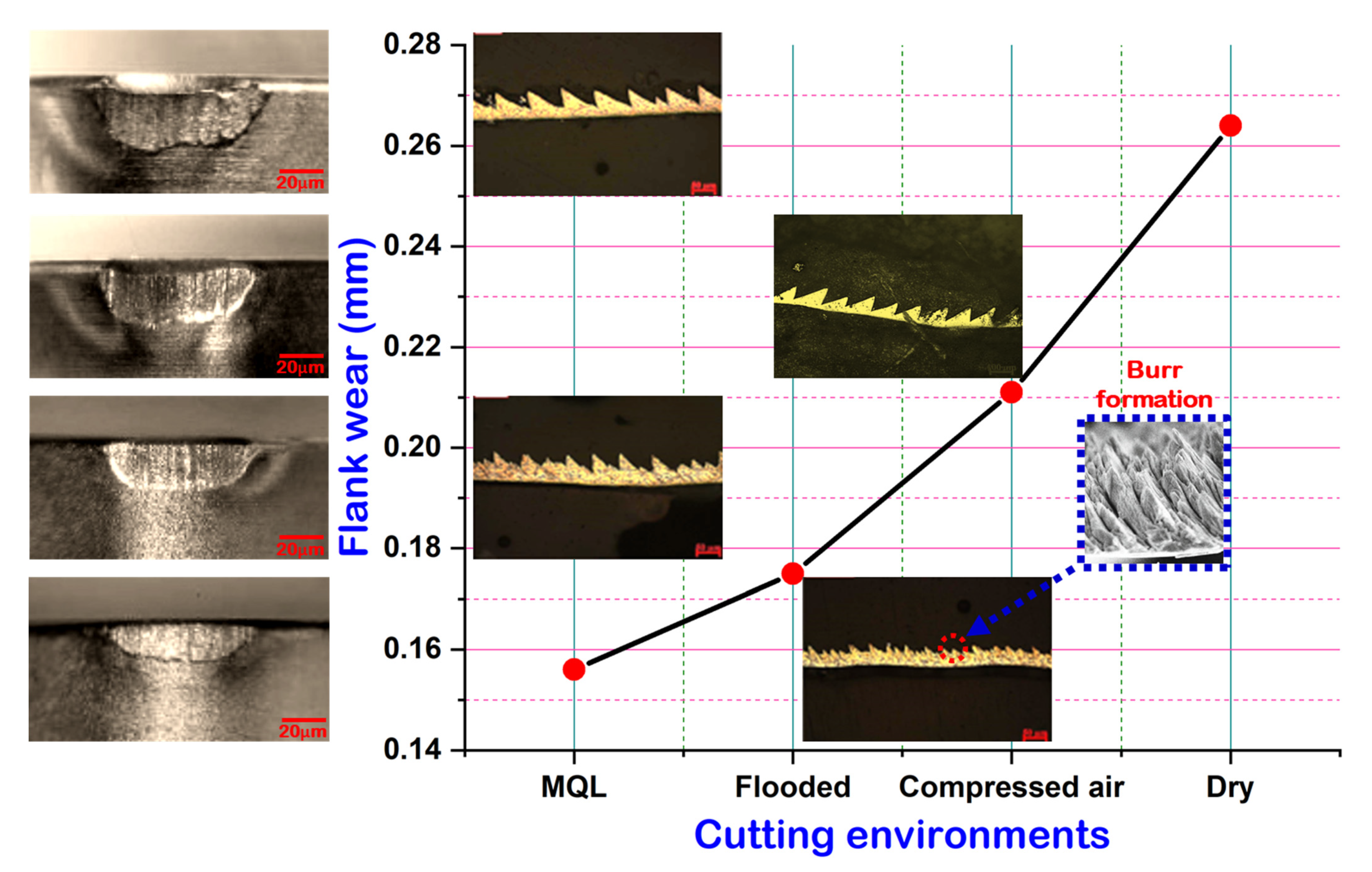

3.1. Analysis on Tool Wear

3.2. Analysis on Tool Life

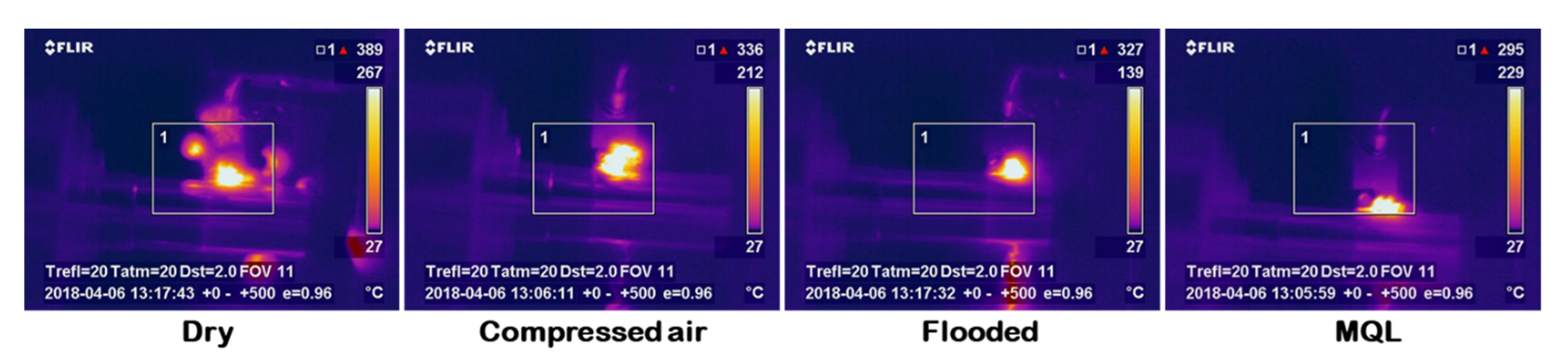

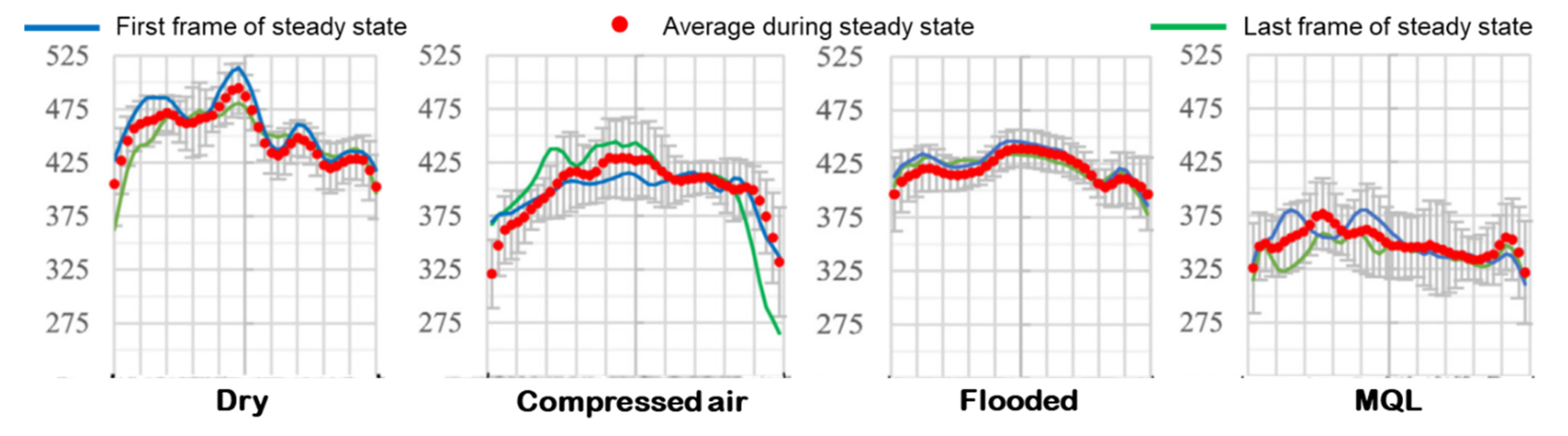

3.3. Analysis on Cutting Temperature

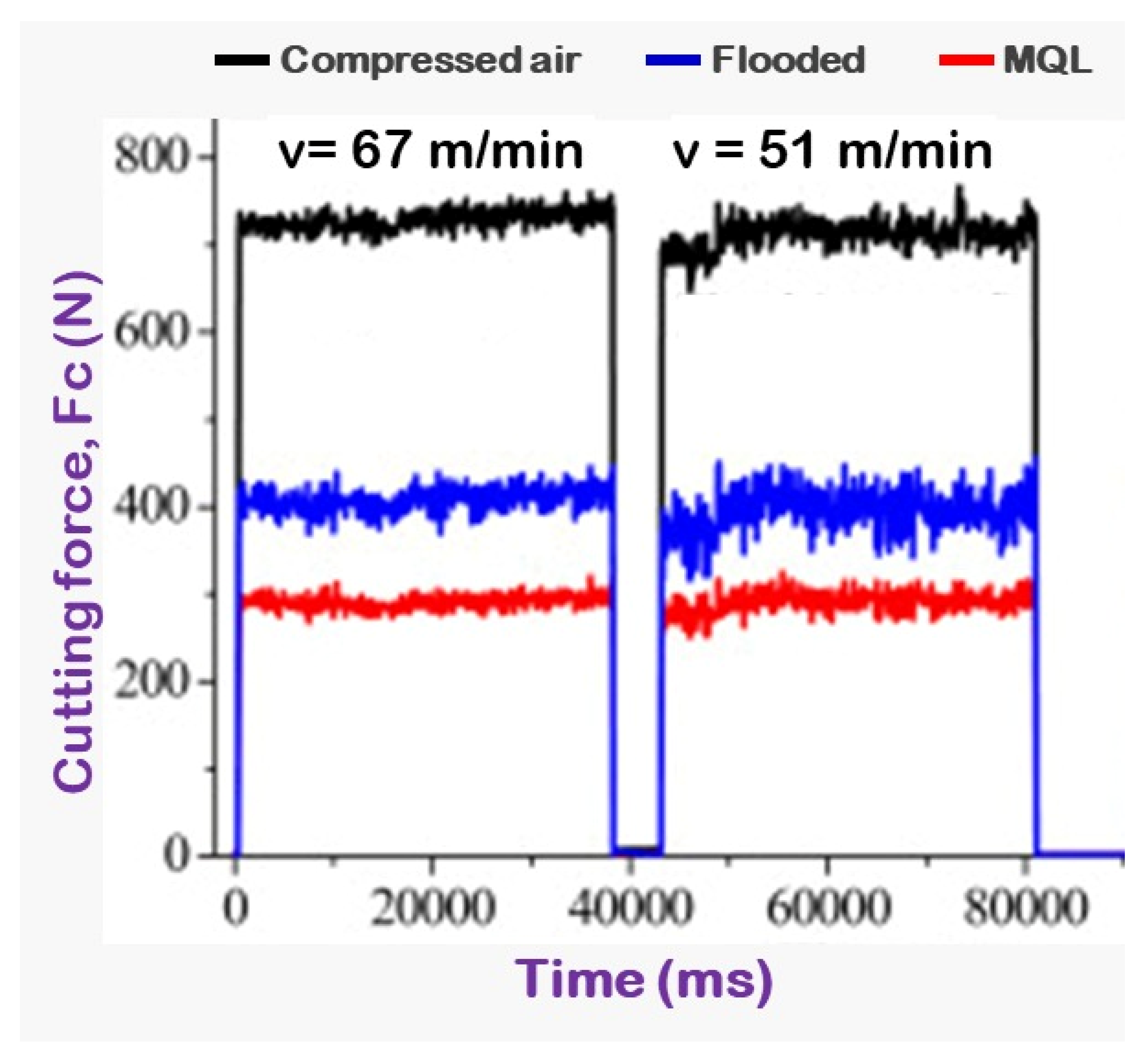

3.4. Analysis on Cutting Force

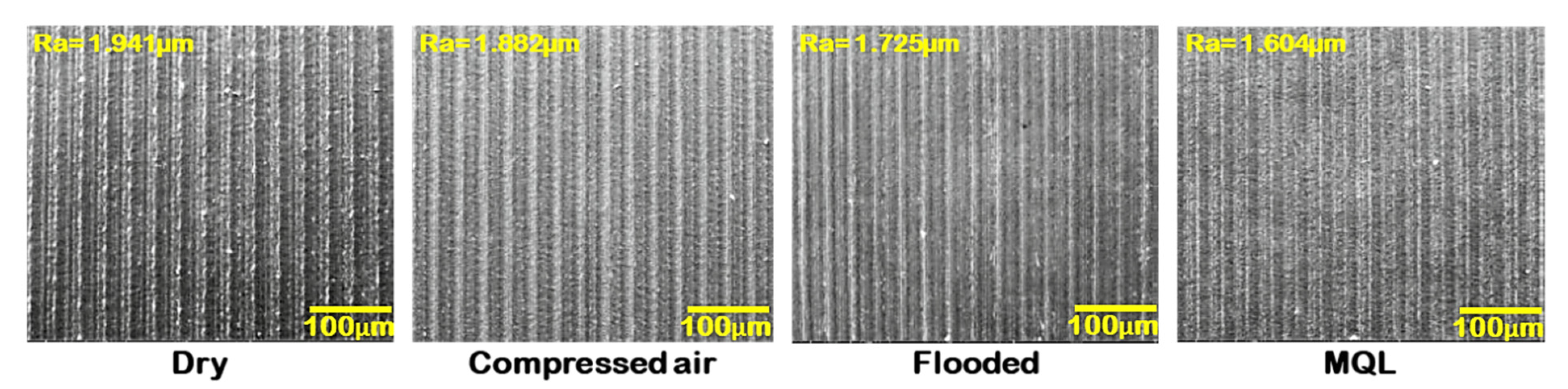

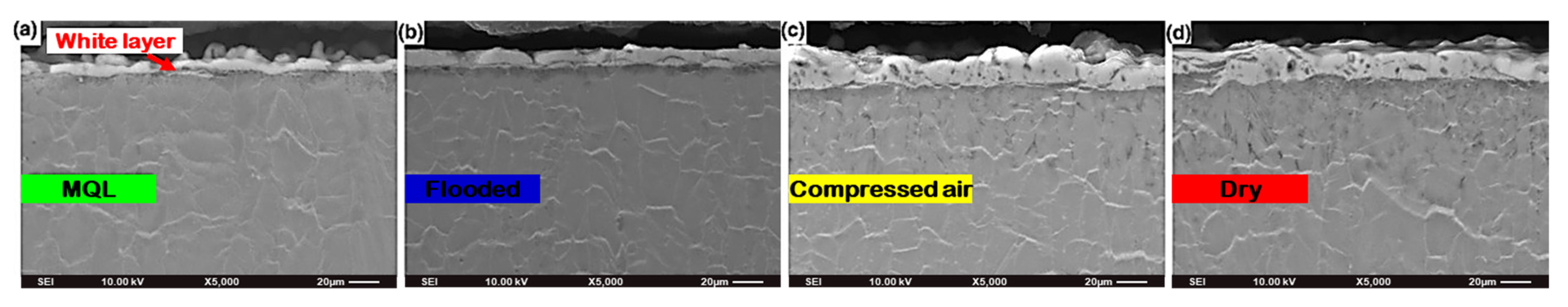

3.5. Analysis on Machined Surface Roughness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Elsheikh, A.H.; Muthuramalingam, T.; Shanmugan, S.; Mahmoud Ibrahim, A.M.; Ramesh, B.; Khoshaim, A.B.; Moustafa, E.B.; Bedairi, B.; Panchal, H.; Sathyamurthy, R. Fine-tuned artificial intelligence model using pigeon optimizer for prediction of residual stresses during turning of Inconel 718. J. Mater. Res. Technol. 2021, 15, 3622–3634. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Guo, J.; Lee, K.M. Thermal deflection and thermal stresses in a thin circular plate under an axisymmetric heat source. J. Therm. Stresses 2019, 42, 361–373. [Google Scholar] [CrossRef]

- Díaz-Álvarez, A.; Díaz-Álvarez, J.; Cantero, J.L.; Miguélez, M.H. High-Pressure Cooling in Finishing Turning of Haynes 282 Using Carbide Tools: Haynes 282 and Inconel 718 Comparison. Metals 2021, 11, 1916. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Shanmugan, S.; Muthuramalingam, T.; Thakur, A.K.; Essa, F.A.; Ibrahim, A.M.M.; Mosleh, A.O. A comprehensive review on residual stresses in turning. Adv. Manuf. 2021. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Guo, J.; Huang, Y.; Ji, J.; Lee, K.M. Temperature field sensing of a thin-wall component during machining: Numerical and experimental investigations. Int. J. Heat Mass Transf. 2018, 126, 935–945. [Google Scholar] [CrossRef]

- Muthuramalingam, T.; Akash, R.; Krishnan, S.; Phan, N.H.; Pi, V.N.; Elsheikh, A.H. Surface quality measures analysis and optimization on machining titanium alloy using CO2 based laser beam drilling process. J. Manuf. Processes 2021, 62, 1–6. [Google Scholar] [CrossRef]

- Srouhgi, G.; Muthuramalingam, T.; Moustafa, E.B.; Elsheikh, A. Investigation and TGRA based optimization of laser beam drilling process during machining of Nickel Inconel 718 alloy. J. Mater. Res. Technol. 2022. [Google Scholar] [CrossRef]

- Sami Abushanab, W.; Moustafa, E.B.; Harish, M.; Shanmugan, S.; Elsheikh, A.H. Experimental investigation on surface characteristics of Ti6Al4V alloy during abrasive water jet machining process. Alex. Eng. J. 2022, 61, 7529–7539. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Elaziz, M.A.; Das, S.R.; Muthuramalingam, T.; Lu, S. A new optimized predictive model based on political optimizer for eco-friendly MQL-turning of AISI 4340 alloy with nano-lubricants. J. Manuf. Processes 2021, 67, 562–578. [Google Scholar] [CrossRef]

- Das, A.; Patel, S.; Biswal, B.; Sahoo, N.; Pradhan, A. Performance evaluation of various cutting fluids using MQL technique in hard turning of AISI 4340 alloy steel. Measurement 2020, 150, 107079. [Google Scholar] [CrossRef]

- Gupta, M.K.; Song, Q.; Liu, Z.; Sarikaya, M.; Jamil, M.; Mia, M.; Kushvaha, V.; Singla, A.K.; Li, Z. Ecological, economical and technological perspectives based sustainability assessment in hybrid-cooling assisted machining of Ti-6Al-4 V alloy. Sustain. Mater. Technol. 2020, 26, e00218. [Google Scholar] [CrossRef]

- Saini, A.; Dhiman, S.; Sharma, R.; Setia, S. Experimental estimation and optimization of process parameters under minimum quantity lubrication and dry turning of AISI-4340 with different carbide inserts. J. Mech. Sci. Technol. 2014, 28, 2307–2318. [Google Scholar] [CrossRef]

- Sen, B.; Mia, M.; Krolczyk, G.; Mandal, U.K.; Mondal, S.P. Eco-friendly cutting fluids in minimum quantity lubrication assisted machining: A review on the perception of sustainable manufacturing. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 249–280. [Google Scholar] [CrossRef] [Green Version]

- Das, A.; Padhan, S.; Das, S.R.; Alsoufi, M.S.; Ibrahim, A.M.; Elsheikh, A. Performance Assessment and Chip Morphology Evaluation of Austenitic Stainless Steel under Sustainable Machining Conditions. Metals 2021, 11, 1931. [Google Scholar] [CrossRef]

- Dash, L.; Padhan, S.; Das, S.R. Design optimization for analysis of surface integrity and chip morphology in hard turning. Struct. Eng. Mech. 2020, 76, 561–578. [Google Scholar]

- Salman, K.; Elsheikh, A.H.; Ashham, M.; Ali, M.K.A.; Rashad, M.; Haiou, Z. Effect of cutting parameters on surface residual stresses in dry turning of AISI 1035 alloy. J. Braz. Soc. Mech. Sci. Eng. 2019, 41. [Google Scholar] [CrossRef]

- Arsene, B.; Gheorghe, C.; Sarbu, F.A.; Barbu, M.; Cioca, L.-I.; Calefariu, G. MQL-Assisted Hard Turning of AISI D2 Steel with Corn Oil: Analysis of Surface Roughness, Tool Wear, and Manufacturing Costs. Metals 2021, 11, 2058. [Google Scholar] [CrossRef]

- Khoshaim, A.B.; Elsheikh, A.H.; Moustafa, E.B.; Basha, M.; Mosleh, A.O. Prediction of residual stresses in turning of pure iron using artificial intelligence-based methods. J. Mater. Res. Technol. 2021, 11, 2181–2194. [Google Scholar] [CrossRef]

- Panday, G.; Ashraf, M.; Ibne, Z.; Ibn Muneer, K.; Hossain, K.S.; Ashik, M.; Kabir, F.; Kamruzzaman, M. Assessing near-dry lubrication (35 ml/h) performance in hard turning process of hardened (48 HRC) AISI 1060 carbon steel. Int. J. Adv. Manuf. Technol. 2018, 99, 2045–2057. [Google Scholar] [CrossRef]

- Dureja, J.; Singh, R.; Singh, T.; Singh, P.; Dogra, M.; Bhatti, M.S. Performance evaluation of coated carbide tool in machining of stainless steel (AISI 202) under minimum quantity lubrication (MQL). Int. J. Precis. Eng. Manuf.-Green Technol. 2015, 2, 123–129. [Google Scholar] [CrossRef] [Green Version]

- Liu, N.; Zou, X.; Yuan, J.; Wu, S.; Chen, Y. Performance evaluation of castor oil-ethanol blended coolant under minimum quantity lubrication turning of difficult-to-machine materials. J. Manuf. Processes 2020, 58, 1–10. [Google Scholar] [CrossRef]

- Nouioua, M.; Yallese, M.A.; Khettabi, R.; Belhadi, S.; Bouhalais, M.L.; Girardin, F. Investigation of the performance of the MQL, dry, and wet turning by response surface methodology (RSM) and artificial neural network (ANN). Int. J. Adv. Manuf. Technol. 2017, 93, 2485–2504. [Google Scholar] [CrossRef]

- Ukamanal, M.; Mishra, P.; Sahoo, A. Effects of spray cooling process parameters on machining performance AISI 316 steel: A novel experimental technique. Exp. Tech. 2020, 44, 19–36. [Google Scholar] [CrossRef]

- Jadam, T.; Rakesh, M.; Datta, S. Machinability of Ti–6al–4v superalloy: Performance of dry cutting and nanofluid MQL (MWCNT-added rice bran oil). Arab. J. Sci. Eng. 2020, 45, 5673–5695. [Google Scholar] [CrossRef]

- Bedi, S.S.; Behera, G.C.; Datta, S. Effects of cutting speed on MQL machining performance of AISI 304 stainless steel using uncoated carbide insert: Application potential of coconut oil and rice bran oil as cutting fluids. Arab. J. Sci. Eng. 2020, 45, 8877–8893. [Google Scholar] [CrossRef]

- Gupta, M.K.; Mia, M.; Jamil, M.; Singh, R.; Singla, A.K.; Song, Q.; Liu, Z.; Khan, A.M.; Rahman, M.A.; Sarikaya, M. Machinability investigations of hardened steel with biodegradable oil-based MQL spray system. Int. J. Adv. Manuf. Technol. 2020, 108, 735–748. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Kıvak, T.; Erzincanlı, F. Tool wear and surface roughness analysis in milling with ceramic tools of Waspaloy: A comparison of machining performance with different cooling methods. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 1–15. [Google Scholar] [CrossRef]

- Tamang, S.; Chandrasekaran, M.; Sahoo, A. Sustainable machining: An experimental investigation and optimization of machining Inconel 825 with dry and MQL approach. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 1–18. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Wojciechowski, S.; Powalka, B.; Klos, S.; Szczotkarz, N.; Matuszak, M.; Khanna, N. Evaluation of turning with different cooling-lubricating techniques in terms of surface integrity and tribologic properties. Tribol. Int. 2020, 148, 106334. [Google Scholar] [CrossRef]

- Mia, M.; Gupta, M.K.; Singh, G.; Królczyk, G.; Pimenov, D.Y. An approach to cleaner production for machining hardened steel using different cooling-lubrication conditions. J. Clean. Prod. 2018, 187, 1069–1081. [Google Scholar] [CrossRef]

- Aouici, H.; Elbah, M.; Yallese, M.; Fnides, B.; Meddour, I.; Benlahmidi, S. Performance comparison of wiper and conventional ceramic inserts in hard turning of AISI 4140 steel: Analysis of machining forces and flank wear. Int. J. Adv. Manuf. Technol. 2016, 87, 2221–2244. [Google Scholar] [CrossRef]

- Bensouilah, H.; Aouici, H.; Meddour, I.; Yallese, M.A.; Mabrouki, T.; Girardin, F. Performance of coated and uncoated mixed ceramic tools in hard turning process. Measurement 2016, 82, 1–18. [Google Scholar] [CrossRef]

- Dash, L.; Padhan, S.; Das, A.; Das, S.R. Machinability investigation and sustainability assessment in hard turning of AISI D3 steel with coated carbide tool under nanofluid minimum quantity lubrication-cooling condition. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 6496–6528. [Google Scholar] [CrossRef]

- Padhan, S.; Das, A.; Santoshwar, A.; Dharmendrabhai, T.R.; Das, S.R. Sustainability assessment and machinability investigation of austenitic stainless steel in finish turning with advanced ultra-hard SiAlON ceramic tool under different cutting environments. Silicon 2021, 13, 119–147. [Google Scholar] [CrossRef]

- Şirin, Ş.; Sarıkaya, M.; Yıldırım, Ç.V.; Kıvak, T. Machinability performance of nickel alloy X-750 with SiAlON ceramic cutting tool under dry, MQL and hBN mixed nanofluid-MQL. Tribol. Int. 2021, 153, 106673. [Google Scholar] [CrossRef]

- Kishawy, H.; Elbestawi, M. Effects of process parameters on material side flow during hard turning. Int. J. Mach. Tools Manuf. 1999, 39, 1017–1030. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Muthuramalingam, T.; Abd Elaziz, M.; Ibrahim, A.M.M.; Showaib, E.A. Minimization of fume emissions in laser cutting of polyvinyl chloride sheets using genetic algorithm. Int. J. Environ. Sci. Technol. 2021. [Google Scholar] [CrossRef]

- Abd Elaziz, M.; Elsheikh, A.H.; Oliva, D.; Abualigah, L.; Lu, S.; Ewees, A.A. Advanced Metaheuristic Techniques for Mechanical Design Problems: Review. Arch. Comput. Methods Eng. 2021. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Deng, W.; Showaib, E.A. Improving laser cutting quality of polymethylmethacrylate sheet: Experimental investigation and optimization. J. Mater. Res. Technol. 2020, 9, 1325–1339. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Shehabeldeen, T.A.; Zhou, J.; Showaib, E.; Abd Elaziz, M. Prediction of laser cutting parameters for polymethylmethacrylate sheets using random vector functional link network integrated with equilibrium optimizer. J. Intell. Manuf. 2021, 32, 1377–1388. [Google Scholar] [CrossRef]

- Khoshaim, A.B.; Moustafa, E.B.; Bafakeeh, O.T.; Elsheikh, A.H. An Optimized Multilayer Perceptrons Model Using Grey Wolf Optimizer to Predict Mechanical and Microstructural Properties of Friction Stir Processed Aluminum Alloy Reinforced by Nanoparticles. Coatings 2021, 11, 1476. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Abd Elaziz, M.; Vendan, A. Modeling ultrasonic welding of polymers using an optimized artificial intelligence model using a gradient-based optimizer. Weld. World 2021. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Abd Elaziz, M.; Ramesh, B.; Egiza, M.; Al-qaness, M.A.A. Modeling of drilling process of GFRP composite using a hybrid random vector functional link network/parasitism-predation algorithm. J. Mater. Res. Technol. 2021, 14, 298–311. [Google Scholar] [CrossRef]

- AbuShanab, W.S.; Abd Elaziz, M.; Ghandourah, E.I.; Moustafa, E.B.; Elsheikh, A.H. A new fine-tuned random vector functional link model using Hunger games search optimizer for modeling friction stir welding process of polymeric materials. J. Mater. Res. Technol. 2021, 14, 1482–1493. [Google Scholar] [CrossRef]

- Dash, L.; Padhan, S.; Das, S.R. Experimental investigations on surface integrity and chip morphology in hard tuning of AISI D3 steel under sustainable nanofluid-based minimum quantity lubrication. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 1–25. [Google Scholar] [CrossRef]

| Density | Poisons Ratio | Tensile Strength | Modulus of Elasticity | Thermal Conductivity | Vickers Hardness |

|---|---|---|---|---|---|

| 7622 kg/mm3 | 0.298 | 395 MPa | 200 GPa | 51.9 W/mK | 115 HV |

| Test No. | Cutting Speed, v (m/min) | Feed Rate, f (mm/rev) | Cutting Environments |

|---|---|---|---|

| 1 | 51 | 0.12 | Dry |

| 2 | 51 | 0.16 | Compressed-air |

| 3 | 51 | 0.20 | Flooded |

| 4 | 51 | 0.24 | MQL |

| 5 | 67 | 0.12 | Compressed-air |

| 6 | 67 | 0.16 | Dry |

| 7 | 67 | 0.20 | MQL |

| 8 | 67 | 0.24 | Flooded |

| 9 | 87 | 0.12 | Flooded |

| 10 | 87 | 0.16 | MQL |

| 11 | 87 | 0.20 | Dry |

| 12 | 87 | 0.24 | Compressed-air |

| 13 | 111 | 0.12 | MQL |

| 14 | 111 | 0.16 | Flooded |

| 15 | 111 | 0.20 | Compressed-air |

| 16 | 111 | 0.24 | Dry |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Padhan, S.; Das, S.R.; Das, A.; Alsoufi, M.S.; Ibrahim, A.M.M.; Elsheikh, A. Machinability Investigation of Nitronic 60 Steel Turning Using SiAlON Ceramic Tools under Different Cooling/Lubrication Conditions. Materials 2022, 15, 2368. https://doi.org/10.3390/ma15072368

Padhan S, Das SR, Das A, Alsoufi MS, Ibrahim AMM, Elsheikh A. Machinability Investigation of Nitronic 60 Steel Turning Using SiAlON Ceramic Tools under Different Cooling/Lubrication Conditions. Materials. 2022; 15(7):2368. https://doi.org/10.3390/ma15072368

Chicago/Turabian StylePadhan, Smita, Sudhansu Ranjan Das, Anshuman Das, Mohammad S. Alsoufi, Ahmed Mohamed Mahmoud Ibrahim, and Ammar Elsheikh. 2022. "Machinability Investigation of Nitronic 60 Steel Turning Using SiAlON Ceramic Tools under Different Cooling/Lubrication Conditions" Materials 15, no. 7: 2368. https://doi.org/10.3390/ma15072368

APA StylePadhan, S., Das, S. R., Das, A., Alsoufi, M. S., Ibrahim, A. M. M., & Elsheikh, A. (2022). Machinability Investigation of Nitronic 60 Steel Turning Using SiAlON Ceramic Tools under Different Cooling/Lubrication Conditions. Materials, 15(7), 2368. https://doi.org/10.3390/ma15072368